Patents

Literature

193results about How to "Soft aroma" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nutritious kudzu root black rice seasoned vinegar and its preparing method

The invention discloses kudzu root vinegar and making method in the food and flavoring domain, which comprises the following steps: blending raw materials with 200-300g dried kudzu root particle or powder, 100-150g black rice and 100-150g glutinous rice; adding water to soak; cleaning; drying; cooling; saccharifying; fermenting; blending 850-900g bran, 450-500g rice husk or chaff and 130-140g rice; adding 20-25g salt; ripening; sprinkling; filtering; adding 5-7% sugar to modulate; clarifying; sterilizing; sealing to deposit for 6-12 months; obtaining the product.

Owner:JIANGSU UNIV

Natural dairy spice and preparation method thereof

The present invention discloses a preparing method for a natural daily food spice, which comprises the steps that: 1) the reaction bottom material is hydrolyzed in 20 degrees to 55 degrees under the action of the compound enzyme, and the acid value controlling the hydrolysis is 20 to 90 to get a hydrolysis product; the reaction bottom material is the grease raw material with the butter oil or the mixture of the grease raw material with the butter oil and the vegetable fat; 2) the enzyme eliminating processing is performed for the hydrolysis product; 3) a distillation extracting method is used for recycling the obtained product from step 2) to get the natural daily food spice. The present invention still provides the natural daily food spice produced by the method, and the spice is characterized by high aroma intensity and abundant aroma.

Owner:ZHEJIANG GREEN CRYSTAL FLAVOR

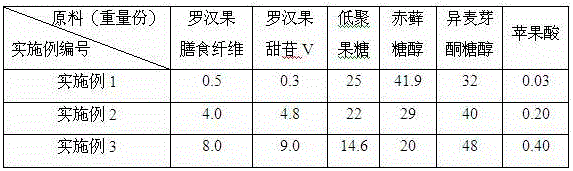

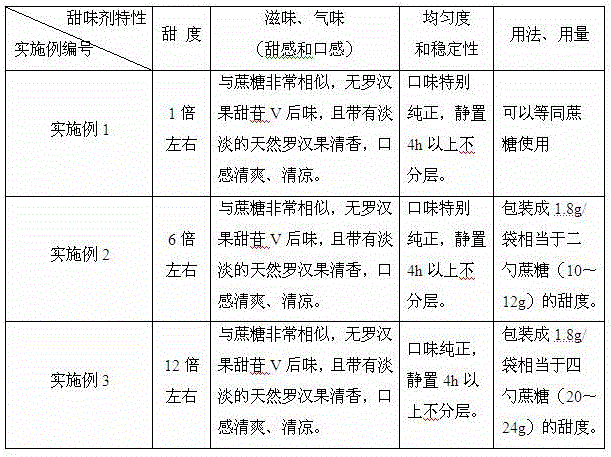

Natural plant product compound sweetening agent and preparation method thereof

InactiveCN106333336ARefreshing tasteShorten the sweetness timeFood ingredient as taste affecting agentFood ingredient as mouthfeel improving agentFiltration membraneIsomalt

Owner:HUNAN AIDALUN TECH CO LTD

Method for preparing egg and milk essence substrate

ActiveCN102232534AImprove securityAdd flavorAnimal feeding stuffWorking-up animal fodderMonoglycerideButterfat

The invention relates to the technology in the field of food and beverage processing, in particular to preparation of an egg and milk essence substrate by using a dual enzymatic method in cooperation with the mailard reaction; and the prepared egg and milk essence substrate can be widely applied to various food industries. The method comprises the following steps of: hydrolyzing natural cream by using lipase and subjecting dried egg yolk to enzymolysis by using protease; mixing a hydrolysis product and an enzymolysis product based on a certain ratio, homogenizing by a homogenizer, and obtain a homogenous emulsification system by using the monoglyceride and lecithin in a mixture per se as emulsifiers; then adding reducing sugar-xylose and amino acid-methionine for producing the egg characteristic flavor, mixing to reach a uniform state, directly heating to 105-110 DEG C, reacting for 1-3 hours; and performing the mailard reaction and enzyme deactivation at the same time. A final product has the flavor mixture of free fatty acid, lactone, methyl ketone, alcohol, aldehyde, black-like essence with antioxidant activity and the like, wherein the free fatty acid is obtained through hydrolyzing the fat, the lactone, methyl ketone, alcohol and aldehyde are obtained through heating the fat, and the black-like essence is generated by the mailard reaction; and thus, the product has an intense egg and milk flavor.

