Patents

Literature

60 results about "TERPINYL ACETATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

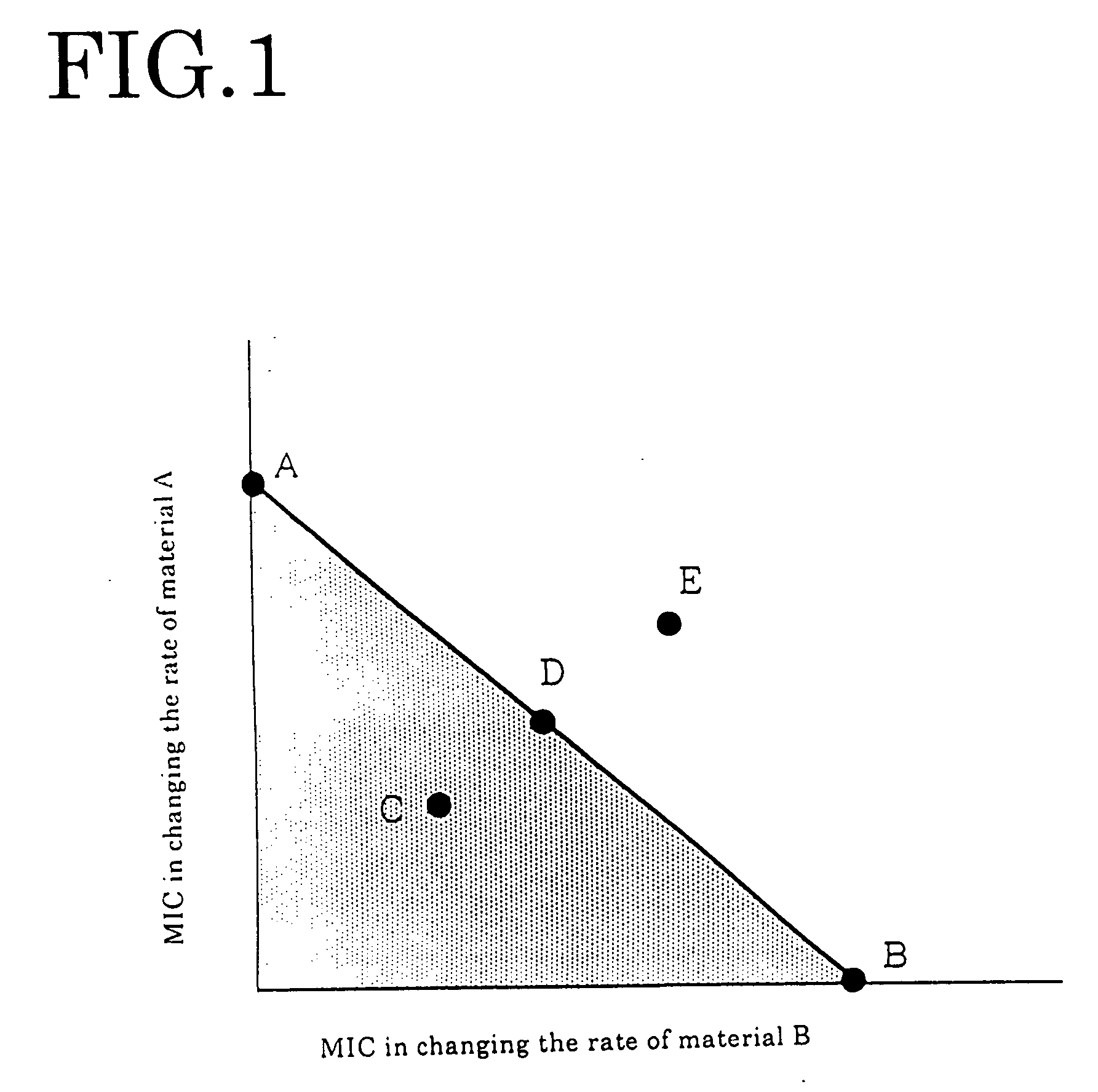

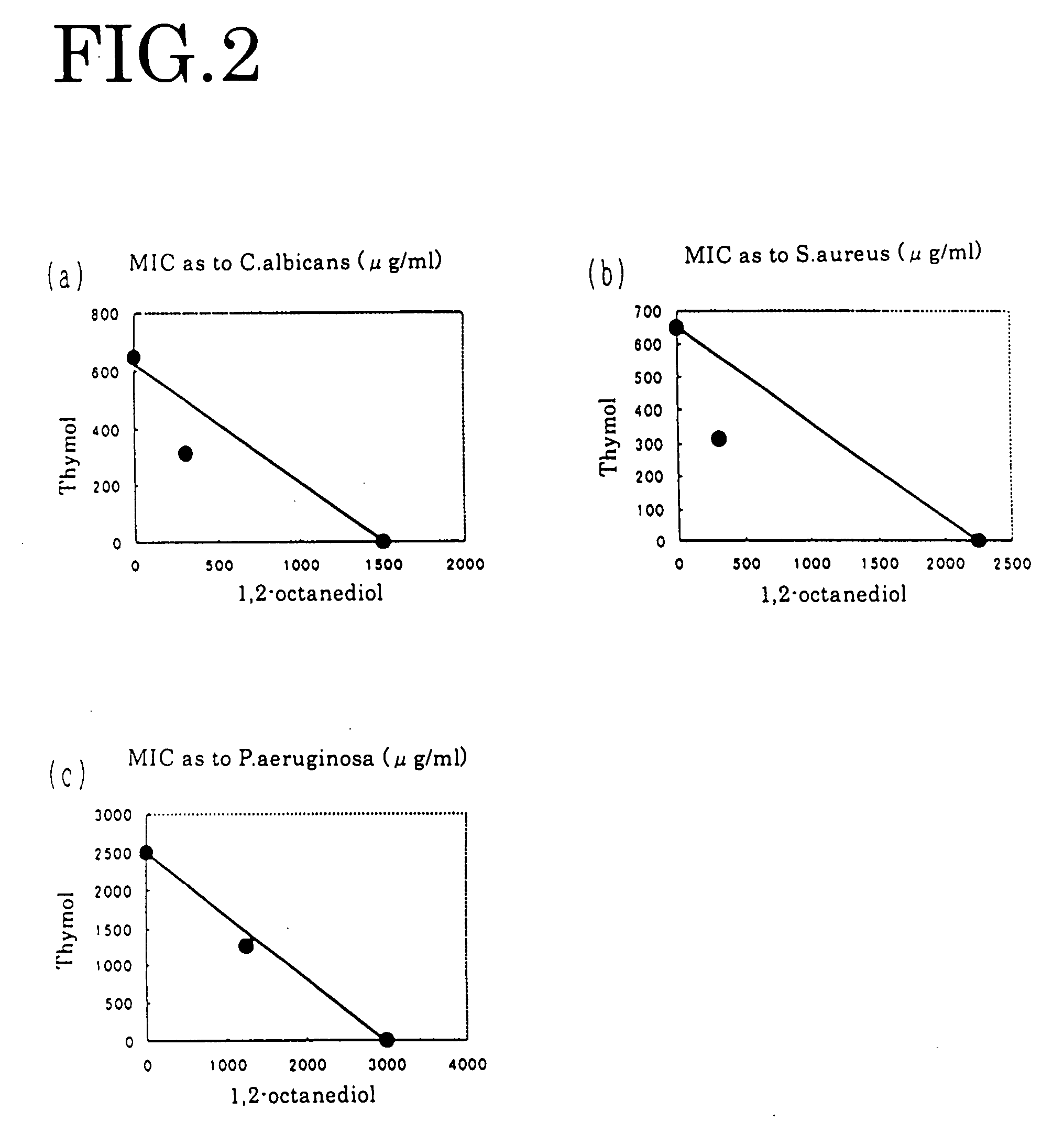

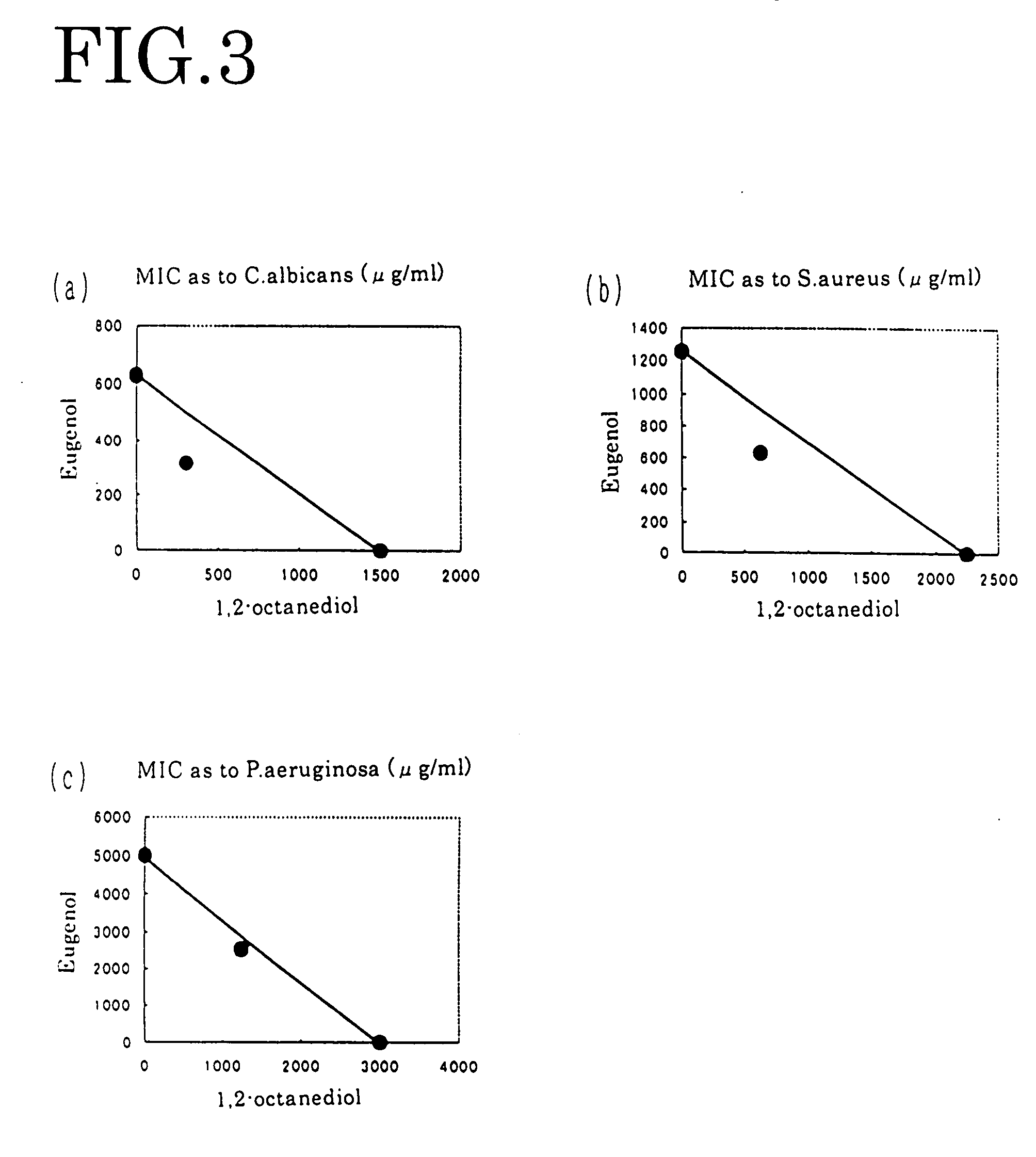

Antiseptic bactericides and cosmetics, drugs and foods containing the antiseptic bactericides

The purpose of the present invention is to provide antiseptic disinfectant, and cosmetics and toiletries, medicine or food containing the same, which enhance the antibacterial activity that 1,2-alkanediol originally have against a broad range of