Patents

Literature

202 results about "Ethyl benzoate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethyl benzoate, C₉H₁₀O₂, is the ester formed by the condensation of benzoic acid and ethanol. It is a colorless liquid that is almost insoluble in water, but miscible with most organic solvents. As with many volatile esters, ethyl benzoate has a pleasant odor described as sweet, wintergreen, fruity, medicinal, cherry, and grape. It is a component of some fragrances and artificial fruit flavors.

Patterning process

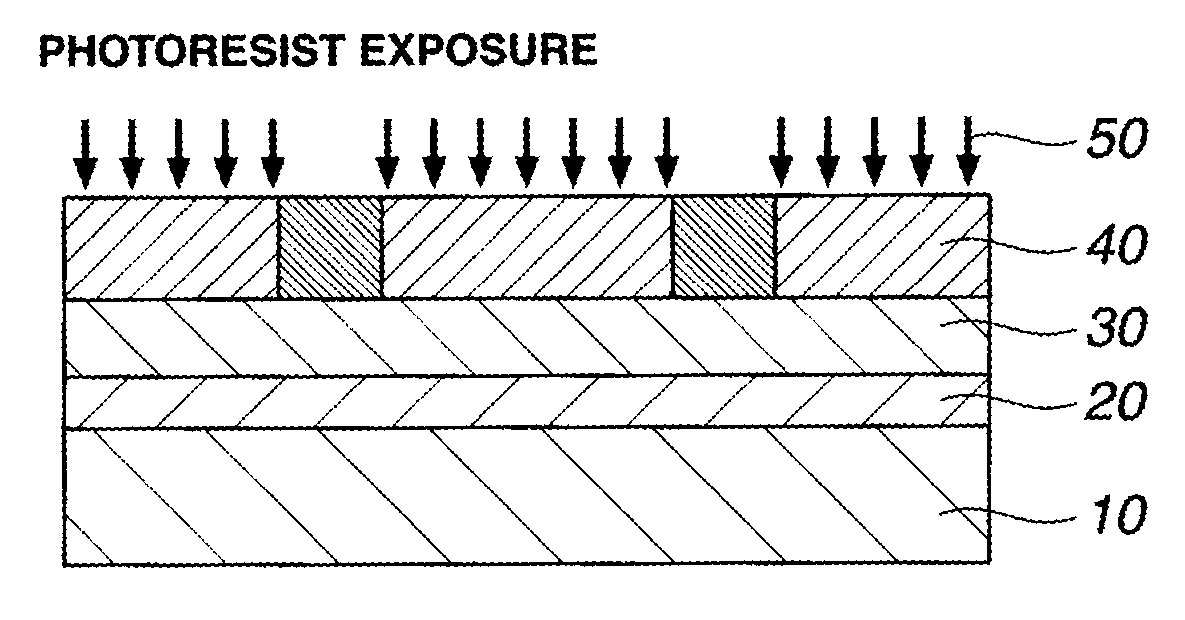

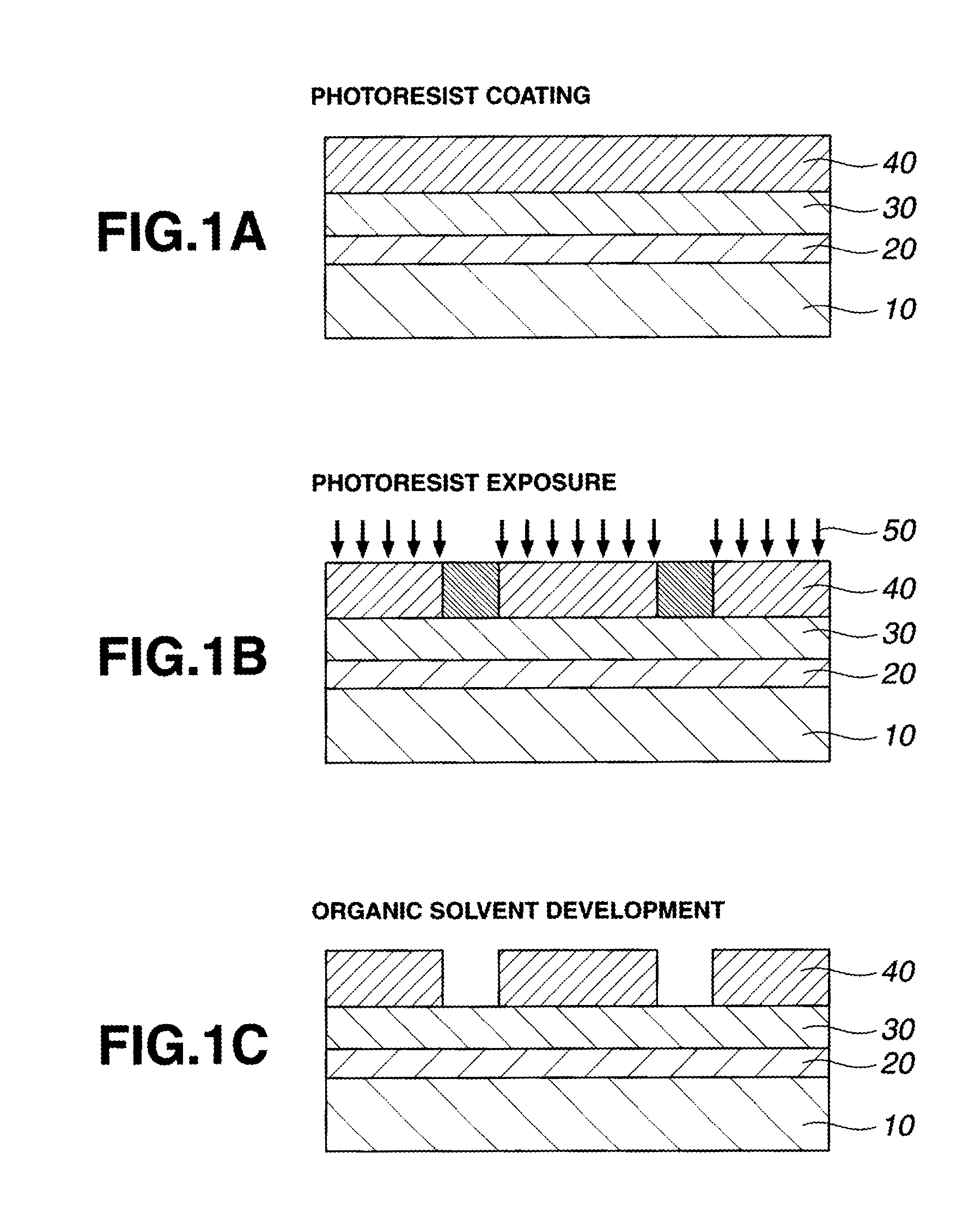

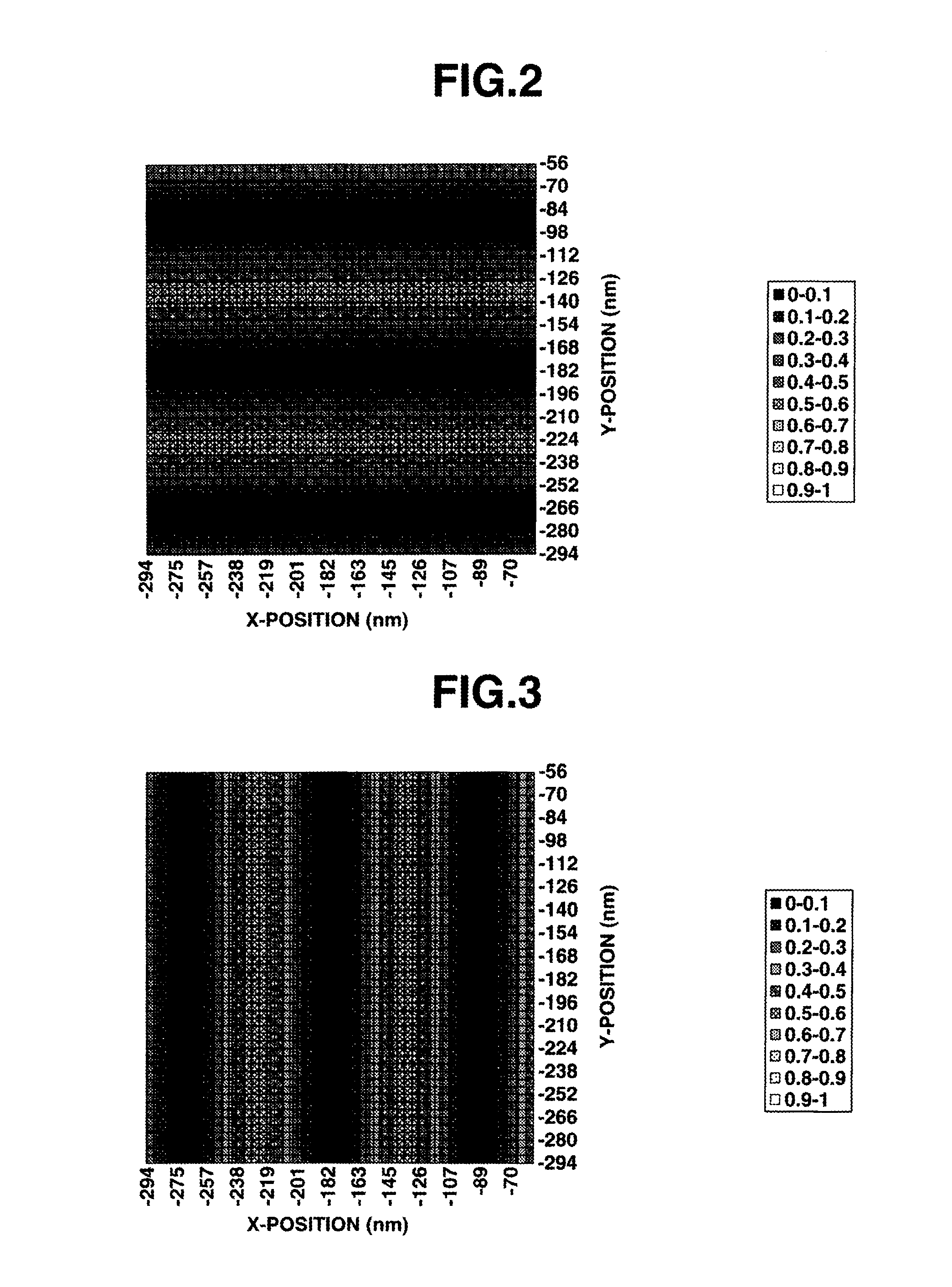

ActiveUS20120009529A1High dissolution contrastIncrease contrastPhotomechanical exposure apparatusMicrolithography exposure apparatusResistMeth-

A pattern is formed by applying a resist composition comprising a (meth)acrylate copolymer comprising both recurring units having an acid labile group-substituted carboxyl group and recurring units having a lactone ring, an acid generator, and an organic solvent onto a substrate, prebaking the composition to form a resist film, exposing the resist film to high-energy radiation, baking, and developing the exposed film with a developer. The developer comprises at least 40 wt % of an organic solvent selected from methyl benzoate, ethyl benzoate, phenyl acetate, benzyl acetate, methyl phenylacetate, benzyl formate, phenylethyl formate, methyl 3-phenylpropionate, benzyl propionate, ethyl phenylacetate, and 2-phenylethyl acetate.

Owner:SHIN ETSU CHEM IND CO LTD

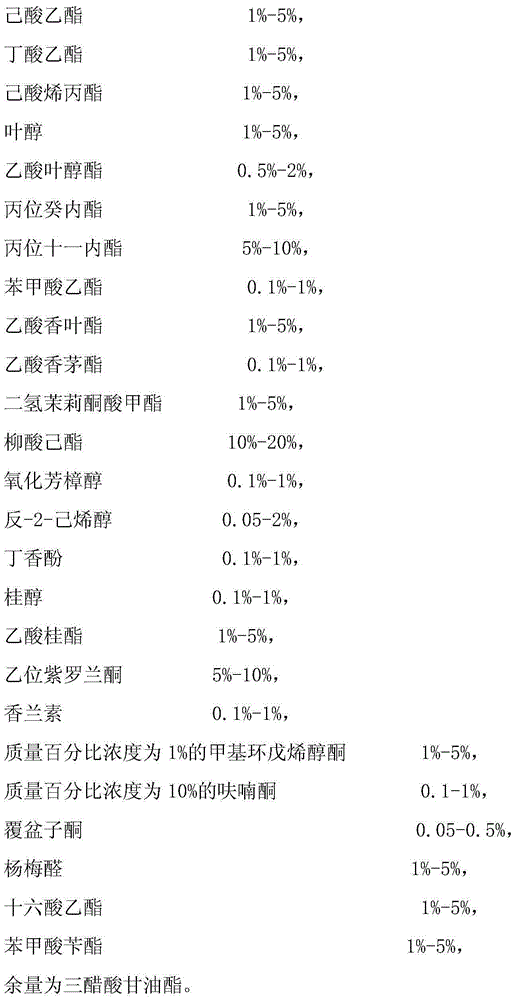

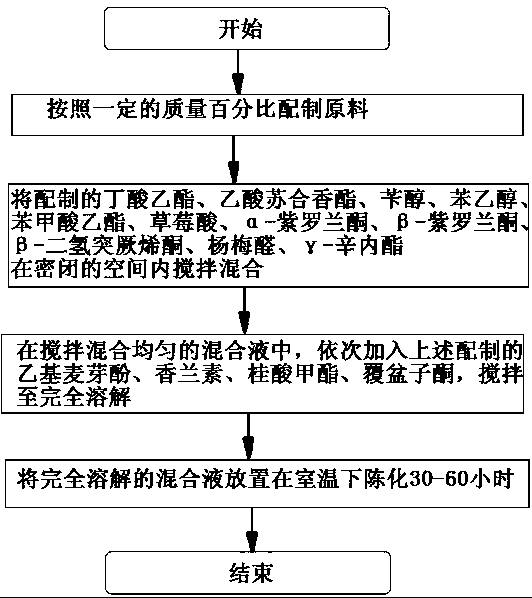

Preparation method of essence for electronic cigarette with strawberry flavor

ActiveCN103849465AIntense, mellow and long-lastingThe process is easy to controlTobacco devicesEssential-oils/perfumesPhenethyl alcoholEthyl butyrate

The invention relates to a preparation method of essence for an electronic cigarette with strawberry flavor. The preparation method comprises the following steps: a first step of preparing materials according to a certain mass percent; a second step of stirring and mixing prepared ethyl butyrate, styralyl acetate, benzyl alcohol, phenethyl alcohol, ethyl benzoate, strawberry acid, alpha-ionone, beta-ionone, beta-dihydrogen damascenone, waxberry aldehyde and gamma-octyl lactone in sealed space; a third step of adding the prepared ethyl maltol, vanillin, methyl cinnamate and raspberry ketone in the uniformly stirred and mixed liquor in sequence, and stirring until dissolving completely; and a fourth step of placing the completely dissolved liquor under the room temperature for ageing for 30 hours-60 hours. According to the preparation method disclosed by the invention, the whole process is simple and controllable, the prepared electronic cigarette has special thick fresh strawberry flavor which is strong and mellow, and lasting, so that breath of a user is fresh.