Owner:GUANGZHOU FLOWER FLAVOURS & FRAGRANCES

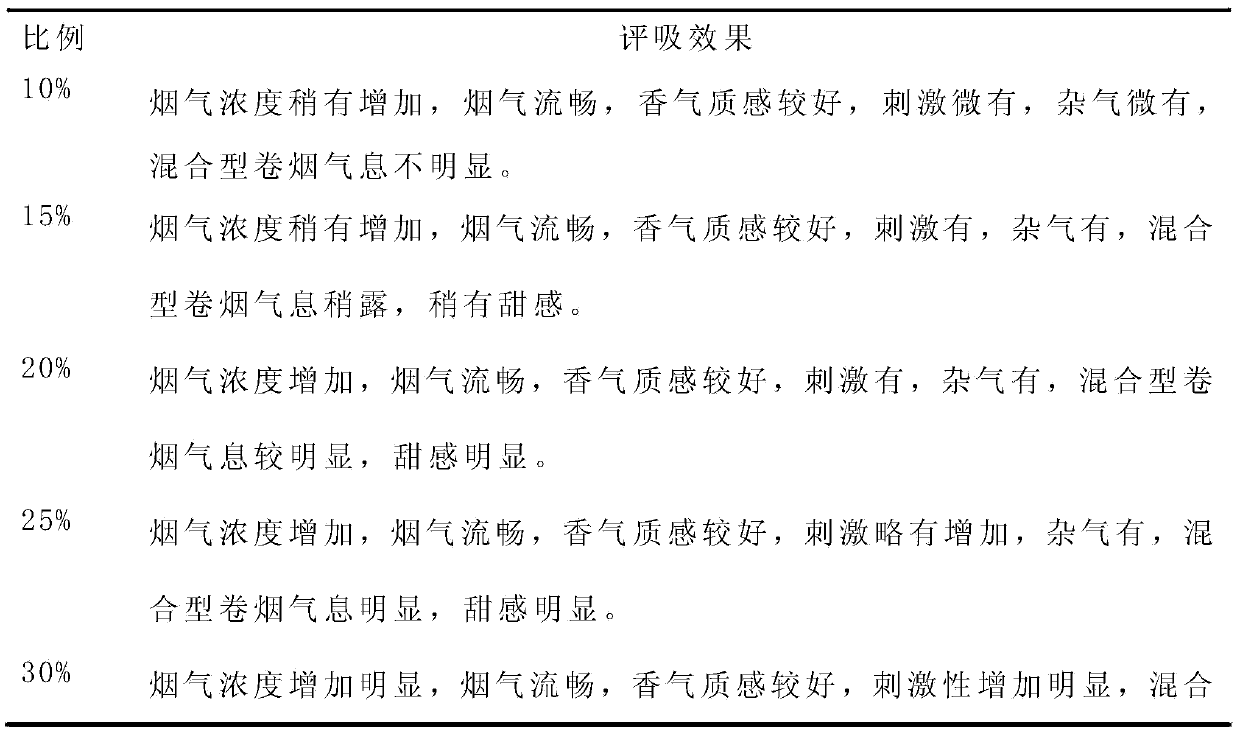

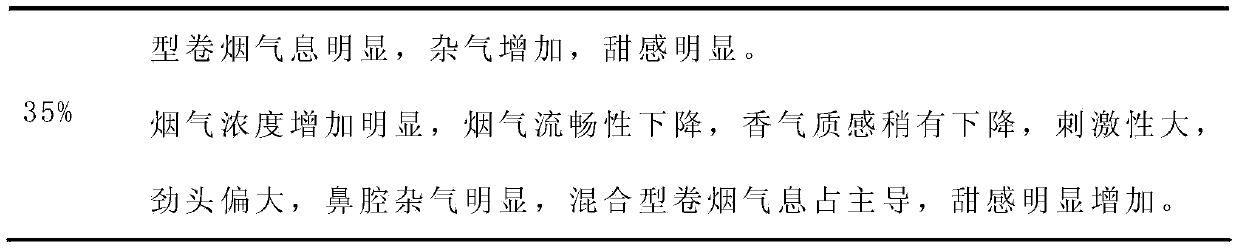

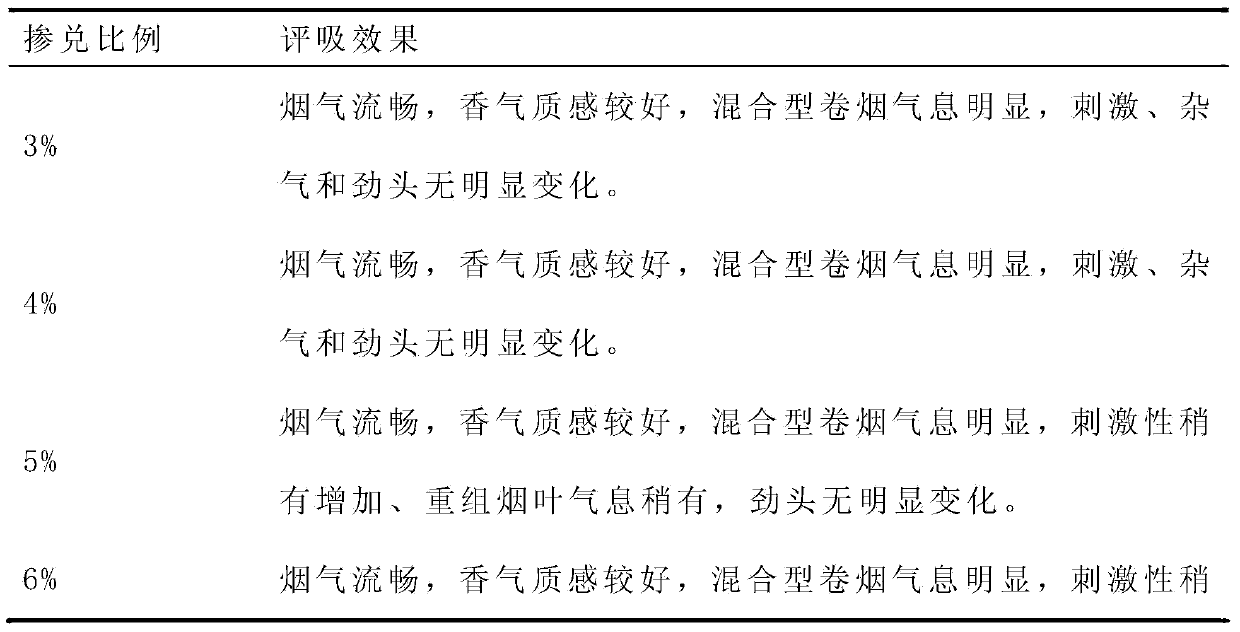

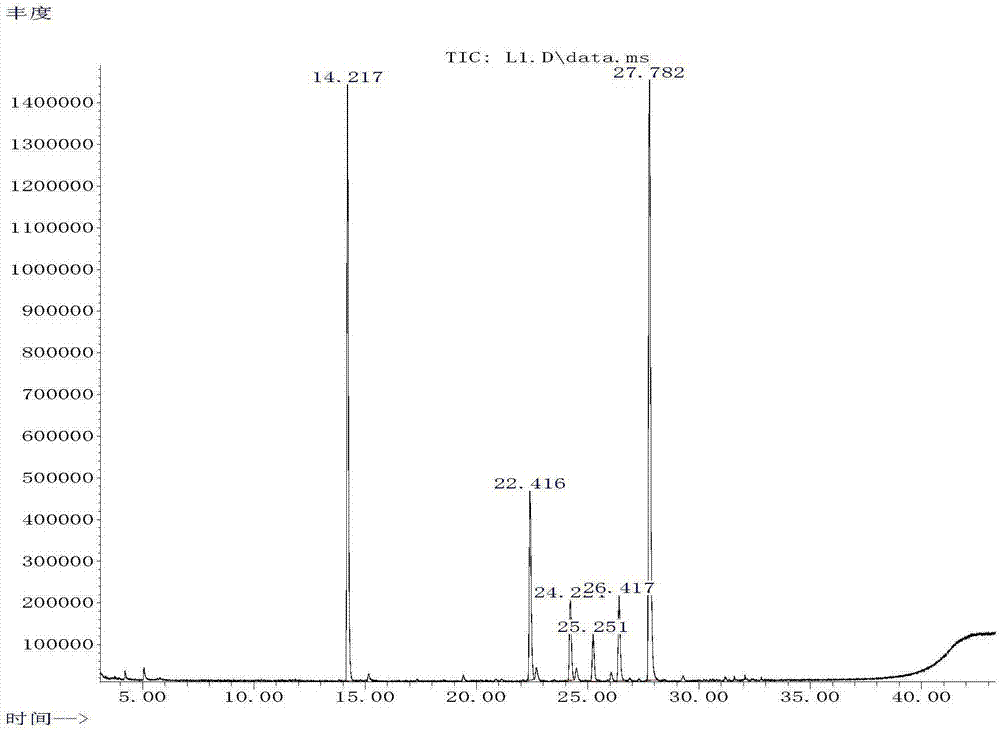

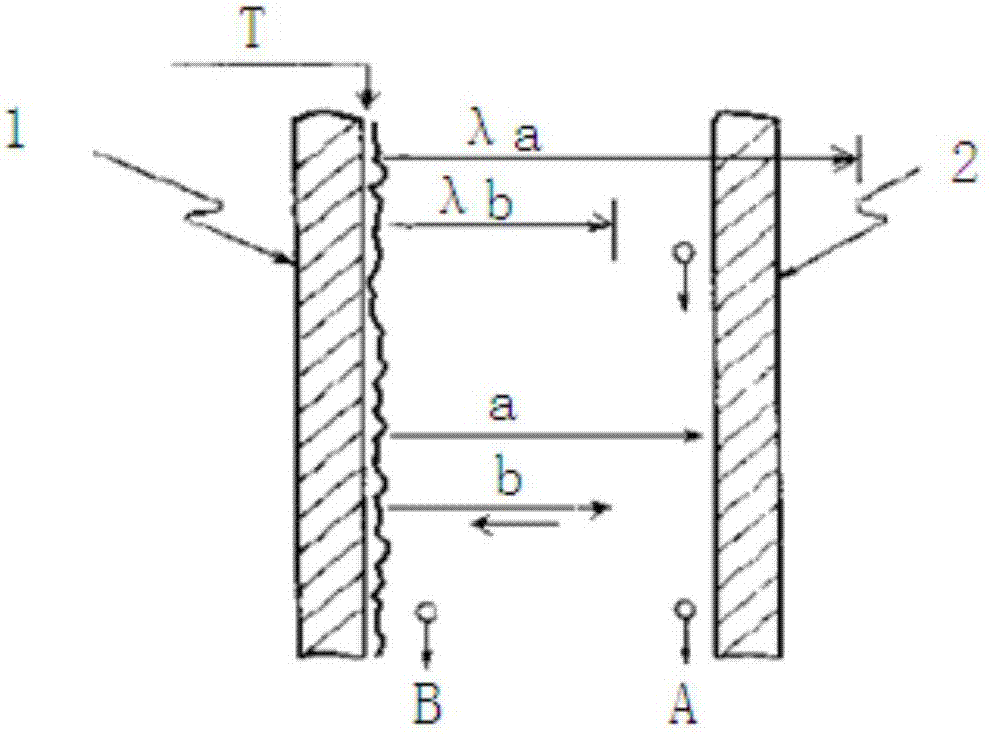

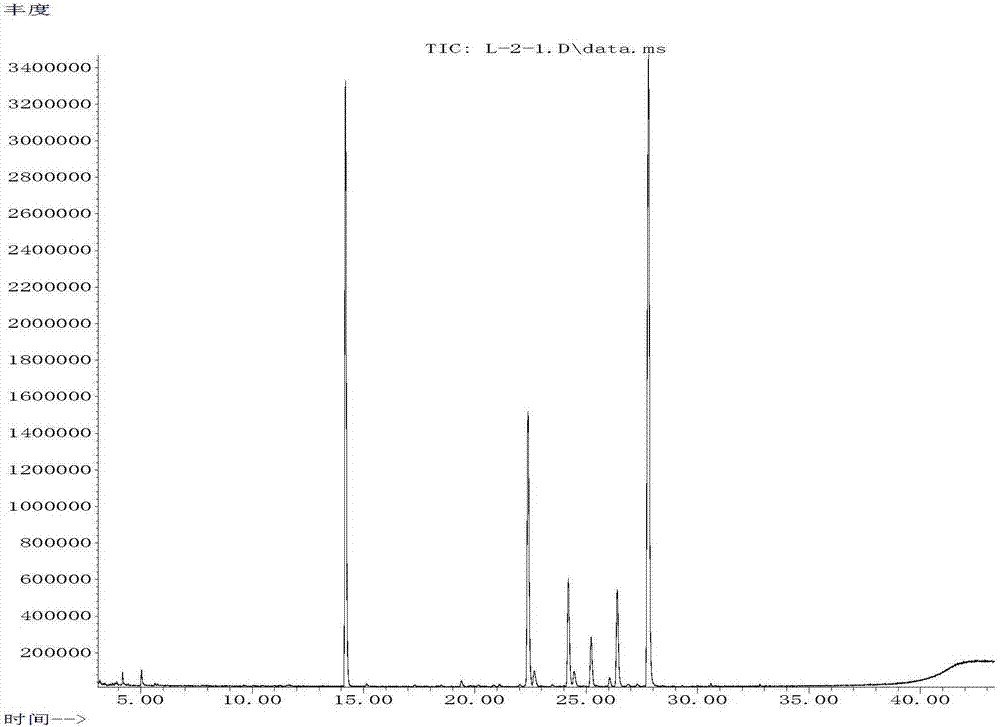

Method for producing novel blended type cigarettes with flue-cured tobacco styles

