Patents

Literature

48results about How to "No change in shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

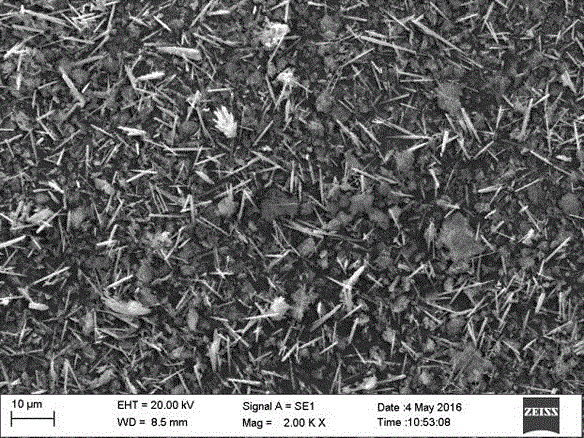

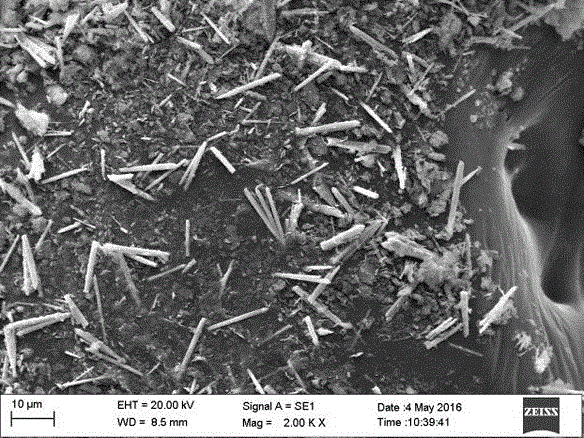

CuO-NiO/rGO composite material with efficient electro-catalysis oxygen reduction performance

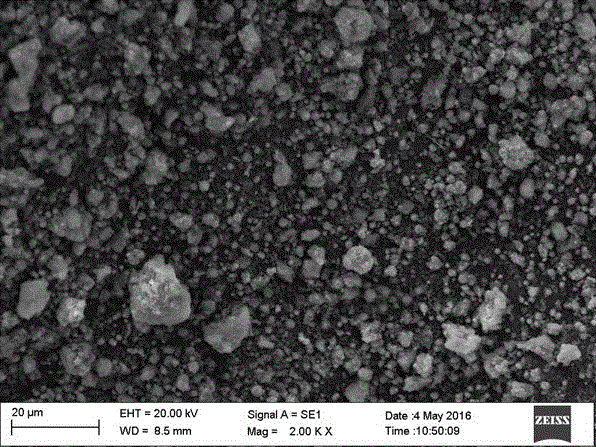

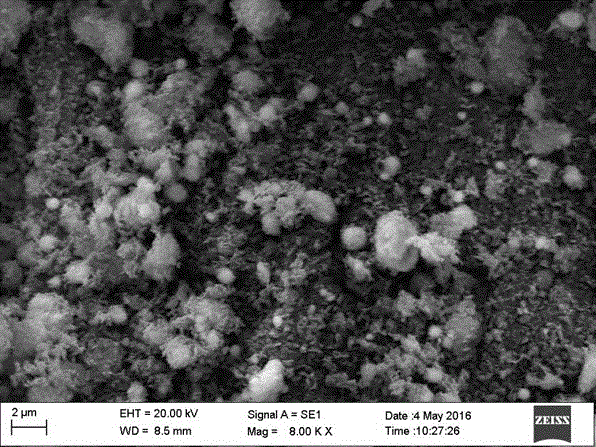

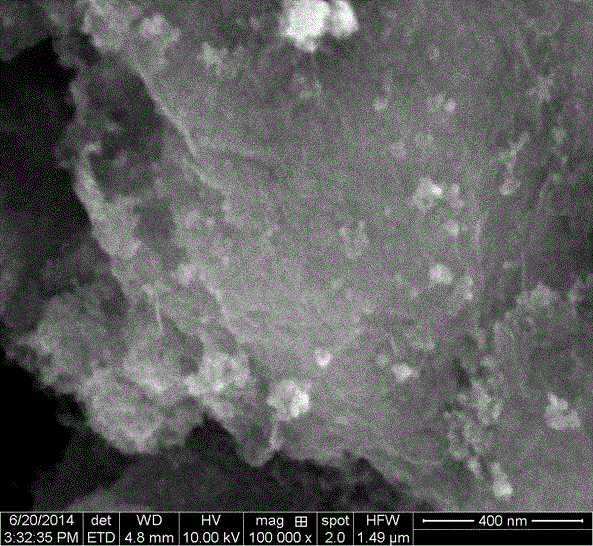

The invention relates to a CuO-NiO / rGO composite material with efficient electro-catalysis oxygen reduction performance, and belonging to the technical field of electro-catalysis materials. In the CuO-NiO / rGO composite material provided by the invention, CuO-NiO nanoparticles are attached to a reduction-oxidized graphene sheet layer, a mass ratio of the CuO-NiO nanoparticles to the rGO is 100:3-5, the sizes of the CuO-NiO nanoparticles are 6-10nm, and the reduction-oxidized graphene sheet layer is a single sheet layer; and the electro-catalysis oxygen reduction performance is provided. Compared with existing oxygen reduction reaction catalysts, the CuO-NiO / rGO composite material provided by the invention is significantly reduced in cost, and is the oxygen reduction reaction catalyst with low price and excellent electro-catalysis oxygen reduction performance. The CuO-NiO / rGO composite material provided by the invention adopts copper salts, nickel salts, hydroxides and oxidized graphene as materials, deionized water and absolute ethyl alcohol as solvents, and glycol as a dispersing agent and a reducing agent, and is synthesized by using a one-pot hydrothermal method. The CuO-NiO / rGO composite material provided by the invention is low in material price, prone to get materials, simple and easy in preparation operation, simple in aftertreatment process, prone to control reaction parameters, short in flow and low in energy consumption.

Owner:UNIV OF JINAN

Elastic facial mask cloth

InactiveCN101643974AThe shape of the mask does not changeNo change in shapePackaging toiletriesPackaging cosmeticsEngineeringAbsorbent cotton

The invention relates to an elastic facial mask cloth, which is manufactured by adopting a spunlaced nonwovens processing technique by a direct web formation method. The elastic facial mask cloth is characterized by containing composite ultrafine chopped fiber, absorbent cotton and bamboo fiber. (First), the composite ultrafine chopped fiber is split into 16 or more than 16 fine denier fibers withtiny diameters from the original one fiber part after being punctured at a high pressure by a spunlace processing technique, the fine diner fibers are adhered to each other, and after the spunlance high-pressure puncturing, the fibers are woven with the fibers and the fine denier fibers in a three-dimensional and staggered mode to form a three-dimensional netlike structure of a tight structure. Afacial mask manufactured by soaking the facial mask cloth in hygroscopic water and facial make-up liquid by a spunlace process of the direct web formation method has an unchanged shape. The facial mask of the same model can be suitable for people of different facial forms after being stretched; and the elastic facial mask cloth also has a certain elastic recoverability and strong comfortable pasting feeling, tightens and relaxes along with a face, generates tightening feeling to the face, and enhances the continuous infiltration and absorption of the facial make-up liquid.

