Patents

Literature

116results about How to "No change in size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

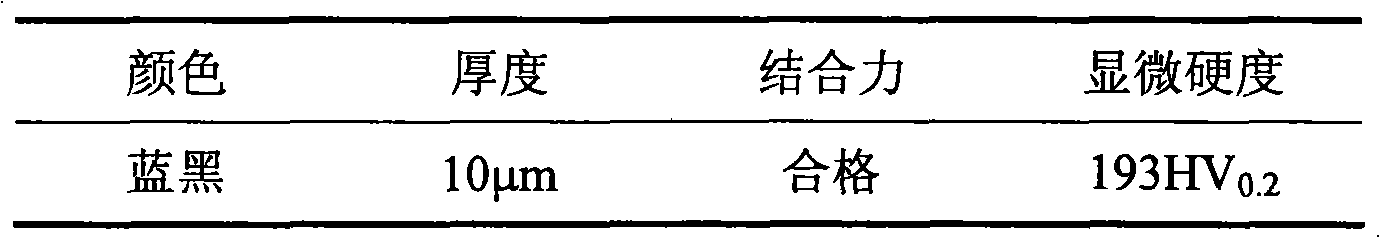

Method for preparing large-area high-performance color stainless steel by laser oxidation coloring

InactiveCN101775570AThe process steps are simpleEasy to operateSolid state diffusion coatingAfter treatmentColor film

The invention discloses a method for preparing large-area high-performance color stainless steel by laser oxidation coloring, relating to the field of material surface modification. The steps are as follows: 1) treating the stainless steel to be a certain size; 2) carrying out pre-treatment on the treated stainless steel; 3) carrying out large-area color treatment of laser oxidation after pre-treatment; and 4) preparing the large-area high-performance color stainless steel by simple after treatment to the stainless steel with oxidation coloring. The method uses optical-heat-chemical effect oflaser to generate oxide films with difference types and thicknesses, colors the surface of the stainless steel together by self color of the oxide films and interference effect of the films, and adopts a specially-made rotating laser head to prepare large-area curved or flat color stainless steel. The large-area color stainless steel prepared by the invention has more stable color film layer, rich color, good reproducibility, high hardness and good wear resistance, also has simple technique, easy operation and no pollution and is suitable for batch production on large scale.

Owner:JIANGSU UNIV

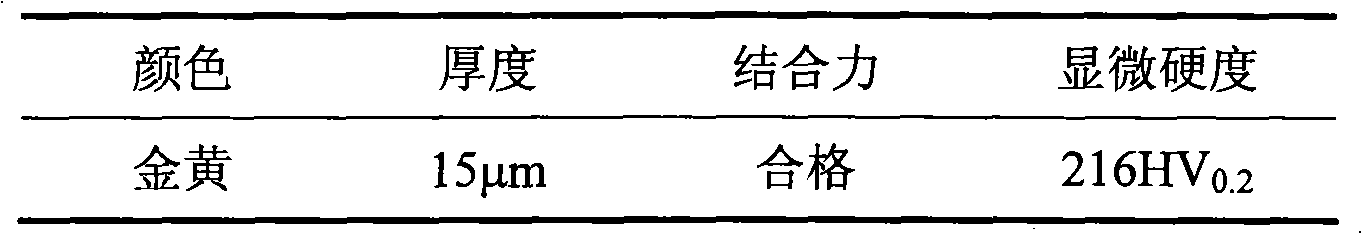

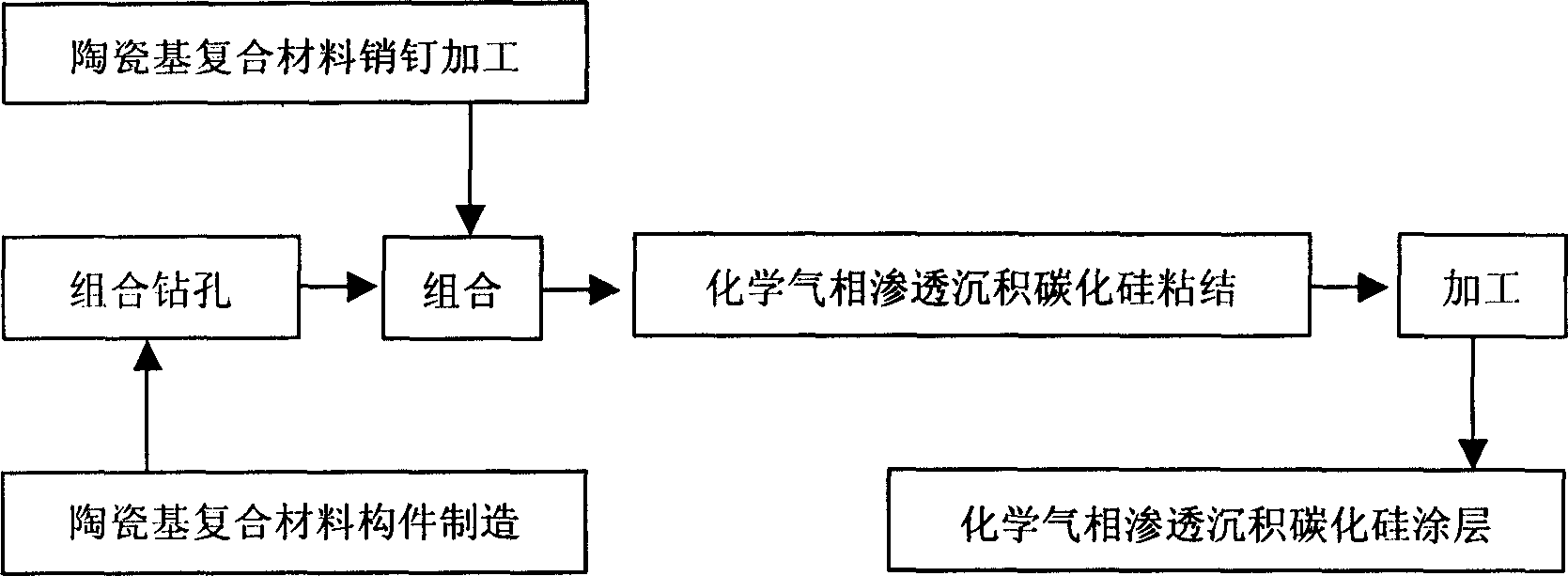

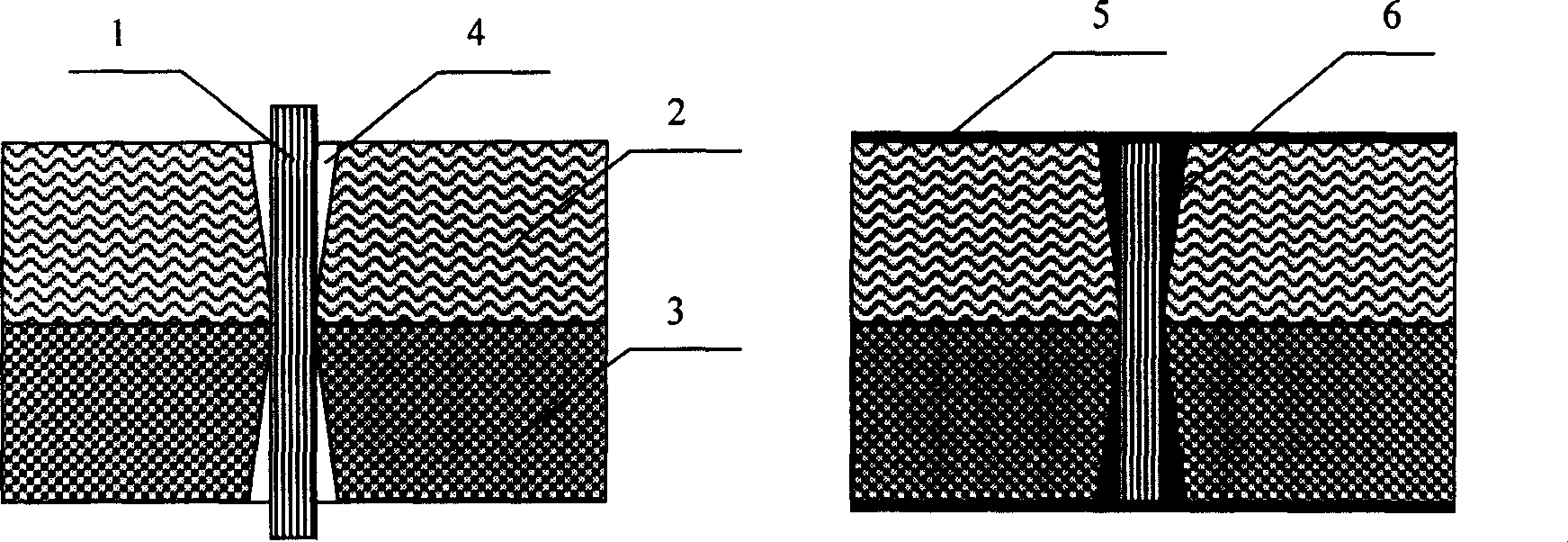

Connecting method of ceramic-base composite

ActiveCN1597621AReduce processing costsDoes not change surface shapeGas phaseChemical vapor deposition