The invention belongs to the technical field of cigarette production, and particularly relates to a method for producing novel blended type cigarettes with flue-cured tobacco styles. The method comprises extracting Hubei Enshi burley tobacco and American burley tobacco with ethyl alcohol in a concentration of 30%; subjecting the extracted tobacco to high-temperature processing in a baking oven, and performing charging for spare; meanwhile, performing charging and perfuming on functional module cut tobaccos according to requirements of blended type cigarette styles; adding an appropriate number of the functional module cut tobaccos, tobacco flake cut tobaccos expanded cut stems and expanded cut tobaccos with cut flue-cured tobaccos serving as basic cut tobaccos, performing evaluation, analysis and screening repeatedly and determining a cigarette blending formula finally. The novel blended type cigarettes produced by the method have the advantages of being delicate in fume, rich and harmonious in fragrance, heavy and soft in fume, comfortable in flavor, and clear and sweet in aftertaste; the style of the novel blended type cigarettes is similar to the style of Chinese flue-cured tobacco type cigarettes, besides, the cigarettes have characteristics of international blended type cigarettes, and requirements of different consumers can be met.

Owner:HUBEI CHINA TOBACCO IND

Corn-nut essence and preparation method thereof

The invention discloses a corn-nut essence and a preparation method thereof. The corn-nut essence comprises the following components in parts by weight: 10-30 parts of methionine, 30-50 parts of serine, 40-60 parts of proline, 30-50 parts of lysine, 10-40 parts of lactamine, 20-40 parts of glycine, 10-30 parts of taurine, 120-140 parts of VB, 20-80 parts of glucose, 10-20 parts of D-xylose, 100-400 parts of corn-nut hydrolysate, 10-30 parts of ethyl maltol, 5-8 parts of [4-hydroxyl-2,5-dimethyl-3(2H)furanone], 50-100 parts of salt, 100-200 parts of white granulated sugar, 2-5 parts of xanthangum, 50-100 parts of sodium glutamate and 40-60 parts of corn starch. The essence has the advantages of soft fragrance, attractive flavor, good mouthfeel, high water solubility, stable quality, rich nutrient value, high safety performance and low carbon emission.

Owner:TIANNING FLAVOR JIANGSU

Preparation method and application of rosemary hydrosol

InactiveCN106929153AImprove applicabilityImprove sensory qualityCosmetic preparationsToilet preparationsWater vaporSteam distillation

The invention provides a preparation method and application of rosemary hydrosol. The preparation method of the rosemary hydrosol comprises the following steps: providing rosemary leaves, putting into water vapor distillation equipment for water vapor distillation, extracting to obtain an oil and water co-mixture and obtaining rosemary essence and rosemary crude hydrosol after oil and water separation; adding the rosemary crude hydrosol into molecule distillation equipment, regulating the distillation temperature of the molecule distillation equipment to be 10-50 DEG C, the condensing temperature to be 0-5 DEG C and the pressure intensity to be 1000-3000 Pa, performing molecule distillation, separation and purification, obtaining light components and heavy components and collecting the heavy components to obtain the rosemary hydrosol.

Owner:SHENZHEN DABAIHUI TECH

Additive agent for osmanthus fragrance type cigarette, preparation and application thereof

InactiveCN101317690ASimple preparation processLow costTobacco preparationTobacco treatmentNicotiana tabacumPropanediol

The invention relates to an osmanthus flower additive for tobacco and the preparation method and applications thereof. The osmanthus flower additive essentially consists of the osmanthus flowers. The preparation method includes the steps that the osmanthus flowers are extracted by heating and refluxing of petroleum ether or ethanol solution or by soaking at ambient temperature; the extracted fluid is filtered and then decompressed and condensed into osmanthus flower soaking cream which is mixed with honey in certain proportion to obtain the osmanthus flower additive for tobacco. The osmanthus flower additive is dissolved in the solution of ethanol and propanediol with certain concentration to form saturated solution, which is then evenly sprayed on cut tobacco, tobacco stems or tobacco sheets which are then prepared into cigarette. The dosage of the osmanthus flower additive accounts for 0.01 to 5 percent of the weight of the cut tobacco, the tobacco stems or the tobacco sheets. The osmanthus flower additive is characterized by the harmony of the osmanthus flower fragrance and the tobacco fragrance and can soften the cigarette fragrance and reduce the irritation of the cigarette smoke to the respiratory system and the harm of smoking.

Owner:CHINA TOBACCO GUANGXI IND

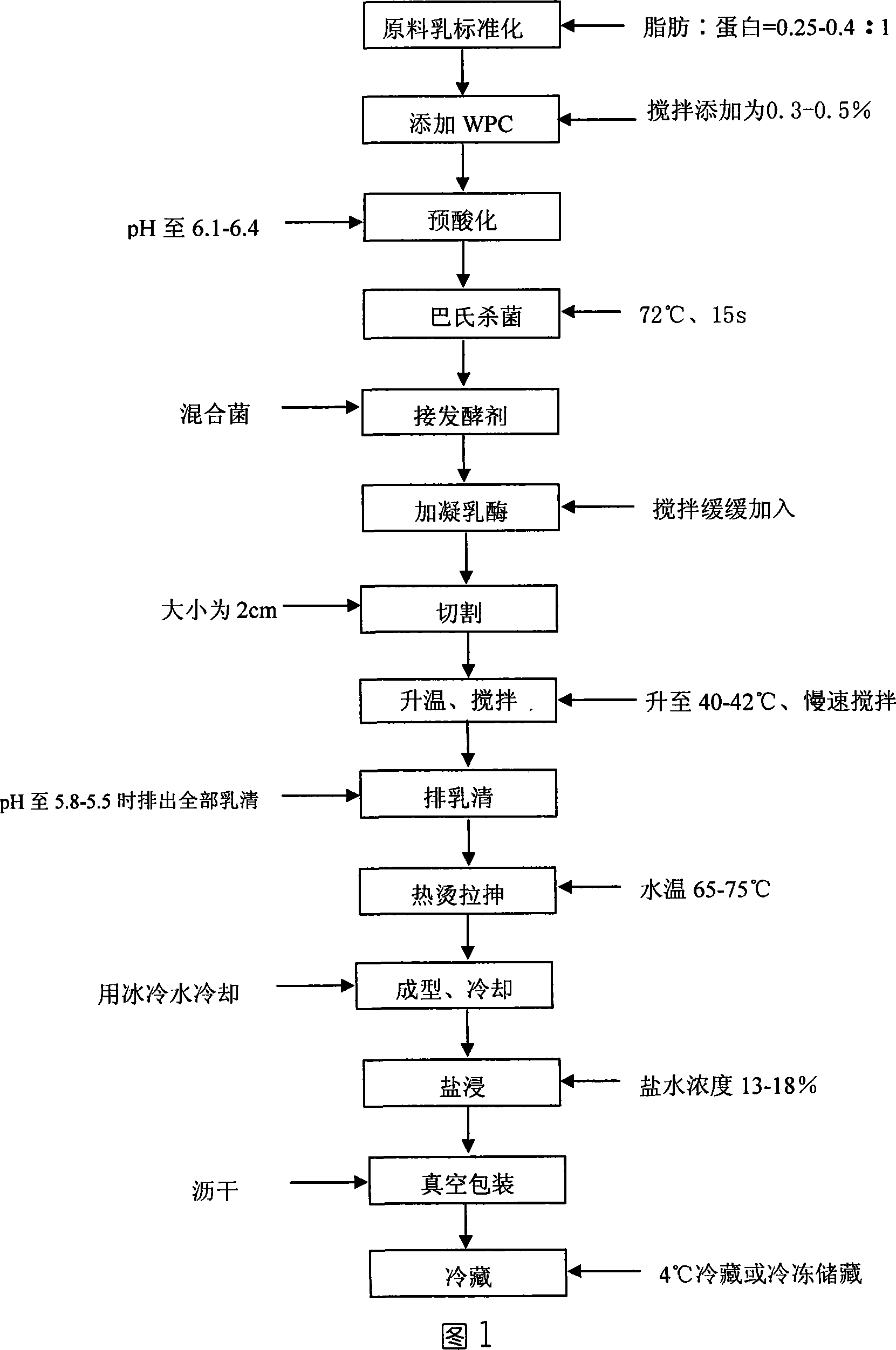

Low fat wire-drawing type cheese and preparation method thereof

InactiveCN101180993AImprove qualityImprove water holding capacityCheese manufactureFlavorMozzarella cheese

