A method for micropatterning metal surfaces

A micro-patterning and metal surface technology, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve problems such as difficulty in finding femtosecond laser transparent media, inability to meet processing requirements, and harsh processing conditions, so as to avoid rapid Effects of degradation, improvement of thermal diffusion, and reduction of production equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below with reference to the accompanying drawings and examples.

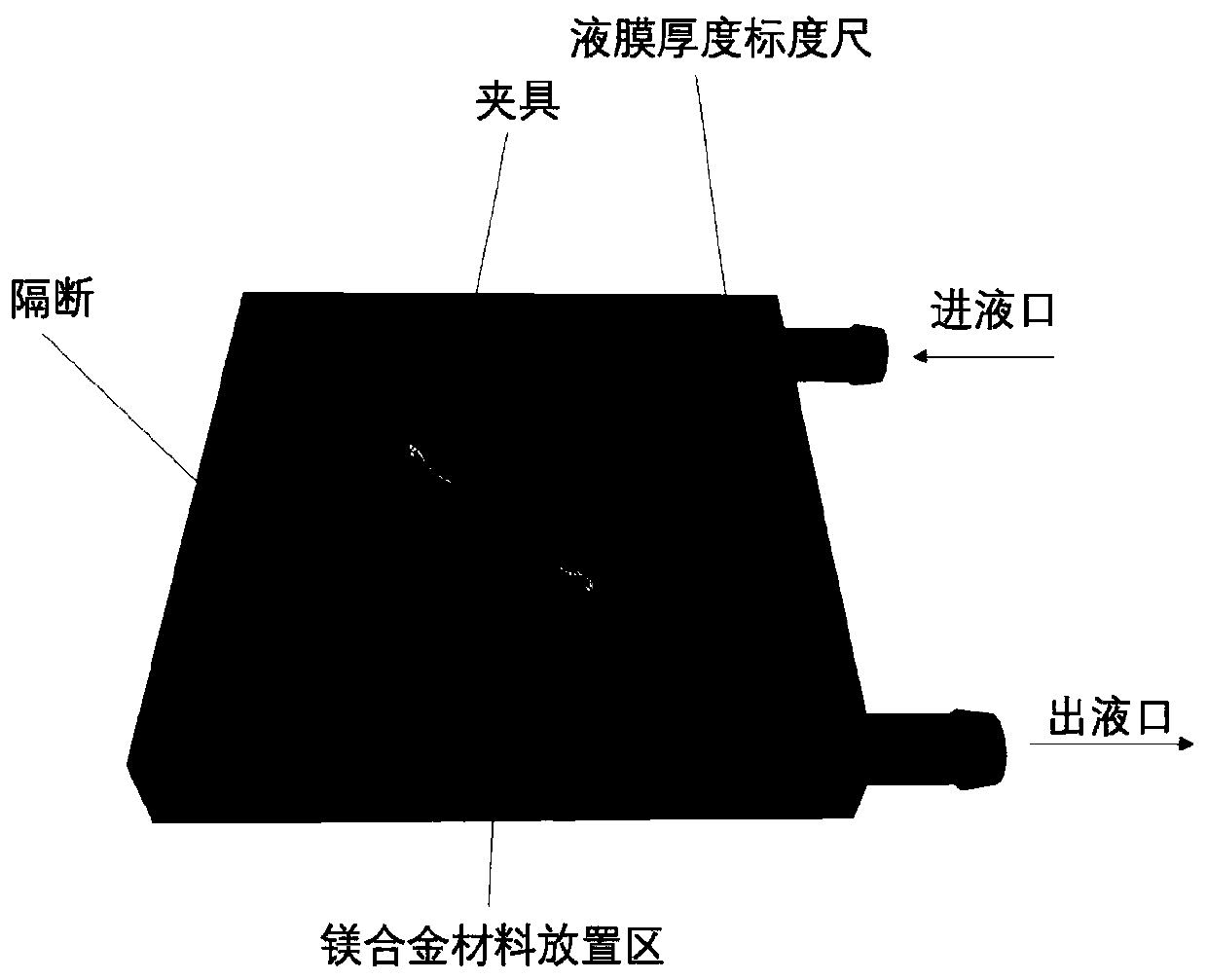

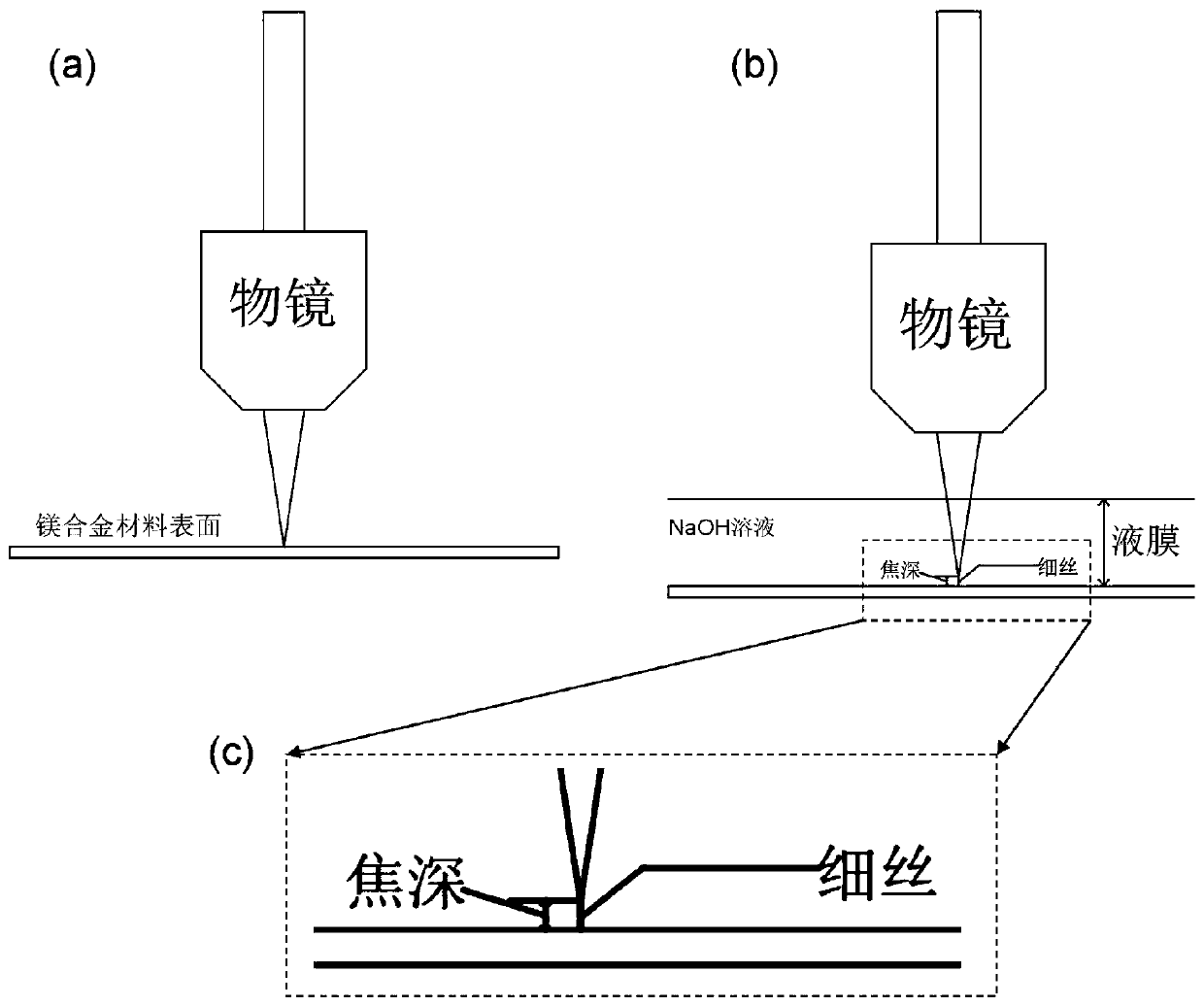

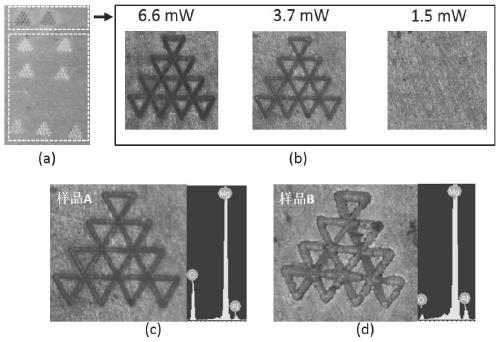

[0033] Such as figure 1 As shown, a container for holding sodium hydroxide solution is provided, and the container includes a liquid inlet, a liquid outlet, a partition, a magnesium alloy material placement area, a clamp for fixing the magnesium alloy material, and a liquid film thickness scale. AQ80 magnesium-aluminum alloy is used as the material to be processed. The femtosecond laser is focused into filaments in the flowing liquid film of sodium hydroxide and the AQ80 magnesium-aluminum alloy material is processed. The processing parameters are adjusted as follows: laser power 300mw, repetition frequency 1khz, The wavelength is 800nm, the pulse width is 140fs, the thickness of the liquid film is 3mm, the velocity of the liquid film is 57.87cm / s, and the depth of focus is 0-1000μm, where the depth of focus is defined as the distance from the laser focus ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com