Connecting method of ceramic-base composite

A composite material and connection method technology, which is applied to the connection of ceramic matrix composite material components and the connection field of carbon matrix and silicon carbide ceramic matrix composite materials, can solve the problem of large structural strength damage of ceramic matrix composite materials and high bolt connection processing cost. , reduce the reliability of connectors, etc., to achieve the effect of high connection strength and reliability, low processing cost, and low connection cost

Active Publication Date: 2005-03-23

XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

View PDF0 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In order to overcome the reduction of the reliability of the connecting parts by bonding in the existing technology; it is not suitable for the connection of large and complex thin-walled parts and the high processing cost of the bolted connection of the ceramic matrix composite material; the damage to the structural strength of the ceramic matrix composite

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

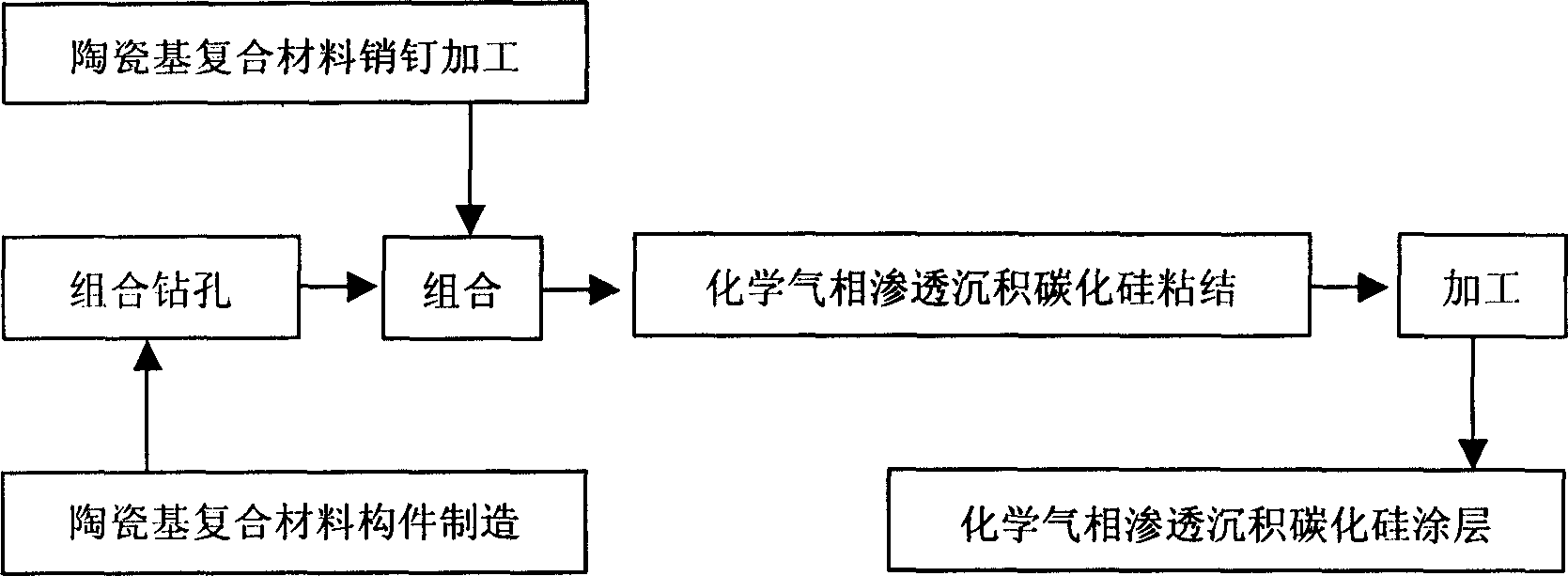

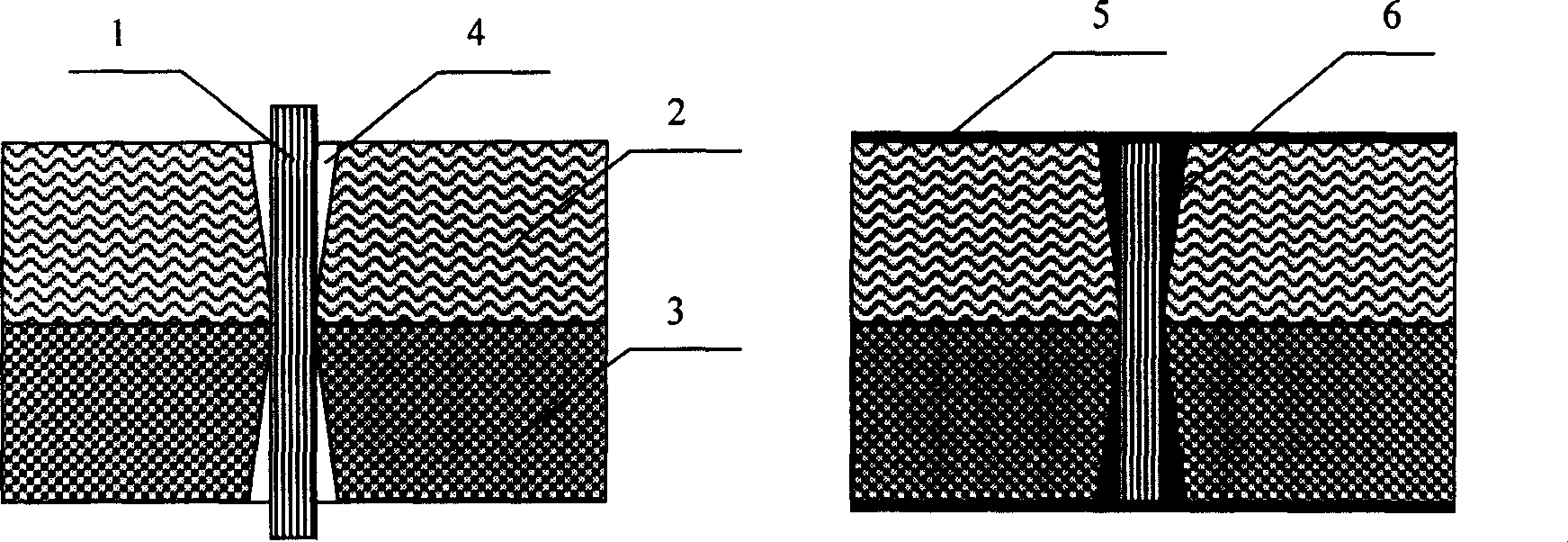

A method for linking two members made of ceramic-based composition includes such steps as making a rivet with ceramic-based composition, drilling hole on said members A and B, linking them together by inserting said rivet in said holes on members A and B, depositing silicon carbide in the gap by CVD, trimming, removing excessive rivet, smoothing surface, and preparing silicon carbide coating.

Description

Technical field [0001] The invention relates to a method for connecting composite materials, particularly a method for connecting carbon-based and silicon carbide ceramic-based composite materials, which is mainly suitable for the connection of ceramic-based composite material components with large complex thin walls and high dimensional accuracy requirements. Background technique [0002] Ceramic matrix composites are a new generation of strategic thermal structural materials that replace metals. The outstanding advantages are high temperature resistance and low density, and they have broad application prospects in aviation, aerospace, aerospace and weapons. With the increasing demand for large and complex thin-walled ceramic matrix composite components, connection has become a key technology that limits its application. Ceramic matrix composites mainly have three toughening methods: continuous fiber, whisker and particle toughening, and continuous fiber toughening has multiple ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B35/565C04B35/577C04B35/83

Inventor 成来飞张立同徐永东刘小瀛童巧英

Owner XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com