Method for packaging glass-silicon wafer-grade chiponboard (COB) of light emitting diode (LED)

A light-emitting diode, chip packaging technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of poor moisture resistance of organic substances, poor light transmittance of lenses, poor light transmittance performance, etc. The effect of strong resistance to high temperature and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

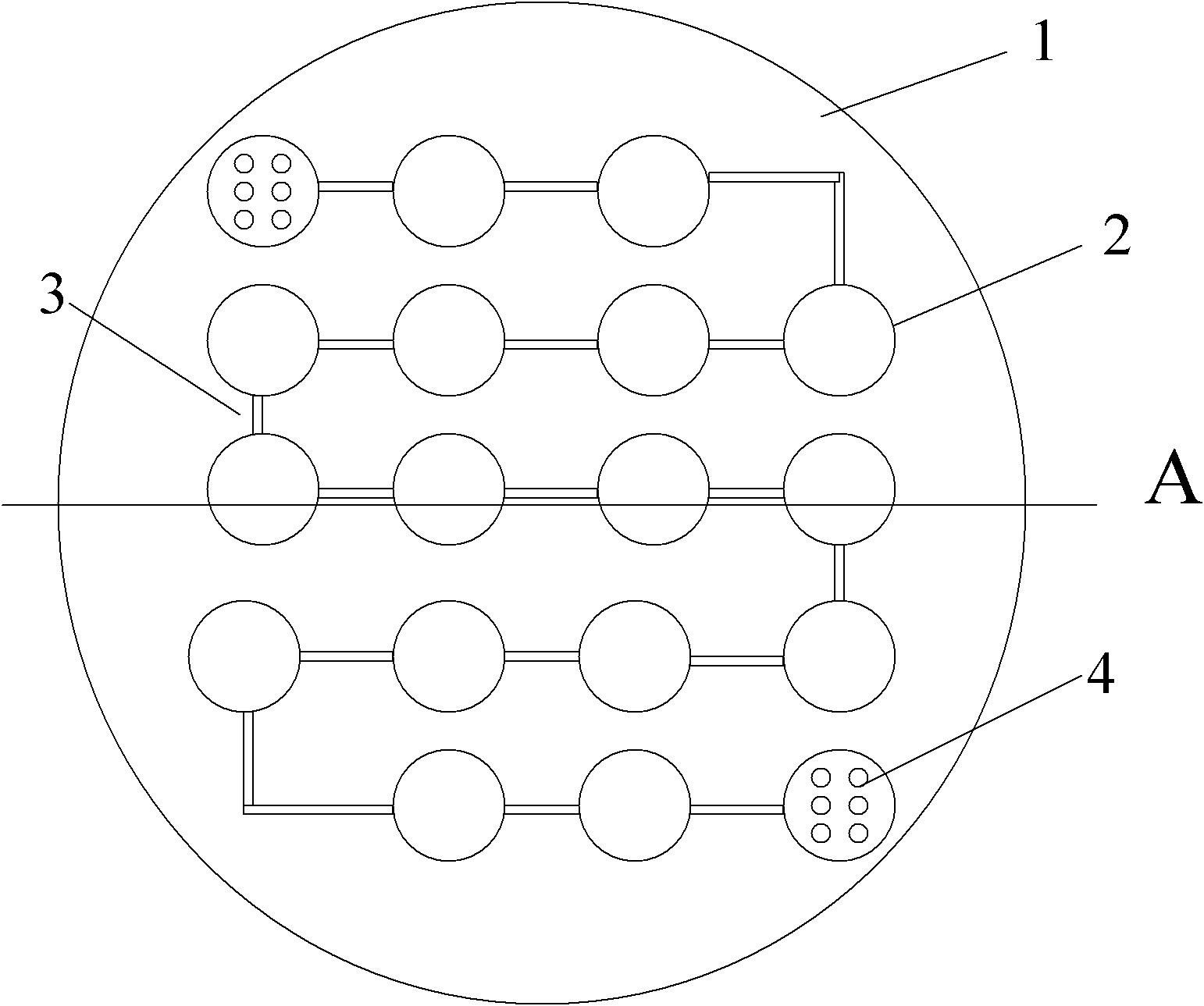

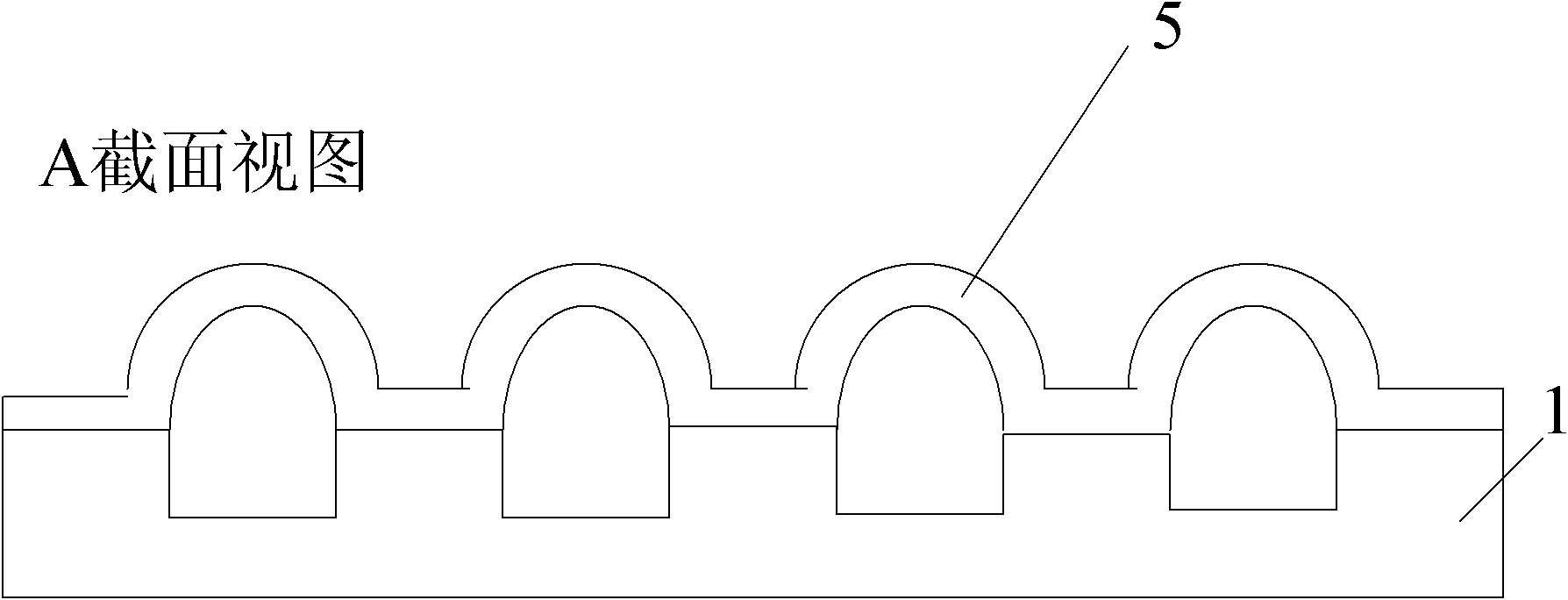

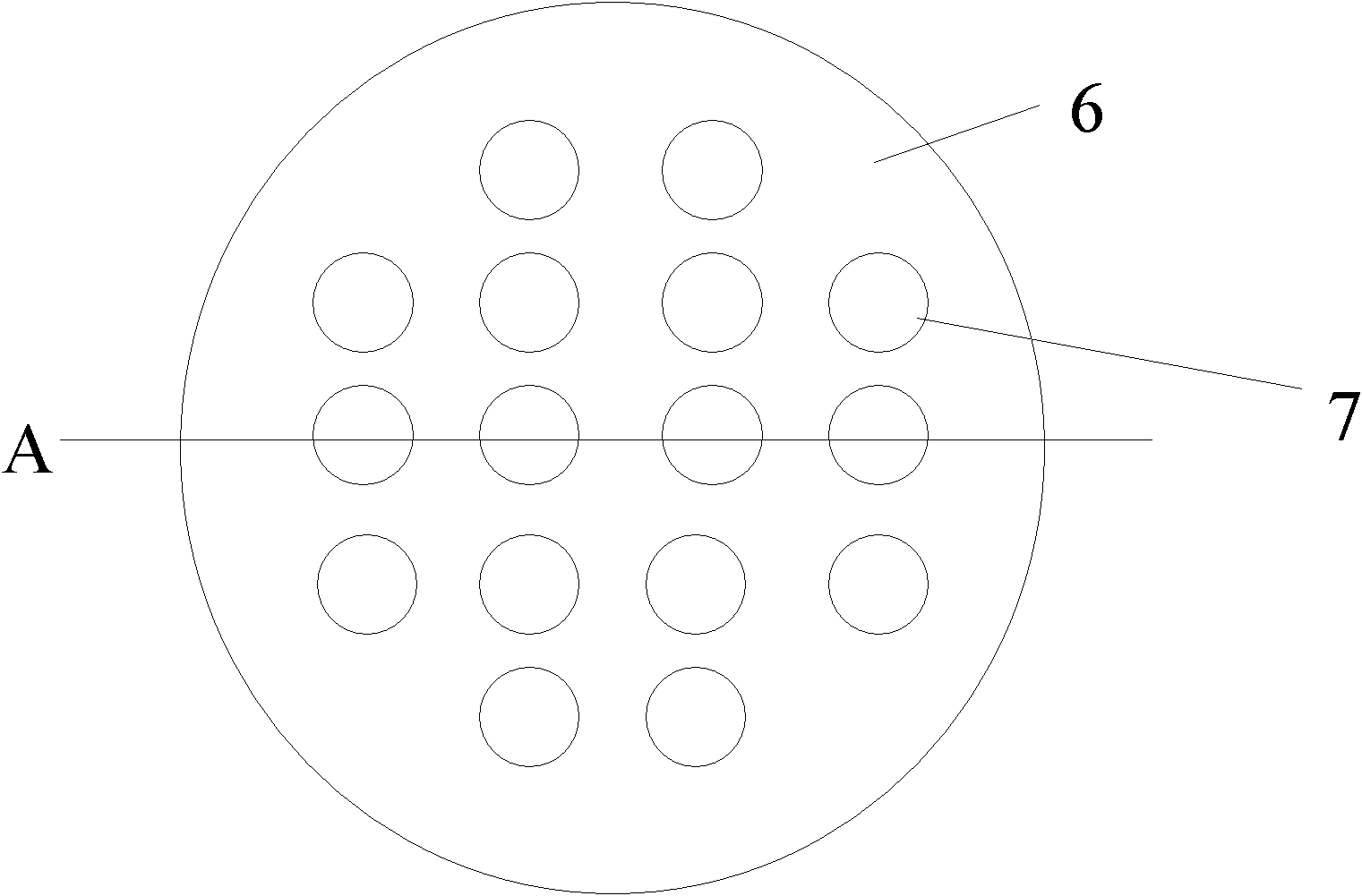

[0039] A wafer-level glass bulb cavity packaging method for light-emitting diodes, comprising the following steps:

[0040] The first step is to use Si micromachining technology to etch specific microgrooves and microchannel patterns on Si wafers (such as 4-inch wafers), and the patterns corresponding to the packaged LED arrays: microgroove arrays, microgrooves The micro-grooves are connected by micro-channels, the micro-grooves are square or circular, the size ratio of micro-grooves and micro-channels is adjusted according to the preparation requirements, and an appropriate amount of heat release agent is placed in the micro-grooves; in the