Owner:NOX BELLCOW COSMETICS CO LTD

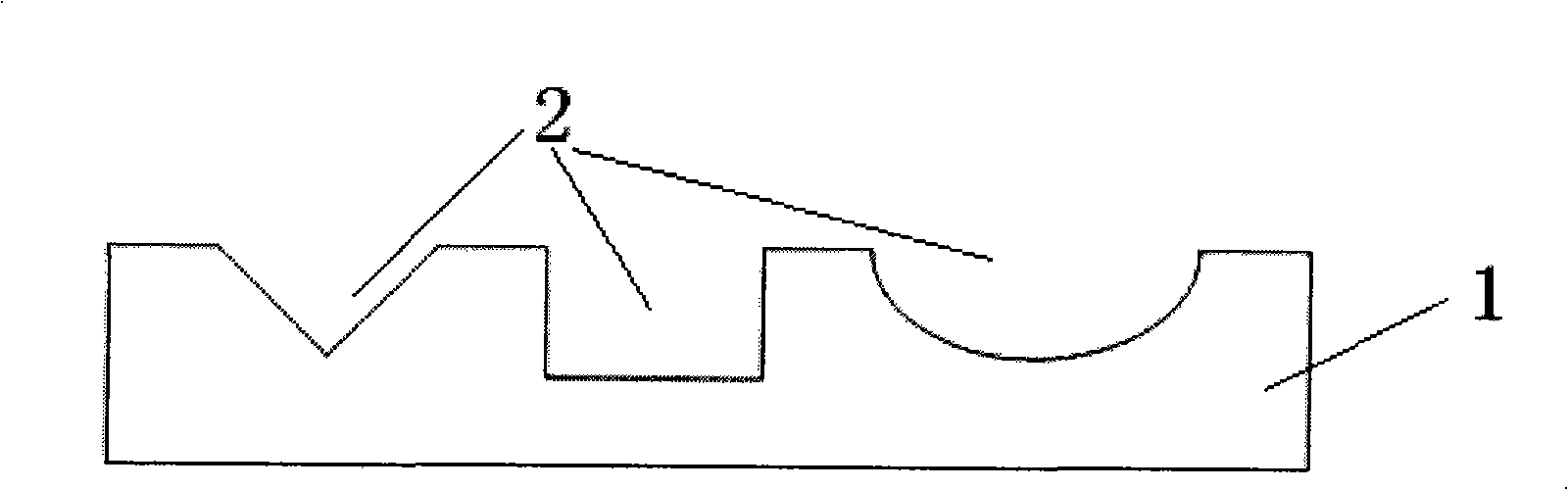

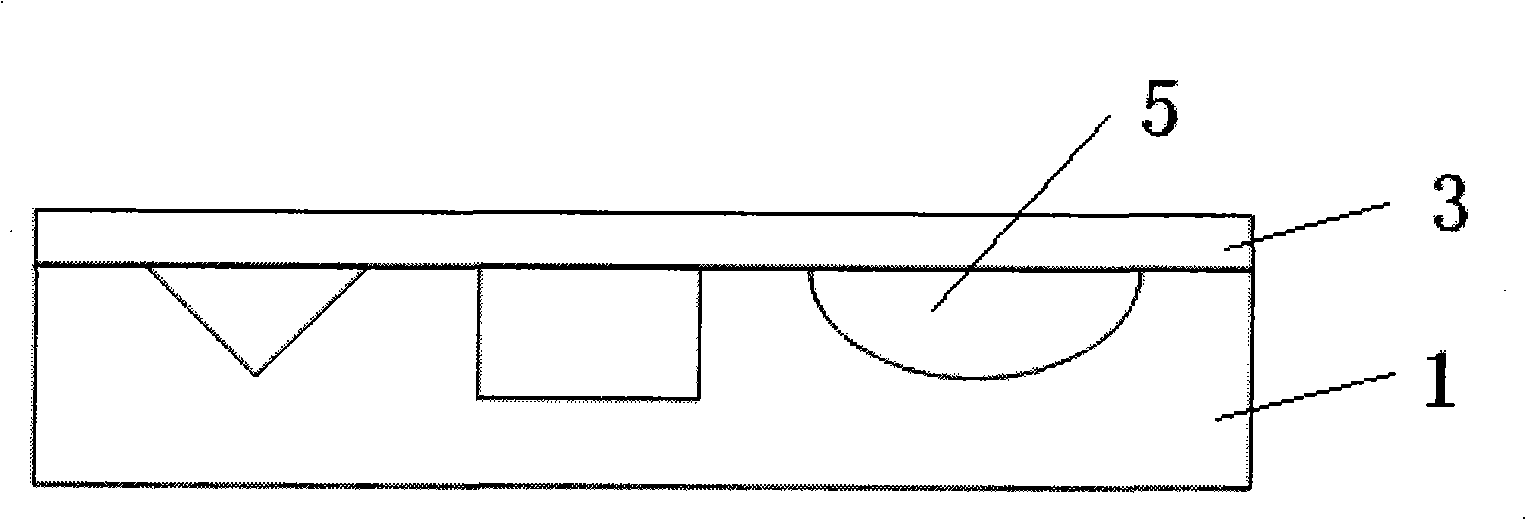

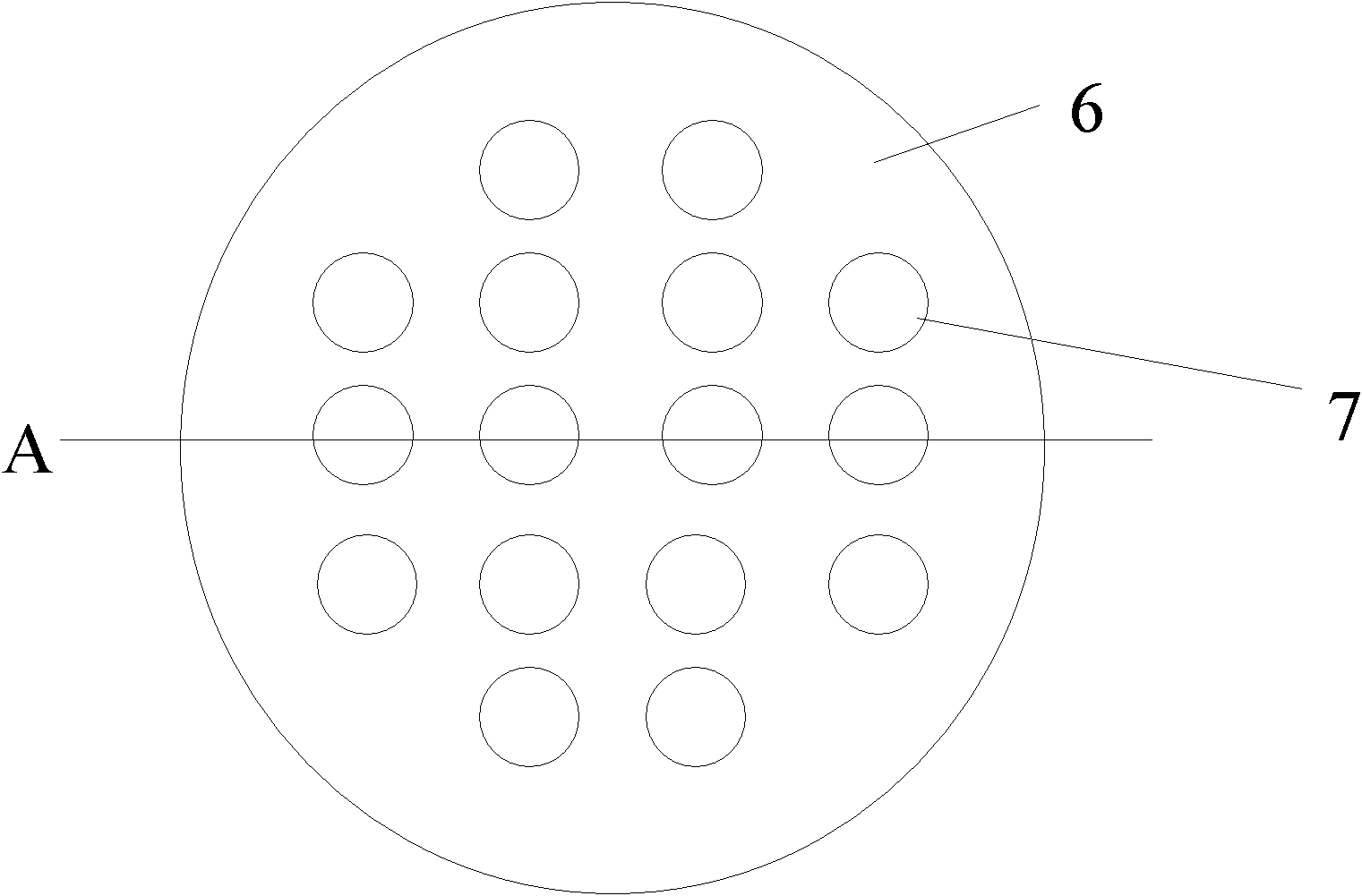

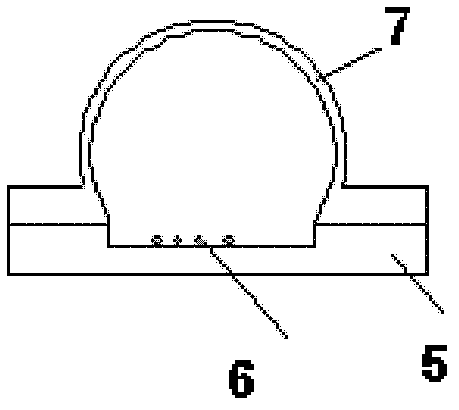

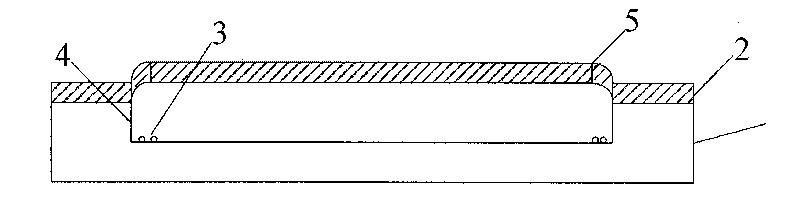

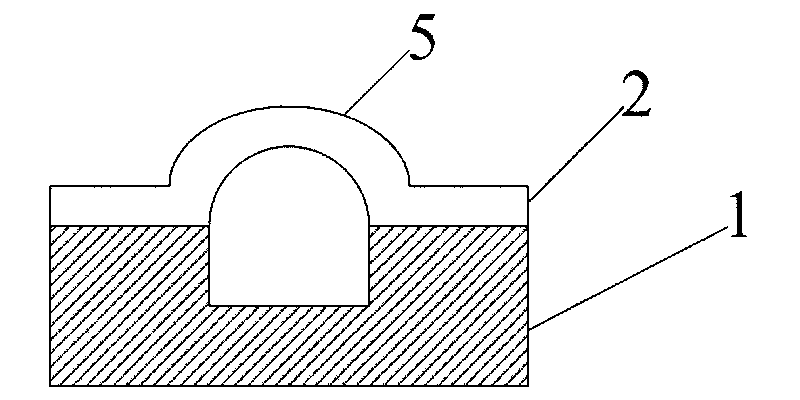

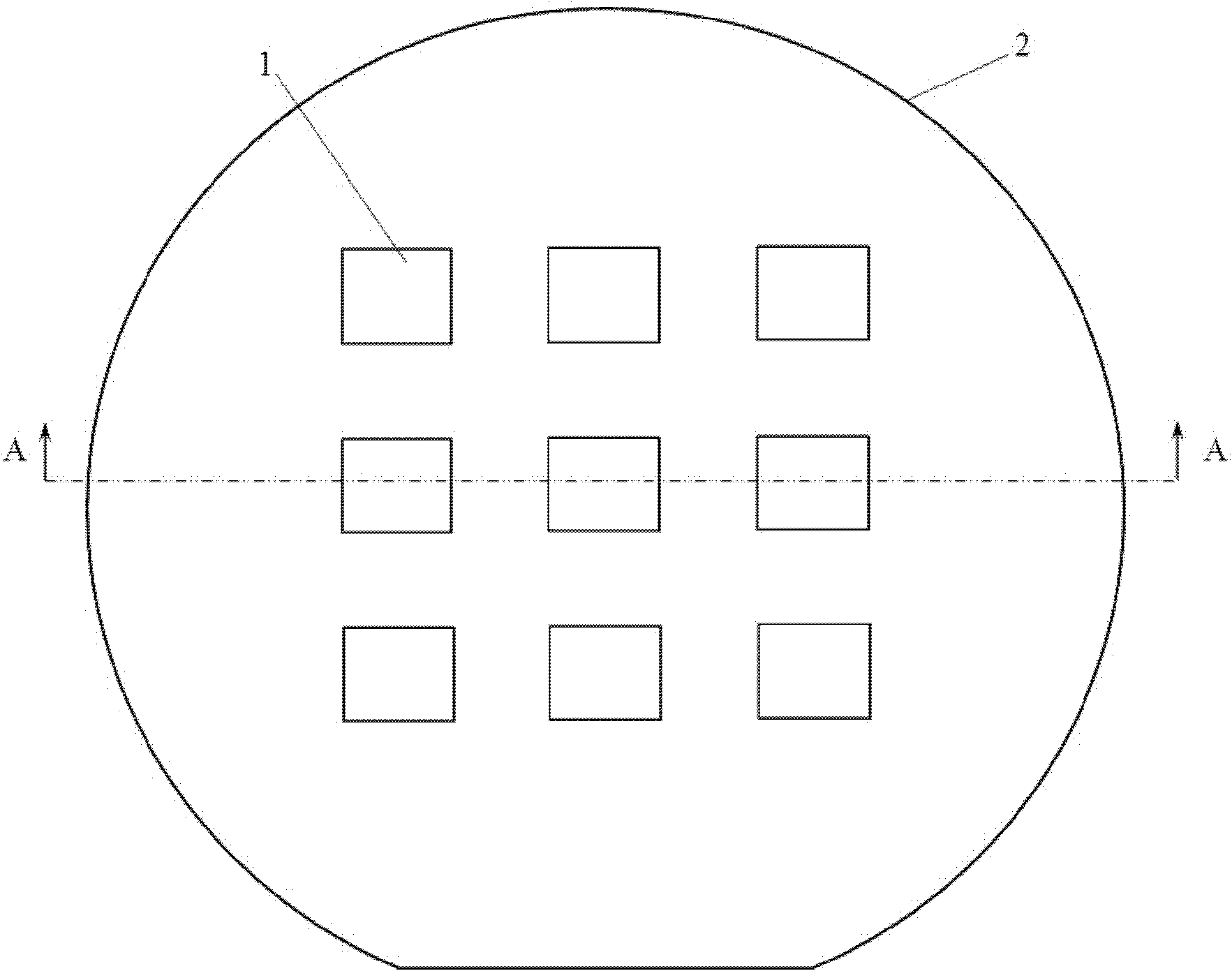

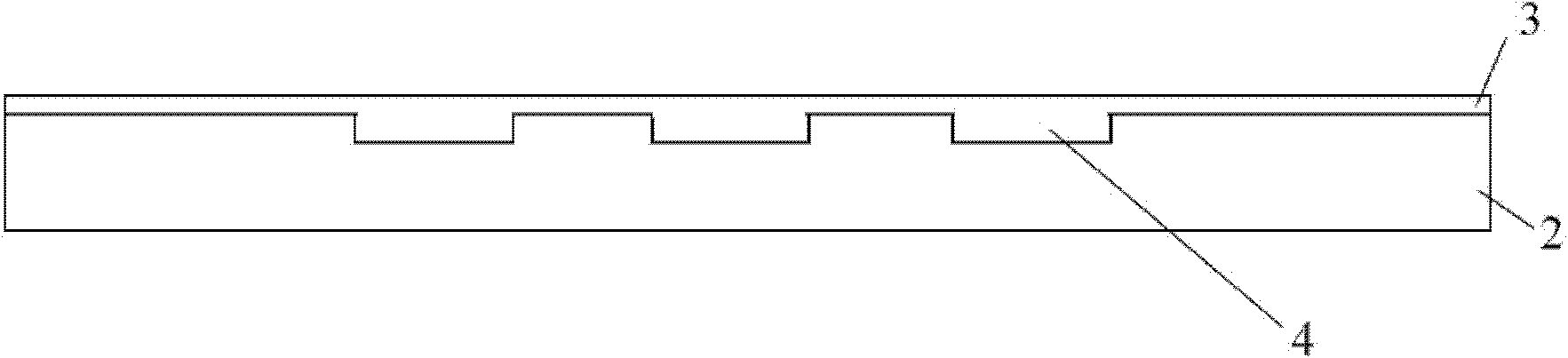

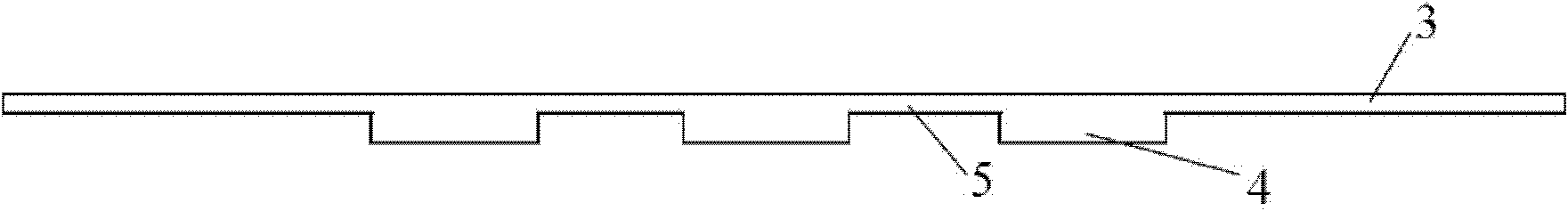

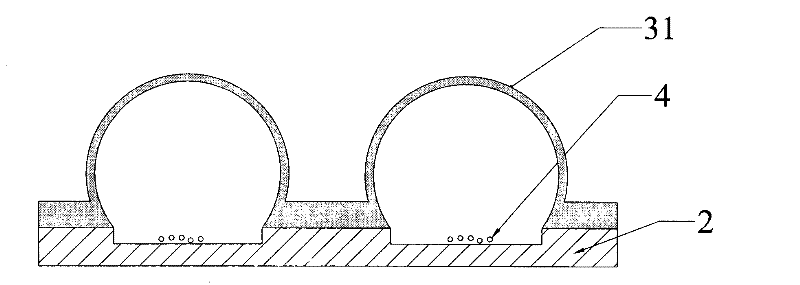

Method for manufacturing wafer-stage glass micro-cavity

InactiveCN101259951AReduce roughnessHigh bonding strengthPrecision positioning equipmentSoldering apparatusMetallurgyMachining process

The invention provides a fabrication method for a wafer-class glass micro-chamber, comprising the steps as follows: a first step: a special pattern is etched on a Si wafer to form a special pattern by a Si micro-machining process; a second step: the Si wafer and a Pyrex7740 glass wafer are bonded to each other under the atmosphere of less than 1Pa, thus leading the special pattern on the Pyrex7740 glass to form a sealing chamber body; a third step: the bonded wafers are heated to 810 to 890 DEG C under one atmosphere and the temperature is kept, the pressure different inside and outside the chamber leads the softened glass to form a structure corresponding to the micro-chamber pattern structure which is then cooled, and the wafer is annealed to eliminate the stress under normal pressure. The fabrication method of the wafer-class glass micro-chamber has the characteristics of simple process, precise forming, high depth-width-ratio of micro-chamber transmission, good surface characteristic of the micro-chamber, etc., can be widely applied to the fabrication of glass micro-chamber in an MEMS (micro-electron mechanical system), and belongs to wafer-class MEME fabrication process.

Owner:SOUTHEAST UNIV

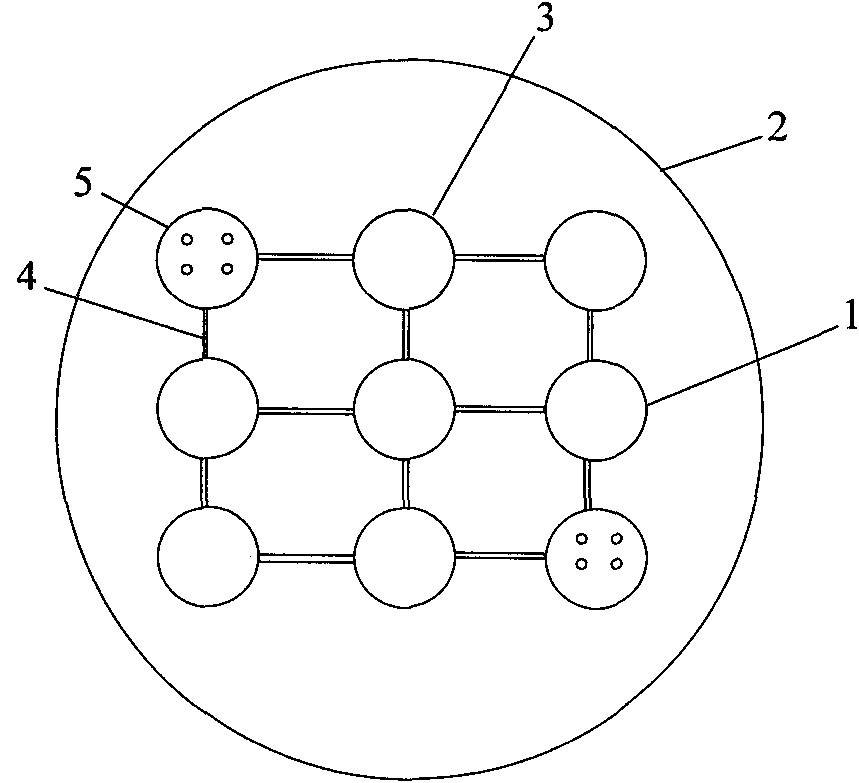

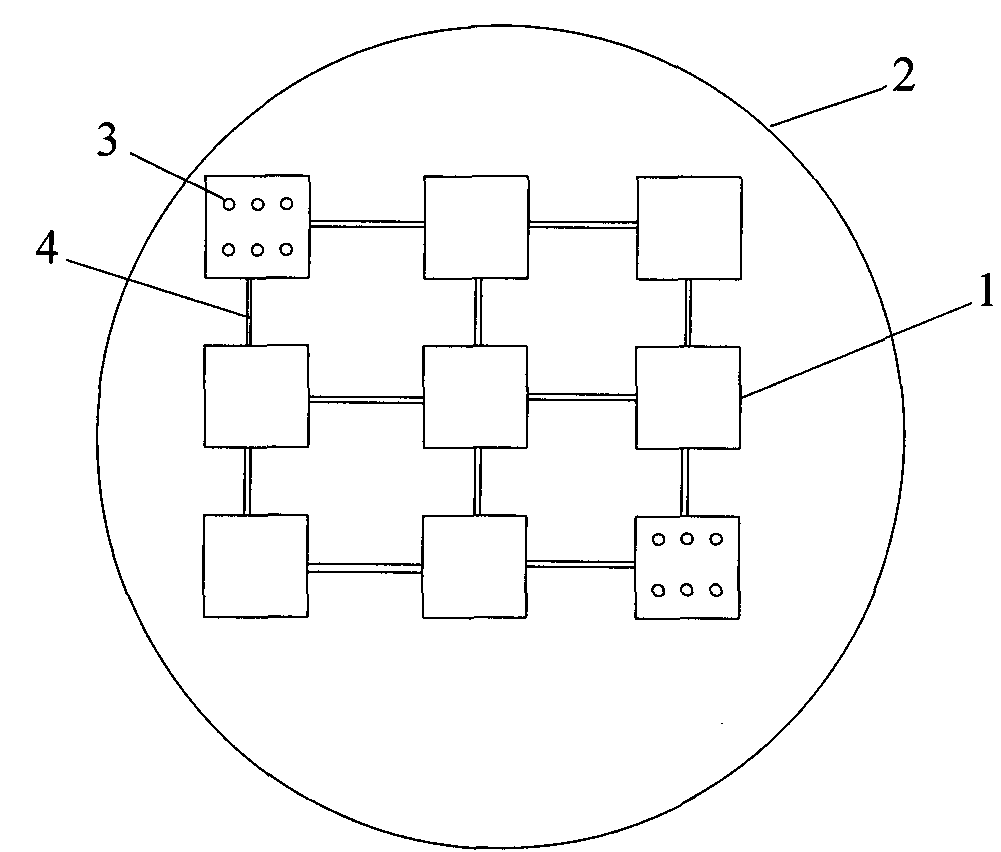

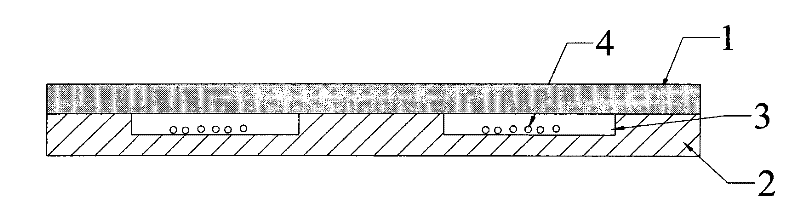

Method for packaging glass-silicon wafer-grade chiponboard (COB) of light emitting diode (LED)

ActiveCN102097545AReduce luminous attenuationImprove performanceSolid-state devicesSemiconductor devicesHeat resistanceSilica gel

The invention discloses a method for packaging a glass-silicon wafer-grade chiponboard (COB) of a light emitting diode (LED). The method comprises the following steps: 1, etching a silicon micro slot array with the micro slots communicated with each other through micro channels, and placing a proper amount of heat outgas agent in the micro slots; 2, performing anodic bonding on the Si wafer with patterns and the heat outgas agent and borosilicate glass wafer in air or in vacuum to form a sealed cavity; 3, heating and preserving heat to form a spherical glass micro cavity, cooling the cavity to normal temperature, annealing and removing silicon to obtain a wafer-grade glass micro cavity; 4, preparing a lead substrate; 5, mounting a chip and leading a wire; 6, carrying out wafer-grade bonding; and 7, filling silica gel to realize the wafer-grade packaging of the LED. By achieving the integration with the wafer-grade LED reflecting cup, the method reduces heat resistance and cost.

Owner:SOUTHEAST UNIV

Method for preparing wafer-level uniform-dimension glass microcavity by positive pressure thermal forming

ActiveCN101905859ANot easy to expandLow costPrecision positioning equipmentSoldering apparatusPhysical chemistrySilicon

The invention discloses a method for preparing a wafer-level uniform-dimension glass microcavity by positive pressure thermal forming. The method comprises the following steps of: etching an array consisting of microgrooves on a silicon wafer, and etching microchannels connecting the microgrooves, wherein the minimum groove width of the microgrooves is 5 times more than the runner width; and putting a proper amount of thermal outgassing agent into at least one microgroove, correspondingly bonding the plurality of microgrooves to form a sealed cavity by using a glass wafer, heating to soften the glass, making the thermal outgassing agent heated to release gases to generate positive pressure, acting the positive pressure on the softened glass corresponding to the plurality of microgrooves which are connected through the microchannels so as to form a spherical microcavity with uniform dimension, and cooling the microcavity. By connecting the same microgrooves through the microchannel, the inside air pressure of the microgrooves is substantially consistent, and the formed glass microcavity has uniform dimension. When the dimension of the microgrooves is far greater than that of the microchannel, the microchannels with smaller radius hardly expand due to higher additional pressure. Therefore, the glass corresponding to the microchannels can keep smooth.

Owner:SOUTHEAST UNIV

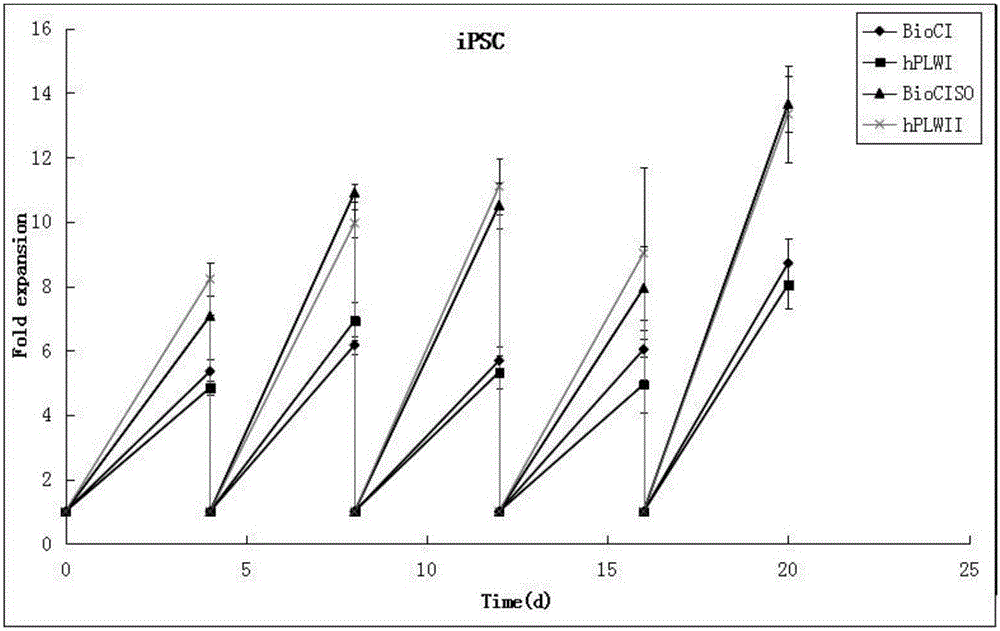

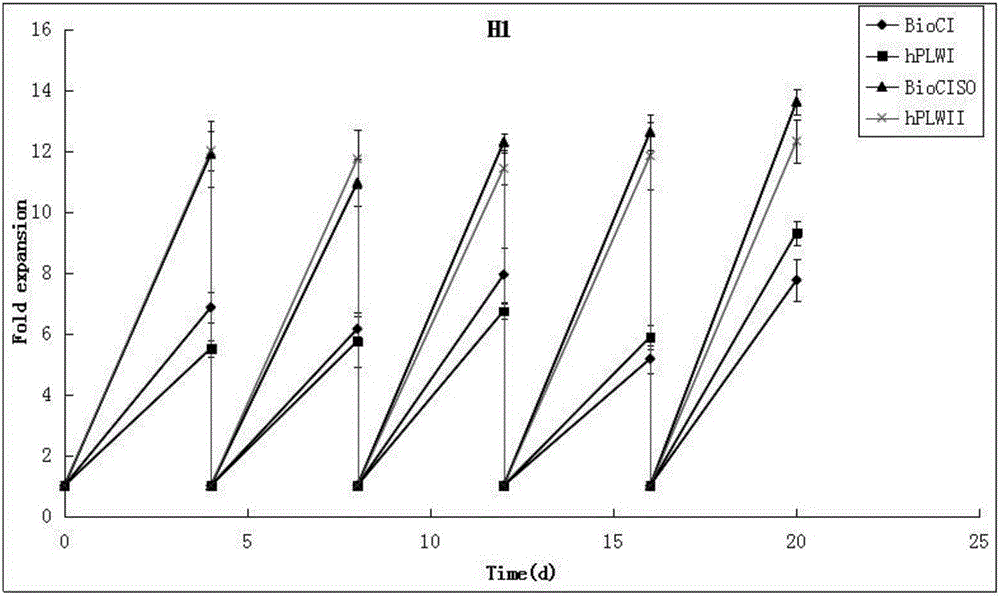

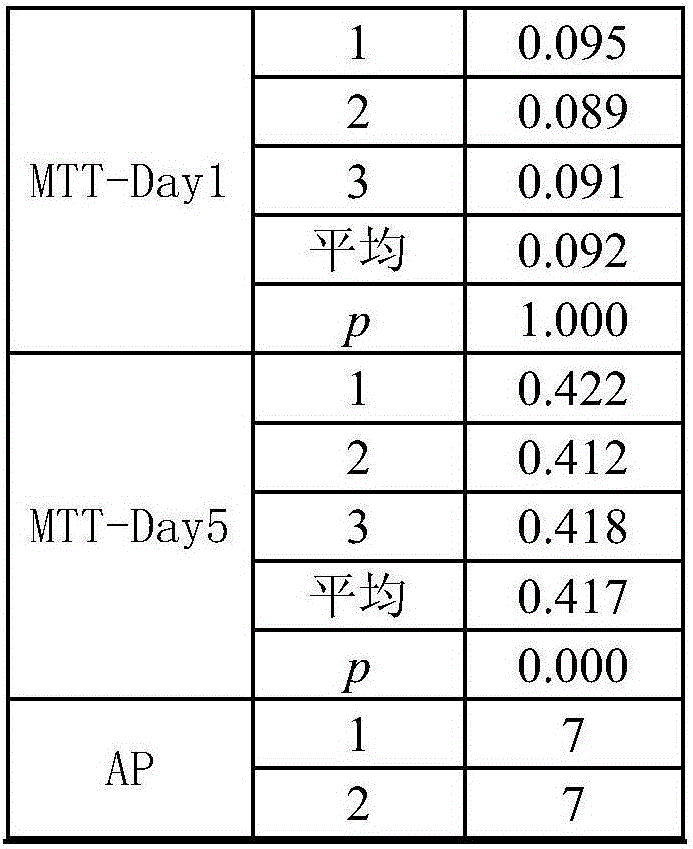

Multi-potent stem cell culture medium

ActiveCN105907705AReduce manufacturing costSerum freeCulture processArtificial cell constructsMagnesium phosphateMagnesium orthophosphate

The invention discloses a multi-potent stem cell culture medium. The multi-potent stem cell culture medium comprises a basic culture medium and following added components: L-ascorbic acid-2-magnesium phosphate, sodium selenite, human insulin, ferric citrate, an alkaline basic fibroblast growth factor and a transforming growth factor beta1. The sodium selenite is successfully introduced into a multi-potent stem cell culture medium system to replace human apo-transferrin, so that the production cost of the multi-potent stem cell culture medium can be reduced; exogenous pathogenic risks are reduced; the multi-potent stem cell culture medium can guarantee normal proliferation of cells in a multi-potent stem cell culture process and the multi-potent property of the stem cells can also be maintained.

