Patents

Literature

49 results about "Acetyl trioctyl citrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acetyl tributyl citrate is used as plasticizer of low toxicity, found in nail polish and other cosmetics. It's chemical formula is C20H34O8. It exists as a clear, colorless liquid.

Heat-resistant insect-proofing polyurethane foam gap filling material

The invention discloses a heat-resistant insect-proofing polyurethane foam gap filling material comprising the raw materials: polyurethane, a styrene-acrylic emulsion, acrylic ester, diphenol propane, xylene, microlite, light calcium carbonate, diatomite, lindane, a talcum powder, zeolite, titanium dioxide, a talcum powder, a cellulose powder, magnesium oxide, nano calcium carbonate, a lamellar-structural mica powder, glass fiber, carbon fiber, quick lime, quartz sand, activated carbon, dichlorinated sodium isocyanurate, sodium potassium tartrate, fumaric acid, glutamine, inulin, borneol, acetyl trioctyl citrate, petroleum sodium sulfonate, sodium lauroyl glutamate, silicone oil, styrene, methyl triethoxysilane, a thickening agent, a silane coupling agent and a foaming agent. The heat-resistant insect-proofing polyurethane foam gap filling material has excellent heat resistant performance and insect-proofing performance.

Owner:CHUZHOU GLOBAL POLYURETHANE TECH CO LTD

Synthetic method of medicinal acetyl trioctyl citrate

ActiveCN104355995AIncrease profitLow costMolecular sieve catalystsOrganic compound preparationTRICAPRYLYL CITRATEAcetic anhydride

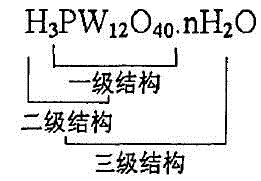

The invention discloses a synthetic method of medicinal acetyl trioctyl citrate, in particular to a method for catalytic synthesis of acetyl trioctyl citrate by using of mesoporous zeolite supported heteropolyacid. The synthetic method comprises the following steps: (1), citric acid and n-caprylic alcohol are used as raw materials, mesoporous zeolite supported heteropolyacid is used as catalyst, after complete reaction, the obtained reaction mixture layers naturally, and n-caprylic alcohol and water in the mixture are distilled out under reduced pressure directly to obtain a crude product; (2), adding acetic anhydride into the crude product obtained in step (1), after complete reaction, the reaction mixture is left to stand for layering, the substance in the upper layer is subjected to distillation under reduced pressure to obtain a coarse product, and the coarse product is refined and purified to obtain the finished product of acetyl trioctyl citrate. The method provided by the invention is mild in reaction condition and short in reaction time; the same catalyst is used in the reaction of two steps and can be reused, so that the method is suitable for industrial production; besides, the product esterification rate is high, the product yield is high, the quality is good, and the microbial limit is controlled effectively.

Owner:HUNAN ER KANG PHARMA

White emulsion with improved water-resistant performance

InactiveCN108676526AImprove water resistanceHigh bonding strengthNon-macromolecular adhesive additivesGraft polymer adhesivesAdditive ingredientCarvacryl acetate

The invention relates to the technical field of an adhesive, in particular to white emulsion with improved water-resistant performance. The white emulsion is prepared from the following ingredients ofpolyvinyl acetate, vinyl acetate, polyvinyl alcohol, glycol, water-resistant modified starch, dibutyl phthalate, vinyl versatate, an emulsifier, an initiator, lyophobic filling materials, a plasticizer, N-hydroxymethyl acrylamide and water, wherein the lyophobic filling materials are mixed inorganic filling materials of nanometer calcium carbonate, roasted kaolin and montmorillonite subjected tohydrophobic modification; the emulsifier is sodium dodecyl benzene sulfonate or sodium oleate; the plasticizer is tributyl citrate or acetyl trioctyl citrate; the initiator is one kind of materials from potassium peroxodisulfate, ammonium persulfate and hydrogen peroxide. The white emulsion has the advantages that the bonding performance is good; the curing time is shorter; the water-resistant performance is excellent; tackless cannot easily occur in the damp environment.

Owner:HEFEI GUANGMIN BUILDING MATERIAL CO LTD

High temperature resistant and wear resistant rubber material for oil sealing

The invention discloses a high temperature resistant and wear resistant rubber material for oil sealing. The rubber material comprises the following raw materials in parts by weight: 50 to 70 parts of hydrogenated nitrile rubber, 30 to 50 parts of fluororubber, 10 to 20 parts of polytetrafluoroethylene, 40 to 60 parts of composite filling material, 10 to 20 parts of microencapsulated red phosphorus, 5 to 15 parts of zinc borate, 20 to 30 parts of ammonium polyphosphate, 15 to 25 parts of acetyl trioctyl citrate, 1 to 3 parts of benzoyl peroxide, 0.2 to 0.4 part of dibutyl tin dilaurate, 0.3 to 0.5 part of promoter D, 0.1 to 0.2 part of promoter ZDC, 1 to 2 parts of Ca / Zn composite stabilizer, 1 to 2 parts of dibutyl tin dichloride, 1 to 2 parts of rare earth stabilizer, 0.2 to 0.4 part of anti-aging agent MB, 0.2 to 0.4 part of anti-aging agent 445, and 2 to 4 parts of montan wax; wherein the composite filling material comprises aerosil, modified molybdenum disulfide, modified graphite, and modified silicon carbide.

Owner:宁国天运橡塑制品有限公司

Heat-resistant anticorrosion cable

InactiveCN105585782AImprove heat resistanceImprove corrosion resistanceInsulated cablesInsulated conductorsElastomerInsulation layer

The invention discloses a heat-resistant anticorrosion cable. The heat-resistant anticorrosion cable comprises a conducting wire, a high-temperature-resistant insulation layer covering the conducting wire, a shielding layer covering the high-temperature-resistant insulation layer and a protection layer covering the shielding layer, wherein the protection layer is prepared from the following raw materials: EPDM, silicone rubber, ethylene-acrylic elastomer, fluororubber, modified diatomite, modified white carbon black, ferric oxide, acetyl trioctyl citrate, 2-ethyl hexyl ester of epoxidized soybean oil, zinc borate, magnesium hydroxide, expansible graphite, maleic anhydride grafted compatilizer, sulfur, 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, triallyl cyanurate, Ca / Zn composite stabilizer, antioxidant 1010, anti-aging agent 264 and polyethylene wax. The heat-resistant anticorrosion cable is good in corrosion resistance and good in heat resistance.

