Improved mixer for a plasticizing screw

A technology of plasticizing screw and mixing part, applied in the field of plasticizing screw, can solve the problems of high cost and increase the space requirement of injection molding device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

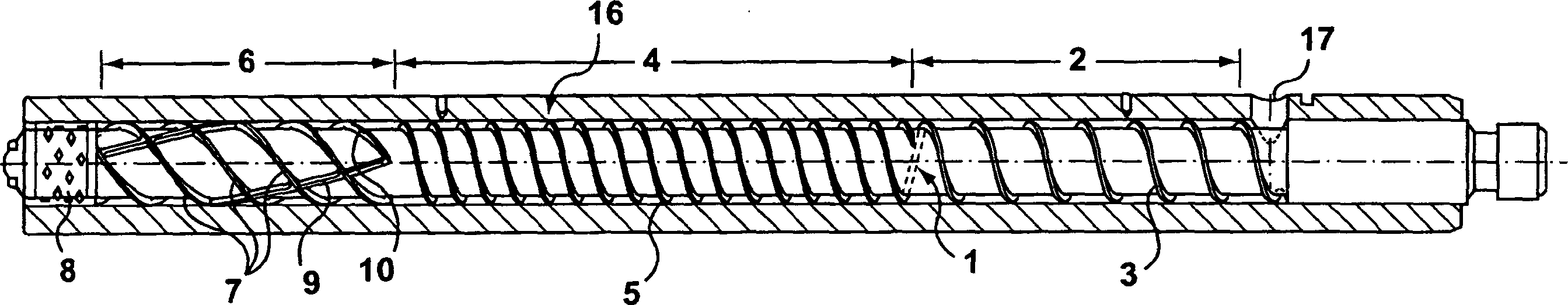

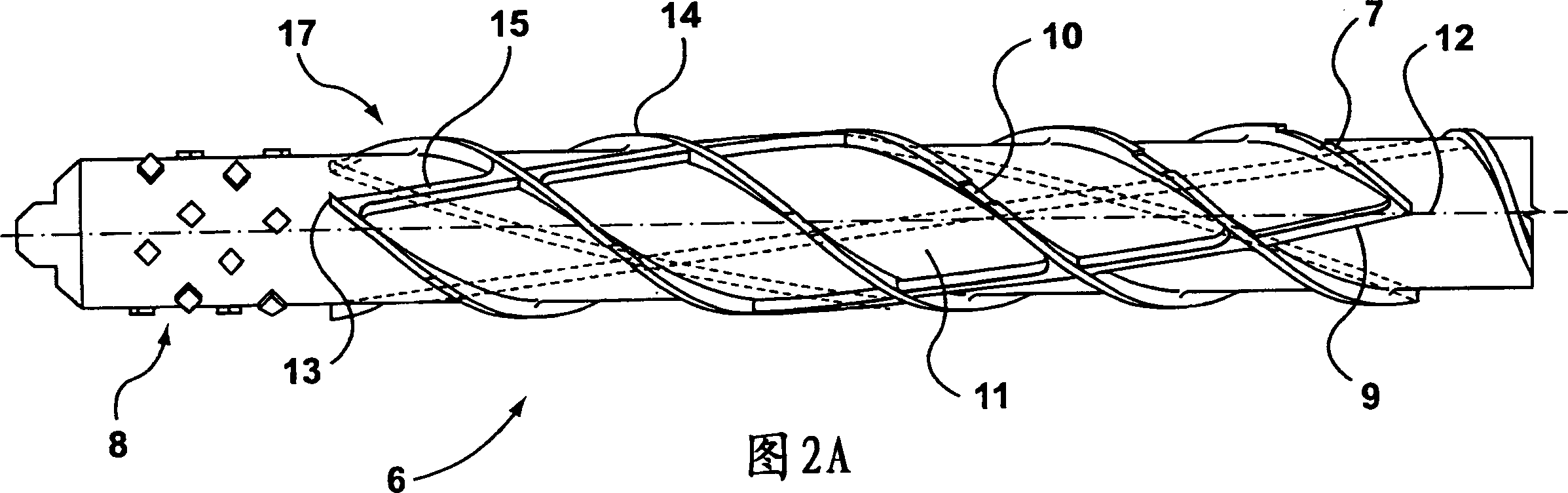

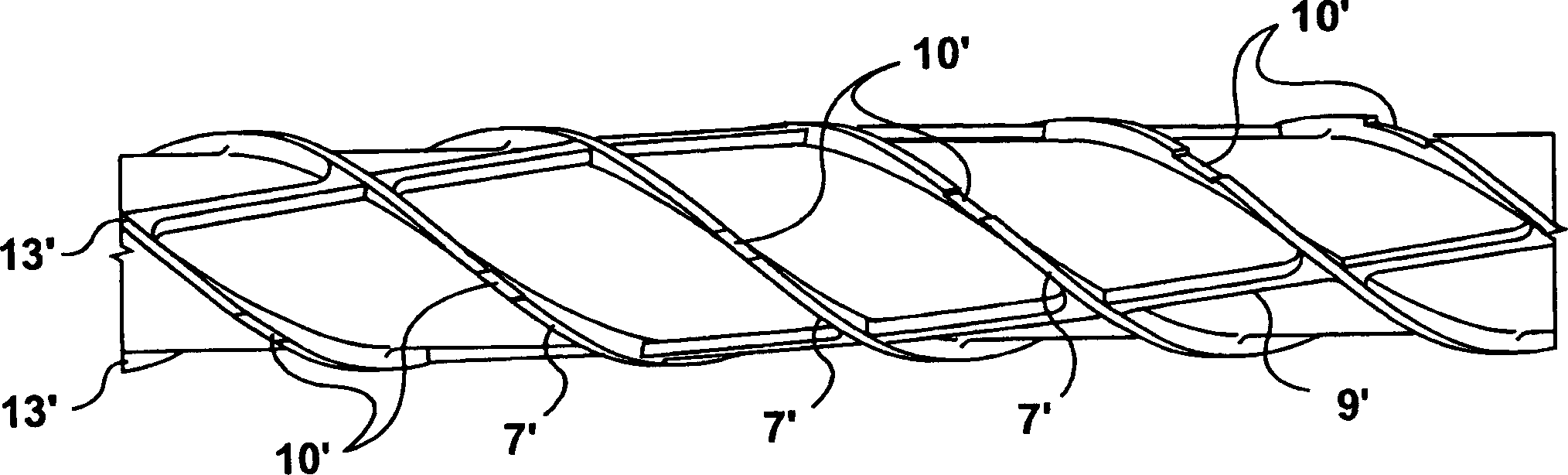

[0021] figure 1 Shown is a plasticizing screw 1 with an improved mixing section 6 provided by the invention. The screw 1 is located in the heating tube 16 . The heating tube 16 has an inlet 17 and an outlet (not shown) at one end of the tube 16 . The screw 1 consists of a feed section 2, a compression section 4, an improved mixing section 6 and a "pineapple" mixer 8 at the top of the screw, wherein the feed section 2 has a single conveying section 3 and the compression section has a double Delivery section 5. In the embodiment shown, the mixing section 6 comprises a triple delivery section 7 with some cutouts 10 and a triple counter-helical overflow section 9 acting as a baffle. The overflow section 9 prevents solid material from moving along the trough formed by the conveying section 7 . The cuts 10 in the section 7 allow for a better mixing of the molten material in the conveying section 7 .

[0022] The feeding part and compression part of the screw adopt the tradition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com