strains by compounding 1,2-alkanediol with 5-10 carbons and a certain fragrance component. The present invention relates to an antiseptic disinfectant, and cosmetics and toiletries, medicine or food containing the same, which include 1,2-alkanediol with 5-10 carbons, and one or more materials selected from a group of thymol, eugenol, citronellal, terpinyl acetate, citronellol and β-pinene.

Owner:MANDOM CORP

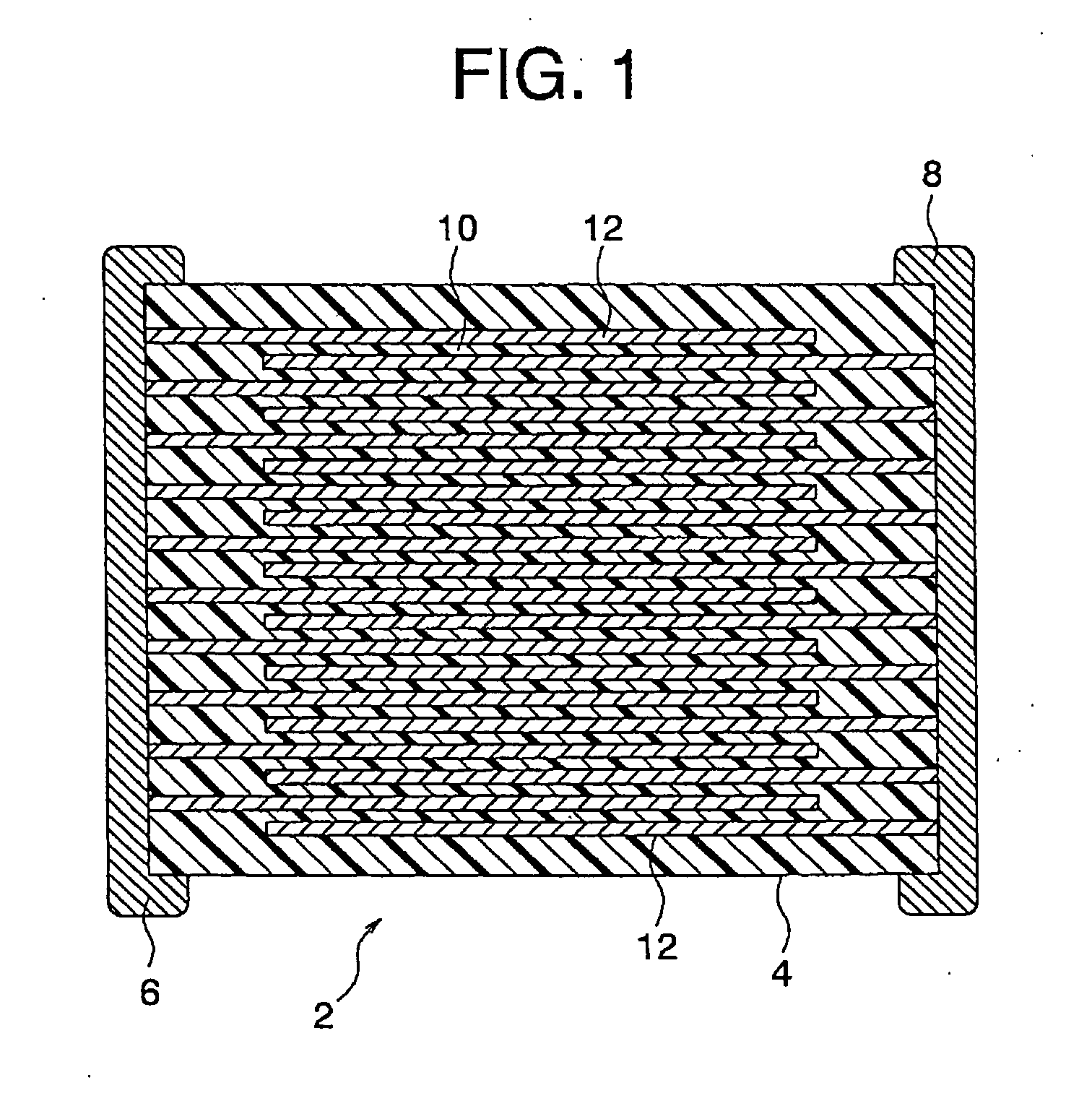

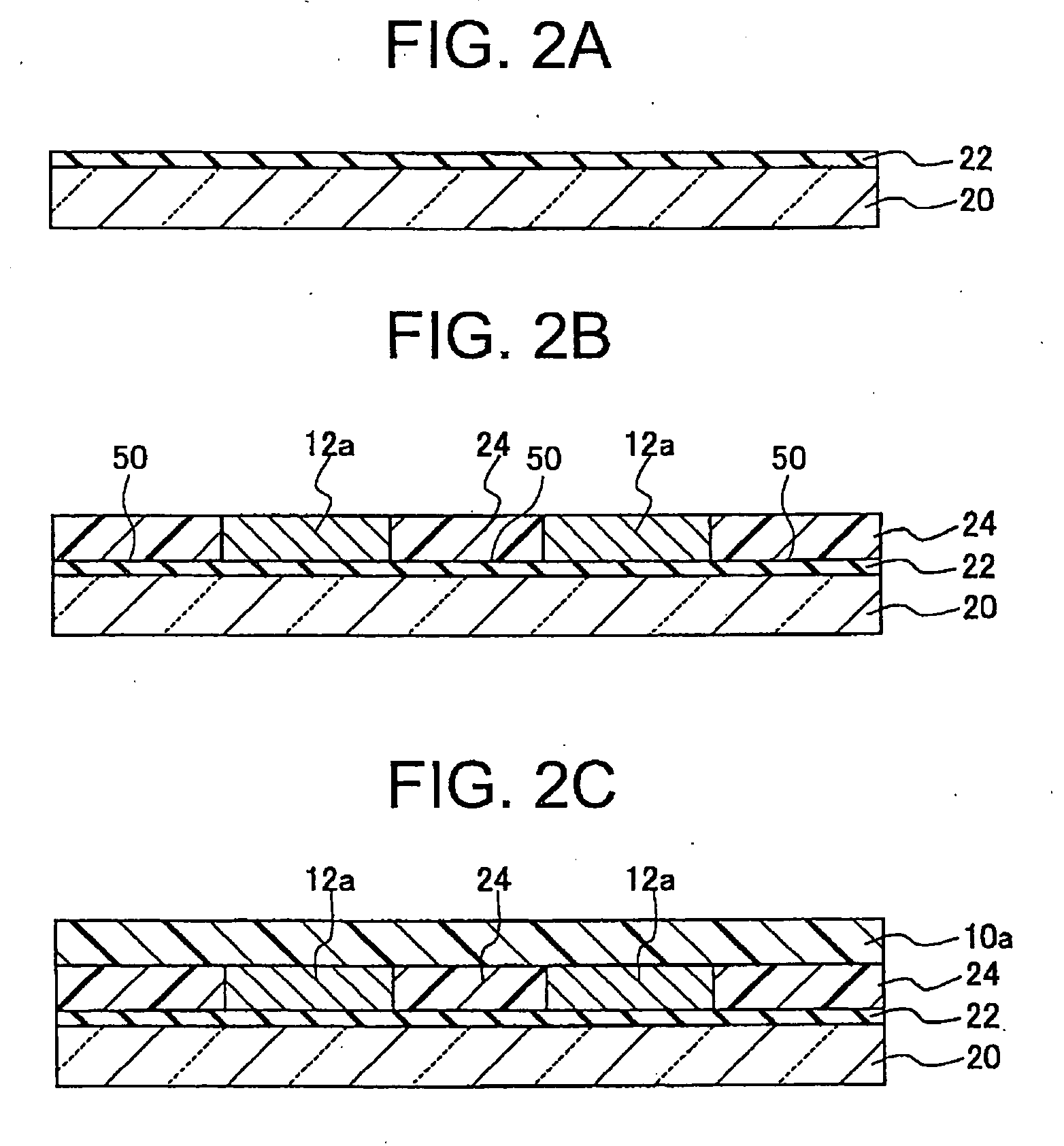

Release layer paste and method of production of a multilayer type electronic device

