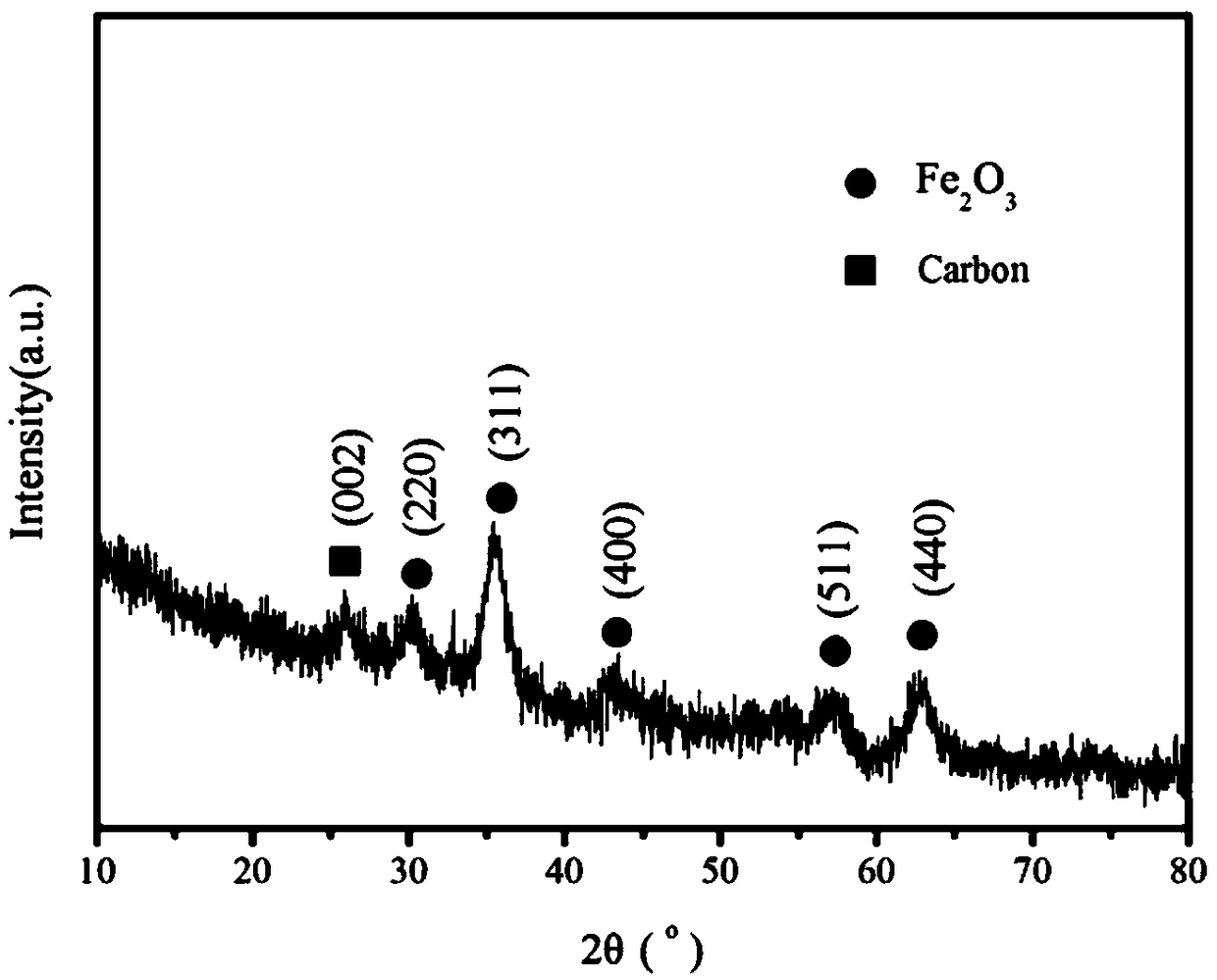

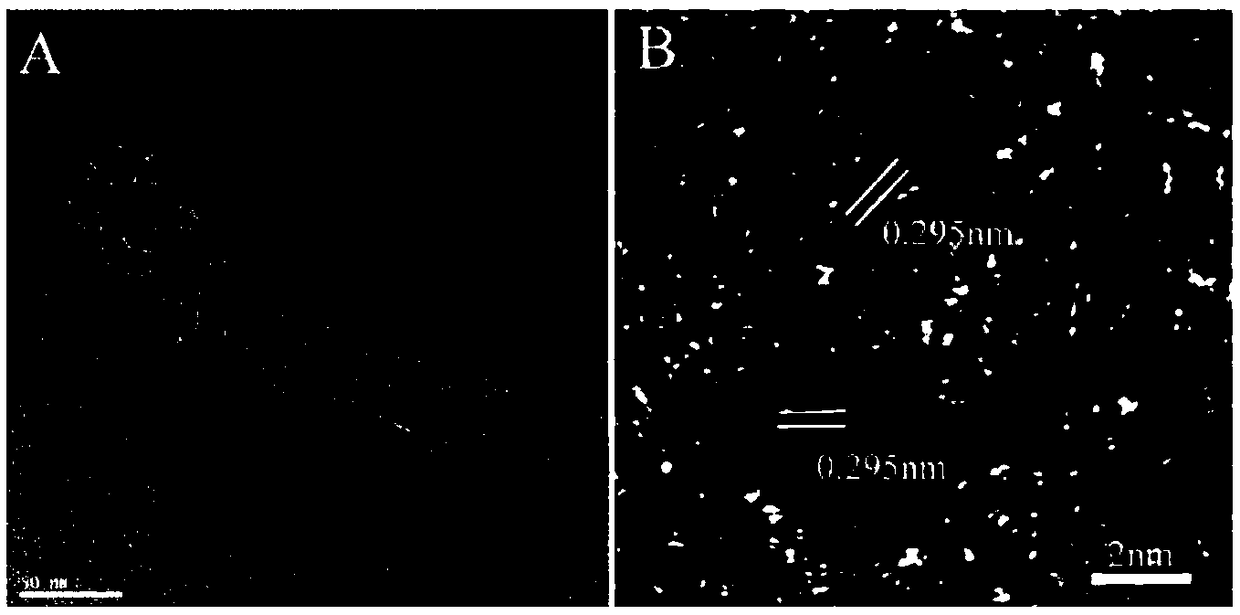

Fe2O3/carbon nanotube composite material, preparation method thereof and supercapacitor

A carbon nanotube and composite material technology, which is applied in the fields of hybrid capacitor electrodes, nanotechnology, nanotechnology, etc., can solve the problems that oxide particles are not easily adsorbed, nano-iron oxide cannot be grown, and the diameter of carbon nanotubes is small. Good redox reaction characteristics, obvious charge-discharge platform, and high preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] For this reason, the applicant improves the process, see Figure 8 , is a kind of Fe in the present invention 2 o 3 / The flow chart of the preparation method of carbon nanotube composite material, comprises the following steps:

[0043] Step S1: Measure DMF and distilled water, mix well and use it as a mixed solvent;

[0044] Step S2: Weigh a certain amount of carbon nanotubes and add them to the mixed solvent prepared in step S1, and uniformly disperse the carbon nanotubes in the solvent by ultrasound to obtain a carbon nanotube dispersion; wherein, the carbon nanotubes in the mixed solution The concentration is 0.5~2mg / mL;

[0045] Step S3: Weigh ferrous chloride tetrahydrate and anhydrous sodium acetate into the carbon nanotube dispersion prepared in step S2, stir and mix evenly by magnetic force; meanwhile, adjust the pH value of the mixed solution to pH = 6. Then put it into a water bath of 60-90 degrees, and continue to stir in the water bath; wherein, the conc...

Embodiment 1

[0052] (1) Measure 8mL of DMF and 2mL of distilled water, and mix them uniformly as a mixed solvent.

