Electrolyte composition, polymer electrolyte membrane, polymer electrolyte and preparation method thereof, all-solid-state battery and preparation method thereof

An electrolyte and composition technology, applied in the field of all-solid-state batteries, can solve the problems affecting the uniformity of the battery, poor uniformity of the pole piece, large particles of the positive electrode material, etc., so as to improve the production/manufacturing efficiency, improve the operability, and simplify the manufacturing process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

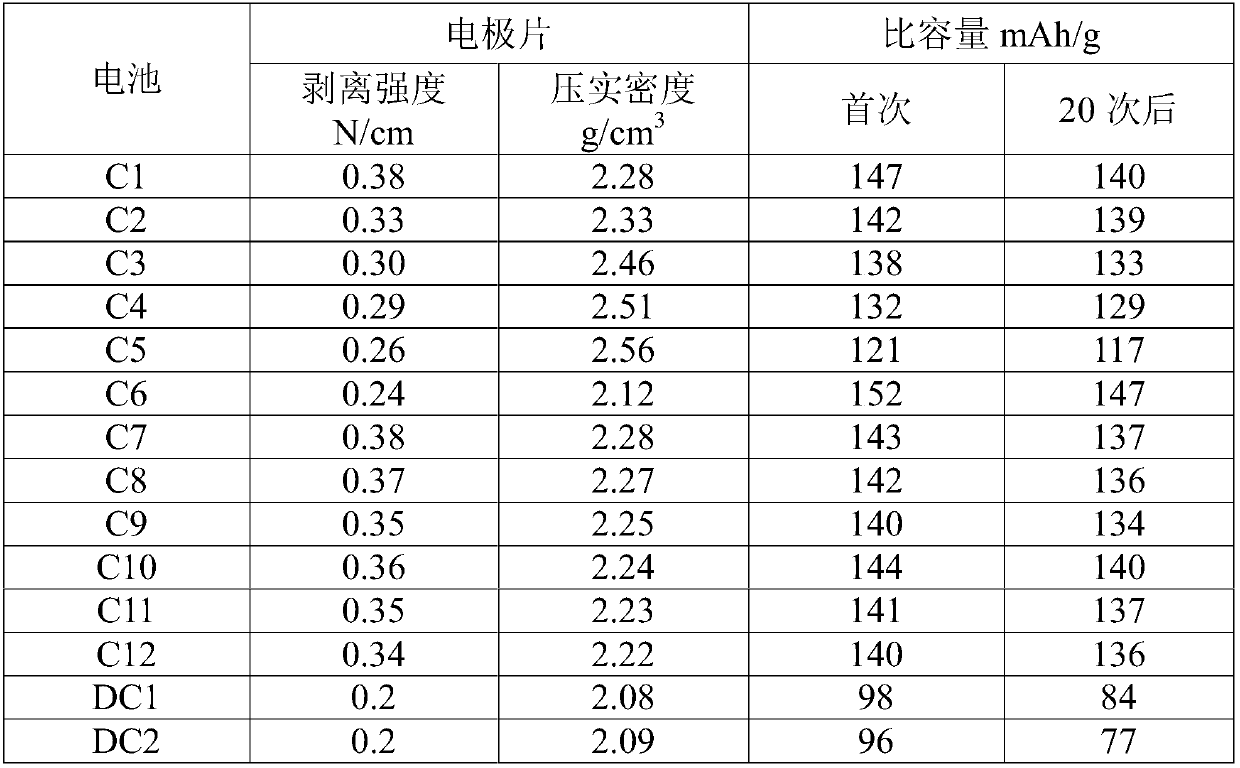

Examples

preparation example Construction

[0036] In a third aspect, the present invention also provides a method for preparing a polymer electrolyte, wherein the preparation method includes: providing an electrolyte slurry containing the above-mentioned electrolyte composition, and then drying to form a film.

[0037] According to the preparation method of the present invention, wherein the method comprises:

[0038] (1) providing an electrolyte slurry containing the above-mentioned electrolyte composition;

[0039] (2) The slurry is cast and molded to obtain a semi-dry film;

[0040] (3) Cross-linking and curing the semi-dry film.

[0041] According to the preparation method of the present invention, in step (1), the solid content of the electrolyte slurry is 1-50%.

[0042] According to the preparation method of the present invention, in step (1), an initiator is also included, which is equivalent to 100 parts by weight of the electrolyte composition, and the content of the initiator is 2-15 parts by weight, and t...

Embodiment 1

[0088] This example is used to illustrate the polymer electrolyte of the present invention and its preparation method and all-solid-state battery and its preparation method.

[0089] Preparation of battery positive sheet:

[0090] (1) 50 parts by weight of the positive electrode material LiFePO 4 , 12.5 parts by weight of copolymer 1#, 6.1 parts by weight of lithium salt LiN(SO 2 CF 2 CF 3 ) 2 , 5.2 parts by weight of pentaerythritol tetraacrylate, 1.2 parts by weight of 2-hydroxyl-2-methylpropiophenone, 15 parts by weight of ionic liquid L1 (1-vinyl-2-ethylimidazole), 5 parts by weight of Polyvinylidene fluoride and 5 parts by weight of conductive graphite are dispersed in 200 parts by weight of N-methylpyrrolidone solvent to obtain positive electrode slurry;

[0091] (2) Coat the positive electrode slurry on both sides of aluminum foil (thickness 20 μm), dry at 60°C for 1 hour, then irradiate with a UV curing instrument for 5 minutes, then continue to dry at 60°C for 24...

Embodiment 2

[0098] This example is used to illustrate the polymer electrolyte of the present invention and its preparation method and all-solid-state battery and its preparation method.

[0099] Preparation of battery positive sheet:

[0100] (1) 60 parts by weight of the positive electrode material LiCoO 2 , 10 parts by weight of copolymer 2#, 4.88 parts by weight of LiN(SO 2 CF 2 CF 3 ) 2 , 4.16 weight parts of pentaerythritol tetraacrylate, 0.96 weight parts of 4-dimethylamino ethyl benzoate, 15 weight parts of ionic liquid L1, 5 weight parts of polyvinylidene fluoride and 4 weight parts of conductive carbon black dispersion In 240 parts by weight of N,N-dimethylformamide solvent, obtain positive electrode slurry;

[0101] (2) Coat the positive electrode slurry on both sides of the aluminum foil (thickness 20 μm), dry at 60°C for 1 hour, then irradiate with a UV curing instrument for 10 minutes, then continue to dry at 60°C for 24 hours, and roll it into a battery positive sheet. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com