Multifunctional coating for electric power insulator and preparation method of multifunctional coating

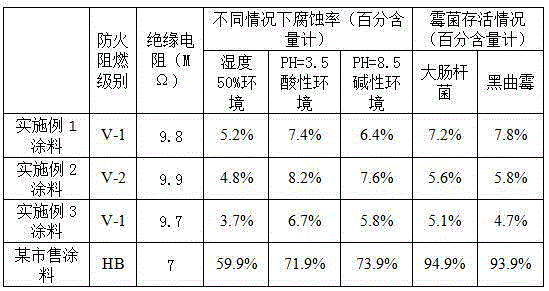

A multifunctional technology for insulators, applied in the field of multifunctional coatings for power insulators and its preparation, can solve the problems of natural pollution on the surface of insulators, and achieve the effects of efficient insecticidal performance, high safety, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]The multifunctional coating for power insulators in this embodiment consists of the following components in parts by mass: 68 parts of cuprous thiocyanate, 70 parts of zinc pyrithione, 66 parts of epoxy menadione, acetyl trioctyl citrate 70 parts of ester, 66 parts of p-phenylene diamine, 70 parts of zinc borate, 66 parts of talc powder, 72 parts of kaolin powder, 66 parts of dipentaerythritol hexaacrylate, 70 parts of dibasic lead phthalate, tetramethrin 66 parts, 70 parts of ethyl spinosad, 66 parts of diafenthiuron, 70 parts of strontium carbonate, 66 parts of polyurethane, 70 parts of diatomaceous earth, 66 parts of stannous zincate, 70 parts of sodium melamine phosphate, 1000 parts of water.

[0036] The steps of the preparation method of the above-mentioned multifunctional coating for electric insulators are as follows:

[0037] (1) Cuprous thiocyanate, zinc pyrithione, epoxymenadione, acetyl trioctyl citrate, p-phenylene diamine, zinc borate, kaolin powder, dipen...

Embodiment 2

[0041] The multifunctional coating for electric insulators in this embodiment consists of the following components in parts by mass: 70 parts of cuprous thiocyanate, 72 parts of zinc pyrithione, 68 parts of epoxy menadione, acetyl trioctyl citrate 72 parts of ester, 68 parts of p-phenylenediamine, 72 parts of zinc borate, 68 parts of talc powder, 74 parts of kaolin powder, 68 parts of dipentaerythritol hexaacrylate, 72 parts of dibasic lead phthalate, tetramethrin 68 parts, 72 parts of ethyl spinosad, 68 parts of diafenthiuron, 72 parts of strontium carbonate, 68 parts of polyurethane, 72 parts of diatomaceous earth, 68 parts of stannous zincate, 72 parts of sodium melamine phosphate, 1500 parts of water.

[0042] The steps of the preparation method of the above-mentioned multifunctional coating for electric insulators are as follows:

[0043] (1) Cuprous thiocyanate, zinc pyrithione, epoxymenadione, acetyl trioctyl citrate, p-phenylene diamine, zinc borate, kaolin powder, di...

Embodiment 3

[0047] The multifunctional coating for power insulators in this embodiment is composed of the following components in parts by mass: 72 parts of cuprous thiocyanate, 74 parts of zinc pyrithione, 70 parts of epoxy menadione, acetyl trioctyl citrate 74 parts of ester, 70 parts of p-phenylene diamine, 74 parts of zinc borate, 70 parts of talc powder, 76 parts of kaolin powder, 70 parts of dipentaerythritol hexaacrylate, 74 parts of dibasic lead phthalate, tetramethrin 70 parts, 74 parts of ethyl spinosad, 70 parts of diafenthiuron, 74 parts of strontium carbonate, 70 parts of polyurethane, 74 parts of diatomaceous earth, 70 parts of stannous zincate, 74 parts of sodium melamine phosphate, 2000 parts of water.

[0048] The steps of the preparation method of the above-mentioned multifunctional coating for electric insulators are as follows:

[0049] (1) Cuprous thiocyanate, zinc pyrithione, epoxymenadione, acetyl trioctyl citrate, p-phenylene diamine, zinc borate, kaolin powder, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com