LDPE (low-density polyethylene) antibacterial plastic and preparation method thereof

A technology of antibacterial plastics and antibacterial agents, which is applied in the field of LDPE plastics, can solve problems such as short service life, poor heat resistance, and poor safety, and achieve the effects of easy processing, improved mechanical properties, and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

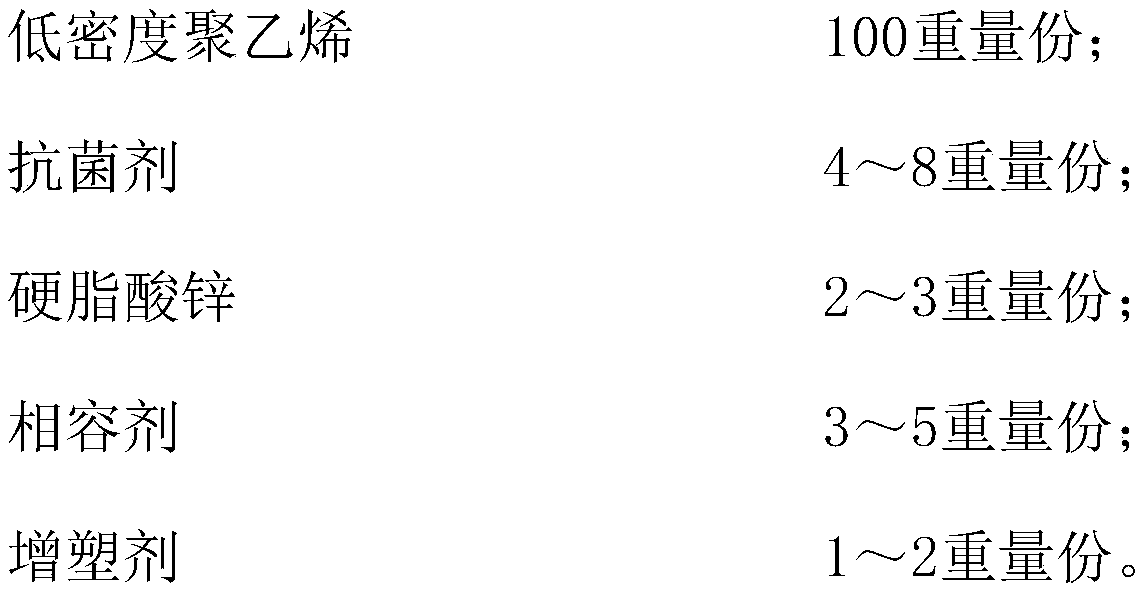

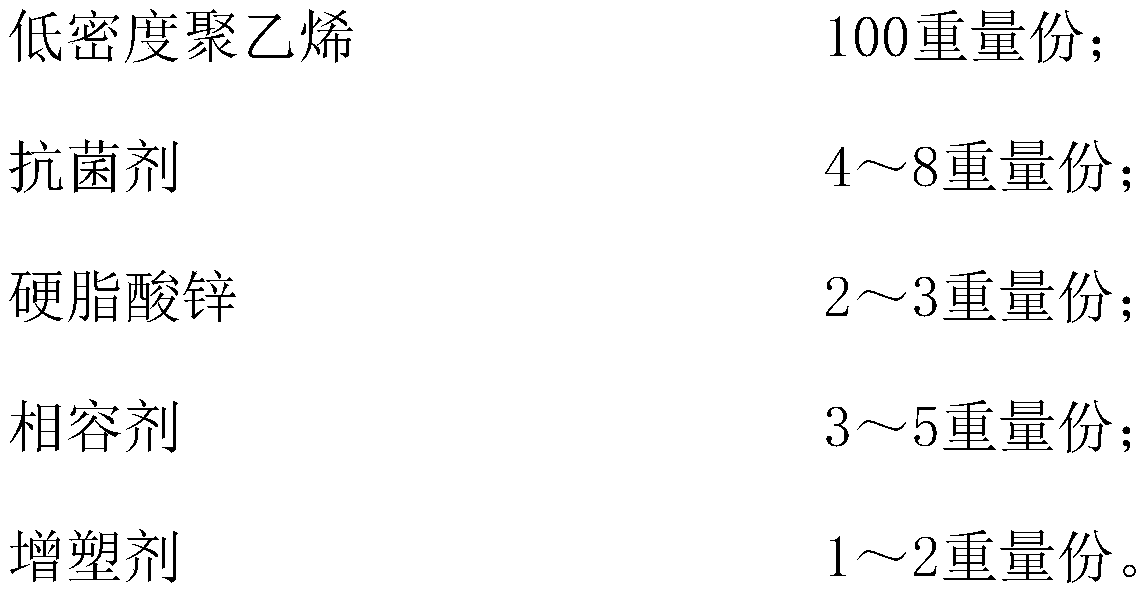

[0036] A preparation method of LDPE antibacterial plastic includes the following steps:

[0037] 1) Premix the antibacterial agent and zinc stearate to obtain a premix;

[0038] 2) Mix the premix obtained in step (1) with low-density polyethylene, polyamide fiber, compatibilizer and germanium oxide. After mixing uniformly, add plasticizer, copper dialkyl dithiophosphate and iso Mix the thiazolinone thoroughly to obtain a mixture;

[0039] 3) The mixture obtained in the above step (2) is granulated and dried at a temperature of 160-180°C to obtain an antibacterial plastic.

