Patents

Literature

140 results about "Menadione" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

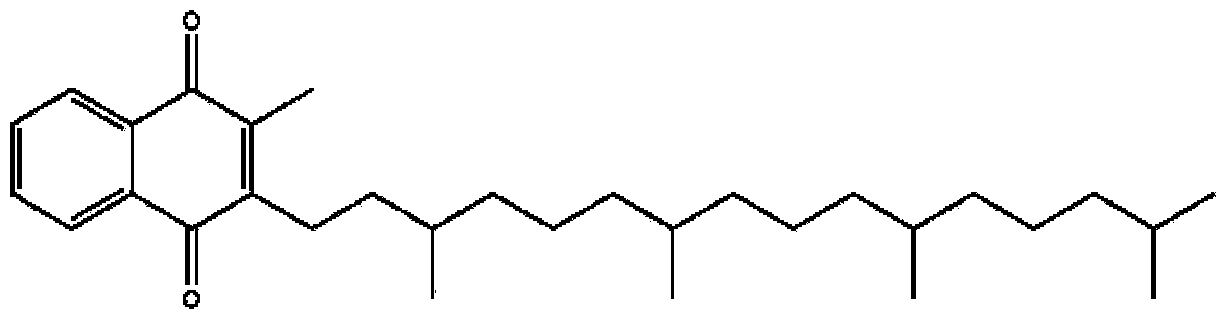

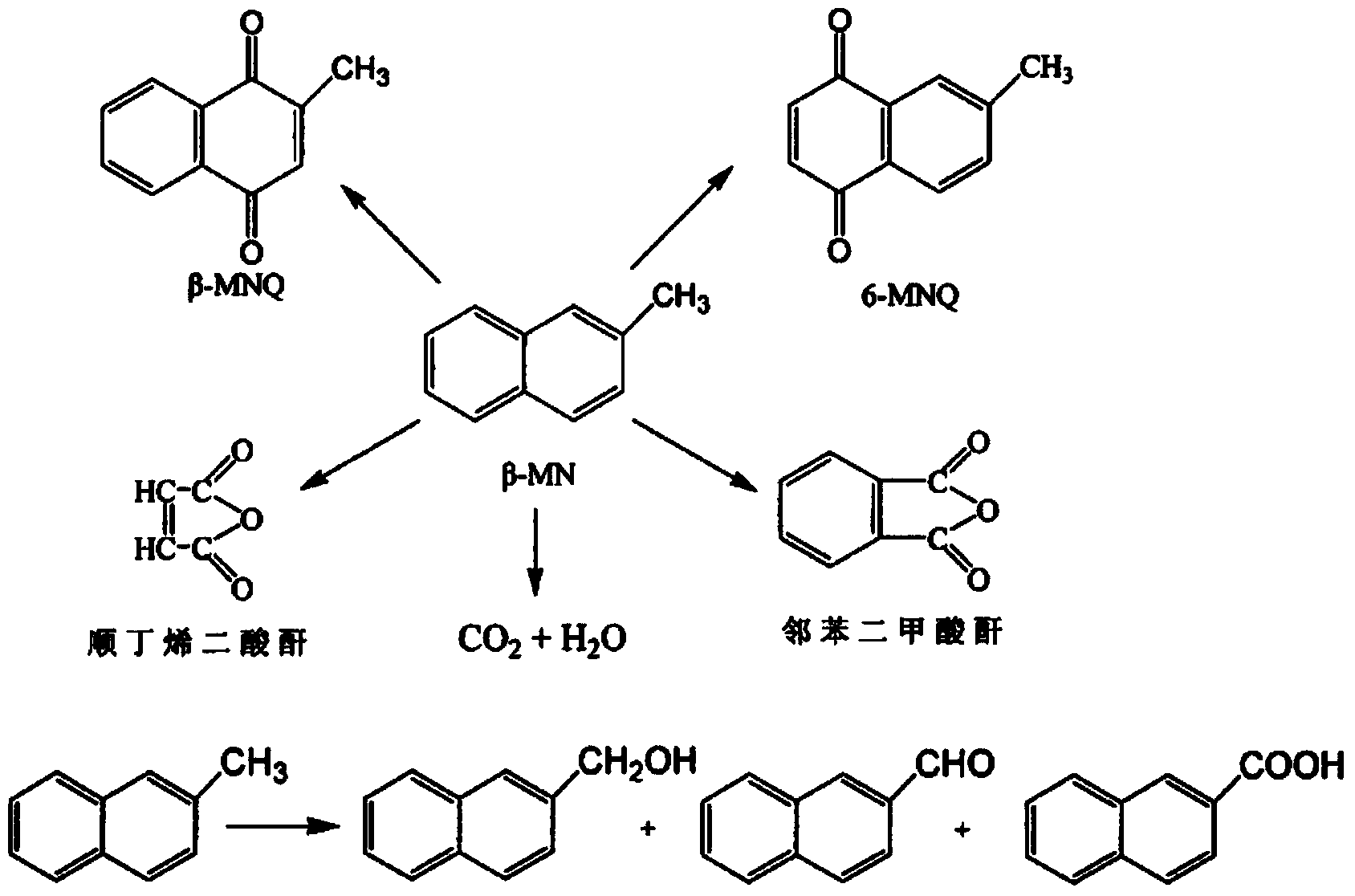

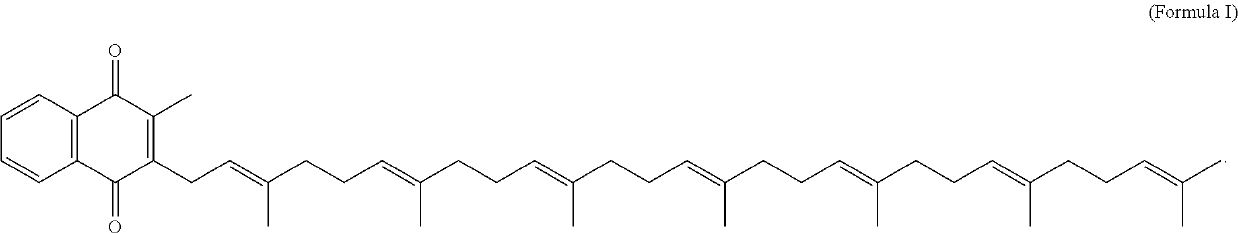

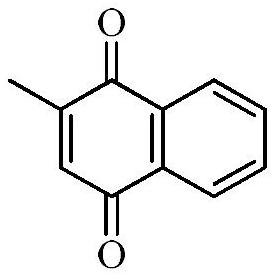

Menadione is an organic compound with the formula C₆H₄(CO)₂C₂H(CH₃). It is an analog of 1,4-naphthoquinone with a methyl group in the 2-position. It is occasionally used as a nutritional supplement in animal feed because of its vitamin K activity.

Bovine oocyte in-vitro fertilization and embryo culture method and transport culture solution

The invention relates to a bovine oocyte in-vitro fertilization and embryo culture method, and a transport culture solution. On one hand, the transport culture solution comprises glycine, alanine, arginine hydrochloride, aspartic acid, cystine dihydrochloride, glutamic acid, L-glutamine, histidine, threonine, tryptophan, tyrosine, valine, ascorbic acid, biotin, choline chloride, calcium pantothenate, folic acid, menadione and the like. The bovine oocyte in-vitro fertilization and embryo culture method comprises the following steps: oocyte collection and in-vitro maturation, in-vitro fertilization, and embryo in-vitro culture and preservation. The method and the related transport culture solution have excellent technical effects as described in the specification.