Owner:广州杰尔克生物技术有限公司 +1

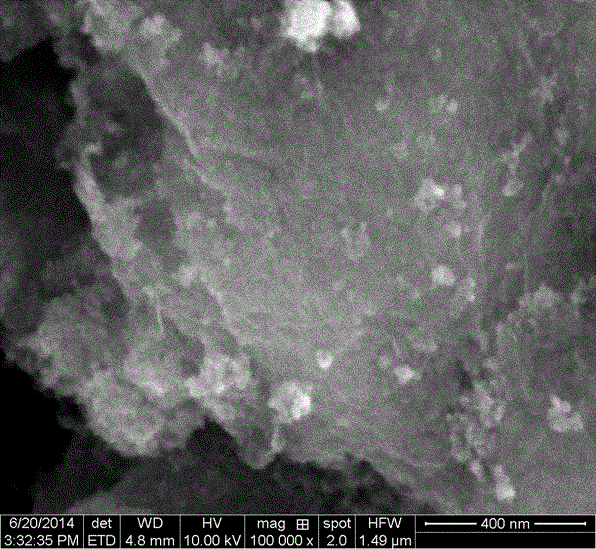

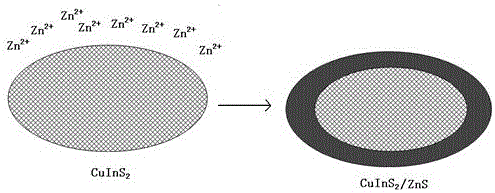

CuInS2/ZnS core-shell quantum dots and preparation method thereof

InactiveCN106634963ANo change in shapeNo change in sizeMaterial nanotechnologyNanoopticsCentrifugationRoom temperature

The invention discloses CuInS2 / ZnS core-shell quantum dots and a preparation method thereof. The method comprises the following steps: in an inert gas atmosphere, heating a prepared zinc precursor to 200-270 DEG C, injecting CuInS2 quantum dots into the zinc precursor, reacting for 5-120 minutes, and stopping heating; and after the reaction solution is cooled to room temperature, repeatedly dissolving and precipitating the product, and carrying out centrifugation purification to obtain the CuInS2 / ZnS core-shell quantum dots. The environment-friendly CuInS2 alloy quantum dots are converted into the CuInS2 / ZnS core-shell quantum dots by the cation exchange technique, thereby implementing the use of the no heavy metal Cd. The composition and crystal lattice of the CuInS2 / ZnS core-shell quantum dots can be completed by previously designing the composition and crystal lattice of the CuInS2 quantum dots. In the cation exchange process, the shape and size of the alloy quantum dots are not changed.

Owner:TCL CORPORATION

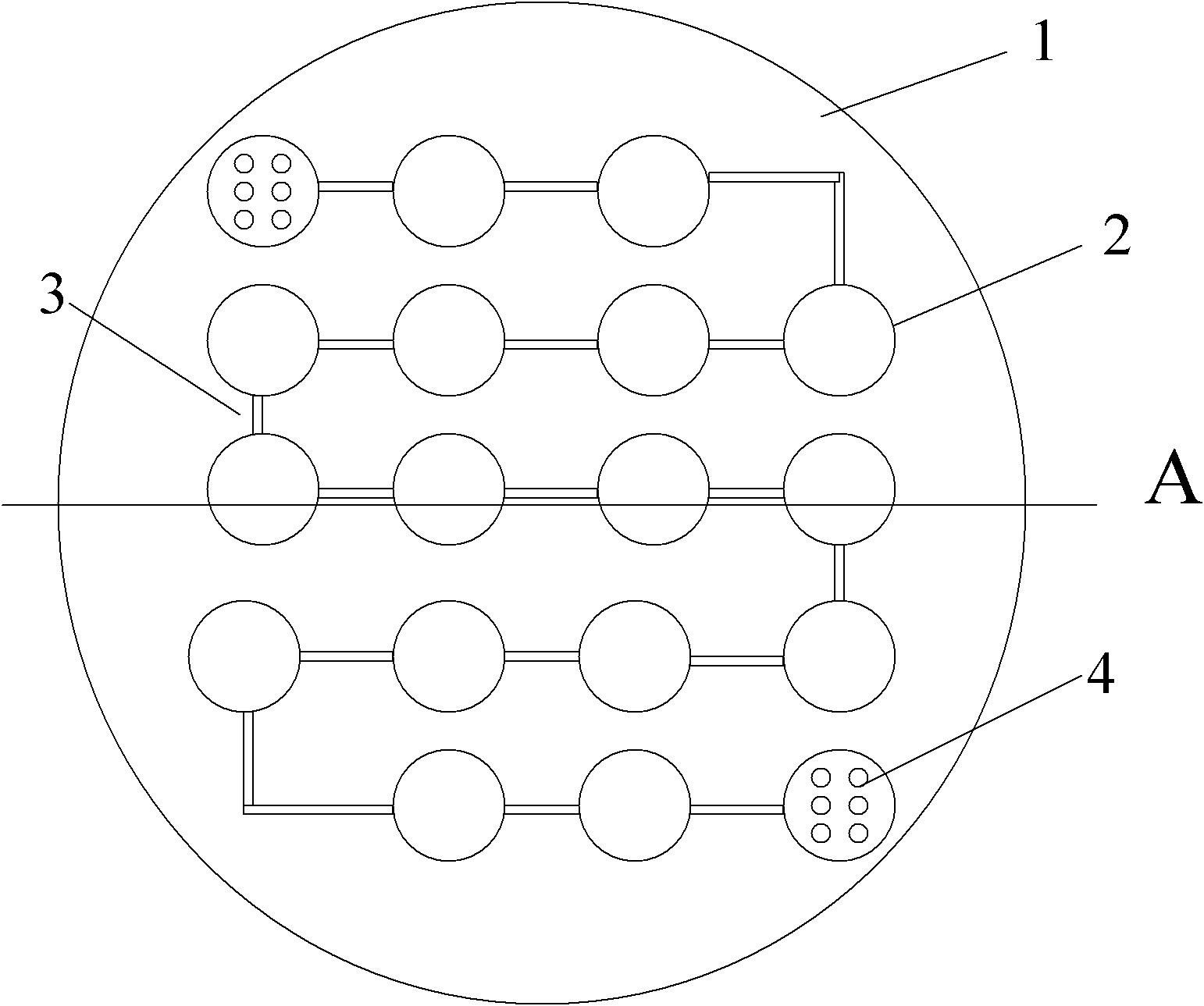

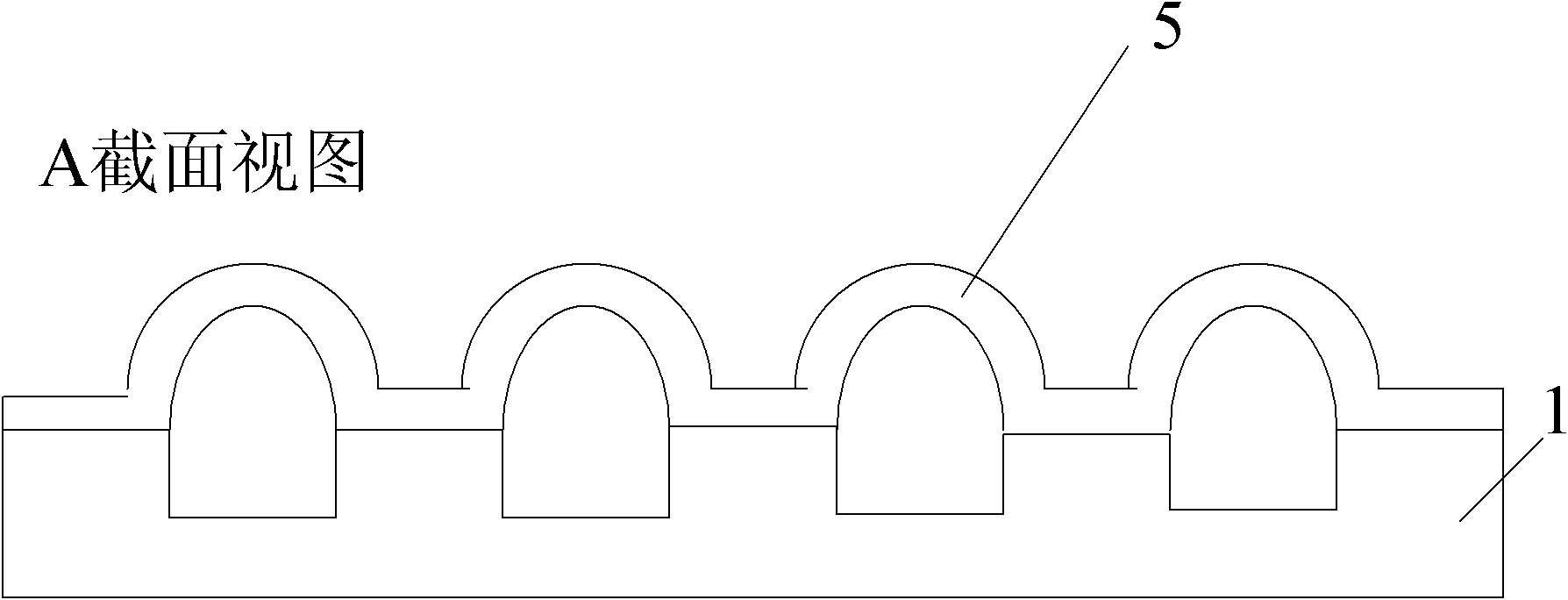

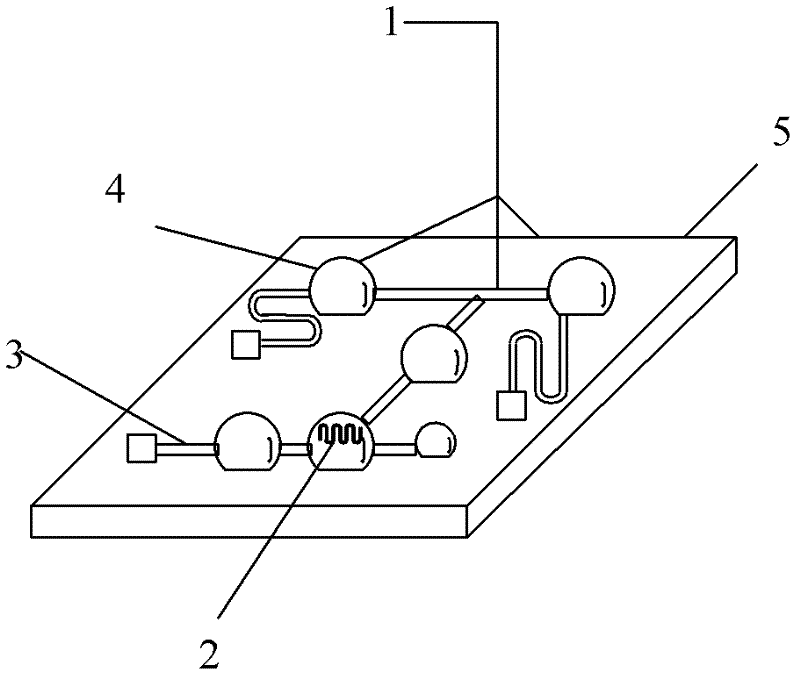

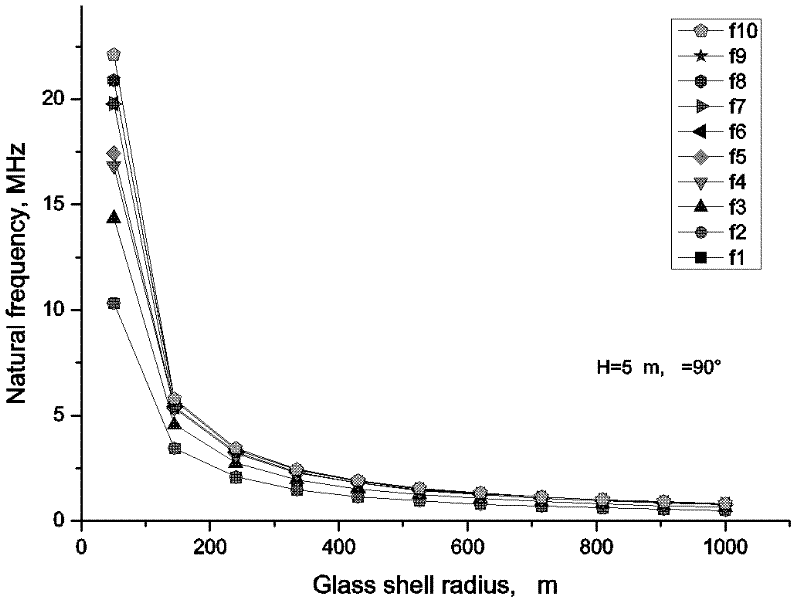

Integrated system on ultrasonic transducer sheet with MEMS (Micro-Electromechanical Systems) glass sphere and preparation method thereof

ActiveCN102430512AHigh forming heightIncrease processing costTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesEngineeringGlass spheres

The invention discloses a preparation method of an experimental system on a micro-runner grid sheet of a focusing ultrasonic transmitter integrated with spherical glass cavity, comprising the steps of: 1, preparing a spherical glass micro-cavity or a cylindrical micro-runner by a thermal forming method; 2, integrating vibration and excitation sources such as a metal strip on the prepared spherical glass micro-cavity or cylindrical micro-runner; 3, placing biological cells or molecules in the experimental system on the glass micro-runner grid integrated sheet with the excitation sources; and 4, treating the biological cells or molecules by the experimental system on the integrated sheet. The invention generates resonance with frequency which is 20kHz-1MHz based on the glass sphere cavity under external electric excitation or electromagnetic excitation. The frequency range of the resonance frequency is ultrasonic range. Cavitation effect generated by ultrasonic wave can be applied to micro-treatment in the field of biology or chemistry, such as cell disruption and DNA interruption and the like.

Owner:SOUTHEAST UNIV

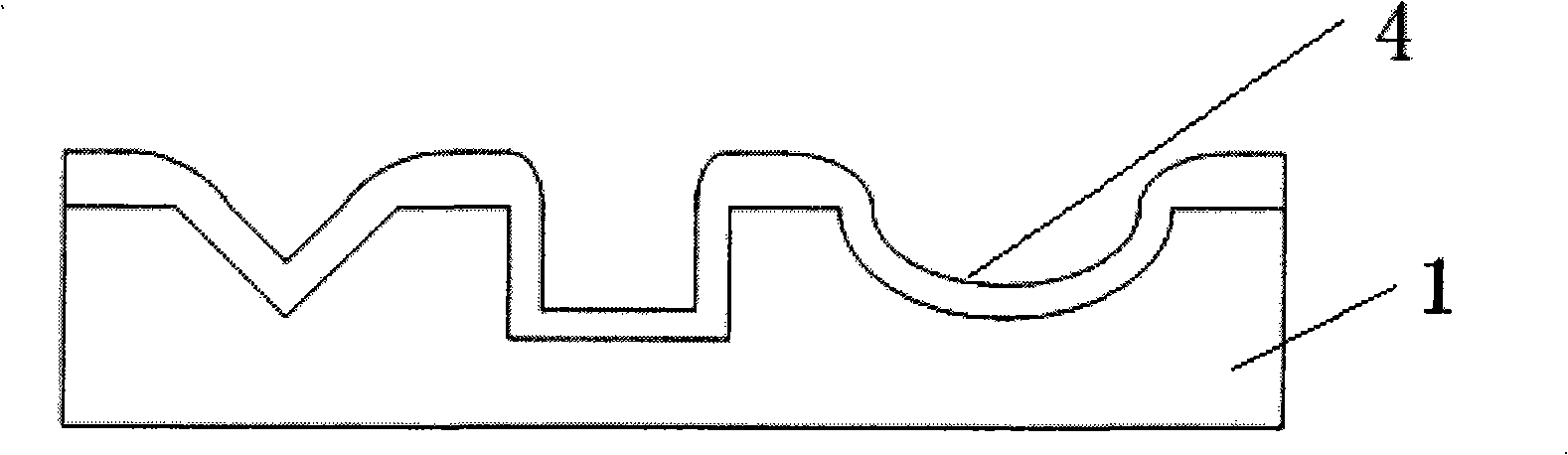

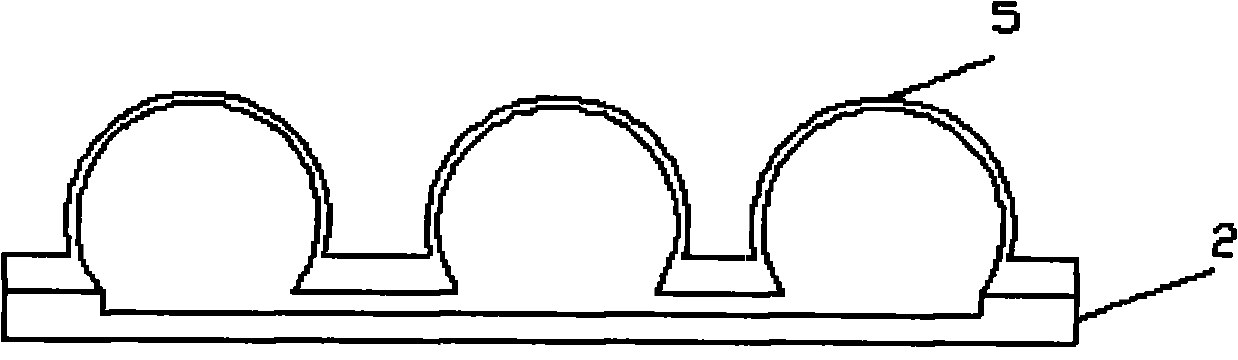

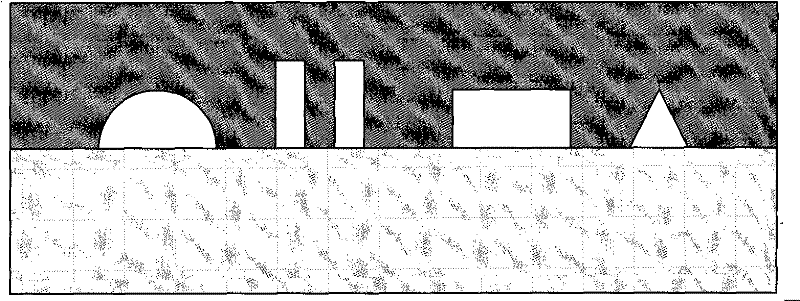

Positive pressure thermoforming manufacturing method of wafer-level glass micro-channel

ActiveCN101759138AHigh forming heightIncrease processing costDecorative surface effectsChemical vapor deposition coatingPositive pressureEngineering

The invention discloses a positive pressure thermoforming manufacturing method of a wafer-level glass micro-channel, which comprises the following steps of: 1. etching a specific silicon micro-channel shallow slot pattern on a Si wafer by utilizing a Si microprocessing process; 2. locally placing a proper amount of high-temperature gas releasing agent at both ends or a specific position of a silicon micro-channel; 3. bonding the Si wafer and a Pyrex7740 glass wafer to enable a shallow slot on Pyrex7740 glass to form a sealed cavity body; and 4. heating the bonded wafers to the temperature of 810-890 DEG C in air, preserving heat for 5-10 minutes, releasing gas by the high-temperature gas releasing agent due to heating, generating a positive pressure to enable molten glass corresponding to the sealed cavity body to deform and form a micro-channel pattern corresponding to the silicon micro-channel shallow slot pattern on the glass, and cooling to obtain the wafer-level glass micro-channel. In the invention, the gas is released by utilizing the high-temperature gas releasing agent, so that the glass can be in the shape of a hemispherical arc pipe to form the glass micro-channel.

