Ventilation and smoke exhaust system of tunnel

A smoke exhaust system and tunnel technology, which is used in mine/tunnel ventilation, climate sustainability, mining equipment, etc., can solve construction difficulties, large pressure difference between lane and smoke exhaust pipe, and increase in negative pressure value of smoke exhaust pipe and other problems, to achieve the effect of reducing the difficulty of construction technology, saving civil construction and installation costs, and improving smoke exhaust power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

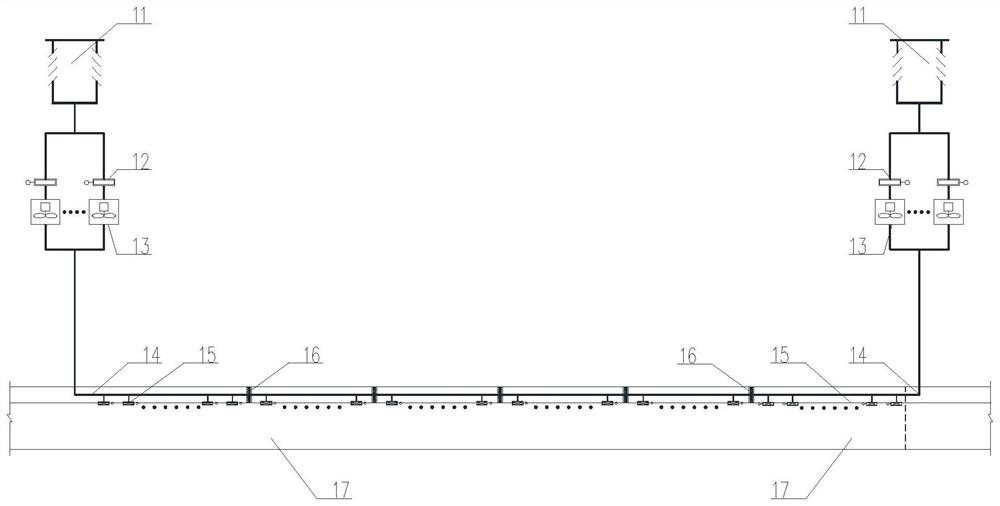

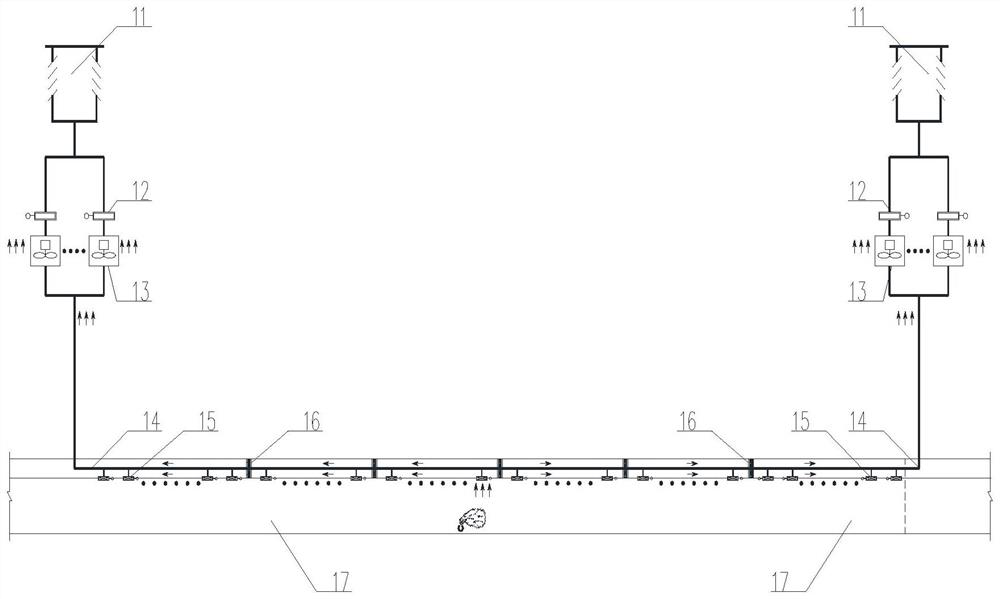

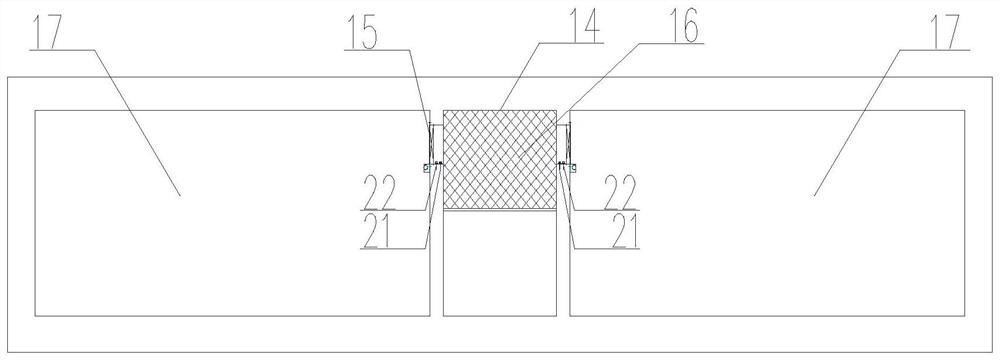

[0066] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a ventilation and smoke exhaust system for a tunnel includes:

[0067] The end smoke exhaust device is arranged at the end of the exhaust air duct 14 of the tunnel;

[0068] A plurality of exhaust duct relay devices 16 are arranged at intervals in the exhaust air duct 14 of the tunnel. The exhaust duct relay devices 16 are used to blow the exhaust air duct in sections to increase the pressure in the exhaust air duct, and are connected to the end exhaust duct. The fume devices jointly discharge the flue gas in the flue gas duct 14 out of the flue gas duct.

[0069] The ventilation and smoke exhaust system of the tunnel according to the embodiment of the present application includes two end smoke exhaust devices and a plurality of exhaust flue relay devices. The two end smoke exhaust devices are respectively arranged at both ends of the smoke exhaust air duct. A plurality of flue exhaust duct ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com