Magnetic fluid composite tilting-pad radial bearing based on Halbach array

A radial bearing and magnetic fluid technology, applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve the problems of dry friction, poor bearing operation, difficult to meet the harsh working conditions of low speed and heavy load, etc., and achieve the bearing structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

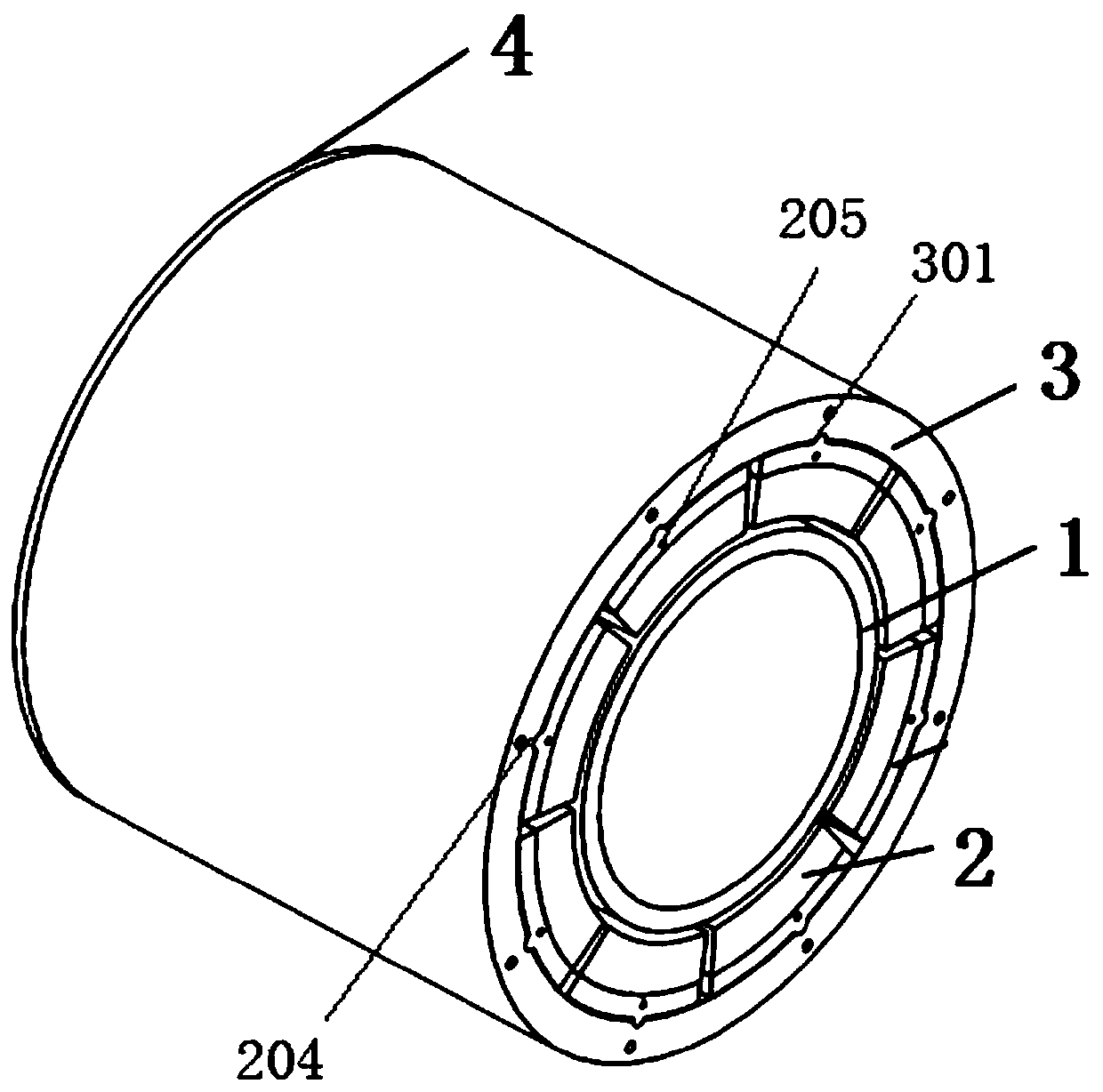

[0033] Such as figure 1 As shown, this embodiment provides a ferrofluid composite tilting pad radial bearing based on the Halbach array, including a bushing 1, a bushing 2, a bearing housing 3 and a stop ring 4, and the bushing 1 is fixed on the rotating shaft Form a pair of friction pairs with the bearing pad, and the bearing pad 2 is used to bear the bearing load.