Owner:SOUTHEAST UNIV

ZnO-NiO/rGO composite material with efficient electrocatalytic oxygen reduction performance

The invention relates to a ZnO-NiO / rGO composite material with efficient electrocatalytic oxygen reduction performance, and belongs to the technical field of electrocatalytic materials. In the ZnO-NiO / rGO composite material disclosed by the invention, nano ZnO-NiO particles are adhered into a reduction-oxidation graphene slice layer, and the mass ratio of nano ZnO-NiO to rGO is 100: (3 to 5); the sizes of the nano ZnO-NiO particles are 5 to 10 nm, and the reduction-oxidation graphene slice layer is a single slice layer; and the ZnO-NiO / rGO composite material has electrocatalytic oxygen reduction performance. Compared with the cost of an existing oxygen reduction reaction catalyst, the cost of the ZnO-NiO / rGO composite material disclosed by the invention is obviously reduced; and the ZnO-NiO / rGO composite material is an oxygen reduction reaction catalyst with low cost and excellent electrocatalytic oxygen reduction performance. The ZnO-NiO / rGO composite material disclosed by the invention is synthesized with a hydrothermal one-pot process by using a zinc salt, a nickel salt, a hydroxide and oxidized graphene as raw materials, using deionized water and absolute ethyl alcohol as solvents and using ethylene glycol as a dispersing agent and a reducing agent. The raw materials are low in price and easy to obtain, the preparation operation is simple and practicable, the post-treatment process is simple, the parameters of reaction are easy to control, the flow path is short, and the energy consumption is low.

Owner:UNIV OF JINAN

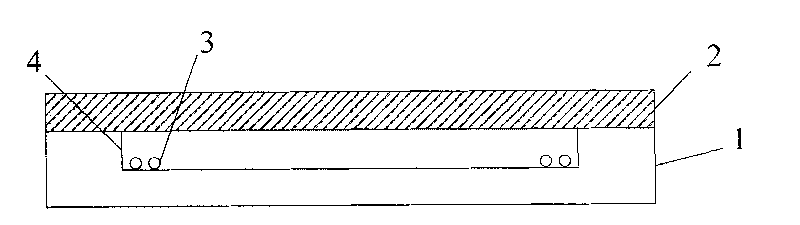

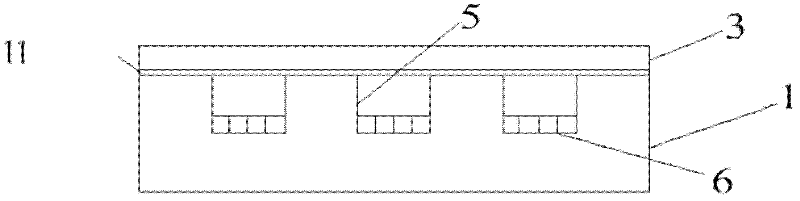

Method for packaging wafer level solid-state image sensor

InactiveCN102502480AControl and adjust heightImprove consistencyDecorative surface effectsChemical vapor deposition coatingSiliconGlass forming

The invention provides a method for packaging a wafer level solid-state image sensor. The method comprises the following steps of: etching a microgroove ring array on a silicon wafer to obtain a silicon wafer mold; bonding a boron silicon glass wafer and the silicon wafer mold under vacuum conditions so as to seal the microgroove rings of the silicon wafer mold; heating the bonded wafer to a temperature above a glass softening point and keeping the temperature for a certain period of time, molding the softened glass to obtain a glass bulge loop through atmosphere of an external environment, cooling to solidify the glass and annealing; removing the silicon wafer mold to obtain a glass wafer with a glass bulge loop and a planar optical window; and after alignment, adhering the glass bulge loop and the planar optical window at an end of the glass bulge loop through an adhesive to seal the solid-state image sensor, and obtaining the packaged solid-state image sensor through a back thinning process. The method has the characteristics that: the method has a simple process flow, low cost, controllable height, high degree of parallelism and high yield.

Owner:SOUTHEAST UNIV

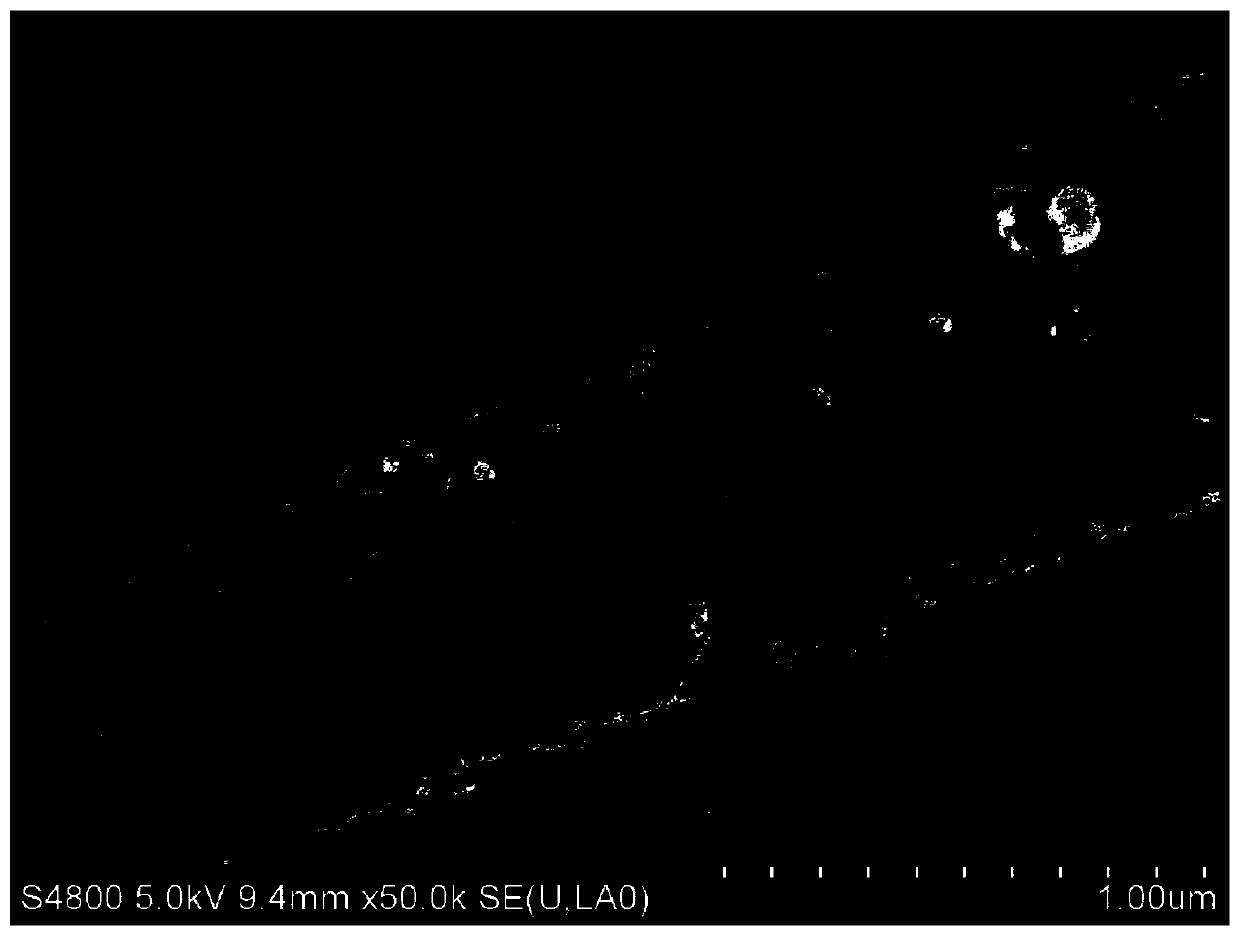

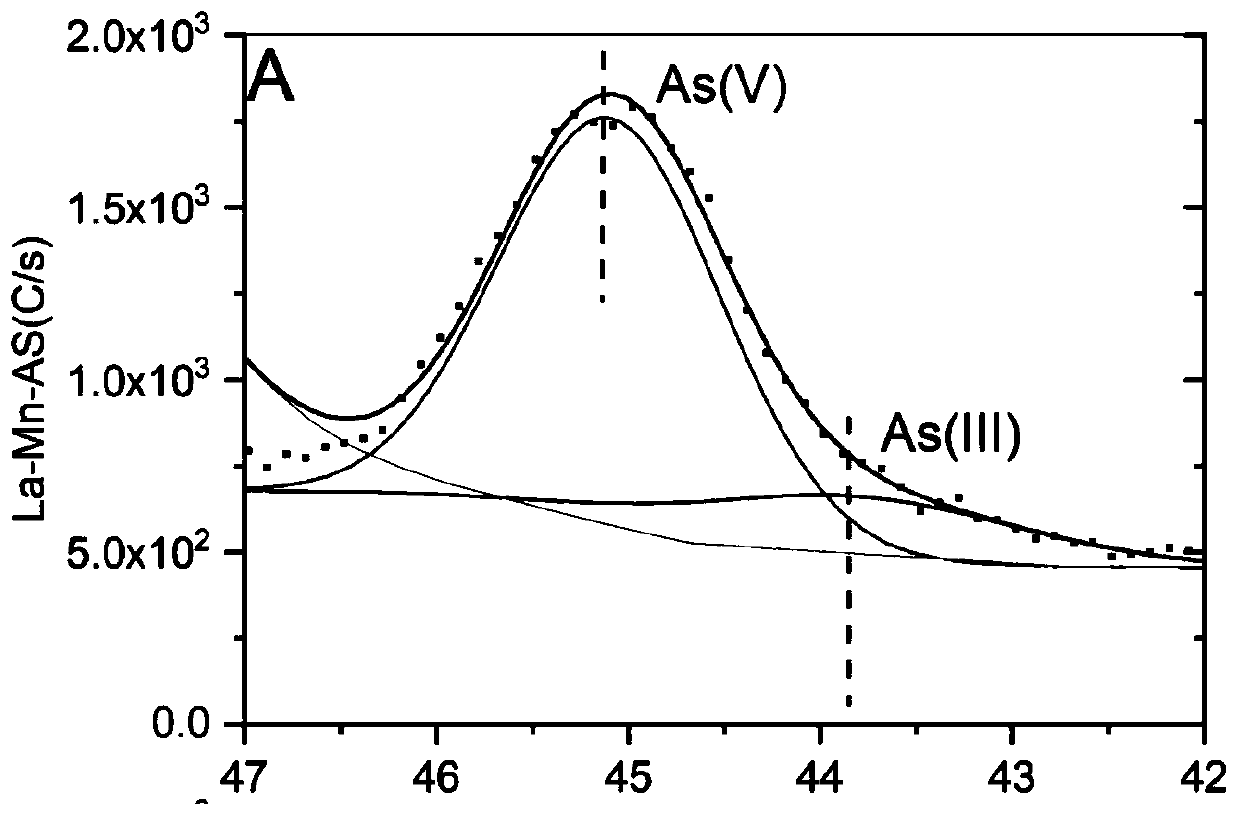

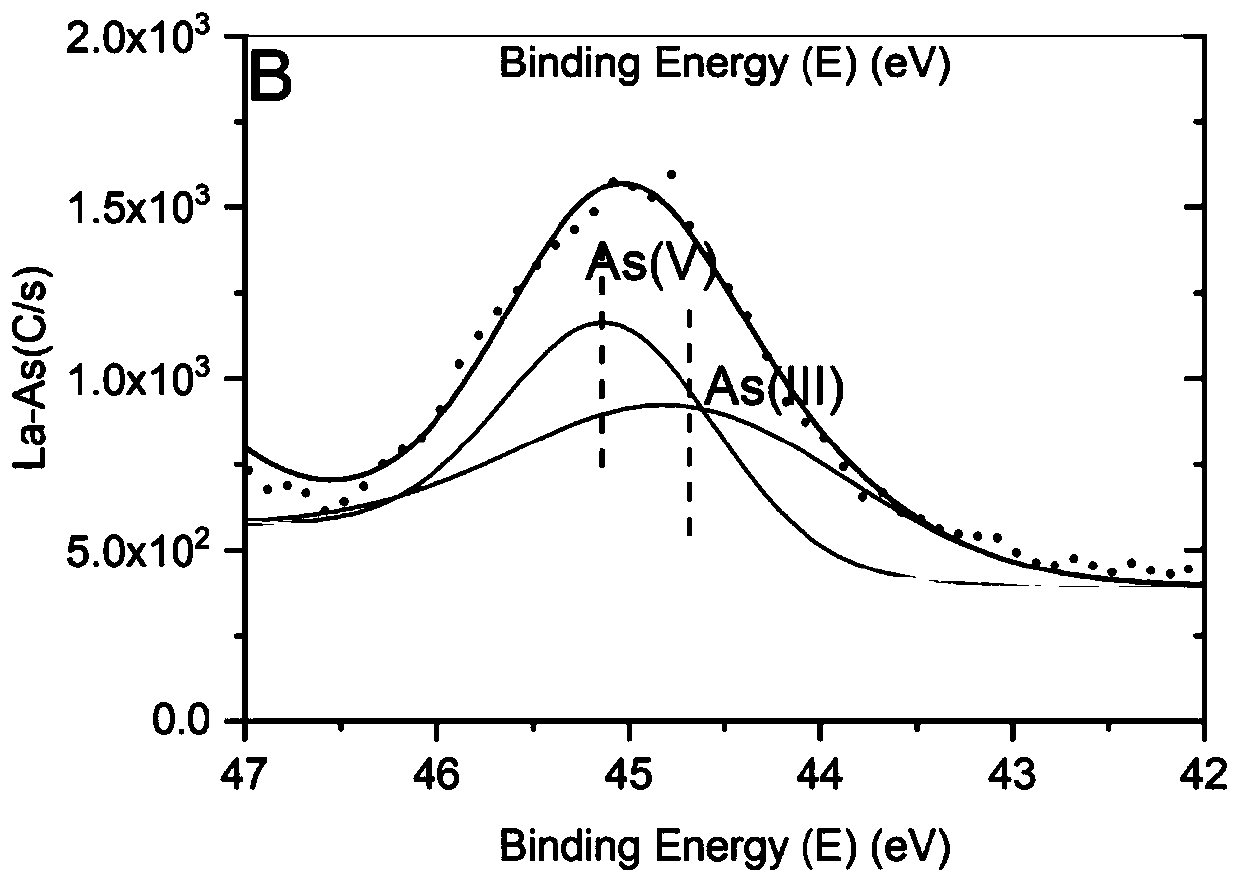

Arsenic removal nanofiber film with dual nanometer function core loads and preparing method thereof

ActiveCN110592806AEfficient removalExcellent chemical affinityElectro-spinningNon-woven fabricsNanofiberPhysical chemistry

The invention discloses an arsenic removal nanofiber film with dual nanometer function core loads and a preparing method thereof, and belongs to the technical field of sewage treatment. The preparingmethod includes the following steps dissolving PAN in a DMF and acetone mixed solvent to obtain a PNA solution, adding La(NO3)3.6H2O to the PAN solution to obtain an electrostatic spinning solution, conducting electrostatic spinning on the obtained electrostatic spinning solution through an electrostatic spinning device to obtain an electric spinning film, putting the electric spinning film in a dopamine hydrochloride solution to be oscillated at a constant temperature, taking out the electric spinning film to be cleaned and dried, putting the obtained electric spinning film into a KMnO4 solution to be oscillated at a constant temperature, taking out the electric spinning film to be cleaned and dried to obtain the target product. The preparing method is simple, and the prepared nanofiber film can effectively remove arsenic ions at different valence states in a water body.

Owner:TONGJI UNIV

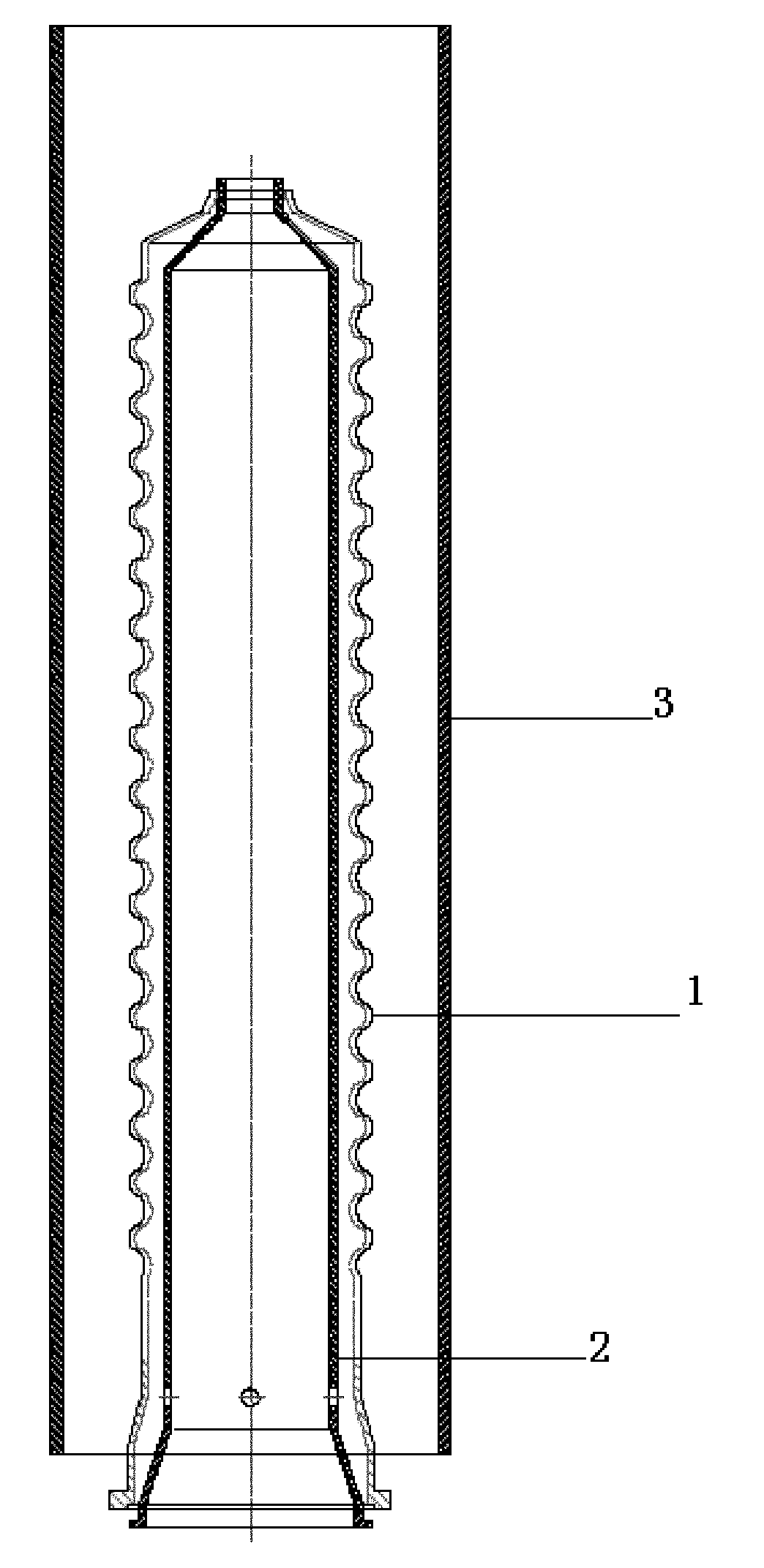

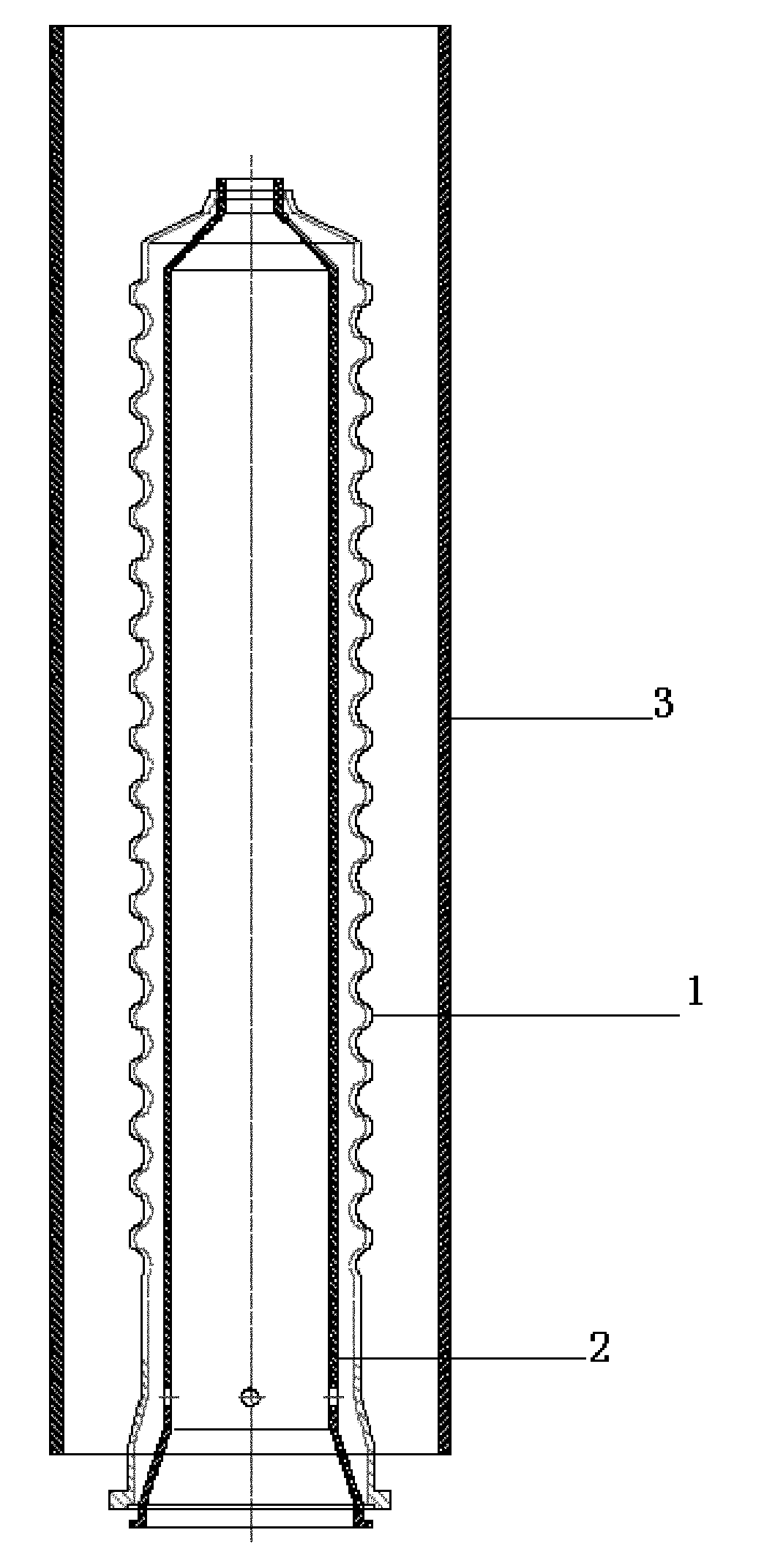

Manufacturing method of long-life high-temperature resistant radiation pipe

InactiveCN101921127AReduce weightImproving the current situation of not being able to withstand high temperaturesPolyvinyl alcoholOxidation resistant