Owner:ENSHI JINHUA BIOLOGICAL ENG

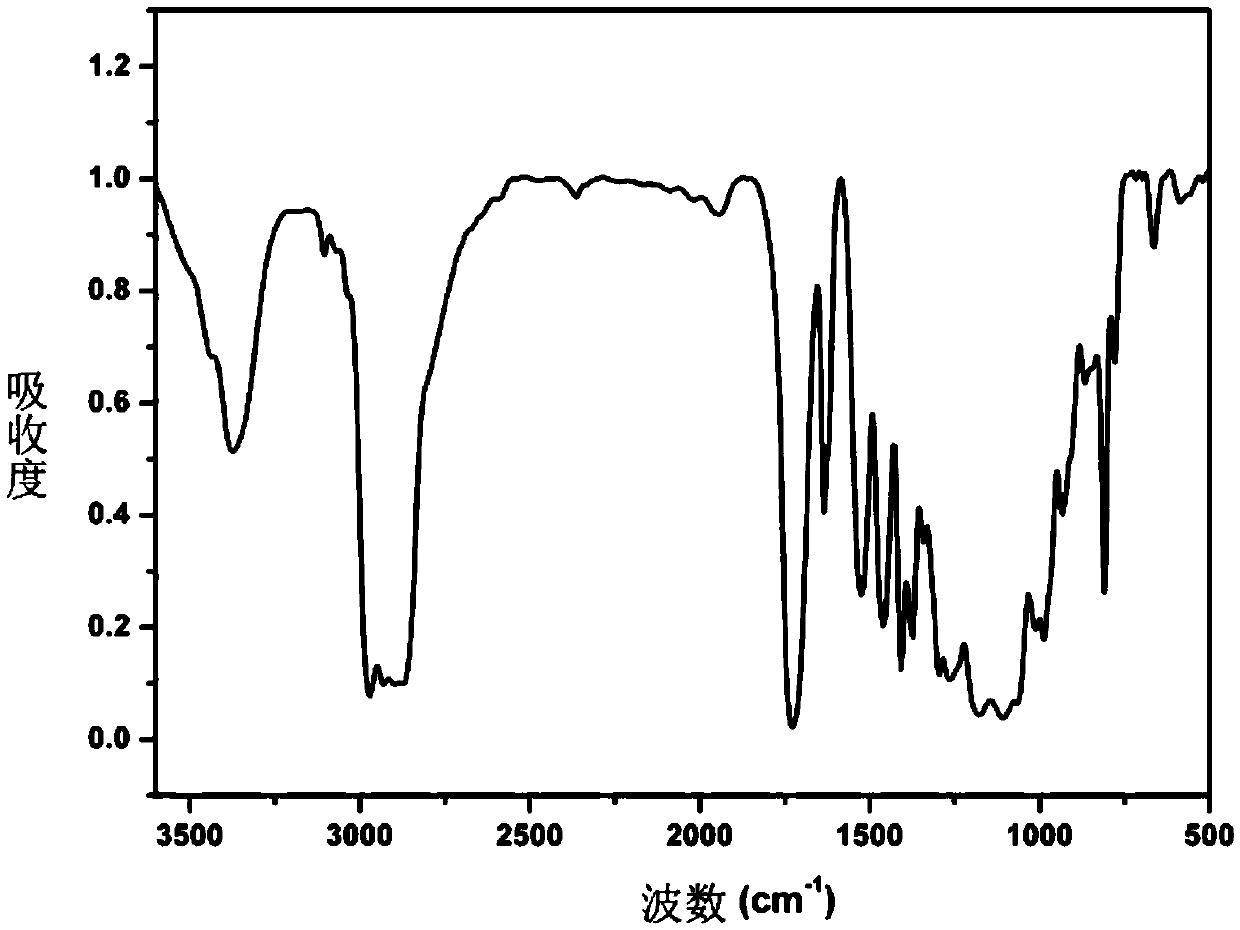

Crystals and process of making 5-({[2-amino-3-(4-carbamoyl-2,6-dimethyl-phenyl)-propionyl]-[1-(4-phenyl-1H-imidazol-2-yl)-ethyl]-amino}-methyl)-2-methoxy-benzoic acid

Owner:FOREST TOSARA +1

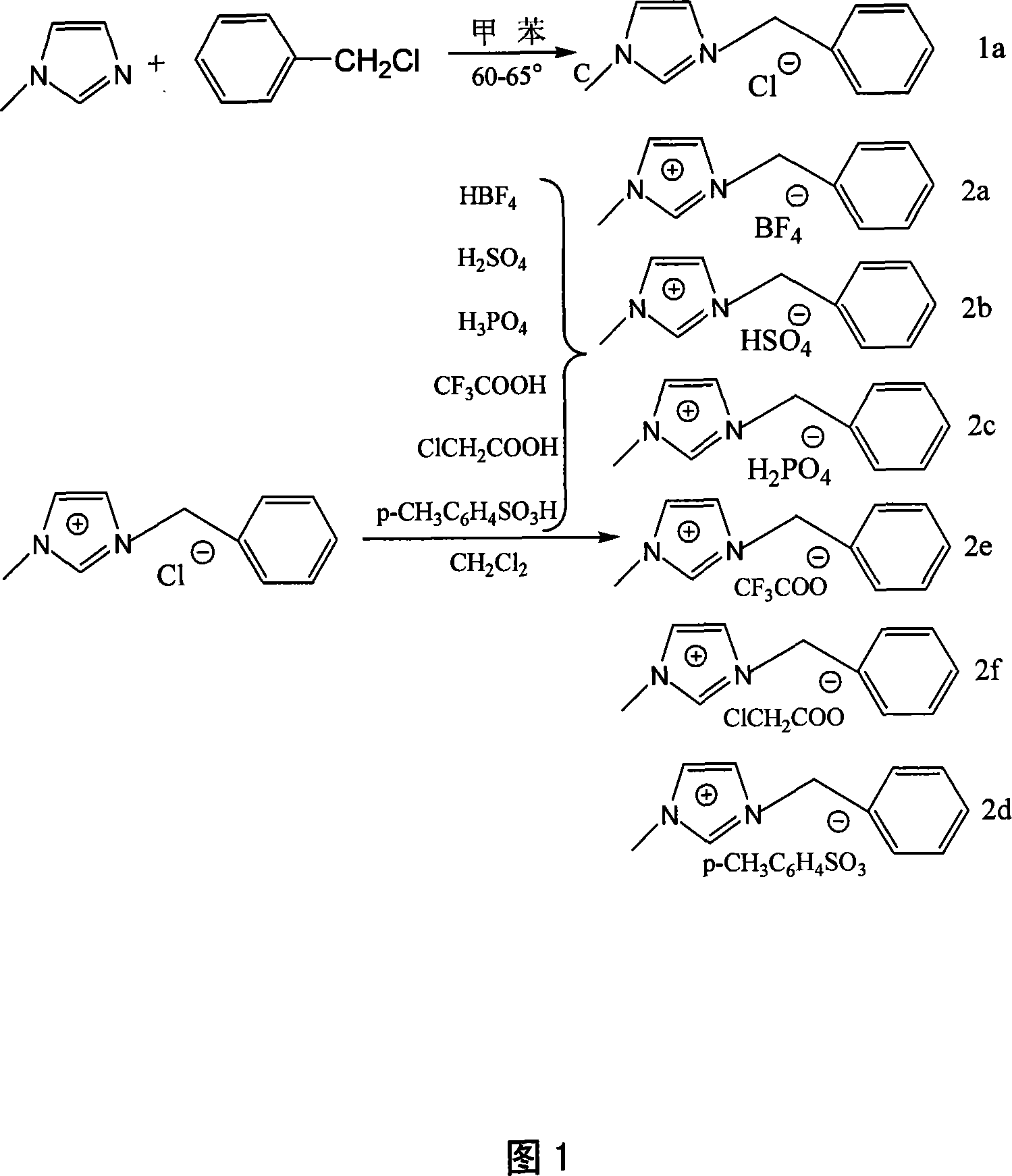

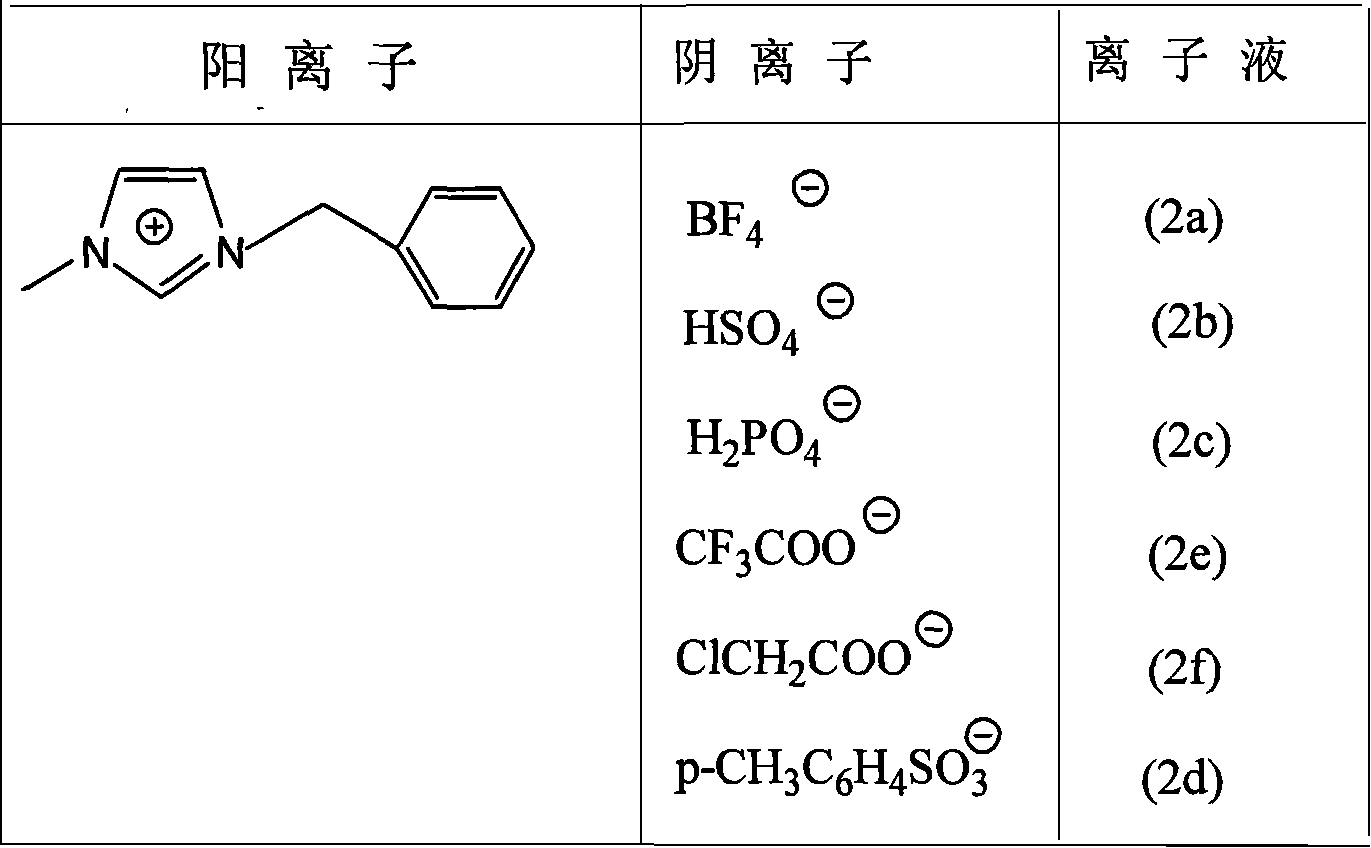

Acidic ionic liquid based on 1-methyl-3-benzyl imidazole cation, synthetic method and use

InactiveCN101058560AAchieve green synthesisEasy to separateOrganic compound preparationCarboxylic acid esters preparationInto-structureSolvent

The invention discloses an acid ion liquid and synthesizing method and application based on 1-methyl-3-benzyl imidazole cation, which is 1-methyl imidazole benzyl methylation organic cation, wherein the inorganic / organic anion is BF4<->,HSO4<->, H2PO4<->, p-CH3C6H4SO<3->, CF3COO<-> and ClCH2COO<->, wherein the ion liquid is liquid phase under indoor temperature, which can repair structure as mother compound due to leading functional group into structure, such as benzene ring, methylene and so on; the BrPhinsted acid can be repeating ring, reacting dielectric and reacting catalytic, which can be used to synthesize important perfume and solvent.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Aerated concrete block and preparation method thereof

InactiveCN107216102AHigh compressive strengthGood heat and sound insulationCeramic shaping apparatusCeramicwareBenzoic acidSlag

The invention discloses an aerated concrete block and a preparation method thereof, and relates to the technical field of building materials. The aerated concrete block is prepared from the following raw materials: modified pulverized fuel ash, slag Portland cement, kaolin, polypropylene fibers, baryta feldspar powder, aerated aluminum powder, heulandite powder, tetrachloroisophthalonitrile emulsion, benzoic acid, ethyl paraben, dimethyl sulfoxide, an early strength agent, a water reducing agent, a water addition agent, a foaming agent and a foam stabilizer. The preparation method comprises the steps of firstly, evenly stirring and mixing the raw materials to prepare slurry, then carrying out pouring, initial curing treatment, cutting and autoclaved curing on the slurry to obtain the aerated concrete block. The aerated concrete block is high in compression strength, good in heat resistance and sound insulation, small in drying shrinkage value, excellent in water resistance, simple to prepare, wide in raw material sources, and low in cost, thus being suitable for being popularized and used.