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

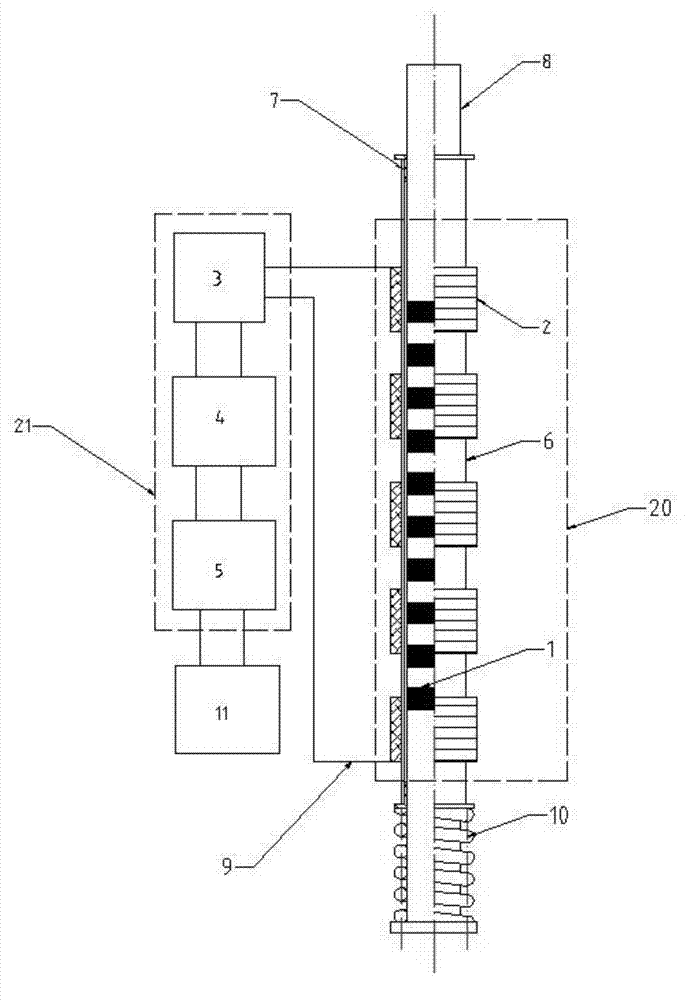

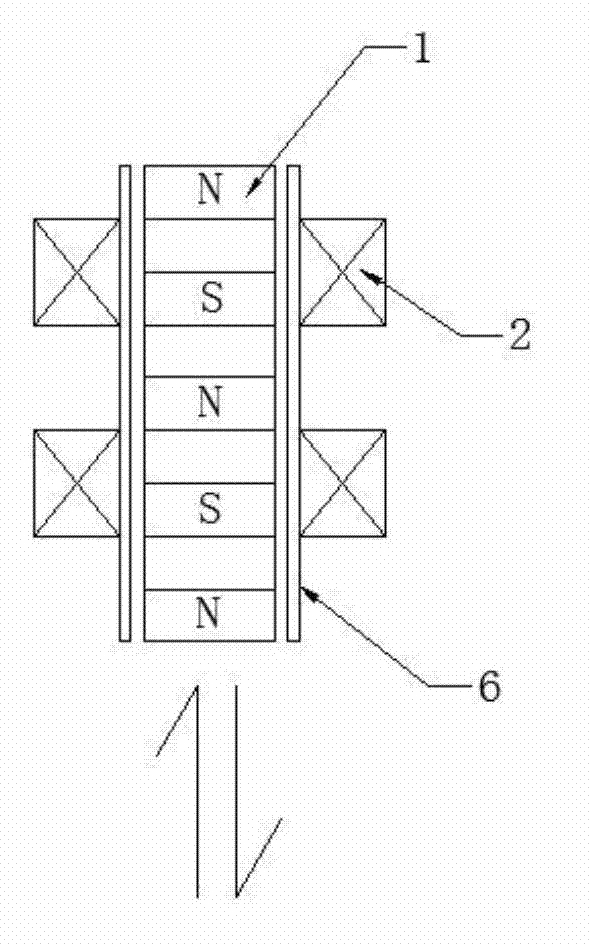

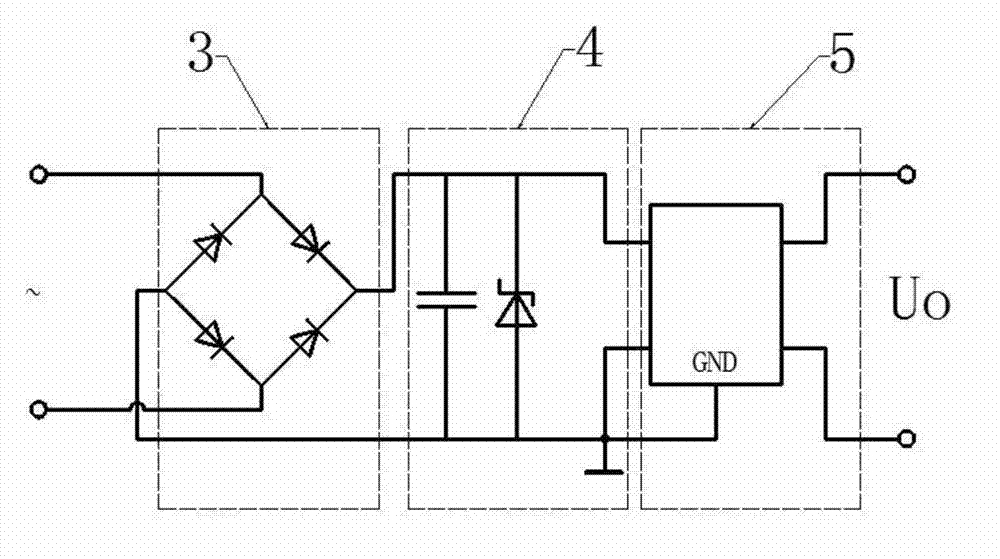

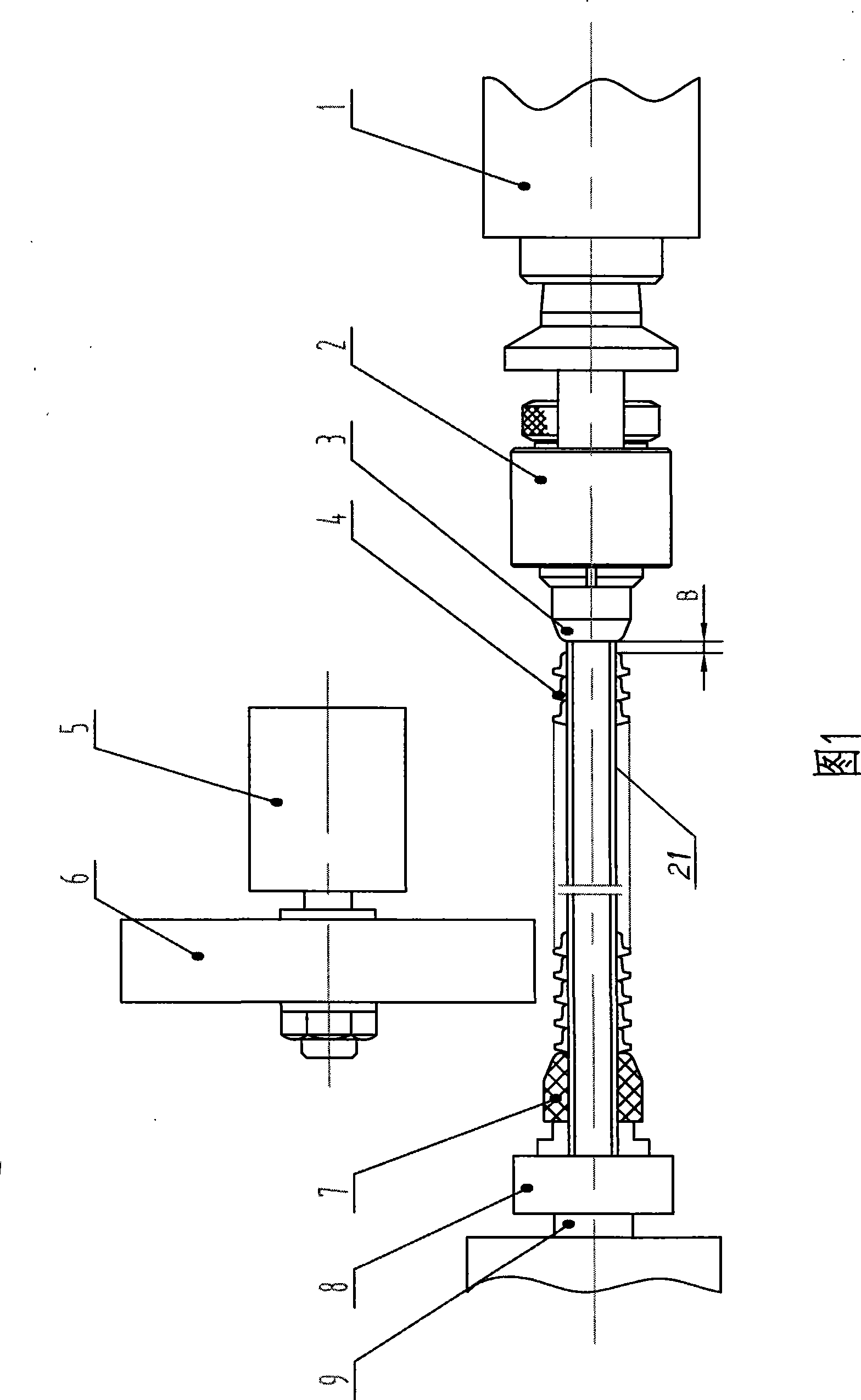

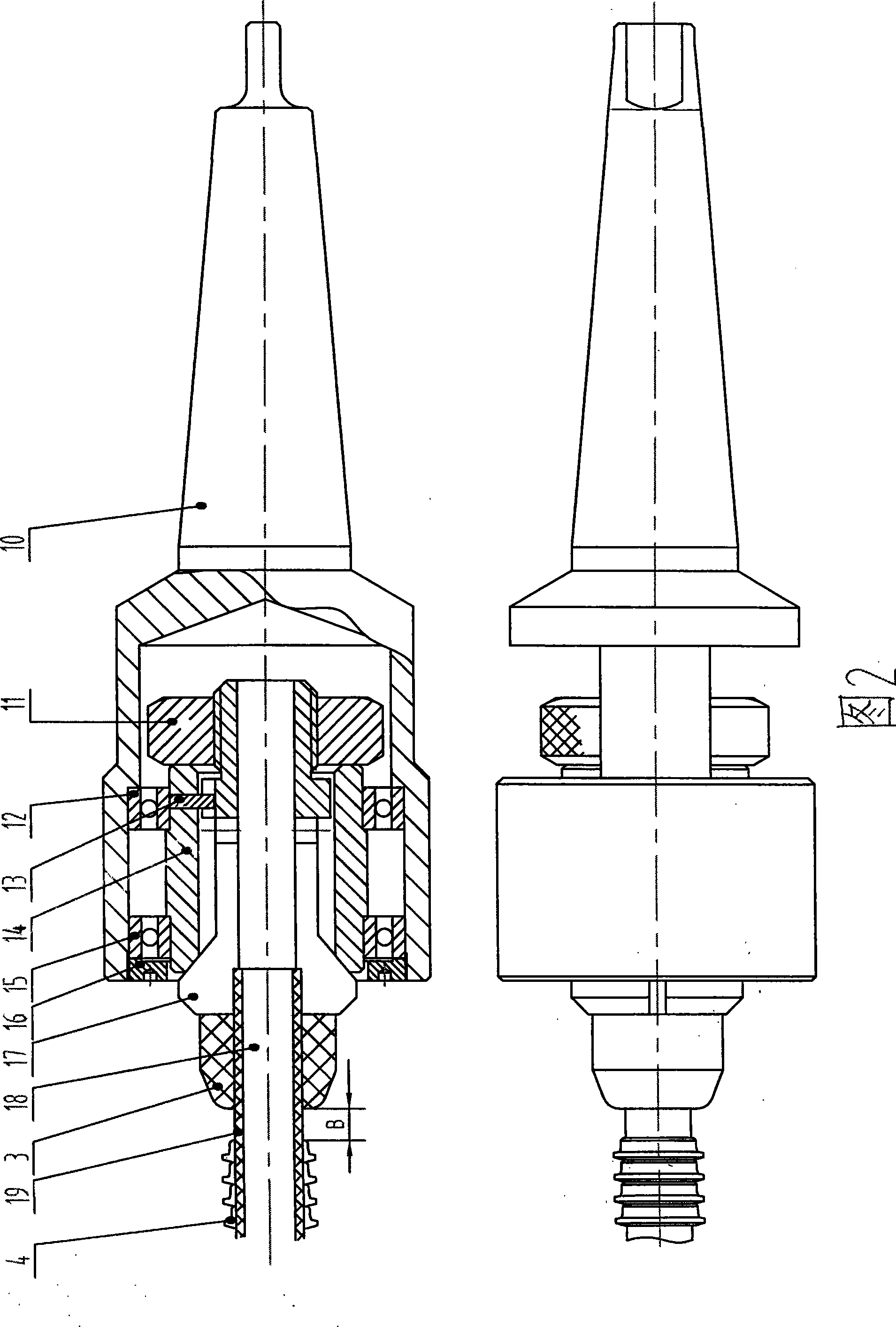

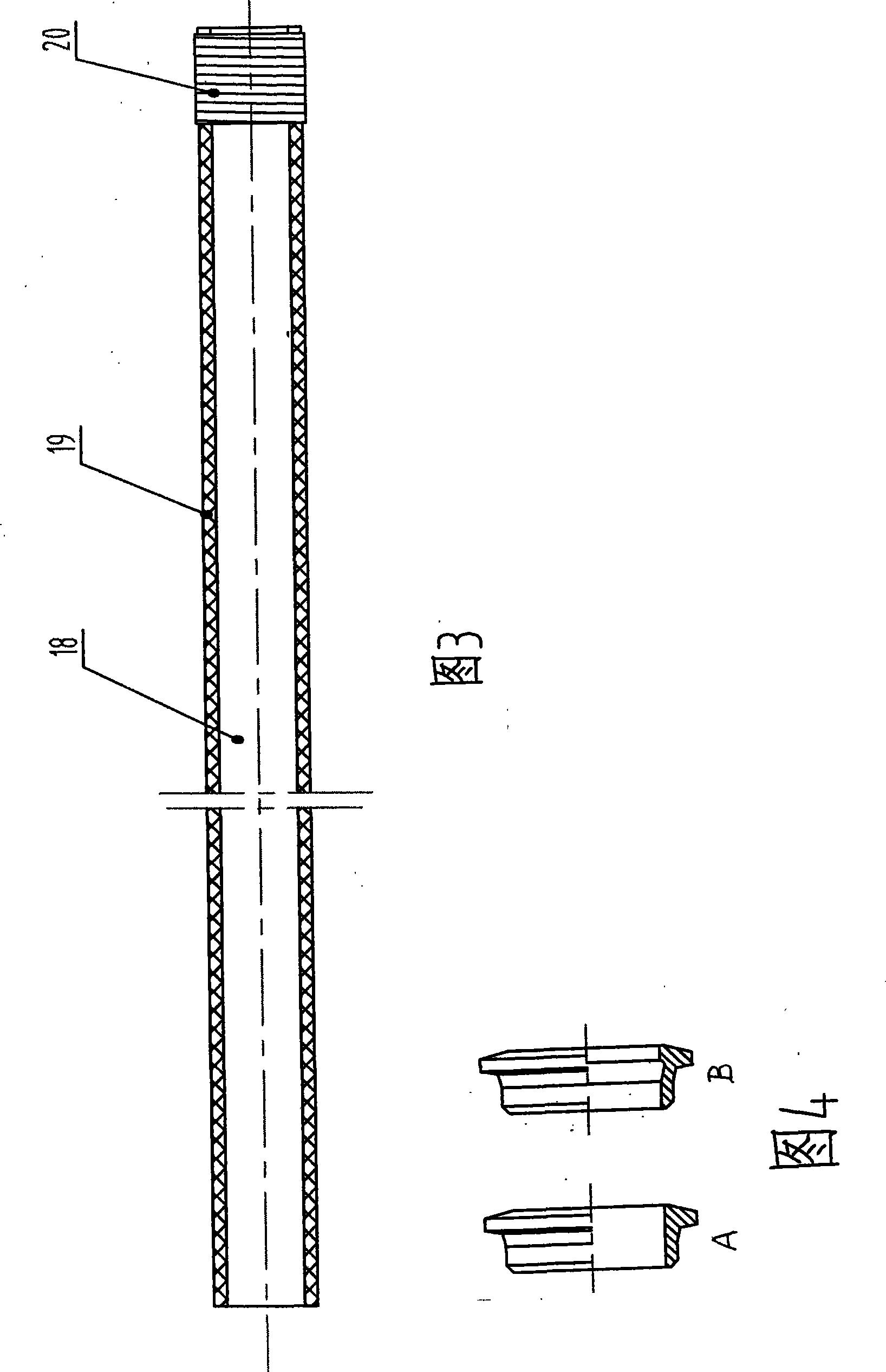

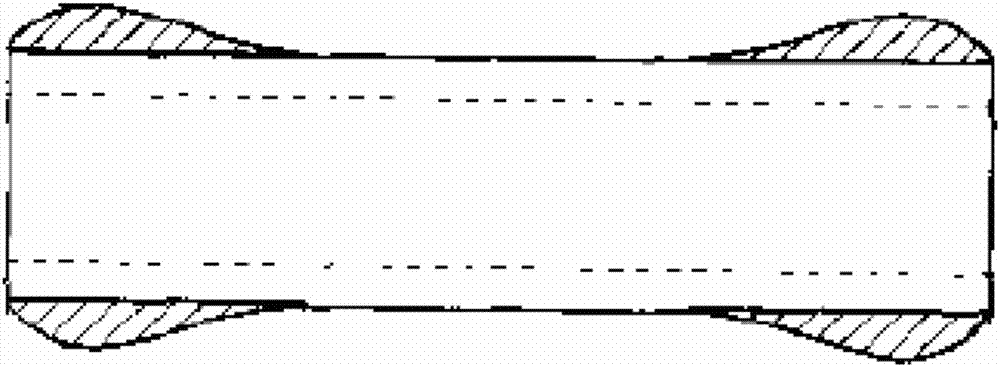

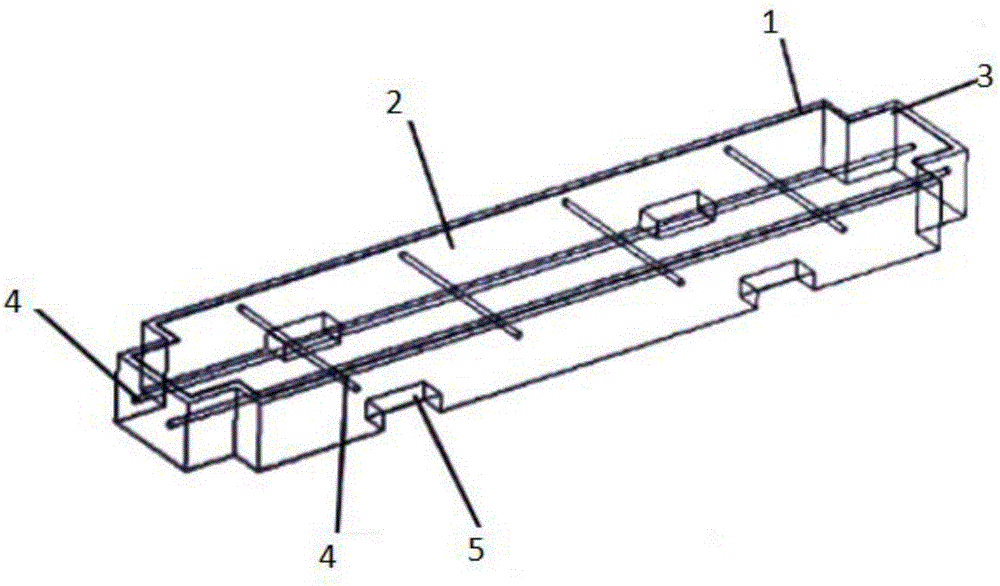

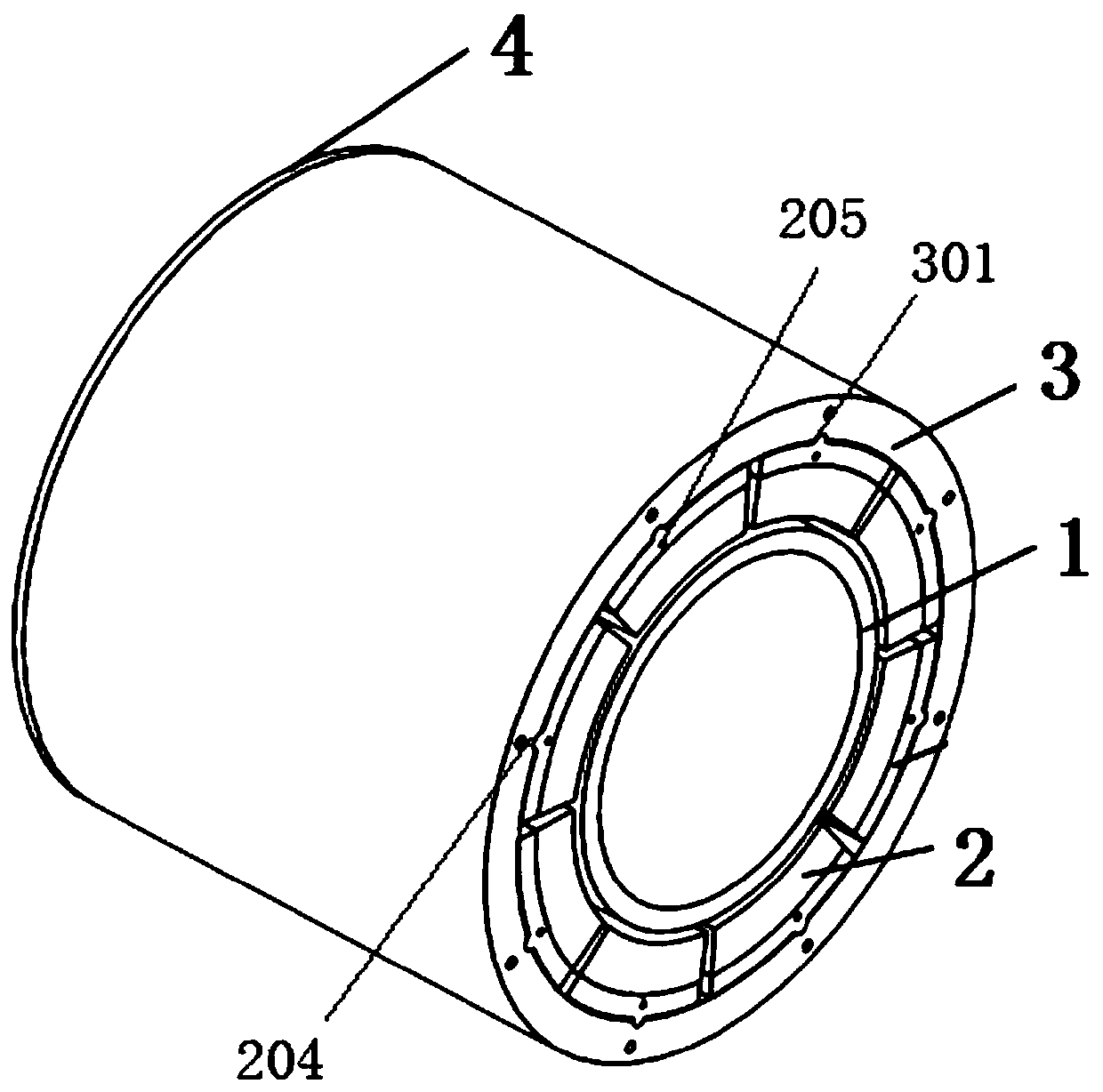

Automobile shock absorber generation device

InactiveCN102761228AImprove utilization efficiencyReduce loadBatteries circuit arrangementsElectric powerEnergy recoveryEngineering

The invention belongs to the technical field of generation devices, and relates to an automobile shock absorber generation device. The device comprises a linear generation structure (20) and a charging regulation circuit (21), wherein the linear generation structure (20) is composed of a permanent magnet group (1) arranged on a piston rod (8) of a shock absorber and a stator induction coil group (2) winding the outer wall of an inner cylinder body (6) of the shock absorber; and the charging regulation circuit (21) is composed of a rectifier circuit (3), a filter circuit (4) and a booster circuit (5). Compared with the prior art, the automobile shock absorber generation device provided by the invention has an energy recovery function, so that the energy utilization efficiency of an automobile is improved, and the load of a vehicle-mounted generator is effectively lightened. The automobile shock absorber generation device adopts a simple principle, is low in cost and convenient to install and does not change the original size of the conventional shock absorber, thus having a good energy-saving effect and good market application and dissemination prospect.

Owner:TONGJI UNIV

Sealing agent for micro-arc oxidation film

The invention discloses a sealing agent for a micro-arc oxidation film. Alcohols solvents and little additives are added to prepare water-soluble liquid on the basis of a silane coupling agent, and the sealing agent is used for generating a nanometer protective layer on the surface of the oxidation film, so that discharge micropores of the micro-arc oxidation film can be effectively sealed and good corrosion resistance is achieved; the sealed surface of the micro-arc oxidation film has a good hydrophobic effect, is anti-scrubbing and anti-pollution, is matte, transparent and traceless, and has no sensory difference in appearance compared with that before micropore sealing.

Owner:NANJING HAORANG ENVIRONMENT SCI & TECH

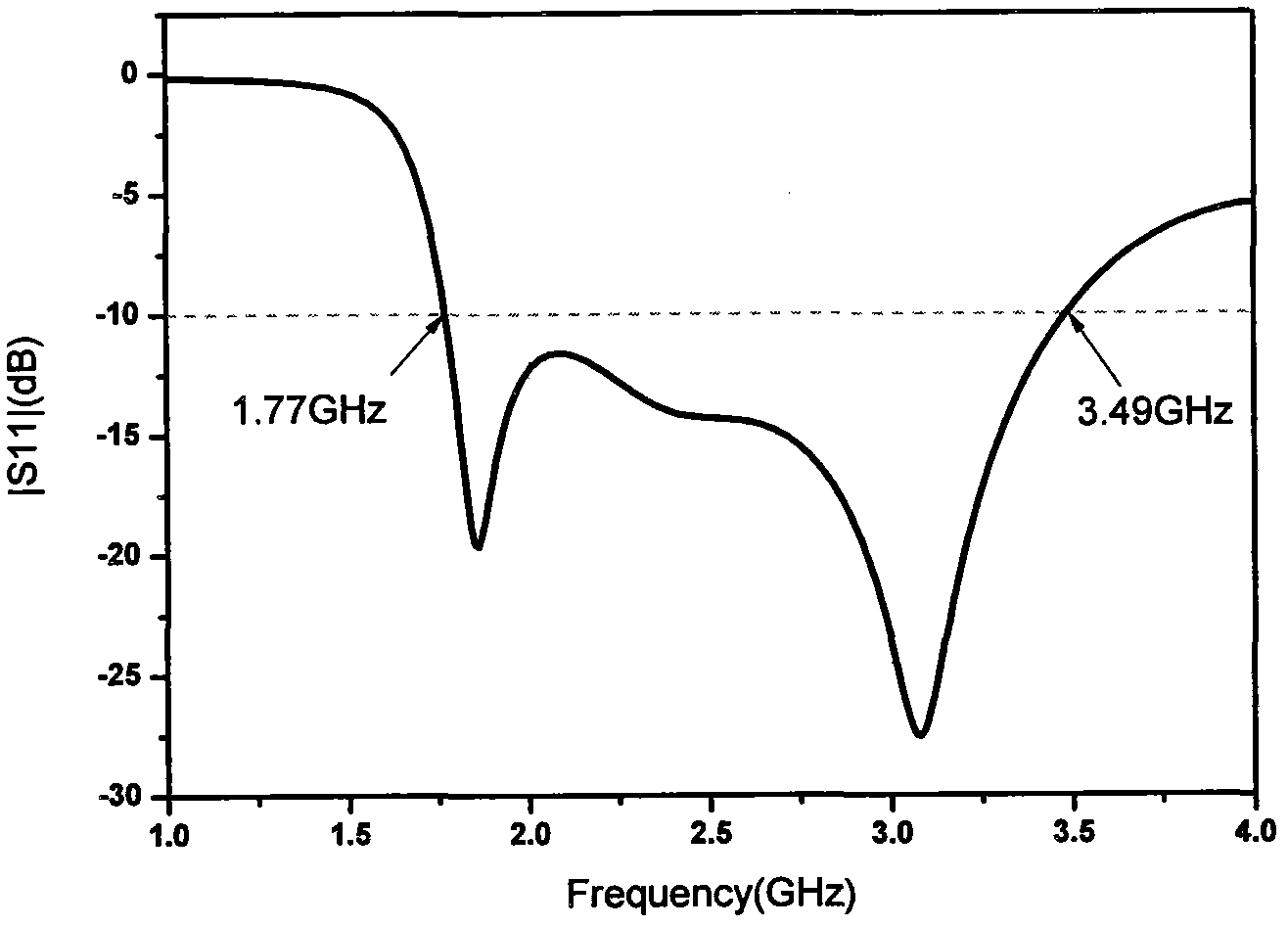

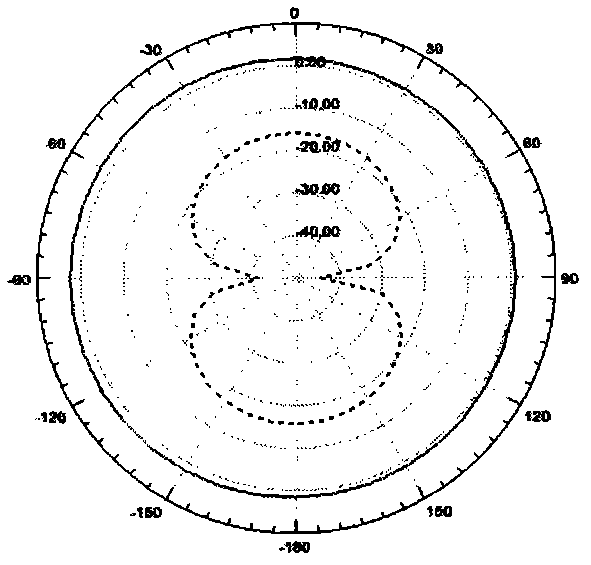

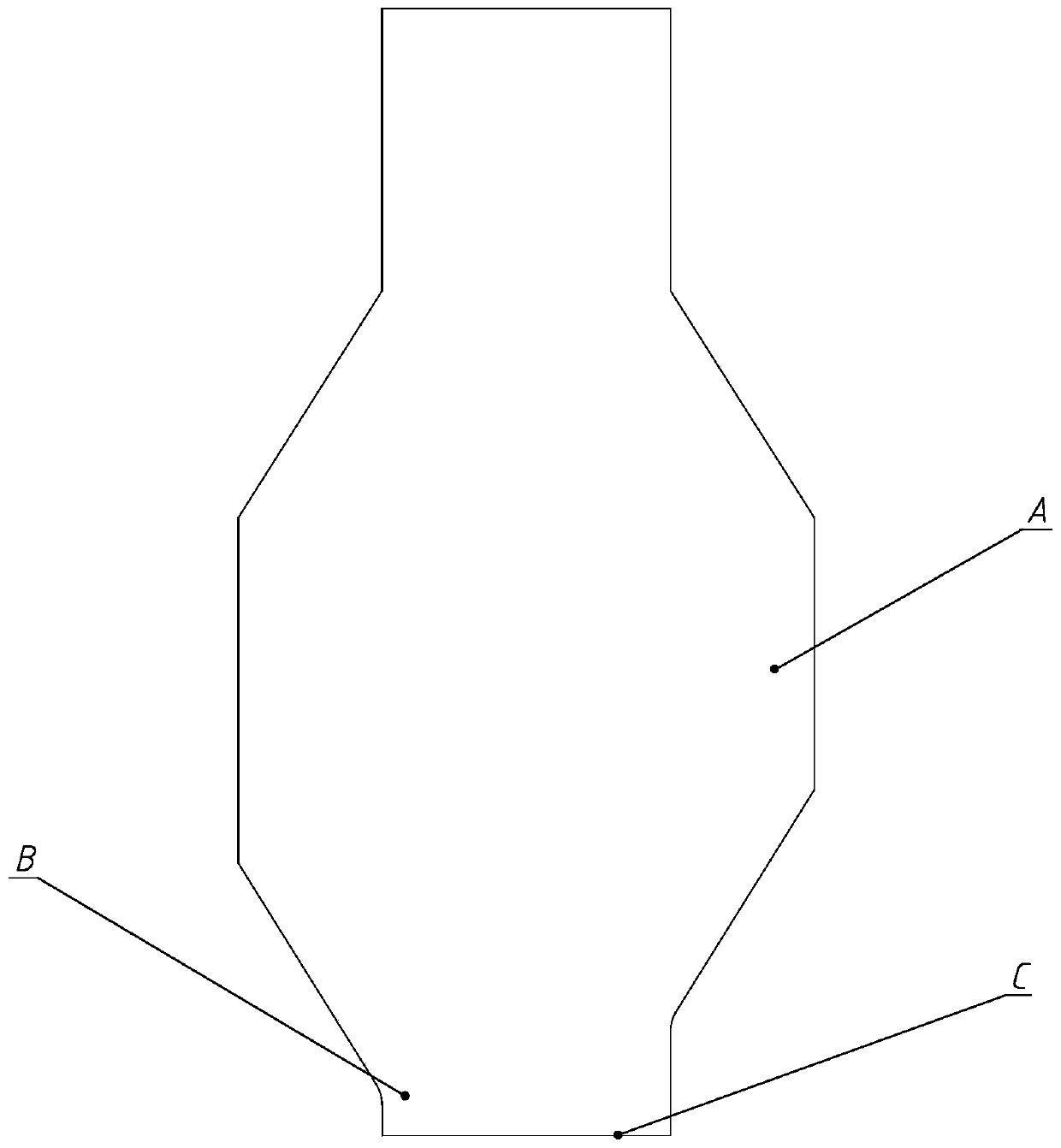

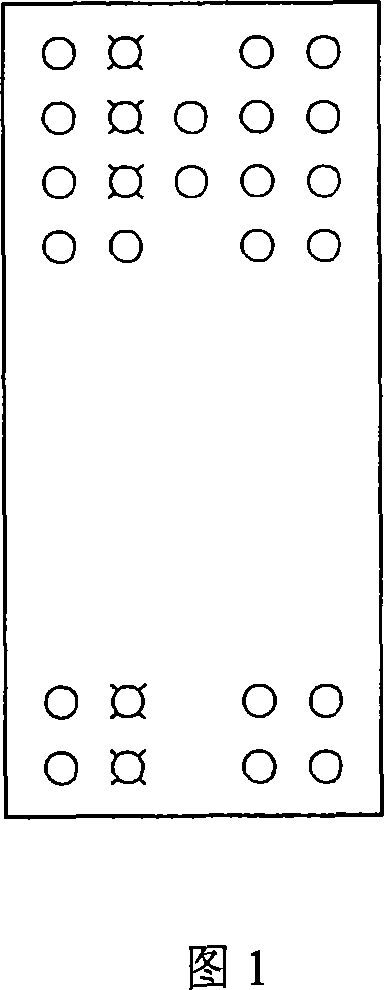

Zero resonance unit-loaded broadband planar inverted-F antenna

InactiveCN102104199AOvercome volumeOvercoming complexityElongated active element feedCapacitancePlanar inverted f antenna

The invention discloses a zero resonance unit-loaded broadband planar inverted-F antenna. The antenna comprises a top microstrip structure, a bottom dielectric substrate and an input / output port, wherein the top microstrip structure comprises a coplanar waveguide transmission line, an antenna main body, a feed line, a loading interdigital capacitor and a ground thin-wire inductor, wherein one end of the coplanar waveguide transmission line is connected with the input / output port and the other end is fed to the antenna main body through the feed line; one terminal of the antenna main body is provided with the loading interdigital capacitor and the ground thin-wire inductor; the ground thin-wire inductor is connected with a floor board; the loading interdigital capacitor, the ground thin-wire inductor and the antenna main body together form a zero resonance unit; and the top microstrip structure is arranged on the bottom dielectric substrate. By loading the zero resonance unit in a broadband planar inverted-F antenna, the problems of large area, complex machining and the like of the broadband planar inverted-F antenna are solved; therefore, the zero resonance unit-loaded broadband planar inverted-F antenna has the advantages that the size is small, the broadband is broad, the structure is simple, the broadband planar inverted-F antenna is easy to machine and the like.

Owner:SOUTH CHINA UNIV OF TECH

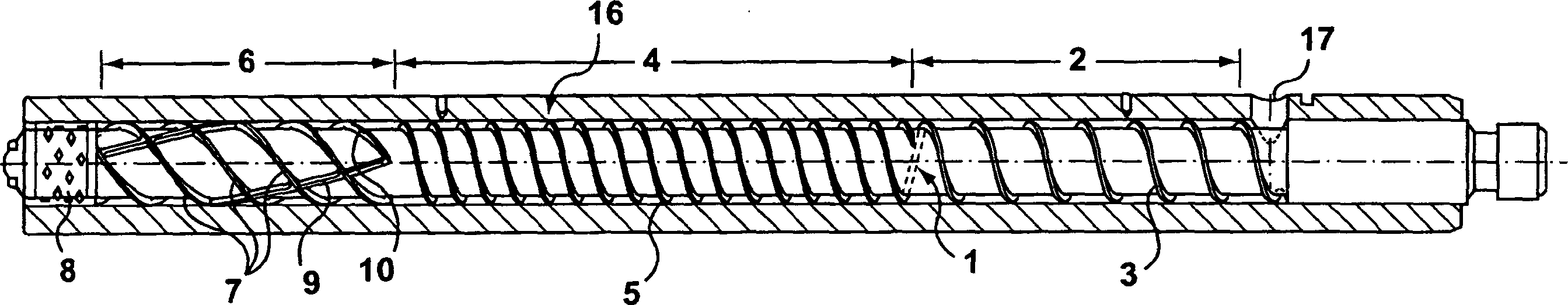

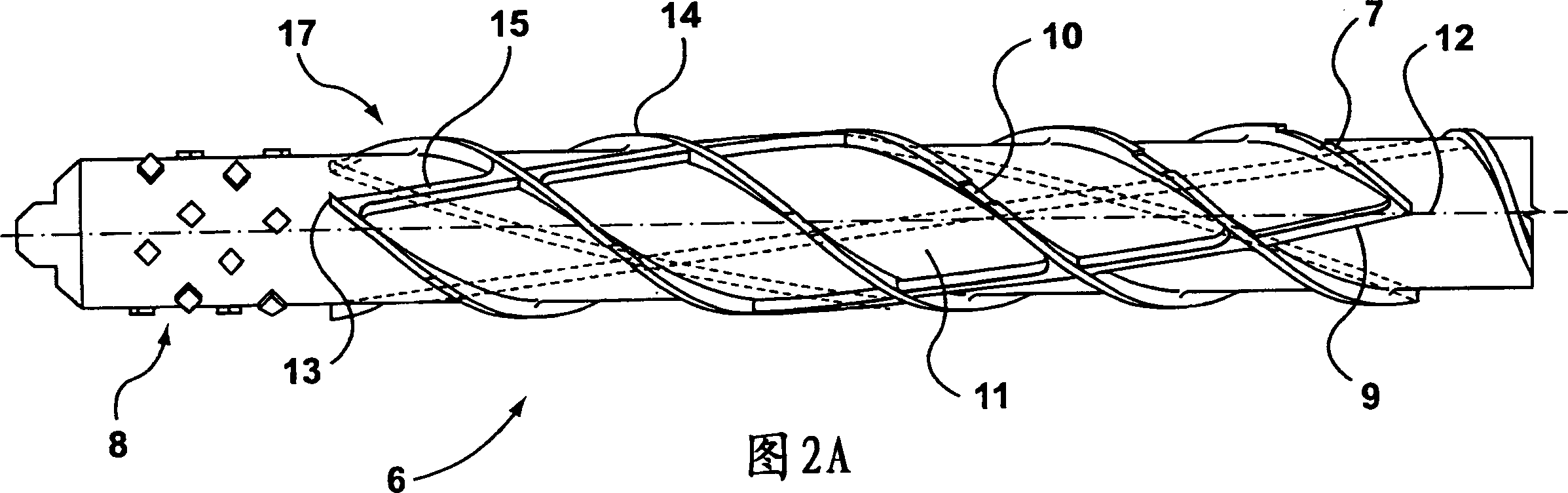

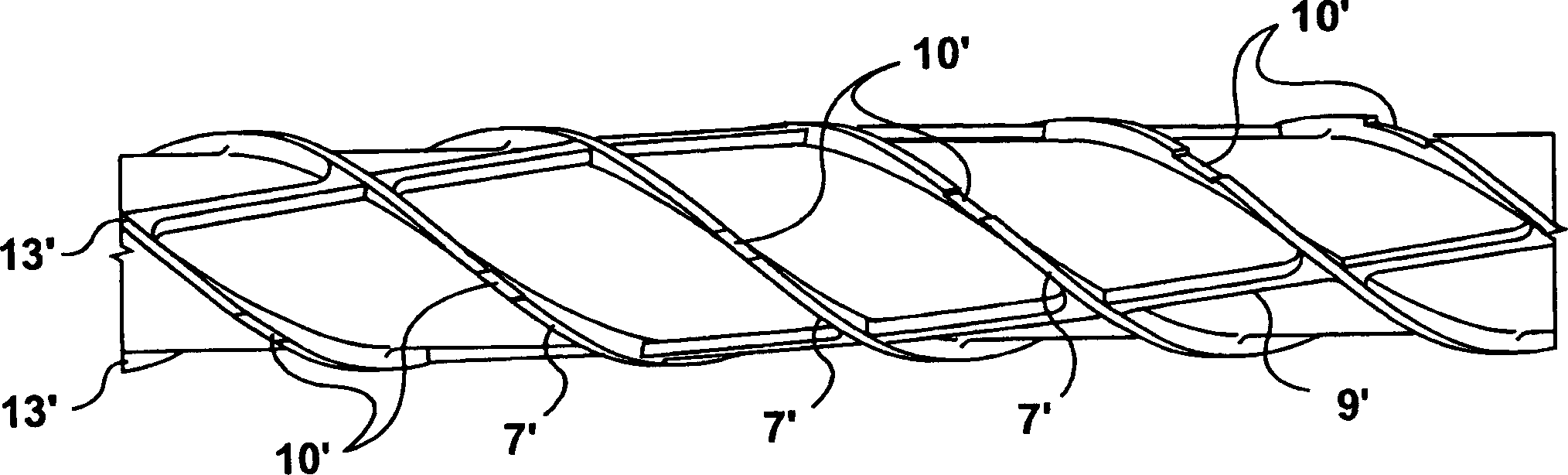

Improved mixer for a plasticizing screw

The invention provides an improved mixer section for a screw for a molding machine. The improved mixer section includes at least one conveying flight (7) and at least one spill flight (9) intersecting with the conveying flight(7) . At 1 east one notch (10) is formed in the conveying flight (7) to enable mixing between adjacent flow channels (18) . The spill flight (9) terminates near the output of the mixer to create a trap zone for any unmelts that reach that area of the mixer.

Owner:HUSKY INJECTION MOLDING SYST LTD

Method for polishing circular stainless-steel accurate parts on old machine tool

InactiveCN101367191AImprove polishing effectChange sizePolishing machinesAcute angleCylindrical grinding

The invention provides a method for polishing an annular stainless steel precise part in an old machine tool, which is applied to the mechanical manufacturing industry. On the premise of not influencing the precision of the dimension of the prior part, the method can ensure that the surface of the part achieves higher luminance brightness and keeps a necessary acute angle. The method is characterized in that a specially-made polishing rod is used; one end of the polishing rod is clamped on a three-claw chuck of a mainshaft of an old cylindrical grinding machine or a common lathe; after spacer rings and a plurality of polished parts are sleeved on the polishing rod, and limit sleeves are mounted; a loose clamp arranged on a tail rack of the machine tool tightly clamps the other end of the polishing rod; a soft cloth polishing wheel is arranged on a grinding wheel machine and is positioned between the three-claw chuck and the loose clamp; after the startup, the soft cloth polishing wheel and the polishing rod clamped on the three-claw chuck rotate along clockwise direction; and the position of the soft cloth polishing wheel rotating at high-speed and the acting force between the soft cloth polishing wheel and the polished part are adjusted so as to implement the inner, the outer and the bilateral soft polishing to the polished part between the three-claw chuck and the loose clamp, thereby achieving the aim of polishing.