The invention relates to a main heat exchange part in various high-temperature heat treatment furnace bodies, such as a carburizing furnace, a fluorinating furnace and the like in the field of iron and steel manufacture, in particular to a manufacturing method of a long-life high-temperature resistant radiation pipe, which comprises the following steps of: A. uniformly mixing the following raw materials in percentage by weight: 45-65 percent of silicon carbide, 20-30 percent of monocrystalline silicon, 10-20 percent of carbon black, 3-5 percent of polyvinyl alcohol and 0.3 percent of lanoline, and then adding water to be mixed into paste; B. injecting the pasty raw materials into a mould for molding by adopting a solid casting method; C. drying a molded blank body after being demolded; and D. placing the dried blank body into a vacuum furnace, and raising the temperature to 1800 DEG C for vacuum reaction sintering. The product prepared by the invention has the advantages of high strength, high rigidity, high-temperature resistance, corrosion resistance, good thermal shock resistance and excellent oxidation resistant performance.

Owner:武钢集团有限公司

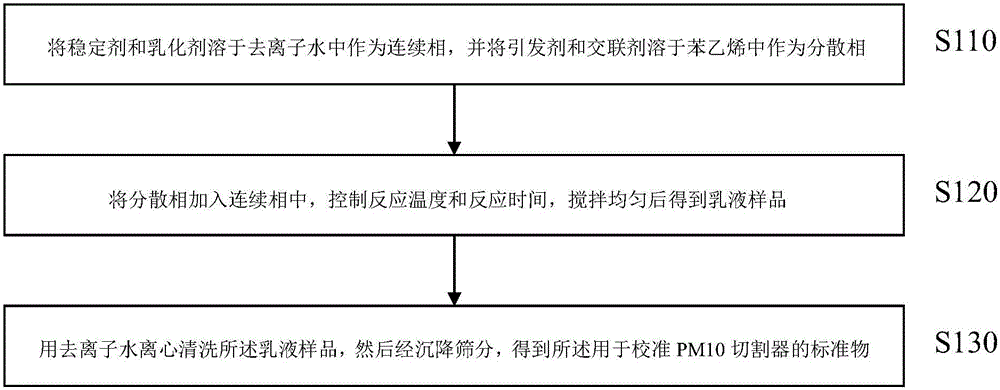

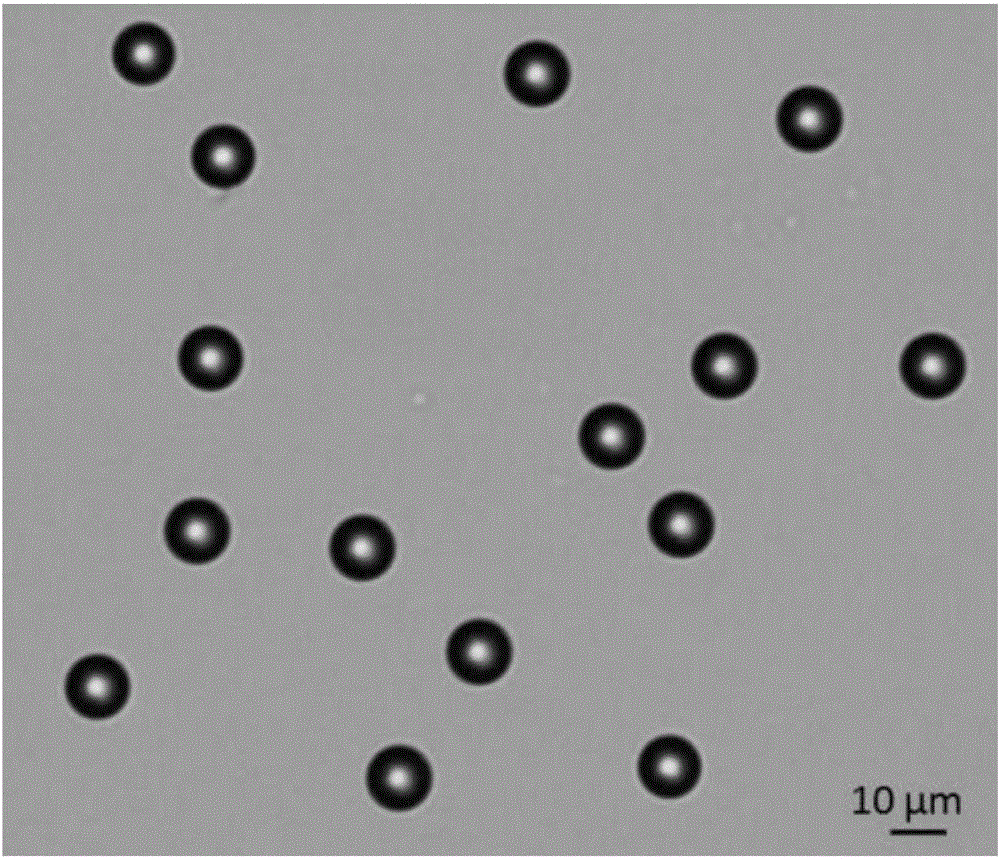

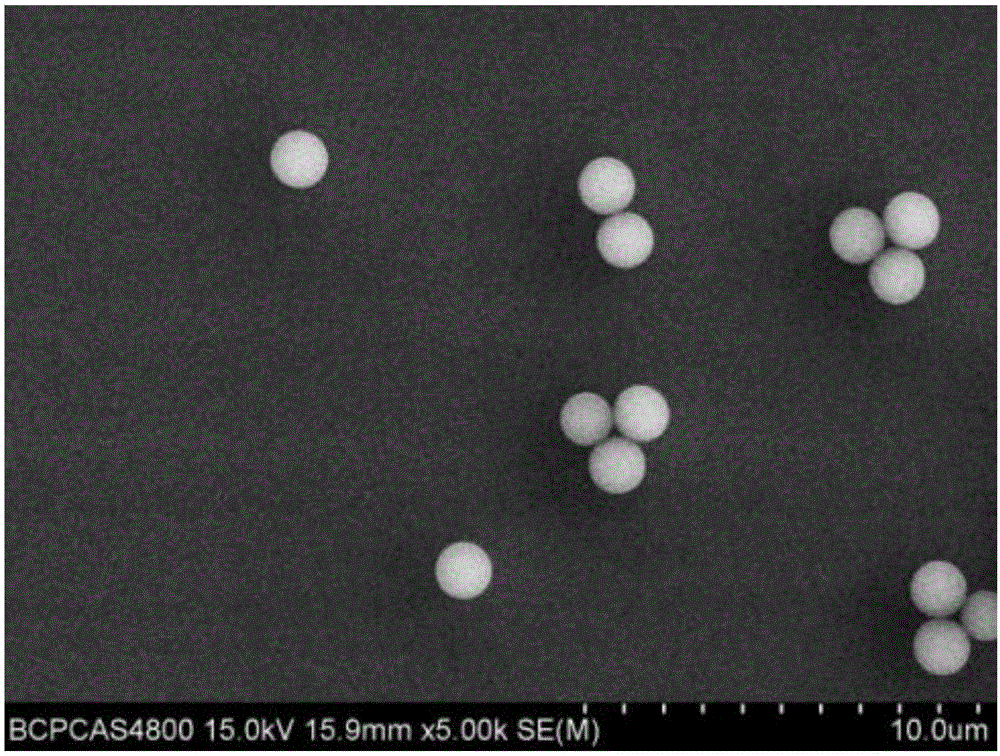

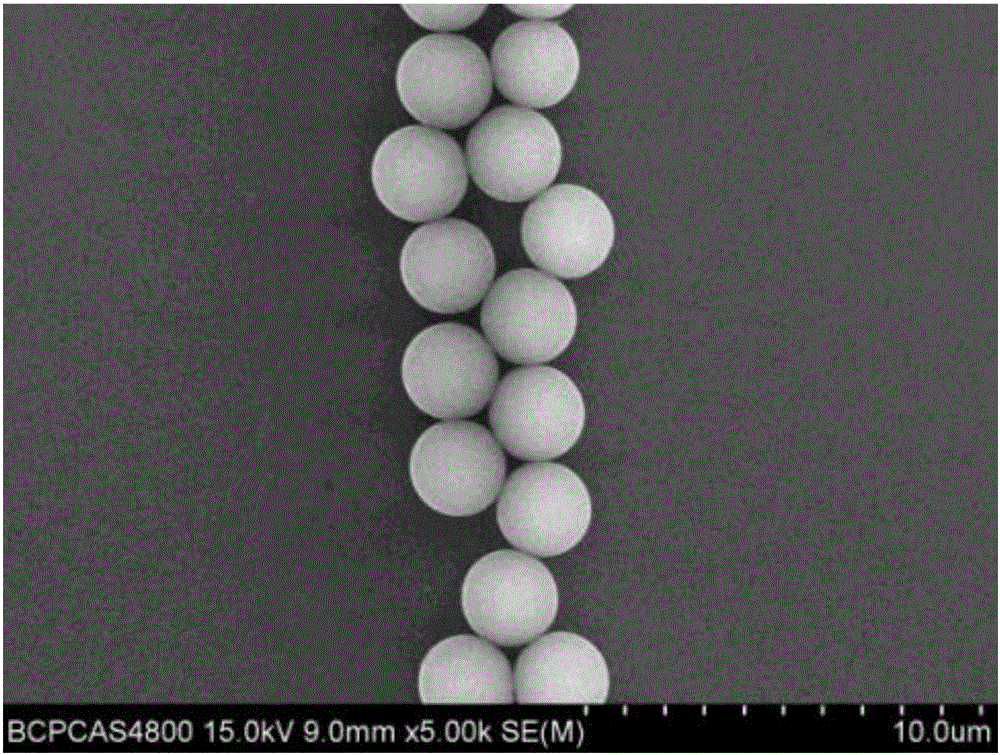

Standard substance for calibrating PM10 cutter, and preparation and certification method thereof

InactiveCN106478856AUnified unit of measurementAccurate and reliable valueParticle size analysisIonEmulsion

The invention relates to a standard substance for calibrating a PM10 cutter. The standard substance consists of 7 spherical particles, and the nominal values of the aerodynamic diameters of the seven spherical particles are 5.0 Mum, 7.0 Mum, 9.0 Mum, 10 Mum, 12 Mum, 14 Mum and 18 Mum respectively, and the spherical particles are spherical monodisperse cross-linked polystyrene standard particles. The standard substance is prepared by the following steps: dissolving a stabilizer and an emulsifier in deionized water to be used as a continuous phase, dissolving an initiator and a cross-linking agent in styrene to be used as a dispersed phase; adding the dispersed phase into the continuous phase, controlling the reaction temperature and the reaction time, stirring the mixture to obtain emulsion sample; subjecting the emulsion sample to centrifuging and washing with deionized water, then settling and screening the sample to obtain the standard substance for calibrating the PM10 cutter. The relative standard deviation of the prepared standard particles is less than 2%, the sphericity of the standard particles is greater than 0.95, the standard substance has good sphericity, monodispersity and stability and can be completely applicable to detection and calibration of the PM10 cutter.

Owner:BEIJING HAIAN HONGMENG STANDARD SUSNCE TECH

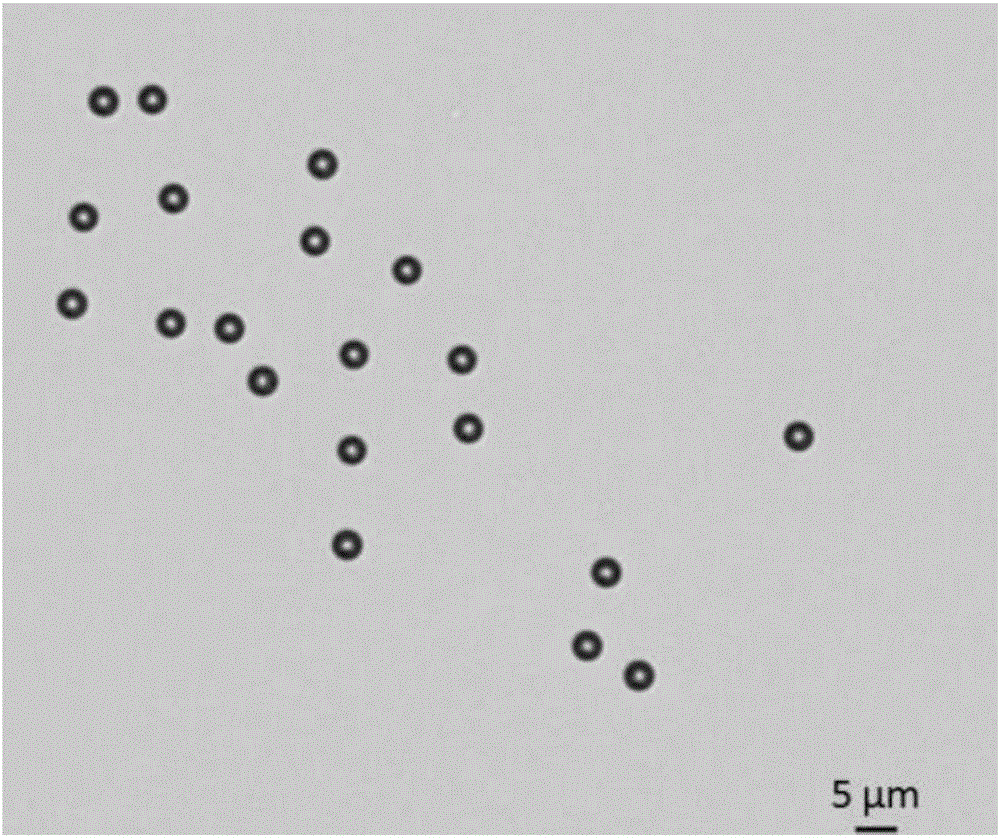

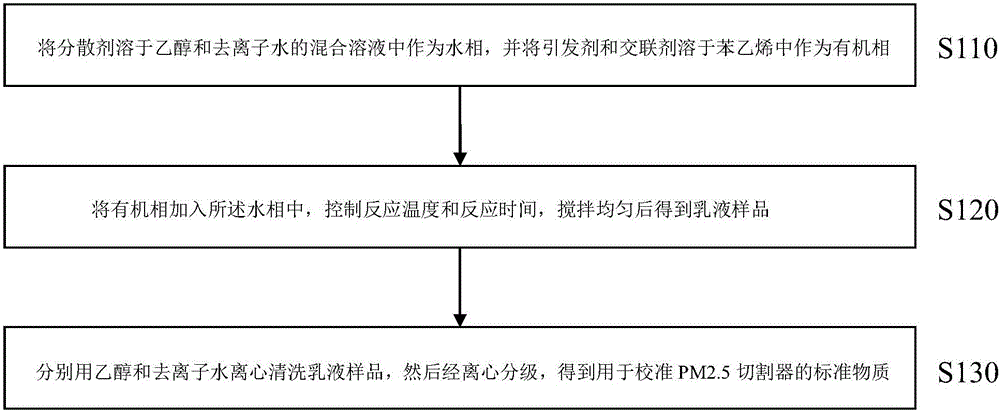

Standard substance for calibrating PM2.5 cutter and preparation and characterization method thereof

InactiveCN106248463AMeet the needs of detection and calibrationSolve unityPreparing sample for investigationRelative standard deviationPolystyrene particle

The invention relates to a standard substance for calibrating a PM2.5 cutter. The standard substance is composed of 8 kinds of spherical particles, the aerodynamic normal diameters Dae of the 8 kinds of spherical particles are 1.5 micrometers, 2.0 micrometers, 2.2 micrometers, 2.5 micrometers, 2.8 micrometers, 3.0 micrometers, 3.5 micrometers and 4.0 micrometers, and the spherical particles are spherical monodisperse crosslinking standard polystyrene particles. The standard substance is prepared through the following steps that a dispersing agent is dissolved in a mixed solution of ethyl alcohol and deionized water to serve as a water phase, and an initiating agent and a crosslinking agent are dissolved in styrene to serve as an organic phase; the organic phase is added into the water phase, and after the mixture is stirred to be uniform, an emulsion sample in obtained; the emulsion sample is washed with ethyl alcohol and deionized water in a centrifugation mode respectively, then centrifugal classification is carried out, and the standard substance for calibrating the PM2.5 cutter is obtained. The relative standard deviations of the prepared standard particles are smaller than 2%, the degrees of sphericity of the prepared standard particles are larger than 0.95, and the prepared standard particles have good degree of sphericity, monodispersity and stability and can be completely suitable for detection and calibration of the PM2.5 cutter.

Owner:BEIJING HAIAN HONGMENG STANDARD SUSNCE TECH

Method for manufacturing novel silicon carbide heat exchanger

InactiveCN101913875AAccelerated corrosionImprove high temperature resistanceOxidation resistantTemperature resistance

The invention relates to a main heat exchange component in various high-temperature heat treatment furnace bodies such as a carburizing furnace, a fluorating furnace and the like in the field of steel manufacturing, in particular to a method for manufacturing a radiant tube with long service life and high temperature resistance. The method comprises the following steps of: A, mixing raw materialsin percentage by weight: 45 to 65 percent of silicon carbide, 20 to 30 percent of monocrystalline silicon, 10 to 20 percent of carbon black, 3 to 5 percent of polyving akohol and 0.3 percent of wool grease uniformly, and adding water to prepare paste; B, injecting the paste raw materials into a die for molding by adopting a solid slip casting method; C, demoulding a molded green body for drying; D, putting the dried green body into a vacuum furnace, raising the temperature to 180 DEG C, and performing vacuum reactive sintering to manufacture a main body of the silicon carbide heat exchanger; and E, sleeving the sintered main body of the heat exchanger outside a guiding pipe, and sleeving an outer pipe outside the main body of the heat exchanger. Products prepared by the method have the advantages of high strength and hardness, high temperature resistance, corrosion resistance, good thermal shock resistance and superior antioxidation performance.