Owner:肥西县碧涛建材有限公司

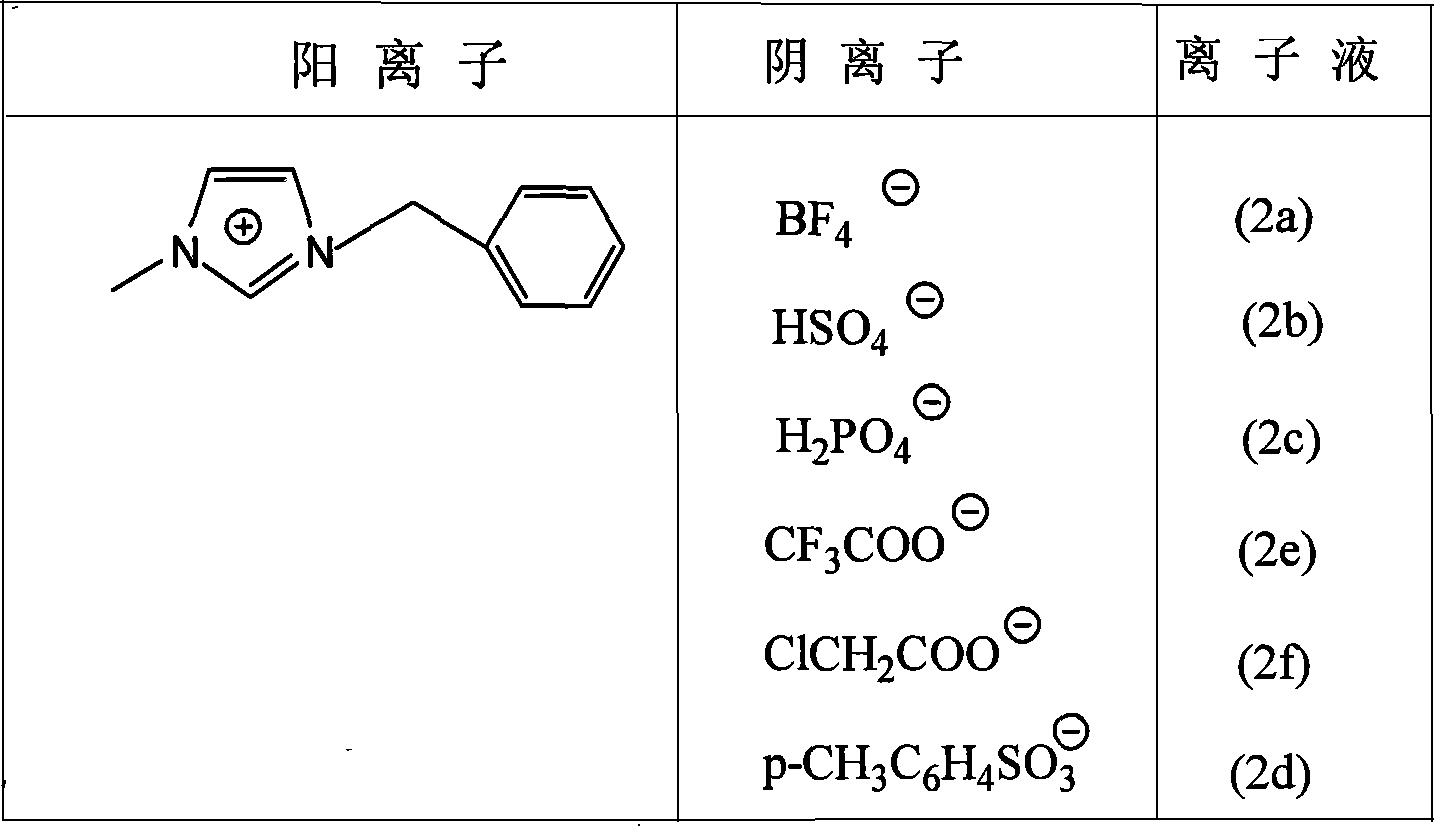

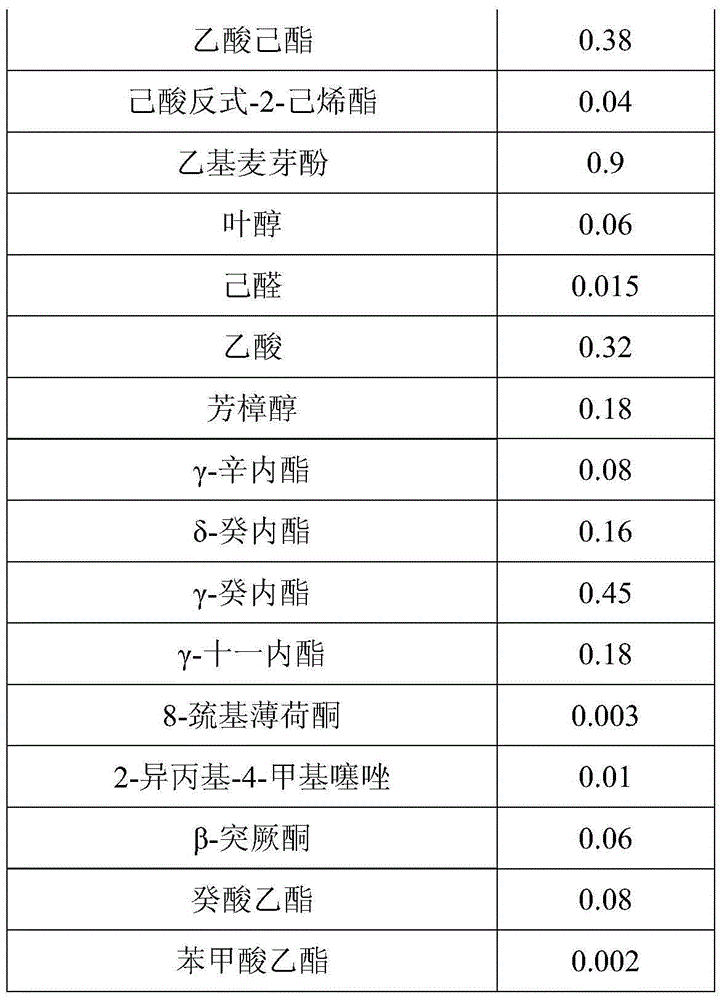

Peach essence

ActiveCN104957584AReduce manufacturing costBroad sales marketFood ingredientsFood preparationAdditive ingredientPhenylacetic acid

The invention discloses a peach essence. The peach essence consists of the following ingredients: propanediol, hexanol, hexenyl phenylacetate, benzaldehyde, ethyl acetate, phenylacetic acid cis-3-ester hexane, methyl acetate, hexyl acetate, hexyl trans-2-ester hexane, ethyl maltol, leaf alcohol, hexanal, acetic acid, linalool, gamma-caprylolactone, theta-decalactone, gama-decalactone, gamma-undecalactone, 8-mercaptomenthone, 2-isopropyl-4-methylthiazole, beta- damascenone, ethyl caprate and ethyl benzoate. The peach essence is moderate in fragrance, saturated, thick, stable in quality, natural in flavor and approximat to the natural fragrance of peach.

Owner:ZHEJIANG GREEN CRYSTAL FLAVOR

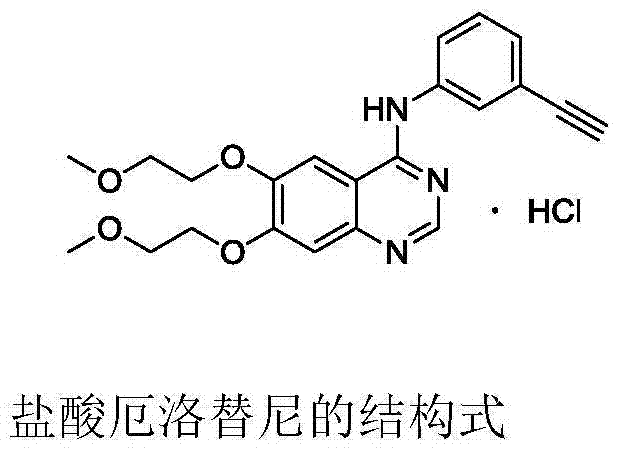

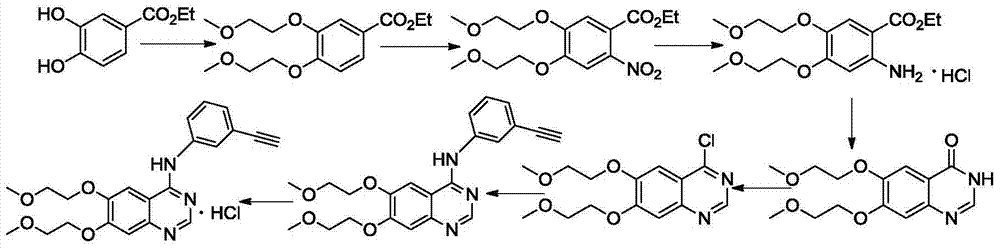

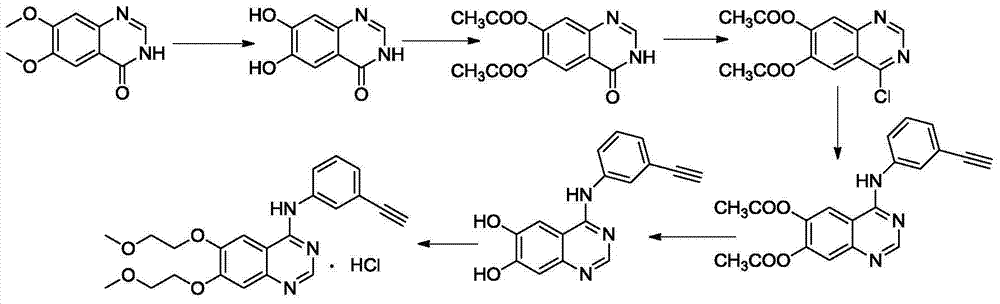

Environment-friendly method for preparing high-yield erlotinib hydrochloride

The invention discloses an environment-friendly method for preparing high-yield erlotinib hydrochloride. The method comprises the following steps: directly performing cyclic condensation by taking 2-amino-4,5-di(2-methoxy ethyoxyl) ethyl benzoate hydrochloride as a key intermediate, reacting with aminophenylacetylene to generate erlotinib hydrochloride after performing chlorination, and refining to obtain the high-purity erlotinib hydrochloride. The process route provided by the invention is mild in reaction condition and high in yield; the first-class reagent and other reagents harmful to the environment and the operators are not used, the byproduct is few, the aftertreatment is simple and the commercial process can be easily processed.