Owner:江苏星河集团有限公司 +1

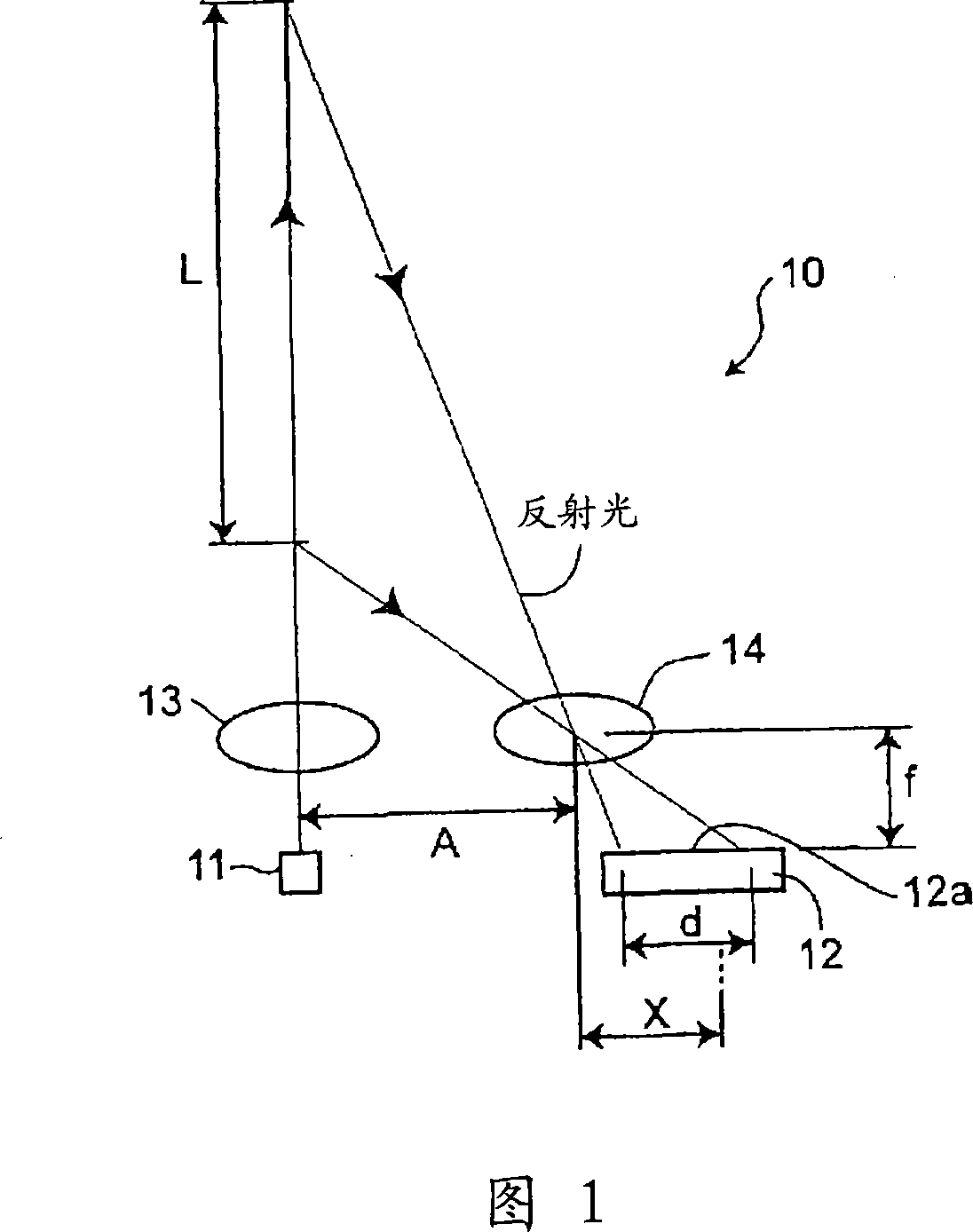

Optical ranging sensor and warm water wash toilet seat

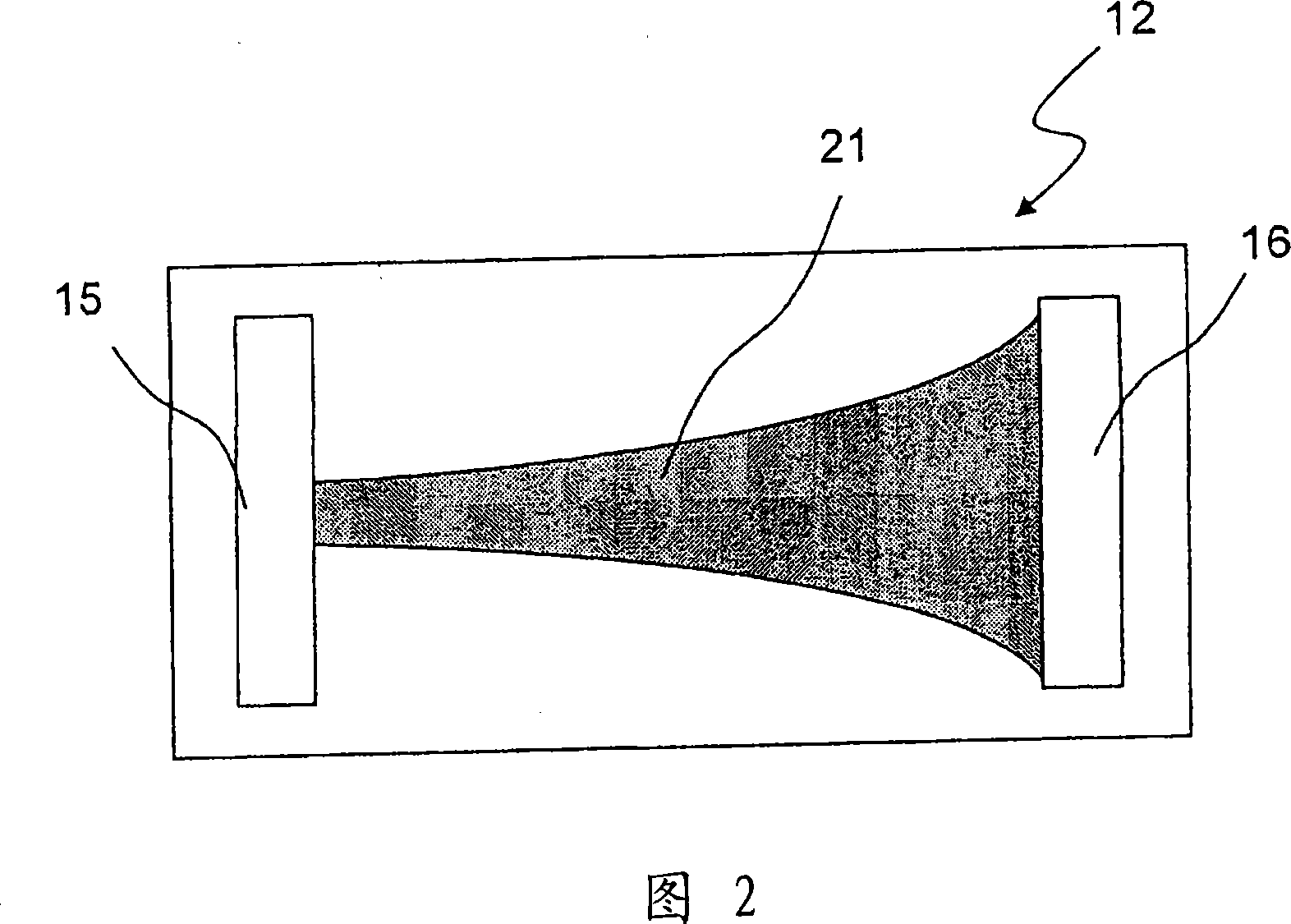

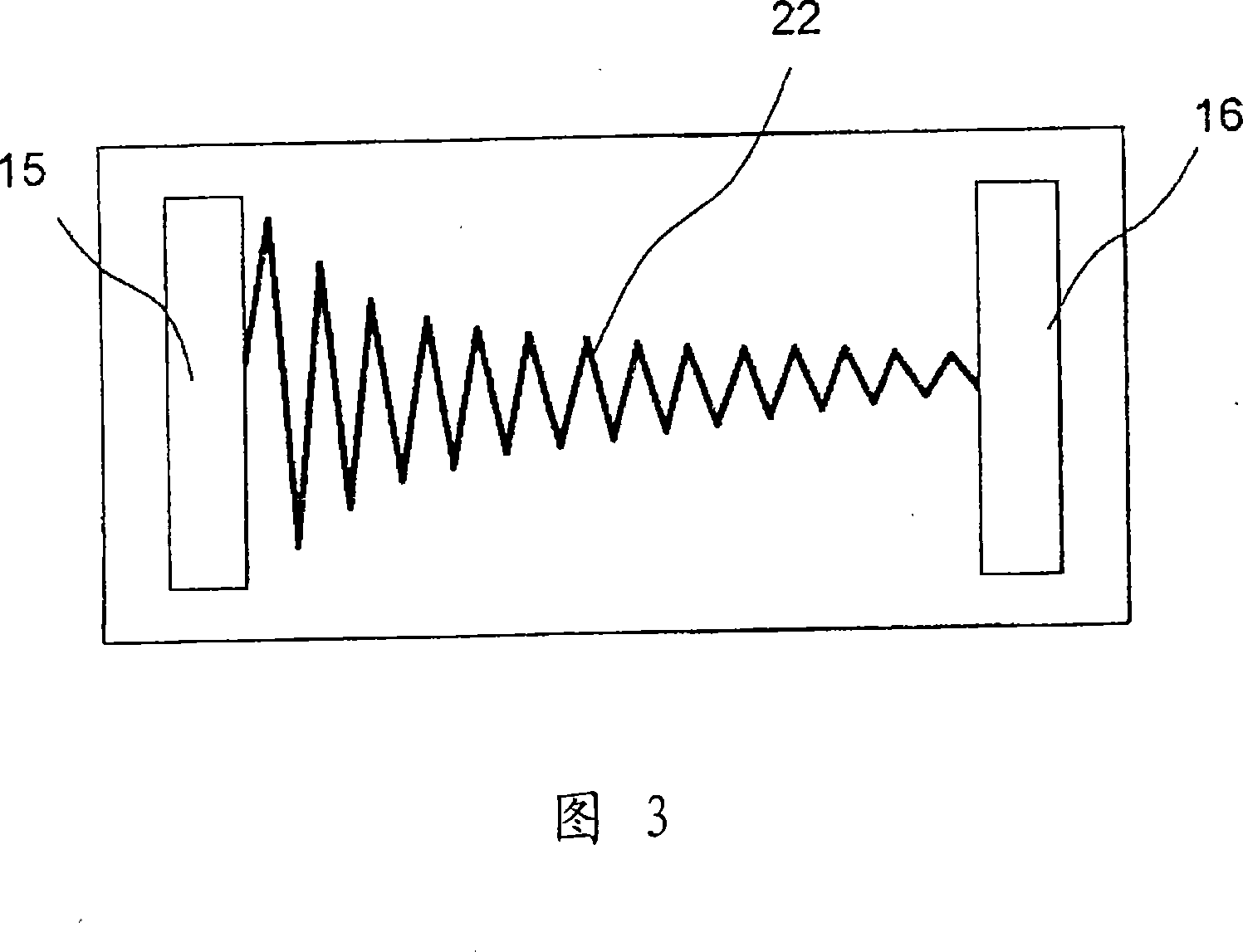

InactiveCN101042298AChange sizeSimple structureOptical rangefindersLavatory sanitoryElectrical resistance and conductanceLight spot

The present invention provides a optical distance measuring sensor and heating water cleaning toilet, the light receiving device 12 that receives reflected light condensed by a light receiving condenser means 14 has two first and second electrodes 15, 16 provided on a light receiving surface at prescribed intervals along a baseline that connects a light emitting device 11 with the light receiving device and a resistive region 21 provided between the two electrodes. An electric charge generated at the incident position of light incident on the light receiving surface of the light receiving device 12 becomes a photo current and outputted from the first and second electrodes 15, 16 via the resistive region 21 . The resistance value of the resistive region 21 of the light receiving device 12 is distributed so as to be roughly inversely proportional to a distance from the optical axis of the light receiving condenser means 14 to the incident position of a light spot on the light receiving surface.

Owner:SHARP KK

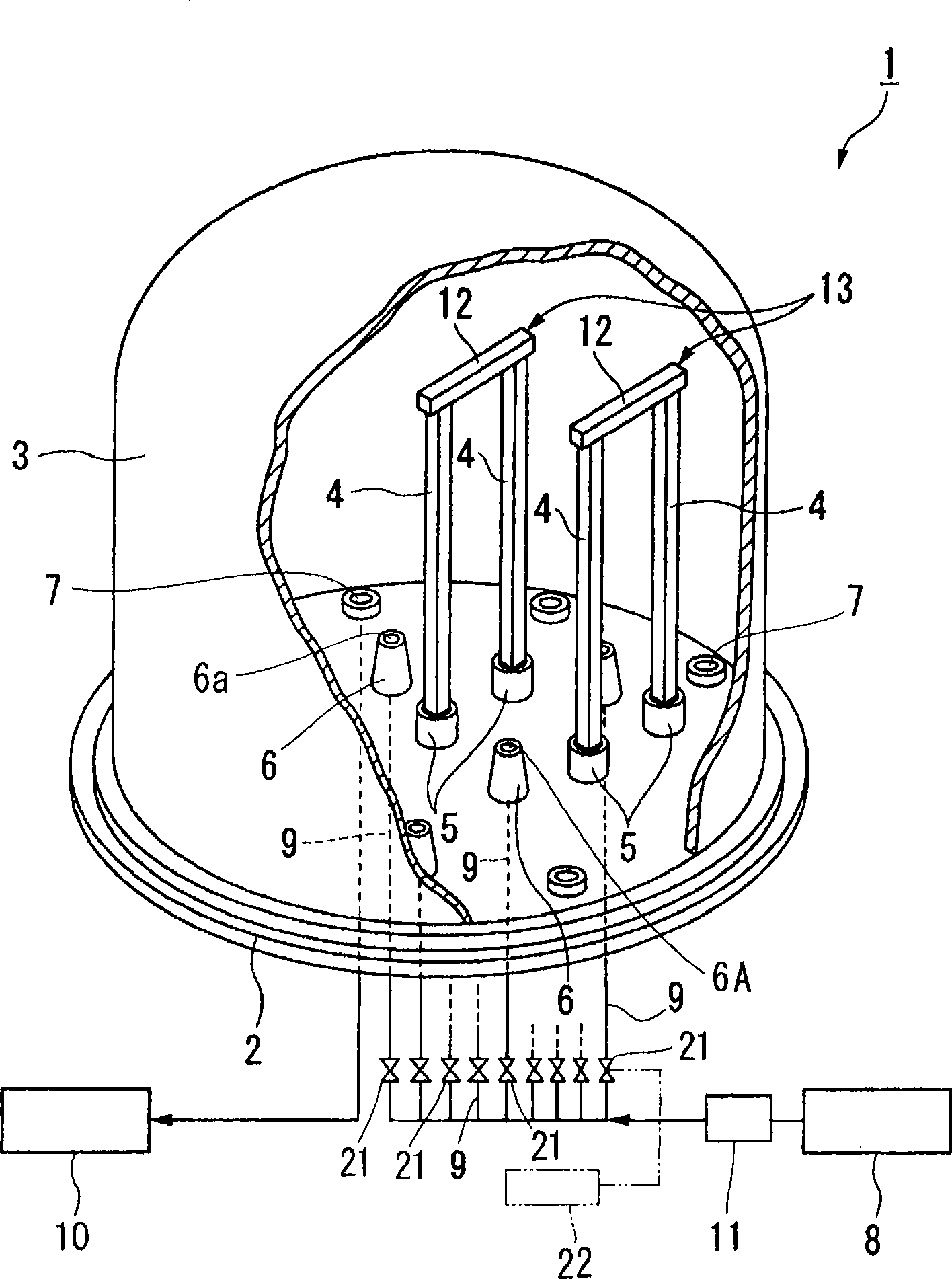

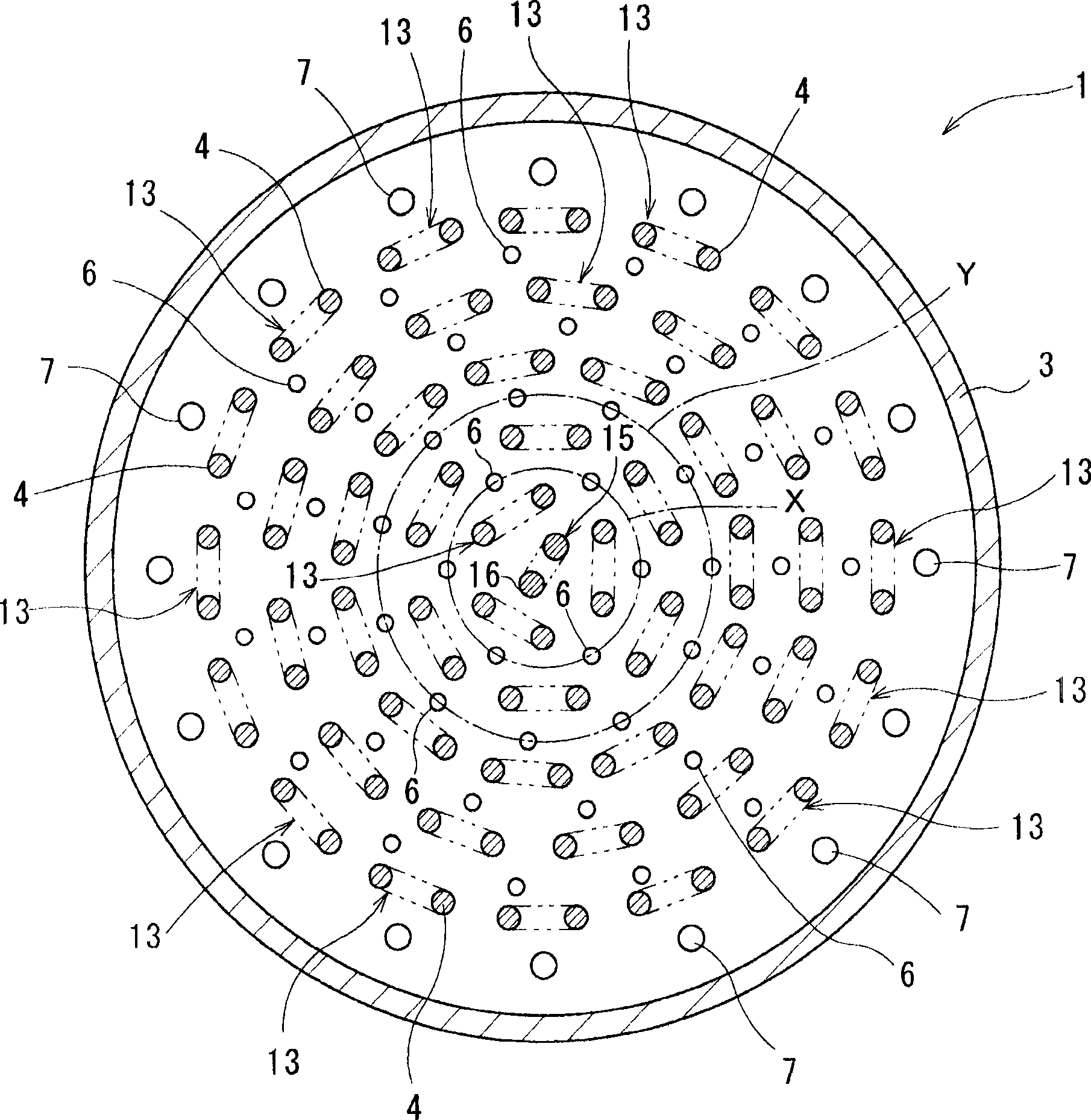

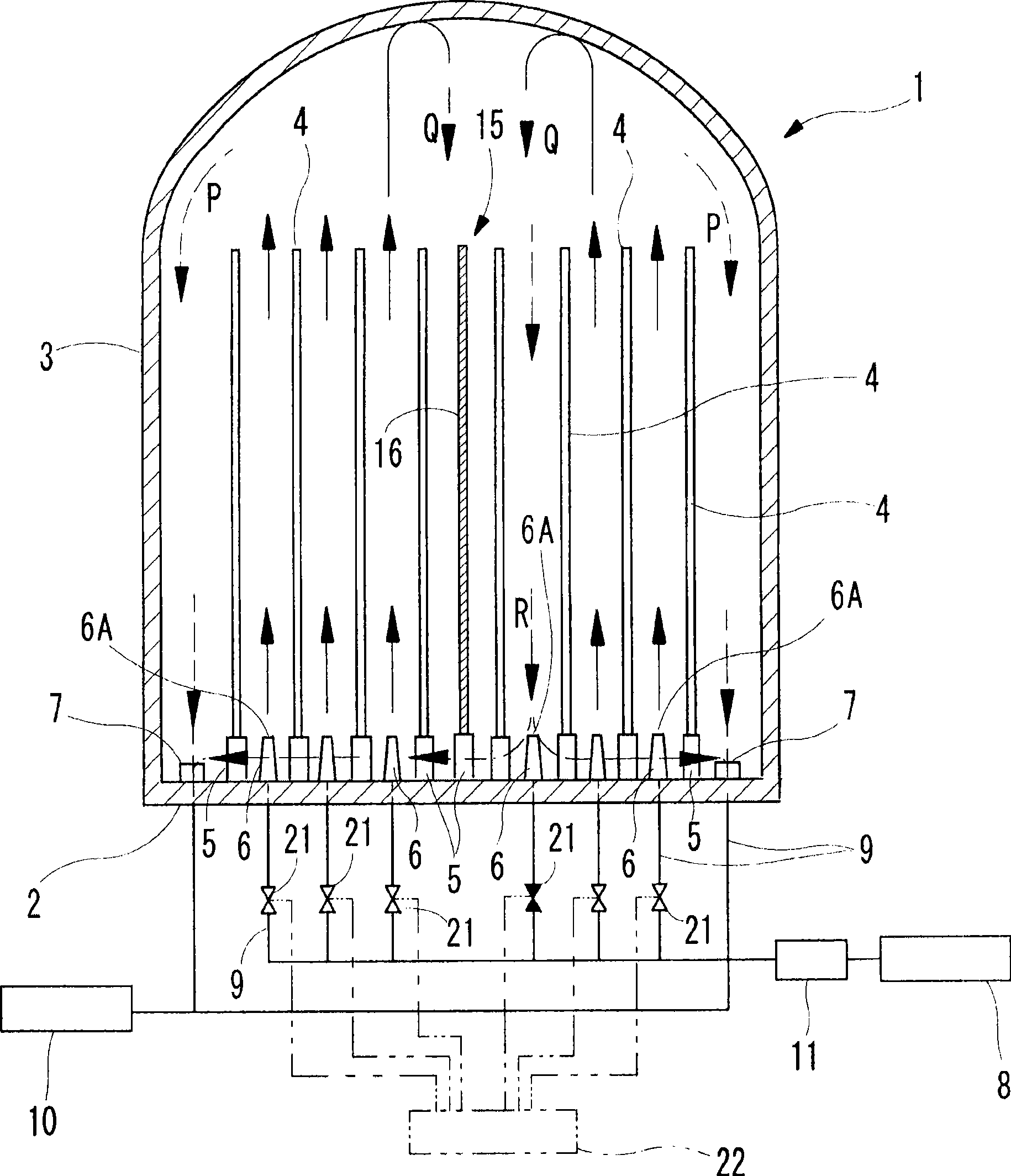

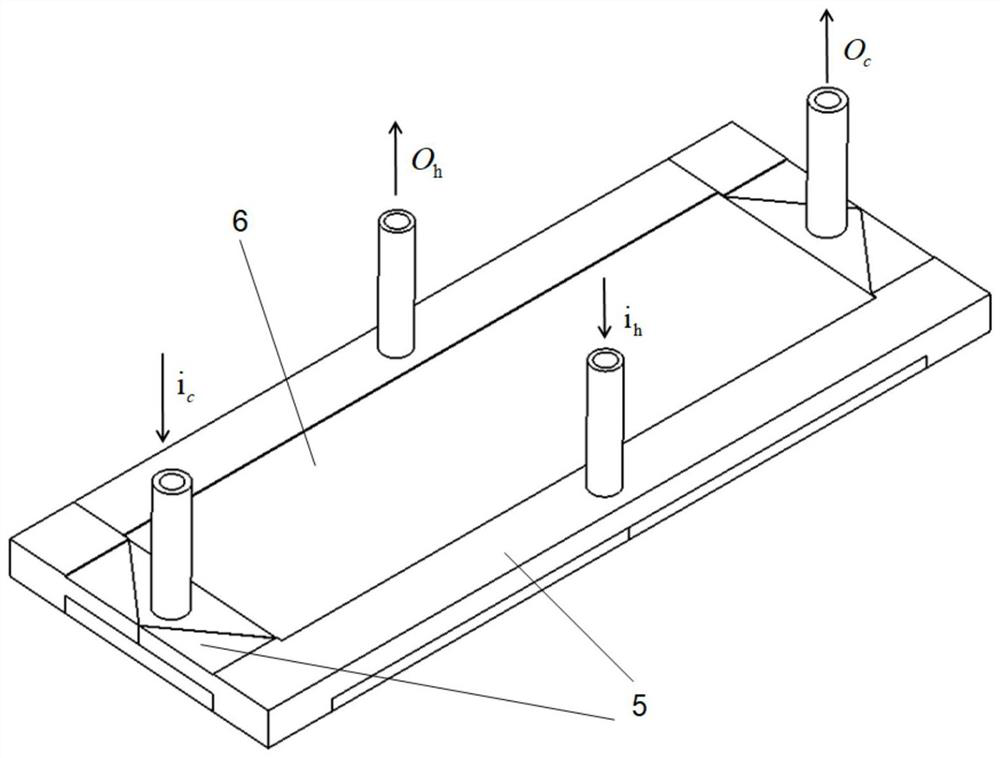

Polycrystalline silicon manufacturing apparatus and manufacturing method

ActiveCN101445239AAvoid interferenceImprove qualitySemiconductor/solid-state device manufacturingSilicon compoundsProcess engineeringGas supply

There is provided a polycrystalline silicon manufacturing apparatus, in which a plurality of gas supplying ports (6A) for ejecting raw gas upward in a reactor (1) and gas exhausting ports (7) for exhausting exhaust gas after a reaction are provided on an inner bottom of the reactor (1) in which a plurality of silicon seed rods (4) are stood, the silicon seed rods (4) are heated and the polycrystalline silicon is deposited from the raw gas on the surfaces. The apparatus includes gas distributing tubes (9) that are respectively connected to the gas supplying ports (6A) and respectively supply the raw gas to the gas supplying ports (6A), valves (21) that are provided on at least the gas distributing tubes connected to the gas supplying ports (6A) adjacent to a center of the reactor (1) and open or close conduit lines of the gas distributing tubes (9), and a valve controlling device (22) that is connected to the valves (21) and controls the conduit lines to be closed for a predetermined time at an early stage of the reaction.