Owner:武钢集团有限公司

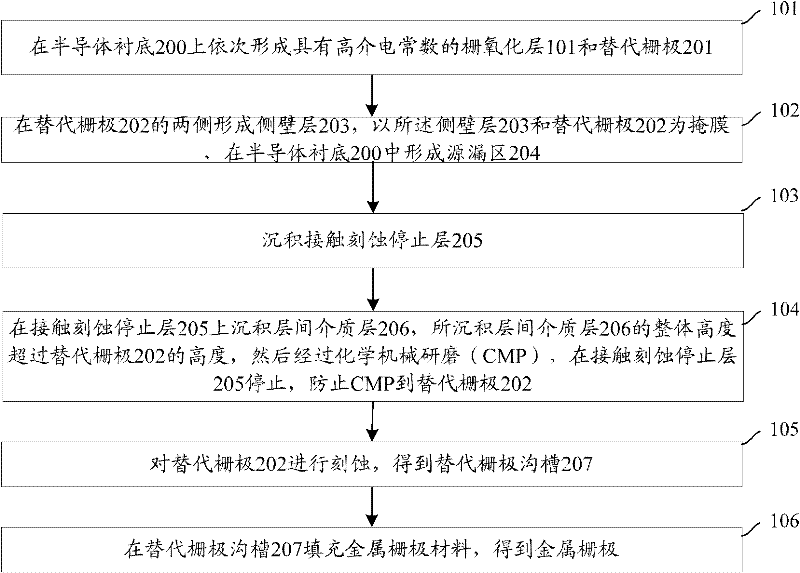

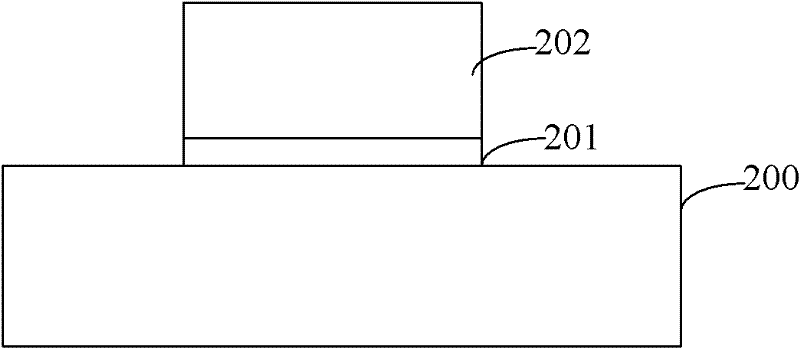

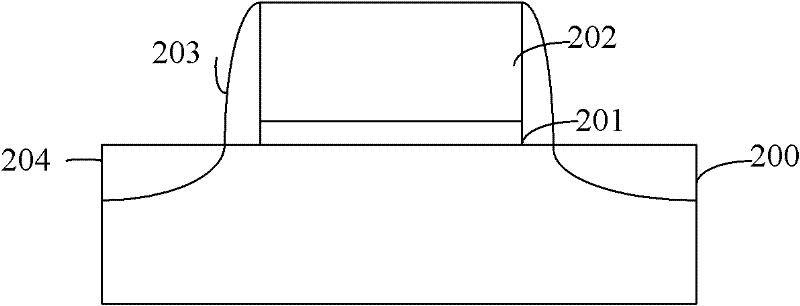

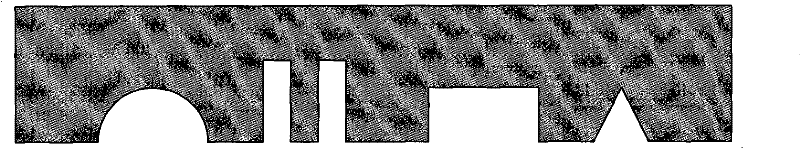

Manufacturing method of metal gate electrode

ActiveCN102543698ACollapse will notNo change in shapeSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringMedia layer

The invention discloses a manufacturing method of a metal gate electrode, which comprises the steps of: forming side wall layers at both sides of a substitution gate electrode after forming a gate oxide layer and the substitution gate electrode on a provided semiconductor substrate; taking the side wall layers and the substitution gate electrode as masking membranes to carry out ion implantation to the semiconductor substrate to form a source leakage area; depositing contact etching stop layers on the semiconductor substrate, the side wall layers and the surface of the substitution gate electrode; after depositing an interlayer medium layer on the contact etching stop layer, polishing the deposited interlayer medium layer of which the height exceeds the surface of the substitution gate electrode to the etching stop layer; after depositing a stretching layer which ensures the pressure of each part of the side wall layers identical in follow-up substitution gate electrode etching on the interlayer medium layer, polishing the stretching layer to the interlayer medium layer; and etching away the substitution gate electrode to obtain a substitution gate electrode groove, and filling a metal gate electrode in the substitution gate electrode groove. The method makes the shape of the manufactured metal gate electrode be the shape of the substitution gate electrode.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Method for manufacturing novel silicon carbide heat exchanger

InactiveCN101913875BReduce weightImproving the current situation of not being able to withstand high temperaturesOxidation resistantTemperature resistance

The invention relates to a main heat exchange component in various high-temperature heat treatment furnace bodies such as a carburizing furnace, a fluorating furnace and the like in the field of steel manufacturing, in particular to a method for manufacturing a radiant tube with long service life and high temperature resistance. The method comprises the following steps of: A, mixing raw materialsin percentage by weight: 45 to 65 percent of silicon carbide, 20 to 30 percent of monocrystalline silicon, 10 to 20 percent of carbon black, 3 to 5 percent of polyving akohol and 0.3 percent of wool grease uniformly, and adding water to prepare paste; B, injecting the paste raw materials into a die for molding by adopting a solid slip casting method; C, demoulding a molded green body for drying; D, putting the dried green body into a vacuum furnace, raising the temperature to 180 DEG C, and performing vacuum reactive sintering to manufacture a main body of the silicon carbide heat exchanger; and E, sleeving the sintered main body of the heat exchanger outside a guiding pipe, and sleeving an outer pipe outside the main body of the heat exchanger. Products prepared by the method have the advantages of high strength and hardness, high temperature resistance, corrosion resistance, good thermal shock resistance and superior antioxidation performance.

Owner:武钢集团有限公司

Coated nuts and processing method thereof

InactiveCN109123560AImprove solubilityLow hygroscopicityFood ingredient as gelling agentIcing sugarColloid

The invention discloses coated nuts and a processing method thereof, and belongs to the technical field of food processing. Raw materials of coats of the nuts comprise natural colloid, maltodextrin and powdered sugar; the natural colloid is gelatin and / or Arabic gum. The processing method of the coated nuts includes the steps that a coating solution is prepared from the raw materials of the coats,the surfaces of nuts are primarily coated with the coating solution, seasoning powder is spread on the surfaces of the primarily coated nuts, the nuts with the powder are secondarily coated, and thecoated nuts are obtained finally. The coated nuts have the advantages that the efficiency of effectively preventing powder shedding is 78% or above, and the efficiency of preventing stickiness to hands is 81% or above; compared with nut products with deep-fried coats in the market, the shelf life is prolonged by 1 month or above.

Owner:CHACHA FOOD CO LTD

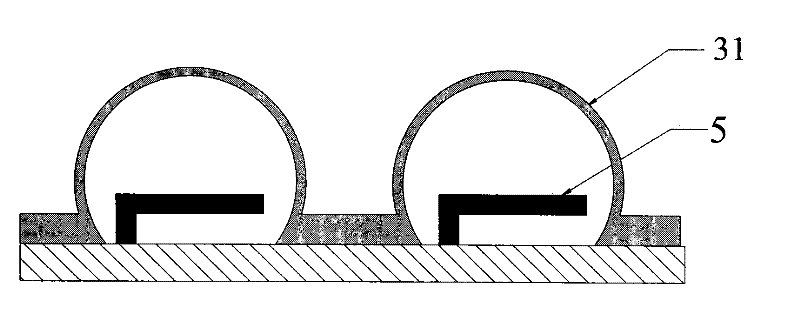

Demouldable foaming preparation method of wafer level glass micro-cavity

The invention discloses a demouldable foaming preparation method of a wafer level glass micro-cavity, which comprises the following steps of: etching a micro-groove array on a silicon wafer to obtain a silicon wafer die; putting hot release gas agent powder in the micro-groove array of the silicon wafer die; bonding the borosilicate glass wafer with the silicon wafer die through a bonding layer, and sealing the micro-groove array of the silicon wafer die; putting the bonded wafer in a heating furnace for heating above a glass softening temperature, keeping temperature, molding the softened glass with gas released by a hot release gas agent to obtain a glass micro-cavity, cooling and annealing; and then putting the molded wafer in a corrosive of the bonding layer, and removing the bonding layer so as to release the silicon wafer die and obtain the wafer level glass micro-cavity. In the invention, the bonding layer is arranged between the borosilicate glass wafer with the silicon wafer, the bonding layer is selectively removed by the corrosive, and the silicon wafer die can be completely released.

Owner:SOUTHEAST UNIV

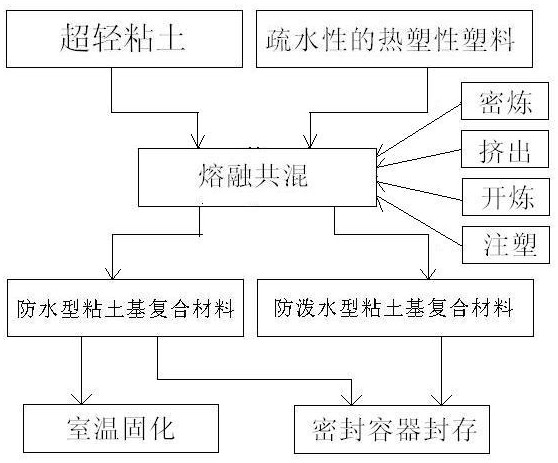

Clay-based composite material as well as preparation and use methods thereof

The invention aims to provide a clay-based composite material as well as a preparation method and a use method thereof. The composite material is prepared from the following components in parts by weight: 1 to 99 parts of ultralight clay and 1 to 99 parts of hydrophobic thermoplastic plastic, the preparation method comprises the following steps: carrying out melt blending on ultralight clay and hydrophobic thermoplastic plastic according to parts by weight, so as to prepare a clay-based composite material; according to the composite material, the ultra-light clay is prepared into the waterproof or water-repellent ultra-light clay-based composite material by utilizing the waterproof property of hydrophobic thermoplastic plastic; a product made of the composite material is molded and air-dried, the temperature of the product is increased to be above the melting point of the thermoplastic plastic, and the product with waterproof performance or water-repellent performance is formed after room temperature cooling and curing; the temperature of the product is increased to be higher than the melting point of the thermoplastic plastic for secondary processing and transformation, and the process can be repeatedly realized; the preparation method of the composite material is simple in process and suitable for industrial production; the material is an environment-friendly material.

