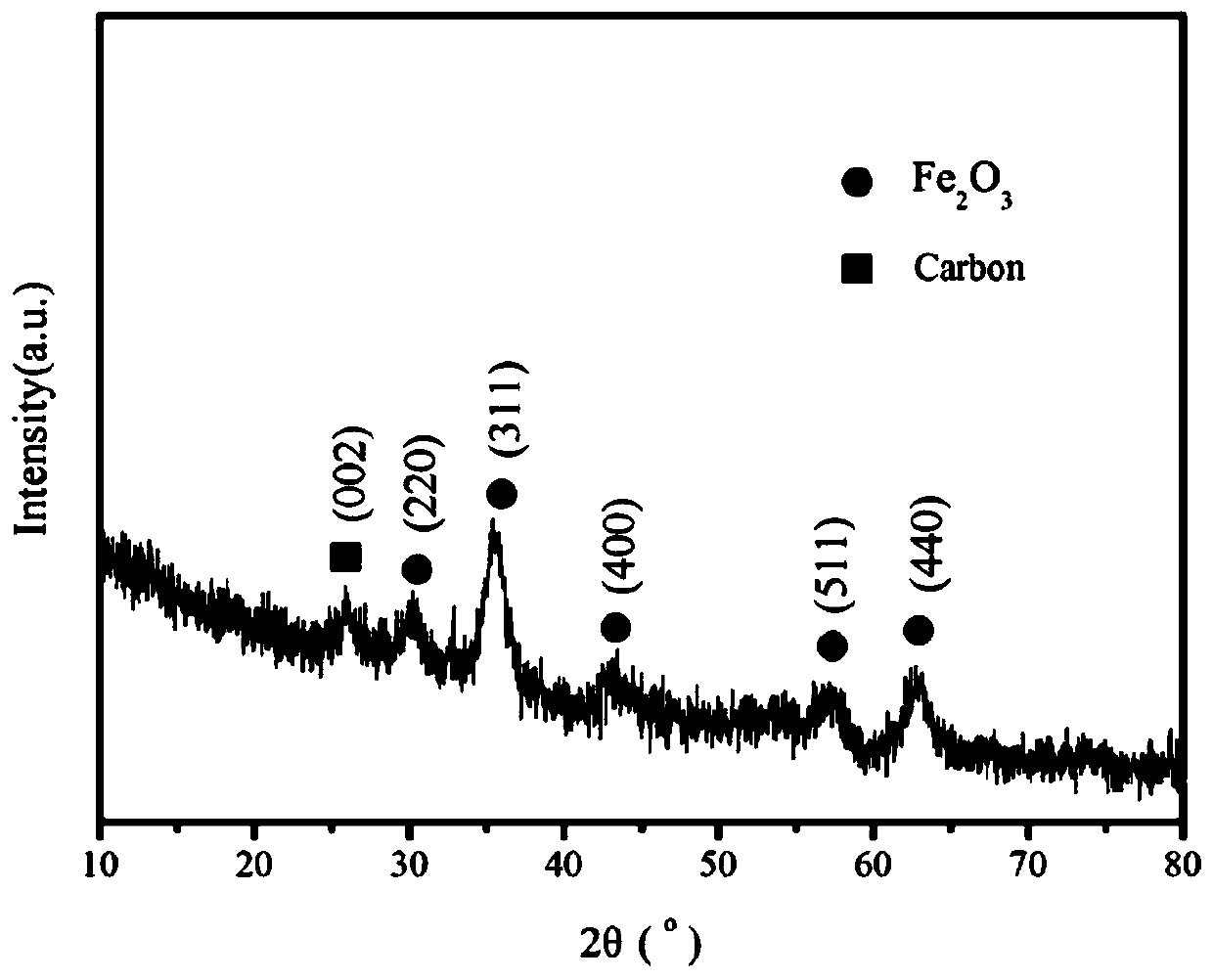

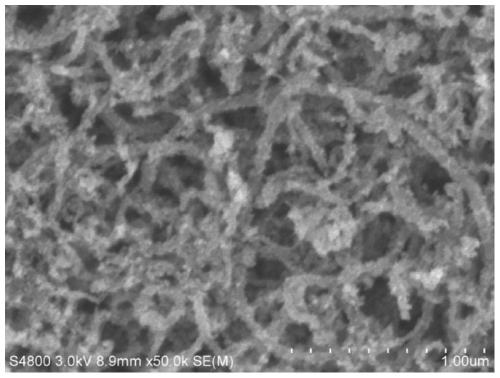

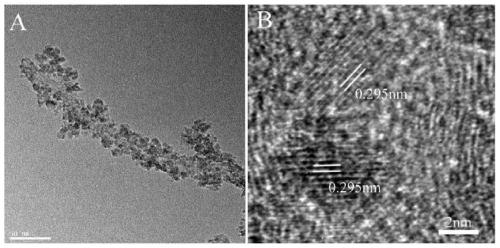

a fe 2 o 3 /Carbon nanotube composite material and its preparation method and supercapacitor

A technology of carbon nanotubes and composite materials, applied in hybrid capacitor electrodes, nanotechnology, nanotechnology, etc., can solve the problems of difficult adsorption of oxide particles, inability to grow nano-iron oxide, small diameter of carbon nanotubes, etc., to achieve Good redox reaction characteristics, improved redox current, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] For this reason, the applicant improves the process, see Figure 8 , is a kind of Fe in the present invention 2 o 3 / The flow chart of the preparation method of carbon nanotube composite material, comprises the following steps:

[0043] Step S1: Measure DMF and distilled water, mix well and use it as a mixed solvent;

[0044] Step S2: Weigh a certain amount of carbon nanotubes and add them to the mixed solvent prepared in step S1, and uniformly disperse the carbon nanotubes in the solvent by ultrasound to obtain a carbon nanotube dispersion; wherein, the carbon nanotubes in the mixed solution The concentration is 0.5~2mg / mL;

[0045] Step S3: Weigh ferrous chloride tetrahydrate and anhydrous sodium acetate into the carbon nanotube dispersion prepared in step S2, stir and mix evenly by magnetic force; meanwhile, adjust the pH value of the mixed solution to pH = 6. Then put it into a water bath of 60-90 degrees, and continue to stir in the water bath; wherein, the conc...

Embodiment 1

[0052] (1) Measure 8mL of DMF and 2mL of distilled water, and mix them uniformly as a mixed solvent.