[0053] (2) Weighing 20 mg of carbon nanotubes and adding them to the mixture of DMF and distilled water, and ultrasonicating for 3 hours, so that the carbon nanotubes are evenly dispersed in the solvent to obtain a carbon nanotube dispersion. The concentration of carbon nanotubes in the mixed solution was 2 mg / mL.

[0054] (3) Weigh 100 mg of ferrous oxide tetrahydrate and 200 mg of anhydrous sodium acetate, and stir magnetically for 10 minutes. The pH of the mixture was adjusted to pH=6 by 5% HCl. Then put it into a 70-degree water bath, continue magnetic stirring, the stirring speed is 300 rpm, and the stirring time is 2 hours. The concentration of ferrous chloride tetrahydrate is 10 mg / mL relative to the concentration in the mixed solution, and the molar concentration ratio of anhydrous sodium acetate to ferrous chloride tetrahydrate is 4.878:1.

[0055] (4) After cooli...

Embodiment 2

[0065] (1) Measure 8mL of DMF and 2mL of distilled water, and mix them uniformly as a mixed solvent.

[0066] (2) Weighing 10 mg of carbon nanotubes and adding them to a mixture of DMF and distilled water, and ultrasonicating for 3 hours to uniformly disperse the carbon nanotubes in the solvent to obtain a carbon nanotube dispersion. The concentration of carbon nanotubes in the mixture was 1 mg / mL.

[0067] (3) Weigh 120 mg of ferrous oxide tetrahydrate and 247.5 mg of anhydrous sodium acetate, that is, the concentration of ferrous chloride tetrahydrate is 12 mg / mL relative to the concentration in the mixed solution, and anhydrous sodium acetate is 12 mg / mL relative to the concentration of tetrahydrate chloride The molar concentration ratio of ferrous iron is 5:1. Stir magnetically for 10 minutes. The pH of the mixture was adjusted to pH=6 by 5% HCl. Then put it into a 60-degree water bath, continue magnetic stirring, the stirring speed is 300 rpm, and the stirring time is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com