Owner:HIGH PURITY SILICON CO LTD

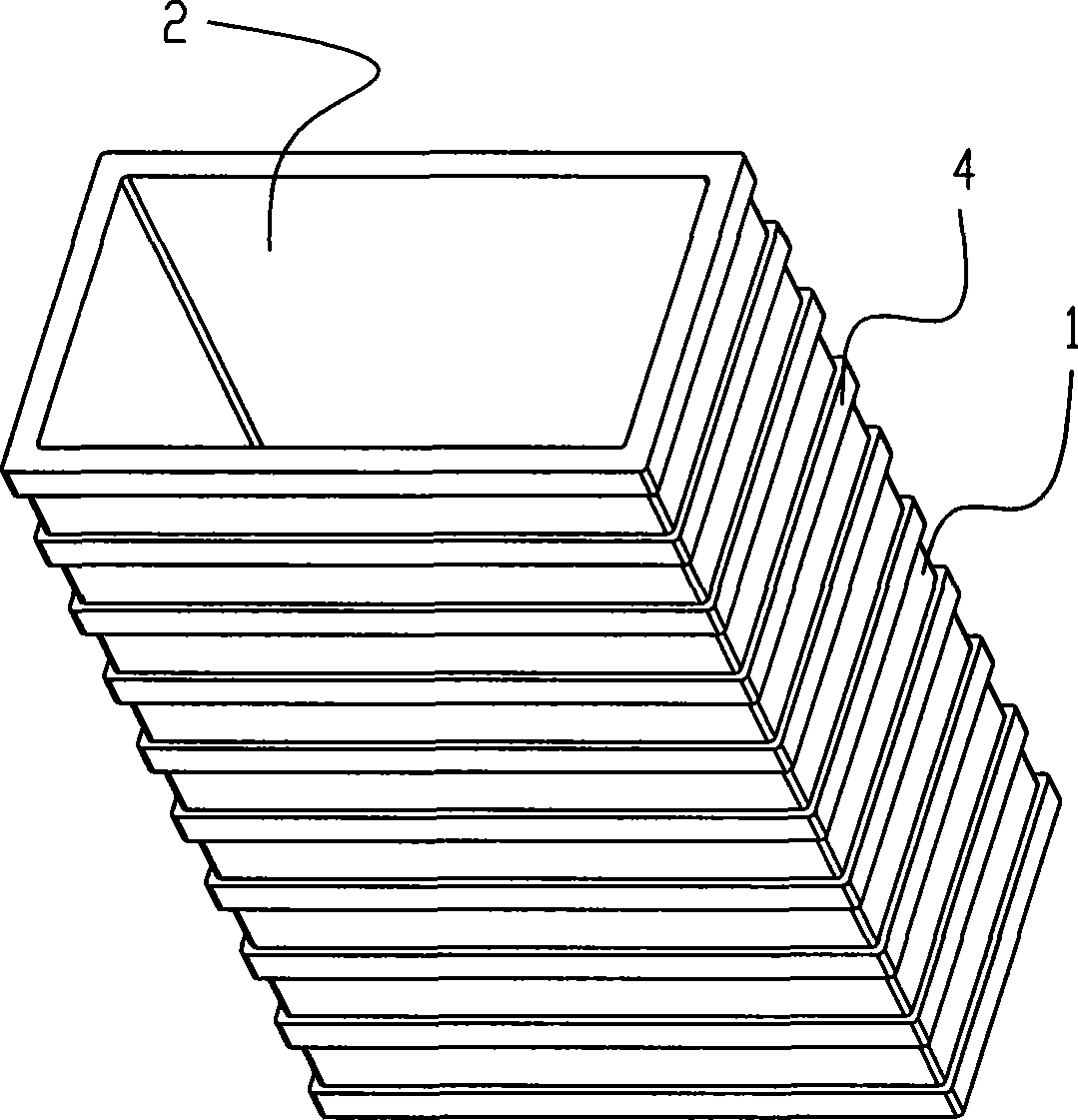

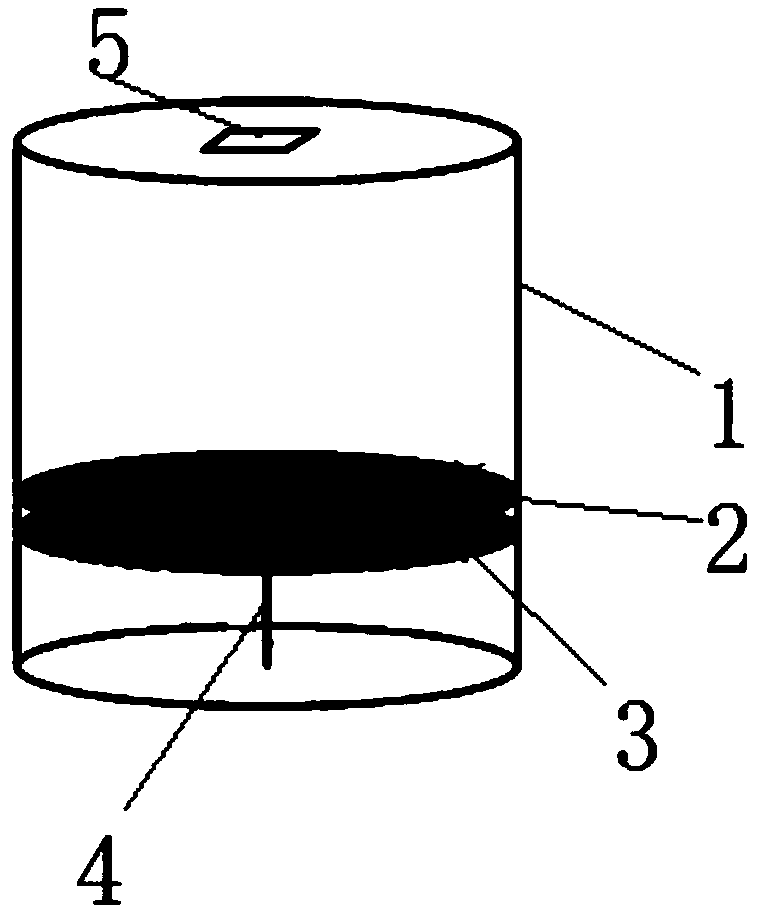

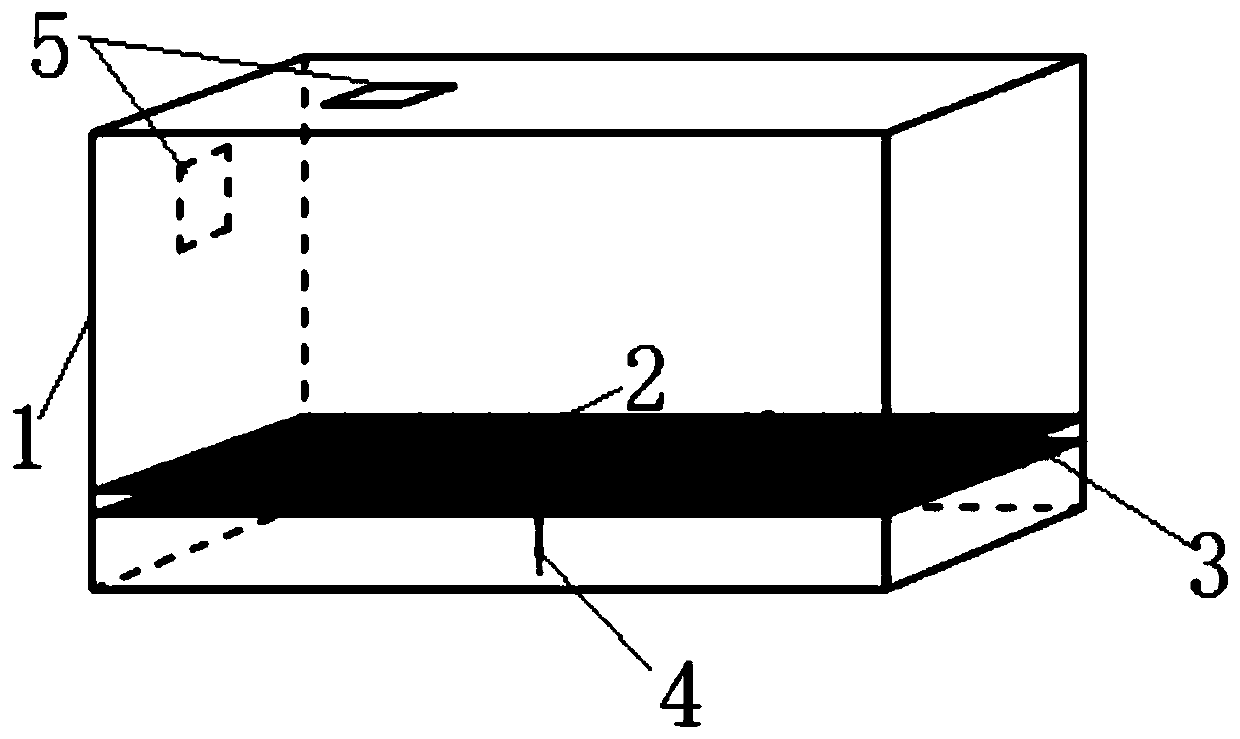

Improved battery

ActiveCN101465412AImprove cooling effectDo not change shapeSmall-sized cells cases/jacketsManufacturing technologyEngineering

The invention belongs to the technical field of battery manufacturing of electric motor cars and in particular relates to an improved battery; the battery comprises a shell, an upper cover, a pole rod, a lithium battery and an electric conducting bar; the shell is a cuboid shape, and the opening of the shell is sealed by the upper cover, and a strengthening rib is formed by the outer wall of the shell forms, and the lithium battery is arranged in the shell; the pole rod is embedded on the upper cover, and the outer end of the pole rod is connected with the electric conducting bar; the strengthening rib is transversely and uniformly distributed by the way that the strengthening rib is parallel to the edge of the opening of the shell. The improved battery has the advantages of high-strength shell, good heat radiating performance, simple structure, high using safety, high sealing property, long service life and the like.

Owner:ZHEJIANG GBS ENERGY

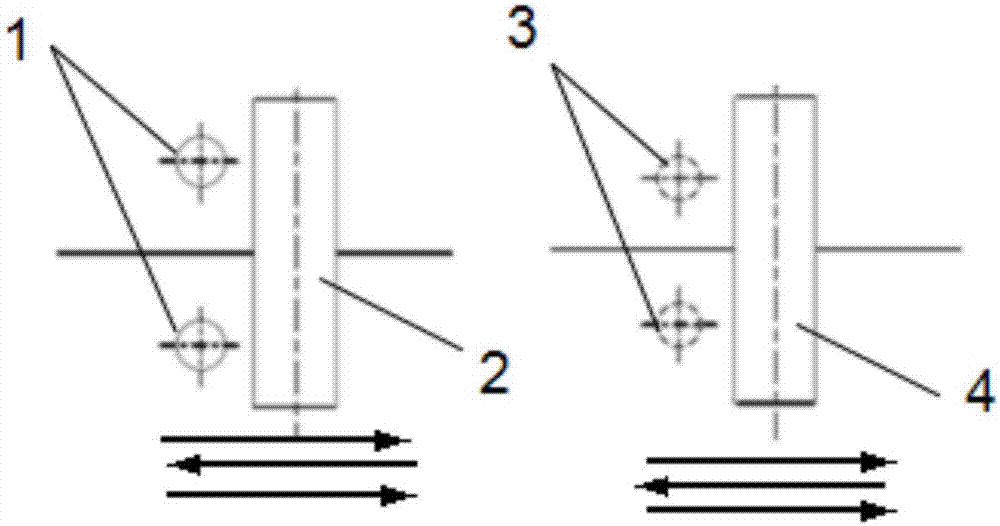

Manufacturing method for reducing edge defects of hot-rolled strip steel

InactiveCN107096795ANo change in processNo change logic controlMetal rolling stand detailsMetal rolling arrangementsProcess systemsStrip steel

The invention relates to a manufacturing method for reducing edge defects of hot-rolled strip steel. The manufacturing method comprises the following steps: carrying out heating control, and heating a slab to 1190-1230 DEG C; setting the width model load, calculating a rough rolling width model according to the thickness and width of the slab and a finished product, and setting the rolling reduction of each pass of a rough rolling vertical roll and a flat roll; carrying out rolling by the rough rolling vertical roll, setting the opening degree of a rough rolling machine E1 and a rough rolling machine E2 according to the model calculation result, and carrying out slab width control; and carrying out rolling on the slab subjected to rolling by the vertical roll through the flat roll, and reducing the thickness of the slab. According to the manufacturing method, process and control optimization are carried out on the basis of existing equipment, so that equipment investment is avoided; the existing process system and logic control are not changed, so that the current production process control is not affected; and adverse effects on other quality indexes such as width control are avoided.

Owner:NINGBO IRON & STEEL

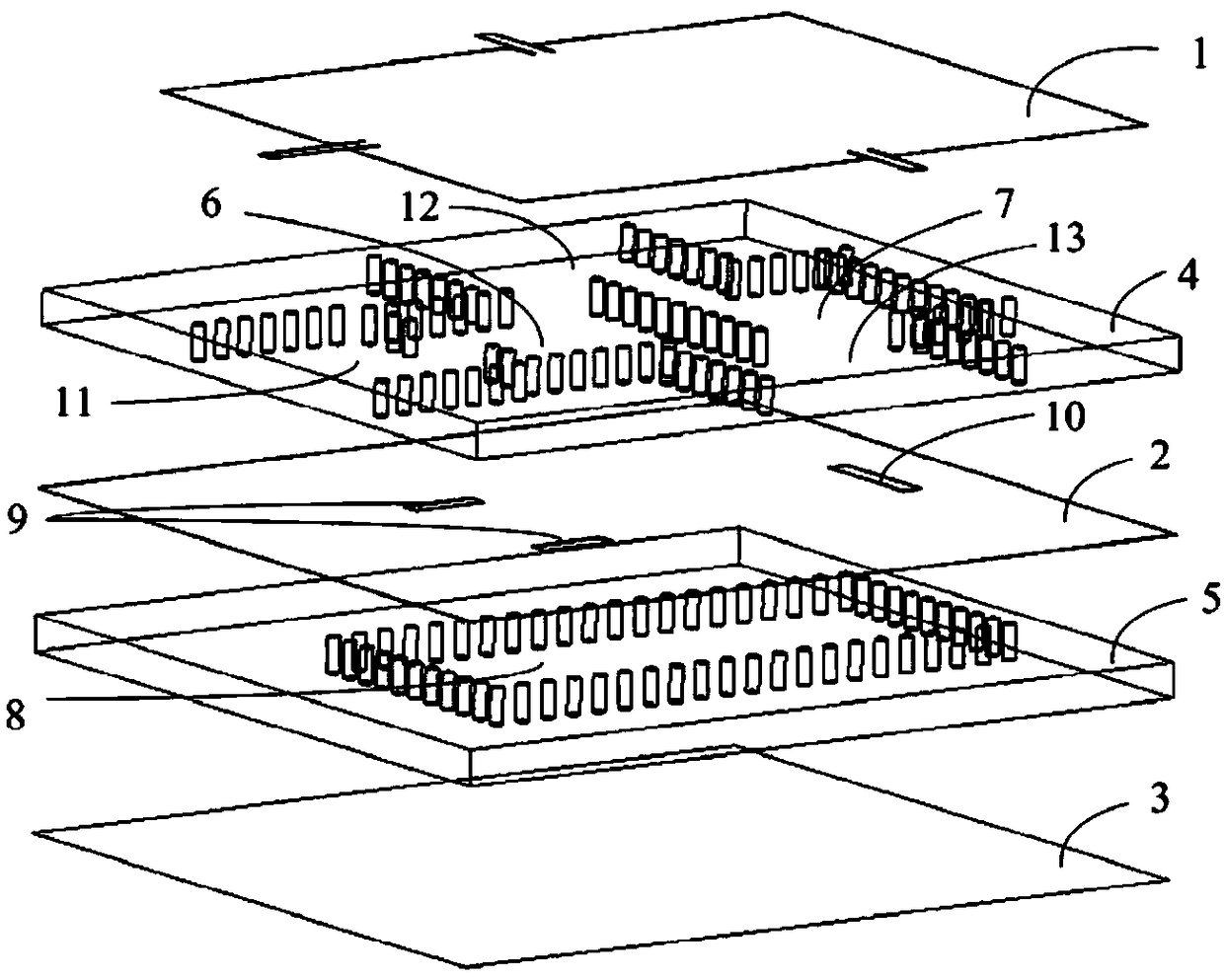

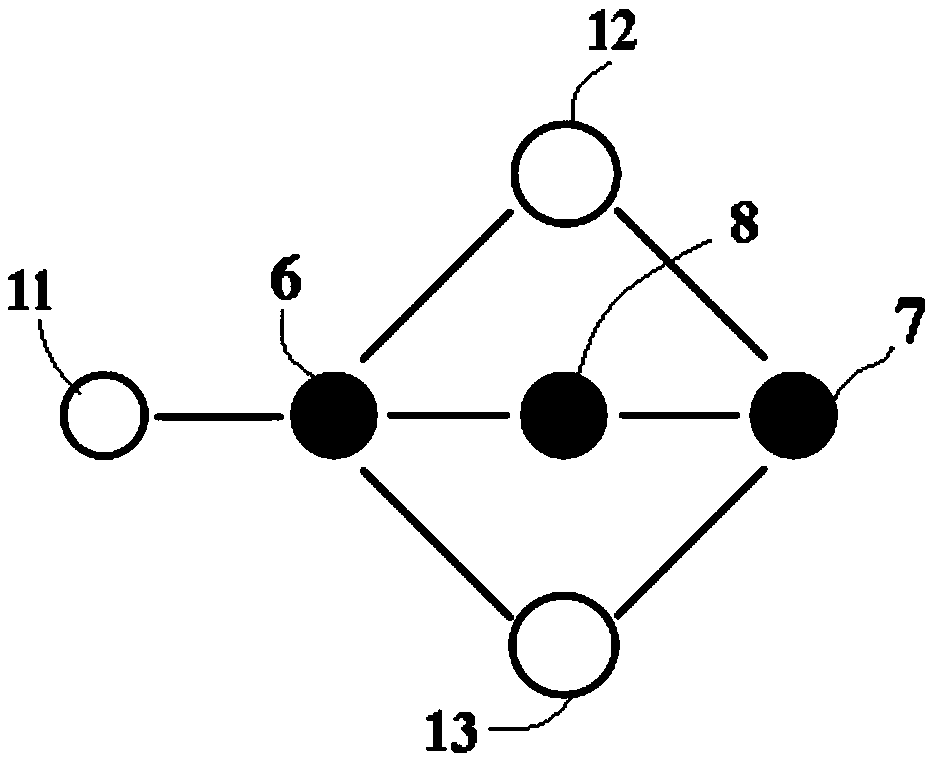

Multilayer substrate integrated waveguide third-order filter power divider

The invention discloses a multilayer substrate integrated waveguide third-order filter power divider, comprising a first metal layer, a second metal layer, a third metal layer, a first dielectric substrate and a second dielectric substrate, wherein the first dielectric substrate is provided with a first resonant cavity, a second resonant cavity, an input waveguide, a first output waveguide and a second output waveguide; the second dielectric substrate is provided with a third resonant cavity, the input waveguide excites the first resonant cavity, the first output waveguide and the second output waveguide simultaneously excite the first resonant cavity and the second resonant cavity, and the second metal layer is configured to adjust magnetic coupling coefficients of the first resonant cavity, the second resonant cavity, and the third resonant cavity to obtain two transmission zeros. The divider obtains additional transmission zeros by adjusting the electromagnetic coupling strength between the upper and lower cavities, and simultaneously integrates the characteristics of the power divider without changing the existing filter size, which has both the frequency selection characteristic and the power division performance.

Owner:SHANGHAI AEROSPACE COMP TECH INST

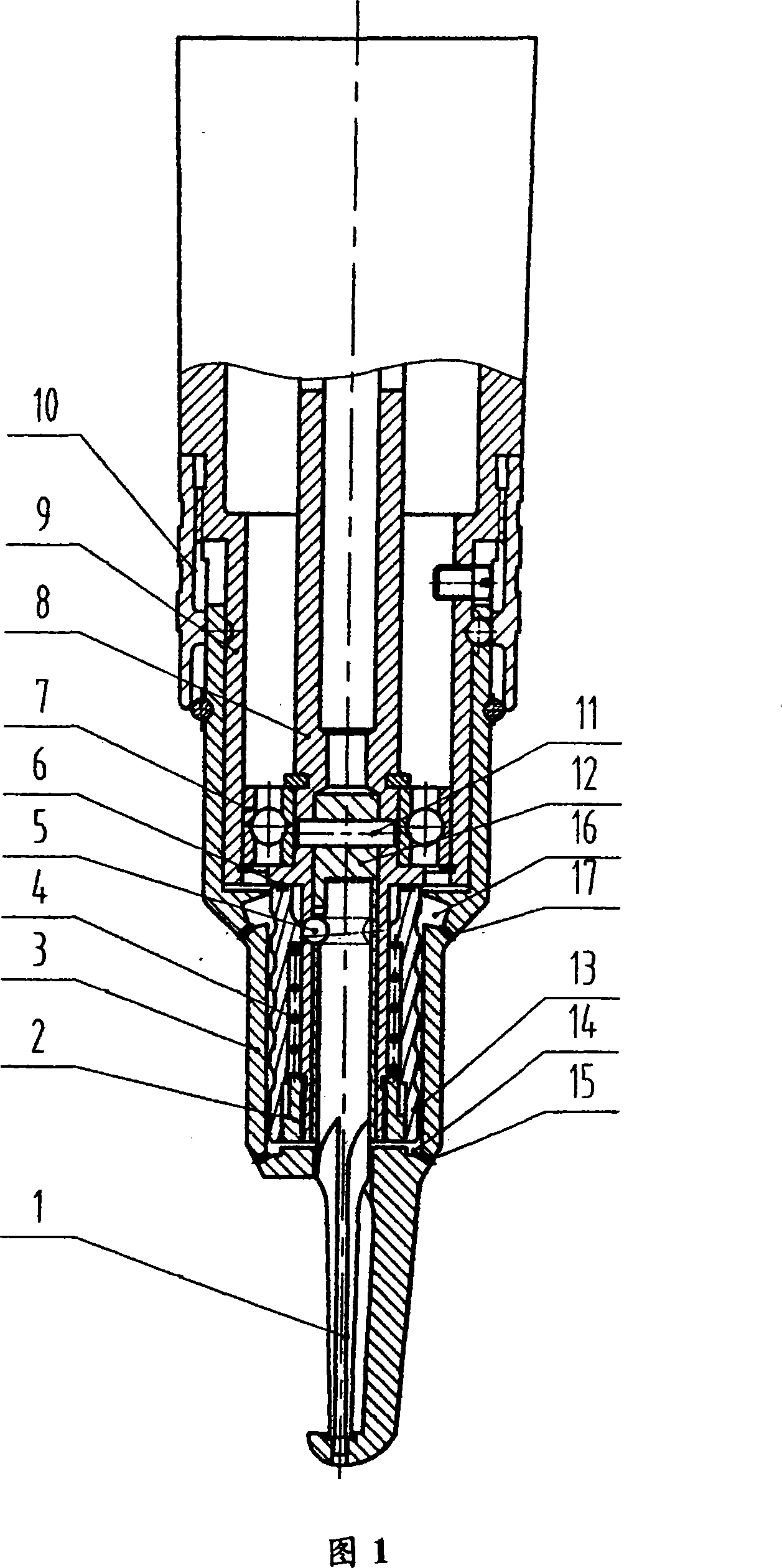

Hand milling machine capable of preventing blood entering

The invention relates to a milling handset for preventing the entering of blood, which comprises an outer sleeve, a boot sleeve which is engaged with the lower part of the outer sleeve, a driving shaft cylinder which is engaged in the outer sleeve, a milling cutter sleeve which is fixedly connected in the lower part of the driving shaft cylinder, a sleeve which is connected with the lower end of the driving shaft cylinder through threads, a hole whose upper part penetrates into the lower part of the boot sleeve and a milling cutter which is fixedly connected in the milling cutter sleeve through steel balls. The invention is characterized in that a spiral sealing sleeve is arranged on the outer sides of the lower portions of the sleeve, the spring and the driving shaft cylinder, the outer side of the spiral sealing sleeve is engaged with the inner wall of the lower part of the boot sleeve, a liquid outlet ring groove is arranged on the bottom of the boot sleeve, liquid outlets are arranged along the bottom of the liquid outlet ring groove, a relief overflow ring groove is arranged on the middle part of the boot sleeve, and overflow holes are arranged along the bottom of the relief overflow ring groove. The invention can effectively prevent blood from entering into the inner portion of the milling handset, largely prolongs the maintenance cycle of the milling handset, and excellently meets the clinical requests.

Owner:CHONGQING XISHAN SCI & TECH

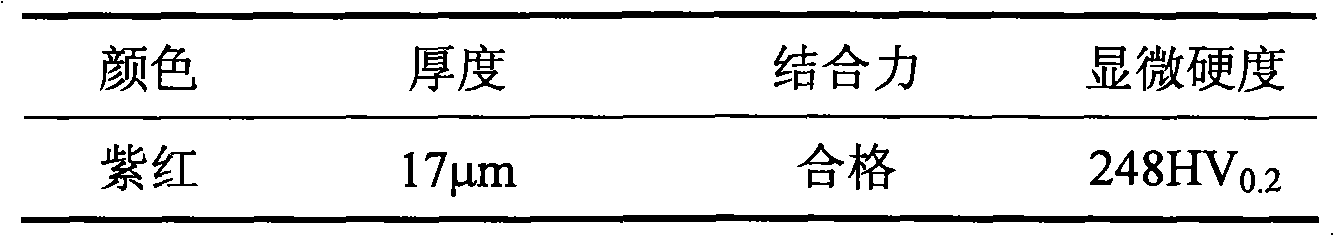

Antibacterial hard stainless steel tool and preparation method thereof

InactiveCN103526175AChange sizeWill not cause high temperature deformationVacuum evaporation coatingSputtering coatingAnti bacterialSS - Stainless steel

The invention relates to an antibacterial hard stainless steel tool and a preparation method thereof. According to the technical scheme, a stainless steel tool to be processed is vertically arranged upwards in a high energy ion implantation machine with the blade facing upwards, ion cleaning is firstly carried out on the surface of the stainless steel tool to be processed, silver ion implantation is then carried out, then nitrogen ion implantation is carried out, and the antibacterial hard stainless steel tool is obtained. The Cr content of the stainless steel tool to be processed is 12-32wt%, and the working condition of the silver ion implantation is that the acceleration voltage of an ion source is 10-100KV, and the implantation dosage of the silver ion is 5.0*1015 - 1.0* 1019 ions / cm2. The working condition of the nitrogen ion implantation is that the acceleration voltage of an ion source is 10-100KV, and the implantation dosage of the nitrogen ion is 5.0*1015 - 1.0* 1019 ions / cm2. The antibacterial hard stainless steel tool and the preparation method thereof have the advantages of being high in processing speed, simple in machining and free of pollution. The prepared antibacterial hard stainless steel tool is good in abrasive resistance, high in hardness, long in service life, and capable of maintaining the original shape and appearance of the tool, and has good lasting antibacterial performance.