Owner:繁昌县菲德通讯材料设计有限公司

Radiation-resistant cable insulation material for nuclear power plant

InactiveCN104672628AEvenly dispersedImprove radiation resistanceRubber insulatorsEthyl butyrateTert butyl

The invention discloses a radiation-resistant cable insulation material for a nuclear power plant. The radiation-resistant cable insulation material comprises the following raw materials in parts by weight: 100-120 parts of EPDM, 70-80 parts of fluorinated silicone rubber, 30-40 parts of polyimide, 10-20 parts of ETFE, 20-30 parts of lead oxide, 20-40 parts of rare earth oxide, 15-25 parts of zinc oxide, 5-15 parts of boron nitride, 18-22 parts of titanium nitride, 10-15 parts of organic bentonite, 35-45 parts of mica powder, 2-3 parts of di-(di-octyl phosphite) tetraisopropyl titanate, 2-5 parts of 3,3-bi-(tert-butyl peroxide) ethyl butyrate, 0.4-1 part of sulfur powder, 0.5-1 part of TAIC, 0.8-1.4 parts of HVA-2, 2-4 parts of sodium cinnamate, 4-6 parts of magnesium oxide, 2-5 parts of acetyl trioctyl citrate, 3-6 parts of stearic acid, 2-5 parts of anti-aging agent 1010-A and 1-2 parts of anti-aging agent D-503-4,2-(2'-hydroxyl-3',5'-tert-amyl phenyl) benzotriazole.

Owner:ANHUI SPECIAL CABLE GRP

Concrete crack resistance modifier

The invention discloses a concrete crack resistance modifier, which is prepared by the following raw materials by weight: 1.2-2.8 parts of polyethylene silicone oil, 1.3-3.3 parts of surfactant JFC, 5-8 parts of polyamide chloropropylene oxide resin, 2.5-3.6 parts of triethyl acetocitrate, 1.3-1.9 parts of sodium lactate, 3.2-3.8 parts of cellulose acetate butyrate, 1.5-3 parts of 3- aminopropyltrimethoxysilane and 1.8-3.6 parts of pesticide emulsifier 700-2. The invention enhances crack resistance performance of concrete and increases viscosity of concrete; the invention greatly improves aperture structure in concrete, thereby substantially enhancing packing of concrete, and reducing water storage of aperture in the concrete structure, and avoiding concrete structure destroy caused by crack due to icing expansion of old water in the aperture, and increasing concrete endurance, prolonging service life of concrete, and reducing maintenance cost.

Owner:QINGDAO HUIERTONG TRADING

Anti-aging damping rubber material

The invention discloses an anti-aging damping rubber material. Raw materials of the anti-aging damping rubber material contain, by weight, 40-60 parts of butadiene styrene rubber, 30-50 parts of cis-butadiene rubber, 10-20 parts of ethylene propylene diene monomer, 55-65 parts of a composite filler, 0.5-0.7 part of 3-aminopropyltriethoxysilane, 20-30 parts of melamine phosphate, 10-15 parts of expansible graphite, 10-20 parts of acetyl trioctyl citrate, 10-20 parts of acetyl tributyl citrate, 0.4-0.6 part of dicumyl peroxide, 0.2-0.3 part of stearic acid, 0.1-0.2 part of zinc oxide, 0.1-0.3 part of a promoter CZ, 1-3 parts of a rare earth stabilizer, 1-3 parts of a Ca / Zn compound stabilizer, 0.2-0.4 part of an anti-ageing agent, 0.1-0.3 part of an anti-fatigue agent PL and 2-4 parts of silicone powder. The anti-aging damping rubber material of the invention has good damping performance and good ageing resistance.

Owner:宁国市开源橡塑汽车零部件有限公司

Improved concrete anti-cracking modifier

The invention discloses an improved concrete anti-cracking modifier, which is made by the following raw materials in parts by weight: 1.2-2.8 parts of organic amine lignin, 1.3-3.3 parts of calcium hydroxide, 5-8 parts of polyamide epichlorohydrin resin, 2.5-3.6 parts of acetyl trioctyl citrate, 1.3-1.9 parts of sodium lactate, 3.2-3.8 parts of cellulose acetate butyrate, 1.5-3 parts of 3-aminopropyltrimethoxysilane and 1.8-3.6 parts of phenethyl isopropyl phenylphenol polyethenoxy ether. The anti-cracking performance of the concrete is improved, the viscosity of the concrete is increased, the inner pore structure of the concrete is greatly improved, the degree of compaction of the concrete is greatly increased and the pore water storage in the concrete structure is reduced, thereby preventing the concrete structure from being cracked and broken due to icing and expanding of water in the pores, improving the durability of the concrete, prolonging the service life of the concrete, and reducing the maintenance cost.