Owner:SHANDONG UNIV +1

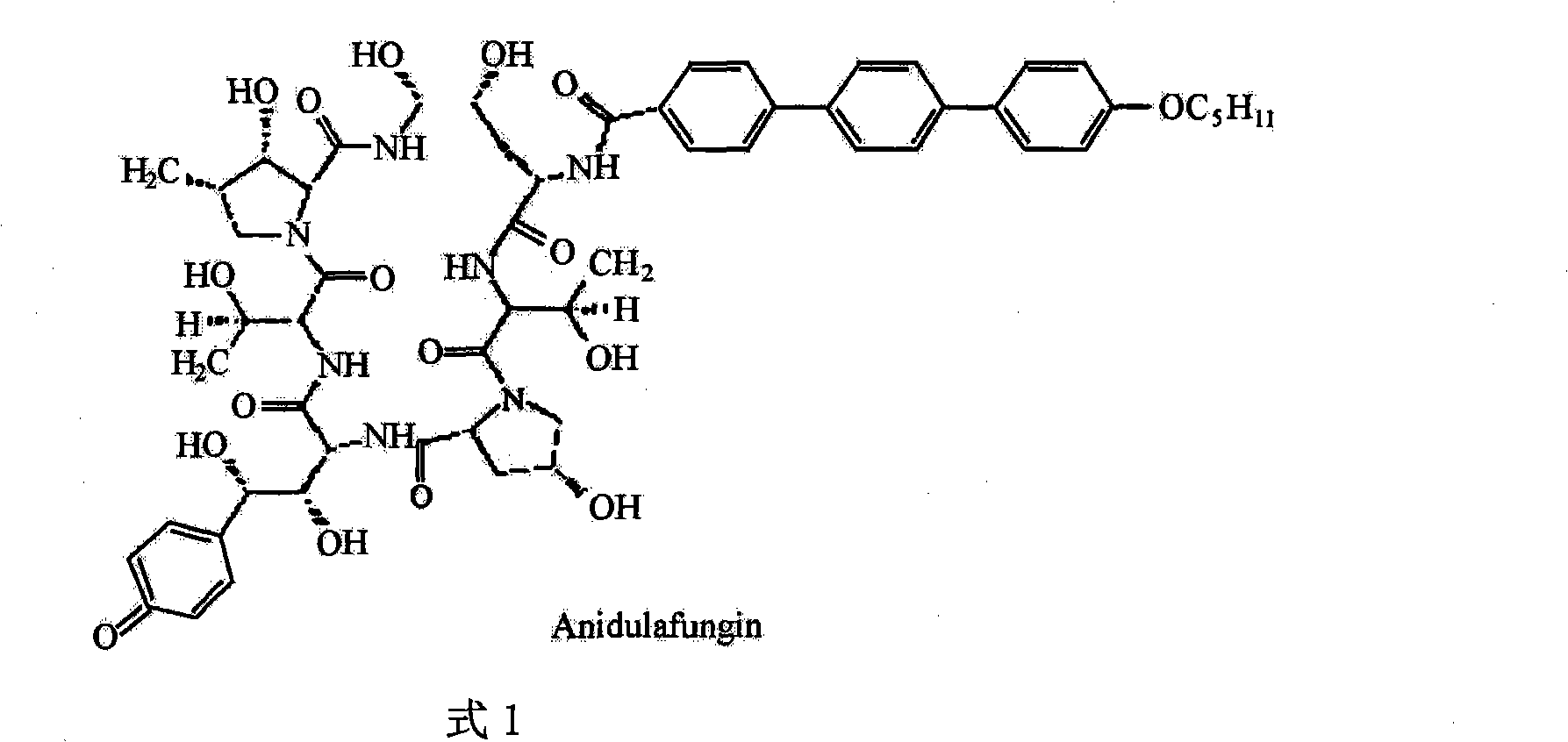

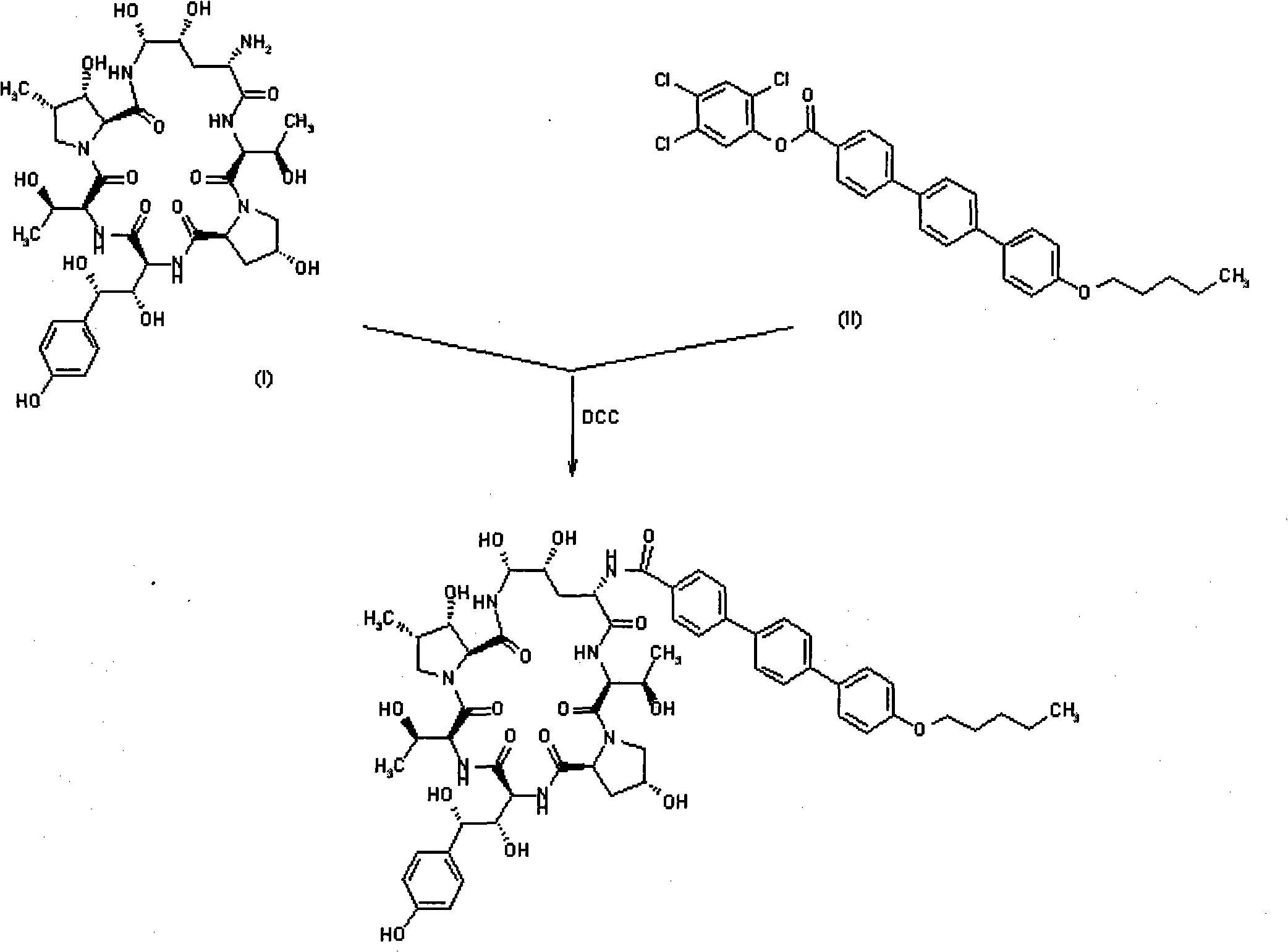

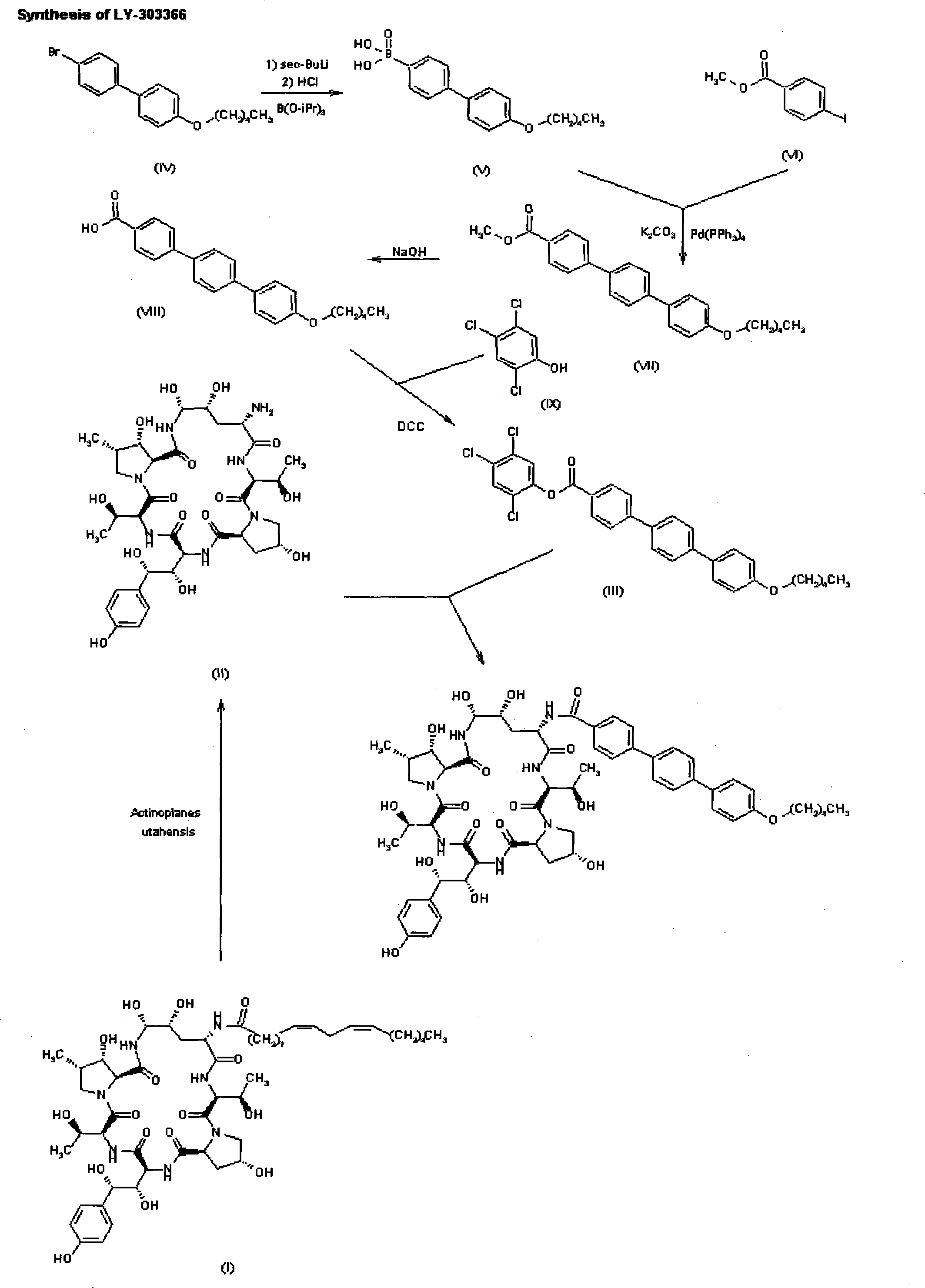

Preparation method of anidulafungin side chain intermediate

ActiveCN103570530ASafe preparationReduce usageOrganic compound preparationCarboxylic acid esters preparationSide chainGrignard reagent

The invention belongs to the field of medicine synthesis and specifically relates to a preparation method of an anidulafungin side chain intermediate 4'-orthopentyloxy-1,1':4',1'-terphenyl-4-carboxylic acid. The preparation method comprises the following steps: initiating a 1,4-dibromo-benzene material which serves as a starting material to carry out Grignard reagent reaction with magnesium by iodine; then, preparing 1,4-benzene hypoboric acid by virtue of addition and hydrolysis with trimethyl borate; and preparing 4'-orthopentyloxy-1,1':4',1'- terphenyl-ethyl carboxylate by virtue of Suzuki reaction of 1,4-benzene hypoboric acid, 4-pentyloxy bromobenzene and 4-halogenated ethyl benzoate in dioxane-ethanol liquor under catalysis of [1,1'-bis(diphenyl phosphino) ferrocene] palladium dichloride, and then, hydrolyzing to obtain a target product. The preparation method disclosed by the invention can lower process cost, is simple, convenient, safe and reliable to operate, and suitable for industrial production.

Owner:鲁南新时代生物技术有限公司

Composition for hard article surface cleaning liquid

InactiveUS7030070B2Organic detergent compounding agentsEssential-oils/perfumesSurface cleaningDamascone

A fragrant compound or fragrant composition stable for a long period of time in an acidic hard article surface cleaning liquid adjusted so as to be acidic, particularly to pH 2.0 to 3.0 with an organic acid. One or more of fragrant compounds selected from the group consisting of 2,6-dimethyl-2-heptanol, 3,3-dimethylcyclohexyl methyl ketone, o-tert-butylcyclohexanol, α-amylcinnamic aldehyde, α-damascone, γ-octalactone, γ-nonalactone, γ-decalactone, anethole, ethyl benzoate, ethyl 2,2,6-trimethylcyclohexanecarboxylate, 2,2,6-trimethyl-1-crotonylcyclohexane, 6-acetyl-1,1,2,4,4,7-hexamethyltetrahydronaphthalene, isoamyl phenylethyl ether, methyl octin carbonate, 6,7-dihydro-1,1,2,3,3-pentamethyl-4(5H)-indanone, tricyclodecenyl acetate, undecyl aldehyde, fenchyl acetate, dihydrojasmone, cedryl methyl ether, p-cresol, hexyl aldehyde, and rosephenone are stable.

Owner:TAKASAGO INTERNATIONAL CORPORATION

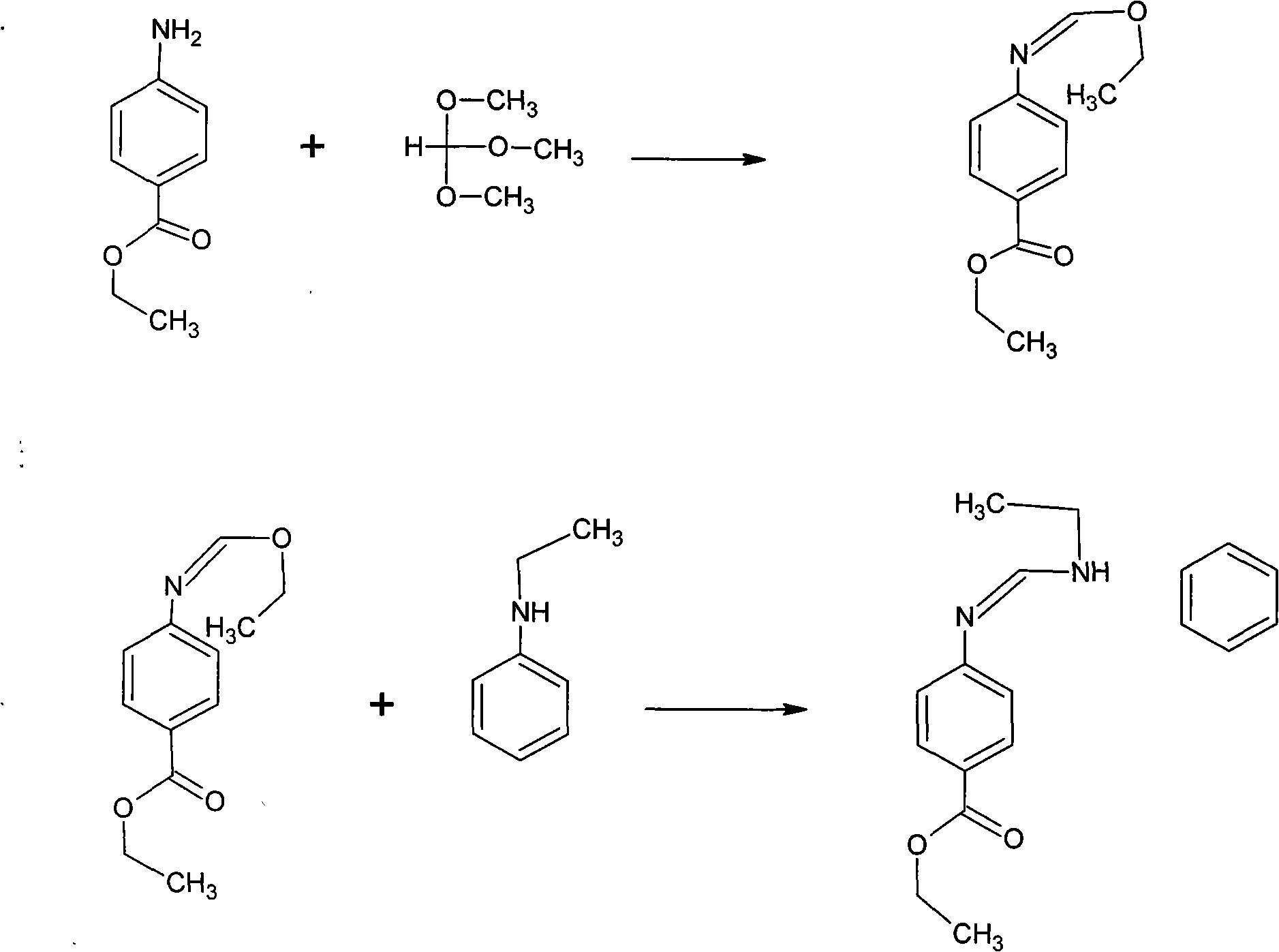

Preparation method of N-(4-ethoxycarbonylphenyl)-N'-ethyl-N'-phenylformamidine

The invention relates to a preparation method of N-(4-ethoxycarbonylphenyl)-N'-ethyl-N'-phenylformamidine, comprising the following steps of: simultaneously adding raw materials which are para-amino ethyl benzoate, tri-alkyl ortho-formate and N-ethylphenylamine into a reaction kettle, mixing and performing one-step condensation in the reaction kettle at 80 to 160 DEG C; distilling a reaction liquid under reduced pressure to produce a distilled product of the N-(4-ethoxycarbonylphenyl)-N'-ethyl- N'-phenylformamidine and then refining with alcohol to produce a finished product of the N-(4-ethoxycarbonylphenyl)-N'-ethyl- N'-phenylformamidine. The method lowers the reaction temperature, reduces the reaction step, improves the purity of product, reduces the pollution and equipment investment, saves labor and reduces energy consumption and labor intensity, has good product color, high content, low cost and simple operation, and is easy to realize large-scale industrial production.