InactiveUS20070190251A1Enable formationPrintabilityOther chemical processesFixed capacitor electrodesAdditive ingredientSolvent

A release layer paste used for producing a multilayer type electronic device and forming a release layer of a thickness of 0.05 to 0.1 μm, used in combination with an electrode layer paste including one or more solvents selected from limonene, dihydroterpinyl methyl ether, α-terpinyl acetate, terpinyl methyl ether, isobornyl acetate, caryophyllene, 1-dihydrocarvyl acetate, menthone, menthyl acetate, perillyl acetate, carvyl acetate, d-dihydrocarvyl acetate, and butyl carbitol acetate and a binder comprised of ethyl cellulose, including a ceramic powder, organic vehicle, plasticizer, and dispersion agent, the organic vehicle containing a binder having polyvinyl acetal as its main ingredient, a ratio (P / B) of the ceramic powder with respect to the binder and plasticizer being controlled to 1.33 to 5.56 (however, excluding 5.56).

Owner:TDK CORPARATION

Lemon essence for water-based ink and preparation method of lemon essence

The invention relates to lemon essence for water-based ink. The lemon essence is prepared from, by weight, 1%-30% of lemon essence, 5%-55% of compound modification oligosaccharide and deionized water. The lemon essence is composed of lemon oil, litsea cubeba oil, citral diethyl acetal, myrac aldehyde, bergamot aldehyde, lemonile, decanal, caprylic aldehyde, dodecanenitrile, citonellye nitrile, ethyl methylphenylglycidate, linalyl acetate, linalool, lilial, benzyl acetate, cyclamen aldehyde, terpilenol, terpinyl acetate, anisic aldehyde, verdyl acetate, geraniol, geranyl acetate, citronellol, citronellyl acetate, isocyclocitral, styralyl acetate, isoeugenol, ionone, heliotropin, iso-longitolanone, HHCB and ethyl alcohol. The invention further provides a preparation method of the lemon essence for the water-based ink. According to the lemon essence for the water-based ink and the preparation method of the lemon essence, the compound modification oligosaccharide is used as a wall material, the lemon essence is wrapped so that lemon nanocapsule slow-release essence can be formed, and therefore fragrance depositing and water solubility of the essence are improved.

Owner:SHANGHAI INST OF TECH

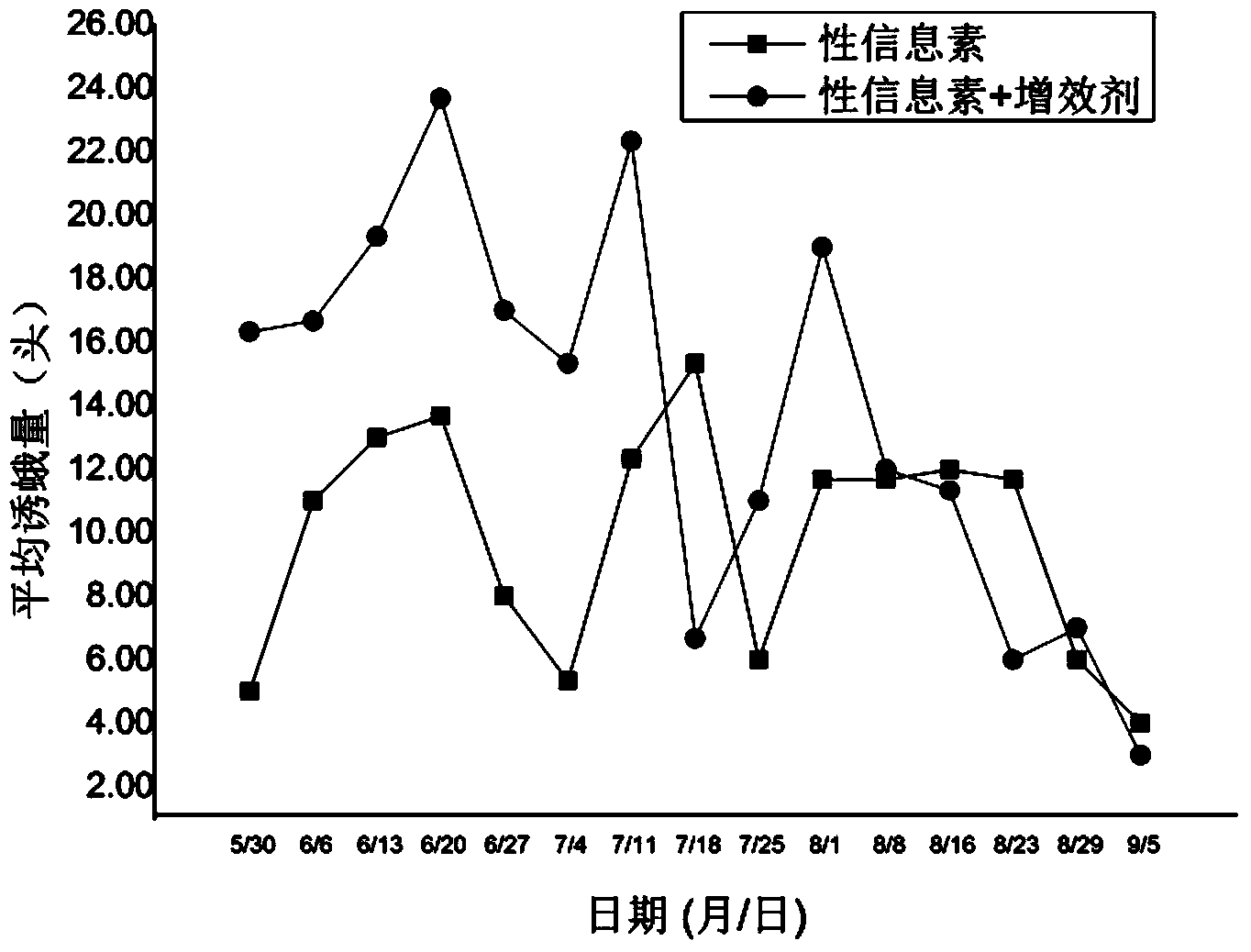

Method for preparing terpinyl acetate

InactiveCN101503354AReduce manufacturing costOvercome many deficienciesPhysical/chemical process catalystsOrganic compound preparationAcetic acidAcetic anhydride

The invention relates to a method for preparing terpinyl acetate, comprising: terpilenol and acetic anhydride are respectively added into a reaction kettle to be stirred, the mixture is added with phosphoric acid to be evenly stirred and then added with SnCl4.5H2O at the room temperature until the SnCl4.5H2O is completely dissolved, and the reaction is carried out under agitation while the temperature gradually raises; the reaction liquid is cooled to be room temperature and added with Na2CO3 to neutralize H3PO4 and SnCl4, and is directly distilled after being neutralized by carbonic acid, so that most acetic acid is evaporated; reaction product is washed by 10% of NaOH solution and saturated saline solution to remove the residual acetic acid until neutrality and then processed by fractionation, so that the terpinyl acetate is obtained. The method has the advantages of providing a novel composite catalyst system and a new technique for synthesizing the terpinyl acetate, being low in cost and simple in post treatment and having higher catalytic activity and reaction selectivity. The method also can ensure the yield of terpinyl acetate, shorten the reaction time, reduce the wastewater in the production and improve the recovery rate of acetic acid byproduct and the concentration of acetic acid.