Owner:QINGDAO HIBOUND CHENGYUAN PLASTIC

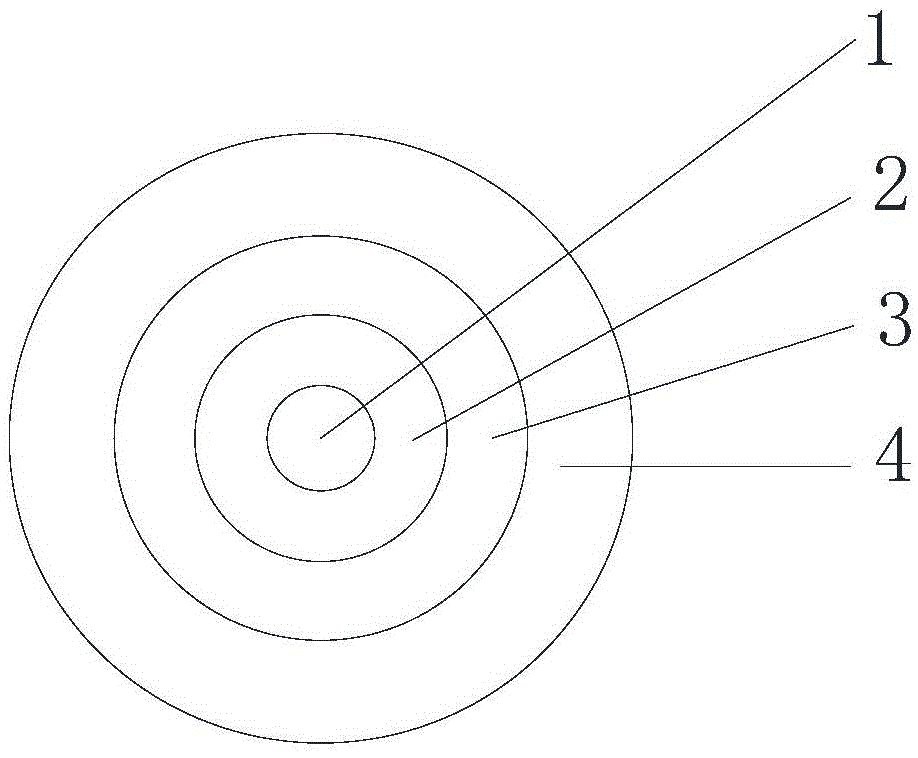

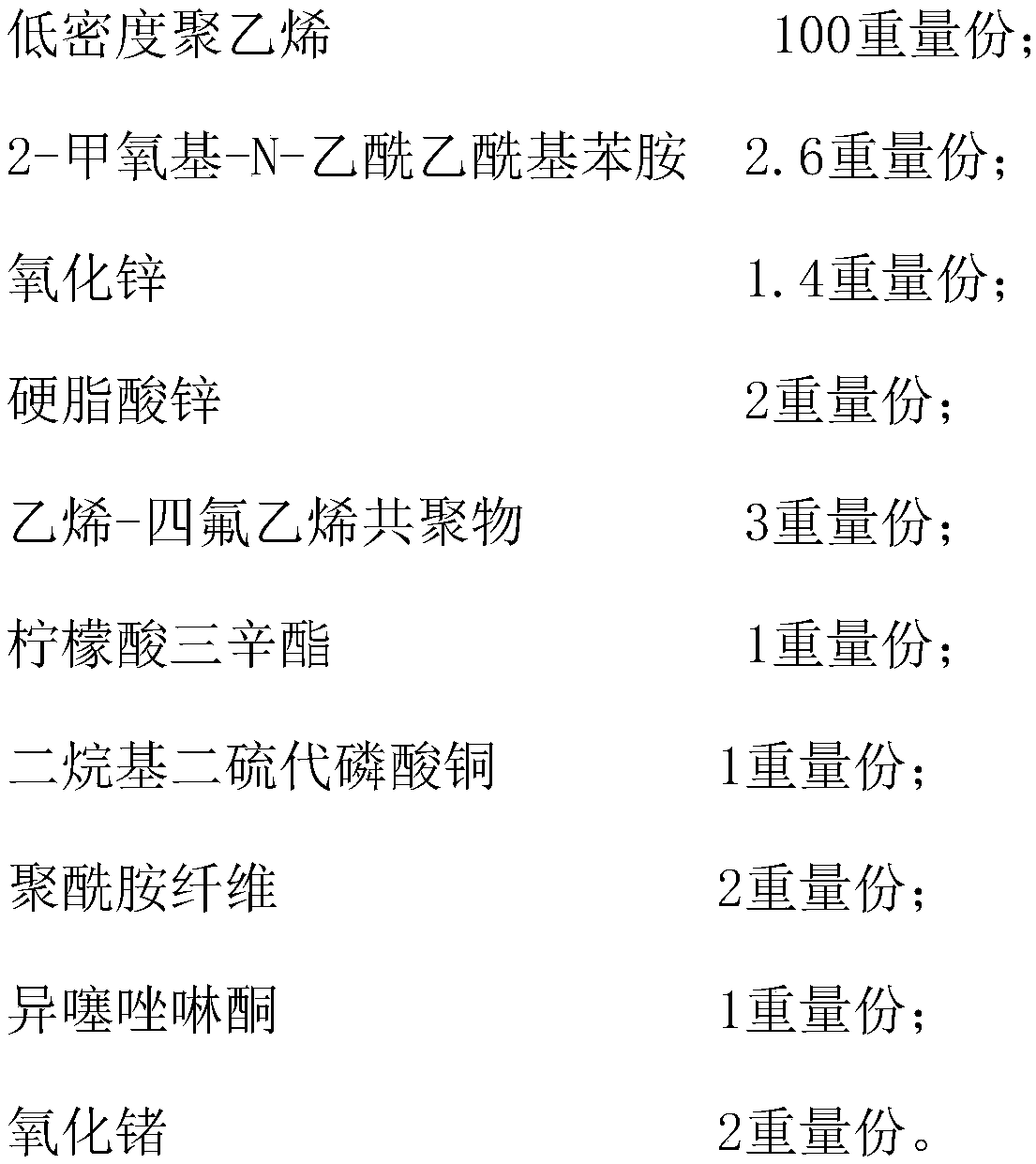

LDPE (low-density polyethylene) antibacterial plastic and preparation method thereof

The invention discloses LDPE (low-density polyethylene) antibacterial plastic, which is mainly prepared from the following raw materials in parts by weight: 100 parts of LDPE, 4-8 parts of an antibacterial agent, 2-3 parts of zinc stearate, 3-5 parts of a compatilizer and 1-2 parts of a plasticizer. The LDPE antibacterial plastic adopts 2-methoxy-N-acetoacetyl aniline and zinc oxide as the antibacterial agent, and through reasonable compatibility, the best pathogenic microorganism killing effect and growth inhibiting effect can be achieved; the LDPE is used as a main body, and the zinc stearate can improve the thermostability of the LDPE; an ethylene-tetrafluoroethylene copolymer is used as the compatilizer; the flexibility and easy-processing performance of the LDPE are improved by addingacetyl trioctyl citrate; the antioxidant performance of the LDPE is improved by adding dialkyl copper dithiophosphate; mechanical properties, heat resistance, abrasion resistance, chemical resistance, flame retardance and easy-processing performance of the LDPE are improved by adding polyamide fibers.

Owner:NANTONG YIXUAN IND DESIGN CO LTD

High-performance concrete expanding agent

The invention discloses a high-performance concrete expanding agent. The high-performance concrete expanding agent is prepared from 6-13 parts by weight of an accelerator, 8-14 parts by weight of diethylenetriamine, 6-8 parts by weight of triethanolamine, 7-9 parts by weight of salicylic acid, 6-10 parts by weight of ferrous sulfate, 5-9 parts by weight of carboxymethylcellulose, 5-7 parts by weight of carragheenan, 3-8 parts by weight of cellulose acetate butyrate, 7-11 parts by weight of acetyl trioctyl citrate, 5-8 parts by weight of polyoxyethylene phenethylcumenylphenol ether, 8-15 parts by weight of aluminum ore and 2-8 parts by weight of lime. The high-performance concrete expanding agent can improve concrete performances, prevent concrete cracking, reduce seepage and improve strength.