The invention provides a preparation method of a low fat Mozzarella cheese, aiming at improving flavor and taste of low fat cheese. The cheese is endowed with excellent qualities by adding whey protein concentrate (WPC) into low fat milk, adopting selective compound bacteria as ferment, and optimizing technique parameters. The preparation steps of the low fat drawing cheese comprise: degrease disposing of cowmilk, pasteurization, preparatory culture, adding renninum, discharging whey, drawing and salting, etc. The cheese obtained with the invention method has the advantages that: the cheese has good plasticity, supple taste and soft incense; fat content of the cheese is 1 / 3 to 1 / 4 of that of the common cheese, and requirements of cheese favorer and specific population are met; quality of the product is easier to be accepted by consumers, therefore the product has practical application significance.

Owner:SANLU GROUP

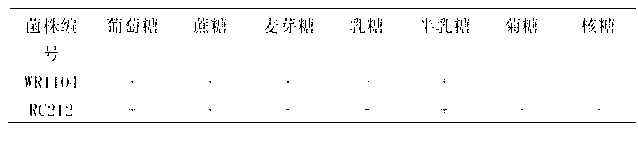

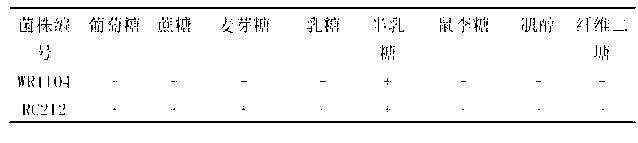

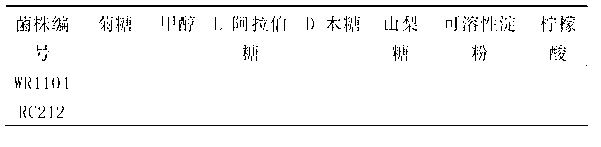

Saccharomyces cerevisiae and application of the same in dry red wine brewing

ActiveCN103215195AStrong stress resistanceImprove permeabilityFungiMicroorganism based processesFruit wineCLARITY

The present invention provides a strain of saccharomyces cerevisiae, wherein a preservation number is CCTCC NO:M 2012500. The saccharomyces cerevisiae has characteristics of strong stress resistance, high sugar resistance, high temperature resistance, high alcohol resistance, good permeability, and high alcoholicity of the produced wine, can be widely used for brewing excellent quality red wines of various characteristic red grape varieties in China production regions, and can further be used for brewing blue berry wines, jujube wines, and other high-end fruit wines with various characteristics and ordinary fruit wines. According to the present invention, compared to a new wine fermented by commercial yeast RC212, a new wine brewed by fermenting a merlot grape raw material through the saccharomyces cerevisiae has characteristics of good clarity, rich aroma, soft and pleasure taste, good attachment to wall, and good mellow taste; compared to the new wine fermented by commercial yeast RC212, a new wine brewed by fermenting a Cabernet Sauvignon grape raw material has characteristics of good clarity, rich aroma, mellow taste, and good attachment to wall; and the saccharomyces cerevisiae of the present invention is suitable for fermenting Syrah, Cabernet Gernischt and other red grape varieties, and can further be used for fermenting blue berry wines, jujube wines, and other high-end fruit wines with various characteristics, and brewing ordinary fruit wines.

