Battery electrode, preparation method thereof, and all-solid-state battery

A battery electrode and electrode material technology, applied in battery electrodes, electrode carriers/current collectors, secondary batteries, etc., can solve the problems of high environmental requirements for lithium powder, low ion conductivity of polymer electrolytes, and poor uniformity of pole pieces. Achieve high ionic conductivity and mechanical strength, improve production/manufacturing efficiency, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The second aspect of the present invention provides a method for preparing a battery electrode, the method comprising:

[0060] (1) provide an electrode slurry containing electrode active materials, crosslinkable copolymers, crosslinking agents, inorganic nanoparticles modified by silane coupling agents, and photoinitiators;

[0061] (2) Coating the electrode slurry in step (1) on the electrode collector, drying, and then performing cross-linking and curing on the electrode collector to form an electrode material layer under ultraviolet light irradiation;

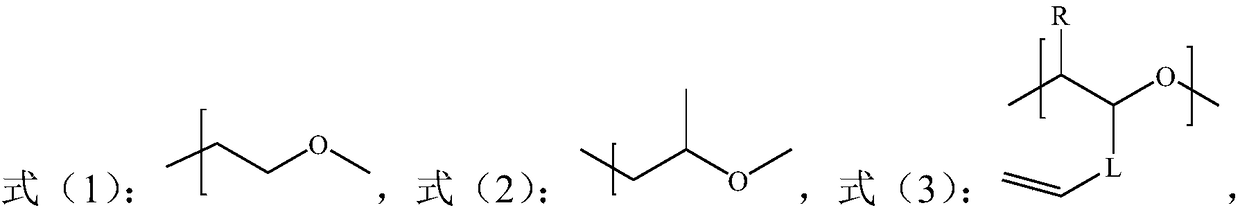

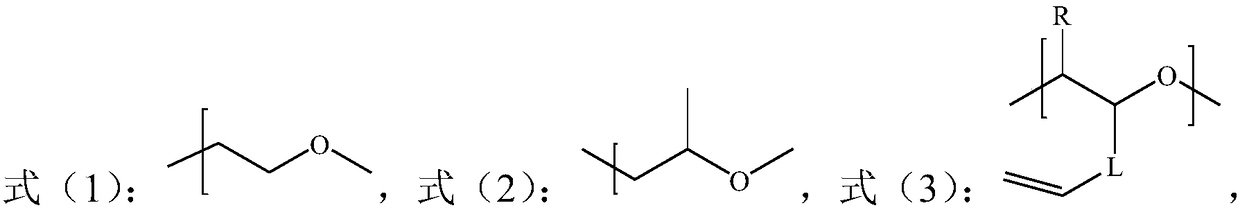

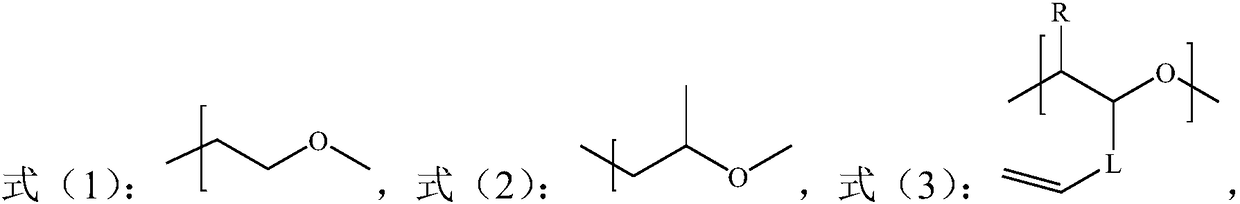

[0062] Wherein, the crosslinkable copolymer contains the structural unit shown in formula (1), the structural unit shown in formula (2) and the structural unit shown in formula (3);

[0063]

[0064] Wherein, R is H or C1-C4 alkyl, L is C0-C4 alkylene or -R 1 -O-R 2 -, R 1 C0-C4 alkylene, R 2 is C0-C4 alkylene;

[0065] The crosslinking agent is one or more of the acrylate crosslinking agents containing at le...

preparation example 1

[0107] This preparation example is used to illustrate the inorganic nanoparticles modified by silane coupling agent.

[0108] Nano-SiO with a mass ratio of 1:2 2 (purchased from Beijing Deke Daojin Technology Co., Ltd., as particles with a particle size of 30nm) and 3-acryloyloxypropyltrimethoxysilane were added to ethanol (ethanol and nano-SiO 2 The mass ratio is 5:1), followed by ultrasonic dispersion for 30 minutes, and reacting at 100° C. for 12 hours to obtain inorganic nanoparticles modified by silane coupling agent C1.

preparation example 2

[0110] Nano Al 2 o 3 (purchased from Sumitomo Corporation, Japan, as particles with a particle size of 300nm) in hydrochloric acid (concentration is 0.1mol / L) to carry out surface treatment to make nano-Al 2 o 3 With hydroxyl groups on it, and then the surface-treated nano-Al according to the mass ratio of 1:3 2 o 3 with 3-methacryloxypropylethyldiethoxysilane added to isopropanol (isopropanol and nano-SiO 2 The mass ratio is 4:1), followed by ultrasonic dispersion for 35 minutes, and reacted at 110° C. for 10 hours, so as to obtain the inorganic nanoparticles C2 modified by the silane coupling agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com