Owner:NANJING FORESTRY UNIV

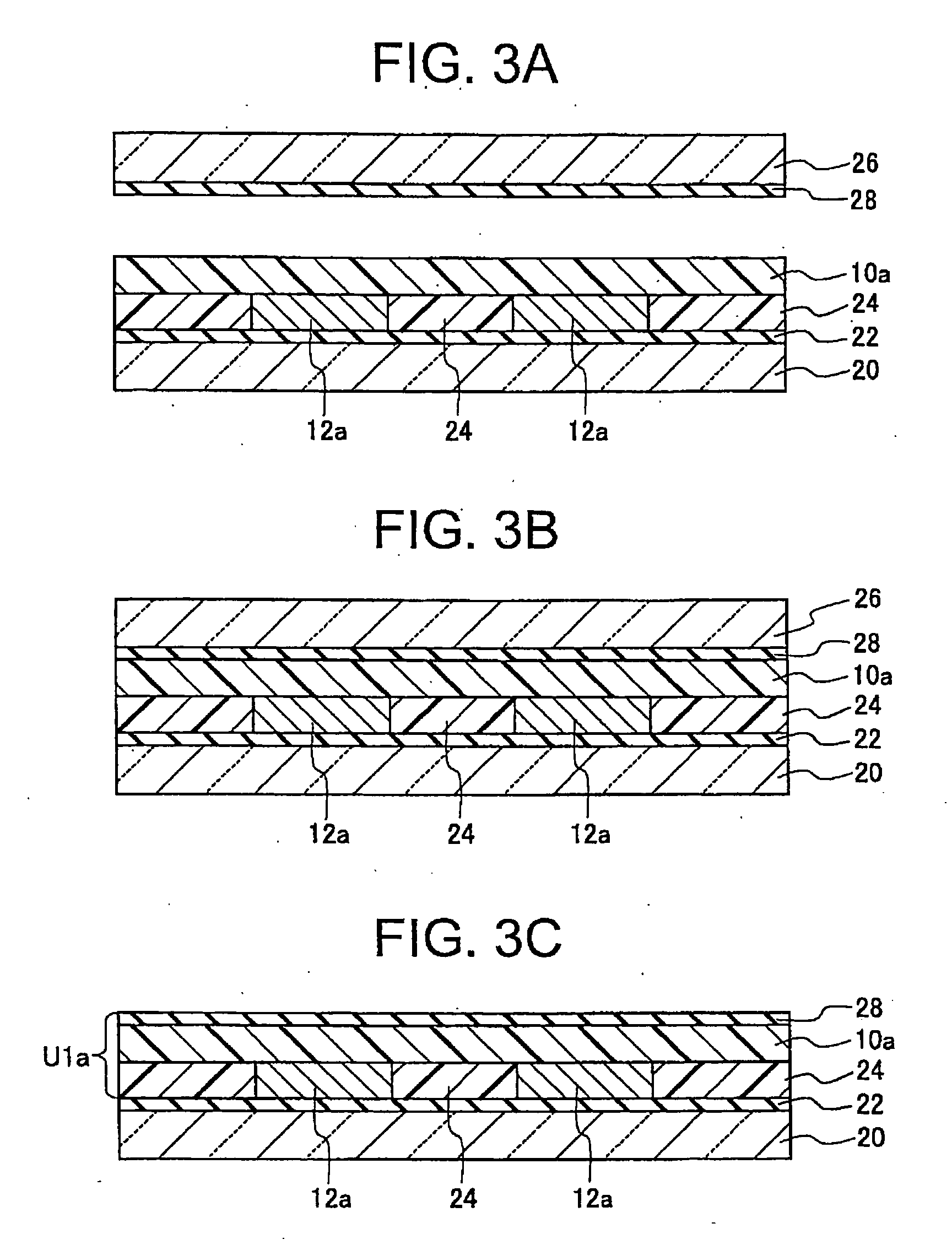

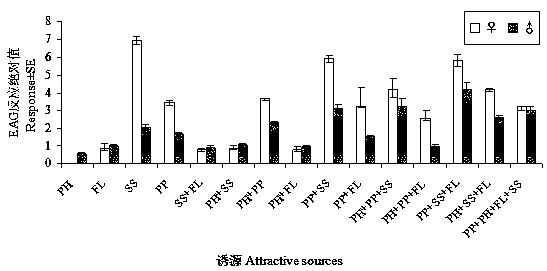

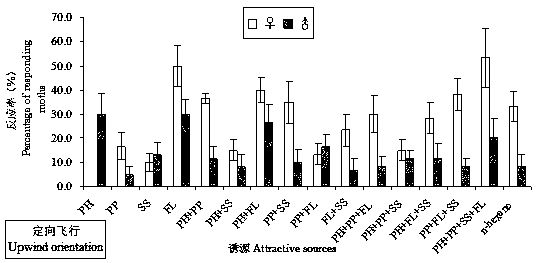

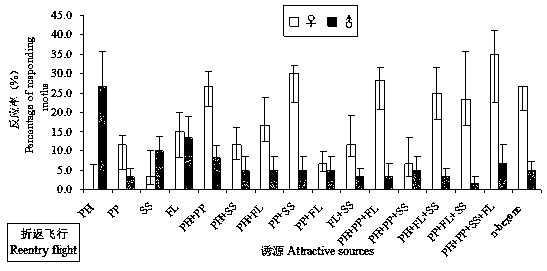

Grapholitha molesta (Busck) sex pheromone synergist and preparation method thereof

InactiveCN104381254AGood lure effectIncrease the amount of moth attractantBiocidePest attractantsAcetic acidTrapping

The invention belongs to the field of agriculture, and provides a Grapholitha molesta (Busck) sex pheromone synergist, which comprises two compounds such as terpinyl acetate and acetic acid, wherein a volume ratio of the terpinyl acetate to the acetic acid is 1-4:1. The invention further provides preparation and applications of the Grapholitha molesta (Busck) sex pheromone synergist. Test results show that the mixture comprising 2000 [mu]L of the alpha-terpinyl acetate and 500 [mu]L of the acetic acid according to the ratio of 4:1 can be adopted as the synergist to increase the attractive capability of the sex pheromone on the male Grapholitha molesta (Busck), such that the moth trapping effect can be optimally enhanced.

Owner:CHINA AGRI UNIV

Antirust agent and preparation method thereof

The invention discloses an antirust agent and a preparation method thereof. The antirust agent is mainly prepared from ammonium gluconate, dodecenylsuccinic acid, sodium nitrite, carrageenin, petroleum calcium sulfonate, ammonium molybdate, acetic acid, hydroxypropyl methyl cellulose, urea, glutamic acid, oxidized petrolatum barium soap, poloxamer, terpinyl acetate, nano titanium dioxide, China wood oil and a modified auxiliary agent. The antirust agent disclosed by the invention adopting ammonium gluconate and terpinyl acetate as main components is good in antirust effect, and also has the effects of resisting sun and sterilizing by matching with nano titanium dioxide, and the modified auxiliary agent improves the overall performance of the antirust performance, so that the antirust agent can achieve an antirust effect normally under the influence of moisture and temperature, and is long in antirust time and small in environmental pollution.

Owner:NANTONG YONGYU ANTI RUST MATERIALS CO LTD

Vapor phase rust inhibitor containing tung oil, and preparation method thereof

The invention discloses a vapor phase rust inhibitor containing tung oil. The vapor phase rust inhibitor containing tung oil is prepared from the following raw materials, by weight, 0.5-1 part of tung oil, 1-2 parts of peanut oil, 0.5-1 part of patchouli oil, 1-2 parts of urotropine, 1-2 parts of glyceryl monooleate, 0.5-1 parts of ethyl cinnamate, 0.5-1 part of terpinyl acetate, 0.1-0.2 parts of bamboo leaf flavone, 6-8 parts of chitosan, 2-4 parts of hydroxypropyl-beta-cyclodextrin, 0.3-0.5 parts of polysorbate 80, 6-8 parts of sodium tripolyphosphate, 1-2 parts of sodium citrate, 8-10 parts of a modification aid and 40-50 parts of water. The rust inhibitor simultaneously has contact rust inhibition and vapor phase rust inhibition efficacies, has the advantages of fast film formation, uniform film, good toughness, good rust inhibition effect, long time, and slow release and controlled release effects, and is suitable for occasions having both requirements of waterborne rust inhibition and sealed space vapor phase rust inhibition.

Owner:ANHUI PROVINCE SUZHOU CITY LONGHUA MACHINERY MFG

Conductive paste for a multi-layered ceramic electronic component and a method for manufacturing a multi-layered unit for a multi-layered ceramic electronic component

ActiveUS7537713B2Avoid short circuit failureGood printabilityConductive materialPretreated surfacesIsobornyl acetateConductive paste

It is an object of the present invention to provide a method for manufacturing a multi-layered unit for a multi-layered ceramic electronic component which can reliably prevent short circuit failure from occurring in a multi-layered ceramic electronic component and form an electrode layer in a desired manner.A method for manufacturing a multi-layered ceramic electronic component includes a step of printing a conductive paste containing a binder containing ethyl cellulose having a weight average molecular weight of MWL and ethyl cellulose having a weight average molecular weight of MWH at a weight ratio of X:(1−X), where MWL, MWH and X are selected so that X*MWL+(1−X)*MWH falls within a range of 145,000 to 215,000 and at least one solvent selected from the group consisting of isobornyl acetate, dihydroterpinyl methyl ether, terpinyl methyl ether, α-terpinyl acetate, I-dihydrocarvyl acetate, I-menthone, I-menthyl acetate, I-perillyl acetate and I-carvyl acetate on a ceramic green sheet containing a butyral system resin as a binder in a predetermined pattern, thereby forming an electrode layer.

Owner:TDK CORPARATION

Elecampane fragrance type tobacco flavor based on perfume threshold value and mixing method thereof

ActiveCN105969521AReduce economic costsEfficiencyTobacco treatmentEssential-oils/perfumesGuaiacolCedrol

The invention relates to elecampane fragrance type tobacco flavor based on a perfume threshold value and a mixing method thereof. The elecampane fragrance type tobacco flavor is prepared from, by weight, 1-20% of a fragrance base and 80-99% of solvent, wherein the fragrance base is prepared from, by weight, 0.5-5.0 parts of thujone, 0.1-2.0 parts of cedrol, 0.5-5.0 parts of terpinyl acetate, 0.5-5.0 parts of guaiol, 0.1-2.5 parts of guaiacol, 0.1-1.0 part of patchoulic alcohol and 0.2-3.0 parts of salvia sclare lactone. Elecampane fragrance type tobacco flavor is added into cut tobacco, a cigarette product is prepared by adopting the routine technology in the field, it is shown through sensory evaluation test results that compared with a blank sample without elecampane fragrance type tobacco flavor, fragrance quality of the cigarette sample with added elecampane fragrance type tobacco flavor becomes higher, fragrance amount is obviously increased, remaining taste is improved, and impurity gas is hidden.