Embodiment 1

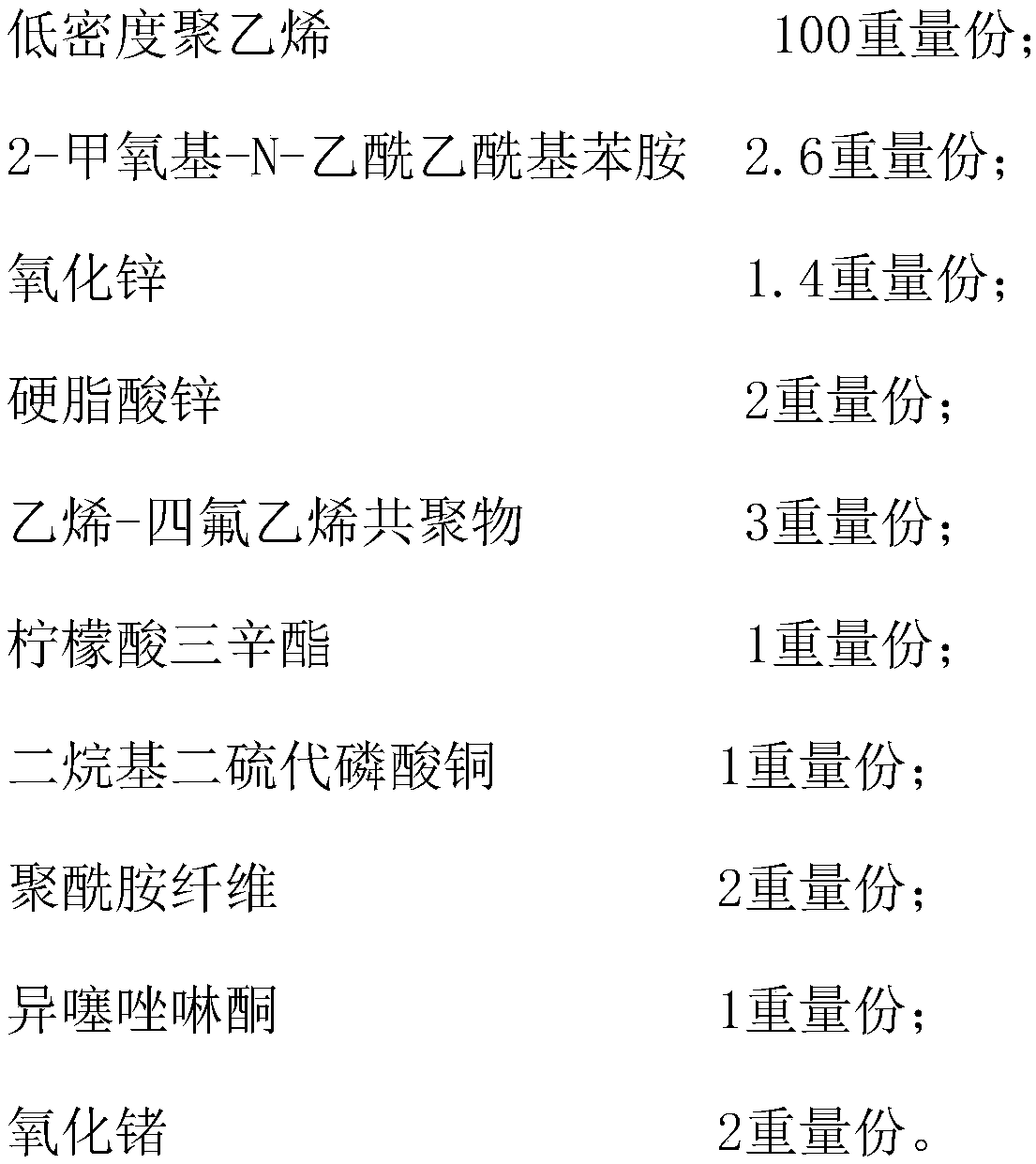

[0042] An LDPE antibacterial plastic, mainly composed of the following parts by weight of raw materials:

[0043]

[0044] The number average molecular weight of the ethylene-tetrafluoroethylene copolymer is 2000 g / mol.

[0045] A preparation method of LDPE antibacterial plastic includes the following steps:

[0046] 1) Premixing 2-methoxy-N-acetoacetylaniline, zinc oxide and zinc stearate to obtain a premix;

[0047] 2) Mix the premix obtained in step (1) with low-density polyethylene, polyamide fiber, ethylene-tetrafluoroethylene copolymer and germanium oxide, and after mixing uniformly, add trioctyl citrate, dialkyl two Copper thiophosphate and isothiazolinone are mixed thoroughly to obtain a mixture;

[0048] 3) The mixture obtained in the above step (2) is granulated and dried at a temperature of 160° C. to obtain an antibacterial plastic.

Embodiment 2

[0050] An LDPE antibacterial plastic, mainly composed of the following parts by weight of raw materials:

[0051]

[0052] The number average molecular weight of the ethylene-tetrafluoroethylene copolymer is 2100 g / mol.

[0053] A preparation method of LDPE antibacterial plastic includes the following steps:

[0054] 1) Premixing 2-methoxy-N-acetoacetylaniline, zinc oxide and zinc stearate to obtain a premix;

[0055] 2) Mix the premix obtained in step (1) with low-density polyethylene, polyamide fiber, ethylene-tetrafluoroethylene copolymer and germanium oxide, and after mixing uniformly, add trioctyl citrate, dialkyl two Copper thiophosphate and isothiazolinone are mixed thoroughly to obtain a mixture;

[0056] 3) The mixture obtained in the above step (2) is granulated and dried at a temperature of 170° C. to obtain an antibacterial plastic.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com