Owner:遵义市倍缘化工有限责任公司

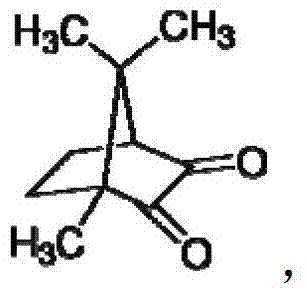

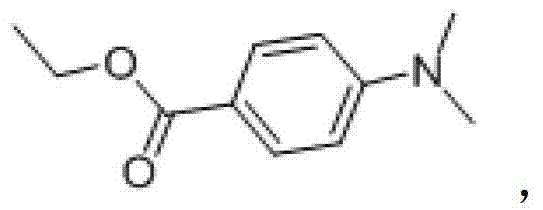

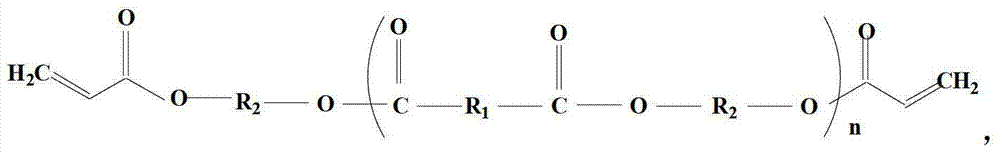

Blue-ray curing formula and textile digital functional finishing method utilizing same

ActiveCN103396698AMeet the requirements of sustainable developmentQuick responsePhysical treatmentInksEthyl benzoateAcetone

The invention relates to a textile photocuring technology and in particular relates to a blue-ray curing formula and a textile digital functional finishing method utilizing the same. The blue-ray curing formula comprises the following components in parts by weight: 0.25-0.5 parts of photoinitiator camphorquinone, 0.25-0.5 parts of auxiliary initiator 4-(dimethylamino) ethyl benzoate, 60-80 parts of oligomer which is acrylate oligomer and 20-40 parts of monomers, wherein the oligomer and the monomers are 100 parts in total. The textile digital functional finishing method which is carried out by utilizing the blue-ray curing formula comprises the following steps of: preparing a reaction liquid after mixing the blue-ray curing formula; diluting the reaction liquid with acetone; then adding a benzotriazole uvioresistant finishing agent to obtain a finishing liquid; adding the finishing liquid into a needle cylinder of a dispensing control system; drawing patterns on the surface of a to-be-finished textile. According to the blue-ray curing formula and the textile digital functional finishing method utilizing the same disclosed by the invention, the conventional thermo-curing way is replaced by the blue-ray curing way, so that sustainable development requirements are satisfied. Moreover, the reaction speed is quick and ranges from a few seconds to hundreds of seconds, the production efficiency is high and ozone exhaustion is avoided.

Owner:浙江中蝶坊新材料科技股份有限公司

Ester plasticizer

The invention discloses an ester plasticizer which consists of the following raw materials in parts by mass: 15-20 parts of epoxidized fatty acid methyl ester, 10-15 parts of p-hydroxybenzoic acid, 10-15 parts of DOP, 10-12 parts of dioctyl sebacate, 8-10 parts of trioctyl trimellitate, 10-15 parts of dioctylterephthalate, 8-10 parts of ethyl benzoate, 10-12 parts of methyl parahydroxybenzoats, 5-10 parts of white carbon black, 5-8 parts of nano carbon fibers, 6-8 parts of diethylene glycol, 7-9 parts of 2-propanol, 8-12 parts of hydrogen peroxide, 8-10 parts of petroleum resin and 6-10 parts of glycerinum. The ester plasticizer is low in cost, non-toxic, harmless, high in performance, high in plasticization efficiency, cold-resistant, heat-resistant, fouling resistant, anti-extraction, high in mobility, high in electric insulation property and stable to light and heat.

Owner:司徒建辉

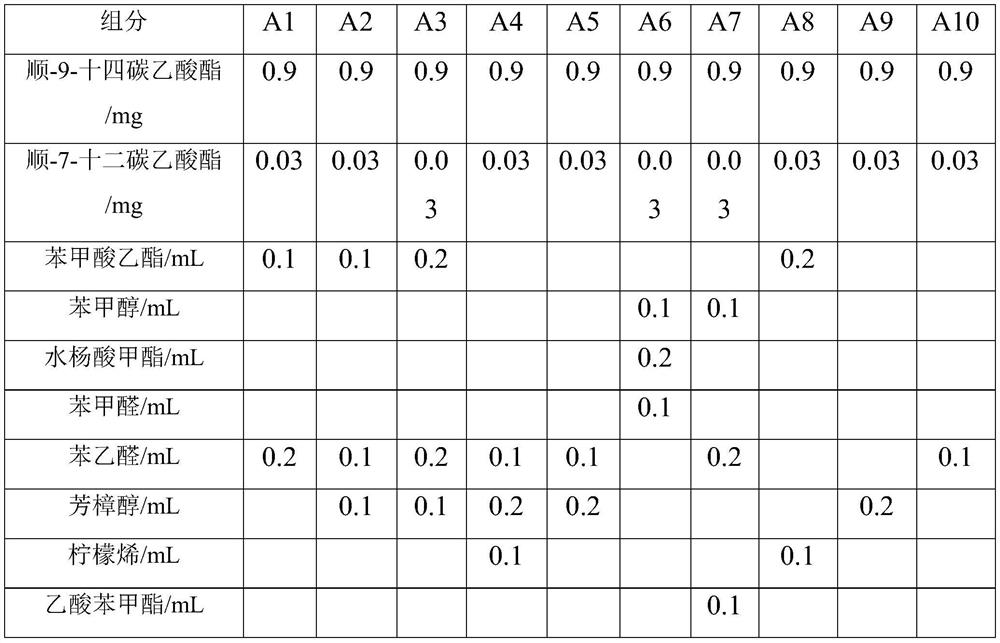

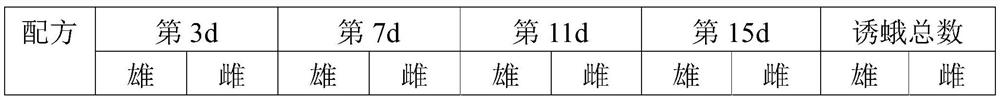

Grassland spodoptera litura adult attractant and trapping device containing attractant

ActiveCN111685118AGood lure effectSolve the difficulty that is hard to lureBiocidePest attractantsBenzoic acidDodecane

The invention relates to a grassland spodoptera litura adult attractant based on a plant volatile matter and a trapping device comprising the grassland spodoptera litura adult attractant. The grassland spodoptera litura adult attractant is composed of a sex attractant and the plant smell volatile matter. The sex attractant is prepared from cis-9-tetradecane acetate and cis-7-dodecane acetate; theplant smell volatile matter is one or more of ethyl benzoate, benzyl alcohol, methyl salicylate, benzaldehyde, phenylacetaldehyde, limonene, linalool and benzyl acetate. The adult attractant for the grassland spodoptera litura has a good attracting effect on the grassland spodoptera litura through synergistic interaction of the sex attractant and the plant smell volatile matter, can attract part of female insects, can be used for monitoring and large-area prevention and control of the grassland spodoptera litura, and has a good application prospect.

Owner:漳州市英格尔农业科技有限公司

Guava essence formula

ActiveCN101070509AKeep natural propertiesNatural aromaEssential-oils/perfumesFood additiveEthyl butyrate

This invention publicized the formula of one kind guava essence, which was mainly composed by trim ethylene glycol, the ethyl benzoate, citral, ethyl acetate, ethyl butyrate, phytol, ethanoic acid leaf alcohol ester, lactic acid ethyl ester, lauric acid ethyl ester, using the inherent fragrance compound in the natural guava juice to draw up the formula to make the guava essence. Take the guava essence as food additive to use, then strengthen final product flavor of the food and the drink, and bring the natural feeling taste. It make the taste and fragrance quality to be higher than the domestic similar essence level.

Owner:SHANGHAI BAIRUN INVESTMENT HLDG GRP CO LTD

Triethyleneglycol ester based plasticizer composition for polyvinyl chloride resin and method of preparing the same

ActiveUS20060229394A1Organic compound preparationCarboxylic acid esters preparationPlasticizerPolyvinyl chloride

Provided is a novel triethyleneglycol based compound, a plasticizer composition for polyvinyl chloride resin including the same, and a method of preparing the plasticizer composition. In particular, the plasticizer composition for polyvinyl chloride resin includes the novel compound, 2-(2-(2-(2-ethylhexanoyloxy)ethoxy)ethoxy)ethyl 2-ethylhexanoate, and 2-(2-(2-phenylcarbonyloxyethoxy)ethoxy)ethyl benzoate in a proper mixture ratio. A polyvinyl chloride prepared using the plasticizer composition has low heating loss, excellent adhesion, high plasticization efficiency, high elongation, high tensile strength, and high transparency.

Owner:LG CHEM LTD

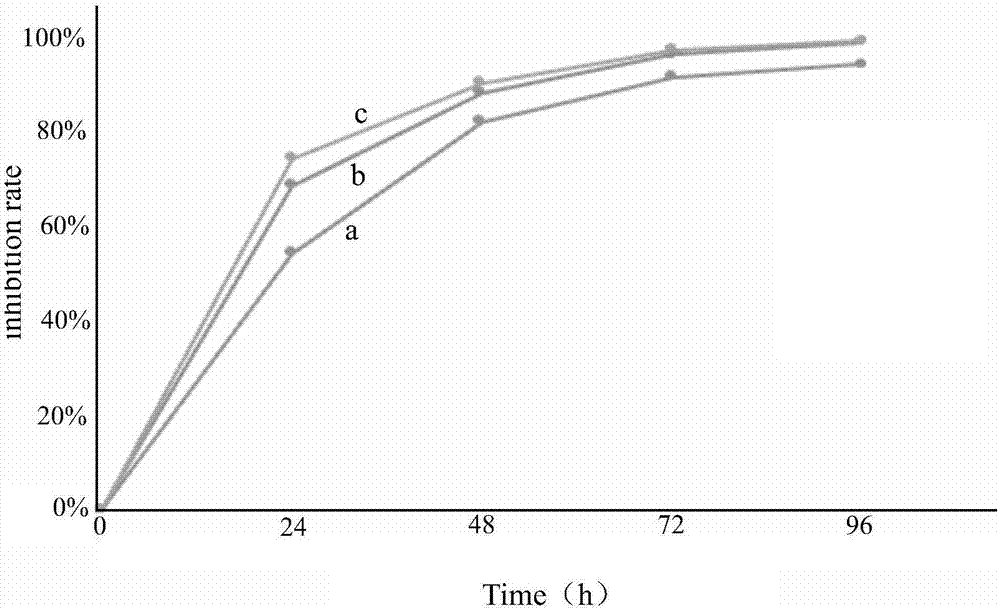

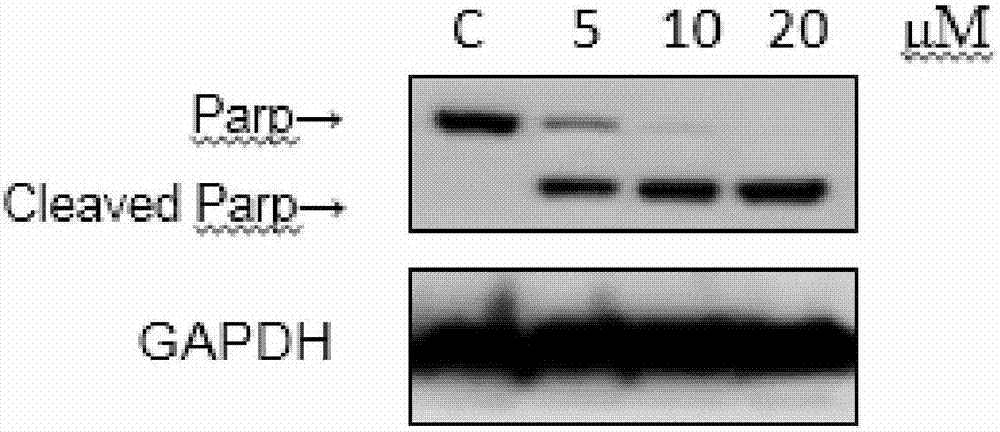

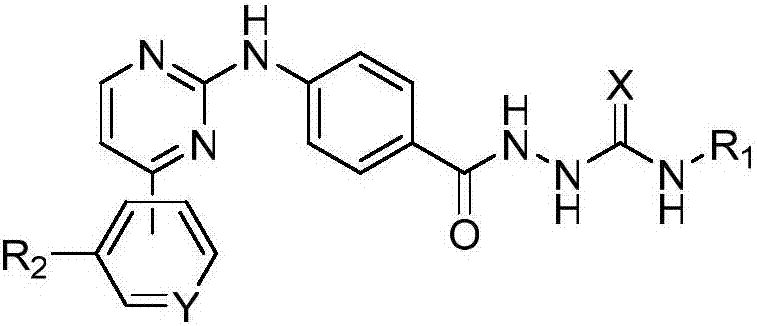

4-((4-substituted aryl-2-pyrimidinyl) amino) benzoyl hydrazide derivative as well as preparation method and application thereof

InactiveCN107056713AImprove responseGrowth inhibitionOrganic active ingredientsOrganic chemistryArylNitrate

The invention provides a 4-((4-substituted aryl-2-pyrimidinyl) amino) benzoyl hydrazide derivative as well as a preparation method and application thereof and relates to a tumor drug. The preparation method comprises the following steps: preparing intermediate p-guanidine benzoate nitrate; preparing intermediate 1-(substituted aryl)-3-(dimethylamino)-2-propylene-1-ketone; preparing intermediate 4-((4-substituted aryl-2-pyrimidinyl) amino) ethyl benzoate; preparing intermediate 4-((4-substituted aryl-2-pyrimidinyl) amino) benzohydrazide; preparing the 4-((4-substituted aryl-2-pyrimidinyl) amino) benzoyl hydrazide derivative. The 4-((4-substituted aryl-2-pyrimidinyl) amino) benzoyl hydrazide derivative can be applied to the preparation of a drug for treating or preventing a tumor-related disease. The 4-((4-substituted aryl-2-pyrimidinyl) amino) benzoyl hydrazide derivative has significant effects of inhibiting tumor cell growth and inducing tumor cell apoptosis and can be used for preparing the drug for treating or preventing the tumor-related disease.

