Hand milling machine capable of preventing blood entering

A technology for milling handpieces and blood, which is applied in the field of milling handpieces for bone tissue cutting, can solve bearing failure. On the one hand, blood may enter the bearing cavity along the gap between the milling cutter and the boot cover; on the other hand, it may, The milling mobile phone is stuck and other problems, to increase the transmission resistance, prevent blood from entering the milling mobile phone, and prolong the maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

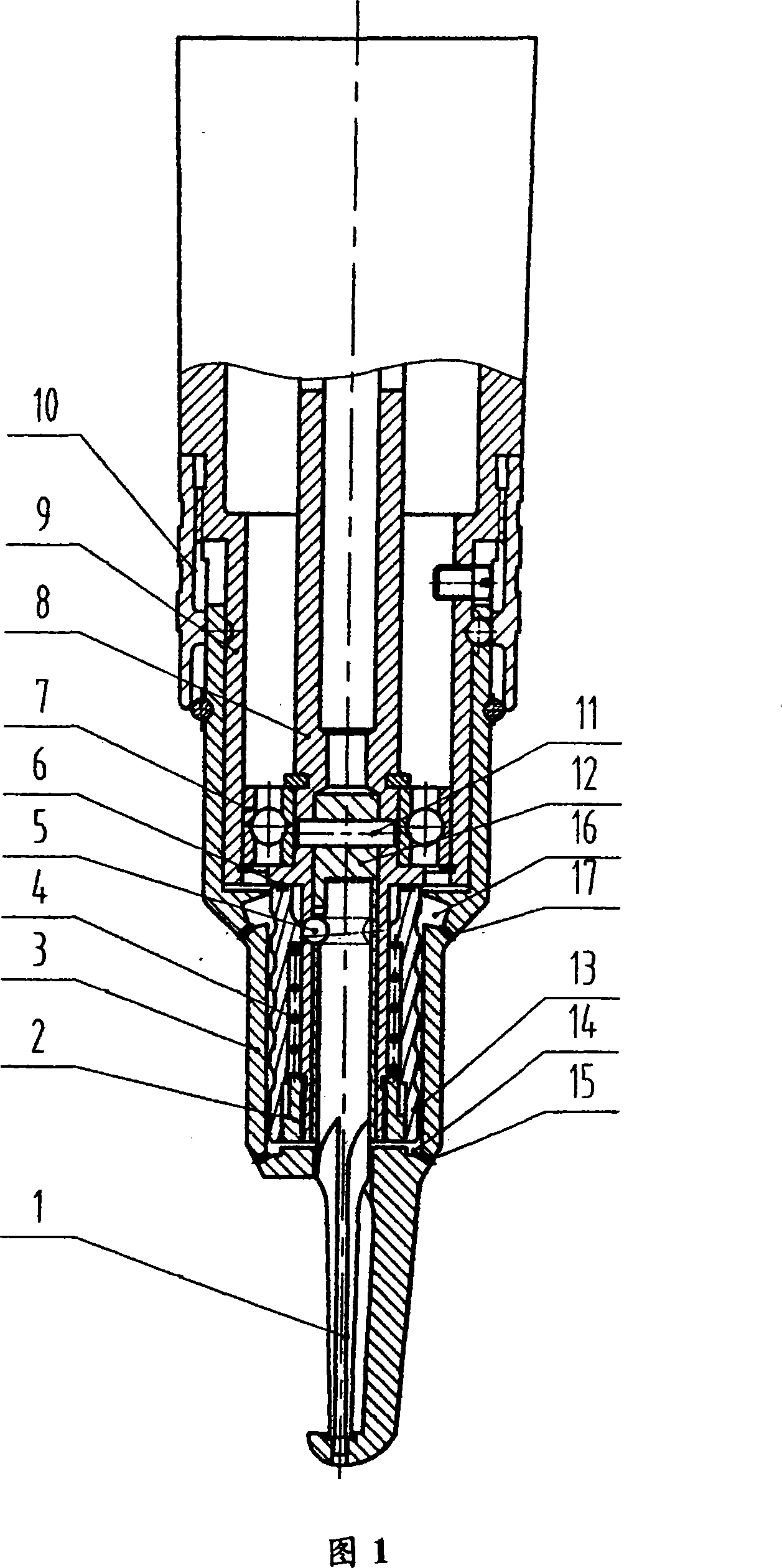

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

[0010] Referring to Fig. 1, the boot cover 3 is fitted on the lower part of the outer sleeve 9, and the locking sleeve 10 is fitted at the junction of the outer sleeve and the boot cover;

[0011] The transmission shaft cylinder 8 is matched in the outer sleeve through the bearing 7, the milling cutter handle sleeve 12 is positioned and connected in the lower part of the transmission shaft cylinder through the connecting pin 11, the sleeve 2 is screwed to the lower end of the transmission shaft cylinder, and the spring 4 is installed On the outside of the lower part of the transmission shaft and on the sleeve, the upper part of the milling cutter 1 passes through the hole in the lower part of the boot cover and is positioned and connected in the milling cutter handle through the steel ball 5. The lower end of the milling cutter and the lower end of the boot cover The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com