Process for preparing ethyl p-dimethylaminobenzoate

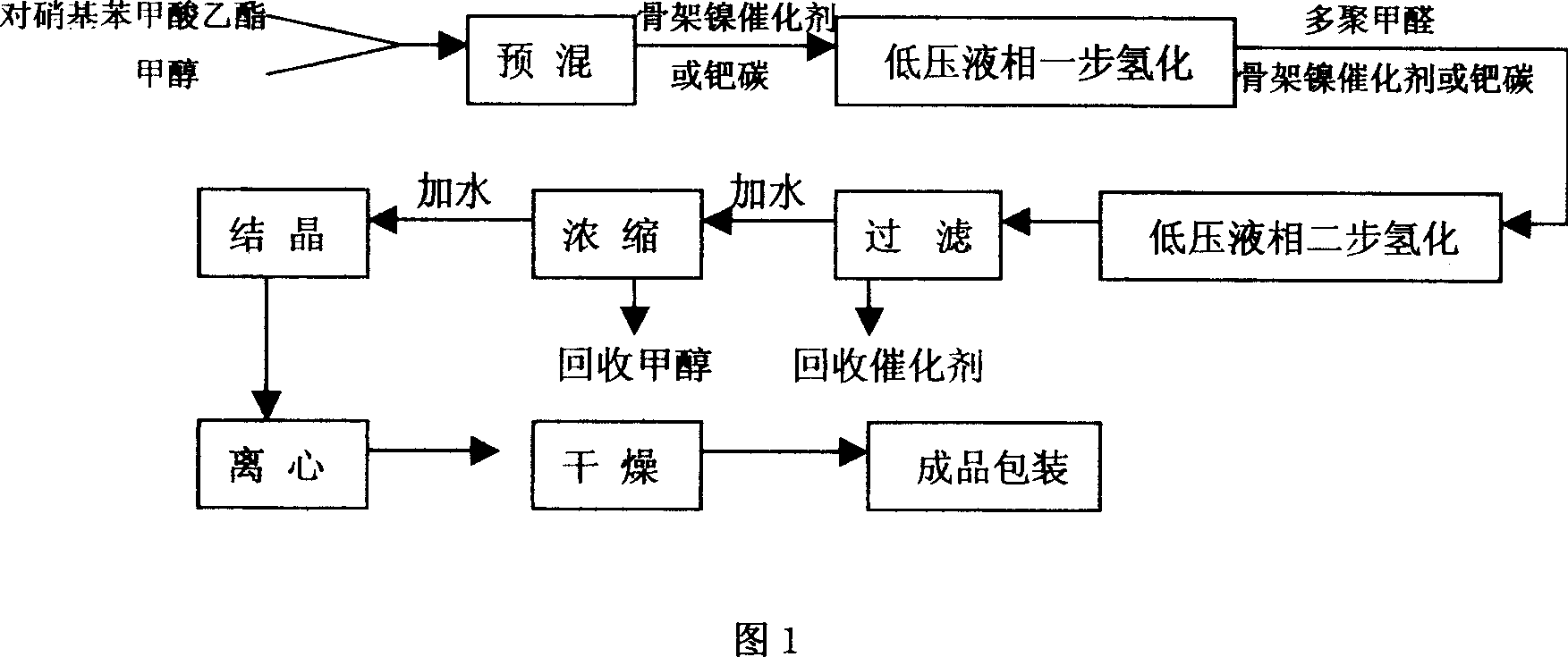

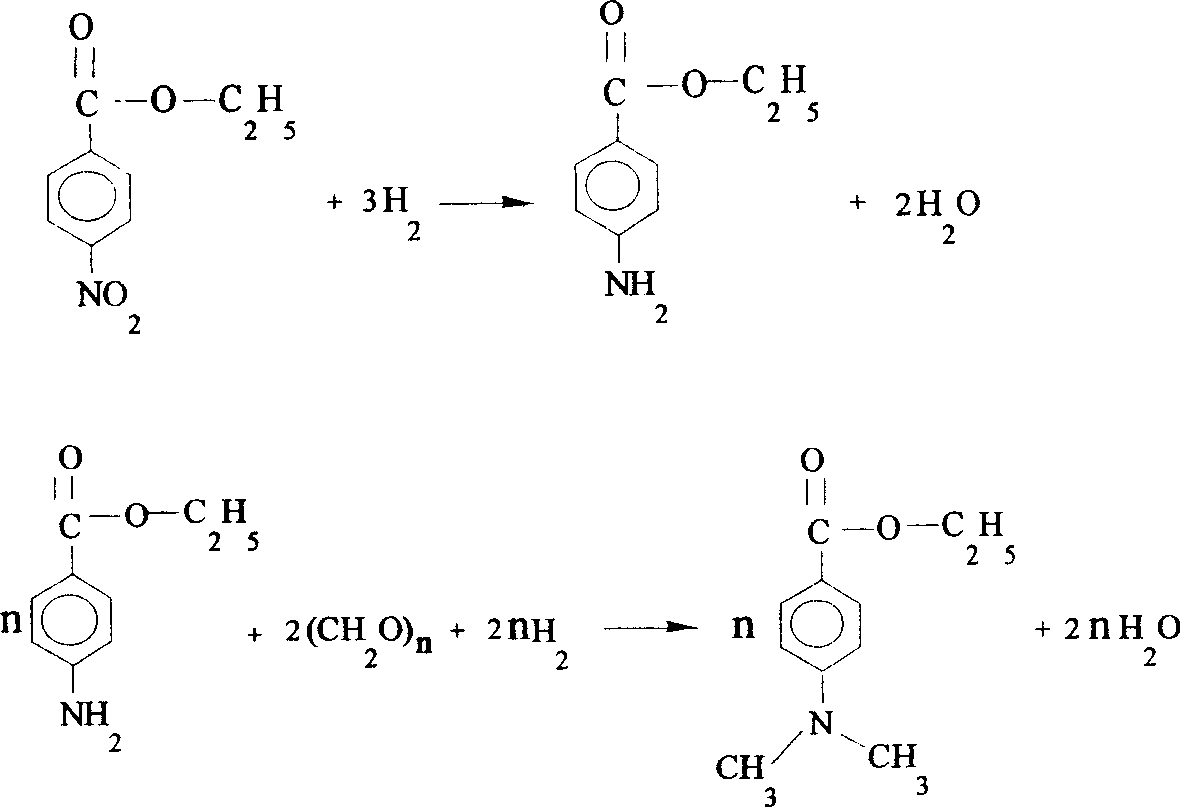

A technology of ethyl dimethylaminobenzoate and ethyl nitrobenzoate is applied in the field of preparation of ethyl p-dimethylaminobenzoate, and can solve the problems of high preparation cost, environmental protection, safety, many three wastes, low yield and the like, Achieve the effect of enhancing market competitiveness, high environmental protection benefits, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Taking a reactor with a volume of 50L as a container, follow the steps below:

[0023] Premixing: put 7kg of ethyl p-nitrobenzoate and 25kg of methanol (99% content) into a 50L reaction kettle at one time, stir at room temperature until completely dissolved.

[0024] The reaction kettle needs to be replaced with nitrogen, the specific method: vacuumize to -0.07~-0.09Mpa, fill with nitrogen 0.05~0.07Mpa, then vacuumize to -0.07~-0.09Mpa, fill with nitrogen 0.05~0.07Mpa, repeat this twice .

[0025] One-step hydrogenation: add 0.2kg skeleton nickel catalyst under the protection of nitrogen, carry out a one-step hydrogenation reaction at a temperature of 70°C and a hydrogenation pressure of 1.0Mpa, and the reaction time is 10 hours; during the hydrogenation reaction, the reaction is exothermic and cooled by adjusting the reactor jacket The flow rate of water is used to control the reaction temperature.