Owner:XIAMEN UNIV

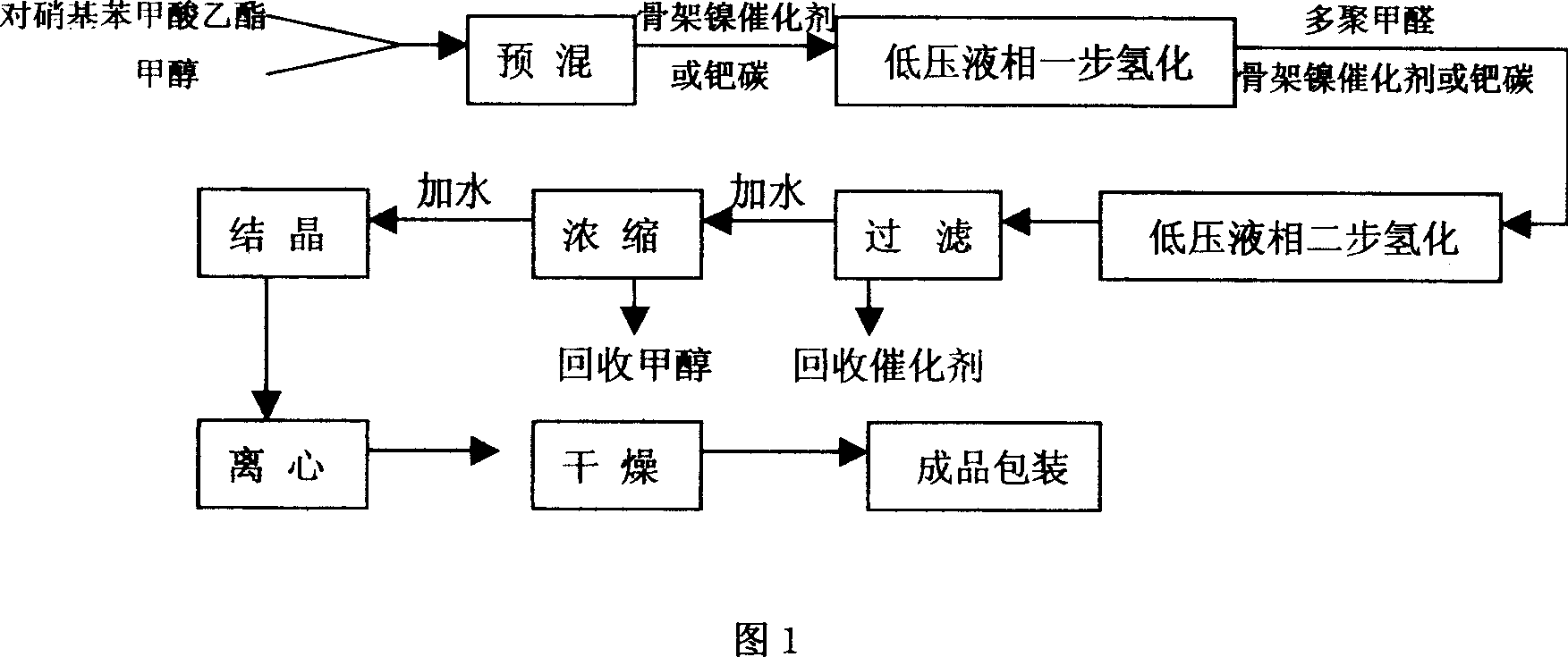

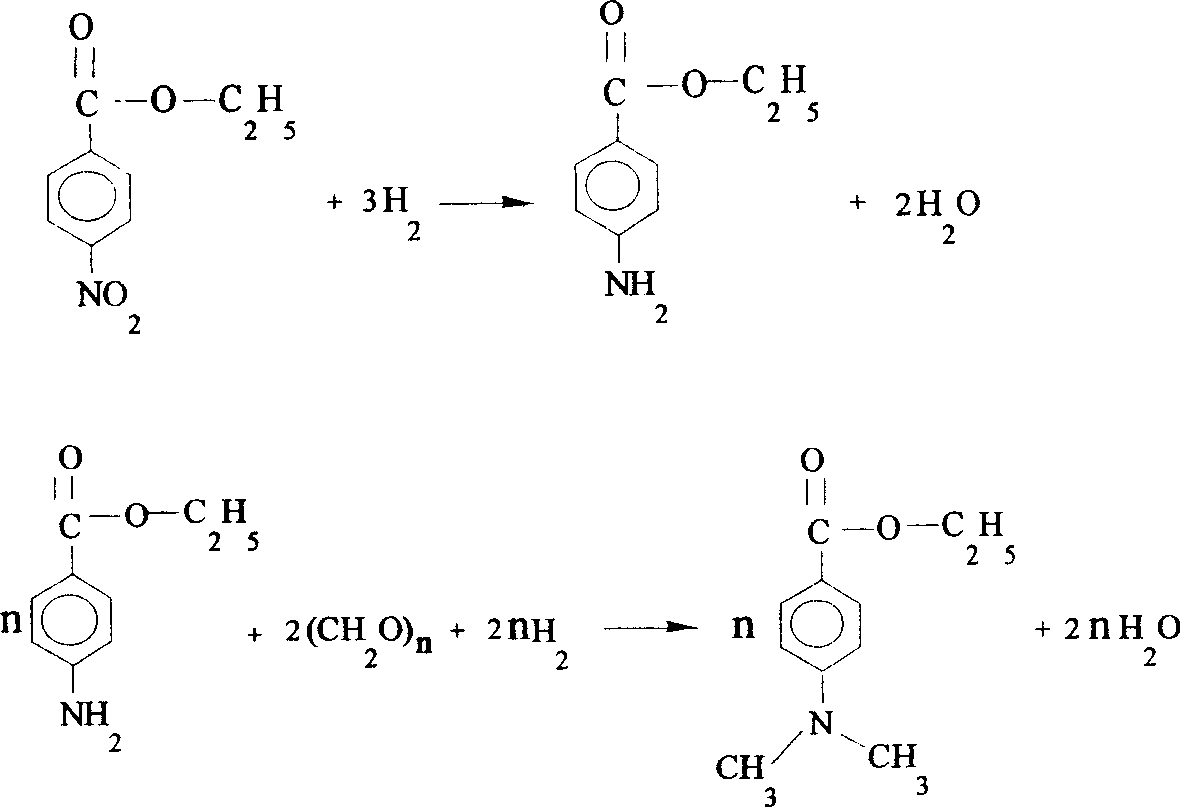

Process for preparing ethyl p-dimethylaminobenzoate

InactiveCN101007773ALow costHigh yieldOrganic compound preparationAmino-carboxyl compound preparationEthyl aminobenzoateEthyl ester

The invention discloses a making method of p-dimethyl ethyl benzoate, which comprises the following steps: preblending ethyl benzoate and carbinol; adding cavaform to do catalytic hydrogenation; filtering; distilling; condensing; crystallizing; drying; obtaining the product.

Owner:吴建龙

Preparation method of ethyl-4-dimethylaminobenzoate intermediate benzocaine

InactiveCN105481707ASolve environmental problemsSimple and fast operationOrganic compound preparationAmino-carboxyl compound preparationBenzoic acidPtru catalyst

The present invention relates to a preparation method of ethyl-4-dimethylaminobenzoate intermediate benzocaine (ethyl-4-aminobenzoate). The specific steps are as follows: adding 4- nitrobenzoic acid, absolute ethyl alcohol, a solid catalyst and a water carrying agent into a reaction vessel with a water separator, wherein the reaction vessel is equipped with the water separator, a reflux condenser and a thermometer; heating, refluxing to separate water, and reacting to no stratification; filtering the reaction solution while hot, adding the reaction solution into a hydrogenation reactor, conducting a hydrogenation reaction by directly using Pd / C until hydrogen-absorption of the system stops, and then insulating for 1 h; filtering, cooling, and precipitating a white solid product of benzocaine with content of more than 99.5%. The method is a pure green route, not only avoids production of a lot of waste acid in the esterification process, but also recycles the solvent and catalyst. The method has the advantages of simple method, mild conditions, continuous two-step reaction, and good prospects in the industry.

Owner:浙江优创材料科技股份有限公司

Hydrophobic resin adhesive, preparation method and application thereof

InactiveCN105368374AImprove wear resistanceImprove adhesionImpression capsPolyureas/polyurethane adhesivesPolyurethane dimethacrylatePhosphate

The invention relates to a resin adhesive material with good hydrophobic performance, a preparation method and an application of the material in filling treatment of tooth hard tissue defects of mouth rehabilitation and belongs to the technical field of stomatological materials. The material is composed of a main component, a diluent and a photoinitiator, wherein the main component is a mixture of isocyanate terminated polyether triol and polyurethane dimethacrylate and accounts for 50-70%; the diluent comprises methyl methacrylate and butyl acrylate which respectively account for 10-20% and 19-27%; and the photoinitiator is a mixed initiation system composed of ethyl-4-dimethylamino ethyl benzoate and camphorquinone and accounts for 1-3%. The material provided by the invention does not contain hydroxyl, carboxyl, phosphate groups and sulfonic groups which are prone to absorb water and swell, has good hydrophobic performance, can effectively prevent infiltration and absorption of water molecules, and meanwhile further has good tensile strength; and the material effectively prevents micro-leakages after repair, so that occurrence of restoration breakage and secondary caries which are common clinically is greatly reduced.

Owner:JILIN UNIV

Strawberry essence for oil-based ink and preparation method of strawberry essence

InactiveCN105132175AIncrease added valueEasy to useInksEssential-oils/perfumesSolubilityCinnamyl acetate

The invention relates to strawberry essence for oil-based ink. The strawberry essence consists of strawberry essence, maltodextrin and starch sodium octenylsuccinate, wherein the strawberry essence consists of ethyl acetate, isoamyl acetate, ethyl caproate, ethyl butyrate, allyl hexanoate, leaf alcohol, cis-3-hexenyl acetate, decalactone, peach aldehyde, ethyl benzoate, geranyl acetate, citronellyl acetate, dihydrojasmonic acid methyl ester, hexyl salicylate, linalool oxide, trans-2-hexenol, eugenol, cinnamyl alcohol, cinnamyl acetate, beta-Ionone, vanillin, methyl cyclopentenolone, furanone, raspberry ketone, ethyl methylphenylglycidate, ethyl palmitate, benzyl benzoate and glycerol triacetate. The invention also provides a preparation method of the strawberry essence for the oil-based ink. The strawberry essence, the maltodextrin, the starch sodium octenylsuccinate and water are mixed; homogenizing and emulsification are performed; then, spray drying is carried out; particular strawberry essence is formed, so that the aroma retaining effect and the oil solubility of the essence are improved; the strawberry essence is applicable to perfuming of the oil-based ink.

Owner:SHANGHAI INST OF TECH

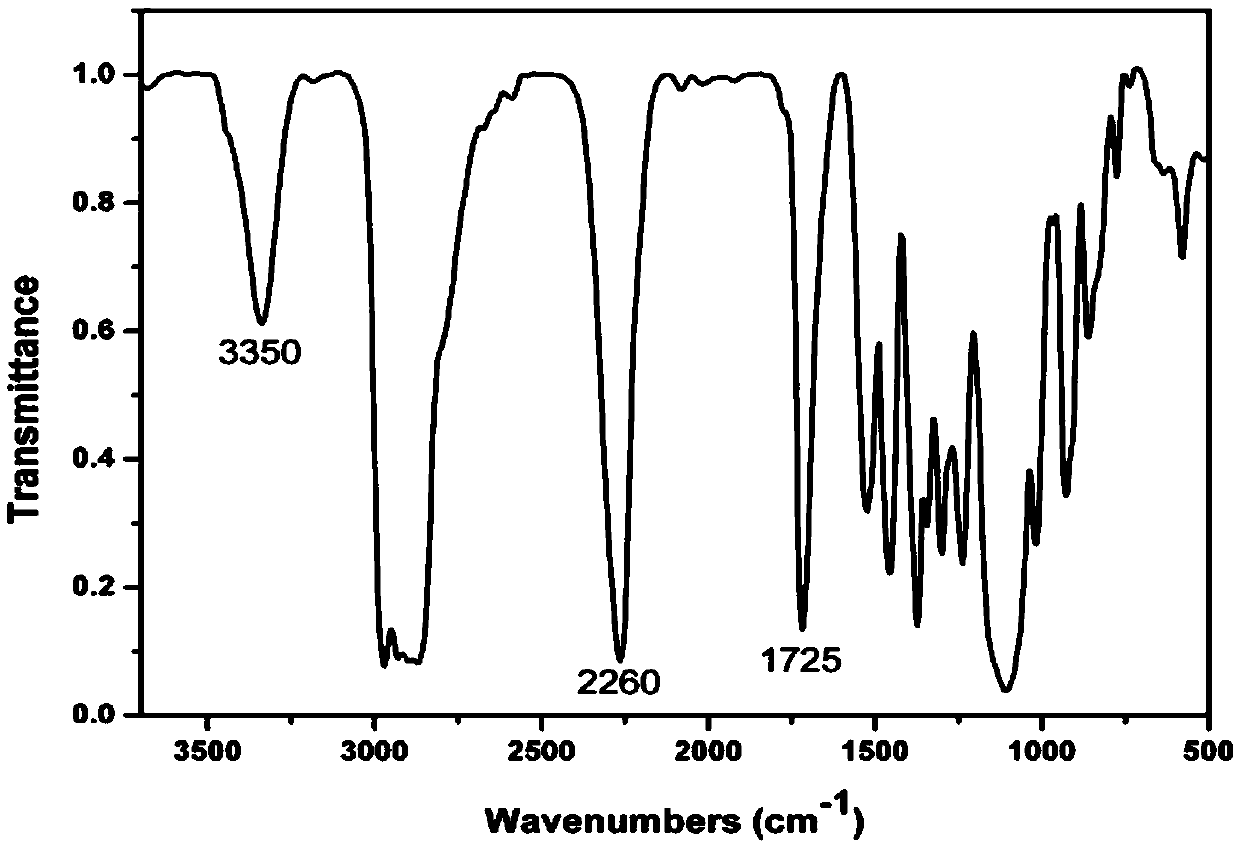

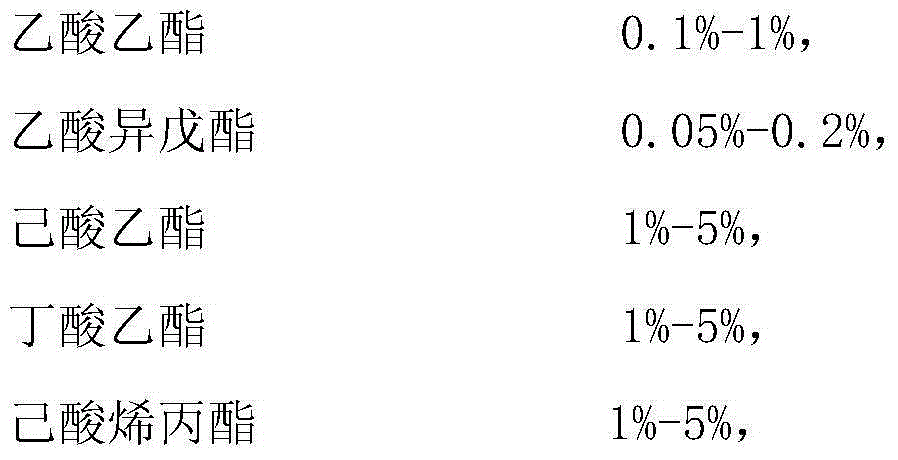

Method for preparing 5-phenyl-4-amino-triazolinthione

The invention discloses a method for preparing 5-phenyl-4-amino-triazolinthione, which comprises the following steps that: step one, phenylformic acid and absolute ethyl alcohol react to form ethyl benzoate; step two, the ethyl benzoate and hydrazine hydrate react to form phenylhydrazide; and step three, the phenylhydrazide and carbon bisulfide react in an absolute ethyl alcohol solution of potassium hydroxide to form potassium salt, and then the potassium salt and the hydrazine hydrate react to form the 5-phenyl-4-amino-triazolinthione. The method ensures that the reaction time is greatly shortened by optimizing preparation conditions; and the method has good application prospect.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Method for preparing hydrogen sulfide corrosion inhibitor used in offshore oilfield produced oil pipeline

InactiveCN104498958APlay the role of hydrogen sulfide corrosion inhibitionDrilling compositionBenzoic acidOil additive

The invention relates to a method for preparing a hydrogen sulfide corrosion inhibitor used in an offshore oilfield produced oil pipeline and belongs to the technical field of petroleum additives. The method comprises the following steps: uniformly mixing an imidazoline compound, SPAN-80, rosin amine polyoxylethylene ether, sodium alga acid, methyl propanediol and ethanol, thereby obtaining a mixture I; uniformly mixing sodium chromate, sodium nitrite, sodium pyrrolidone carboxylate, hydroxyl ethyl benzoate, zinc borate, magnesium borate, dipentaerythritol, hydrogenated soya bean lecithin, triethylamine and propyl alcohol, thereby obtaining a mixture II; and uniformly mixing the mixture I, the mixture II, sodium benzoate, ammonium benzoate, sodium gluconate, sodium acrylate, thiosemicarbazide, carboxymethyl chito-oligosaccharide vanillic aldehyde Schiff base, thereby obtaining the hydrogen sulfide corrosion inhibitor. The corrosion inhibitor provided by the invention can effectively achieve a corrosion inhibition effect on the hydrogen sulfide in the pipeline under high salt conditions.