Owner:QINGDAO VLAND BIOTECH GRP

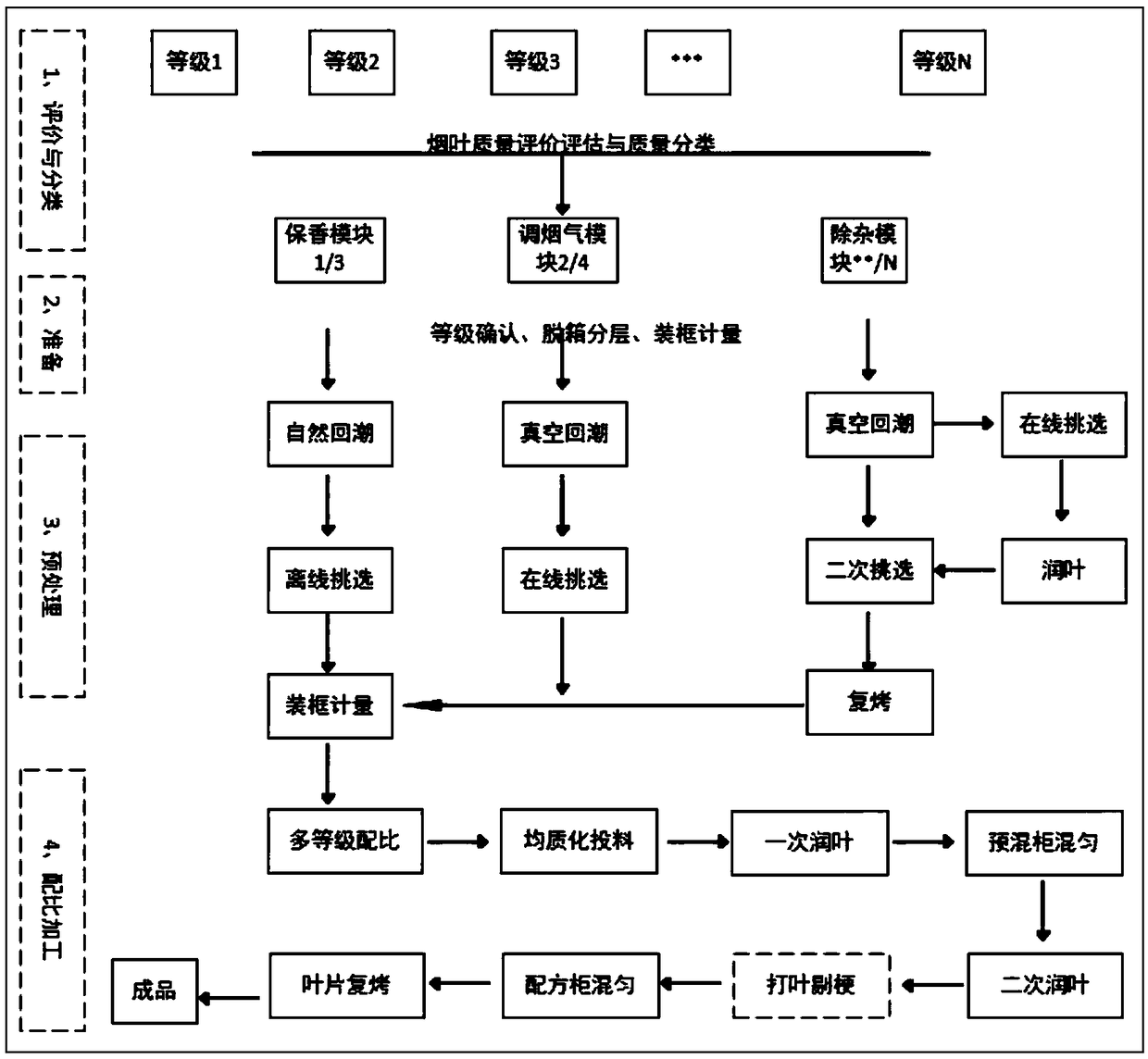

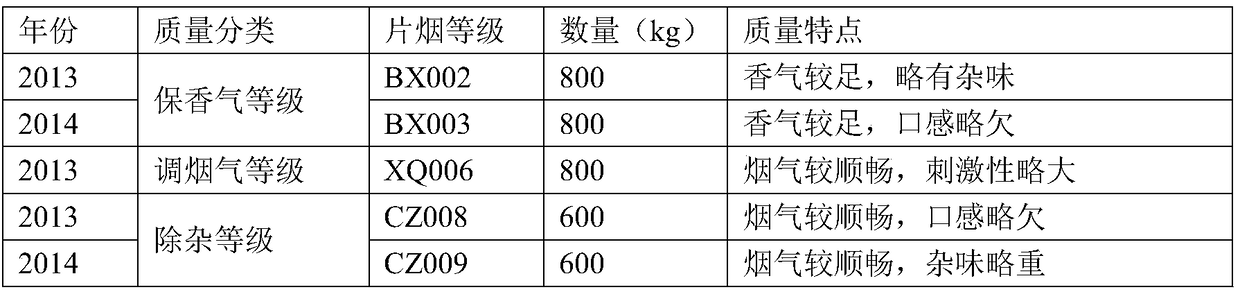

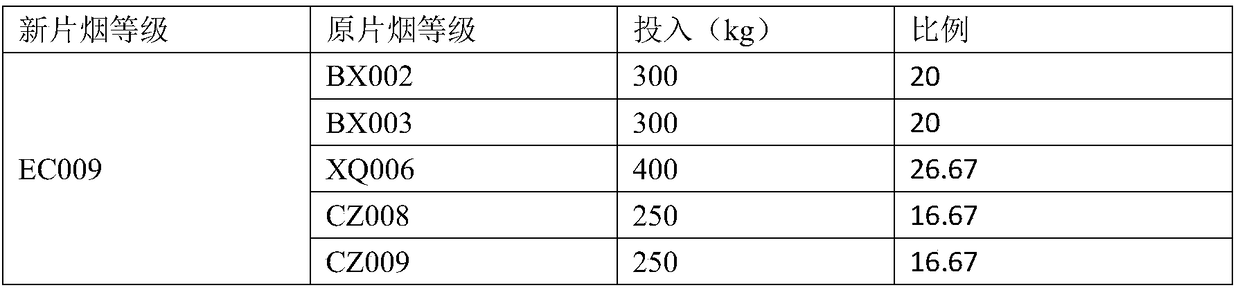

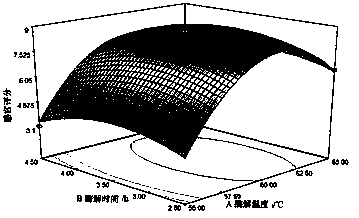

A slice tobacco processing method for improving the use value of raw materials by using a redrying production line

InactiveCN109171000AThe process technology method is simpleScientific and reasonable designTobacco preparationProduction lineChemical composition

The invention provides a slice tobacco processing method for improving the use value of raw materials by utilizing a redrying production line, which comprises the following steps: (1) sensory evaluation of the quality of the slice tobacco and classification of the quality categories; (2) adopting an appropriate pretreatment moisture regain and leaf selection method according to the slice tobacco of different quality grades; and (3) mixing the slice tobacco of different grades and processing the slice tobacco to obtain a finished product. The invention has the advantages of simple technologicalmethod, scientific and reasonable design, strong operability, easy realization of continuous production, pure aroma, smoother smoke, obvious improvement of irritation and aftertaste, more coordination of chemical composition content, more reasonable blade structure, and remarkable improvement of formula value after the processing of the tablet tobacco raw material.

Owner:HUBEI CHINA TOBACCO IND

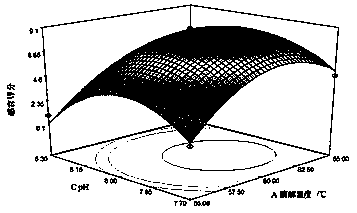

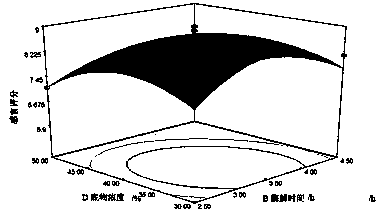

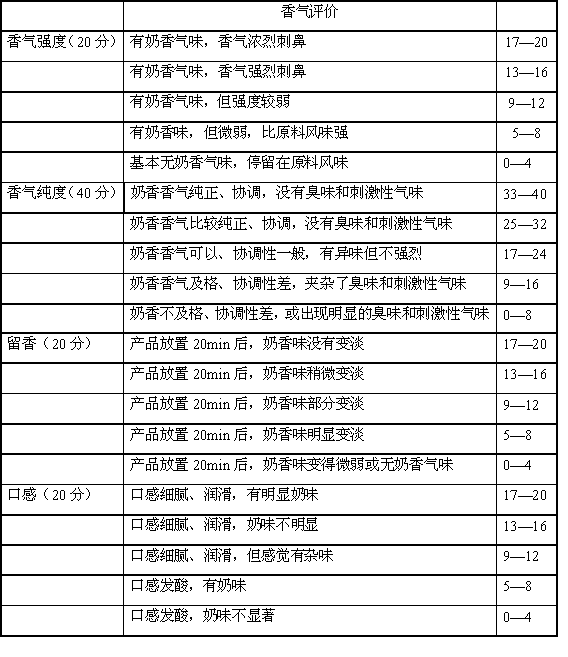

Preparation method of natural milk flavor essence

InactiveCN103404828AOptimizing the enzymatic hydrolysis processReduce the impactFood preparationSingle creamEngineering

The invention discloses a preparation method of natural milk flavor essence. The preparation method takes single cream as a starting raw material, and comprises the following steps: adding an emulsifying agent and mixing with water; homogenizing and emulsifying by using a high-speed homogenizing shearing machine; pasteurizing and cooling; adjusting the pH (Potential of Hydrogen) of the system to be 7.2-8.4; adding 20,000L of lipase Palataste which accounts for 0.5-2.0% of the mass of the single cream, controlling the temperature to be 40 DEG C-70 DEG C, and carrying out enzymolysis for 2.5-5.0 hours; then controlling the temperature to be 85 DEG C, carrying out enzyme deactivation and cooling to obtain the natural milk flavor essence. The natural milk flavor essence prepared by the preparation method disclosed by the invention has the advantages of natural and soft aroma and long aroma keeping time, which cannot be realized by same-type milk essence prepared from a single spice. The preparation method of the natural milk flavor essence disclosed by the invention has the characteristics of low production cost, no pollution in a production process, great economic benefits, high product purity, good safety and the like.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

Method for preparing natural milk essence

The invention discloses a method for preparing a natural milk essence. The preparation method is characterized by comprises the following steps: 1, mixing butter with whey powder according to the mass percentage of 5:1 to 11:1; 2, adding 95% ethanol, stirring and dissolving, wherein the adding amount of the ethanol conforms to the requirement of just dissolving the butter and the whey powder; 3, sterilizing for 5min at the temperature of 85 DEG C, cooling to 40 DEG C to 60 DEG C; 4 and adding butter lipase, wherein the added lipase is 0.2 to 0.4% of the mass of the butter, and carrying out a reaction for 3h to 5h at the temperature of 40 DEG C to 60 DEG C with pH (potential of hydrogen) of 6 to 8 so as to obtain a hydrolysate; 5, adding a reactant to the hydrolysate, emulsifying by using an emulsifying stirrer and carrying out a Maillard reaction for 90min under the condition of 85 DEG C; and finally, obtaining a finished product. The milk essence prepared by the method has a natural, delicate and realistic flavor, so that the internal quality of a flavored product is enhanced and improved obviously. Therefore, the flavored product has a natural milk flavor.

Owner:NANYANG INST OF TECH

Additive agent for jasmine fragrance type cigarette, preparation and application thereof

ActiveCN101317692AImprove tasteAroma harmonyTobacco preparationTobacco treatmentChemistryNicotiana tabacum

The invention relates to a jasmine flower additive for tobacco and the preparation method and applications thereof. The jasmine flower additive essentially consists of the jasmine flowers. The preparation method includes the steps that the jasmine flowers are extracted by heating and refluxing petroleum ether or ethanol solution or by soaking at ambient temperature; the extracted fluid is filtered and then decompressed and condensed into jasmine flower soaking cream which is mixed with honey in certain proportion to obtain the jasmine flower additive for tobacco. The jasmine flower additive is dissolved in the solution of ethanol and propanediol with certain concentration to form saturated solution, which is then evenly sprayed on cut tobacco, tobacco stems or tobacco sheets which are then prepared into cigarette. The dosage of the jasmine flower additive accounts for 0.01percent to 5percent of the weight of the cut tobacco, the tobacco stems or the tobacco sheets. The jasmine flower additive is characterized by the harmony of the jasmine flower fragrance and the tobacco fragrance and can soften the cigarette smoke and reduce the irritation of the cigarette fragrance to the respiratory system and the harm of smoking.

Owner:CHINA TOBACCO GUANGXI IND

Hawthorn essence and preparation method thereof

ActiveCN102894340ANatural and freshSoft aromaAnimal feeding stuffEssential-oils/perfumesEugenolEthyl ester

The invention discloses a hawthorn essence and a preparation method thereof. The hawthorn essence comprises the raw materials by weight percent: 10.0-20.0% of hawthorn extract, 0.3-1.0% of eugenol, 0.05-0.2% of lemon oil, 0.1-0.3% of geraniol, 0.1-0.5% of hexenyl acetate, 1.0-2.0% of 2-methyl butyric acid, 0.1-0.5% of strawberry acid, 0.1-0.3% of acetic acid, 0.5-1.0% of ethyl acetate, 0.5-1.0% of ethyl butyrate, 0.1-0.5% of isoamyl acetate, 0.1-0.3% of trans-2-hexene aldehyde, 0.05-0.2% of furanone and the balance of propylene glycol. The hawthorn essence provided by the invention has natural hawthorn fragrance and taste, is high in natural feel and fresh feel, and is mild and lasting in fragrance.

