Wall body coating composition

A composition and coating technology, applied in the field of coatings, can solve the problems that electromagnetic wave anti-interference and shielding effect cannot eliminate electromagnetic pollution, affect the value of building coating products, life and work and electrical equipment hazards, etc., to reduce interference damage, inhibit The generation of mold, the effect of good heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

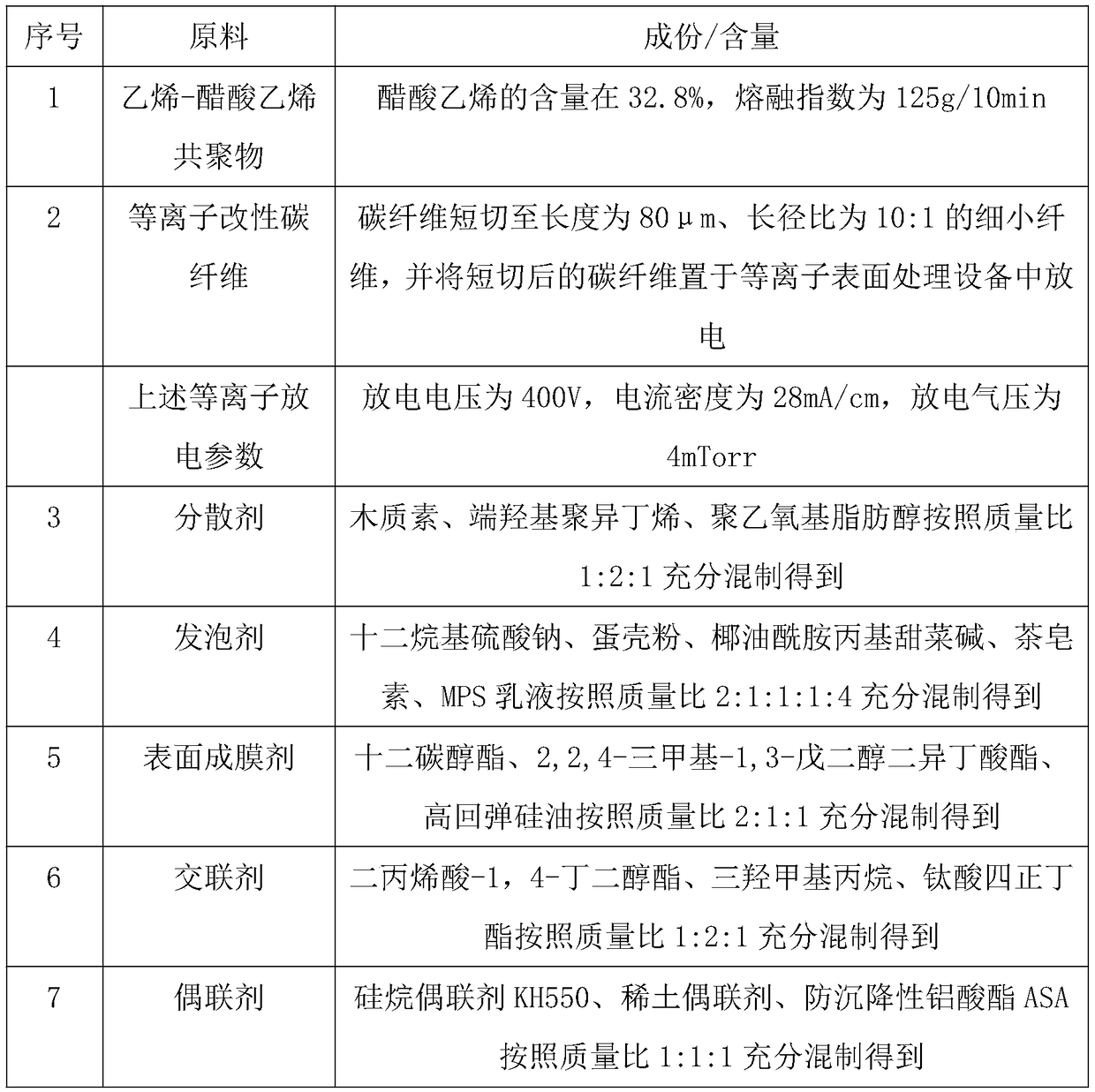

Embodiment 1

[0047] This embodiment relates to a wall coating composition and a preparation method thereof, which is prepared by weighing the following raw materials in parts by weight:

[0048] 72 parts of styrene-acrylic emulsion;

[0049] 15 parts of ethylene-vinyl acetate copolymer;

[0050] 3 parts of plasma modified carbon fiber;

[0051] 2 parts of niobium yttrium ore powder;

[0052] 3 parts porous basalt;

[0053] 2 parts of chlorite;

[0054] 1 part of expandable graphite with an expansion rate of 300ml / g;

[0055] 3 parts of Wudalianchi volcanic ash;

[0056] 1 part of ITO powder;

[0057] Acetyl trioctyl citrate 0.5 parts;

[0058] 0.4 parts of diacetone acrylamide;

[0059] 0.8 parts of cyclohexanol;

[0060] 10 parts of magnetized water;

[0061] 1.5 parts of dispersant;

[0062] 1 part foaming agent;

[0063] 1.6 parts of coupling agent;

[0064] 1 part of crosslinking agent;

[0065] 0.75 parts of surface film-forming agent.

[0066] The preparation of the ab...

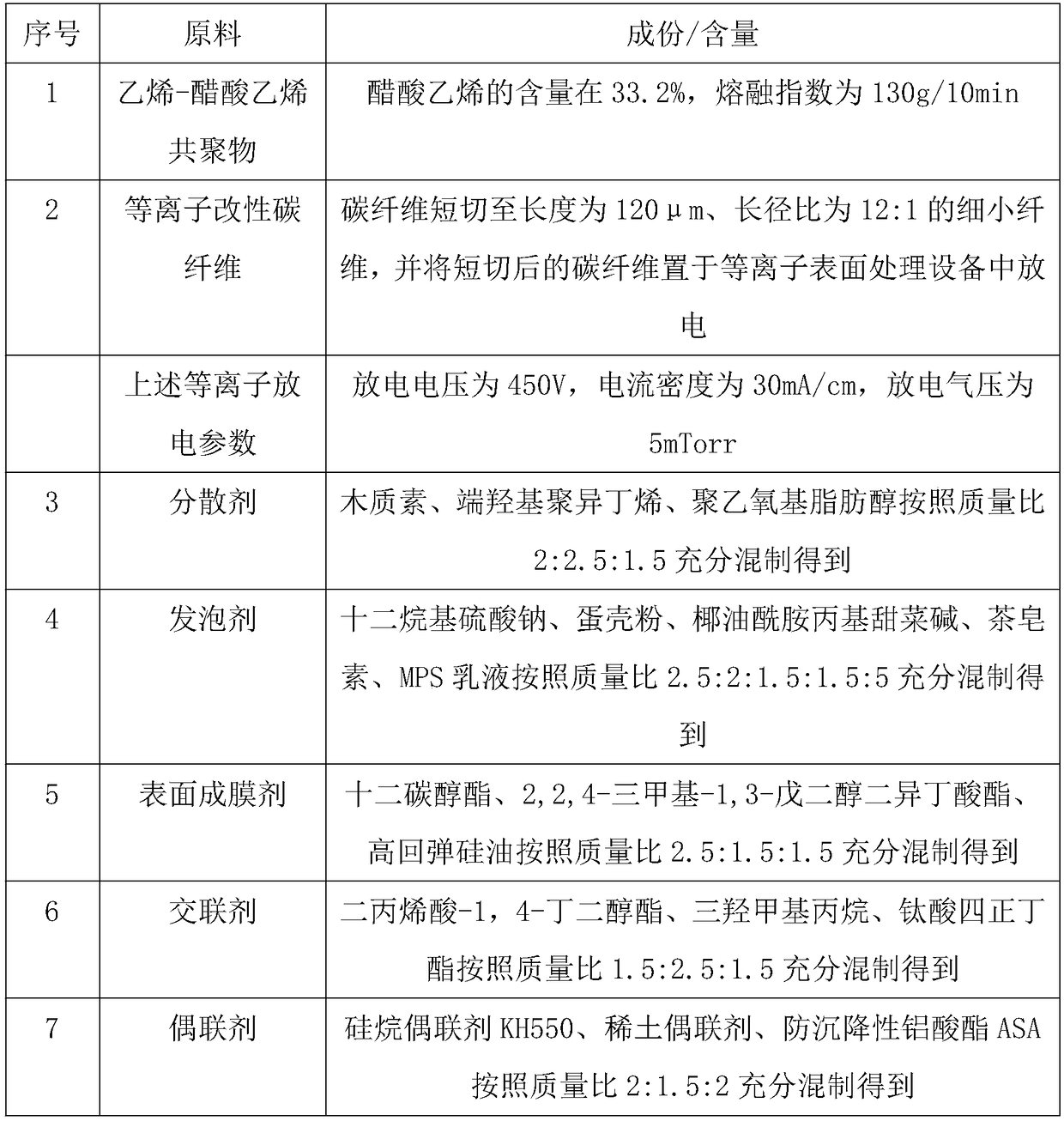

Embodiment 2

[0114] This embodiment relates to a wall coating composition and a preparation method thereof, which is prepared by weighing the following raw materials in parts by weight:

[0115] 78 parts of styrene-acrylic emulsion;

[0116] 18 parts of ethylene-vinyl acetate copolymer;

[0117] 4 parts of plasma modified carbon fiber;

[0118] 2.5 parts of niobium yttrium ore powder;

[0119] 4 parts porous basalt;

[0120] 2.5 parts of chlorite;

[0121] 1.25 parts of expandable graphite with expansion ratio of 300ml / g;

[0122] 4 parts of Wudalianchi volcanic ash;

[0123] 1.5 parts of ITO powder;

