Hydrophobic resin adhesive, preparation method and application thereof

A technology of hydrophobic resin and adhesive, applied in the field of stomatology materials, can solve the problems of unsatisfactory bonding interface quality, decreased bonding strength, micro-leakage at the edge of the restoration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Accurately weigh 5.55 g of isophorone diisocyanate and add it to 20 g of polyether diol, add 0.1 g of dibutyl tin dilaurate, and react with mechanical stirring at 68°C. After 3 hours, 3g of hydroxyethyl methacrylate was added, and the reaction was continued for 3 hours to obtain the required polyurethane dimethacrylate of the present embodiment;

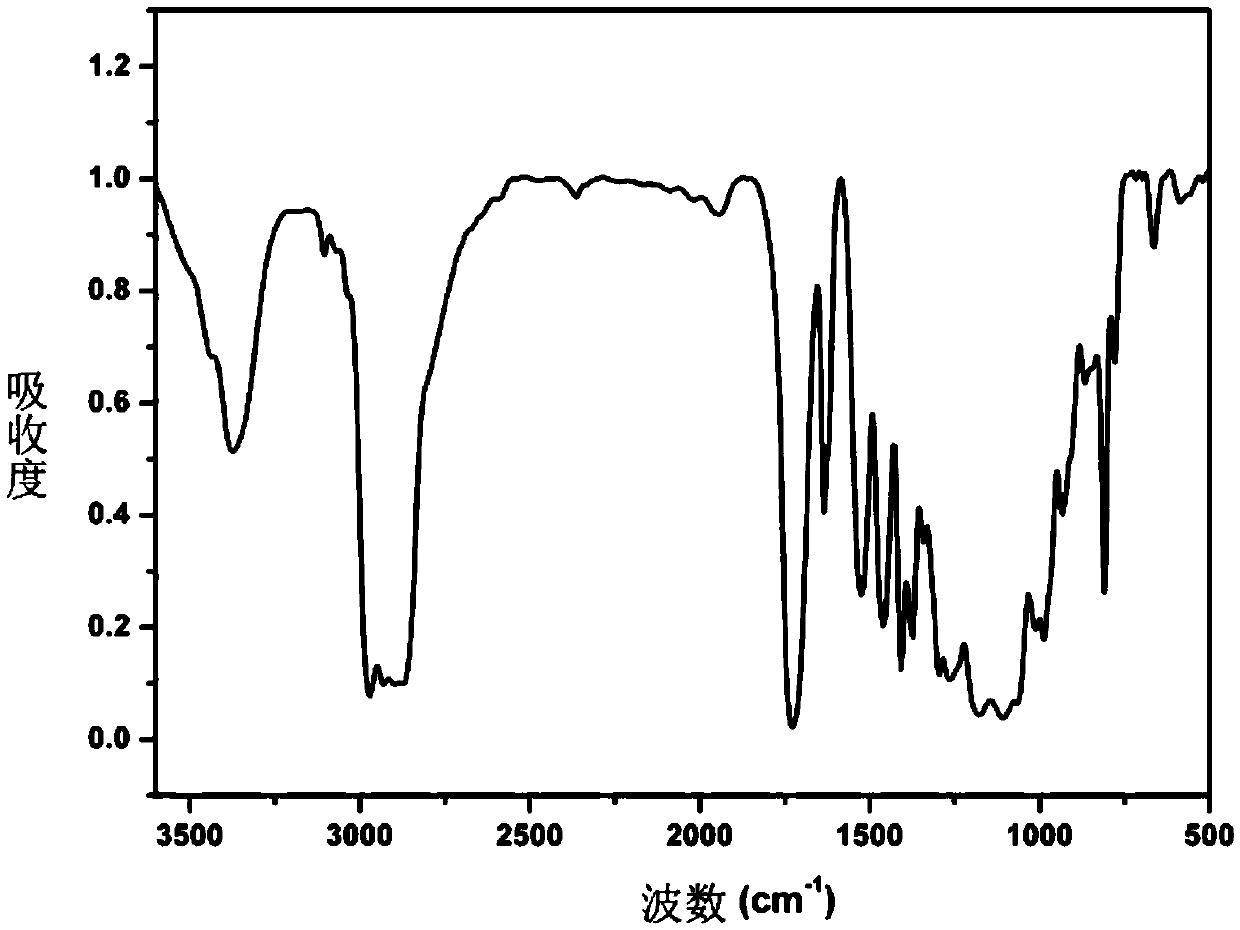

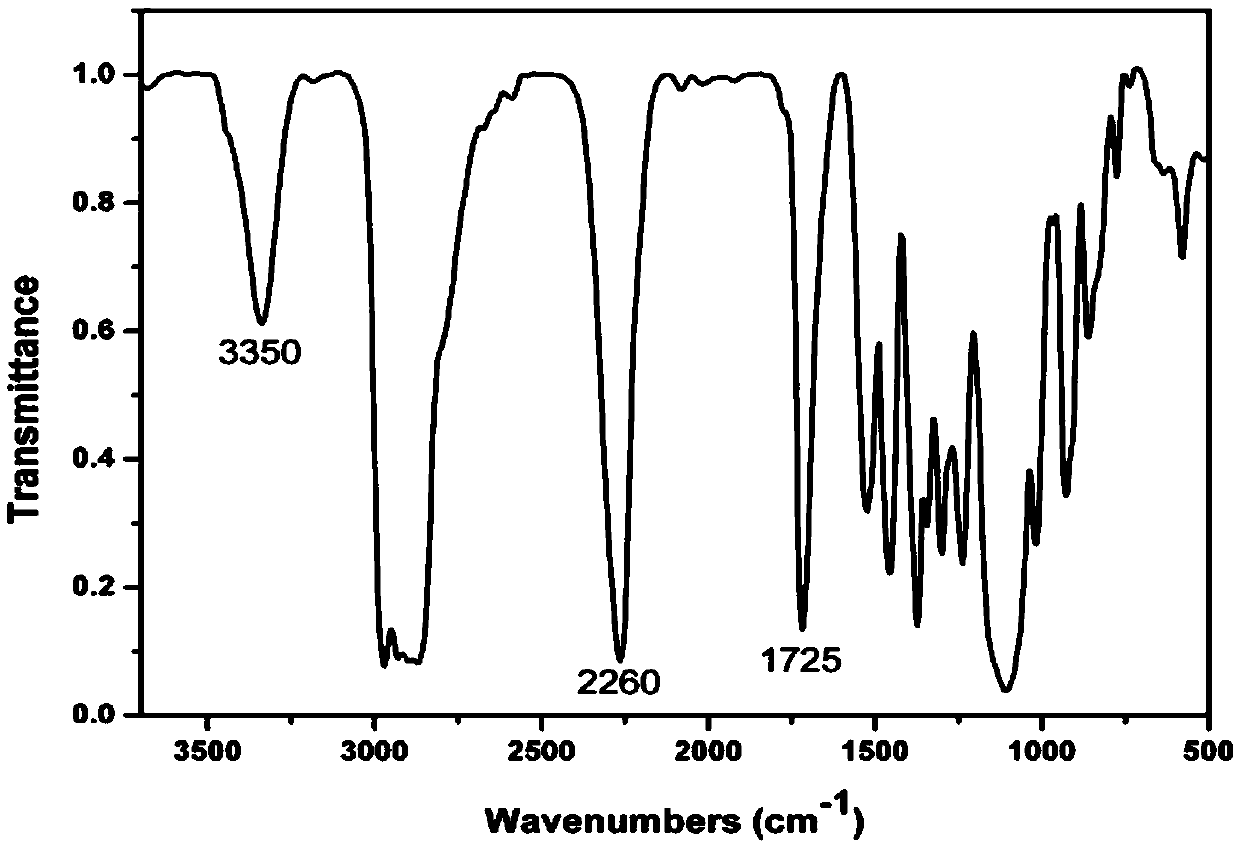

[0022] Accurately weigh 7.77 g of isophorone diisocyanate and 0.2 g of dibutyltin dilaurate into a 150 mL three-neck flask, and stir mechanically under the condition of oil bath temperature control at 75°C. Then, 9 g of polyether triol 900 was added dropwise, and the reaction was continued for 6 hours. After observing the absence of hydroxyl groups through infrared spectroscopy, the isocyanate group-terminated polyether triol required in this example can be obtained;

[0023] Accurately weigh 5g of polyurethane dimethacrylate and 0.9g of isocyanate group-terminated polyether triol, add 1.5g of methyl methacrylate, 2.5g of but...

Embodiment 2

[0028] Accurately weigh 5.55 g of isophorone diisocyanate and add it to 20 g of polyether diol, add 0.1 g of dibutyl tin dilaurate, and react with mechanical stirring at 68°C. After 3 hours, 3g of hydroxyethyl methacrylate was added, and the reaction was continued for 3 hours to obtain the required polyurethane dimethacrylate in this example;

[0029] Accurately weigh 7.77 g of isophorone diisocyanate and 0.2 g of dibutyltin dilaurate into a 150 mL three-neck flask, and stir mechanically under the condition of oil bath temperature control at 75°C. Then, 9 g of polyether triol 900 was added dropwise, and the reaction was continued for 6 hours. After observing the absence of hydroxyl groups through infrared spectroscopy, the isocyanate group-terminated polyether triol required in this example can be obtained;

[0030] Accurately weigh 6 g of polyurethane dimethacrylate and 0.9 g of isocyanate group-terminated polyether triol, add 1 g of methyl methacrylate, 2 g of butyl acrylat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com