Owner:成都大帝汉克生物科技有限公司

Compound type fruit vinegar beverage

InactiveCN103393181ASoft aromaHas therapeutic and health effectsMicroorganism based processesVinegar preparationNutritive valuesLimonium

The invention relates to a fruit vinegar beverage, and in particular relates to a compound type fruit vinegar beverage. The compound type fruit vinegar beverage is characterized by comprising the following components in parts by weight: 3-5 parts of lemon, 3-5 parts of green plum, 1-2 parts of roselle, 6-8 parts of Citrus oleocarpa Tanaka, and 6-8 parts of pineapple through alcoholic fermentation and acetic fermentation. The compound type fruit vinegar beverage prepared from the five common tropical and subtropical fruits including lemon, green plum, roselle, Citrus oleocarpa Tanaka and pineapple through alcoholic fermentation and acetic fermentation has the ruby red color which can not be seen from common fruit vinegar beverages, is clear and transparent, has the special compound fruit scent of the tropical and subtropical fruits, has the soft aroma, is pure, fresh and pleasant, has the unique fermentation flavor of fermented vinegar, as well as palatable sour and sweet, and all the flavors are coordinated, so that the compound type fruit vinegar beverage has the special flavor of compound fruit vinegar; moreover, the fruit vinegar has rich nutritive values and certain dietary therapy health efficacy, thus also being nutrition vinegar and health care vinegar.

Owner:赵国华

Method of preparing natural milk-flavored essence by virtue of enzymatic hydrolysis of double enzymes and fermentation of multiple microorganisms

ActiveCN103907890AIncrease pleasureEnhance the sense of durabilityFood hydrolysisFood ingredient as taste affecting agentMicroorganismWax

The invention discloses a method of preparing natural milk-flavored essence by virtue of enzymatic hydrolysis of double enzymes and fermentation of multiple microorganisms, with natural cream as a raw material. The method comprises the following operating steps of melting the cream; adding a medium and an emulsifier; carrying out homogeneous emulsification; carrying out pasteuring; carrying out enzymatic hydrolysis of the double enzymes, anddeactivating the double enzymes; carrying out fermentation of the microorganisms, and drying to prepare the milk-flavored essence. With the adoption of the method, the enzymatic hydrolysis time is shortened; middle-and-short-chain fatty acids of C4-C12 are generated; meanwhile, as milk proteins are hydrolyzed into flavor such as polypeptide and amino acid by virtue of protease to form a unique milk flavor, the strong, pleasure and lasting feelings of the taste of the milk in the essence are strengthened, and the bitterness and the wax taste caused by the middle-and-short-chain fatty acids are eliminated; by virtue of the fermentation of multiple microorganisms, flavor compounds are increased; as a great deal of lactic acids are generated due to the fermentation of lactic acid bacillus, the flavor and the taste can be improved to form diversified acides and milk flavors, and the fragrance is further softened. The natural milk-flavored essence prepared according to the invention is pure and soft in fragrance and is strong in milk flavor; and compared with the natural cream without treatment, the fragrance of the natural milk-flavored essence can be strengthened by 20-300 times.

Owner:I&D INT FLAVOURS & FRAGRANCES GZ

Honeysuckle ice cream and processing technology thereof

The invention discloses a honeysuckle ice cream and a processing technology thereof, relating to ice creams and processing technologies thereof. The honeysuckle ice cream provided by the invention is unique in fragrance of honeysuckle, cool and tasty and enriched in nutrition. The honeysuckle ice cream comprises the following components in percentage by weight: 0.5-0.7 percent of honeysuckle, 8-10 percent of whole milk powder, 10-16 percent of white granulated sugar, 2-6 percent of margarine, 0.1 percent of essence, 1.0-2.0 percent of cyclodextrin, 6-8 percent of syrup, 0.2-0.3 percent of sodium alginate, 0.1-0.2 percent of monostearin and 0.1-0.2 percent of sucrose ester.

Owner:黎雅悦

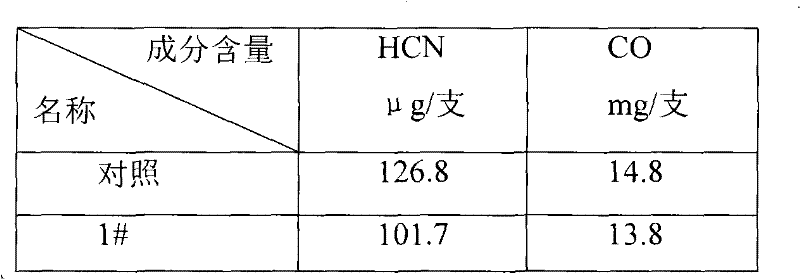

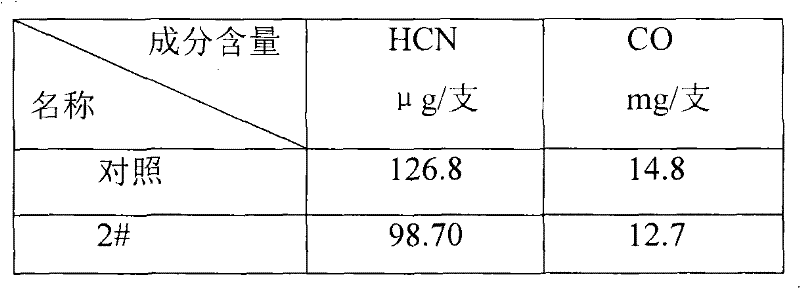

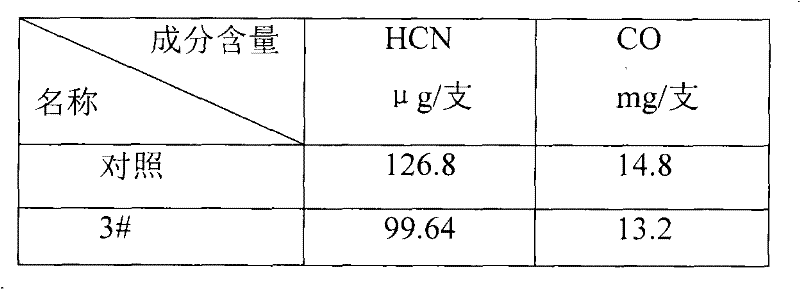

Preparation and adding methods of additive capable of reducing HCN and CO content of cigarettes

ActiveCN102125300AImprove qualityQuality and safetyTobacco treatmentBULK ACTIVE INGREDIENTActive ingredient

The invention discloses preparation and adding methods of an additive capable of reducing HCN and CO content of cigarettes. The additive for cigarette is prepared by a stage extraction or direct water extraction method, wherein thamnolia vermicularis asahina serves as a raw material. The adding method comprises the following steps of: fully stirring and uniformly dissolving one or more of the prepared first additive, the prepared second additive and the prepared third additive in 95 percent ethanol of which the weight is 5 to 20 times that of the additive; freezing the mixture for 5 to 15 hours at the temperature of between -5 and -20 DEG C; taking out and suction-filtering the mixture to obtain a filtrate; taking the filtrate of which the weight is 0.01 to 0.05 percent of that of tobaccoshreds, and adding the 95 percent ethanol until the total weight of the ethanol and the filtrate is 2 percent of the weight of the tobacco shreds; uniformly mixing the ethanol and the filtrate; uniformly spraying the mixture onto the tobacco shreds; and balancing the tobacco shreds for 48 hours under the conditions that the temperature is 22 DEG C and the humidity is 60 percent. An active ingredient is extracted from the thamnolia vermicularis asahina with excellent effects and serves as the additive. The additive is applied to the production of cigarettes to reduce the content of harmful components, namely HCN and CO, of the cigarettes.