Owner:QINGDAO LAOXIANG TEA PROD

Pipe for municipal ecological garden greening drainage construction

The invention relates to a pipe for municipal ecological garden greening drainage construction. The pipe is prepared from the following components: copper powder, ethylenediamine, acetone, butantriol, magnesium oxide, chloroprene rubber, titanium dioxide, wollastonite powder, polyethylene polyamine, novolac epoxy resin, sodium lauroyl sarcosine, sodium hydrogen sulphite, rosin resin, ethylene bisstearamide, benzidine, polyoxyethylene monolaurate, phosphonitrilic chloride trimer, acrylic resin, sodium stearate, dilauryl thiodipropionate, acetyl trioctyl citrate, dibasic lead stearate, castor oil, bisphenol-A diglycidyl ether and metallocene polyethylene. According to the pipe, a plurality of ingredients are mixed with one another to form a novel compound toughening and reinforcing system; the toughness, rigidity and elasticity modulus performance indexes are good; the anti-aging performance and the using performance of a product are greatly improved; the pipe has a good corrosion resisting effect, good comprehensive performance and a good using effect.

Owner:龚灿锋

Environment-friendly cement expanding agent

The invention discloses an environment-friendly cement expanding agent and belongs to the technical field of concrete addition agents. The expanding agent is prepared from, by weight, 15-20 parts of acetyl trioctyl citrate, 1-3 parts of phenethyl cumenyl phenol polyoxyethylene ether, 5-15 parts of alunite, 2-6 parts of aluminum-oxygen clinker, 10-30 parts of calcium sulphoaluminate, 4-12 parts of aluminum slag, 1-5 parts of calcium carbonate powder, 4-12 parts of nanometer aluminum titanate fibers and 8-16 parts of pitchstone ore sand. The environment-friendly cement expanding agent is high in expansion rate, low in alkalinity content and capable of improving the concrete performance, concrete cracking is prevented, meanwhile, leakage is reduced, the strength is improved, the price is low, the production process is simple, the cost is low, and the expanding agent is suitable for large-scale production.

Owner:王嘉文

PVC building material and preparation method thereof

InactiveCN106280127AMeet the requirements of green environmental protectionImprove anti-corrosion performanceAntioxidantStearic acid

The invention discloses a PVC building material and a preparation method thereof. The PVC building material is prepared from, by weight, 30-50 parts of PVC resin, 10-15 parts of acetyl trioctyl citrate, 5-10 parts of stearic acid, 8-15 parts of perlite powder, 12-15 parts of ethyl acetate, 12-18 parts of straw powder, 15-25 parts of kaolin, 4-9 parts of carbonyl iron powder, 10-20 parts of corundum powder, 11-17 parts of olive oil, 2-8 parts of titanium dioxide, 3-7 parts of foaming additive, 1-5 parts of antioxidant and 2-6 parts of toughening agent. According to the PVC building material, the PVC resin, the acetyl trioctyl citrate, the stearic acid, the perlite powder, the ethyl acetate, the straw powder, the kaolin, the carbonyl iron powder, the corundum powder, the olive oil and the titanium dioxide are effectively proportioned, and the PVC building material has good anticorrosive, heat-insulation, waterproof and fireproof performance and the like and can meet the green and environmentally friendly requirements of the green and environmentally friendly, and it can be also ensured that the material has the same stability as an original building material.

Owner:芜湖浩权建筑工程有限公司

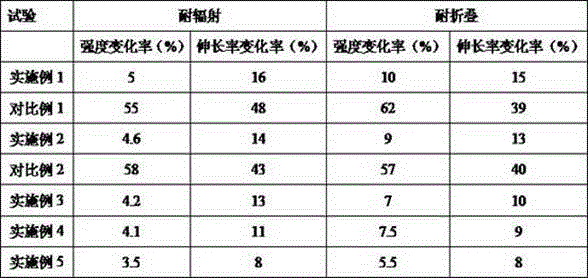

Radiation-resistant and folding-resistant cable and preparation method thereof

InactiveCN105670181AImprove radiation resistanceImprove folding resistanceRubber insulatorsPlastic/resin/waxes insulatorsSilicon monoxidePolyvinyl chloride

The invention discloses a radiation-resistant and folding-resistant cable.The radiation-resistant and folding-resistant cable is prepared from, by weight, 40-50 parts of polyvinyl chloride, 10-20 parts of butyl rubber, 9-13 parts of magnesium hydroxide, 5-8 parts of calcium carbonate, 10-14 parts of tris 2-propane-1,2,3-tricarboxylate, 2-6 parts of titanium dioxide, 3-8 parts of magnesium aluminum zirconium oxide, 3-7 parts of chromium silicon monoxide, 10-15 parts of diveratryl ether, 2-5 parts of hydroxybenzoic acid benzyl ester, 10-15 parts of terpinyl acetate, 1-4 parts of benzotriazole-1-formamide and 12-16 parts of allyl isosulfocyanate.The cable has good radiation resistance and folding resistance.

Owner:SUZHOU KEMAO ELECTRONICS MATERIALS TECH

Heat-proof insect preventing modified polyurethane thermal insulation composite board

InactiveCN106046758AImprove tensile propertiesImprove wear resistanceClimate change adaptationBuilding componentsPotassium sodium tartrateCement board

The invention discloses a heat-proof insect preventing modified polyurethane thermal insulation composite board which comprises a gypsum board layer, a thermal insulation board layer and a cement board layer sequentially arranged from inside to outside, wherein the thermal insulation board layer is prepared from the following raw materials: modified polyurethane, a styrene-acrylic emulsion, acrylate, polyvinylidene fluoride resin, organic silicon resin, microlite, light calcium carbonate, kieselguhr, chlorinated paraffin, talc powder, zeolite, titanium dioxide, talc powder, cellulose powder, magnesium oxide, nano calcium carbonate, mica powder, glass fiber, carbon cellulose, quicklime, quartz sand, active carbon, sodium dichloroisocyanurat, potassium sodium tartrate, fumaric acid, glutamine, inulin, borneol, trioctyl acetylcitrate, petroleum sodium sulfonate, sodium lauroyl glutamate, silicone oil, styrene, methyl triethoxy silane, a thickening agent, a silane coupling agent and a foaming agent. The heat-proof insect preventing modified polyurethane thermal insulation composite board disclosed by the invention has excellent heat resistance and insect preventing property.