[0026] Then still need to carry out nitrogen replacement again to r...

Embodiment 2

[0033] Taking a reactor with a volume of 50L as a container, follow the steps below:

[0034] Premixing: put 7kg of ethyl p-nitrobenzoate and 30kg of methanol (95% content) into a 50L reaction kettle at one time, stir at room temperature until completely dissolved.

[0035] The reaction kettle needs to be replaced with nitrogen, the specific method: vacuumize to -0.07~-0.09Mpa, fill with nitrogen 0.05~0.07Mpa, then vacuumize to -0.07~-0.09Mpa, fill with nitrogen 0.05~0.07Mpa, repeat this twice .

[0036] One-step hydrogenation: add 0.1kg skeleton nickel catalyst under the protection of nitrogen, carry out a one-step hydrogenation reaction at a temperature of 80°C and a hydrogenation pressure of 0.8Mpa, and the reaction time is 12 hours; during the hydrogenation reaction, the reaction is exothermic and cooled by adjusting the reactor jacket The flow rate of water is used to control the reaction temperature.

[0037] Then still need to carry out nitrogen replacement again to r...

Embodiment 3

[0044] In the one-step hydrogenation, the catalyst is replaced by a 0.02kg palladium-carbon catalyst, and in the two-step hydrogenation, the catalyst is replaced by a 0.05kg palladium-carbon catalyst. The obtained product content is 99.5%, and the reaction yield is 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com