Owner:云南瑞升香料技术有限公司

Application method of tobacco raw material particles in cabo product

InactiveCN103005695AImprove suction qualityIncrease aromaTobacco treatmentMaterials scienceRaw material

The invention relates to an application method of tobacco raw material particles in a cabo product, which comprises the following steps that after expansion treatment is performed on cabo raw materials, the cabo raw materials are shattered into cabo particles with the moisture content less than or equal to 10% and the particle diameter less than or equal to 5 mm by adopting a mechanical shattering mode, or the cabo raw materials are shattered into the cabo particles with the moisture content less than or equal to 3% and the particle diameter less than or equal to 3 mm by adopting an airflow shattering mode; after tobacco raw materials are dried, the tobacco raw materials are shattered into tobacco fragments with the moisture content less than or equal to 10% and the particle diameter less than or equal to 5 mm by adopting the mechanical shattering mode, or the tobacco raw materials are shattered into the tobacco fragments with the moisture content less than or equal to 3% and the particle diameter less than or equal to 3 mm by adopting the airflow shattering mode; then the cabo particles or the tobacco fragments are shattered into 400 meshes to 1000 meshes, so as to obtain the tobacco raw material particles; and finally, the tobacco raw material particles are uniformly mixed with a functional material liquid of the cabo product which needs to be added in accordance with 0.1% to 1% of the weight of the cabo product, so as to be added to the cabo product in a feeding mode. After the tobacco raw material particles are added by adopting the application method, the smoking quality of the cabo product is obviously improved, the source aroma of tobaccos is enhanced, stimulation and offensive odor are obviously weakened, the aroma is smooth, and the availability of the cabo product is obviously increased after treatment.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

Preparation method of tobacco flakes through tobacco stems using biochemical machinery method

InactiveCN103082393APreserve aroma componentsReduce energy consumptionTobacco preparationBiotechnologyAdditive ingredient

The invention discloses a preparation method of tobacco flakes through tobacco stems using a biochemical machinery method. The preparation method of the tobacco flakes through the tobacco stems using the biochemical machinery method comprises (1) conducting pretreatment to tobacco stem materials, (2) putting the tobacco stems into white rot fungi solution, then adding water, preparing biological enzymolysis solution, conducting enzymolysis of the tobacco stems in the biological enzymolysis solution, (3) mixing urea which is 4-10 % of the tobacco stem materials by mass and sodium hydroxide which is 5-15 % of the tobacco stem materials by mass, and adding water to dissolve to obtain lignin degradation solution, spraying the lignin degradation solution into the biological enzymolysis solution to obtain biochemical reaction soak solution, soaking the tobacco stems into the biochemical reaction soak solution and generating biochemical reaction, (4) conducting concentrate fluid exhaustion treatment, (5) conducting pulp abrading and pulp washing treatments, (6) conducting purifying treatment, acquiring tobacco stem pulp, (7) manufacturing tobacco base flakes, and (8) obtaining the tobacco flakes. The preparation method of the tobacco flakes through the tobacco stems using the biochemical machinery method can remove the lignin in the tobacco stems effectively, reserves tobacco ingredients in the tobacco stem, and thus turns the waste to wealth, and is safe and environment friendly.

Owner:广州神韵香料科技发展有限公司

Lemon essence for water-based ink and preparation method of lemon essence

The invention relates to lemon essence for water-based ink. The lemon essence is prepared from, by weight, 1%-30% of lemon essence, 5%-55% of compound modification oligosaccharide and deionized water. The lemon essence is composed of lemon oil, litsea cubeba oil, citral diethyl acetal, myrac aldehyde, bergamot aldehyde, lemonile, decanal, caprylic aldehyde, dodecanenitrile, citonellye nitrile, ethyl methylphenylglycidate, linalyl acetate, linalool, lilial, benzyl acetate, cyclamen aldehyde, terpilenol, terpinyl acetate, anisic aldehyde, verdyl acetate, geraniol, geranyl acetate, citronellol, citronellyl acetate, isocyclocitral, styralyl acetate, isoeugenol, ionone, heliotropin, iso-longitolanone, HHCB and ethyl alcohol. The invention further provides a preparation method of the lemon essence for the water-based ink. According to the lemon essence for the water-based ink and the preparation method of the lemon essence, the compound modification oligosaccharide is used as a wall material, the lemon essence is wrapped so that lemon nanocapsule slow-release essence can be formed, and therefore fragrance depositing and water solubility of the essence are improved.

Owner:SHANGHAI INST OF TECH

Method for preparing flavor for elsholtzia kachinensis prain tobacco through multi-strain composite fermentation

The invention discloses a method for preparing a flavor for elsholtzia kachinensis prain tobacco through multi-strain composite fermentation. The flavor for the elsholtzia kachinensis prain tobacco is prepared through twice fermentation, concentration and refining, wherein the first fermentation process comprises the steps of activating strains, preparing seed liquor, treating a raw material, fermenting to obtain primary fermentation liquor and inactivating; the second fermentation process comprises the steps of activating the strains, preparing the seed liquor to obtain secondary seed liquor, inoculating the secondary seed liquor into the primary fermentation liquor, fully and uniformly mixing, and fermenting the inoculated primary fermentation liquor to obtain secondary fermentation liquor; the secondary fermentation liquor is concentrated under reduced pressure to form extractum; and then the extractum is refined to obtain the flavor for the elsholtzia kachinensis prain tobacco. The tobacco flavor prepared with the method has high harmony with tobacco, also has the effects of reducing stimulus, softening smoke and improving after taste and has an obvious effect of improving scent and smoking quality of cigarette, so that the tobacco has faint scent and prominent sweet smell, and fullness and richness are improved.

Owner:YUNNAN REASCEND TOBACCO TECH GRP +1

Preparation method of natural banana spice

ActiveCN104939014ARaw material conversion rate is highIncrease the income of fruit farmersFood ingredient as clouding agentFood ingredient as flavour affecting agentAlglucerasePectinase

The invention discloses a preparation method of natural banana spice. The preparation method comprises the following steps that a whole washed banana is subjected to microwave enzyme deactivation and mashed into thick liquid; pectinase, cellulose and beta glucosidase are added to the obtained thick banana liquid, the mixture is stirred and reacts for 30-120 min at the temperature ranging from 40 DEG C to 50 DEG C, and banana syrup is obtained after enzymolysis is conducted; the banana syrup subjected to enzymatic hydrolysis is filtered centrifugally, and centrifugate is obtained; acid proteinase is added into the centrifugate to be subjected to enzymolysis and clarification at the temperature ranging from 34 DEG C to 36 DEG C for 30-90 min; the obtained matter is subjected to instant enzyme deactivation at the superhigh temperature and then is subjected to sterile filling and sealing, and the liquid natural banana spice is obtained. The natural banana spice has rich, pure and mellow banana flavor, and can be applied to flavor allocation and directly used for food charging.

Owner:ZHEJIANG GREEN CRYSTAL FLAVOR

Powdery yeast extract with chicken flavor and preparation method thereof

The invention discloses a powdery yeast extract with a chicken flavor. The preparation method for the powdery yeast extract with the chicken flavor comprises the following steps of: charging chicken enzyme hydrolysate prepared from chicken, chicken ossein or chicken bone oil and yeast hydrolysate prepared from active yeast and neutral protease into a reactor, raising the temperature to 95 DEG C, and holding the temperature for 20 minutes; adding common salt, white granulated sugar and glucose into the reactor, and fully stirring the mixture for several minutes to dissolve the mixture and obtain a solution; and spraying and drying the solution to obtain the powdery yeast extract with the chicken flavor. The raw materials of the powdery yeast extract with the chicken flavor are purely natural; and the obtained product has the advantages of full and soft aroma, heavy aftertaste, persistent flavor and high temperature resistance, is endowed with a specific aroma with a main aroma of chicken, and can cover up odor and enhance natural flavors. Moreover, the powdery yeast extract with the chicken flavor has the characteristics of small amount, full-bodied taste, and fresh and sweet tasteequalization. The protein content is high, so that the protein standard within chicken essence (powder) national standards can be obviously improved. Furthermore, the product is not added with additional flavor essences, aromatic chemicals and antiseptic agents, and thus is purely natural and environment-friendly.

