Si-conductive ceramic composite negative electrode material for lithium battery and preparation method thereof

A technology of conductive ceramics and negative electrode materials, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc. The effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

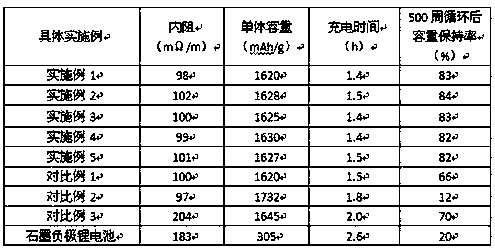

Examples

Embodiment 1

[0028] A kind of Si-conductive ceramic composite negative electrode material that is used for lithium battery, its preparation step is as follows:

[0029] Mix 9.6kg of coke with 6.4kg of silicon dioxide powder evenly, and heat it to 2800°C for reduction to obtain crude silicon; after fully grinding and refining the obtained crude silicon, pass in chlorine gas and heat to 485°C to react until silicon particles It is completely converted into silicon tetrachloride, and after slow cooling, hydrogen gas is introduced and then heated to 1100°C to reduce silicon tetrachloride to obtain a nanoparticle precursor of elemental silicon; the precursor is soaked in N-methylpyrrolidone to obtain an average particle size of less than 5nm passivated silicon nanoparticles; mixing the passivated silicon nanoparticles with the conductive ceramic slurry and stirring evenly, wherein the weight ratio of the passivated silicon nanoparticles to the solid phase components of the conductive ceramic slu...

Embodiment 2

[0032] A kind of Si-conductive ceramic composite negative electrode material that is used for lithium battery, its preparation step is as follows:

[0033] Mix 12kg of coke and 7.4kg of silicon dioxide powder evenly, and heat it in a sealed chamber to 2900°C for reduction to obtain crude silicon; fully grind and refine the obtained crude silicon, then pass in chlorine gas and heat to 495°C to react until the silicon particles are completely Converted into silicon tetrachloride, after slow cooling, pass in hydrogen and then heat up to 1150°C to reduce silicon tetrachloride to obtain nanoparticle precursor of elemental silicon; use tetrahydropyrrole to treat the precursor to obtain passivated silicon with an average particle size of less than 5nm Nanoparticles: Mix the obtained passivated silicon nanoparticles with 15kg of conductive ceramic slurry and stir evenly, wherein the conductive ceramic slurry contains 3.75kg of aluminum powder, 3.3kg of titanium powder and 3.85kg of tit...

Embodiment 3

[0036] A kind of Si-conductive ceramic composite negative electrode material that is used for lithium battery, its preparation step is as follows:

[0037] Mix 10kg of coke with 6.4kg of silicon dioxide powder evenly, and heat it to 2850°C for reduction to obtain crude silicon; after fully grinding and refining the obtained crude silicon, pass in chlorine gas and heat to 485°C to react until the silicon particles are completely Converted into silicon tetrachloride, after slow cooling, pass in hydrogen gas and then heat up to 1120°C to reduce silicon tetrachloride to obtain the nanoparticle precursor of elemental silicon; use N-methylpyrrolidone to treat the precursor to obtain passivation with an average particle size of less than 5nm Silicon nanoparticles; the obtained passivated silicon nanoparticles are mixed with 16.5kg conductive ceramic slurry and stirred evenly, wherein the conductive ceramic slurry contains 4.2kg aluminum powder, 4.14kg titanium powder and 3.6kg titaniu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com