Owner:WUHAN UNIV OF SCI & TECH +1

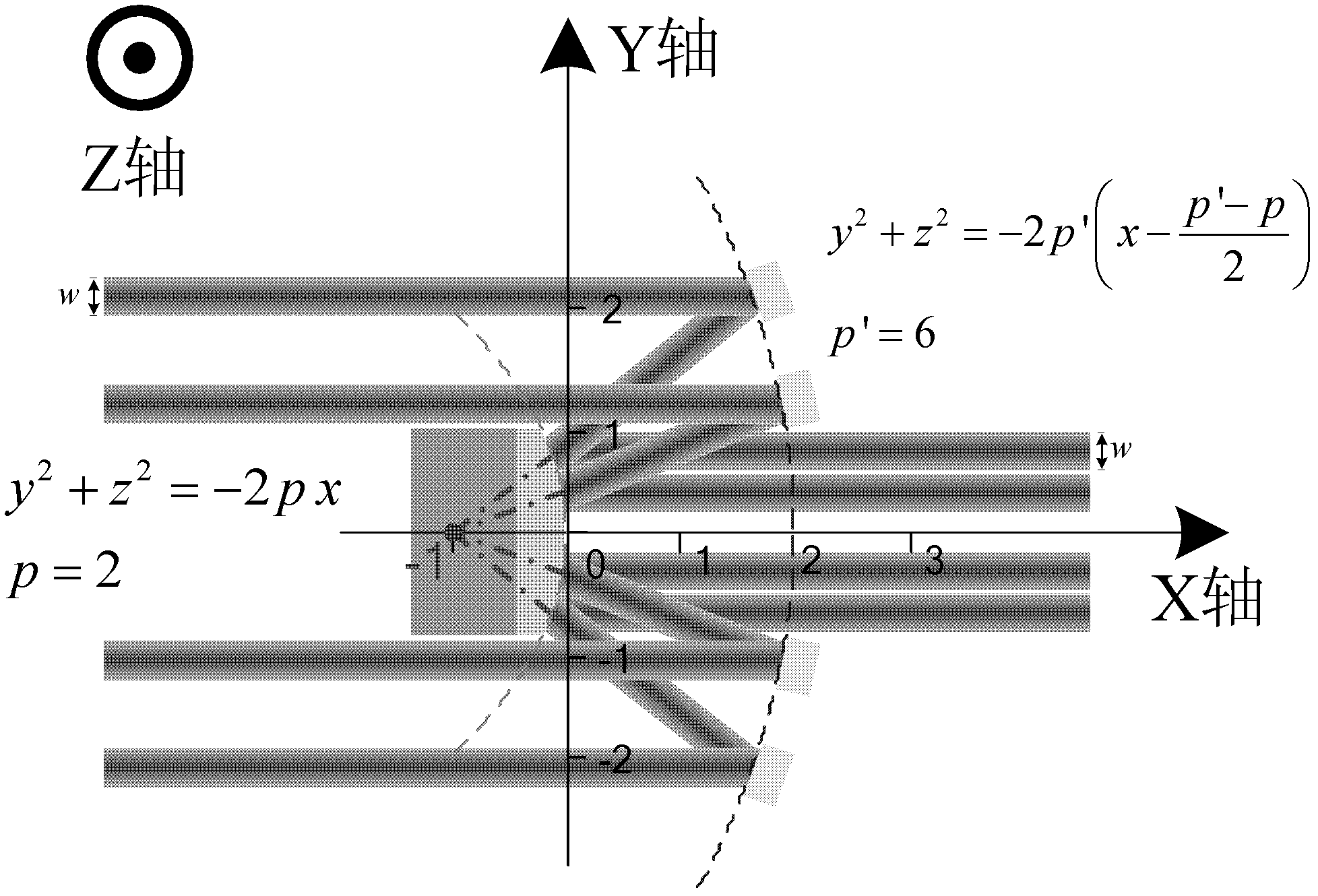

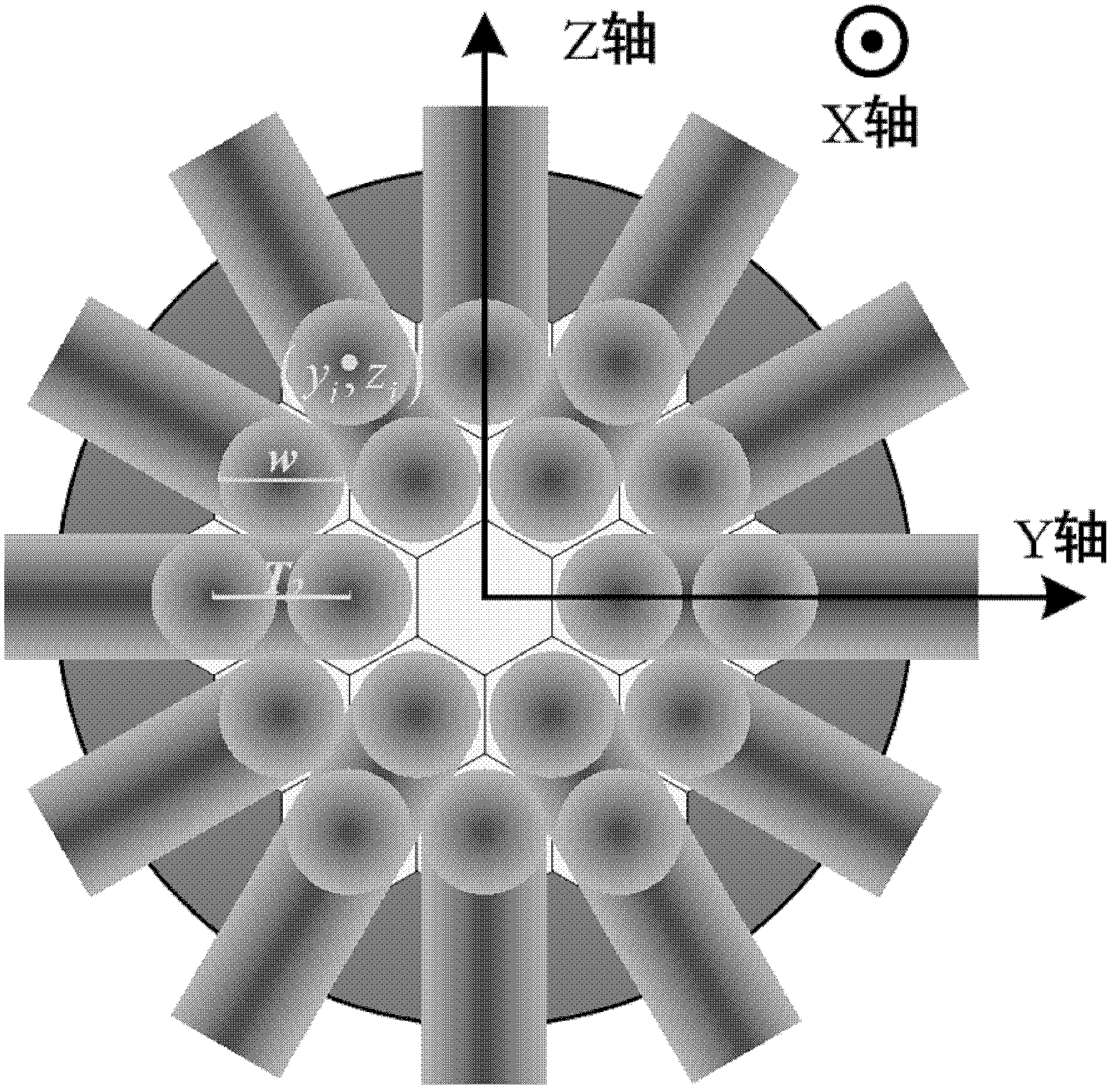

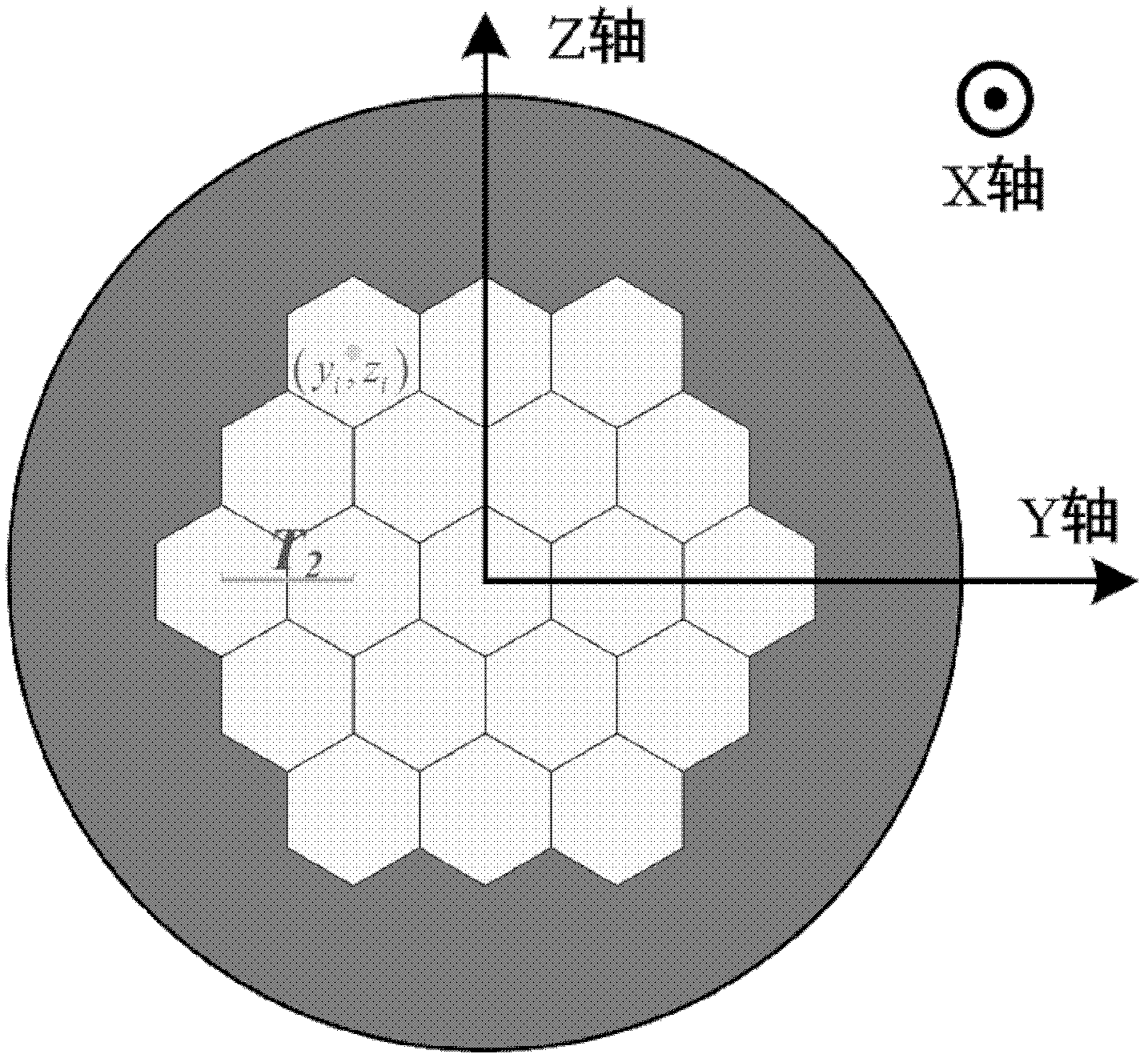

Cassegrain type light beam synthesizer with high duty ratio

ActiveCN102213833AImplement conformal emissionCompact structureOptical elementsPlane mirrorLight beam

The invention provides a cassegrain type light beam synthesizer with high duty ratio, and the synthesizer provided by the invention can be used for realizing the high duty ratio splicing of multiple paths of parallel light beams. In the design method of the compact light beam synthesizer provided by the invention, the geometric characteristics of revolution paraboloids and the structural features of a cassegrain light beam transformation system are combined; and the main technical points are as follows: the synthesizer comprises two reflectors, namely an independent incidence reflector and an integrated emergence reflector; the two reflectors are ranked into the cassegrain light beam transformation system in the space; each reflector is a plane mirror, and the centers of the reflectors are ranked on the two revolution paraboloids which have the same axis, the same focal point and the same direction; and the normal direction of the reflector surfaces is the normal direction at which the revolution paraboloids are positioned. The beam contraction ratio and duty ratio of the synthesizer which adopts the design provided by the invention have the clear and accurate mathematic description; and the synthesizer provided by the invention can be widely applied to the fields of the coherence synthesizing and non-coherence synthesizing of multiple light beams and the other synthesizing of light beams and has greater application prospects.

Owner:NAT UNIV OF DEFENSE TECH

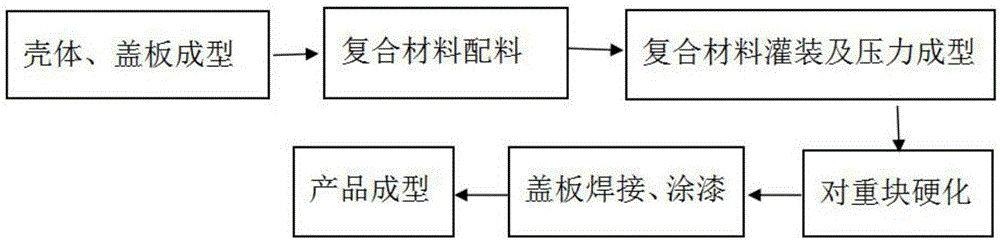

Elevator counterweight block and production method thereof

ActiveCN106380134AImprove early strengthIncrease late strengthMine liftsAdhesiveCompressive strength

The invention discloses an elevator counterweight block and a production method thereof. The counterweight block comprises a shell, a composite material filled in the shell, a metal mesh coated in the shell by the composite material as well as a cover plate fixedly connected with the shell. The composite material comprises the following raw materials in parts by weight: 50-80 parts of cement, 150-200 parts of hematite, 3-5 parts of a cement additive, 5-10 parts of an adhesive, 5-8 parts of an antifoaming agent, 3-5 parts of an anti-cracking agent, 3-5 parts of a water reducing agent, 5-8 parts of dense agent, 2-5 parts of a hardening agent, 1-3 parts of expansion coordination agent and 20-50 parts of water. According to the invention, the counterweight block is reasonable in design, the final compressive strength of the counterweight block is ensured to be greater than 30MPa, and the cost of the counterweight block is reduced on the premise that the performance of the counterweight block is not reduced; the composite material of the counterweight block is scientific in proportioning, and the specific gravity of the counterweight block reaches 3.6g / cm<3>; the counterweight block is compact in structure and excellent in strength and does not generate cracks after being used for a long time; and the size of a well is not changed, and meanwhile, the cost of the counterweight block is lowered.

Owner:河北科莱电梯有限公司

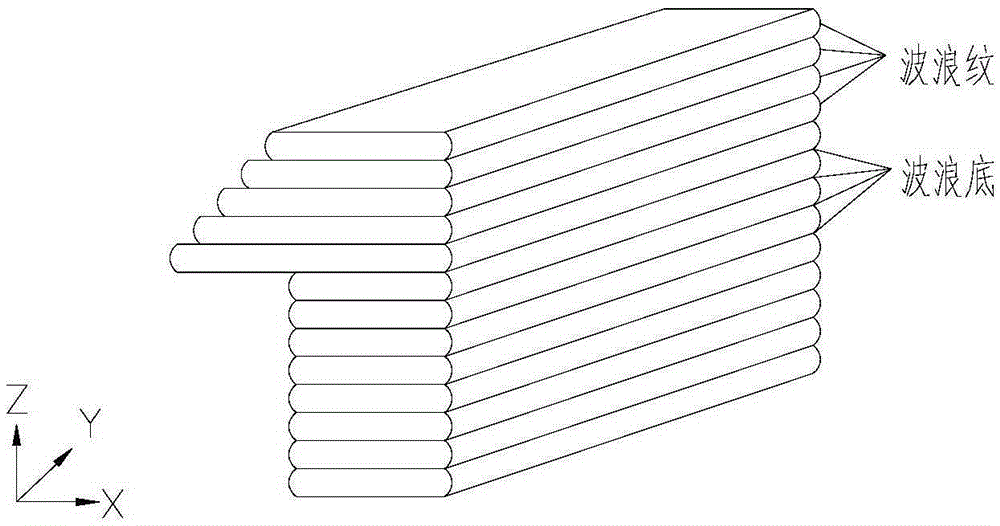

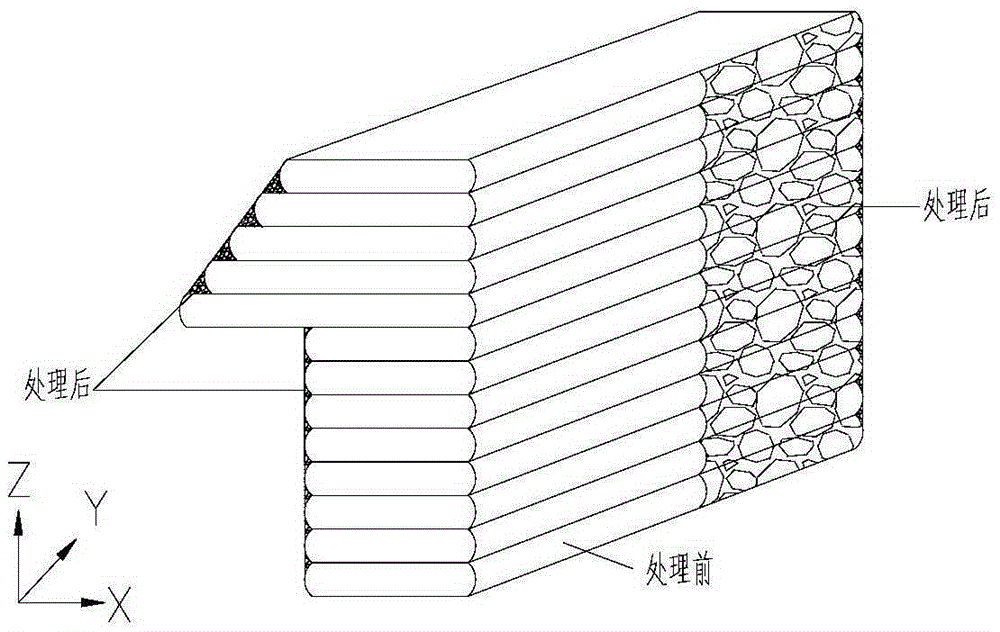

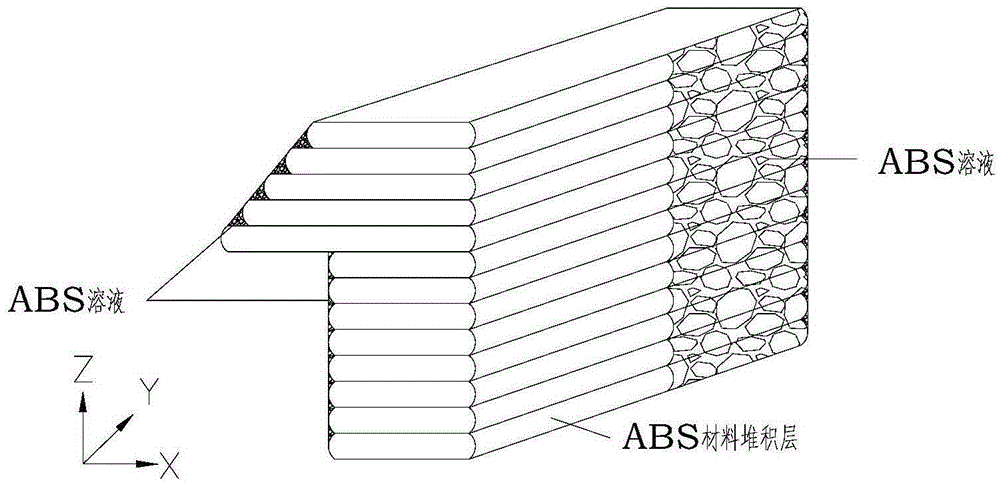

Method for enhancing strength of 3D printed products

The invention belongs to the field of a 3D printing technology and specifically relates to a method for enhancing strength of 3D printed products. The invention aims to solve the technical problem that strength of 3D printed products, especially 3D printed products printed by a fused deposition modeling method in the part-forming Z direction is poor. A raw material of the printed part product is a solute, and a cooperative solvent can effectively dissolve a shallow surface layer of the product. Thus, the shallow surface layer of the product and the solute are fused as a whole. Juncture of 3D printed stack layers is effectively filled, shallow surface layer strength of the juncture is increased, and strength of the 3D printed product is further enhanced. By the method, strength of parts is enhanced, and dimension of parts is basically not changed. The method is very beneficial to expand application range of special plastic parts 3D printed by an FDM technology. The technical problem that has existed in the field all the time is solved. The method has a good application prospect.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

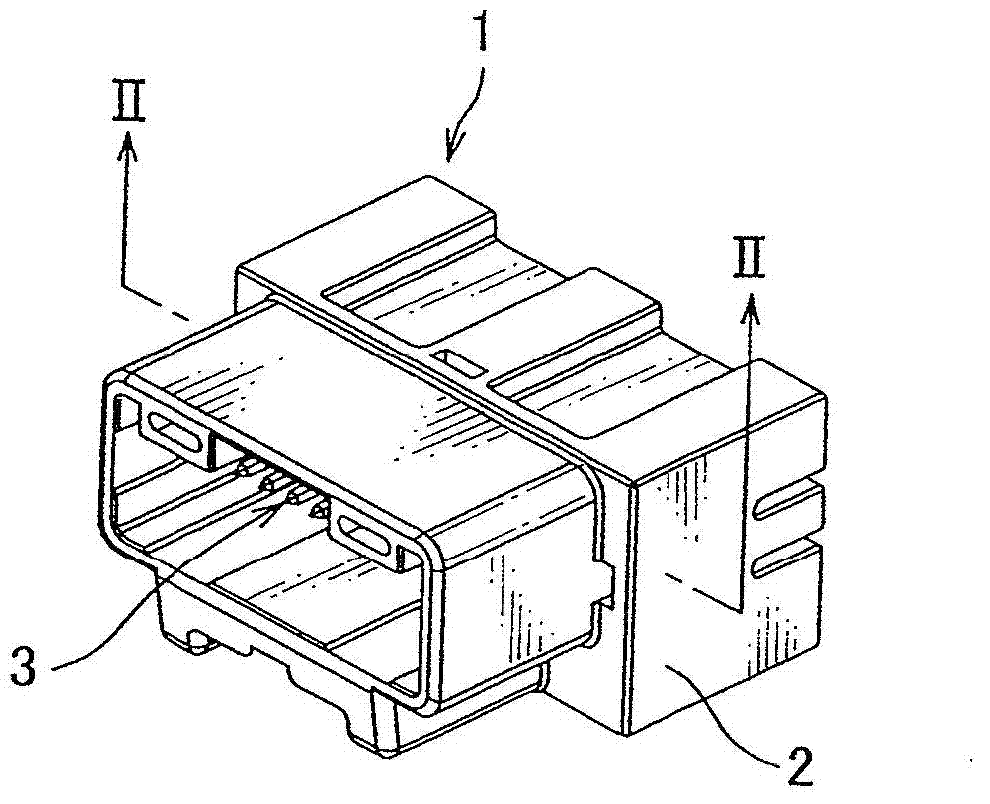

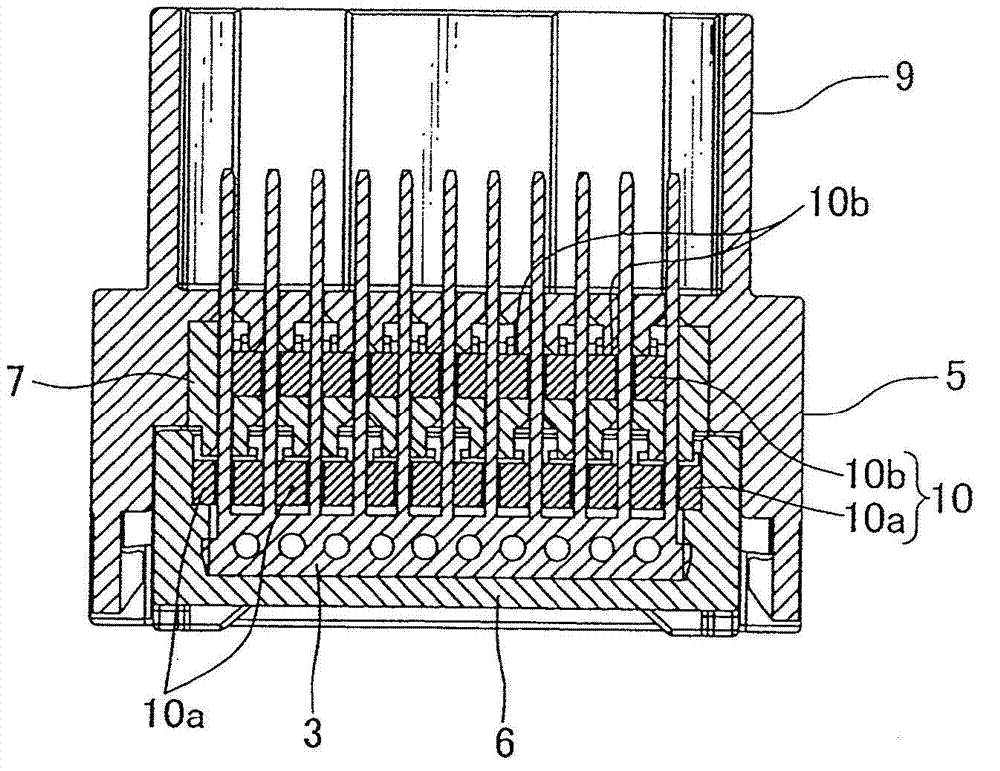

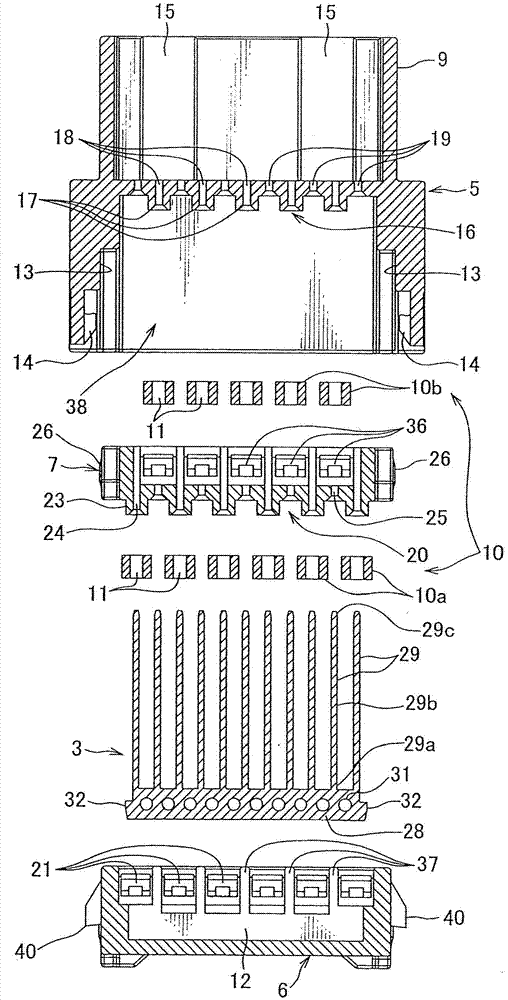

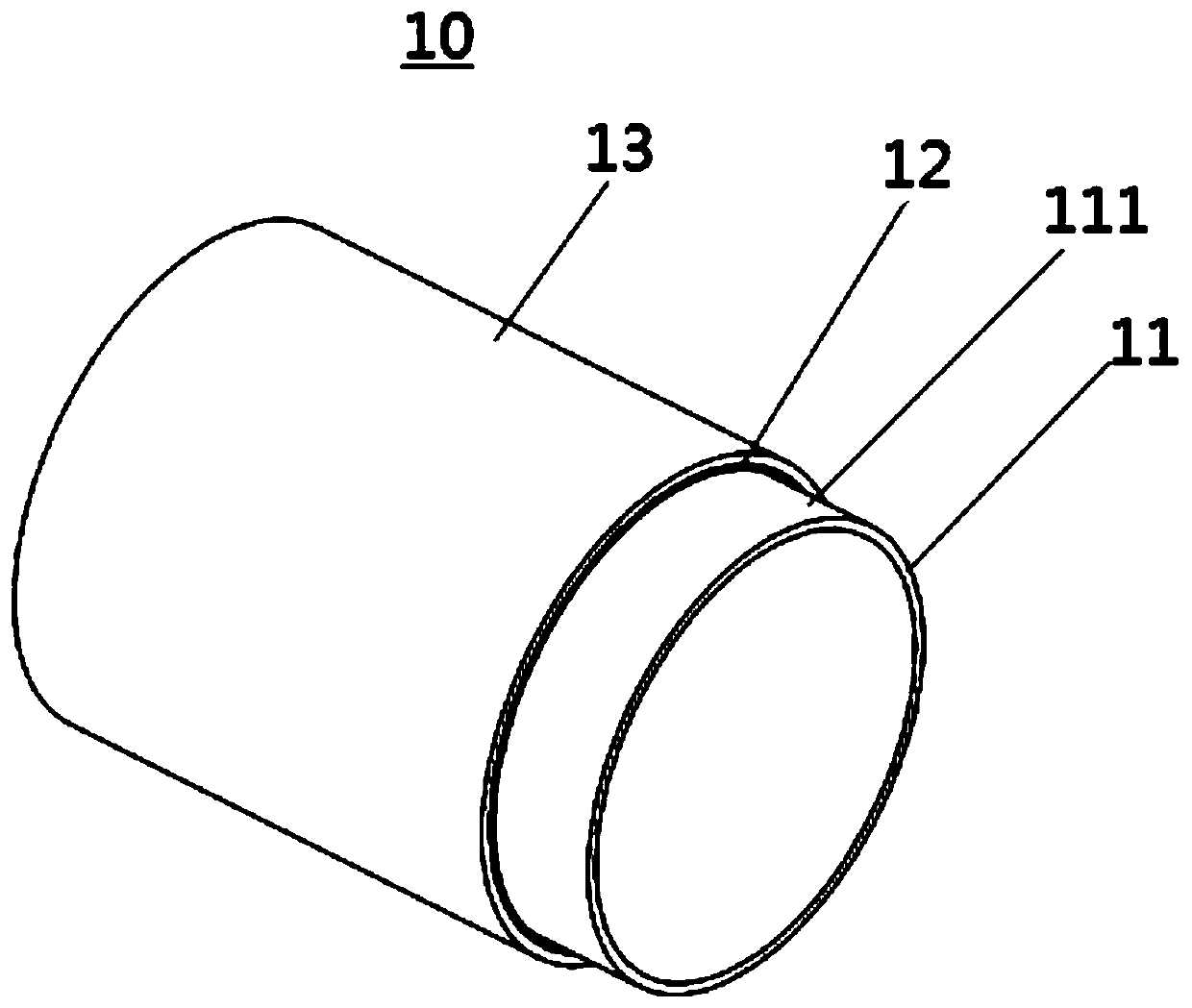

Butting connector

Through making intervals among acicular terminal portions be equal to intervals among terminals of a universal connector, a miniaturization butting connector with versatility is provided. The butting connector (1) comprises a terminal (3) possessing a ferrite core (10) and a connector shell (5) which accommodates the terminal (3). The terminal (3) comprises a busbar (28) and a plurality of acicular terminal portions (29) which are extended from the busbar as a certain interval and are along a length direction of the busbar (28). The ferrite core (10) comprises first ferrite cores (10a) arranged on base ends (29a) of the acicular terminal portions (29) and second ferrite cores (10b) arranged on middle portions (29b) of the acicular terminal portions (29). The first ferrite cores (10a) and the second ferrite cores (10b) are alternately arranged on the plurality of acicular terminal portions (29).