Owner:秦皇岛砥厉科技有限公司

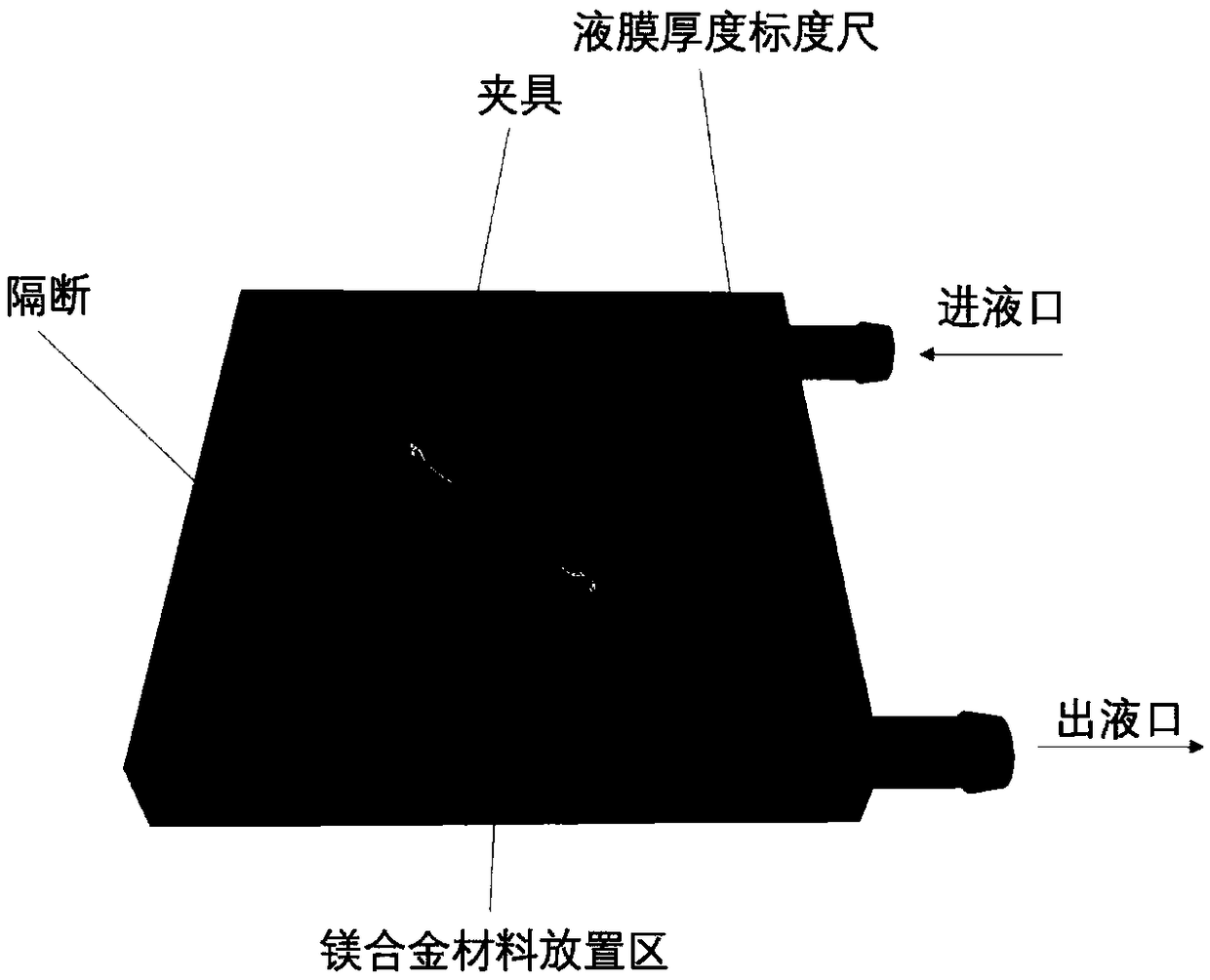

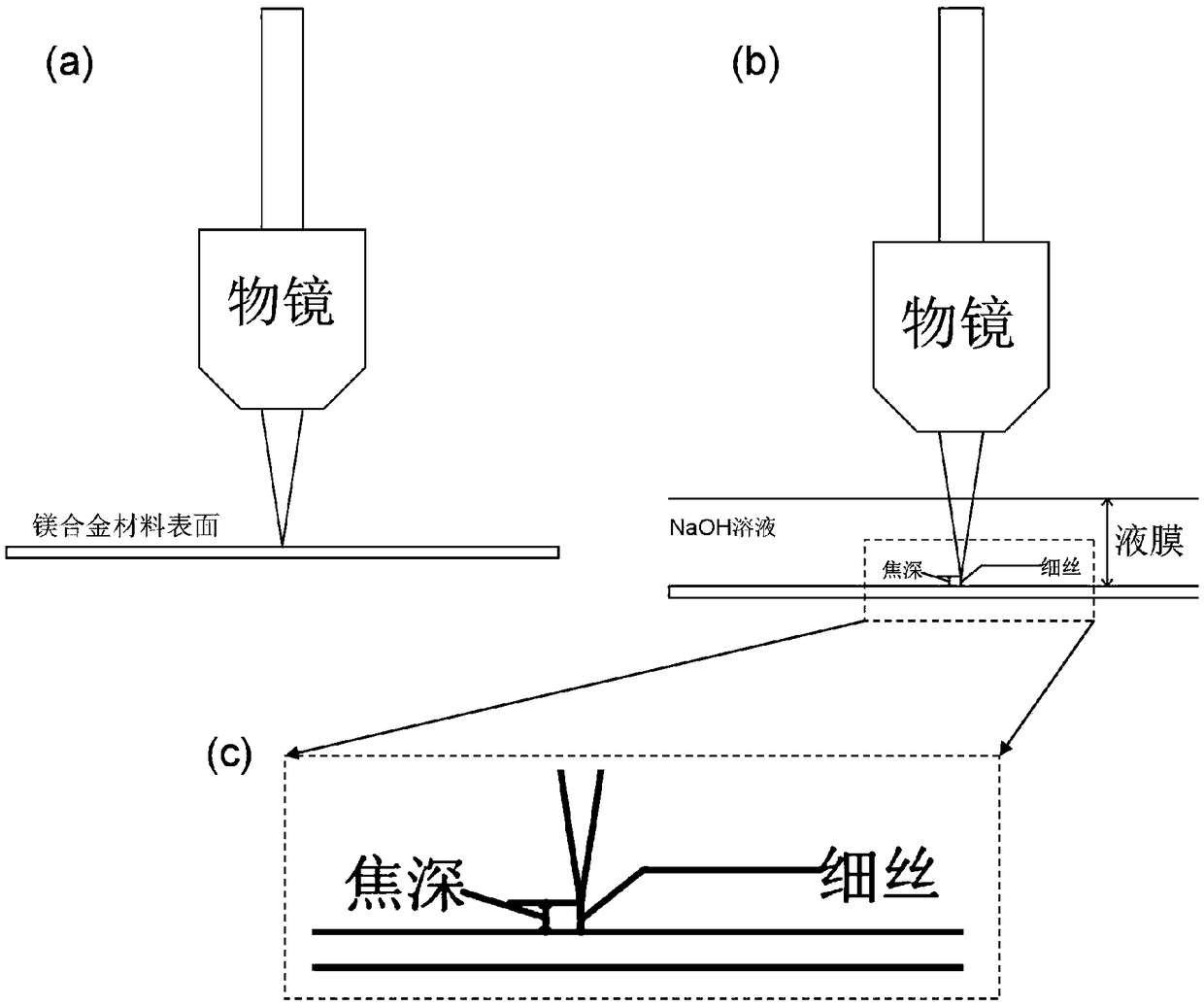

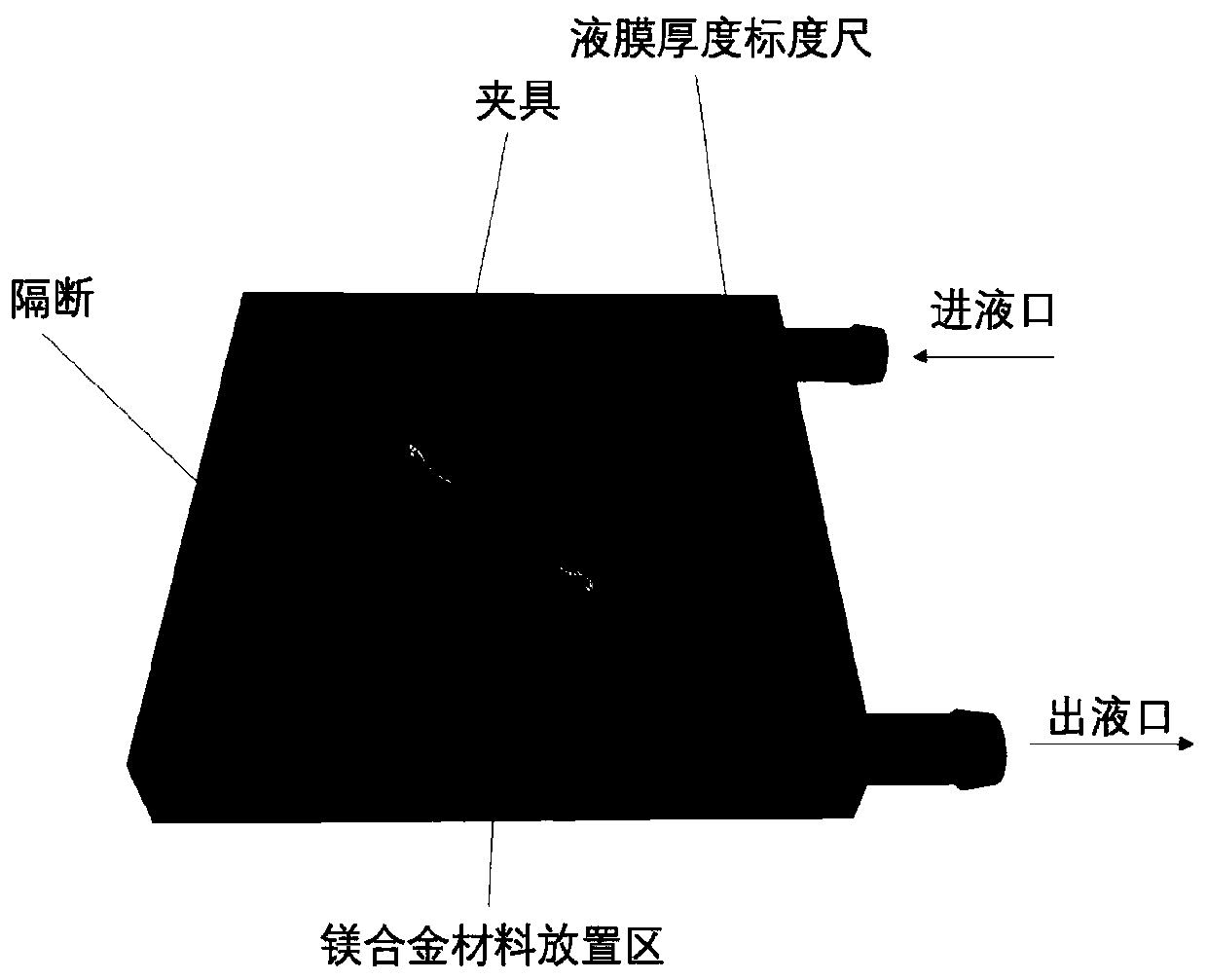

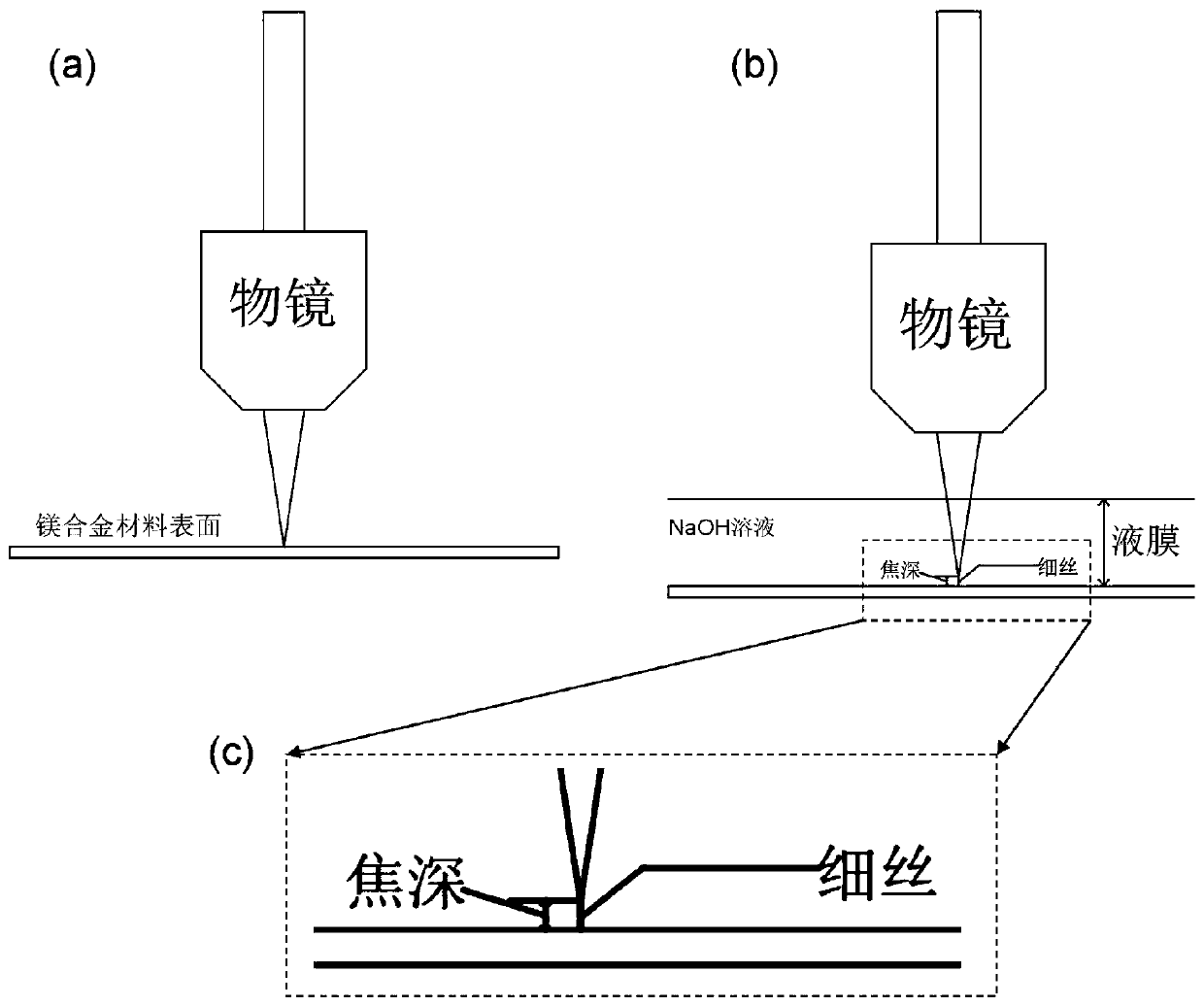

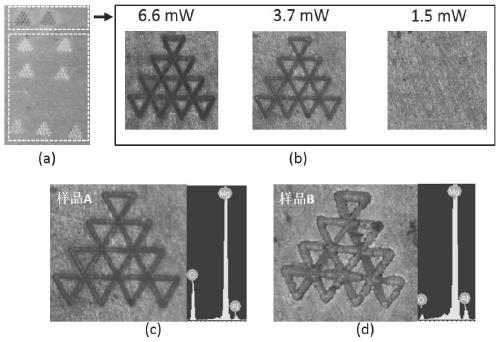

Metal surface micro-patterning method

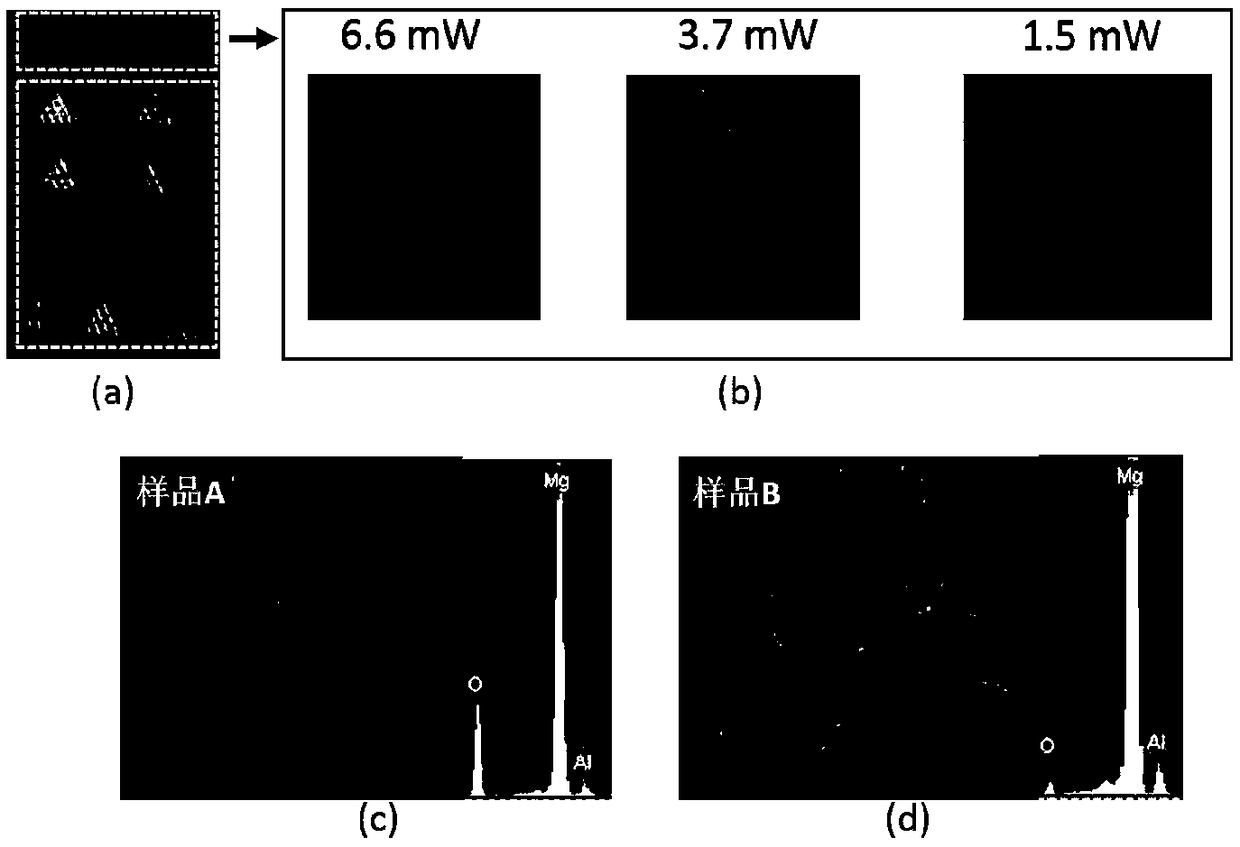

ActiveCN109175708AAvoid rapid degradationImprove heat dissipationLaser beam welding apparatusMicro patternFilamentation

The invention discloses a metal surface micro-patterning method. A transparent liquid medium not reacted with metal is adopted as protecting liquid; and in particular, when sodium hydroxide solution is adopted, the quick degradation of magnesium in water is prevented, and the machining of a magnesium alloy material by femtosecond laser filamentation in water is realized. When a flowing liquid filmis adopted, the heat dissipation condition of the periphery of a machined part can be prominently improved; and meanwhile, bubbles generated in machining are taken away to prevent accumulation of chips, so that the self-cleaning in the machining process is realized. In addition, compared with high-energy femtosecond laser filamentation in air, on the basis of guaranteeing the machining quality ofa metal surface micro-nano structure, the machining precision can be prominently improved to reach about 10 microns, and meanwhile, the production equipment cost is reduced. More importantly, an active oxidation atmosphere formed by femtosecond laser in the air is prevented, and oxides in machined products are prominently reduced, so that the metal surface and the microcosmic substance forms in machined grooves are not changed to the greatest extent.

Owner:BEIHANG UNIV

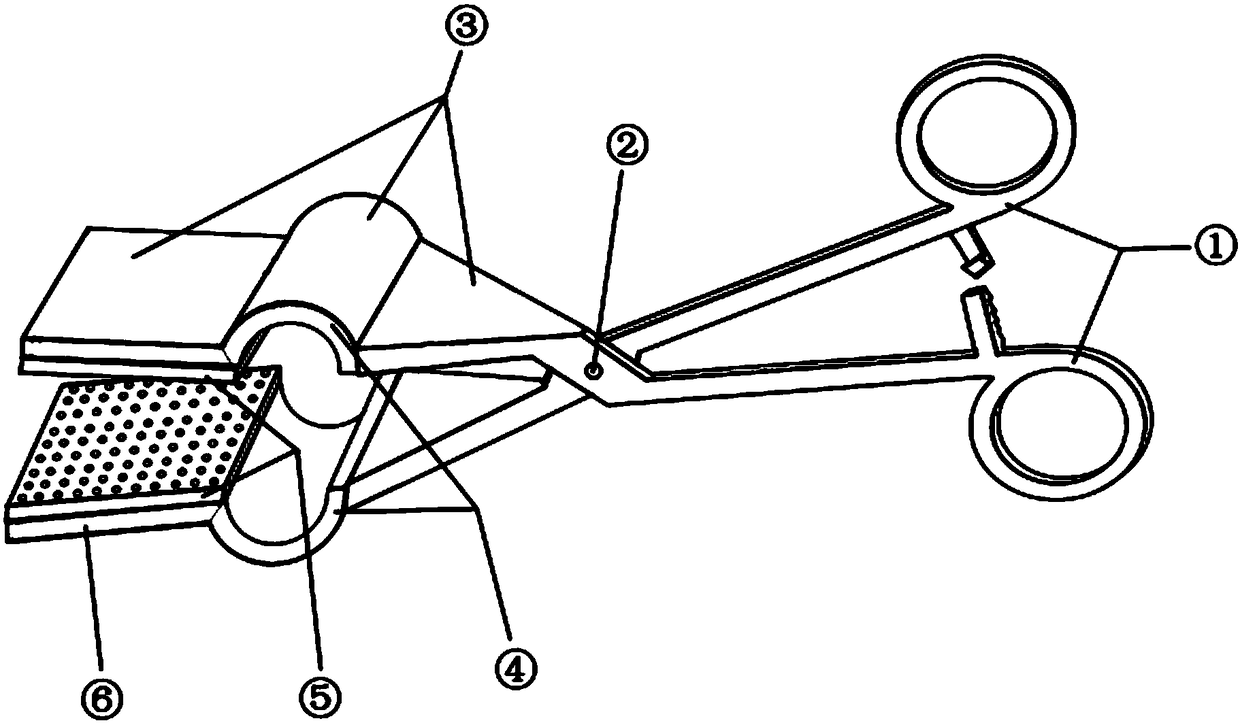

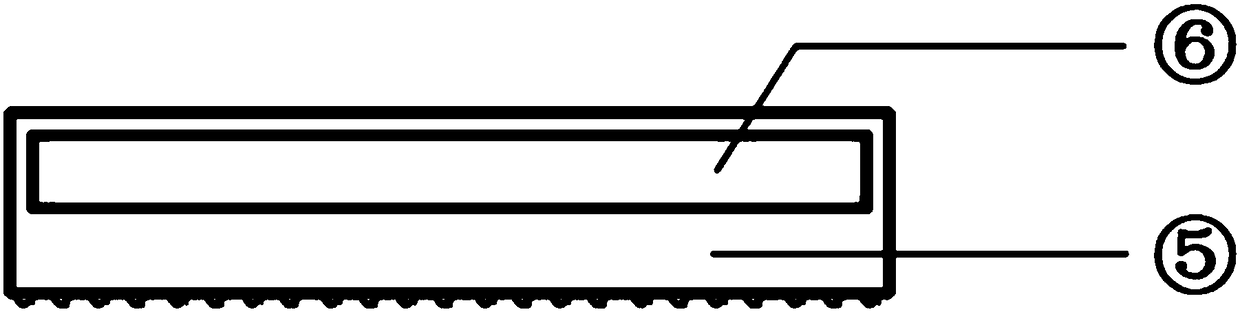

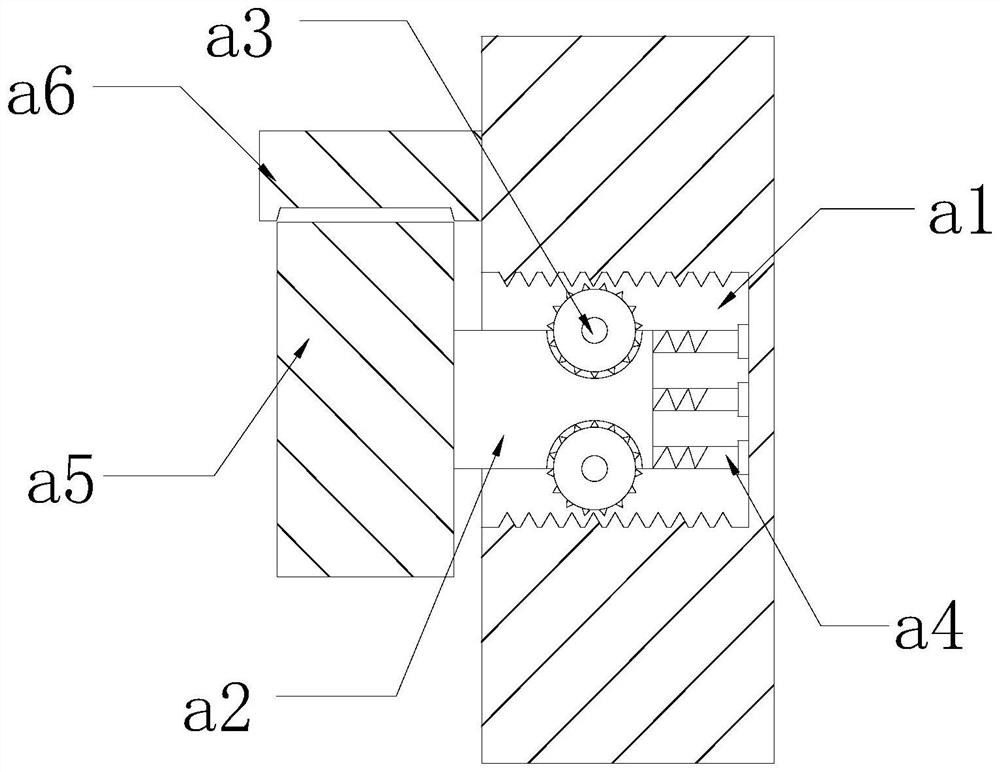

Guide wire fixing pliers

The invention discloses a pair of guide wire fixing pliers comprising pliers handles, a pliers shaft and pliers heads. Each pliers head includes a guide wire through hole, a guide wire clamping plateand a rubber buffer pad. The guide wire through hole is defined by half-cylindrical portions of the two pliers heads. A plurality of point-shaped protrusions are evenly arranged on the pliers clampingsurface of the guide wire clamping plate and used for fixing and winding a guide wire. The rubber buffer pad covers the pliers clamping surface of the guide wire clamping plate, and a plurality of small holes are formed evenly in the rubber buffer pad. The point-shaped protrusions on the pliers clamping surface pass through the small holes in the rubber buffer pad and are exposed out of the rubber buffer pad. The pliers heads drive the guide wire clamping plate of the rubber buffer pad to clamp the guide wire, can be simultaneously fixed on a surgical drape, and are used for fixing and the winding the guide wire when required in an operation, to protect the guide wire from displacement and sliding; the guide wire through hole in the pliers head can fix the guide wire on the surgical drape, at the time the guide wire cannot be horizontally shifted, the sliding of the guide wire is effectively prevented, and longitudinal advancement and retreatment and axial torsion can be performed without affecting the operation of an operator.