Owner:刘旸 +14

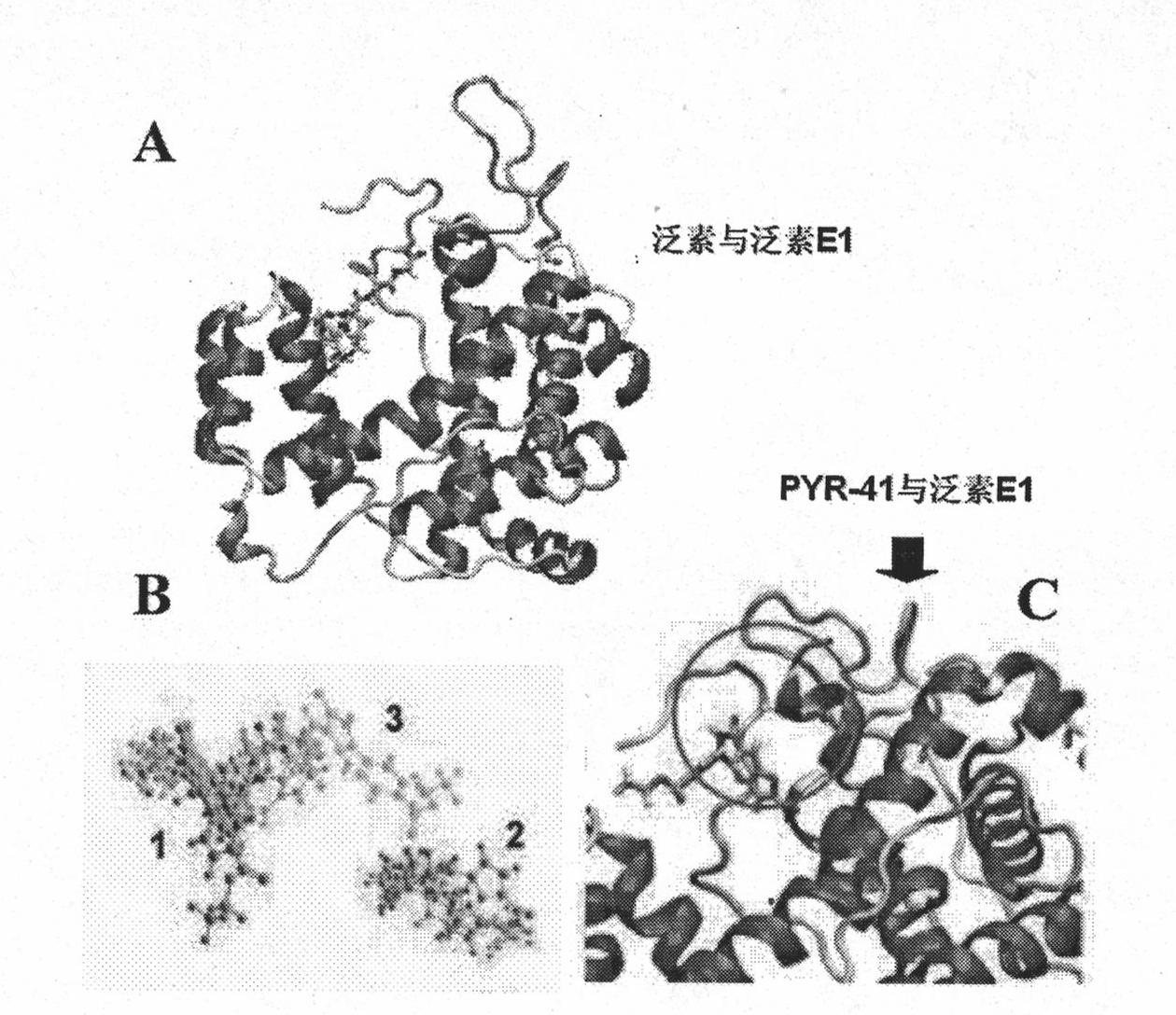

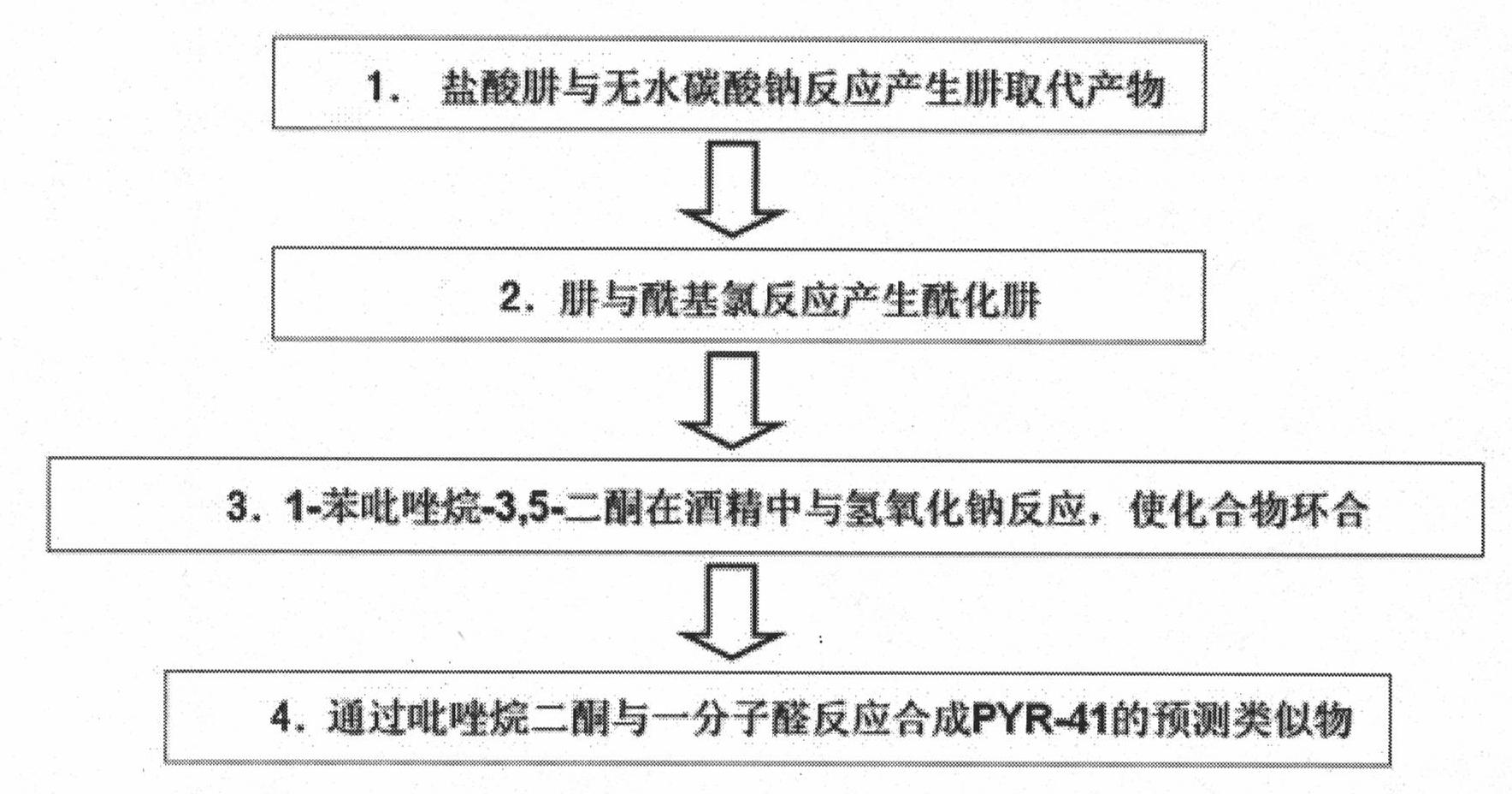

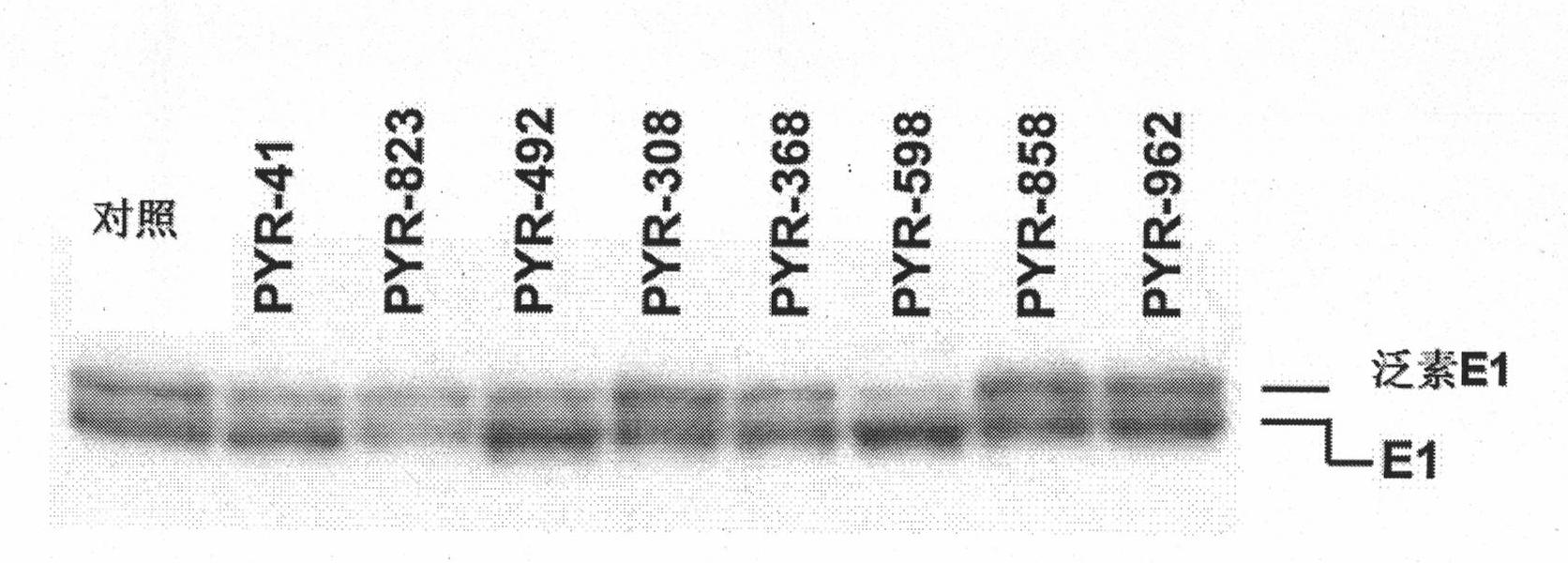

Ubiquitin E1 inhibitor and preparation method thereof

InactiveCN101961331AEasy to passGood water solubilityOrganic active ingredientsOrganic chemistryFuranProtein Degradations

The invention relates to an ubiquitin E1 inhibitor and a preparation method thereof. Series compound Y-1-benzene pyrazole silane-3,5-diketone and relevant derivative (such as 4-(4-ethyoxyl-3-methoxybenzylidene)-1-benzene pyrazole silane-3,5-diketone, and the like) with different alternative groups are prepared by a liquid-phase organic synthesis method according to the structure of PRY-41(4(4-(5-nitro-furan group-methylene]-3,5-dioxo-pyrazolidine-1-radical)-ethyl benzoate). The ubiquitin E1 inhibitor can be used for inhibiting protein degradation mediated by ubiquitination and nondegradation of ubiquitination, and can kill transformed cells containing p53 in the process of blocking up the NFkB activity by the inhibitor, that is to say, the inhibitor possibly has the potential property of treating tumor and can be used as an important tool for researching ubiquitin proteinase system mechanism.