Owner:ANHUI GUANGYAN NEW MATERIAL TECH

Flame retardant polyurethane sealant

ActiveCN104327785ANon-flammableImprove flame retardant performanceNon-macromolecular adhesive additivesOther chemical processesSilicon dioxidePhenol

The invention discloses a flame retardant polyurethane sealant. The flame retardant polyurethane sealant comprises polyurethane resin, a flame retardant, a coupling agent, filler, a plasticizer and a dispersant, wherein the flame retardant is 2,2-bis(3,5-dibromo-4-hydroxyphenyl) propane; the coupling agent is di(octyl phenol polyoxyethylene ether) phosphide; the filler is silicon dioxide; the plasticizer is acetyl trioctyl citrate; the dispersant is polyethylene wax. The flame retardant polyurethane sealant is prepared from the polyurethane resin, the flame retardant, the coupling agent, the filler, the plasticizer and the dispersant; the prepared flame retardant polyurethane sealant is unlikely to combust, good in flame resistance, ageing-resistant, convenient to process, stable in quality and low in cost.

Owner:佛山市元通胶粘实业有限公司

Antifouling environment-friendly oil paint for steel rim wheels

InactiveCN106221502AIncrease viscosityGood flexibilityFireproof paintsAntifouling/underwater paintsEpoxyOil paint

Owner:ANHUI JIANGHUAI WHEEL CO LTD

Crack resistance concrete modifier

The invention discloses a concrete crack resistance modifier, which is prepared by the following raw materials by weight: 1.2-2.8 parts of polyethylene silicone oil, 1.3-3.3 parts of petroleum sulfonate, 5-8 parts of double diphenylamine, 2.5-3.6 parts of triethyl acetocitrate, 1.3-1.9 parts of sodium lactate, 3.2-3.8 parts of cellulose acetate butyrate, 1.5-3 parts of 3- aminopropyltrimethoxysilane and 1.8-3.6 parts of pesticide emulsifier 700-2. The invention enhances crack resistance performance of concrete and increases viscosity of concrete; the invention greatly improves aperture structure in concrete, thereby substantially enhancing packing of concrete, and reducing water storage of aperture in the concrete structure, and avoiding concrete structure destroy caused by crack due to icing expansion of old water in the aperture, and increasing concrete endurance, prolonging service life of concrete, and reducing maintenance cost.

Owner:QINGDAO HUIERTONG TRADING

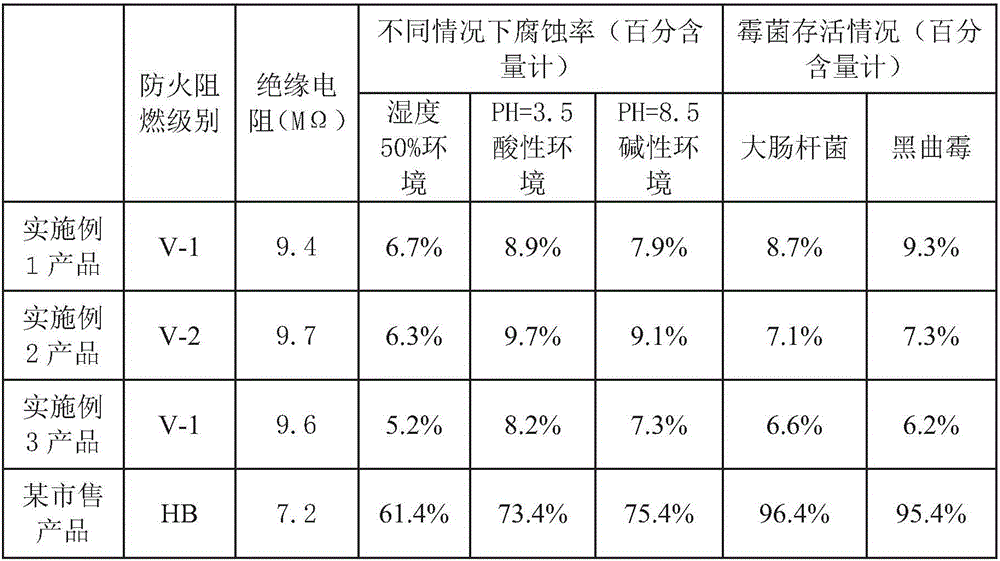

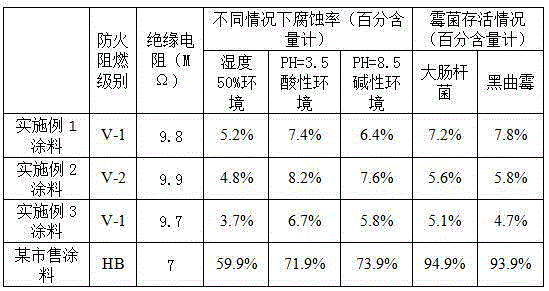

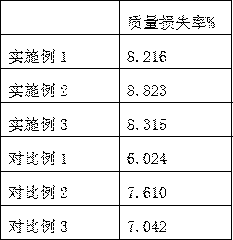

Wall body coating composition

InactiveCN108624159AEasy to prepareGood compatibilityAntifouling/underwater paintsPaints with biocidesFiberCross-link

