Demouldable foaming preparation method of wafer level glass micro-cavity

A glass micro- and wafer-level technology, which is applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of corroding glass, taking a long time, and removing silicon molds, and achieves short removal time, reduced costs, and shortened Effect of time to silicon removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

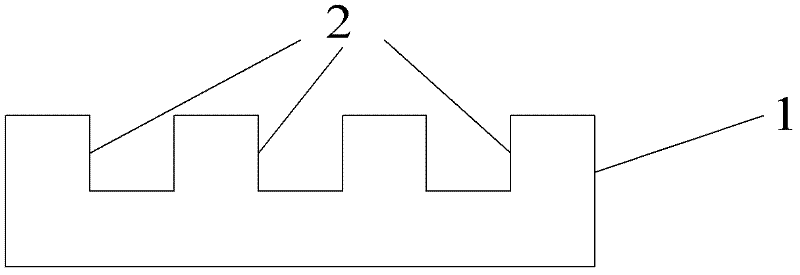

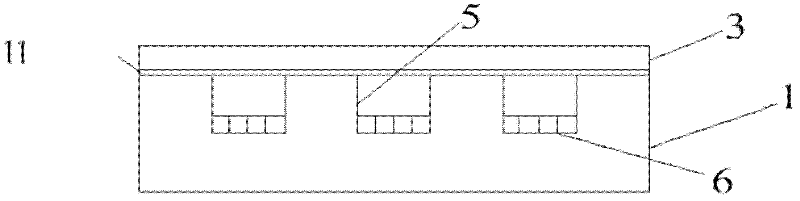

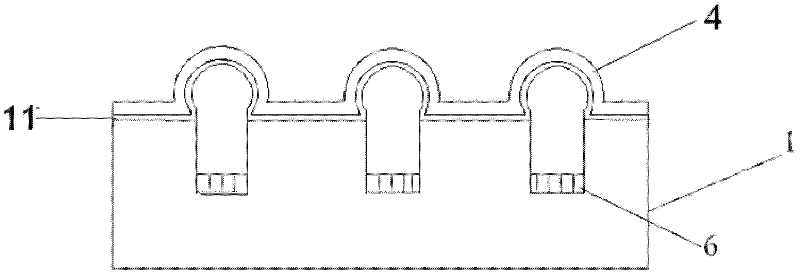

[0021] A method for preparing a wafer-level glass microcavity by releasing and foaming includes the following steps: the first step: etching a shape on a silicon wafer (for example, a 4-inch wafer) to form a microcavity array of a specific size. The microcavity is round or square, and the process for preparing the pattern structure on the silicon wafer is one of wet etching process, reactive ion etching process or deep reactive ion etching. The second step: coating the thermal outgassing agent in the microcavity array. The hot air release agent is a powder that can release gas after heating, such as calcium carbonate powder or titanium hydride powder, and the particle size of the powder is 300 mesh, 800 mesh or 1000 mesh. The added mass is calculated according to the size of the required molding cavity. For example, calcium carbonate is used. If the mass can be 0.1mg, 0.5mg, 1mg, 1.5mg, 2mg, the third step: the borosilicate glass disc and the silicon circle The wafer molds are...

Embodiment 2

[0024] A method for preparing a wafer-level glass microcavity by releasable foaming includes the following steps:

[0025] In the first step, 15 micron thick aluminum was sputtered on a 4-inch Si wafer.

[0026] In the second step, the aluminum on the silicon wafer is etched by a wet etching process to form a square array, and the aspect ratio of the micro groove is 1:1.

[0027] The third step is to place 0.1 mg of calcium carbonate powder in the aluminum microgrooves on the above Si wafer, and then mix it with Pyrex 7740 glass wafer (a brand of borosilicate glass, produced by Corning Corporation in the United States, available in the market, usually It has been polished, and its size is the same as that of the Si wafer.) Bonding is carried out under vacuum to make the Pyrex7740 glass and the aluminum microgroove on the silicon wafer form a sealed cavity. The bonding surface should be kept highly clean before bonding And very small surface roughness. The bonding process between th...

Embodiment 3

[0031] A method for preparing a wafer-level glass microcavity by releasable foaming includes the following steps:

[0032] The first step is to use a 25% TMAH solution wet etching method to etch a specific pattern on a 4-inch Si wafer (actually, in three dimensions, grooves are carved on the silicon wafer, and patterns in two dimensions). Is a square slot array, the silicon wafer is polished,

[0033] The second step is to place 0.2 mg of calcium carbonate powder in the microgrooves of the above Si wafer, and then mix it with the same size (4 inches) Pyrex 7740 glass wafer (a brand of borosilicate glass, produced by Corning Corporation, USA) Commercially available, it has been polished) and aluminum foil of the same size are bonded with a low melting point metal, so that Pyrex7740 glass and aluminum foil and the above-mentioned specific pattern form a sealed cavity.

[0034] In the third step, the above-mentioned bonded wafer is heated to 850°C under one atmospheric pressure, and ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com