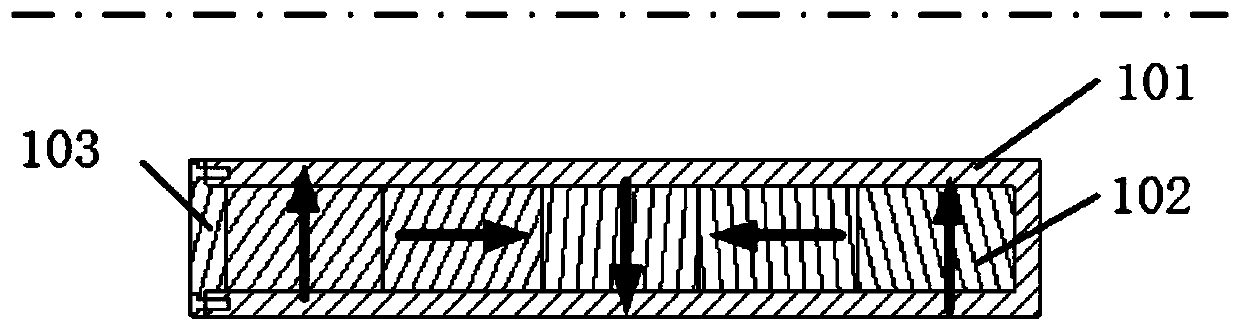

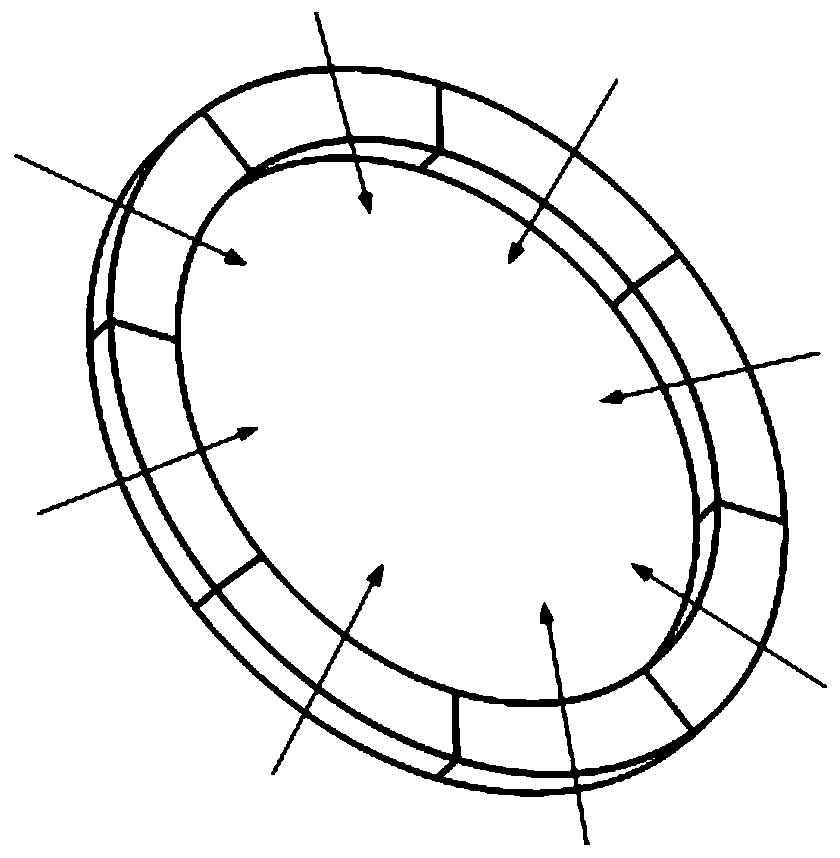

[0034] The sleeve is provided with a first permanent magnet inner core, and the first permanent magnet inner core is respectively magnetized radially and axially, and is arranged in a linear array according to Halbach, and a second permanent magnet is provided in the bearing bush The inner core of the second permanent magnet is magnetized radially and axially respectively, and arranged in a linear array according to Halbach. The magnetization direction of the inner core of the first permanent magnet in the bushing is the same as that of the second permanent magnet in the bearing The magnetization direction of th...

Embodiment 2

[0045] As shown in Figure 9, the second embodiment is basically the same as the first embodiment, the difference lies in: the structure of the bearing pad, the bearing pad surface 201 of this embodiment is made of materials such as Sailong Feilong or graphite, and this bearing is mainly suitable for oil lubrication In the field, the arrangement order of the Halbach array of the inner core segment of the permanent magnet of the bearing bush is opposite to that of the ring block of the bushing, that is, there is a permanent magnetic repulsion between the bushing and the bushing, and the permanent magnetic repulsion generated is the same as the water film force generated by the dynamic pressure lubrication. Bear the bearing load. The tile surface layer 201 is made into a fan-shaped block shell structure, and the second permanent magnet inner core 202 is embedded in a stainless steel shell 206 and fixed and sealed with a cover plate 207 by screws. The slats cancel the tile-based s...

Embodiment 3

[0047] The structure of this embodiment is basically the same as that of Embodiment 1, the difference lies in: the structure of the bearing pad, the surface layer 201 of the bearing pad is made of metal material, the bearing is mainly suitable for the field of oil lubrication, and the arrangement sequence of the Halbach array of the inner core segment of the permanent magnet of the bearing pad The arrangement order of the ring blocks of the bushing is opposite, that is, there is a permanent magnetic repulsion between the bushing and the bearing bush, and the generated permanent magnetic repulsion and the water film force generated by the dynamic pressure lubrication jointly bear the bearing load. The tile surface layer 201 is made into a sector block shell structure, and the second permanent magnet inner core 202 is embedded in the tile surface shell 201 and fixed and sealed with a cover plate 207 by screws. The slats cancel the tile base structure, and directly process the arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com