Owner:YAZAKI CORP

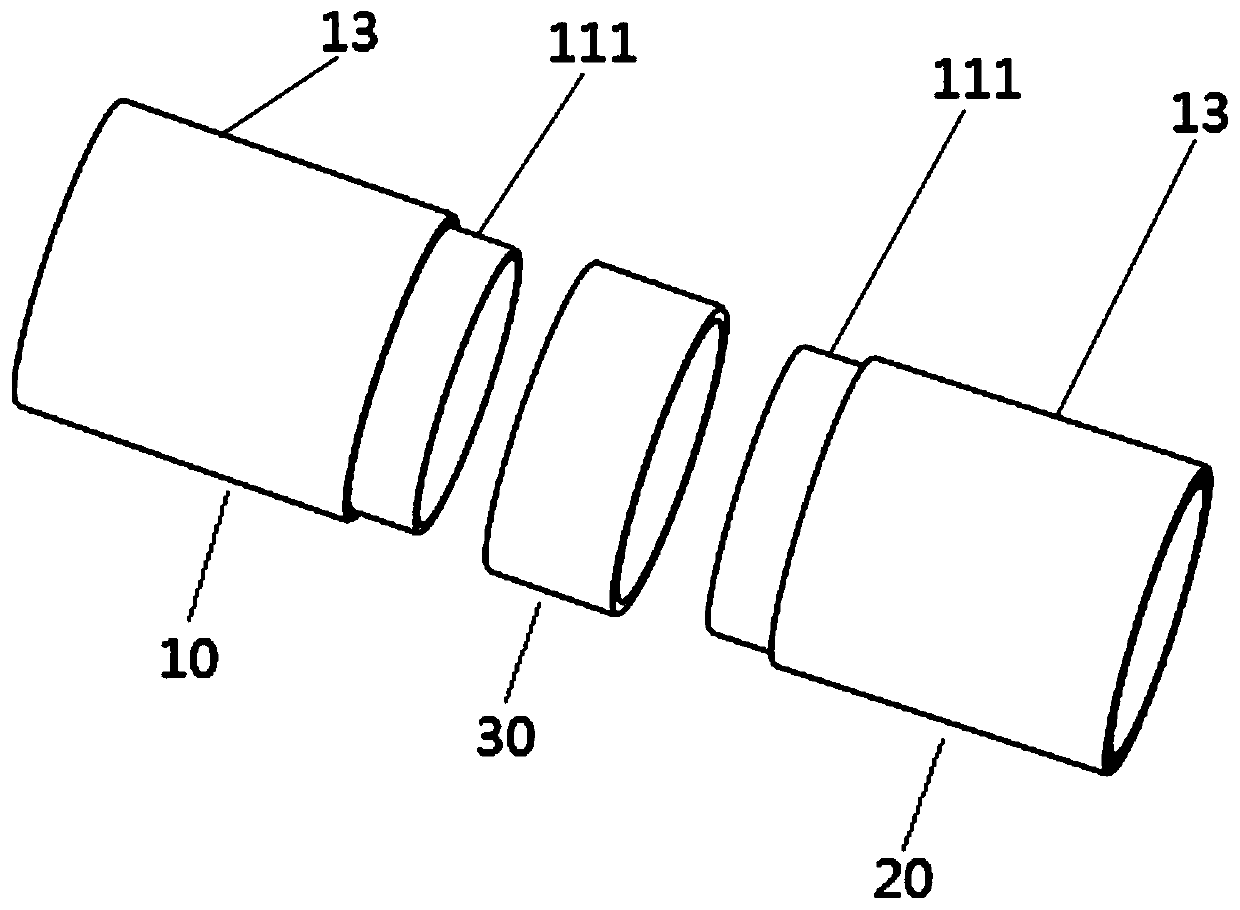

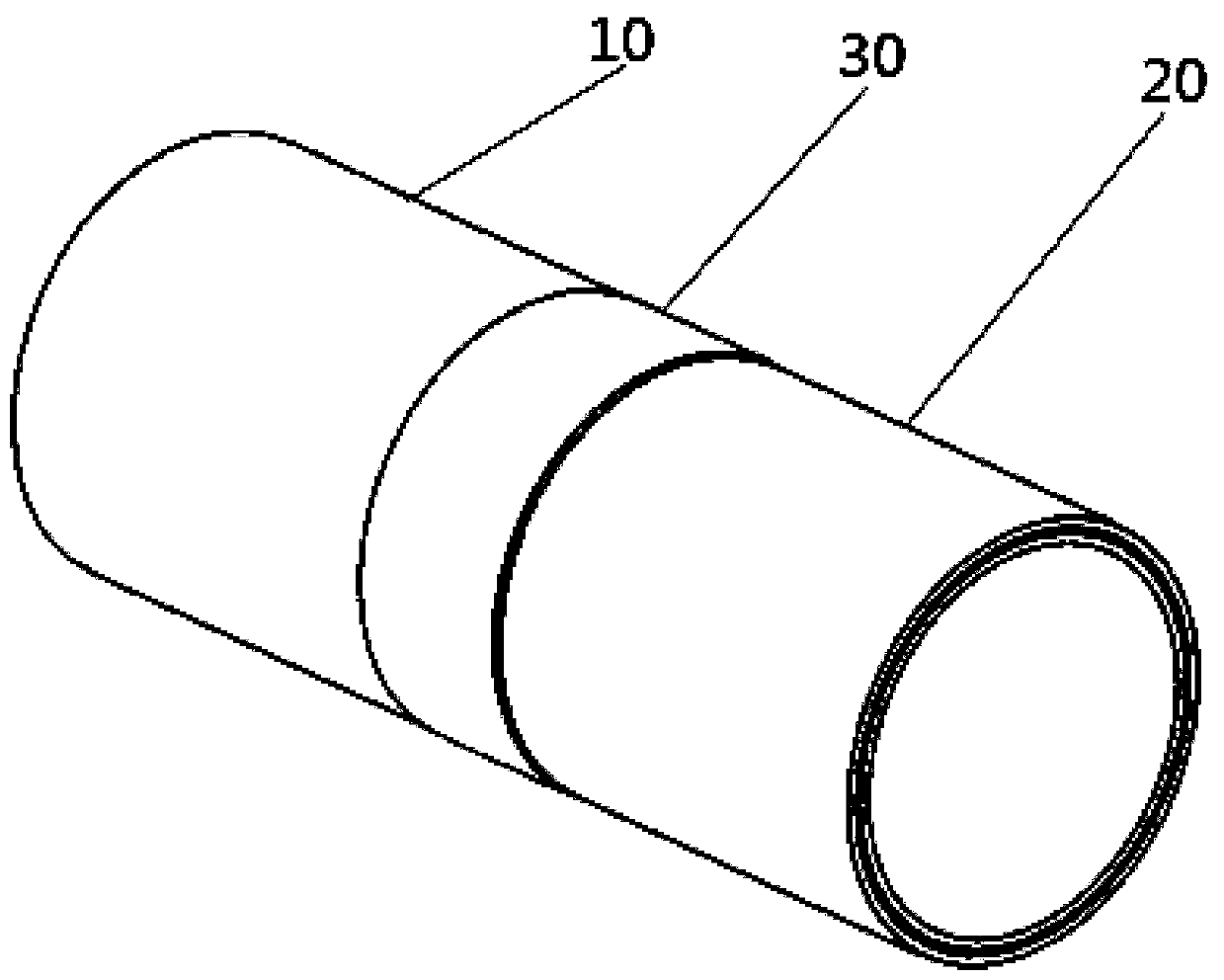

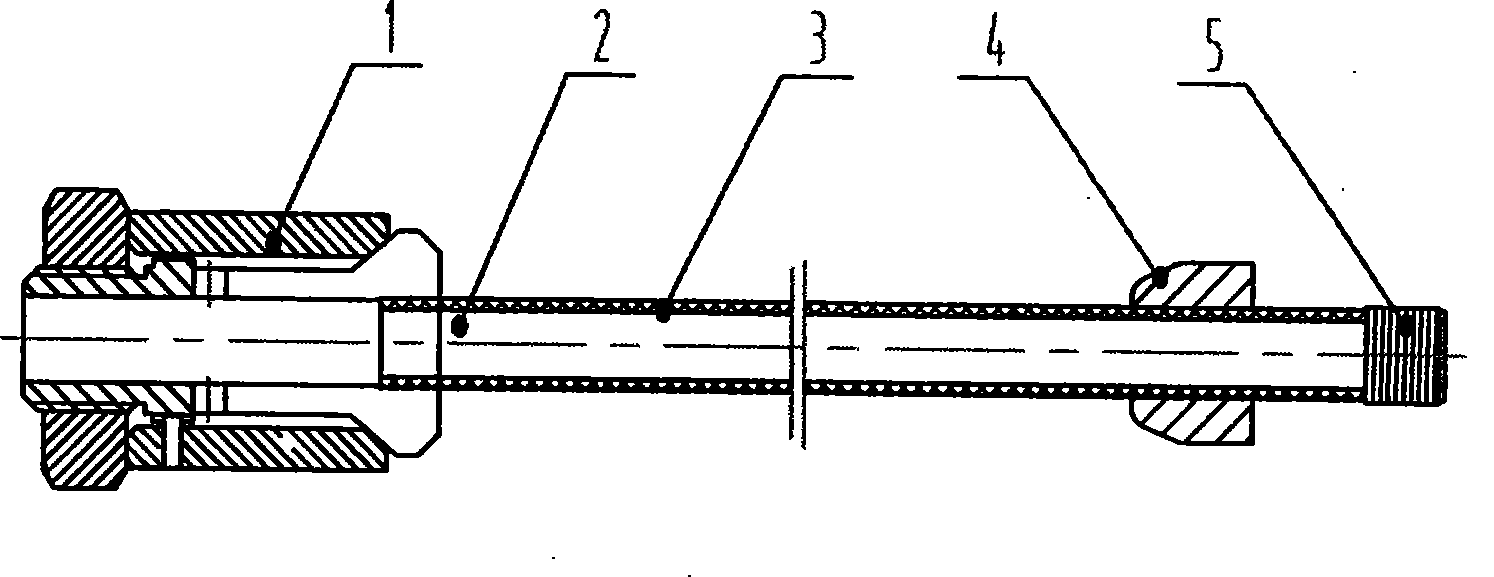

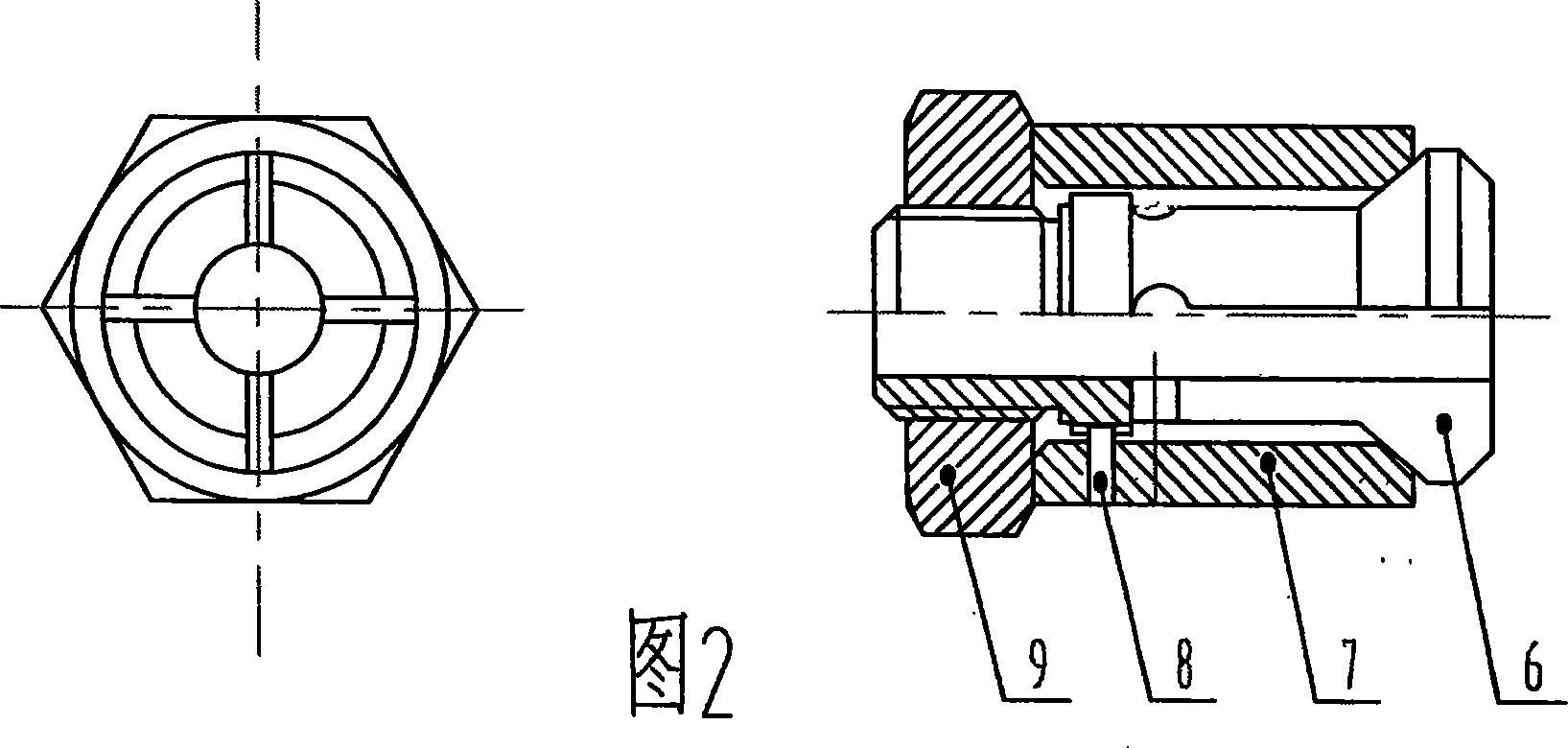

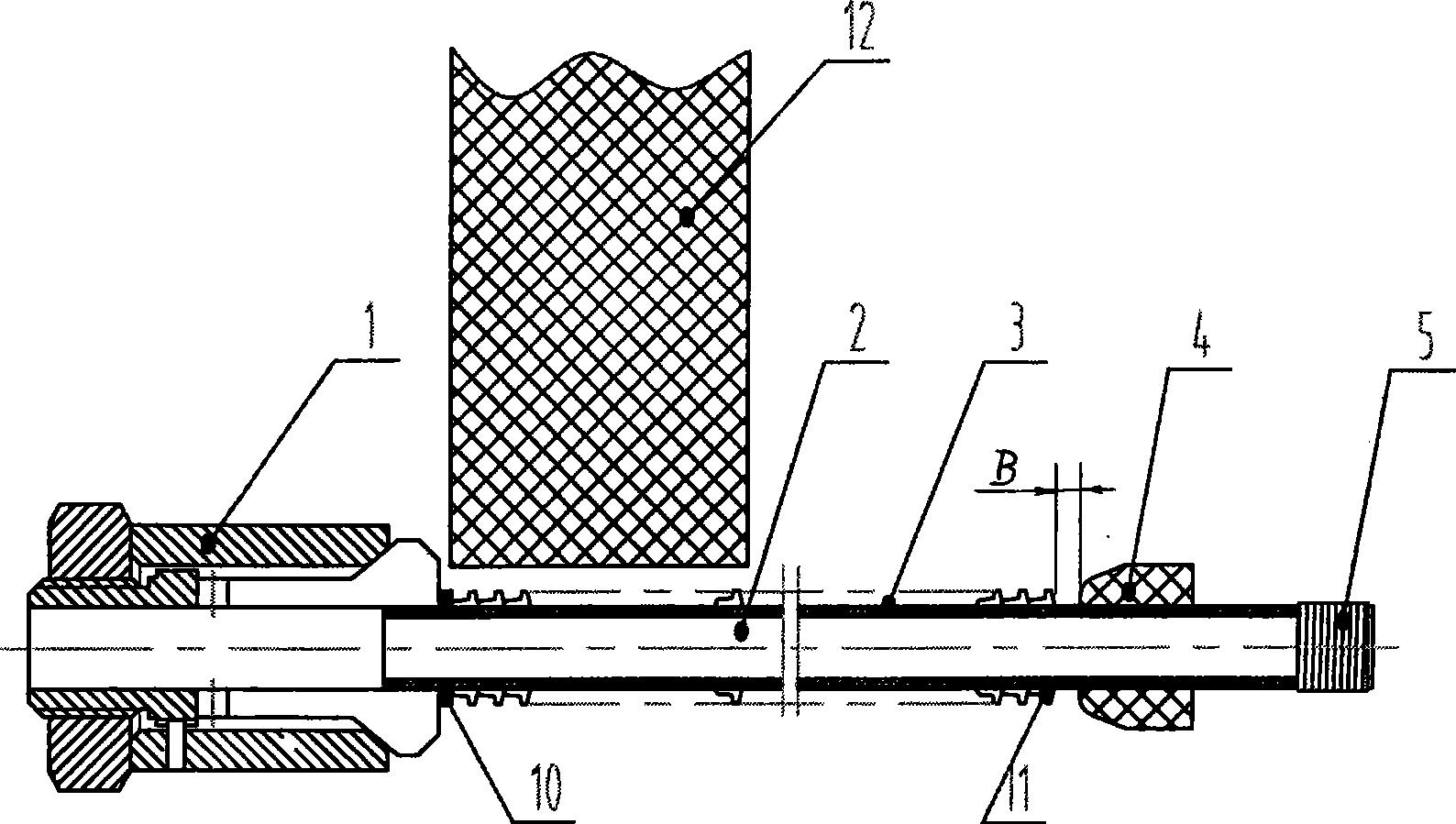

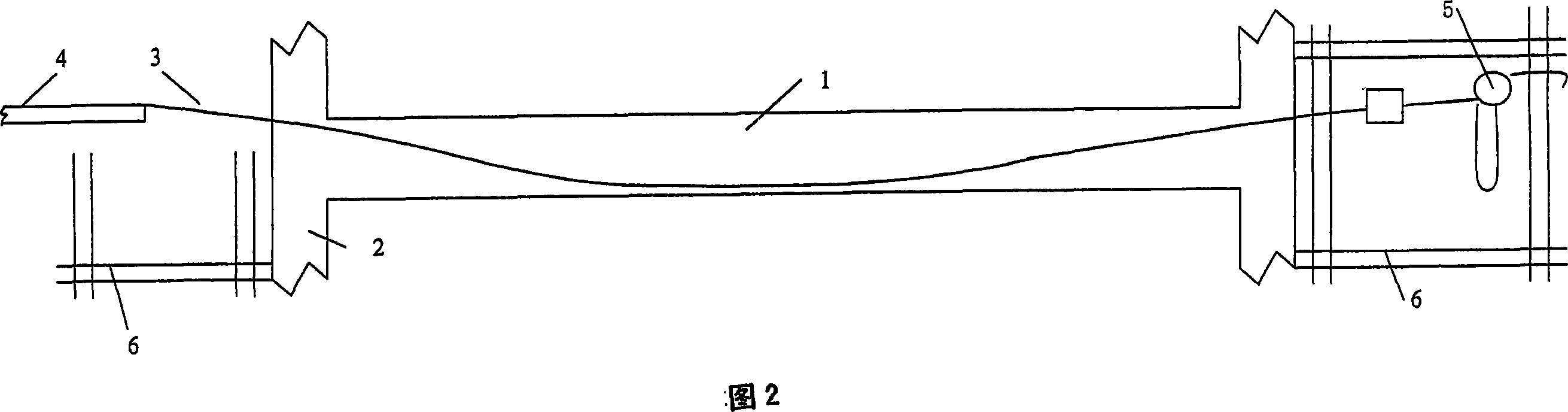

RTP tube electric-melting non-variable-size connecting structure and connecting method thereof

PendingCN110131511AIncreased solder contact surfaceWelding strength is sufficientPipe connection arrangementsElectricityGlass fiber

The invention relates to an RTP tube electric-melting non-variable-size connecting structure and a connecting method thereof. The connecting structure comprises a first RTP tube, a second RTP tube anda glass fiber reinforced PE sleeve which are in butt joint, wherein a section of pre-melting section is arranged at the end of a PE inner tube of the first RTP tube in the axial direction; the structure of the second RTP tube is the same as the structure of the first RTP tube; the length of the glass fiber reinforced PE sleeve is equal to twice the length of the pre-melting section, an outer diameter of the glass fiber reinforced PE sleeve is the same as an outer diameter of the RTP tube, and a heating coil is embedded in the glass fiber reinforced PE sleeve or a self-hot-melt material is added into the glass fiber reinforced PE sleeve; the pre-melting section of the first RTP tube and the pre-melting section of the second RTP tube are oppositely inserted into the glass fiber reinforced PE sleeve, and an outer surface of the pre-melting section and an inner surface of the glass fiber reinforced PE sleeve are subjected to electric smelting or hot melt welding. According to the connecting method, the connection of the PE inner tube is realized, the strength of a pipeline connection part is improved, the pipeline transportation safety is ensured, the size of the connection part is not changed, the safety coefficient of the design of a composite material pipeline system is improved, and the large-scale industrial application process of the RTP pipeline is promoted.

Owner:武汉海威船舶与海洋工程科技有限公司

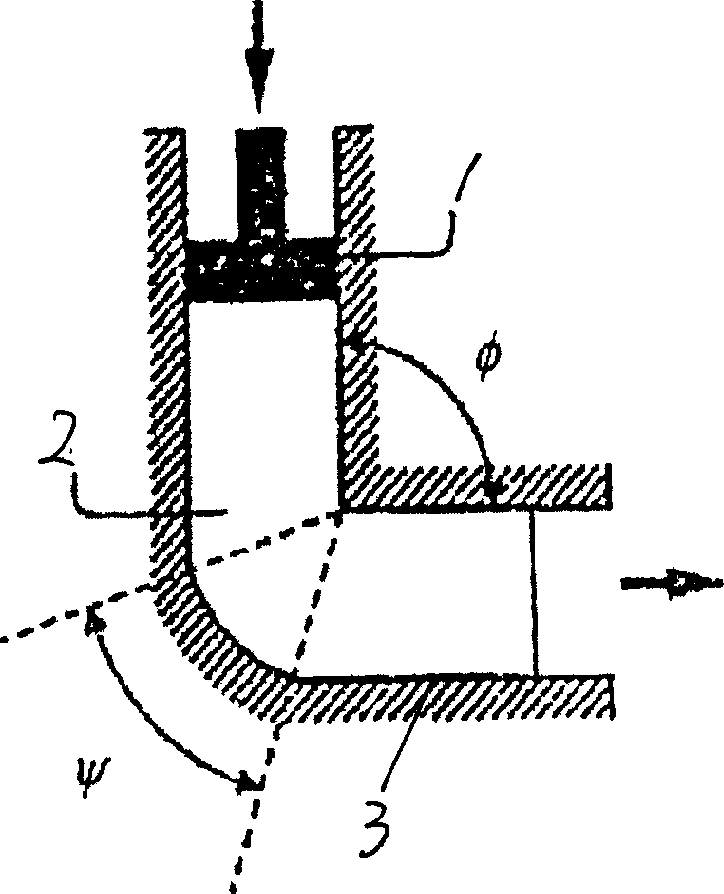

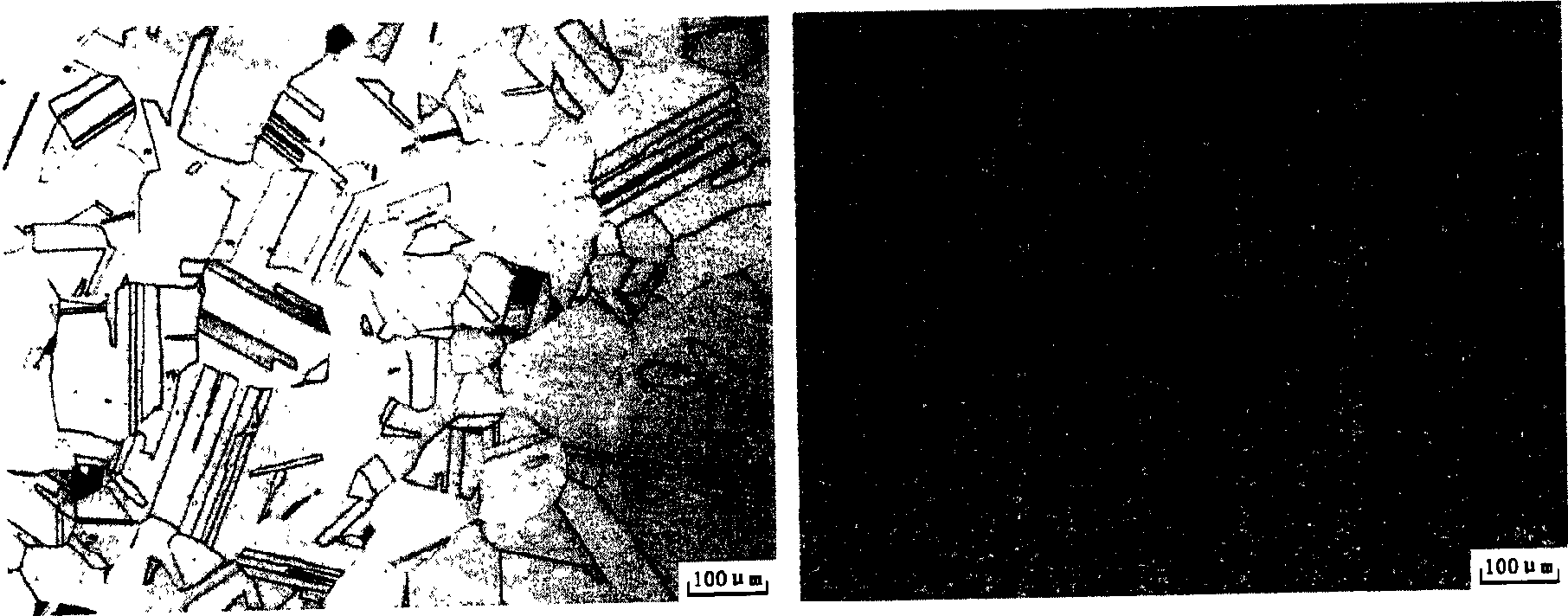

High strength austenite steel crystal fining method and miter angle extruding deforming mould

The present invention belongs to the field of alloy steel production, and especially crystal fining method for high strength austenite steel. The method features that austenite steel is processed through one or two gates of miter angle extruding deformation, and annealing heat treatment at 800-1000 deg.c for 20-120 min to re-crystallize completely and fine crystal size from 120 microns to 2-10 microns. The miter angle extruding deformation mold is one L-shaped elbow pipe with inner angle of 90-120 deg and outer angle of 20-60 deg; the extruding rod has yield strength over 1.5 times that of the extruded rod material; and the tolerance of the extruded rod material diameter to the inner diameter of the elbow pipe is 0.02-0.05 mm. Compared with available technology, the present invention has the advantages of raising the strength of austenite steel and maintaining the toughness while maintaining the size of the austenite steel.