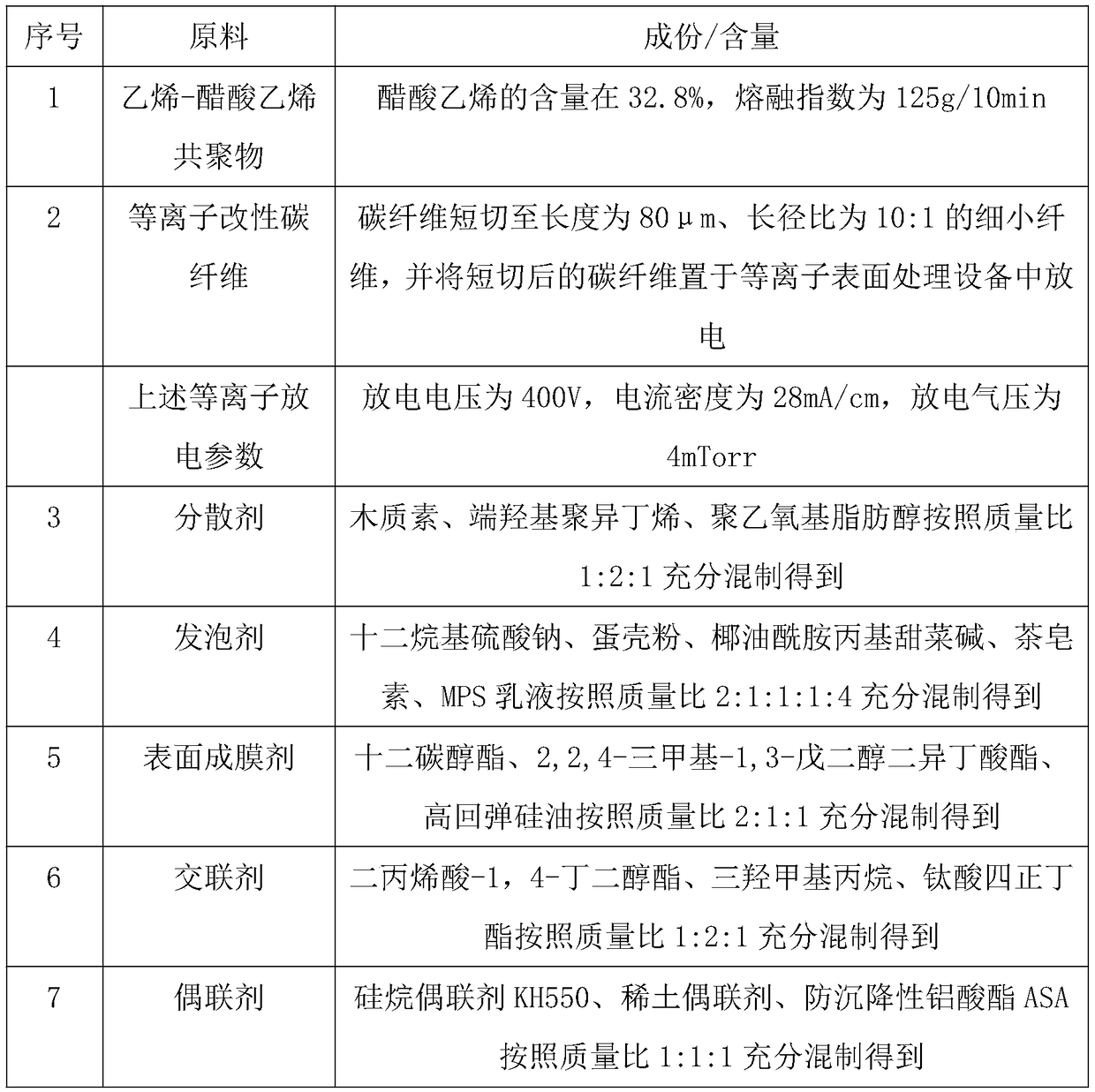

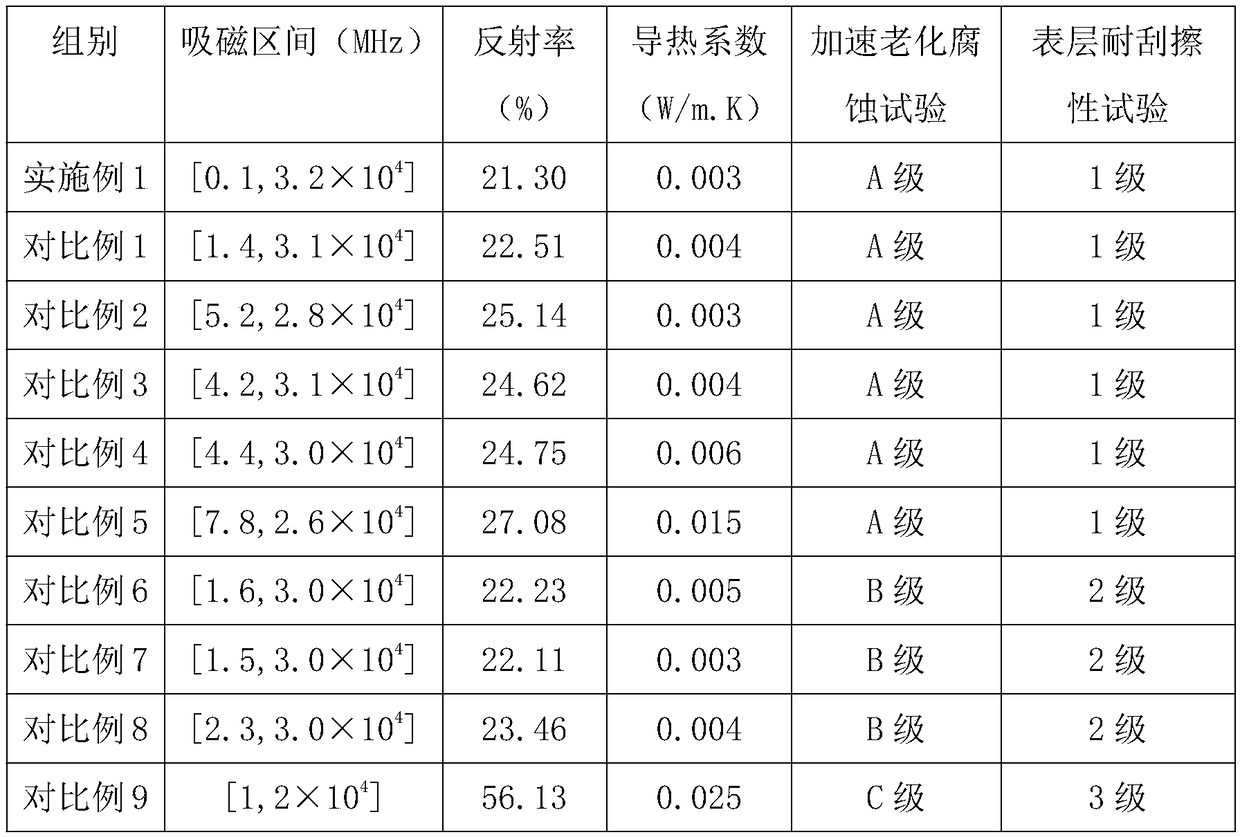

The invention discloses a wall body coating composition and relates to the technical field of coatings. The wall body coating composition consists of the following raw materials: a styrene-acrylic emulsion, a vinyl-vinyl acetate copolymer, plasma-modified carbon fibers, niobium and yttrium ore powder, porous basalt, chlorite, expanded graphite, Wudalianchi volcanic gray matters, ITO powder, acetyltrioctyl citrate, diacetone acrylamide, cyclohexanol, magnetized water, a dispersing agent, a foaming agent, a surface film forming agent, a cross-linking agent and a coupling agent. The wall body coating composition disclosed by the invention is simple to prepare, green and environmentally-friendly, has excellent durability and functionality and solves the problem of environmental pollution caused by electromagnetic wave energy transfer and radiation to a certain extent, thereby greatly reducing the interference damage of electromagnetic waves to surrounding equipment and a human body.

