Method for preparing wafer-level uniform-dimension glass microcavity by positive pressure thermal forming

A wafer-level, thermoforming technology, used in manufacturing tools, welding equipment, microstructure technology, etc., can solve the problems of increased cost, high cost, long time, etc., and achieve the effect of low cost, good sphericity, and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

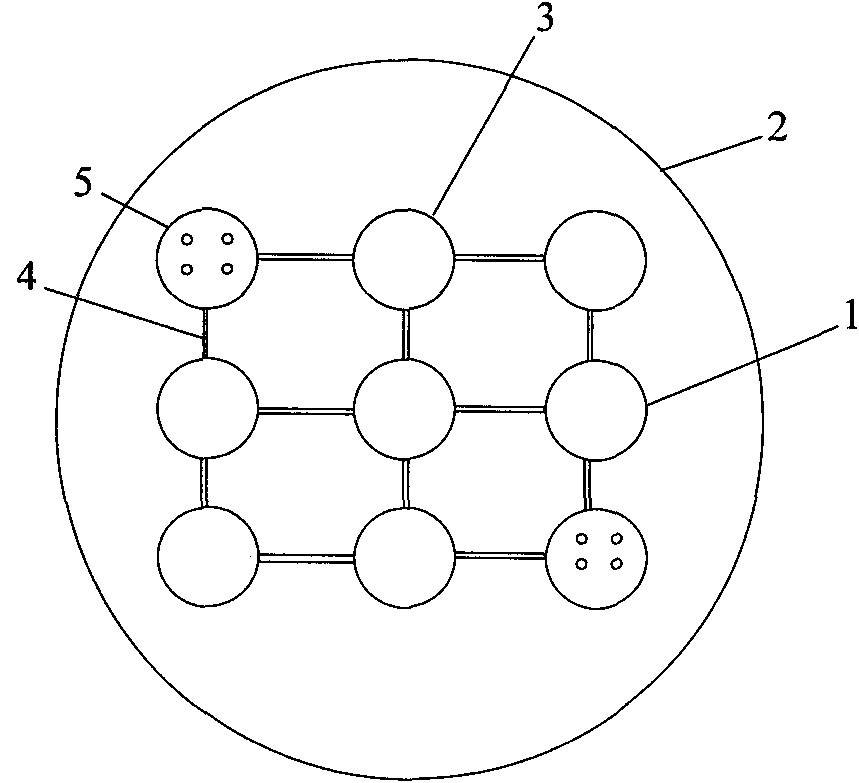

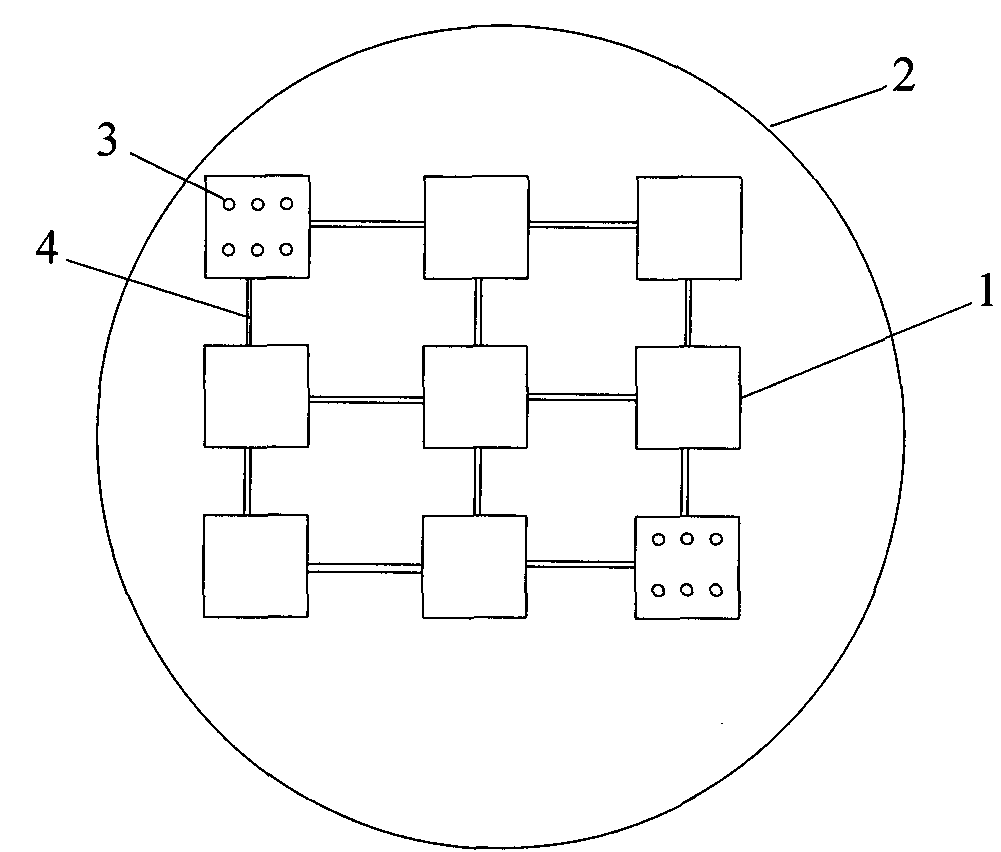

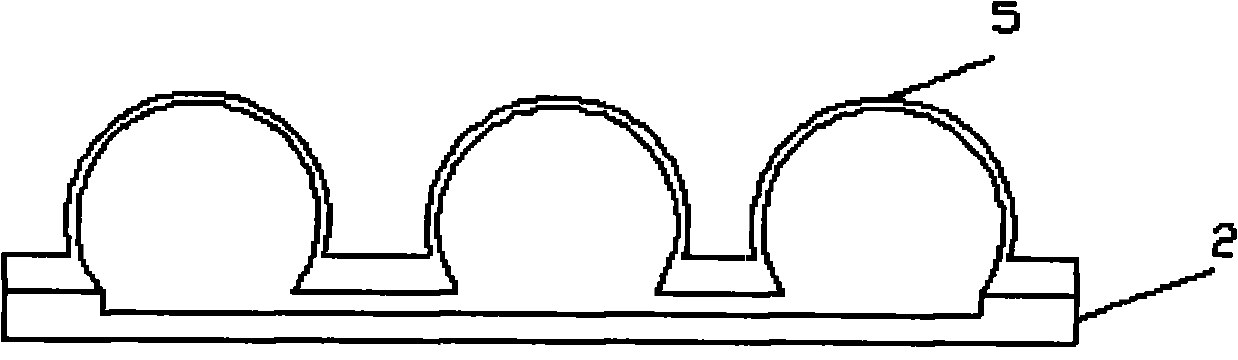

[0023]A kind of method that positive pressure thermoforming prepares the glass microcavity of disc level uniform size, comprises the following steps: engrave the array (the size of microgroove is identical) that same microgroove forms on silicon wafer, the method for etching microgroove can be Dry method and wet method, preferably wet method (the depth of the microgroove required by the present invention can place the heat release agent, so the shallower depth of wet etching can meet the requirements, such as the depth of 50-100 microns) , the etched microgrooves have the same size (for example, 5, 10, 15, 50), microchannels are engraved between the microgrooves, and the minimum groove width of the microgrooves is greater than 5 times of the flow channel width. Place an appropriate amount of heat release agent in at least one microgroove (can place heat release agent in two or more microgrooves, the consumption of heat release agent is calculated according to the volume space o...

Embodiment 2

[0026] A method for preparing a wafer-level uniform-sized glass microcavity by positive pressure thermoforming, comprising the following steps:

[0027] The first step is to oxidize a 5000A oxide layer on a single-sided polished silicon wafer by a combination of dry and wet oxygen, spin-coat AZ P4620 photoresist on the polished surface, expose and develop to remove the photoresist that needs to be etched on the surface of the microgroove. Utilize the Si micromachining process to etch the microcavity and the microchannel shallow groove on the 4-inch Si wafer, and the microchannel connects the shallow groove. The silicon wafer used can be a standard thickness silicon wafer with a thickness of 500 microns. The depth of the groove is 60-100 microns, the micro-groove is a square groove with a width of 2000 microns, and the micro-channel used to connect two micro-grooves is a strip-shaped groove with a width of 50 microns. Square groove, the micromachining process of the pattern str...

Embodiment 3

[0033] A method for preparing a wafer-level uniform-sized glass microcavity by positive pressure thermoforming, comprising the following steps:

[0034] The first step is to oxidize a 5000A oxide layer on a single-sided polished silicon wafer by a combination of dry and wet oxygen, spin-coat AZ P4620 photoresist on the polished surface, expose and develop to remove the photoresist that needs to be etched on the surface of the microgroove. Utilize Si micromachining process to etch microgrooves and microchannels on 4-inch Si wafers, microchannels connect microgrooves, used silicon wafers can be silicon wafers of standard thickness, and thickness is 500 microns, and the depth of described microgrooves is 60-100 microns, square groove with a width of 2000 microns, the number of micro-grooves is 15, the size is the same, the micro-channel groove is a strip-shaped groove with a diameter of 50 microns, and the length of the groove is 5 mm, connecting two adjacent microcavity squares ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com