[0053] (2) Weighing 20 mg of carbon nanotubes and adding them to the mixture of DMF and distilled water, and ultrasonicating for 3 hours, so that the carbon nanotubes are evenly dispersed in the solvent to obtain a carbon nanotube dispersion. The concentration of carbon nanotubes in the mixed solution was 2 mg / mL.

[0054] (3) Weigh 100 mg of ferrous oxide tetrahydrate and 200 mg of anhydrous sodium acetate, and stir magnetically for 10 minutes. The pH of the mixture was adjusted to pH=6 by 5% HCl. Then put it into a 70-degree water bath, continue magnetic stirring, the stirring speed is 300 rpm, and the stirring time is 2 hours. The concentration of ferrous chloride tetrahydrate is 10 mg / mL relative to the concentration in the mixed solution, and the molar concentration ratio of anhydrous sodium acetate to ferrous chloride tetrahydrate is 4.878:1.

[0055] (4) After cooli...

Embodiment 2

[0065] (1) Measure 8mL of DMF and 2mL of distilled water, and mix them uniformly as a mixed solvent.

[0066] (2) Weighing 10 mg of carbon nanotubes and adding them to a mixture of DMF and distilled water, and ultrasonicating for 3 hours to uniformly disperse the carbon nanotubes in the solvent to obtain a carbon nanotube dispersion. The concentration of carbon nanotubes in the mixed solution was 1 mg / mL.

[0067] (3) Weigh 120 mg of ferrous oxide tetrahydrate and 247.5 mg of anhydrous sodium acetate, that is, the concentration of ferrous chloride tetrahydrate is 12 mg / mL relative to the concentration in the mixed solution, and anhydrous sodium acetate is 12 mg / mL relative to the concentration of tetrahydrate chloride The molar concentration ratio of ferrous iron is 5:1. Stir magnetically for 10 minutes. The pH of the mixture was adjusted to pH=6 by 5% HCl. Put into 60 degree water bath then, continue to carry out magnetic stirring, stirring speed 300 revs per minute, stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com