Owner:CHINA TOBACCO HENAN IND +1

Dampness-heat-resistant water-based antirust agent and preparation method thereof

InactiveCN104387940AExcellent heat and humidity resistanceGood weather resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedSucrose

The invention discloses a dampness-heat-resistant water-based antirust agent. The dampness-heat-resistant water-based antirust agent is characterized by being prepared from the following raw materials in parts by weight: 4-6 parts of waterborne polyurethane resin, 0.5-1 part of polydimethylsiloxane, 1-2 parts of sodium N-acyl glutamate, 0.2-0.4 part of octadecyl dihydroxyethyl amine oxide, 1-2 parts of sodium potassium tartrate tetrahydrate, 0.2-0.4 part of terpinyl acetate, 2-4 parts of triethanolamine borate, 0.5-1 parts of poloxamer, 1-2 parts of mannitol, 1-2 part of flaxseed gum, 0.5-1 part of sucrose fatty acid ester, 6-8 parts of a modifying auxiliary and 30-40 parts of water. A film formed by the dampness-heat-resistant water-based antirust agent on a metal surface has good dampness-heat resistance, good corrosion resistance, a good antifouling and antistatic effect and good resistance, and corrosion can be effectively prevented.

Owner:HEFEI DAAN PRINTING

Terpene profile replication blends and their applications

InactiveUS20160374388A1Add flavorReduce harmTobacco preparationOrganic active ingredientsPhellandreneEugenol

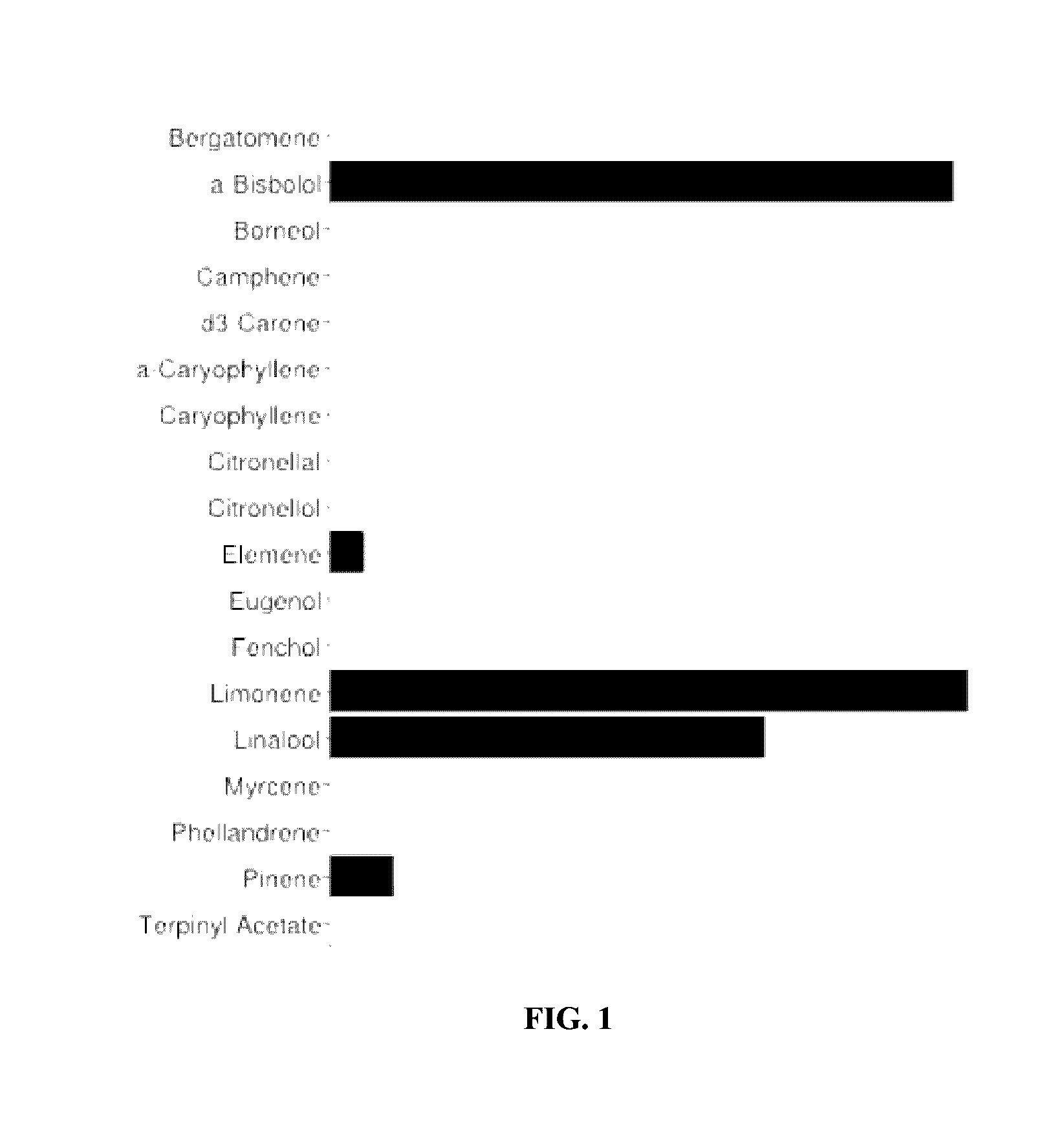

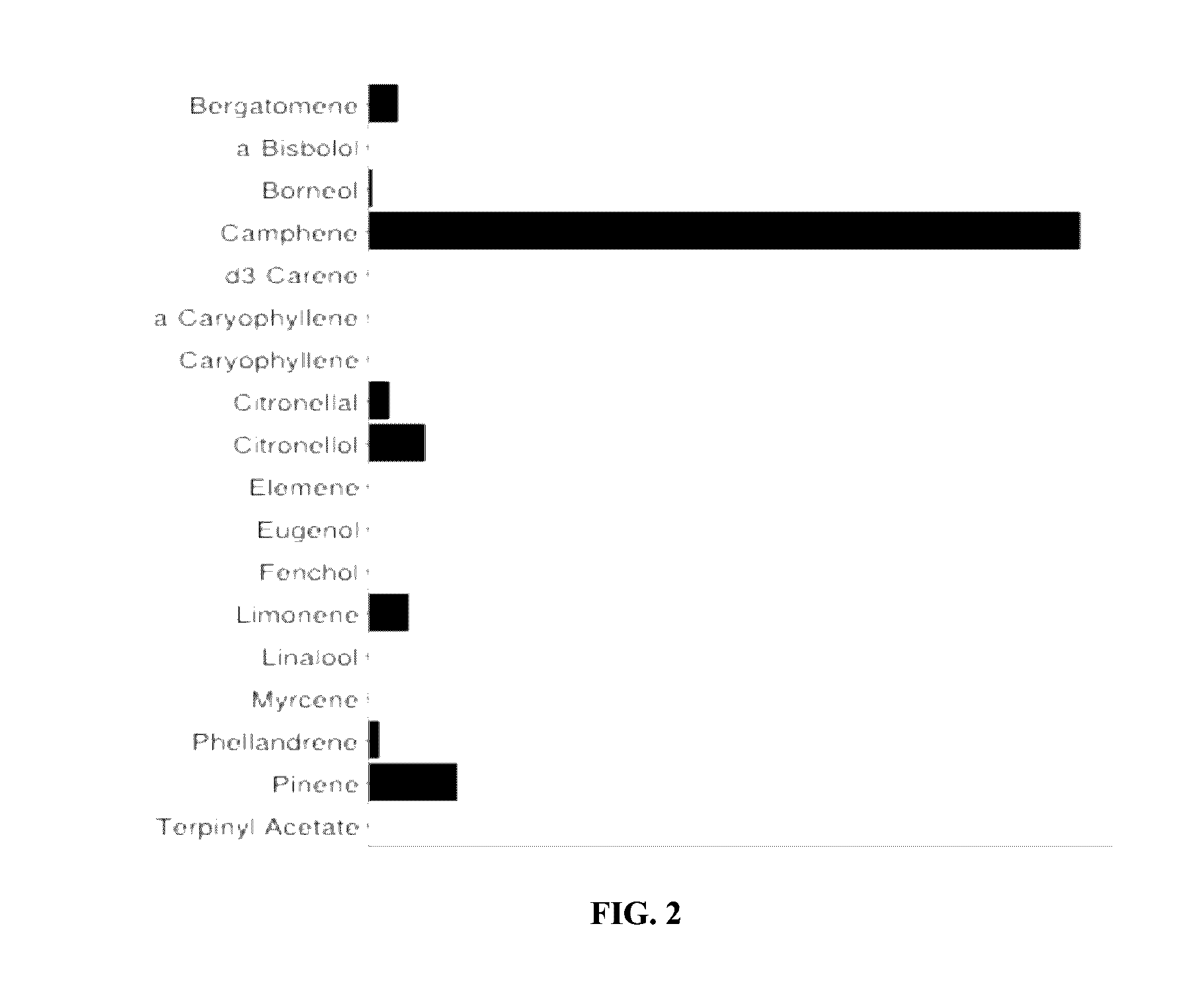

The embodiments herein relate to a method of preparing a terpene profile replication blend. The method comprises determining a combination of terpene for a predetermined application and blending a predetermined quantity of the terpene in a blender for a predetermined time. The combination of terpenes is selected from the group consisting of limonene, linalool, alpha humulene, alpha perpineole, pinene, bergatomene, a-bisbolol, borneol, camphene, d3-carene, a-caryophyllene, caryophyllene, citronellal, citronellol, elemene, eugenol, fenchol, myrcene, phellandrene, or terpinyl acetate.