Owner:合肥谦尧建筑装饰工程有限公司

Mildew-resistant antimicrobial coating

InactiveCN104292993AAvoid generatingRubber derivative coatingsAntifouling/underwater paintsWater vaporMildew

The invention relates to the field of building decoration, and especially relates to a mildew-resistant antimicrobial coating, which is characterized by comprising the following components by weight: 10-15 parts of chlorinated rubber, 30-40 parts of acetyl trioctyl citrate, 10-15 parts of phthalate, 3-5 parts of tributyltin oxide, 20-25 parts of cuprous oxide, 5-10 parts of a paint solvent oil, 5-10 parts of coal tar and a proper amount of pigment. The invention adopts oxygen and fluorinated rubber with very low water vapour transmission rate as the main raw materials, which are supplemented with antiseptic and antifouling agent to prepare the coating through mixing modulation. As an architectural coating, the coating can effectively prevent the generation of fungi, algae and organic dirt, and can also be used as bottom coating.

Owner:翁洵

Flex-resistant vehicle USB2.0 connecting wiring harness outer sheath material

InactiveCN106380704AImprove corrosion resistanceHigh tensile strengthRubber insulatorsDi-tert-butyl peroxideRare earth

The invention discloses a flex-resistant vehicle USB2.0 connecting wiring harness outer sheath material. The material comprises, by weight, 40-60 parts of ethylene propylene diene monomer, 20-30 parts of styrene butadiene rubber, 10-30 parts of nylon 66, 10-20 parts of butadiene rubber, 60-90 parts of a composite filler, 15-25 parts of ammonium polyphosphate, 8-12 parts of microencapsulated red phosphorus, 5-6 parts of epoxidized soybean oil, 3-4 parts of acetyl trioctyl citrate, 1.5-2 parts of sulfur, 0.1-0.3 parts of di-tert-butyl peroxide, 0.1-0.2 parts of a promoter M, 0.1-0.2 parts of a promoter D, 1-2 parts of Si69, 1-3 parts of a rare earth stabilizer, 2-4 parts of a Ca / Zn composite stabilizer, 0.2-0.4 parts of an antioxidant, 0.3-0.5 parts of an anti-ageing agent and 2-4 parts of paraffin. The material has the advantages of good flex resistance, high elasticity, and good wear and corrosion resistance.

Owner:HEFEI BANGLI ELECTRONICS

E-commerce logistic conveying packaging film material

InactiveCN106084719AThe preparation process is simpleExcellent flame retardantPolymer scienceLead phosphate

The invention relates to an E-commerce logistic conveying packaging film material. The material is prepared from vancomycin, sodium diacetate, tetrabutyl titanate, stearin, octamethyl cyclotetrasiloxane, citronellyl formate, epoxy acrylic ester, trimethylolpropane acrylate, triethylene glycol di-2-ethylhexoate, aluminum hydroxide powder, montmorillonite, polycarbonate, bamboo charcoal powder, dibasic lead phosphate, triethyl citrate, nano silicon carbide, castor oil, 2-mercapto benzimidazole, tetraethoxysilane, tributyl phosphate, zinc borate, tributyl citrate, fluorescent powder, tri(2-ethylhexyl)acetocitrate, chlorothalonil and polypropylene glycol adipate. The E-commerce logistic conveying packaging film material is simple in preparation process, and the prepared material has excellent flame retardancy, acid and alkali resistance, mildew-proof performance and antibacterial performance and improves product performance.

Owner:龚灿锋

Multifunctional coating for electric power insulator and preparation method of multifunctional coating

InactiveCN105111803AThe preparation process is simpleImprove insulation performanceFireproof paintsAntifouling/underwater paintsCarbamateSodium phosphates

The invention relates to a multifunctional coating for an electric power insulator. The multifunctional coating for the electric power insulator consists of the following components in part by mass: 68-72 parts of copper thiocyanate, 70-74 parts of zinc pyrithione, 66-70 parts of menadione epoxy, 70-74 parts of acetyl trioctyl citrate, 66-70 parts of p-phenylene diamine, 70-74 parts of zinc borate, 66-70 parts of talcum powder, 72-76 parts of kaoline powder, 66-70 parts of dipentaerythritol hexaacrylate, 70-74 parts of dibasic lead phthalate, 66-70 parts of tetramethrin, 70-74 parts of ethyl spinosad, 66-70 parts of diafenthiuron, 70-74 parts of strontium carbonate, 66-70 parts of polyurethane, 70-74 parts of siliceousearth, 66-70 parts of stannous octoate, 70-74 parts of melamine sodium phosphate and 1000-2000 parts of water. A technological preparation method of the multifunctional coating for the electric power insulator is simple; prepared products have good corrosion resistance, fireproofing, flame retardance, insulating property and anti-bacterial property; and the multifunctional coating for the electric power insulator is suitable to be used in various fields.

Owner:龚灿锋

Efficient flame-retardant wear-resistant subway cable and preparation method thereof

InactiveCN109438986AEfficient flame retardantFlame retardant and wear-resistantRubber insulatorsWear resistantTemperature resistance

The invention relates to the technical field of cables, and discloses an efficient flame-retardant wear-resistant subway cable and a preparation method thereof. The efficient flame-retardant wear-resistant subway cable comprises the following raw materials in parts by weight: 20-40 parts of silicone rubber, 5-15 parts of ethylene propylene diene monomer, 3-8 parts of butyl rubber, 3-10 parts of polyurethane, 3-4 parts of acetyl trioctyl citrate, 10-20 parts of modified aluminum oxide, 10-15 parts of kaolin, 10-15 parts of micro-encapsulation red phosphorus, 5-10 parts of zinc borate, 2-6 partsof 3-aminopropyltriethoxysilane, 1-2 parts of an accelerant, 2-4 parts of a Ca / Zn composite stabilizer, 1-3 parts of an anti-ageing agent, 3-7 parts of silicone powder and a cable body. The modifiedaluminum oxide is dispersed uniformly in a cable material, the properties are synergistic, the strength and wear resistance of the cable material are further improved, the kaolin and the silicone powder cooperate with each other, and the high temperature resistance, impact resistance, wear resistance and machinability of the efficient flame-retardant wear-resistant subway cable can be improved further.