second step, the patterned The above-mentioned Si wafer and the Pyrex7740 borosilicate glass wafer with thermal air release agent are anodically bonded in air or vacuum, so that the above-mentioned microgroove and micro-channel are sealed to form a sealed cavity; the third step is to bond the above-mentioned The combined wafer is heated to...

Embodiment 2

[0043] A wafer-level glass bulb cavity packaging method for light-emitting diodes, comprising the following steps:

[0044] The first step is to use the Si micromachining process to etch the wet pattern corresponding to the packaged LED array on the Si wafer (such as a 4-inch wafer): a micro-groove array (80um in depth), and the micro-grooves are separated by micro-grooves. The flow channels are connected, the micro-groove is circular, and an appropriate amount of heat-releasing agent calcium carbonate is placed in the micro-groove;

[0045] In the second step, the above-mentioned Si wafer with a pattern and a thermal air release agent is anodically bonded to the Pyrex7740 glass wafer in a vacuum, so that the Pyrex7740 glass forms a sealed cavity with the above-mentioned microgrooves and microflow channels;

[0046] The third step is to heat the above-bonded wafers to 880°C in the air and keep it warm for 10 minutes. The heat release agent calcium carbonate will generate posit...

Embodiment 3

[0053] A method for manufacturing a wafer-level glass microcavity for LED packaging, comprising the following steps:

[0054] The first step is to oxidize a 5000A oxide layer on a single-sided polished silicon wafer by a combination of dry and wet oxygen, spin-coat AZ P4620 photoresist on the polished surface, expose and develop to remove the photoresist that needs to be etched on the surface of the microgroove. Use Si micromachining technology to etch shallow grooves on Si wafers (such as 4-inch wafers). The silicon wafers used can be silicon wafers with a standard thickness, such as 500 micron thick silicon wafers. The shallow grooves are etched by TMAH wet etching. For etching, heat in a water bath at 90°C for 2 to 2.5 hours, and the etching depth is 80 to 120. This depth can be relatively easy to build a high-temperature air release agent, and can provide a certain space between the high-temperature air release agent and the wafer to avoid contact with the glass. The conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com