Owner:THOMSON ANDREW JON

Cat-driving essence as well as preparation method and application thereof

ActiveCN103911214AEffective in repelling catsEssential-oils/perfumesAnimal repellantsLemon oilYlang-Ylang oil

The invention discloses cat-driving essence as well as a preparation method and an application thereof. The cat-driving essence is obtained by adding a certain amount of bergamot oil, lemon oil, citral, linalyl acetate, sweet orange oil, terpilenol, terpinyl acetate, methyl ortho-aminobenzoate, decanal, geranyl acetate, lemonile, geranium oil, menthol, benzyl acetate, benzyl alcohol, linalool, dihydro jasmine with mass fraction of 10%, hydroxycitronellal, benzpyrole with mass fraction of 10%, dihydromyrcenol, methyl ionone, lyral, oil of daidai leaf, ylang ylang oil, gamma-delta-lacton, leaf alcohol, benzyl benzoate, benzyl propionate, methyl dihydrojasmonate, p-cresyl acetate, jasmonyl, phenylacetic acid, eugenol, myracaldehyde, absolute of jasmine, geraniol, cis-3-hexenyl benzoate, galaxolide with mass fraction of 50% and propylene glycol into a container in sequence, shaking uniformly, standing and ageing for two weeks. The cat-driving essence is remarkable in cat-driving effect.

Owner:福建中益制药有限公司

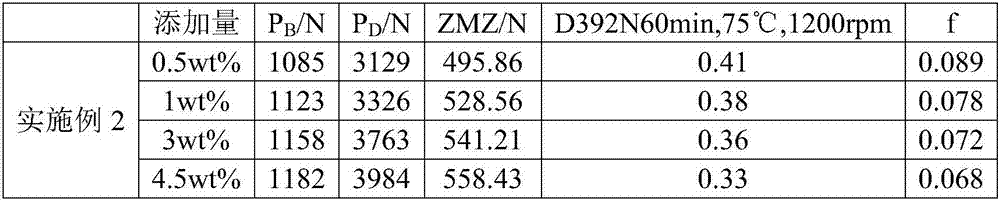

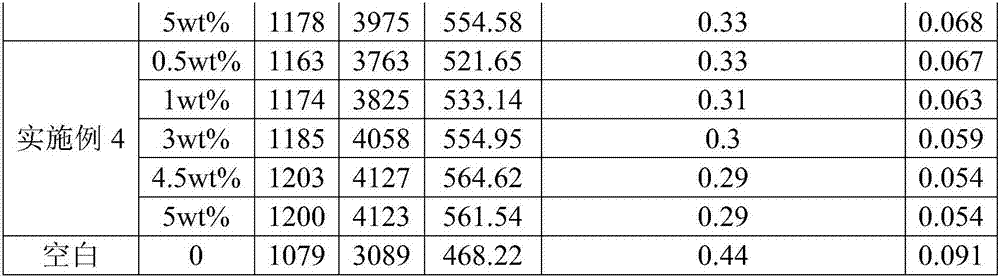

Environment-friendly high-performance antiwear agent

The invention discloses an environment-friendly high-performance antiwear agent. The environment-friendly high-performance antiwear agent is prepared from the following preparation raw materials in parts by weight: 100 parts of sulfonated graphene, 8 to 12 parts of terpinyl acetate, 4 to 6 parts of nano molybdenum disulphide, 14 to 16 parts of anionic surfactant and 55 to 75 parts of solvent soil.

Owner:温凯环保科技(上海)有限公司

Method for synthesizing terpinyl acetate from turpentine oil

ActiveCN108409563AHigh puritySimple processOrganic compound preparationCarboxylic acid esters preparationAcetic acidDistillation

The invention discloses a method for synthesizing terpinyl acetate from turpentine oil, wherein the turpentine oil, glacial acetic acid and a catalyst are added into a reaction kettle, and heating andstirring are started; after the reaction is finished, a reaction liquid is transferred into a freezing tank for freezing to crystallize and precipitate unreacted acetic acid crystal in the systerm; the precipitated acetic acid crystal is centrifuged, the centrifuged acetic acid crystal is used as a raw material for the next reaction, and centrate is mixed with the reaction liquid; the liquid mixture is added to a distillation pot, water is added, stirring and heating are started, a product is accompanied by water vapor to enter an oil-water separator for separation, a separated oil layer is transported to a water washing tank, and lower layer water is returned to the distillation pot; water is added into the water washing tank for washing to obtain crude terpinyl acetate; the crude terpinyl acetate is fractionated to obtain a side product and a high purity terpinyl acetate product. The method not only can promote the conversion of pinene to the target product, pine oil ester, and improves the purity of the product, and has the advantages of simple process, less emission of three wastes, low cost, greenness, environmental protection and the like, and industrial production is easy to realize.

Owner:GUANGXI FORESTRY RES INST

Articles comprising malodor reduction compositions

An absorbent article comprising a malodor reduction composition. The malodor reduction composition comprises a perfume mixture comprising about 5% to about 100%, by weight of said perfume mixture, of at least two perfume materials selected from the group consisting of terpinyl acetate, methyl iso-eugenol, phenyl acetaldehyde dimethyl acetal, and patchone.

Owner:THE PROCTER & GAMBLE COMPANY

Cleaning cloth with skin protecting function

InactiveCN106176442AKeep healthyCosmetic preparationsToilet preparationsCaprylyl GlycolProtection Skin

The invention discloses cleaning cloth with a skin protecting function. The cleaning cloth comprises a cleaning cloth body and a skin moisturizer capable of being sprayed on the cleaning cloth body, wherein the skin moisturizer is prepared from raw materials in parts by weight as follows: 10-15 parts of aloe, 8-12 parts of honeysuckle flower, 2-4 parts of sodium chloride, 1-3 parts of terpinyl acetate, 1-3 parts of ethyl alcohol, 1-2 parts of caprylyl glycol, 2-4 parts of vitamin, 2-6 parts of essential oil and an appropriate amount of water. The skin moisturizer of the cleaning cloth with the skin protecting function is prepared from natural raw materials, has the advantages of refreshing the skin, killing bacteria, removing dead skin cells and activating skin vigor, and can clear away impurities in pores of the skin and guarantee the skin health.

Owner:明光市瑞洁日用品有限公司

Terpinyl acetate synthesizing method

ActiveCN105218365AIncrease added valueReduce dosageOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidDistillation

The invention discloses a terpinyl acetate synthesizing method and particularly relates to a method for synthesizing terpinyl acetate through an alpha-pinene one-step method. The method is characterized by including the following steps that firstly, SiO2 aerosol and a lewis acid aqueous solution are mixed, heated to 70-90 DEG C and stirred for 3-5 h; secondly, the stirred mixed solution is filtered, obtained solid SiO2 is dried and activated for 1-3 h at the temperature of 100-200 DEG C under the pressure reduction condition, and a SiO2 loaded catalyst is obtained; thirdly, raw oil containing alpha-pinene, an acetic acid aqueous solution and the SiO2 loaded catalyst are added into a reaction flask and stirred for reaction; fourthly, reaction liquid is filtered, the catalyst is recycled, reduced pressure distillation is carried out on an oil phase, and high-purity terpinyl acetate can be obtained. The conversion rate of raw oil alpha-pinene is as high as 98%, selectivity of the terpinyl acetate can be over 70%, and the utilization rate of the raw oil is greatly increased. The method has the advantages of being simple in process, convenient to operate, low in production cost and the like.

Owner:云南森美达生物科技股份有限公司

Method of preparing terpinyl acetate

InactiveCN101270047AEasy to prepareLow costOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAcetic anhydrideSolid acid

The present invention provides a preparation method of terpinyl acetate. The method is characterized in that the acid solution of one of hydrochloric acid, sulfuric acid, nitric acid, phosphoric acid and hydriodic acid is divided into two portions; aniline monomer and ammonium persulfate are respectively added; then aniline monomer solution and ammonium persulfate solution can be prepared. The aniline monomer solution and the ammonium persulfate solution are mixed rapidly and treated through a series of processes to prepare the nano polyaniline solid-acid catalyst. The prepared catalyst is used for the esterification of terpinyl and acetic anhydride to prepare the terpinyl acetate. The nano polyaniline catalyst doped with acid and prepared in the method has the advantages of simple preparation, low cost, and higher catalytic activity and selectivity in the esterification of the terpinyl and the acetic anhydride so as to prepare the terpinyl acetate (the transformation ratio of the terpinyl reaches to more than 95 percent, and the yield of the terpinyl acetate reaches to more than 80 percent). At the same time, the catalyst has the characteristics of easy separation and long service life.

Owner:KUNMING UNIV OF SCI & TECH

Grapefruit essence for water-based ink and preparing method of grapefruit essence

InactiveCN105087161ASystem stabilityLong lasting fragranceInksEssential-oils/perfumesBiotechnologyGrapefruit oil

The invention discloses grapefruit essence for water-based ink. The grapefruit essence for the water-based ink consists of the following ingredients in percentage by weight: 1 to 30 percent of grapefruit essence, 5 to 55 percent of composite modified oligosaccharide and deionized water, wherein the grapefruit essence consists of grapefruit oil, nootkatone, sweet orange oil, lemon oil, tangerine oil, capraldehyde, caprylaldehyde, ethyl butyrate, octyl acetate, linalool, linalyl acetate, terpilenol, terpinyl acetate and ethyl alcohol. The invention also provides a preparing method of the grapefruit essence for the water-based ink. According to the preparing method, the composite modified oligosaccharide is used as a wall material; the grapefruit essence is coated to form grapefruit nanocapsule slow-release essence, so that the fragrance retention and the water solubility of the essence are improved; the preparing method is applicable to the perfuming of the water-based ink. The grapefruit essence for the water-based ink has the advantages that the fragrance is fresh, intensive and lifelike; the natural feeling is high; the fragrance retention is durable.

