Radiation-resistant and folding-resistant cable and preparation method thereof

A folding-resistant and radiation-resistant technology, applied to rubber insulators, plastic/resin/wax insulators, organic insulators, etc., can solve problems such as information transmission and physical safety hazards, information transmission is not smooth, and affects information transmission. Radiation and anti-folding performance, improved internal structural state, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

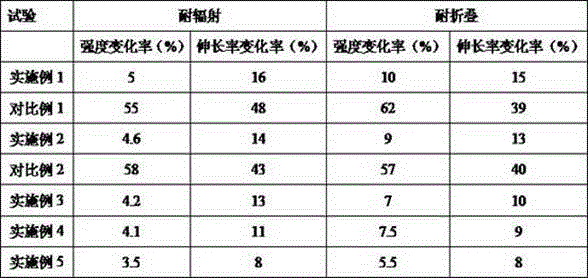

Examples

Embodiment 1

[0016] S1: 40 parts of polyvinyl chloride, 10 parts of butyl rubber, 9 parts of magnesium hydroxide, 10 parts of acetyl trioctyl citrate, 5 parts of calcium carbonate, 2 parts of titanium dioxide, 3 parts of zirconia magnesium aluminum oxide, silicon chromium oxide 3 parts and 10 parts of bisveratryl ether were added to the open mixer and mixed at a temperature of 50°C for 8 minutes;

[0017] S2: Add 2 parts of benzyl salicylate, 10 parts of terpineol acetate and 12 parts of allyl isothiocyanate to step S1 and mix for 10 minutes at a temperature of 40°C;

[0018] S3: After the kneaded film is parked, 1 part of benzotriazole-1-carboxamide is added, and the film is thin-passed at a temperature of 30° C. for 4 times, and then the film is glued out to obtain the radiation-resistant and folding-resistant cable.

Embodiment 2

[0024] S1: 50 parts of polyvinyl chloride, 20 parts of butyl rubber, 13 parts of magnesium hydroxide, 14 parts of acetyl trioctyl citrate, 8 parts of calcium carbonate, 6 parts of titanium dioxide, 8 parts of zirconia magnesium aluminum oxide, silicon chromium oxide 7 parts and 15 parts of bisveratrol ether were added to the open mixer and mixed for 10 minutes at a temperature of 60°C;

[0025] S2: Add 5 parts of benzyl salicylate, 15 parts of terpineyl acetate and 16 parts of allyl isothiocyanate to step S1 and knead at a temperature of 50° C. for 15 minutes;

[0026] S3: After the kneaded film is parked, 1 part of benzotriazole-1-carboxamide is added, and the film is thin-passed at a temperature of 35° C. for 6 times, and then the film is glued out to obtain the radiation-resistant and folding-resistant cable.

Embodiment 3

[0032] S1: 42 parts of polyvinyl chloride, 12 parts of butyl rubber, 10 parts of magnesium hydroxide, 11 parts of acetyl trioctyl citrate, 6 parts of calcium carbonate, 3 parts of titanium dioxide, 4 parts of zirconia magnesium aluminum oxide, silicon chromium oxide Add 4 parts and 12 parts of bisveratryl ether into the open mixer and knead at a temperature of 50°C for 8 minutes;

[0033] S2: Add 3 parts of benzyl salicylate, 12 parts of terpineol acetate and 13 parts of allyl isothiocyanate to step S1 and knead at a temperature of 40°C for 10 minutes;

[0034] S3: After the kneaded film is parked, 2 parts of benzotriazole-1-carboxamide is added, and the film is thin-passed at a temperature of 30° C. for 6 times, and then the film is glued out to obtain the radiation-resistant and folding-resistant cable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com