Corrosion-resistant terafluoroethylene-propylene rubber/chlorosulfonated polyethylene rubber sealing gasket and preparation method thereof

A technology of chlorosulfonated polyethylene and tetrapropylene fluorine rubber, which is applied in the field of gaskets and their preparation, can solve the problems of corrosion resistance, unsuitable service life equipment requirements, etc., and achieve low expansion, high compressive strength, and sealing performance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

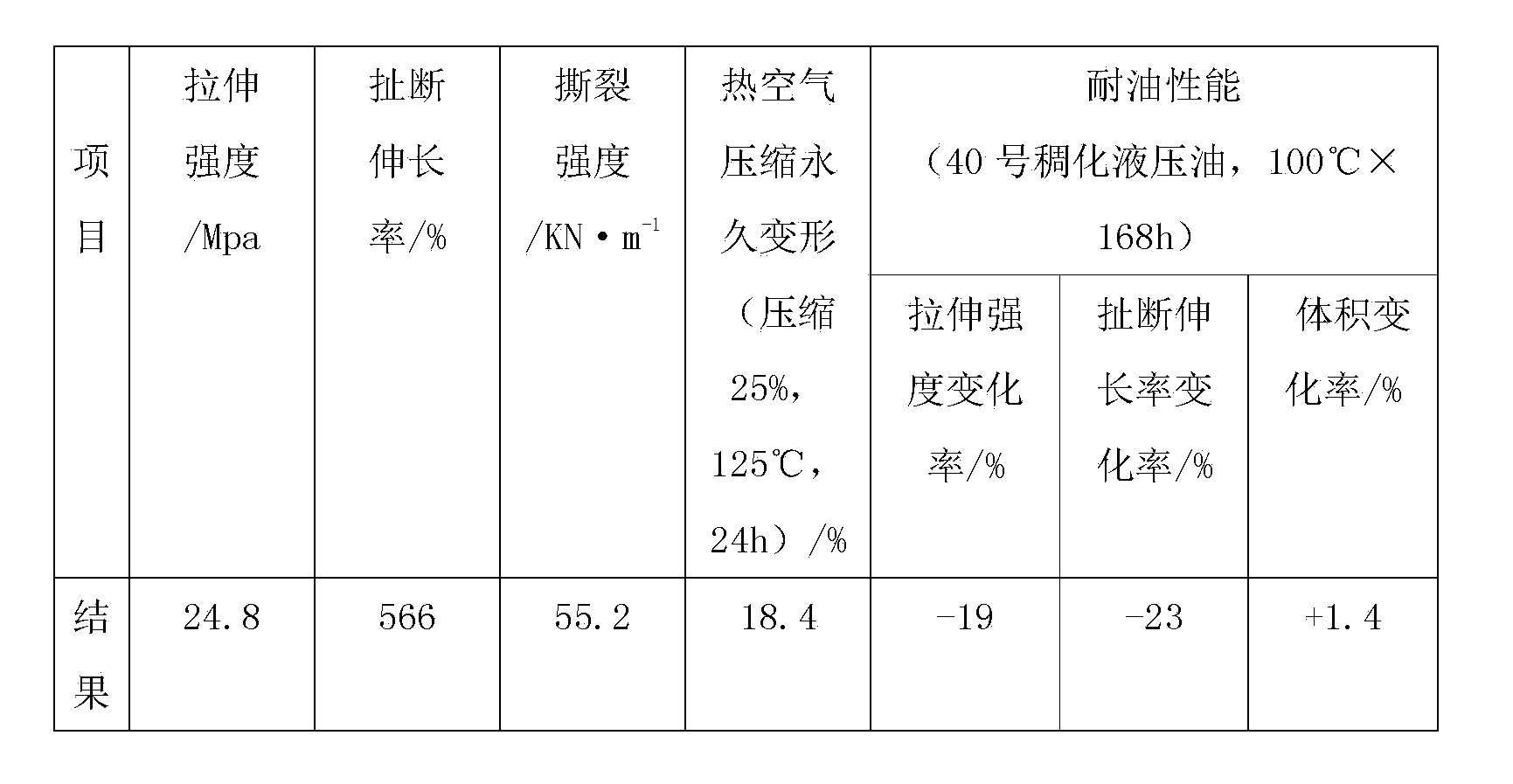

[0012] A corrosion-resistant tetrapropylene fluororubber / chlorosulfonated polyethylene rubber gasket, made of the following weight (kg) raw materials: tetrapropylene fluororubber (TP-2) 80, chlorosulfonated polyethylene rubber (CSM2305) 30 , polyether ether ketone 15, carbon black N330 20, nano tin dioxide 5, calcined clay 12, modified nano ceramics 10-15, mica powder 5-10, dicumyl peroxide 2, 2,5-dimethyl Base-2,5-di-tert-butylperoxyhexane 1.5, triallyl isocyanurate 8, accelerator CZ 2, accelerator ZDC 1, lead stearate 1.5, zinc oxide 2, magnesium oxide 1.5. Antiaging agent TPPD2, antiaging agent ODA 2 .

[0013] The modified nano-ceramic is made from raw materials with the following weight (kg):

[0014] Nano-aluminum nitride 20, nano-titanium carbide 10, nano-zirconium boride 8, glass powder 2, fatty alcohol polyoxyethylene ether sodium sulfate 3, polyvinylpyrrolidone 12, calcium lignosulfonate 6, trifluoropropyl methyl silicone oil 22. Polyvinyl acetate emulsion 65, bis(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com