Owner:SHANGHAI INST OF TECH

Field integrated attractant for control of grapholitha molesta

PendingCN110419532AIncrease chance of encounterHigh trapping rateBiocidePest attractantsEcological environmentPeach orchard

Belonging to the technical field of pest attractants, the invention provides a field optimal integrated attractant for control of grapholitha molesta. The integrated attractant comprises: sex pheromone, a food bait and a protective component. The sex pheromone comprises cis-8-dodecenyl acetate, trans-8-dodecenyl acetate, cis-8-dodecenol and dodeca-1-ol in a mass ratio of 100:6-7:15-20:2-7. The food bait includes terpinyl acetate, and the protective component includes honey and an antioxidant. The attractant effectively reduces the population of grapholitha molesta in different peach orchards and harm thereof, especially the pregnant female moths. For effective integration of amphoteric attractants, while ensuring the control effect, the integrated attractant provided by the invention promotes the reduction of chemical pesticides, accelerates the promotion of green control products and technologies, is conducive to protecting ecological environment and ensuring food safety and ecological safety, and is beneficial to the sustainable development of agriculture.

Owner:SHANXI AGRI UNIV +1

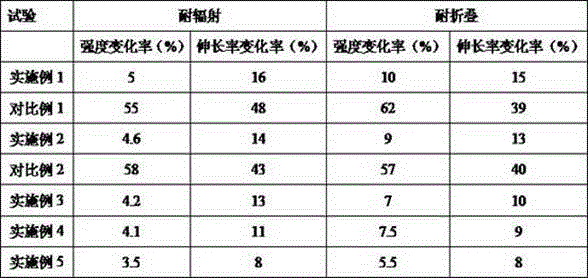

Radiation-resistant and folding-resistant cable and preparation method thereof

InactiveCN105670181AImprove radiation resistanceImprove folding resistanceRubber insulatorsPlastic/resin/waxes insulatorsSilicon monoxidePolyvinyl chloride

The invention discloses a radiation-resistant and folding-resistant cable.The radiation-resistant and folding-resistant cable is prepared from, by weight, 40-50 parts of polyvinyl chloride, 10-20 parts of butyl rubber, 9-13 parts of magnesium hydroxide, 5-8 parts of calcium carbonate, 10-14 parts of tris 2-propane-1,2,3-tricarboxylate, 2-6 parts of titanium dioxide, 3-8 parts of magnesium aluminum zirconium oxide, 3-7 parts of chromium silicon monoxide, 10-15 parts of diveratryl ether, 2-5 parts of hydroxybenzoic acid benzyl ester, 10-15 parts of terpinyl acetate, 1-4 parts of benzotriazole-1-formamide and 12-16 parts of allyl isosulfocyanate.The cable has good radiation resistance and folding resistance.

Owner:SUZHOU KEMAO ELECTRONICS MATERIALS TECH

Magnolia essence and preparation method thereof

InactiveCN107460053AFull of fragranceRich fragranceEssential-oils/perfumesTert butyl phenolDimethyl acetal

The invention discloses a magnolia essence and a preparation method thereof. The magnolia essence is composed of, by weight part, 3-5 parts of allyl hexanoate, 1-3 parts of geranyl formate, 1-3 parts of geranyl acetate, 1-3 parts of butyl acetate, 18-20 parts of benzyl acetate, 8-10 parts of amyl cinnamic aldehyde, 3-5 parts of cinnamic alcohol, 3-5 parts of clove oil, 3-5 parts of terpinyl acetate, 3-5 parts of phenylacetaldehyde dimethyl acetal, 8-10 parts of linalool, 3-5 parts of dihydromyrcenol, 3-5 parts of terpilenol, 2-3 parts of phenethyl alcohol, 3-5 parts of nonanediiol acetate, 8-10 parts of Superfix(1,1,3-Trimethyl-3-phenylindan), 2-3 parts of ethyl butyrate, 2-3 parts of aurantiol, 1-2 parts of o-tert-butyl phenol, 5-6 parts of benzyl salicylate, 5-6 parts of rhodinol, 2-3 parts of benzpyrole, 2-3 parts of fructone, 1-3 parts of amyl acetate and 1-3 parts of allyl amyl glycolate. The preparation method of the magnolia essence comprises the following steps of (1) placing, (2), stirring, (3) standing, (4) filtering, (5) detection and (6) filling. The magnolia essence has fresh and pleasant magnolia flavor and can substitute for magnolia essence oil for being widely applied to products.

Owner:安徽香杰香精科技有限公司

Nose mask facilitating pore shrinking

InactiveCN103585061ANo side effectsNo damageCosmetic preparationsToilet preparationsSide effectAlcohol

Owner:曲肇勋

Essence capable of dispelling cats and dogs

The invention discloses essence capable of dispelling cats and dogs. The essence comprises components in percentage by mass as follows: 2%-2.3% of natural lavender oil, 4.4%-4.7% of natural eucalyptus oil, 5%-5.3% of methyl dihydrojasmonate, 7%-7.3% of linalyl acetate, 1.8%-2.1% of terpinyl acetate, 0.7%-1% of citral, 7%-7.3% of ambrotone, 0.7%-1% of terpilenol, 7%-7.3% of galaxolide (50% dipropylene glycol), 15%-15.3% of linalool, 0.6%-0.9% of synthetic sandalwood 208, 2.7%-3% of synthetic sandalwood 803, 2%-2.3% of borneol, 35%-35.3% of synthetic camphor, 3.1%-3.4% of sweet orange terpene, 1%-1.3% of beta-caryophyllene and the balance of dipropylene glycol. The essence is herbal lavender odor type essence, the cats and the dogs can feel unhappy after smelling the essence and then get away, and the essence retains the odor lastingly and is fresh, pleasant, safe and harmless.

Owner:TIANJIN DOUBLE HORSE FLAVOR & FRAGRANCE NEW TECH

Method for extracting cinnamomum micranthum hagata oil by using supercritical carbon dioxide and cinnamomum micranthum hagata oil

ActiveCN103695161ANo chemical reactionImprove securityLiquid carbonaceous fuelsFatty-oils/fats productionPhellandreneEugenol

The invention relates to a method for extracting cinnamomum micranthum hagata oil by using supercritical carbon dioxide and the cinnamomum micranthum hagata oil. The cinnamomum micranthum hagata oil comprises the following components by weight: 25 to 30 percent of cineole, 23 to 25 percent of terpinyl acetate, 13 to 15 percent of linalool, 12 to 13 percent of isoeugenol methyl ether, 5 to 7 percent of alpha-terpineol, 3 to 5 percent of eugenol, 2 to 4 percent of beta-phellandrene, 3 to 5 percent of alpha-cadinene and 2 to 4 percent of geraniolene. The method and the cinnamomum micranthum hagata oil have the advantages that the method is simple, convenient to implement and control and low in production cost, damage to active ingredients of the cinnamomum micranthum hagata oil, organic solvent residues and harm to human bodies and the environment are avoided, and the obtained cinnamomum micranthum hagata oil is purely natural and pollution-free.

Owner:河南红枫生物高科股份有限公司 +1

Preparation method of terpinyl acetate

InactiveCN104926651AHigh purityHigh yieldOrganic compound preparationCarboxylic acid esters preparationAcetic anhydrideDistillation

The invention discloses a preparation method of terpinyl acetate and belongs to the technical field of preparation of sylvichemical products. The preparation method of terpinyl acetate comprises the following steps: adding terpilenol and acetic anhydride into a reactor according to a certain ratio, then adding a self-prepared catalyst under nitrogen condition, heating to 50-60 DEG C and reacting for 4-6 hours, then carrying out reduced-pressure distillation and washing to prepare terpinyl acetate. According to the method, the special self-prepared catalyst is matched with the corresponding raw material ratio and is used for controlling the corresponding nitrogen gas supply amount, so that the purity and the yield of the product, namely terpinyl acetate, are improved.

Owner:WUZHOU SONGHUA AROMATIC CHEM

Treating method for removing three kinds of dioxin-like compounds in waste incineration waste off gas

InactiveCN105327598AFast precipitationStrong complexing abilityDispersed particle separationBenzeneN-Butyllithium

The invention relates to a treating method for removing three kinds of dioxin-like compounds in waste incineration waste off gas. The method comprises the steps that waste incineration waste off gas is introduced into a sufficient treating agent through a pipeline, 2,3,7,8-tetrachlorodibenzo-p-dioxin, 1,2,3,7,8-pentachlorodibenzo-p-dioxin, and 1,2,3,4,6,7,8-heptachlorodibenzo-p-dioxin in the off gas react with the treating agent, and complex precipitate is formed and filtered out. The treating agent is formed by compounding terpinyl acetate, n-butyllithium, 2-amino-3,5-dibromopyrazine, 2-amino butane, 4-(4-hydroxy-3-methoxyphenyl)butan-2-one, 4-acetoxyl group-3-methoxy-(2-propenyl) benzene, 2-methylpiperazine, 6-methyl chromene, 3alpha,12alpha-dihydroxy-5beta-cholanic acid and the like. The treating agent has the strong complexing power with target matter, the complex precipitate forming speed is high, the removing rate can reach 99%, the cost is low, consumption is small, the application range is wide, and no damage is produced to the environment.