Owner:西安杰诺瓦生物科技有限公司

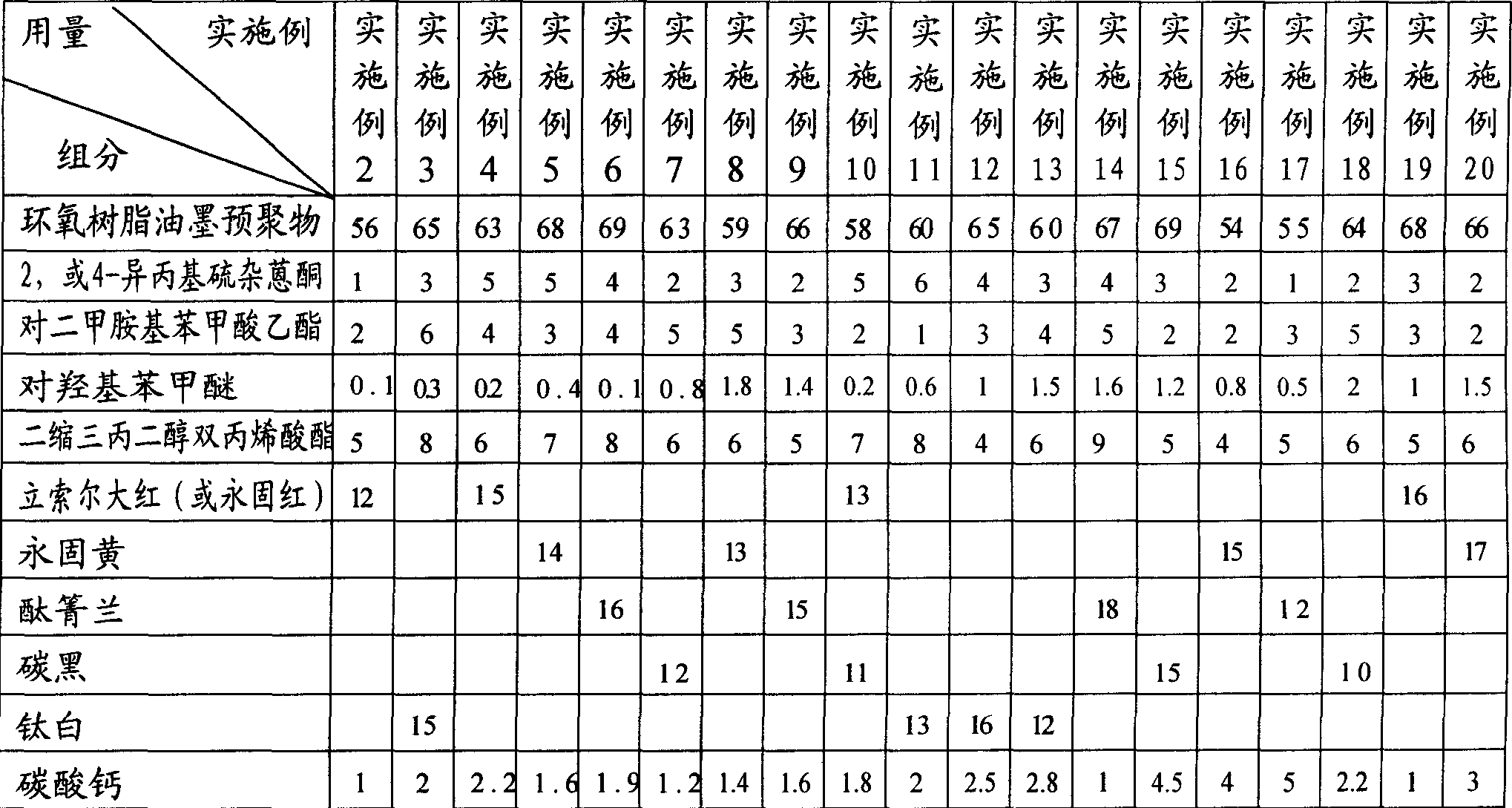

Ultraviolet cured offset printing ink

The invention discloses an ultraviolet light curing offset printing ink which is formed by epoxide resin printing ink pre-polymer, 2, or 4-isopropyl thioxanthone, dimethylin ethyl benzoate, triethylene glyceryl alcohol methyl acrylate, painting and calcium carbonate. It can adjust the painting ink by different painting craft with the ink moving speed: 2-35mm / normal temperature, the viscosity ratio: 100-300pa.s / 30 deg. and the drying time: 150-800s / normal temperature.

Owner:石家庄印钞有限公司 +1

Method for cleanly producing high-purity (methyl) acryloyl ethoxy benzyldimethyl ammonium chloride

InactiveCN101717340AHigh boiling pointReduce volatilityOrganic compound preparationAmino compound preparationBenzoic acidIodide

The invention provides a method for cleanly producing high-purity (methyl) acryloyl ethoxy benzyldimethyl ammonium chloride. Methyl benzoate or ethyl benzoate is adopted as a reaction solvent, and iodides, such as lithium iodide, potassium iodide, tetramethyl-ammonium iodide, tetraethyl-ammonium iodide or tetrabutyl-ammonium iodide, and the like are adopted as a catalyst, and the reaction is carried out at 35-38 DEG C for 10-24 hours. The yield of one-path (methyl) acryloyl ethoxy benzyldimethyl ammonium chloride is between 93 percent and 95 percent, a rough product is washed for three times by ethylacetate, and the analytical purity of the (methyl) acryloyl ethoxy benzyldimethyl ammonium chloride is larger than 99 percent.

Owner:HUAIHAI INST OF TECH

Modified polycarbonate material for cable and preparation method thereof

InactiveCN107722588AReduce electrical dendrationReduce coronaPlastic/resin/waxes insulatorsNano al2o3High pressure

The invention discloses a polycarbonate modified material for cables and a preparation method thereof. The polycarbonate modified material for cables is prepared from the following raw materials in parts by weight: 0.3-0.8 parts of nano-alumina, 8-12 parts Porous ceramics, 0.001-0.003 parts of graphene, 12-18 parts of polyoxyethyl benzoate, 55-75 parts of polycarbonate, 0.5-1.2 parts of coupling agent, 1-5 parts of stabilizer ; The cable uses polycarbonate modified material to add modified nano-alumina particles to polycarbonate for mixed modification, which significantly improves the breakdown voltage of polycarbonate. The modified polycarbonate material Can be used in high voltage cables.

Owner:SICHUAN LIZHI JIUCHUANG INTPROP OPERATION CO LTD

Method for relieving stress response in manual operations of juvenile fish of sebastes schlegeli hilgendorf

InactiveCN101720703AEasy to carry and transportConducive to manual operationClimate change adaptationPisciculture and aquariaDiseaseSulfonate

The invention relates to technology of relieving stress response of fish, in particular to a method for relieving stress response in the manual operations of juvenile fish of sebastes schlegeli hilgendorf. The method is characterized by firstly stopping feeding the juvenile fish of sebastes schlegeli hilgendorf for a day to ensure the food in the intestines and stomach of the fish to be emptied; computing the dose of the required isotopic ethyl aminobenzoate alkane sulfonate (MS-222) according to the concentration of 90-110mg / L and dissolving the isotopic ethyl aminobenzoate alkane sulfonate into seawater and stirring to fully dissolve the isotopic ethyl aminobenzoate alkane sulfonate; and then spooning the juvenile fish of sebastes schlegeli hilgendorf into the MS-222 seawater solution, carrying out various test operations when the fish lies at the bottom of a water tank three minutes later and moving the juvenile fish of sebastes schlegeli hilgendorf into common seawater after the operations are completed. The optimum range of the concentration of the seawater solution is 100mg / L. Obviously, the method brings great convenience for such manual operations as transportation, individual marking, immunization injection, physiological experiment and the like, is characterized in that the juvenile fish does not contract diseases, and is fast and safe.

Owner:MARICULTURE INST OF SHANDONG PROVINCE

Fermentation bed padding for air purification of pig house

InactiveCN106234236AIncrease appetiteIncrease feed intakeFood processingAnimal feeding stuffSuspended particlesProtease preparation

The invention discloses a fermentation bed padding for air purification of a pig house. The fermentation bed padding is prepared from the following raw materials in parts by weight: 42-46 parts of corncobs, 6-8 parts of cynomorium songaricum, 3-4 parts of sepiolite powder, 16-18 parts of pine needle leaf powder, 22-24 parts of chestnut shell powder, 4-5 parts of stevia rebaudiana residues, 0.4-0.5 part of ethyl benzoate, 44-48 parts of corn stalks, 33-35 parts of a beer yeast paste, 1-2 parts of a protease preparation, 0.6-0.8 part of cysteine hydrochloride, 1.5-1.9 parts of oryzanin, 25-27 parts of vanilla pods, an appropriate amount of a 45% ethanol solution and an appropriate amount of water. A large amount of vegetative residues are added into the fermentation bed padding disclosed by the invention, and by matching the addition of high-adsorbability sepiolite powder, the fermentation bed padding can effectively adsorb free ammonia, suspended particles and the like in the air of the pig house, reduce irritation of respiratory tracts of pigs due to these things, and avoid the happening of pig respiratory diseases.

Owner:王青

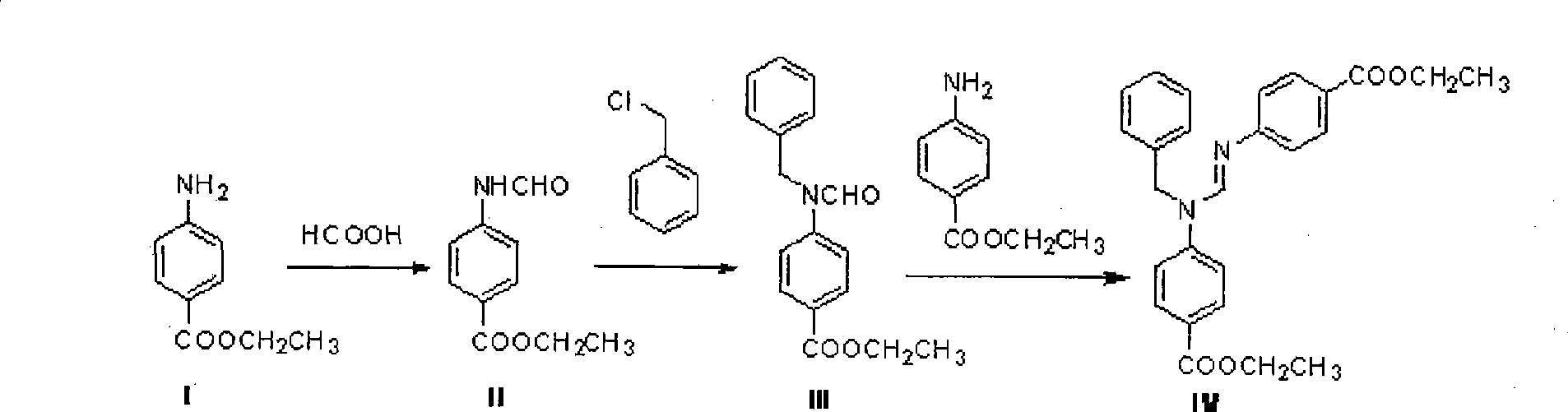

N,N'-bis(4-ethoxy carbonyl phenyl)-N'-benzyl formamidine

ActiveCN101481331AHigh yieldEasy to separate and purifyOrganic chemistryOrganic compound preparationFormylation reactionFiltration

The invention relates to the technical field of fine chemistry industry, in particular to a method for preparing N, N'-di(4-ethoxycarbonylphenyl)-N'-phenylformamidine. Parathesin and benzyl chloride are taken as raw materials. The method comprises a formylation reaction process, an N alkylation reaction process and a condensation reaction process; wherein, in the N alkylation reaction process, 4-formamido ethyl benzoate generated in the formylation reaction process is added into dipolar aprotic solvent, and then inorganic weak base and the benzyl chloride are added, the temperature rises and is preserved and the reaction lasts for 20-25 hours; then the temperature is lowered to the room temperature and suction filtration and washing are carried out on the separated pale yellow solid to obtain pale yellow intermediate; the intermediate and the parathesin are added into halogenated hydrocarbon and then dehydrant is added; after heatingup and reflux for 15-17 hours, the temperature is cooled to the room temperature; NaOH aqueous solution is added to steam out the halogenated hydrocarbon under normal pressure and then separate out offwhite solid; suction filtration, washing by water and drying are carried out on the solid and the white solid of N, N'-di(4-ethoxycarbonylphenyl)-N'-phenylformamidine is obtained by recrystallization and cooling the solid to the room temperature afterwashing.

Owner:CHANGZHOU SUNLIGHT PHARMA +1

Pear essence for water-based inks and preparation method thereof

The invention provides a pear essence for water-based inks, which is composed of the following components in percentage by weight: 1-30% of pear essence, 5-55% of composite modified oligosaccharide and the balance of deionized water. The pear essence is composed of ethyl acetate, propyl acetate, butyl acetate, hexyl acetate, cis-3-hexenyl acetate, isoamyl acetate, ethyl propionate, ethyl butyrate, ethyl 2-methylbutyrate, ethyl hexanoate, ethyl oenanthate, ethyl caprilate, ethyl benzoate, peach aldehyde, hexanal, hydroxy citronellal, trans-2-hexenal, acetic acid, butanol, linalool, damascone, ethyl 3-methylthiopropionate, lemon oil and ethanol. The invention also provides a preparation method of the pear essence for water-based inks. The composite modified oligosaccharide is used as a wall material to be coated on the pear essence so as to form the pear nanocapsule slow-release essence, thereby enhancing the fragrance persistence and water solubility of the essence; and thus, the pear essence is suitable for perfuming the water-based ink. The pear essence for water-based inks has the advantages of fresh and realistic fragrance, high naturalness and high fragrance persistence.

Owner:SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Crystals and process of making 5-({[2-amino-3-(4-carbamoyl-2,6-dimethyl-phenyl)-propionyl]-[1-(4-phenyl-1H-imidazol-2-yl)-ethyl]-amino}-methyl)-2-methoxy-benzoic acid Crystals and process of making 5-({[2-amino-3-(4-carbamoyl-2,6-dimethyl-phenyl)-propionyl]-[1-(4-phenyl-1H-imidazol-2-yl)-ethyl]-amino}-methyl)-2-methoxy-benzoic acid](https://images-eureka.patsnap.com/patent_img/d093267b-f668-47cc-b8ea-78a5d07ea5c9/US07994206-20110809-D00001.png)

![Crystals and process of making 5-({[2-amino-3-(4-carbamoyl-2,6-dimethyl-phenyl)-propionyl]-[1-(4-phenyl-1H-imidazol-2-yl)-ethyl]-amino}-methyl)-2-methoxy-benzoic acid Crystals and process of making 5-({[2-amino-3-(4-carbamoyl-2,6-dimethyl-phenyl)-propionyl]-[1-(4-phenyl-1H-imidazol-2-yl)-ethyl]-amino}-methyl)-2-methoxy-benzoic acid](https://images-eureka.patsnap.com/patent_img/d093267b-f668-47cc-b8ea-78a5d07ea5c9/US07994206-20110809-D00002.png)

![Crystals and process of making 5-({[2-amino-3-(4-carbamoyl-2,6-dimethyl-phenyl)-propionyl]-[1-(4-phenyl-1H-imidazol-2-yl)-ethyl]-amino}-methyl)-2-methoxy-benzoic acid Crystals and process of making 5-({[2-amino-3-(4-carbamoyl-2,6-dimethyl-phenyl)-propionyl]-[1-(4-phenyl-1H-imidazol-2-yl)-ethyl]-amino}-methyl)-2-methoxy-benzoic acid](https://images-eureka.patsnap.com/patent_img/d093267b-f668-47cc-b8ea-78a5d07ea5c9/US07994206-20110809-D00003.png)