Owner:PEKING UNION MEDICAL COLLEGE HOSPITAL CHINESE ACAD OF MEDICAL SCI

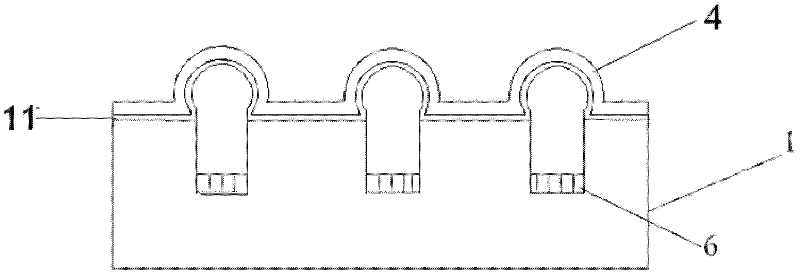

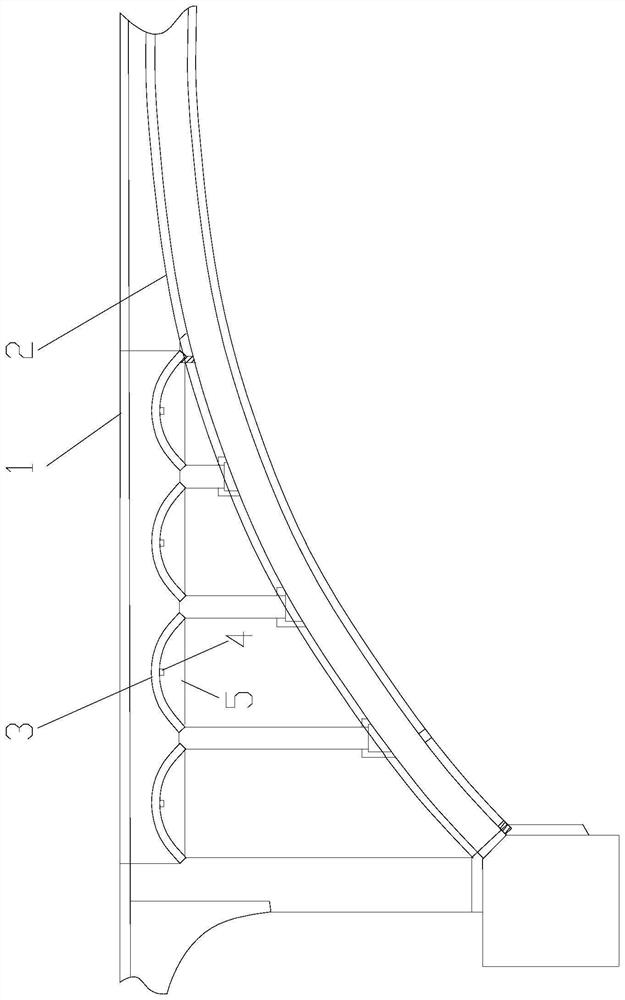

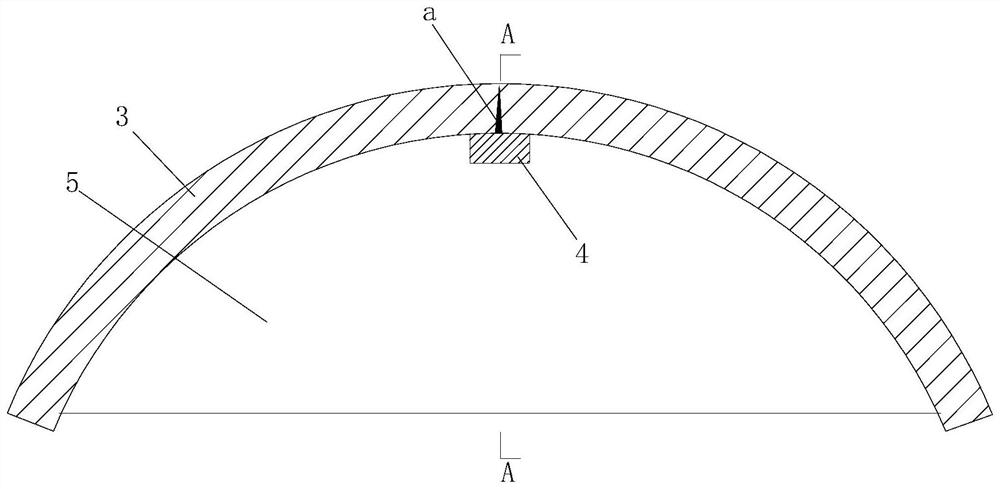

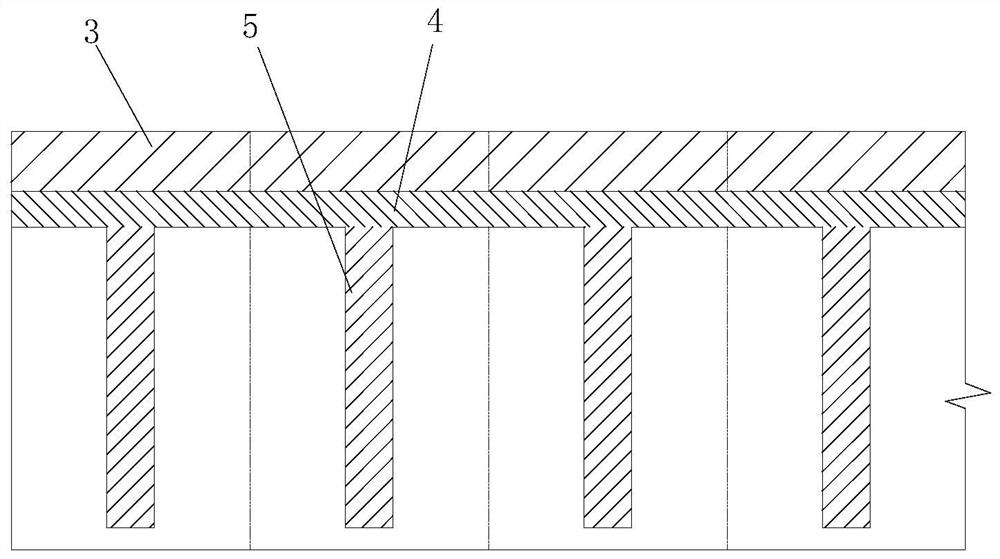

Web arch structure reinforced by frame type reinforcing structure

PendingCN114016443AAvoid damagePrevent extensionBridge structural detailsBridge erection/assemblyFiberCarbon fibers

The invention discloses a web arch structure reinforced by a frame type reinforcing structure, which comprises a web arch. The web arch is provided with a reinforcing structure, the reinforcing structure comprises a longitudinal rib and a diaphragm plate, the longitudinal rib is poured at the arch top part of the inner side of the web arch along the longitudinal direction of the web arch, and the diaphragm plate is fixedly poured at the inner side of the web arch along the spanning direction of the web arch, and the diaphragm plate and the longitudinal ribs are poured and connected into a whole to form a space reinforcing frame structure of the web arch. A reinforced space frame structure is formed, and the resistance of the web arch structure for resisting various load effects is obviously improved; the main reinforcing steel bars of the reinforced diaphragm plate can effectively restrain the opening deformation of the web arch under load and prevent the expansion of the midspan vertical crack of the web arch; construction is relatively easy and convenient, compared with a reinforced concrete reinforced web arch, the material consumption and the dead weight of the reinforced structure are remarkably reduced, the better reinforcing effect is achieved, damage to the original web arch caused by reinforcing embedded steel bars is reduced, and on-site reinforcing construction operation is remarkably reduced; and compared with sticking of carbon fibers or steel plates, the web arch reinforcing effect is remarkably improved.

Owner:SHENZHEN UNIV

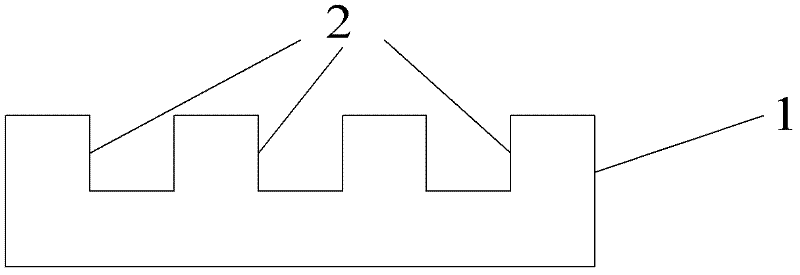

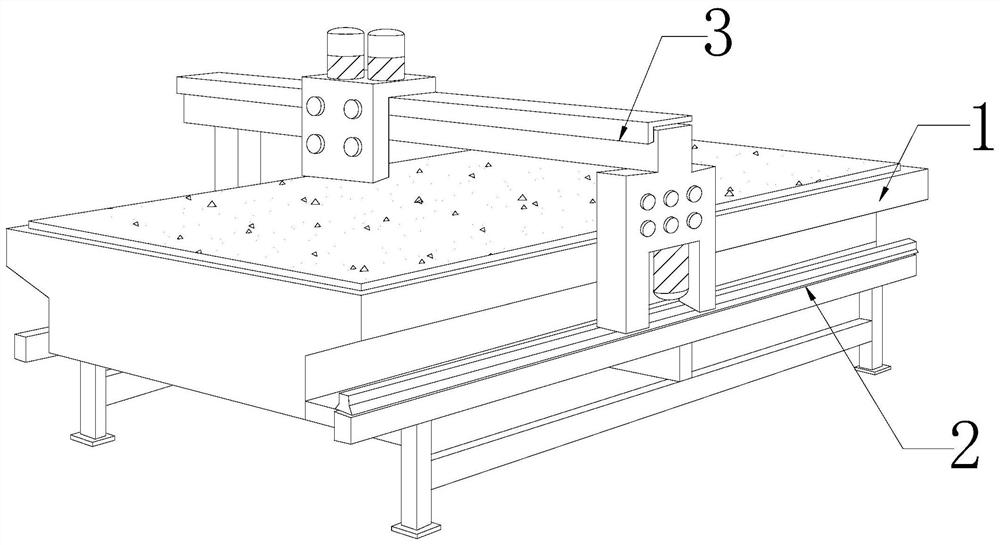

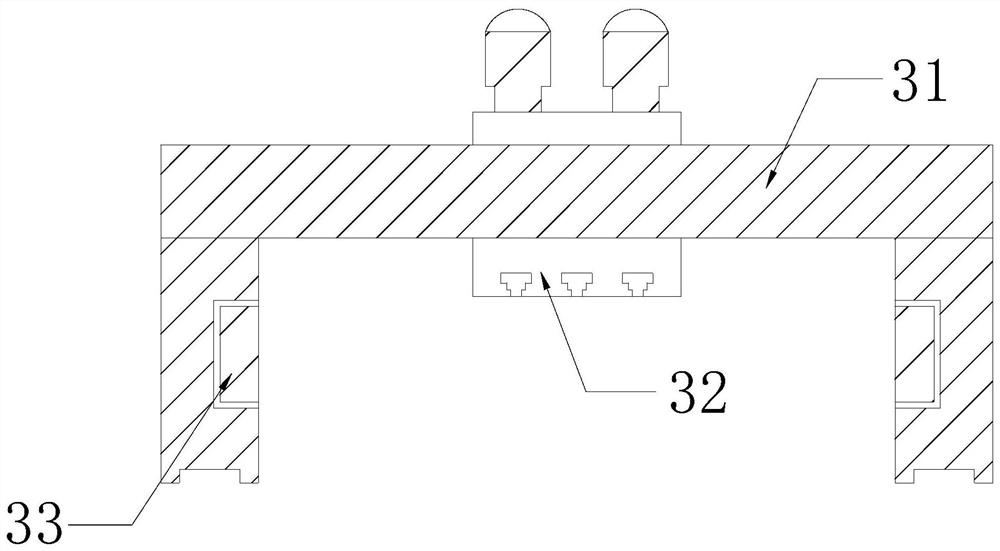

Adhesive film cutting device for wafer

InactiveCN112757620ANo change in shapeReduce floatingCleaning using toolsMetal working apparatusEngineeringMechanical engineering

The invention discloses an adhesive film cutting device for a wafer. The adhesive film cutting device for the wafer structurally comprises a machine body, sliding blocks and a portal frame. Considering the problem that since the portal frame moves on the top of a cutting table and drives surrounding airflow to flow, the edge of an adhesive film is prone to floating upwards under the action of the airflow, a rotating ring in a limiting mechanism makes contact with the surface of the edge of the adhesive film along with movement of the portal frame, the rotating ring presses downwards and smooths the edge of the adhesive film, the phenomenon that the adhesive film on the edge of the cutting table floats upwards under the action of airflow is reduced, the phenomenon that the edge of the adhesive film is wrinkled is reduced, the cut shape of the adhesive film keeps unchanged beneficially, the adhesive film is matched with the surface size of a wafer, and the adhesive film can be normally used for covering the surface of the wafer. Considering the problem that since adhesive film fluid is attached to the outer wall of the rotating ring, the phenomenon that the adhesive film rotates along with the rotating ring under the action of adsorption force of the fluid is prone to happen, the adhesive film fluid on the outer wall of the rotating ring is removed through a scraping plate in a matching block, so that the outer wall of the rotating ring can be kept clean.

Owner:李岁敏

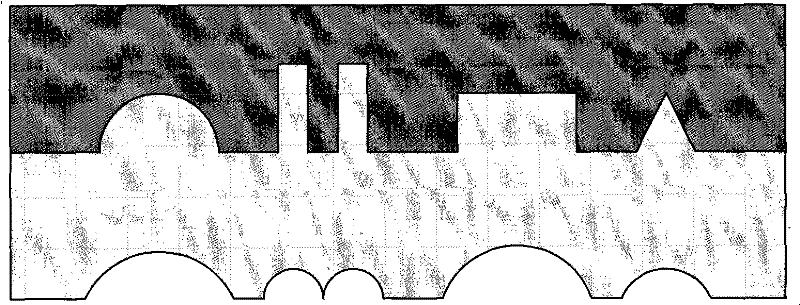

Method for moulding disc grade glass device by using micro-mould

InactiveCN101475298BReduce roughnessHigh bonding strengthGlass shaping apparatusSilicon moldAtmospheric pressure

The invention provides a method for molding a wafer-level glass device by using a micro mold, which comprises the following steps: etching a polished silicon wafer by a micro-electronic processing technique to form a mold deep cavity with a specific structure, bonding the silicon wafer with a Pyrex7740 glass wafer under the vacuum environment so that the mold deep cavity with the specific structure on the silicon wafer forms a sealed cavity, heating the two bonded wafers under one atmospheric pressure, carrying out hot molding, forming a microstructure corresponding to the mold deep cavity with the specific structure by the softened glass due to internal and external pressure difference of the cavity, cooling the wafers, annealing the wafers and relieving stress, chemically and mechanically polishing the glass back of the thermally annealed bonding sheets, planishing the glass back of the bonding sheets, and removing a silicon mold layer by a single-side corrosion method. The method can prepare the glass microstructure with large height-width ratio (more than 50:1), has low cost, and has important application in the fields of micro-fluid device, MOEMS and the like.

Owner:SOUTHEAST UNIV

A method for micropatterning metal surfaces

ActiveCN109175708BAvoid rapid degradationImprove heat dissipationLaser beam welding apparatusNano structuringMachine parts

The invention discloses a metal surface micro-patterning method. A transparent liquid medium not reacted with metal is adopted as protecting liquid; and in particular, when sodium hydroxide solution is adopted, the quick degradation of magnesium in water is prevented, and the machining of a magnesium alloy material by femtosecond laser filamentation in water is realized. When a flowing liquid filmis adopted, the heat dissipation condition of the periphery of a machined part can be prominently improved; and meanwhile, bubbles generated in machining are taken away to prevent accumulation of chips, so that the self-cleaning in the machining process is realized. In addition, compared with high-energy femtosecond laser filamentation in air, on the basis of guaranteeing the machining quality ofa metal surface micro-nano structure, the machining precision can be prominently improved to reach about 10 microns, and meanwhile, the production equipment cost is reduced. More importantly, an active oxidation atmosphere formed by femtosecond laser in the air is prevented, and oxides in machined products are prominently reduced, so that the metal surface and the microcosmic substance forms in machined grooves are not changed to the greatest extent.

Owner:BEIHANG UNIV

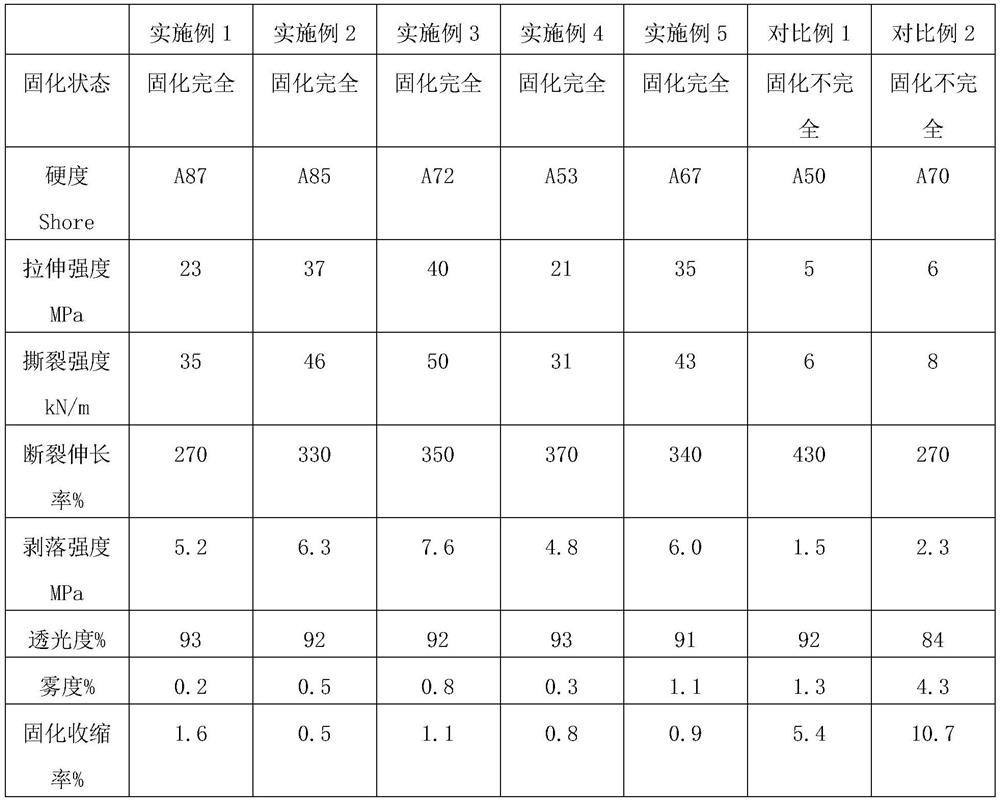

Polycarbonate and polymethyl methacrylate lamination adhesive resin, preparation method and application thereof

The invention relates to polycarbonate and polymethyl methacrylate laminating adhesive resin, a preparation method and application thereof. The polycarbonate and polymethyl methacrylate laminating adhesive resin comprises a component A and a component B, wherein the component A is an NCO-terminated polyurethane prepolymer; the component B comprises hydroxyl acrylic resin, first polyol, transparentmicrospheres and an auxiliary agent; the molar ratio of isocyanate groups in the component A to hydroxyl groups in the component B is 0.9 to 1.3. The adhesive resin not only can be well adhered to polycarbonate and polymethyl methacrylate, but also can guarantee optical properties of an adhered laminated component.

Owner:CHINA BUILDING MATERIALS ACAD

Manufacturing method of wafer level glass microcavity used for packaging MEMS

ActiveCN101734612BHigh forming heightLow costPrecision positioning equipmentSoldering apparatusPositive pressureMicrofabrication

The invention provides a manufacturing method of a wafer level glass microcavity used for packaging an MEMS, which comprises the following steps of: (1) etching a shallow slot on an Si wafer by an Si microfabrication process; (2) placing a right amount of high-temperature gas release agent in the shallow slot; (3) carrying out anodic bonding on the Si wafer and a Pyrex7740 glass wafer in air or vacuum and enabling the shallow slot on the Pyrex7740 glass to form a sealed cavity body; and (4) heating the bonded wafer in the air to the temperature of 810-890 DEG C, keeping the temperature for 3-5min, enabling molten glass corresponding to the sealed cavity body to be in a spherical shape by the high-temperature gas release agent because of positive pressure generated by gas generated by heating, cooling to the normal temperature, annealing and removing a silicon wafer to obtain a wafer level spherical glass microcavity array. The invention adopts the release of the high-temperature gas release agent to provide a gas source, is used for forming the glass microcavity and has the characteristics of low cost, simple method, high forming height and good degree of sphericity.

Owner:SOUTHEAST UNIV

A cuo-nio/rgo composite with high-efficiency electrocatalytic oxygen reduction performance

The invention relates to a CuO-NiO / rGO composite material with efficient electro-catalysis oxygen reduction performance, and belonging to the technical field of electro-catalysis materials. In the CuO-NiO / rGO composite material provided by the invention, CuO-NiO nanoparticles are attached to a reduction-oxidized graphene sheet layer, a mass ratio of the CuO-NiO nanoparticles to the rGO is 100:3-5, the sizes of the CuO-NiO nanoparticles are 6-10nm, and the reduction-oxidized graphene sheet layer is a single sheet layer; and the electro-catalysis oxygen reduction performance is provided. Compared with existing oxygen reduction reaction catalysts, the CuO-NiO / rGO composite material provided by the invention is significantly reduced in cost, and is the oxygen reduction reaction catalyst with low price and excellent electro-catalysis oxygen reduction performance. The CuO-NiO / rGO composite material provided by the invention adopts copper salts, nickel salts, hydroxides and oxidized graphene as materials, deionized water and absolute ethyl alcohol as solvents, and glycol as a dispersing agent and a reducing agent, and is synthesized by using a one-pot hydrothermal method. The CuO-NiO / rGO composite material provided by the invention is low in material price, prone to get materials, simple and easy in preparation operation, simple in aftertreatment process, prone to control reaction parameters, short in flow and low in energy consumption.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com