Owner:珠海天香苑生物科技发展股份有限公司

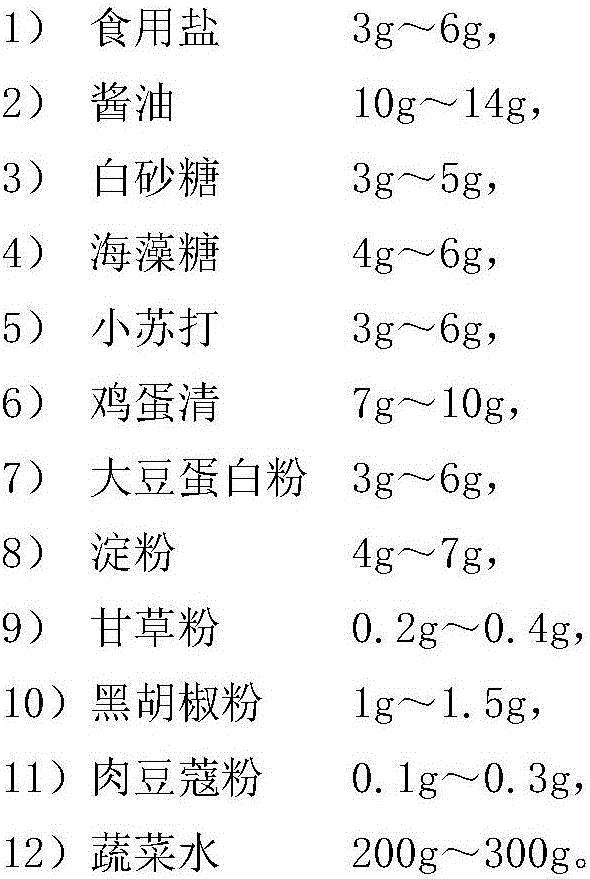

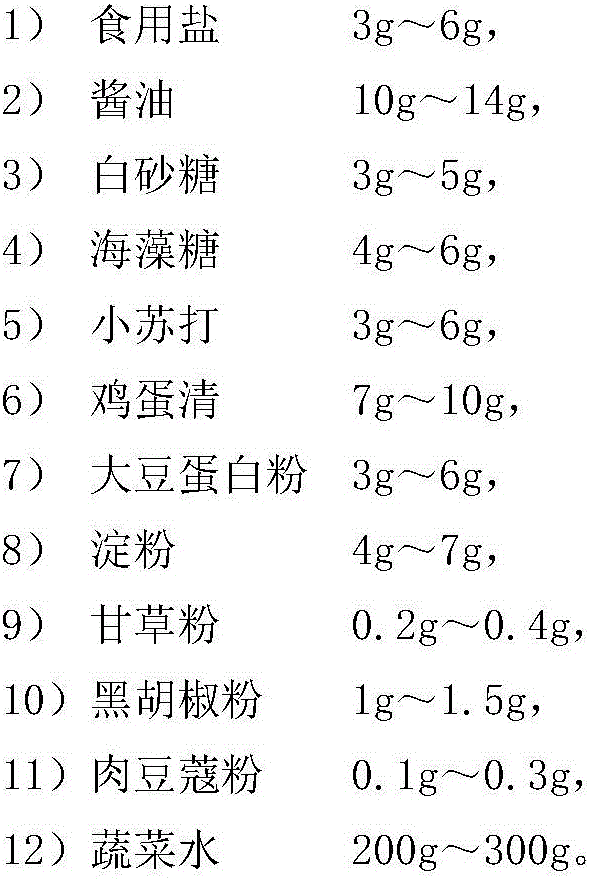

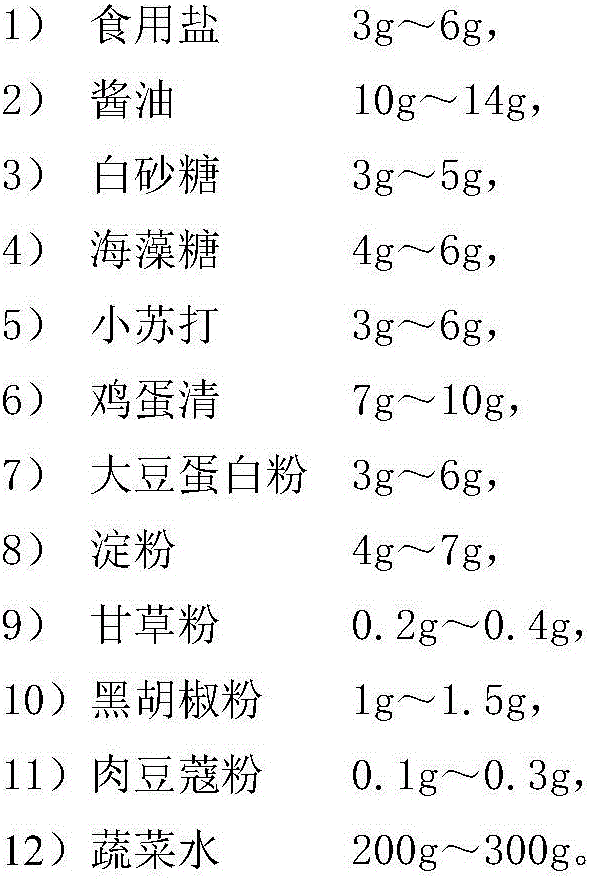

Steak for children and manufacturing method thereof

The invention relates to the technical field of steak processing, in particular to a steak for children and a manufacturing method thereof. The steak for children comprises steak raw materials and seasoning. The seasoning comprises, by weight, 3-6 g of edible salt, 10-14 g of soy, 3-5 g of white granulated sugar, 4-6 g of trehalose, 3-6 g of baking soda, 7-10 g of egg white, 3-6 g of soyabean protein powder, 4-7 g of starch, 0.2-0.4 g of licorice powder, 1-1.5 g of ground black pepper, 0.1-0.3 g of ground myristica fragrans and 200-300 g of vegetable oil. The product is ruddy in color, soft and natural in fragrance, salty, fresh and palatable, the beef is fine, smooth and rich in elasticity, and the steak is fresh, tender, juicy, rich in nutrition, easy to absorb and absorb and is a product suitable for being eaten by children.

Owner:上海联豪食品有限公司

Leavening with violet perfume and production method and purpose thereof

InactiveCN102492729AElegant aromaUnique aromaTobacco preparationComponent separationFlavorMicroorganism

The invention relates to a microbial leavening with violet perfume and a preparation method thereof. The method includes Paenibacillus amylolyticus BM-B-340 seed culture, shaking fermentation, leavening separation and other steps. The leavening containing 7,8-dihydro-Beta-ionol has the perfume of natural tobacco plant. Compared with the perfume of the conventional tobacco essence Beta-irisone, the perfume of the product is more elegant and unique and milder, so the product has a good market prospect and high application value.

Owner:HUABAO FLAVOURS & FRAGRANCES CO LTD

Agilawood essential oil atomized liquid and preparation method thereof

The invention provides agilawood essential oil atomized liquid. The agilawood essential oil atomized liquid is mainly prepared from the following raw materials in parts by mass: 1 to 20 parts of agilawood essential oil and 60 to 90 parts of natural plant extract, wherein the agilawood essential oil comprises the components of aromatic compound and sesquiterpenoids; the natural plant extract comprises the components of N-acetylglucosamine, aloe gel and aloe polysaccharide. A preparation method comprises the following steps of sequentially adding the agilawood essential oil and the natural plant extract, and uniformly mixing and stirring the mixture to obtain the agilawood essential oil atomized liquid. The agilawood essential oil atomized liquid provided by the embodiment of the invention does not contain glycerinum and propylene glycol, and has the effects of health, health care, environment protection, smooth, soft, mellow and unique taste and elegant and noble fragrance.

Owner:深圳合创源生物科技有限公司 +1

Production technology for baijiu with improvement in fragrance

ActiveCN106318833AReduce sulfur-containing pungent odorSoft tasteAlcoholic beverage preparationAcetic acidAlcohol

The invention belongs to the field of baijiu brewing technologies, and particularly relates to a production technology for baijiu with improvement in fragrance. At the high-temperature fermentation stage, a ceramic kiln with ceramic balls is adopted for fermentation, so that ethyl alcohol molecules in the baijiu are arrayed in order gradually, the activity of the ethyl alcohol molecules is reduced, and the taste of the baijiu is softer and milder; by adding apple juice into baijiu, acetic acid generated by fermentation of the apple juice and ethyl alcohol overflowing from the baijiu have an esterification reaction to generate ester as a new product, and alcohol in the baijiu is converted into ester with fragrance. Compared with the method that in the prior art, baijiu is formed by fermentation in a cellar, the baijiu which is prepared through the technology has a fragrant aroma, and the problem that baijiu has a poor taste if people directly drink the baijiu which is stored within short time and still has non-volatized spicy gas is solved.

Owner:湖南小勤人酒业有限责任公司

Paeonia ostii flower kvass and production method thereof

ActiveCN104357300ASoft aromaUnique tasteAlcoholic beverage preparationPlant ingredientsFlavorPaeonia ostii

The invention discloses Paeonia ostii flower kvass and a production method thereof. A Paeonia ostii flower kvass beverage is produced from Paeonia ostii flowers, Paeonia ostii bark and radix glehniae, all of which have health-care efficacy and are subjected to processes such as raw material preparation, fermentation, filtration, filling and sterilization. Specific medicinal components of Paeonia ostii flowers are remained, and the Paeonia ostii flower kvass beverage is sweet, sour and unique in taste, gentle in flavor and rich in nutrition, has the health-care efficacy of removing heat to cool blood and nourishing yin to clear away the lung-heat, and is a health-care beverage with wide market foreground and low alcoholic strength.

Owner:NANLING ZHENHUI GREEN AGRI PROD PRODN & MARKETING FARMER PROFESSIONAL COOP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com