Owner:陈逸君

Dielectric Paste for a Multi-Layered Ceramic Electronic Component and a Method for Manufacturing a Multi-Layered Unit for a Multi-Layered Ceramic Electronic Component

InactiveUS20080233270A1Reliably prevent defectAvoid defectsFixed capacitor dielectricStacked capacitorsDielectricAcetic acid

It is an object of the present invention to provide a method for fabricating a multi-layered unit for a multi-layered ceramic electronic component which can reliably prevent defects from being generated in a multi-layered ceramic electronic component and form a spacer layer in a desired manner.A method for fabricating a multi-layered unit for a multi-layered ceramic electronic component includes a step of printing a dielectric paste containing ethyl cellulose having an apparent weight average molecular weight of 110,000 to 190,000 as a binder and at least one kind of solvent selected from the group consisting of isobornyl acetate, dihydroterpinyl methyl ether, terpinyl methyl ether, α-terpinyl acetate, I-dihydrocarvyl acetate, I-menthyl acetate, I-menthone, I-perillyl acetate and I-carvyl acetate on a ceramic green sheet containing a butyral system resin as a binder in a predetermined pattern, thereby forming a spacer layer.

Owner:TDK CORPARATION

Preparing method of tert-amyl acetate

ActiveCN102126946ATo achieve the effect of suppressing side effectsReduce usageOrganic compound preparationCarboxylic acid esters preparationAmyl acetateMethyl group

The present invention relates to a method for preparing tert-amyl acetate through the reaction between an alkene compound with 5-6 carbon atoms and an acetic acid. More particularly, a low boiling point alkene mixture of fluidized catalytically cracked naphtha which is obtained through a naphtha cracking technique and contains the alkene with five to six carbon atoms in each module as the main component is used. In the mixture, only 2-methyl-1-butylene and 2-methyl-butylene are selected from the mixture for reacting with the acetic acid, and the purpose is obtaining high-purity tert-amyl acetate. Furthermore, the invention relates to a method for easily separating the alkene component which has high possibility of incomplete combustion in the low boiling point catalytically cracked naphtha.

Owner:SK INNOVATION CO LTD +1

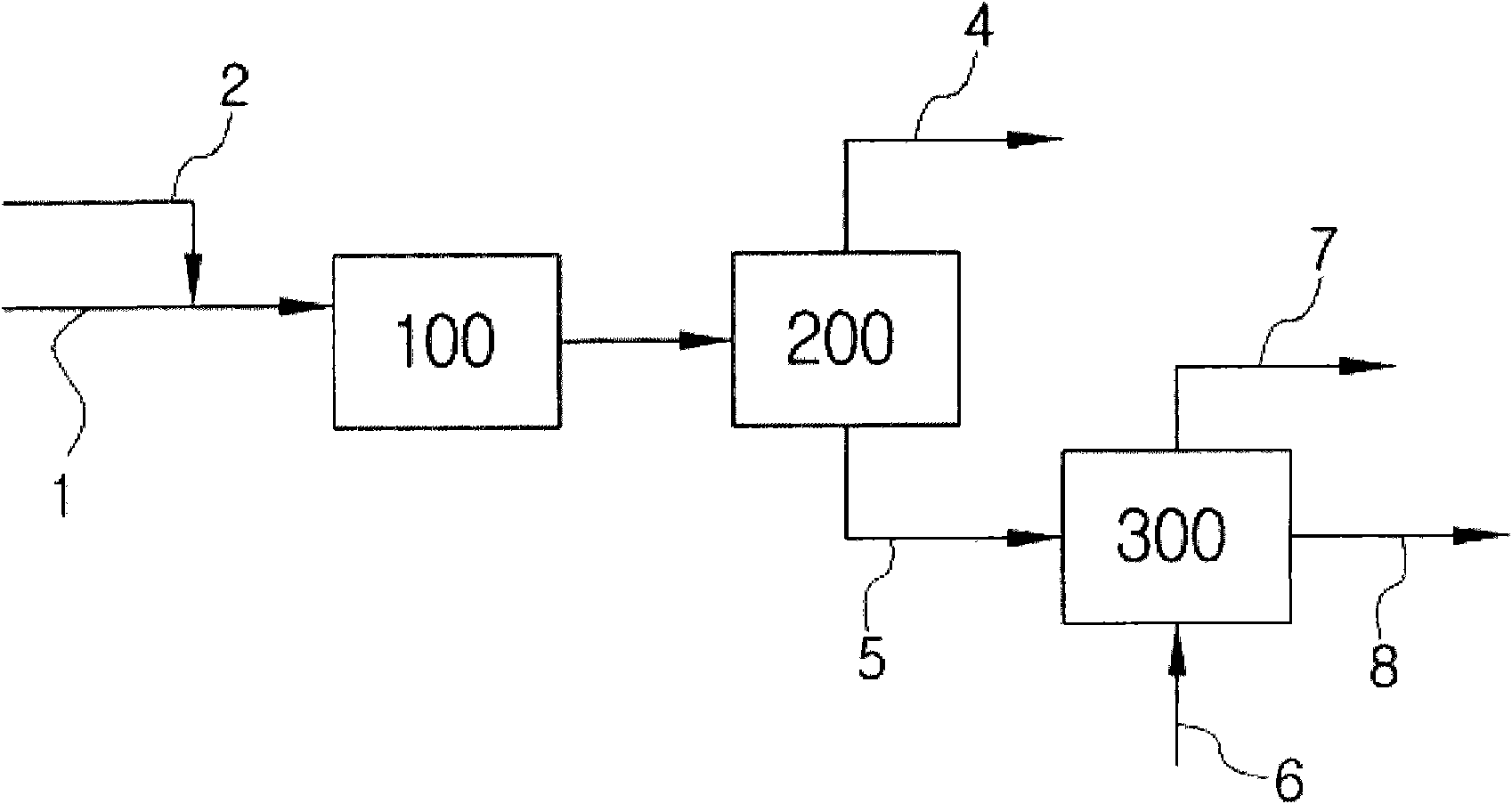

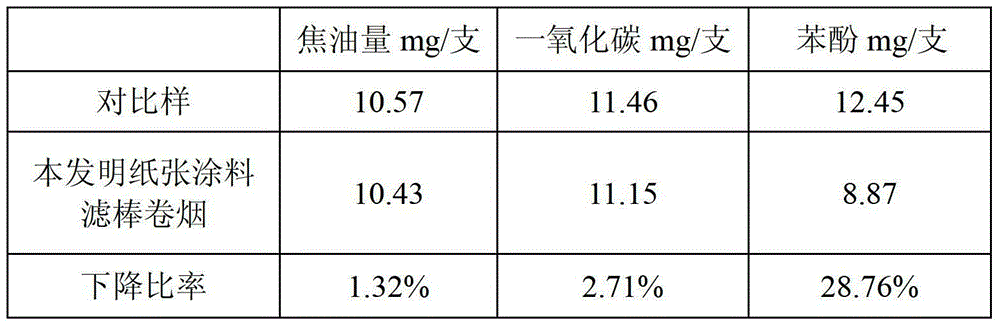

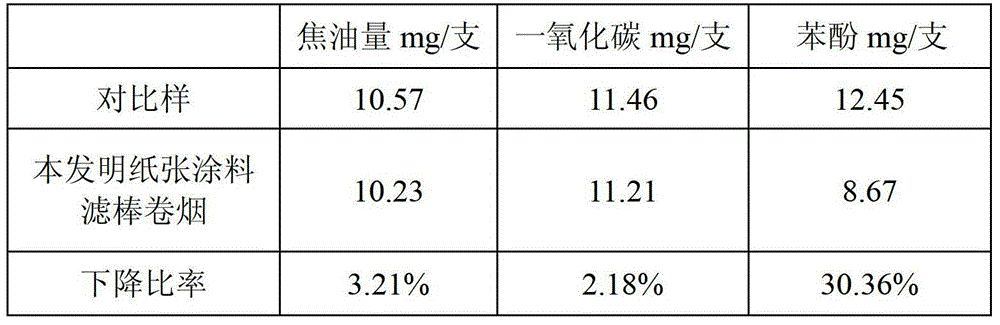

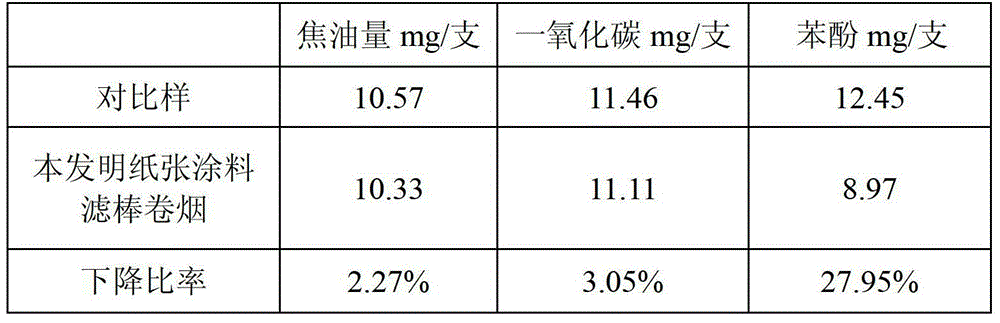

Selective phenol reduction paper coating material, preparation method and application thereof

ActiveCN103334337ASimple production processLow pricePaper coatingCoatingsPolyethylene glycolN-Butanol

Owner:CHINA TOBACCO HUNAN INDAL CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com