Method for preparing agricultural water-retaining agent from degummed alga dreg

A technology for agricultural water-retaining agent and seaweed slag, which is applied in chemical instruments and methods, applications, agriculture, etc., can solve the problems of poor water-absorbing effect of water-retaining agent, difficult to control high pressure, etc., achieves high water absorption multiple, is conducive to retention, and accelerates the reaction rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

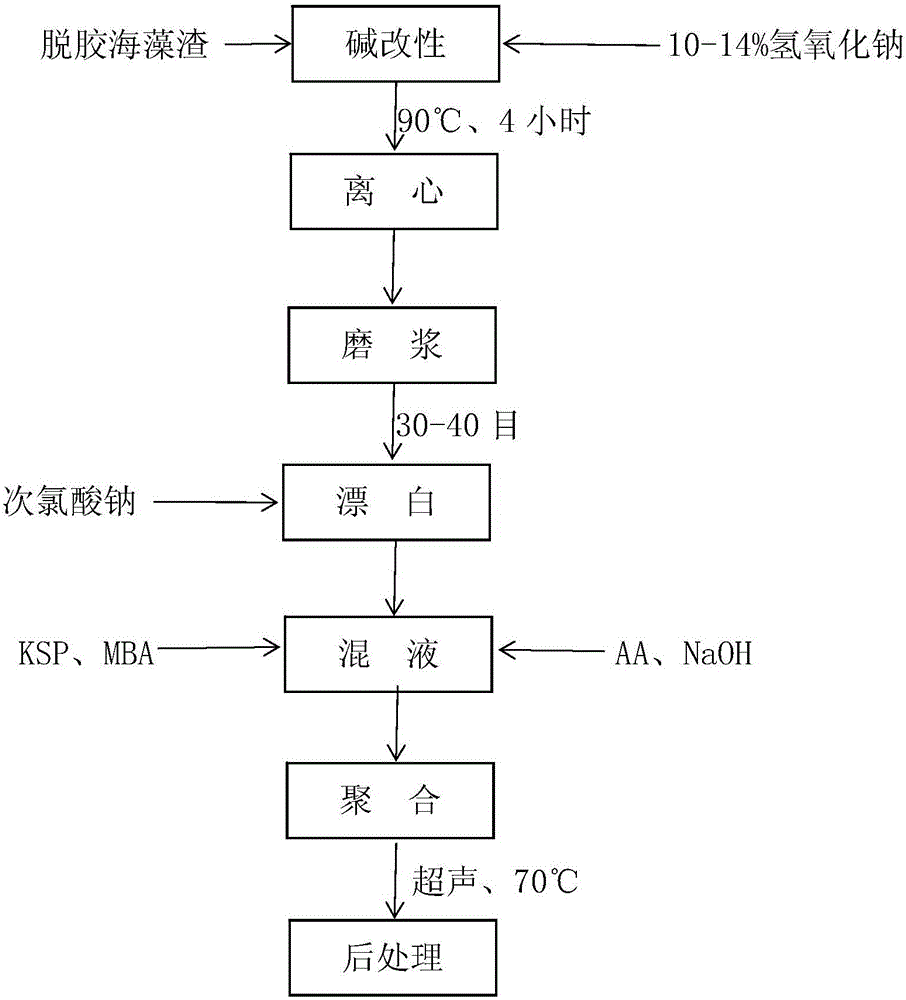

[0028] Such as figure 1 As shown, the preparation method of the agricultural water-retaining agent of the present invention specifically comprises the following steps:

[0029] Step 1. Alkali modification, put the degummed seaweed residue into the alkali treatment tank, add 10%-14% sodium hydroxide solution with a mass concentration, control the liquid-to-solid ratio at about 3:1, and conduct alkali treatment at 90°C for 4 hours to obtain seaweed extract one;

[0030] Step 2, centrifuging and refining, the seaweed extract is centrifuged and washed, and then passed into a refiner for refining, so that the refined extract passes through a 40-mesh sieve, and the sieved extract is centrifuged for later use;

[0031] Step 3, bleaching and washing, add water to the refined extract according to the liquid-to-solid ratio of 4:1, and add 10% available chlorine sodium hypochlorite solution to bleach for 30 minutes, the amount of sodium hypochlorite solution added is five minutes of the...

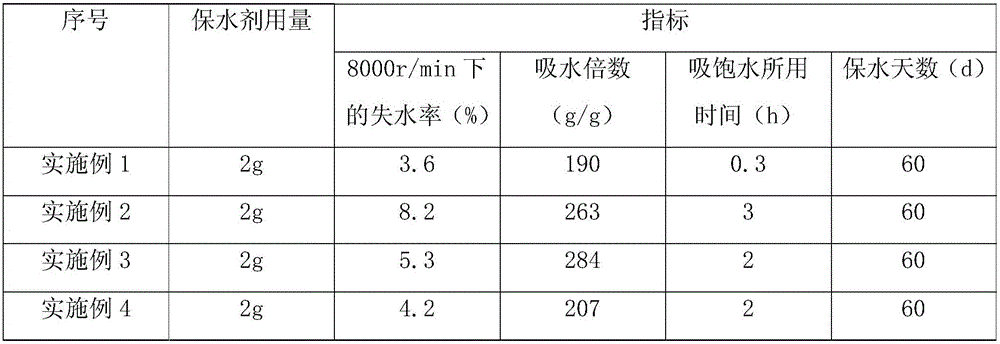

Embodiment 1

[0037] In the alkali treatment reaction tank, add 100 g of degummed seaweed residue, then add 300 g of 10% sodium hydroxide solution, and perform alkali treatment at 90° C. for 4 hours to obtain seaweed extract 1; the seaweed extract 1 is centrifuged and washed , and then passed into a refiner for refining, making the refined extract pass through a 40-mesh sieve, and the sieved extract is centrifuged for subsequent use; add about 400g of water to the refined extract, and add 10% effective Chlorine sodium hypochlorite solution 20g bleach for 30 minutes, then add industrial hydrochloric acid, make the pH in the bleaching tank reach between 4-5, acidify for 30 minutes, get white fluffy seaweed extract 2, wash and centrifuge for later use; add 40g in the mixing tank Industrial-grade acrylic acid, neutralize with 40g of 30% sodium hydroxide, control neutralization temperature below 45°C, neutralization degree is 75%, add 0.5g of potassium persulfate, 0.08g of MBA (N, N- Methylenebi...

Embodiment 2

[0039]In the alkali treatment reaction tank, add 100 g of degummed seaweed residue, then add 300 g of sodium hydroxide solution with a mass fraction of 14%, and perform alkali treatment at 90 ° C for 4 hours to obtain seaweed extract 1; the seaweed extract 1 is washed after centrifugation , and then passed into a refiner for refining, making the refined extract pass through a 40-mesh sieve, and the sieved extract is centrifuged for subsequent use; add about 400g of water to the refined extract, and add 10% effective Chlorine sodium hypochlorite solution 20g bleach for 30 minutes, then add industrial hydrochloric acid, make the pH in the bleaching tank reach between 4-5, acidify for 30 minutes, get white fluffy seaweed extract 2, wash and centrifuge for later use; add 40g in the mixing tank Industrial grade acrylic acid, neutralize with the sodium hydroxide of 30% concentration of 40g, control neutralization temperature at 30 ℃, neutralization degree is 65%, add the MBA of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com