Owner:安徽华网电缆有限公司

Novel woodware adhesive

InactiveCN105349059AEasy to prepareGood storage stabilityNon-macromolecular adhesive additivesStarch adhesivesPolymer scienceTert butyl phenol

The invention discloses a novel woodware adhesive prepared from the following raw materials in parts by weight: 2.5-3.8 parts of polyvinyl alcohol, 1.8-3.6 parts of a calcium carbonate powder, 3.5-6.5 parts of lignin, 5-10 parts of corn starch, 1.2-2.4 parts of baking soda, 2.5-5 parts of glycerin, 1.2-3.6 parts of 4-tert butyl phenol, and 2.5-5 parts of acetyl trioctyl citrate. Compared with conventional products, the novel woodware adhesive is a water-soluble adhesive, does not contain formaldehyde, and is safe and environmentally friendly. The adhesive has the advantages that a water soluble alkenyl monomer is used for grafting, and wood materials are adhered by grafting and crosslinking on the surface of wood meal, so that the adhesive has high bonding strength and has the initial bonding strength of up to 2.2 MPa. The water-soluble non-formaldehyde wood adhesive can be subjected to microwave curing or heat curing, is simple in preparation method, and has the excellent performance of good storage stability, fast strength establishment and the like.

Owner:黄艳

Preparation method of polylactic acid plasticizing compound

The invention provides a preparation method of a polylactic acid plasticizing compound. The polylactic acid plasticizing compound comprises the following components in parts by weight: 70-95 parts ofpolylactic acid and 5-30 parts of a compound plasticizer, and the compound plasticizer is composed of a component A and a component B, wherein the weight ratio of the component A to the component B is(1-5):(1-25). The component A is one or more with any proportion selected from glycerin of polyhydric alcohol, xylitol and sorbitol, and the component B is one or more with any proportion selected from dioctyl phthalate, polyethylene glycol with a molecular weight of 1000-8000, triethyl citrate, tributyl citrate, trioctyl citrate, triethyl acetyl citrate, tributyl acetyl citrate and trioctyl acetyl citrate. Compared with polylactic acid plasticized by a single plasticizer, the polylactic acid plasticized by the polylactic acid plasticizing compound has a tensile strength increased by 15.74% and an elongation at break increased by 11.05%, and meanwhile, the usage amount of the polylactic acid plasticizing compound is 41.67% lower than the usage amount of the single plasticizer.

Owner:吉林省龙展新材料科技有限公司

Degradable plastic film raincoat

InactiveCN108727727APromote degradationGood improvement in biodegradabilityOvergarmentsPolyvinyl chlorideGlucoside

The invention discloses a degradable plastic film raincoat, and relates to the technical field of new materials. The raincoat is prepared from the following components: polyvinyl chloride resin, silicon-doped starch, phenolic resin, dilauryl thiodipropionate, trioctyl acetylcitrate, dodecyl polyglucoside, aluminum borate whisker, polycaprolactone, inorganic filler, a plasticizer and a dispersant.The added silicon-doped starch cooperates with nano diatomite modified phenolic resin, biodegradability of the environment-friendly film raincoat can be significantly improved, the same technical effect cannot be achieved by adopting unmodified starch or starch modified with other modification methods. Meanwhile, different types of starch also have different influences on biodegradability of the prepared film raincoat, and cassava starch is better than soybean starch in improvement of biodegradability of the plastic film raincoat.

Owner:枞阳县陶波雨具有限公司

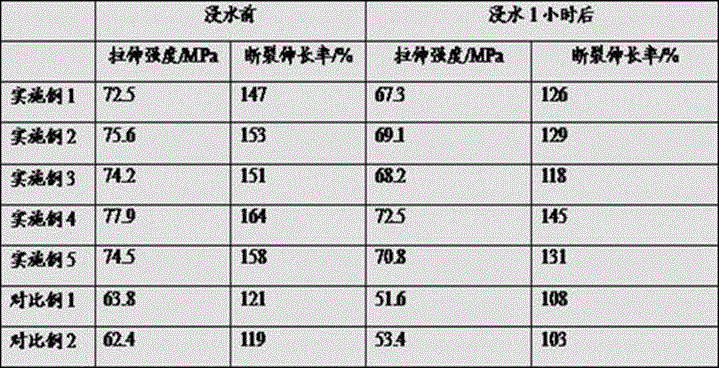

Enhanced starch based packaging composite material and preparation method thereof

InactiveCN105860147AImprove mechanical propertiesImprove water resistanceMechanical propertyCastor oil

The invention discloses an enhanced starch based packaging composite material and a preparation method thereof. The enhanced starch based packaging composite material is prepared from the following raw materials in parts by weight: cassava starch, corn starch, nightshade seed powder, calcium chloride, nano attapulgite, boric acid, limonite powder, phosphoguanidine, calcium lignosulphonate, erucyl amide, beewax, trioctyl acetylcitrate, methyl ethylene oxide, zinc stearate, castor oil and a silane coupling agent. The enhanced starch based packaging composite material disclosed by the invention is good in mechanical property, the tensile strength of the material is as high as 72.5-77.9 MPa, the breakage elongation is as high as 147-164%, the tensile strength and the breakage elongation of the material are still kept being in relatively high value after the material is soaked for 1 hour, property defects of a conventional starch based packaging material are avoided, and good application values can be achieved.

Owner:苏州倍力特物流设备有限公司

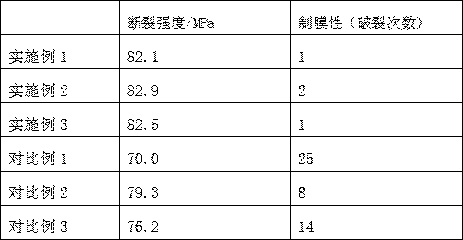

PVC plastic film raincoat

InactiveCN108948567AHigh breaking strengthExcellent film forming propertyOvergarmentsProtective garmentPolymer scienceTrimethylolpropane trimethacrylate

The invention discloses a PVC plastic film raincoat, and relates to the technical field of new materials, the PVC plastic film raincoat is made of the following components: PVC resin, a maleic acid / 2-acrylamido-2-methylpropanesulfonic acid binary copolymer, trimethylol propane trimethacrylate, zinc stearate, Trioctyl acetylcitrate, Methyltriacetoxysilane, an inorganic filler and a plasticizer; thePVC plastic film raincoat has better breaking strength and film preparation property and improved durability, the number of cracks during film preparation can be significantly reduced, and the breaking strength and the film preparation property of the PVC plastic film raincoat can be modified and improved by synergistic effects of the maleic acid / 2-acrylamido-2-methylpropanesulfonic acid binary copolymer, the Trioctyl acetylcitrate and modified zeolite powder together.

Owner:枞阳县陶波雨具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com