Owner:CENT IRON & STEEL RES INST

Billet making die for differential velocity cyclic extrusion of high performance rare earth magnesium alloy

InactiveCN109909412AFully deformedIncreased cumulative strainExtrusion diesForging/hammering/pressing machinesRare earthShearing deformation

The invention discloses a billet making die for differential velocity cyclic extrusion of a high performance rare earth magnesium alloy. The billet making die for the differential velocity cyclic extrusion of the high performance rare earth magnesium alloy comprises an upper die assembly, a "T"-shaped punch, a split concave die and a lower die assembly. The split concave die comprises an upper concave die and a lower concave die. The upper concave die is provided with an upper rectangular die cavity and an upper half polygons expansion die cavity, the lower concave die is provided with a lowerrectangular die cavity and a lower half polygons expansion die cavity, and the upper concave die and the lower concave die combine to form a polygons expansion die cavity. Differential velocity angles are arranged on both sides of the lower half polygons expansion die cavity, and the height of the differential velocity angles on both sides is different. The lower die assembly comprises a first lower template of a solid body, a gasket block and a second lower template with a through hole. The first lower template is used for fixing at the bottom of the lower concave die during upsetting, and the gasket block blocks the lower rectangular die cavity. By changing the die cavity structures of the concave dies, the metal flow state is changed, the shear deformation is introduced, the strain growth is realized, the deformation times are reduced, the strain effect is improved, the production efficiency is improved, the grain structure is refined, and the second phase structure is optimized.

Owner:ZHONGBEI UNIV

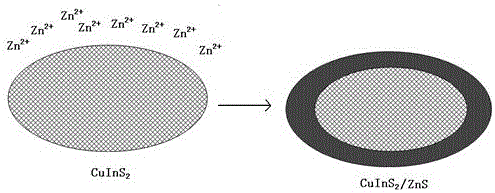

CuInS2/ZnS core-shell quantum dots and preparation method thereof

InactiveCN106634963ANo change in shapeNo change in sizeMaterial nanotechnologyNanoopticsCentrifugationRoom temperature

The invention discloses CuInS2 / ZnS core-shell quantum dots and a preparation method thereof. The method comprises the following steps: in an inert gas atmosphere, heating a prepared zinc precursor to 200-270 DEG C, injecting CuInS2 quantum dots into the zinc precursor, reacting for 5-120 minutes, and stopping heating; and after the reaction solution is cooled to room temperature, repeatedly dissolving and precipitating the product, and carrying out centrifugation purification to obtain the CuInS2 / ZnS core-shell quantum dots. The environment-friendly CuInS2 alloy quantum dots are converted into the CuInS2 / ZnS core-shell quantum dots by the cation exchange technique, thereby implementing the use of the no heavy metal Cd. The composition and crystal lattice of the CuInS2 / ZnS core-shell quantum dots can be completed by previously designing the composition and crystal lattice of the CuInS2 quantum dots. In the cation exchange process, the shape and size of the alloy quantum dots are not changed.

Owner:TCL CORPORATION

Polishing technique of ring stainless steel precise parts and preparation method thereof

InactiveCN101386147AImprove polishing effectChange sizePolishing machinesGrinding machinesWaxMachine building

The invention provides a polishing technique of an annular stainless steel precision component and a preparation method thereof, which is applied to the machine building industry and can obtain a surface with higher brightness and maintain necessary acute angles on the premise of not affecting the size precision of the component. The polishing technique and the preparation method are characterized in that: a strap is used for closely and evenly wrapping from one end of a round metal bar to the other end thereof in a clockwise manner; the beginning end of the strap is clamped with the round metal bar by a tightener, while the other end thereof is fastened and fixed with the round metal bar by a fine line, thus forming a polishing bar with a surface evenly coated with polishing wax; a plurality of components to be polished are sheathed on the polishing bars and then a stop collar is arranged; the tightener is held by the left hand, and the stop collar and the end of the polishing bar are grabbed by the right hand; the components to be polished are slowly and horizontally moved to get close to the excircle of a soft cloth polishing wheel with rotates at a high speed and is coated with polishing wax; force is gradually increased, and the components to be polished between the tightener and the stop collar are moved back and forth until the components to be polished meet polishing requirements.

Owner:江苏星河集团有限公司 +1

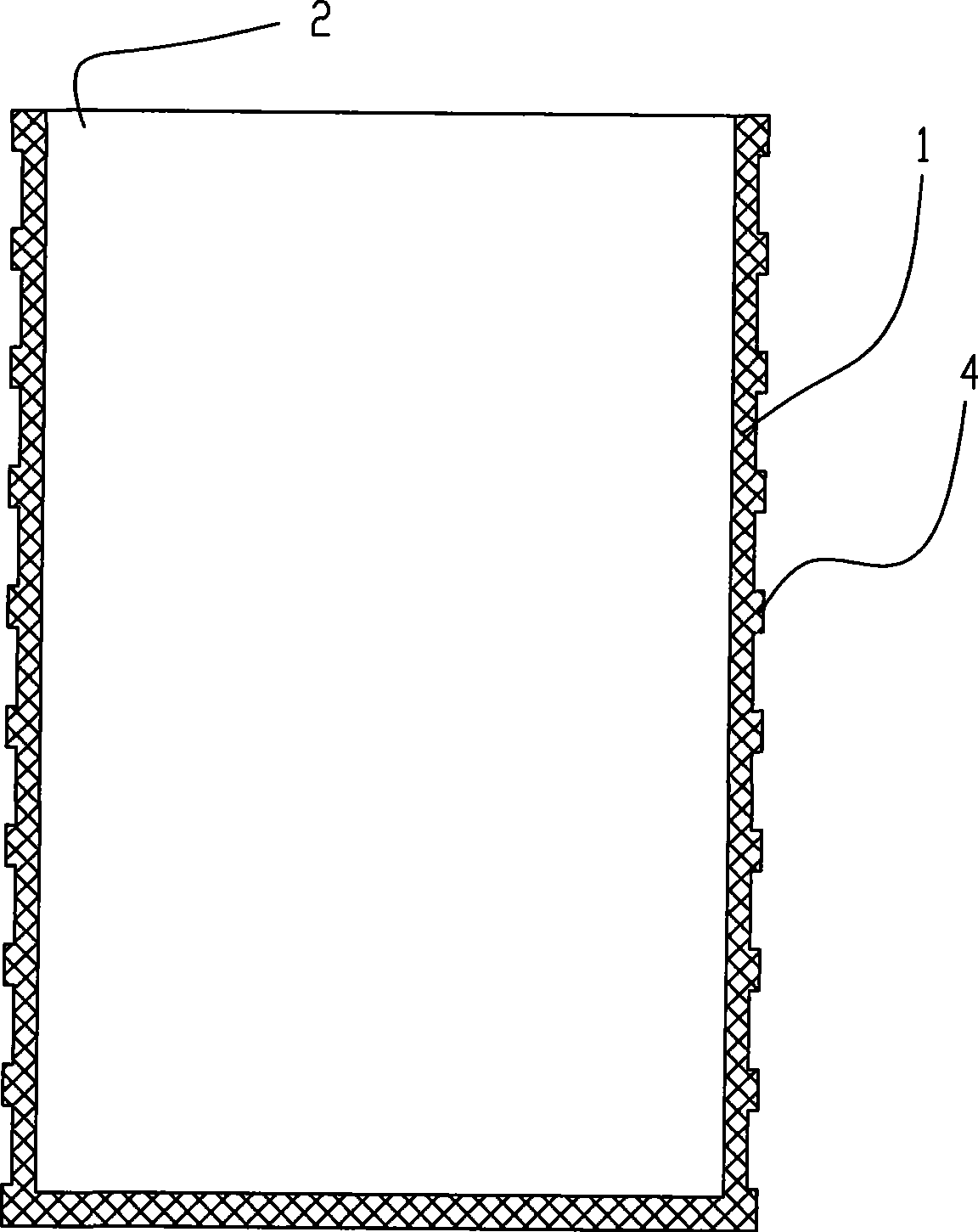

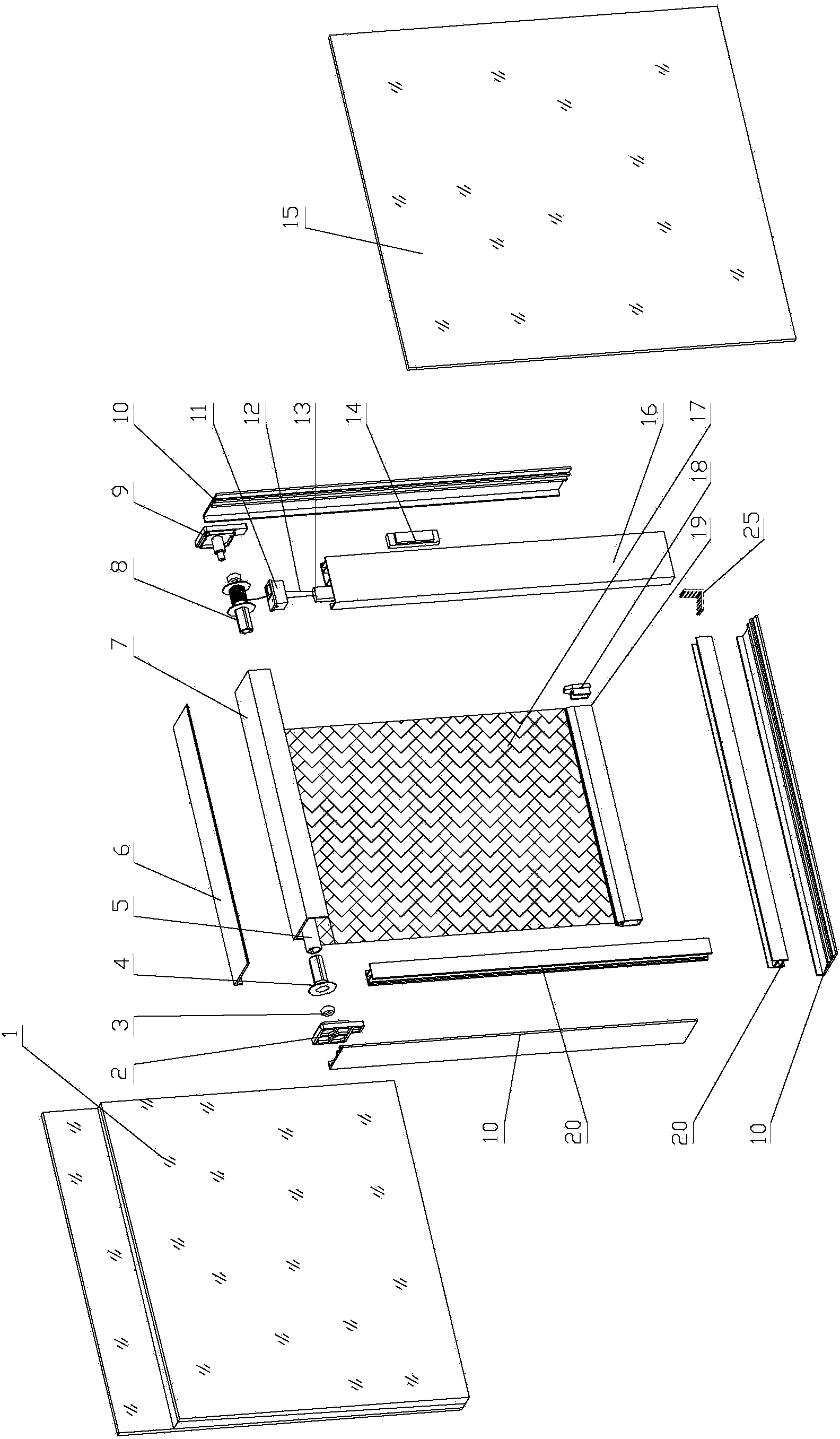

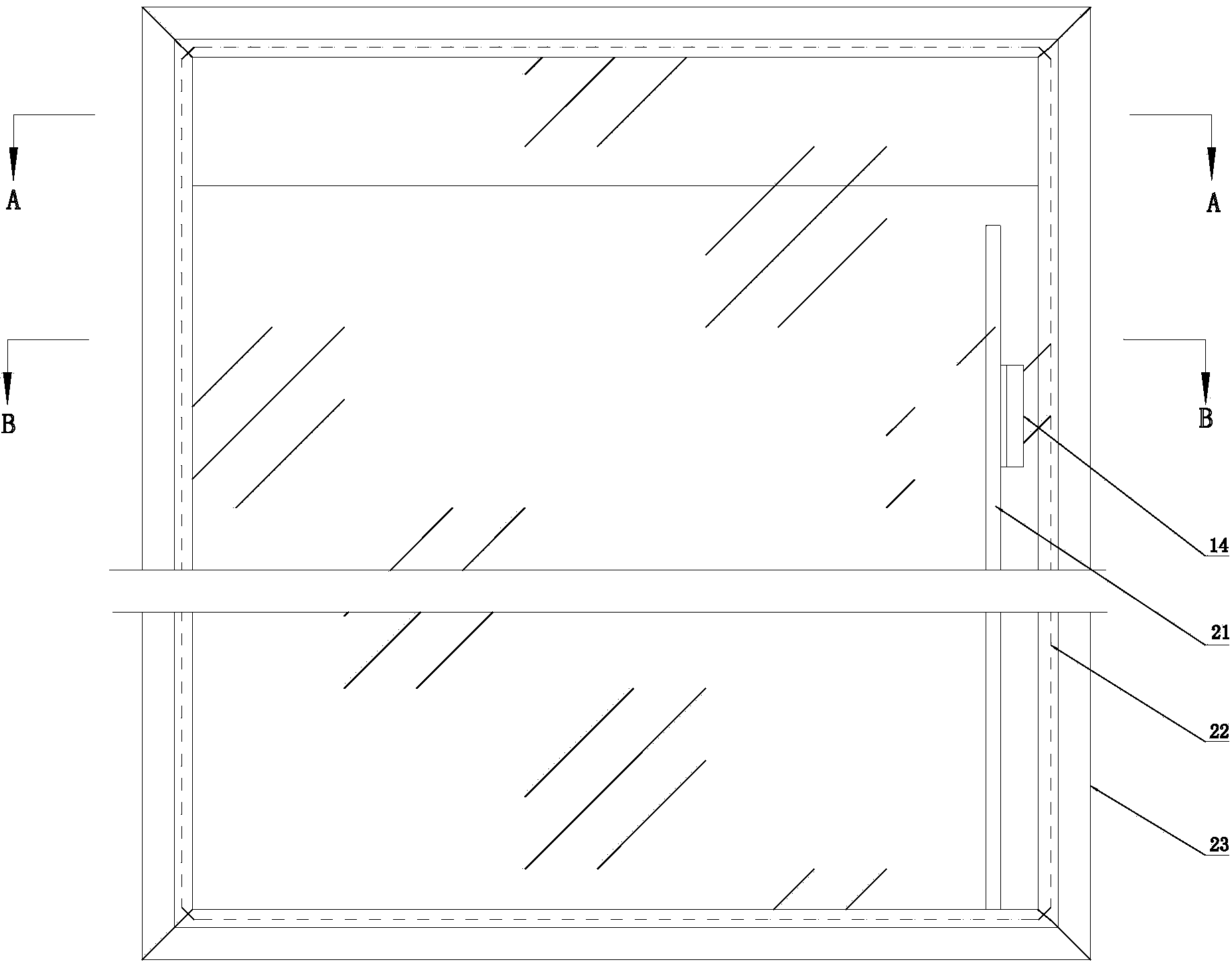

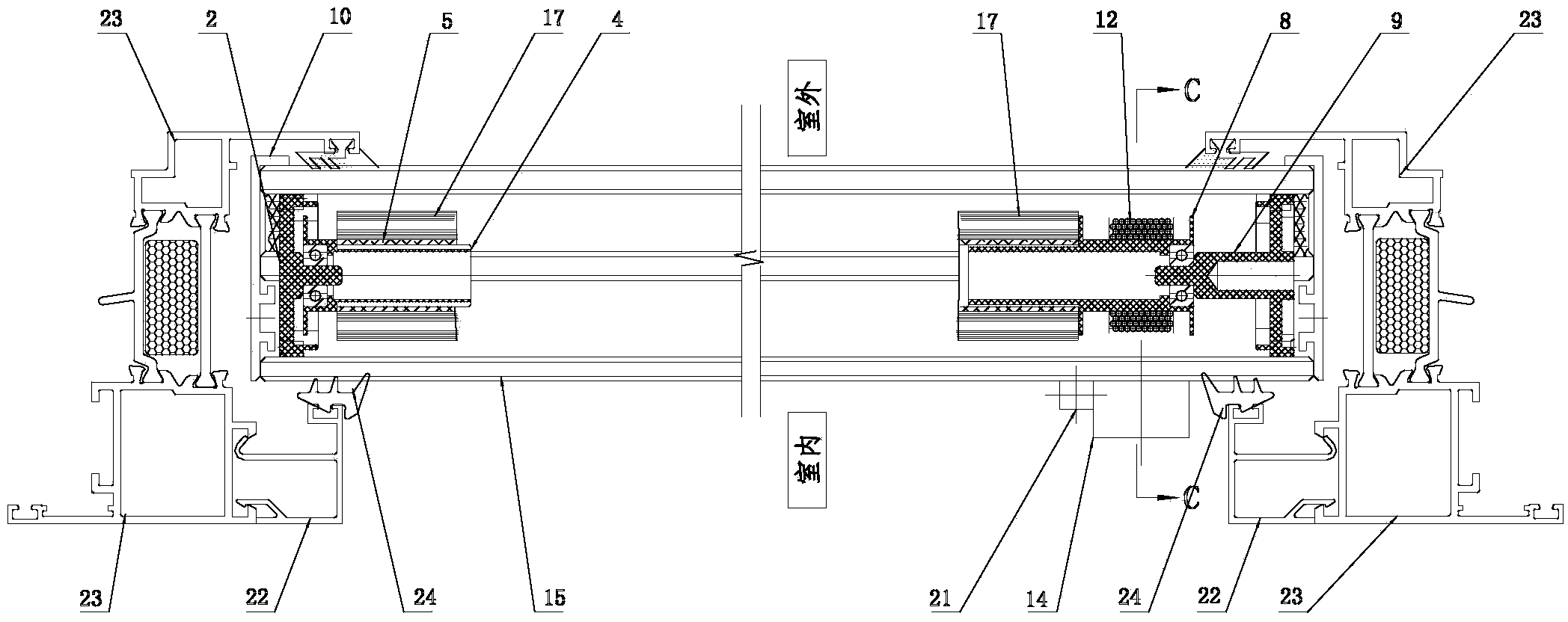

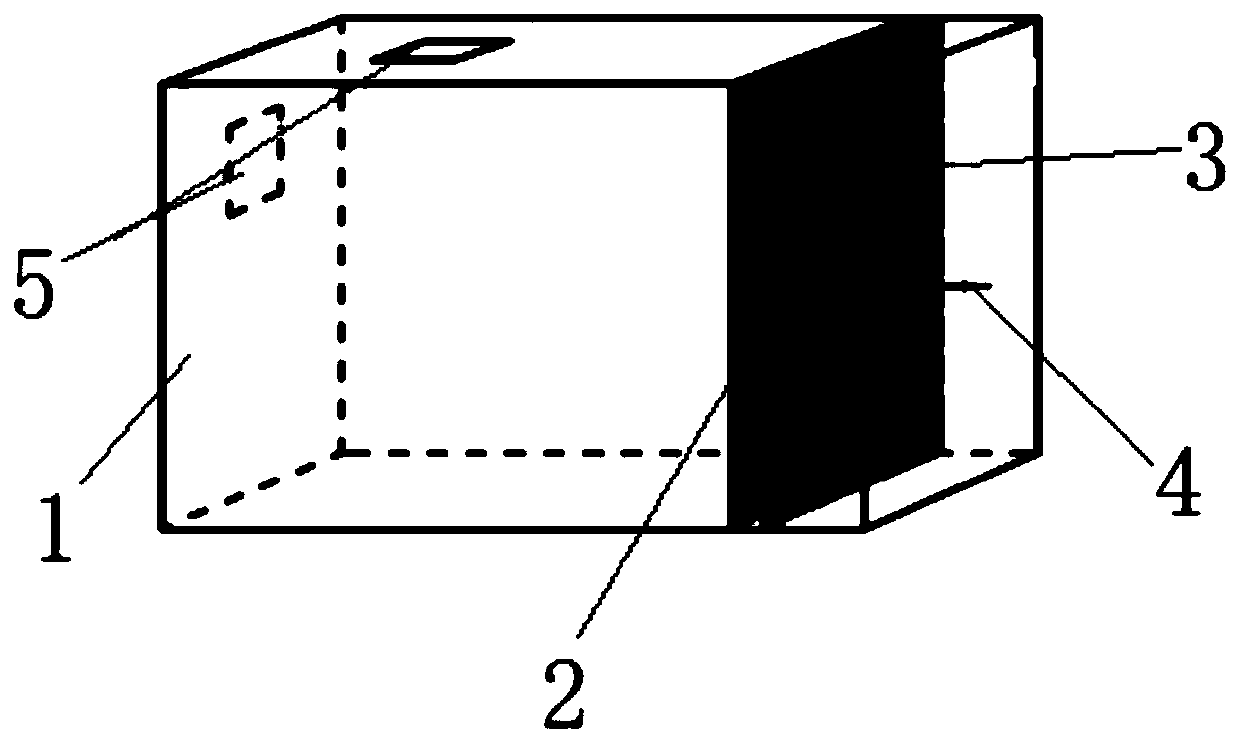

Integrated energy-saving window internally provided with sun-shading roller shutter

ActiveCN103628801ASafe implementation of the installationSafe Implementation MaintenanceLight protection screensBuilding energyEngineering

The invention discloses an integrated energy-saving window internally provided with a sun-shading roller shutter. The integrated energy-saving window comprises a window frame and window glass, wherein the window glass is composed of a set of a vacuum glass assembly and a piece of inner window glass; a sun-shading roller shutter device is arranged above the vacuum glass assembly; the sun-shading roller shutter device comprises a winding shaft, a sun-shading roller shutter wound on the winding shaft and a roller shutter extending-retracting mechanism; the sun-shading roller shutter is extended and retracted between one set of the vacuum glass assembly and one piece of the inner window glass; the roller shutter extending-retracting mechanism comprises tail inserting parts arranged at the two ends of the winding shaft and a winding disc tail inserting part with a reel; a separation strip is arranged on one side of a sun-shading roller shutter and a guiding separation strip is arranged on the other side of the sun-shading roller shutter; a pull rope is wound on the winding disc tail inserting part with the reel; a magnetic control device is arranged at one side of the pull rope; a bearing is arranged on each of the tail inserting part and the winding disc tail inserting part with the reel; the bearings are arranged in a left end plate and a right end plate; the left end plate and the right end plate are connected with the separation strip and the guiding separation strip respectively. According to the integrated energy-saving window internally provided with the sun-shading roller shutter, the sun-shading roller shutter is internally mounted between the vacuum glass assembly and the inner window glass to construct the integrated building energy-saving window; the window glass is mounted and dismounted indoors to safely mount, maintain and repair the internally-arranged sun-shading roller shutter.