[0124] Acetyl trioctyl citrate 0.75 parts;

[0125] 0.6 parts of diacetone acrylamide;

[0126] 1 part cyclohexanol;

[0127] 12.5 parts of magnetized water;

[0128] 2 parts of dispersant;

[0129] 1.5 parts of blowing agent;

[0130] 1.9 parts of coupling agent;

[0131] 1.2 parts of crosslinking agent;

[0132] 0.95 parts of surface film-forming agent.

[0133] The preparat...

Embodiment 3

[0146] This embodiment relates to a wall coating composition and a preparation method thereof, which is prepared by weighing the following raw materials in parts by weight:

[0147] 86 parts of styrene-acrylic emulsion;

[0148] 21 parts of ethylene-vinyl acetate copolymer;

[0149] 5 parts of plasma modified carbon fiber;

[0150] 3 parts of niobium yttrium ore powder;

[0151] Porous basalt 5 parts;

[0152] 3 parts of chlorite;

[0153] 1.5 parts of expandable graphite with an expansion rate of 300ml / g;

[0154] Wudalianchi volcanic ash 5 parts;

[0155] 2 parts of ITO powder;

[0156] Acetyl trioctyl citrate 1 part;

[0157] 0.8 part of diacetone acrylamide;

[0158] 1.2 parts of cyclohexanol;

[0159] 15 parts of magnetized water;

[0160] 2.5 parts of dispersant;

[0161] 2 parts foaming agent;

[0162] 2.2 parts of coupling agent;

[0163] 1.4 parts of crosslinking agent;

[0164] 1.15 parts of surface film-forming agent.

[0165] The preparation of above-m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com