Owner:无锡市纵横科技有限公司

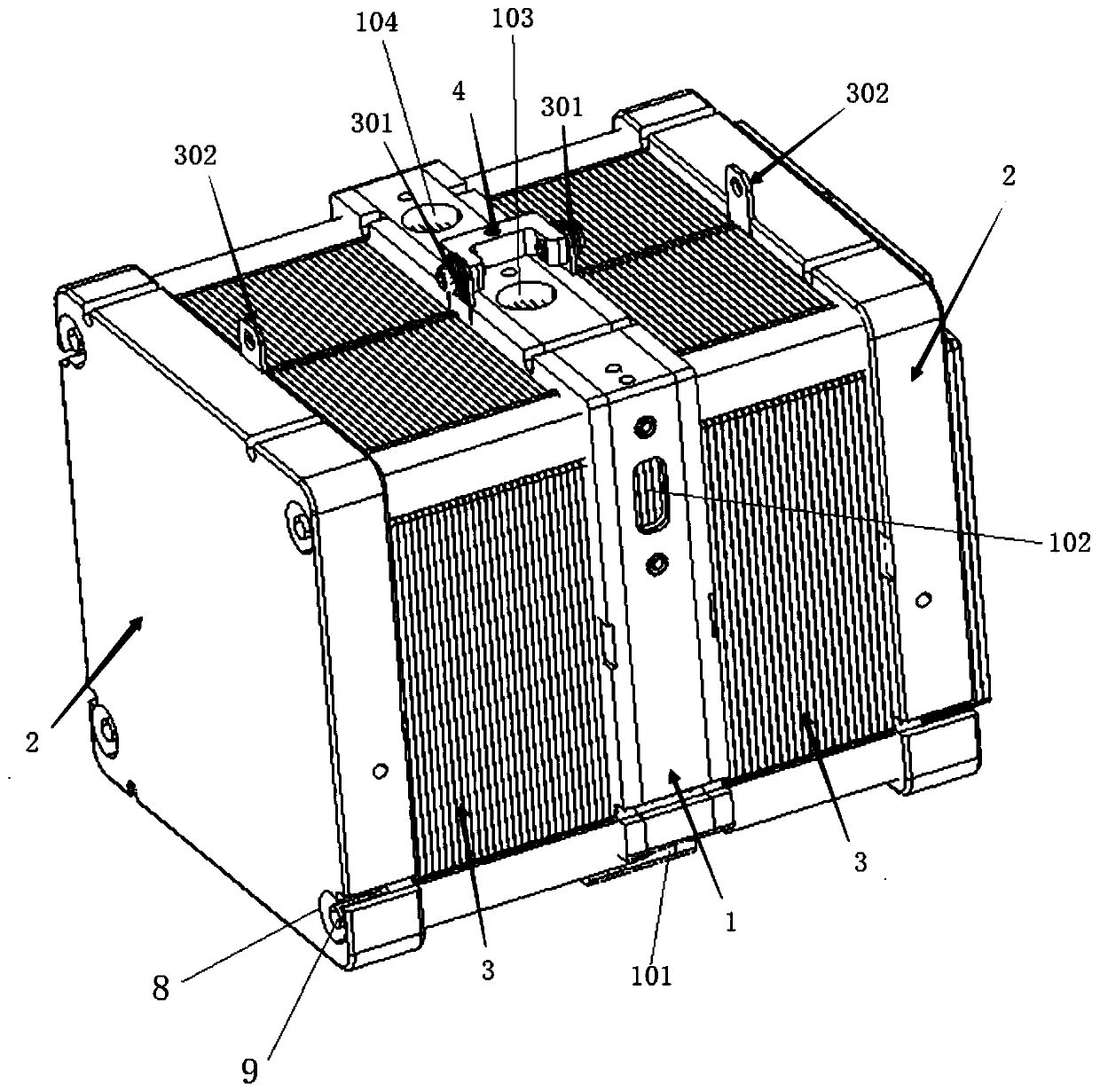

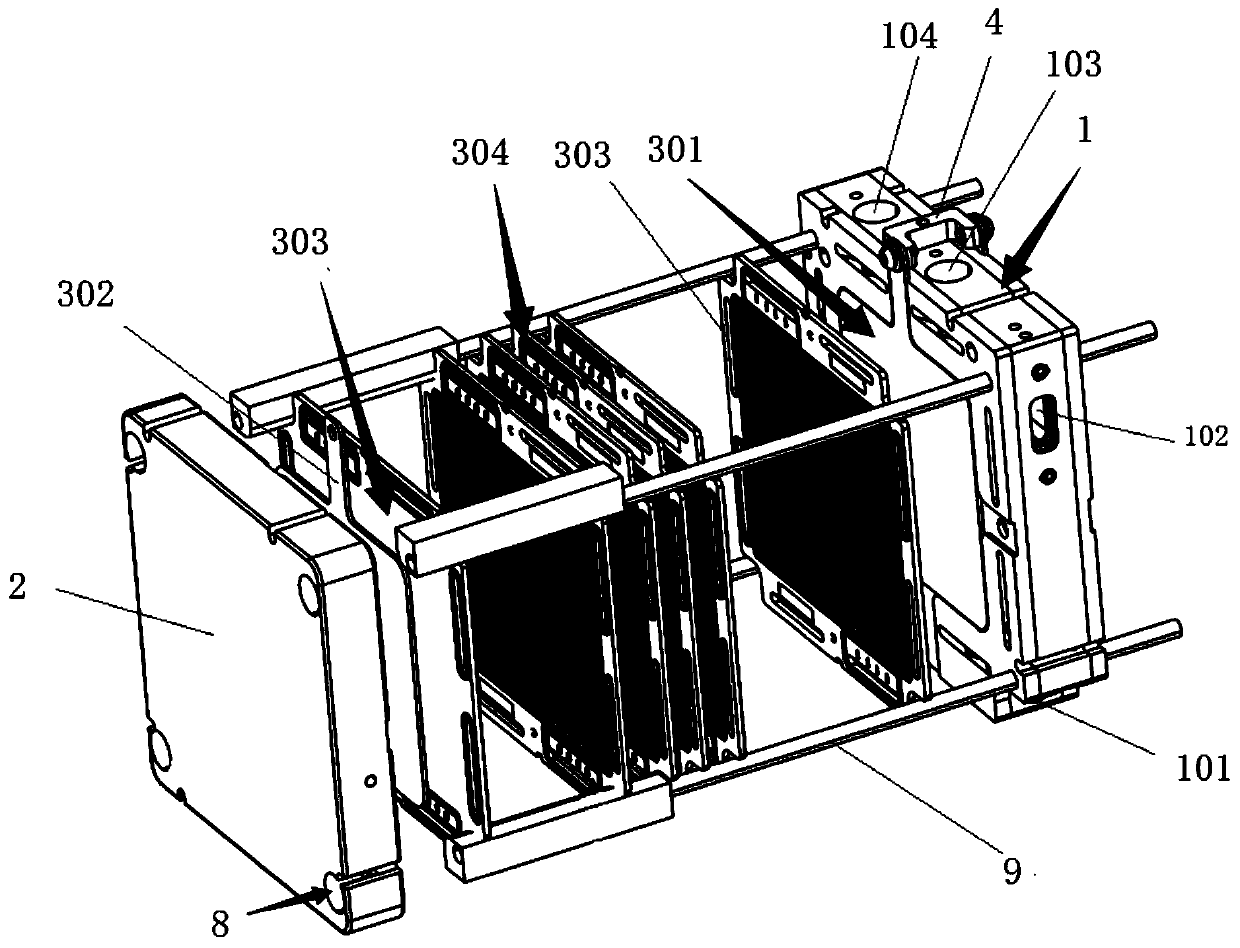

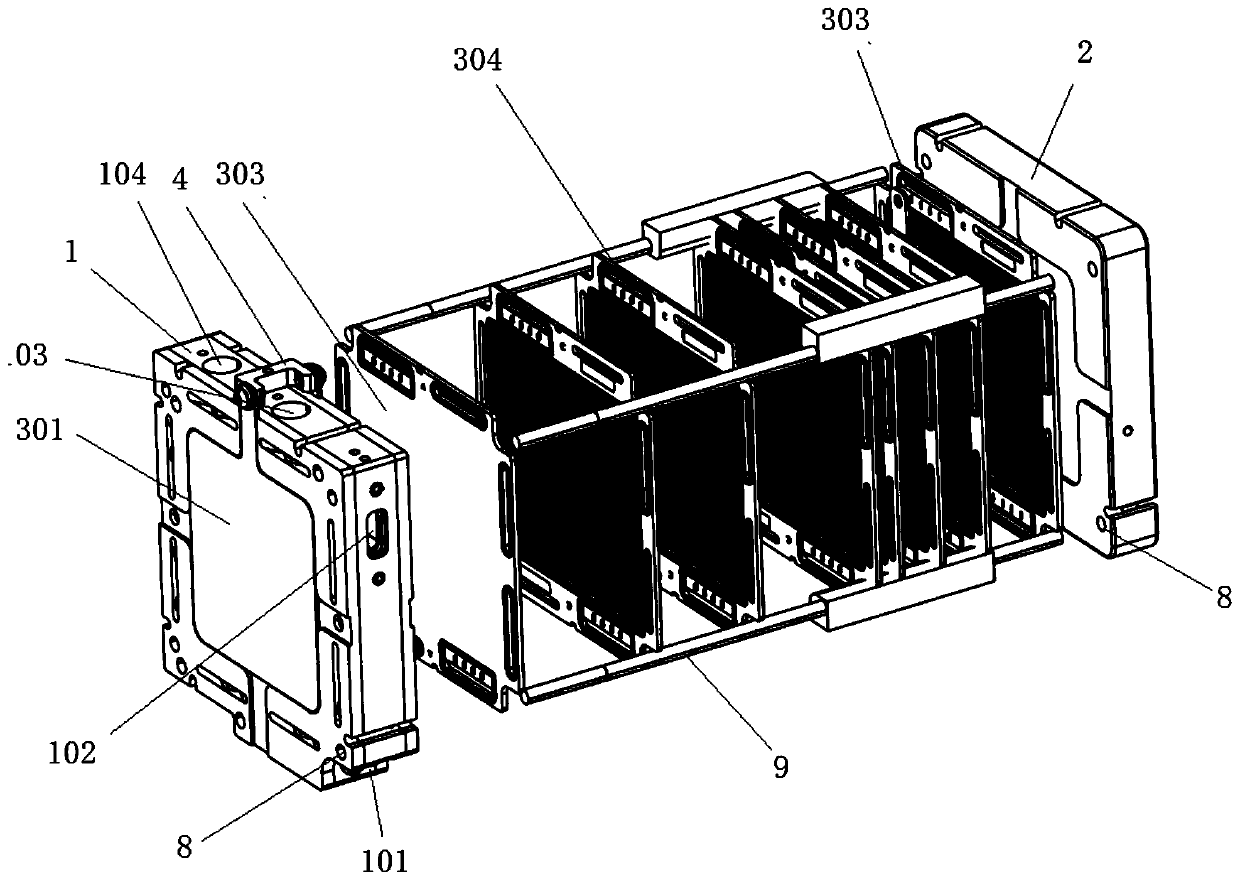

Fuel cell stack with central manifold

PendingCN110277569ASave spaceReduce volumeReactant parameters controlFinal product manufactureEngineeringFuel cells

The invention discloses a fuel cell stack with a central manifold. The fuel cell stack is characterized by comprising two fuel cell stacks which are fixed between the central manifold and two side end plates, share the central manifold and are connected in series; each fuel cell stack includes a plurality of single cells which are arranged in a laminated manner, the central manifold is internally provided with an anode distribution cavity and a cathode distribution cavity which are respectively used for simultaneously supply anode reaction fuel and cathode reaction fuel to the anode and the cathode of the single cells in the fuel cell stacks on the two sides, the central manifold is further provided with an anode confluence cavity and a cathode confluence cavity which are respectively used for simultaneously collecting anode reaction substances and cathode reaction substances from the anode and the cathode of the single cells in the fuel cell stacks on the two sides; and the central manifold is provided with an anode inlet interface, a cathode inlet interface, an anode outlet interface and a cathode outlet interface which are respectively communicated with the cavities. The fuel cell stack with the central manifold allows the series connection of small fuel cell stacks through sharing the central manifold, thereby establishing a cell stack with a large size and higher power in the compact space, and saving the space and the production cost.

Owner:苏州奥加华新能源有限公司

Construction technique for rebuilding prestressing force system after built prestressing force system destroyed in reinforced concrete structure

InactiveCN101063374AChange sizeReduce loadBuilding repairsBuilding material handlingReinforced concretePre stress

The invention discloses a construction art for rebuilding a broken inherent stress system after breaking a built inherent stress system in a reinforcement concrete structure, comprising the steps as removing a former broken inherent stress cable via an anchorage, stripping a surface plastic hood of a new inherent stress cable with same size and intensity of the former broken inherent stress cable, preparing a reinforcement with smaller diameter to the diameter of the former broken inherent stress cable, wherein the length of the reinforcement should be more then the cable of 50cm, and pulling out the former broken inherent stress cable, inserting the reinforcement into a former structure pore path, welding one end of the new inherent stress cable with one end of the reinforcement, connecting another end of the reinforcement with a chain block and pulling the reinforcement, inserting the new inherent stress cable into a hole via the reinforcement in the hole, extending the new inherent stress cable to meet a former design stress of a single cable and then anchoring.

Owner:浙江省二建建设集团有限公司

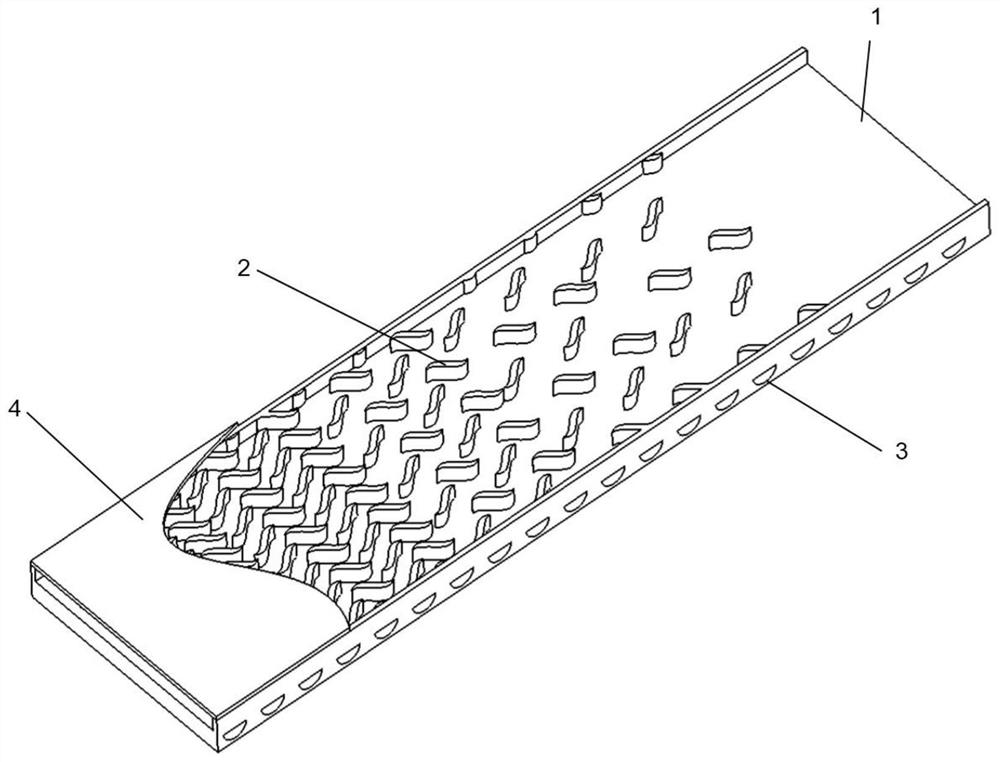

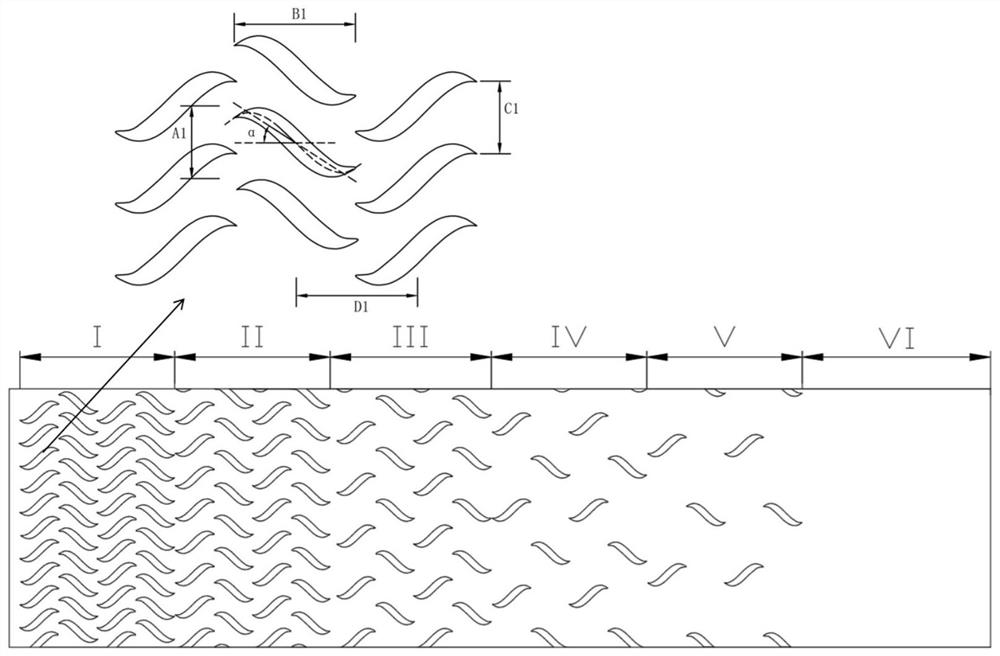

Self-adaptive non-uniform fin plate bundle for heat exchanger and design method of flow channel thereof

InactiveCN112378278AAdapt to complex flowsImprove heat transfer performanceLaminated elementsStationary plate conduit assembliesHeat flowEngineering

The invention discloses a self-adaptive non-uniform fin plate bundle for a heat exchanger. The fin plate bundle comprises one or more groups of fin substrates stacked up and down, wherein cold and hotfluid flow channels are arranged in the substrates and form an integrated structure; the cold flow channels are concave channel-shaped structural bodies; a plurality of fins are arranged in the grooves from dense to sparse along the flowing direction; the hot flow channels are provided with a plurality of semicircular independent channels at equal intervals in the vertical direction of the cold flow channels; and a cover plate in sealed connection is arranged at the upper parts of the cold flow channels. The self-adaptive non-uniform fin plate bundle for the heat exchanger provided by the invention is suitable for heat exchange requirements under various different conditions, is more suitable for thermotechnical and hydraulic changes of fluid in the heat exchange process, is capable of effectively enhancing the heat transfer characteristic and effectively improving the hydraulic performance, and is wider in application field. The invention further discloses a flow channel design method of the self-adaptive non-uniform fin plate bundle for the heat exchanger.

Owner:JIANGSU UNIV OF SCI & TECH

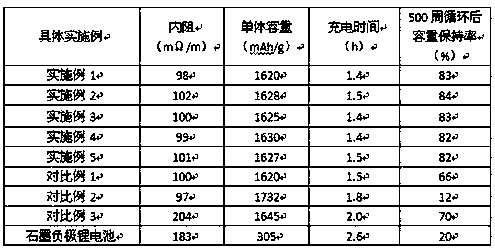

Si-conductive ceramic composite negative electrode material for lithium battery and preparation method thereof

ActiveCN107819116ABetter than capacityImprove conductivityMaterial nanotechnologyCell electrodesCarbon coatingVolume expansion

The invention provides a Si-conductive ceramic composite negative electrode material for a lithium battery and a preparation method thereof. The Si-conductive ceramic composite negative electrode material is characterized in that the volume change of a silicon negative electrode material during charging and discharging is inhibited by taking conductive ceramics as a skeleton. Silicon nano-particles are passivated and distributed with conductive ceramics so as to form secondary particles, so that the volume expansion of the silicon material is relieved without changing the sizes of the secondary particles. The conductive ceramics serve as the skeleton, and the silicon nano-particles have electrochemical activities, so that the negative electrode material has excellent specific capacity; andthe conductive ceramics have excellent mechanical properties, so that an internal stress produced by a volume effect of silicon can be absorbed. Furthermore, the mobility of the surface nanometer material is reduced by a carbon coating layer, the solid-electrolyte interface is improved, an active material is prevented from being corroded by electrolyte, and the electrode integration rate and conductivity during the volume change can be maintained. Therefore, the conductivity, electron mobility and cycling stability are improved.

Owner:江苏贝肯新材料有限公司

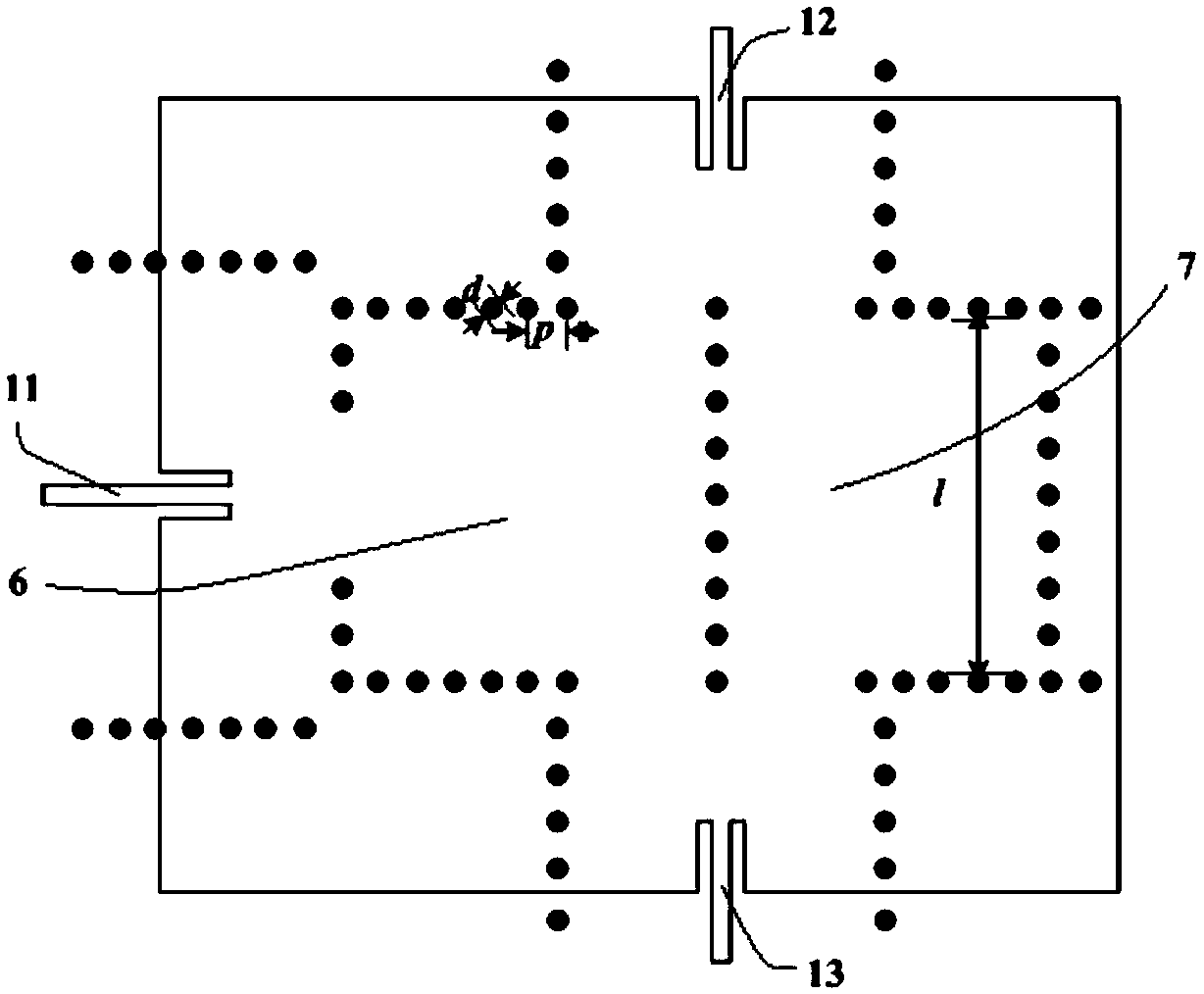

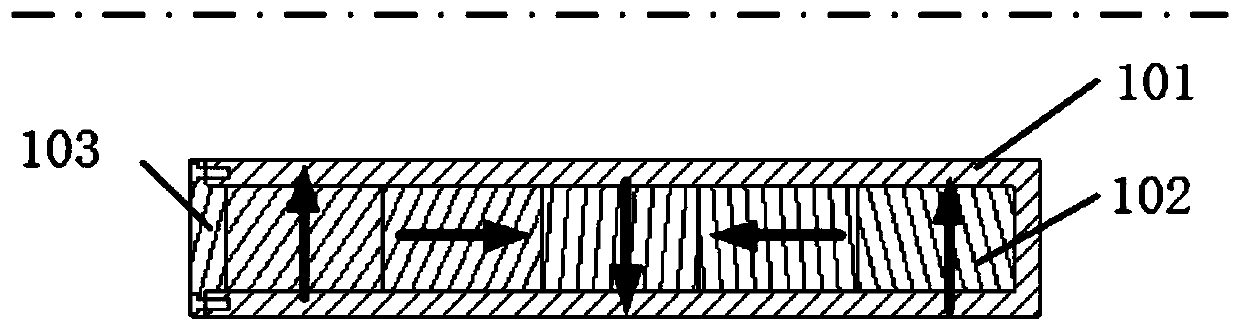

Method for improving heating uniformity of microwave oven by continuously adjusting position of reflective surface

PendingCN110006077AImprove heating uniformitySolve the problem of uneven heatingDomestic stoves or rangesLighting and heating apparatusMicrowave ovenReciprocating motion

The invention belongs to the technical field of microwave oven control, and discloses a method for improving the heating uniformity of a microwave oven by continuously adjusting the position of a reflective surface. A fixed glass window or plastic window capable of allowing the microwave to pass through is mounted in the microwave oven in the perpendicular or horizontal direction, a cavity with the depth less than 20mm is formed behind the glass window or plastic window, a movable metal reflective surface is arranged at the bottom of the cavity, the moving position of the metal reflective surface is adjusted by an intelligent control system, and the continuous reciprocating motion is conducted, or movement in a certain interval or standstill in a position is conducted. The method solves the problem of uneven microwave heating from the principle, improves the uniformity of microwave heating, and does not change the size of a cooking cavity, the operation is simple, and in addition, themethod can further be combined with an existing metal rotor and a rotating disc to achieve higher heating uniformity.

Owner:SHANGHAI OCEAN UNIV

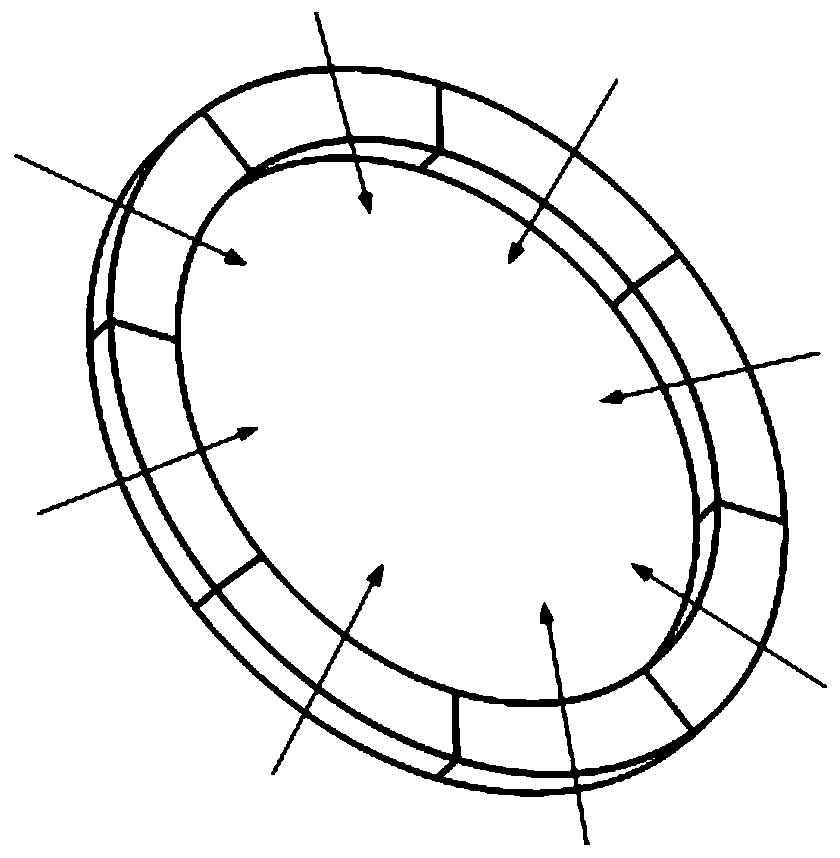

Magnetic fluid composite tilting-pad radial bearing based on Halbach array

The invention discloses a magnetic fluid composite tilting-pad radial bearing based on a Halbach array. The magnetic fluid composite tilting-pad radial bearing comprises a shaft sleeve, a bearing bush, a bearing shell and a stop check ring, a first permanent magnet inner core is arranged in the shaft sleeve, a second permanent magnet inner core is arranged in the bearing bush, the magnetizing direction of the first permanent magnet inner core in the shaft sleeve and the magnetizing direction of the second permanent magnet inner core in the bearing bush are opposite, permanent magnet repulsiveforce exists between the shaft sleeve and the bearing bush, the bearing bush comprises a plurality of sector plate strip-shaped bearing bush units distributed circumferentially and evenly, an arc bossis arranged on the outer sides of the sector plate strip-shaped bearing bush units, and the arc boss and an inward-concave arc groove formed in the bearing shell are matched to constitute a tilting-pad structure. The idea that permanent magnetic force and liquid membrane force jointly bear the bearing load and the tilting-pad structure is proposed, and the load is borne jointly by permanent magnetic repulsive force generated between the permanent magnet inner cores and the liquid membrane force provided by a lubrication fluid membrane in the bearing operation process; and meanwhile, the tilting-pad structure enables lubrication fluid to be more easily wedged into a friction pair gap, and thus the stability of bearing operation is ensured.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com