Owner:天津力牧生物科技有限公司

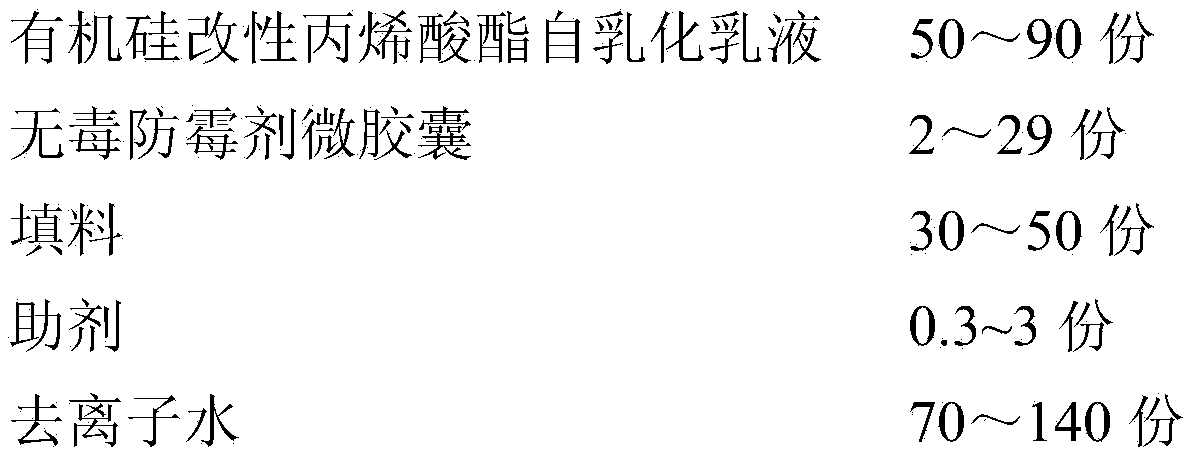

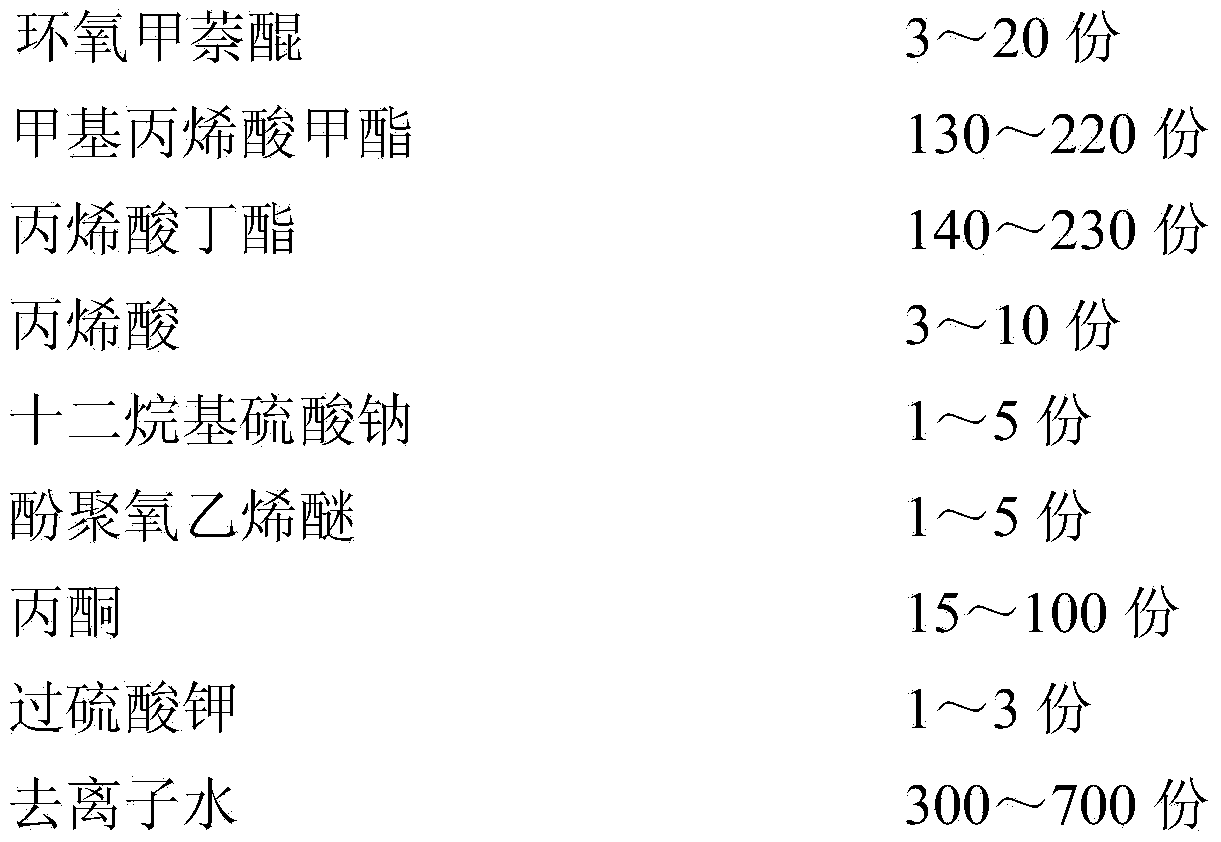

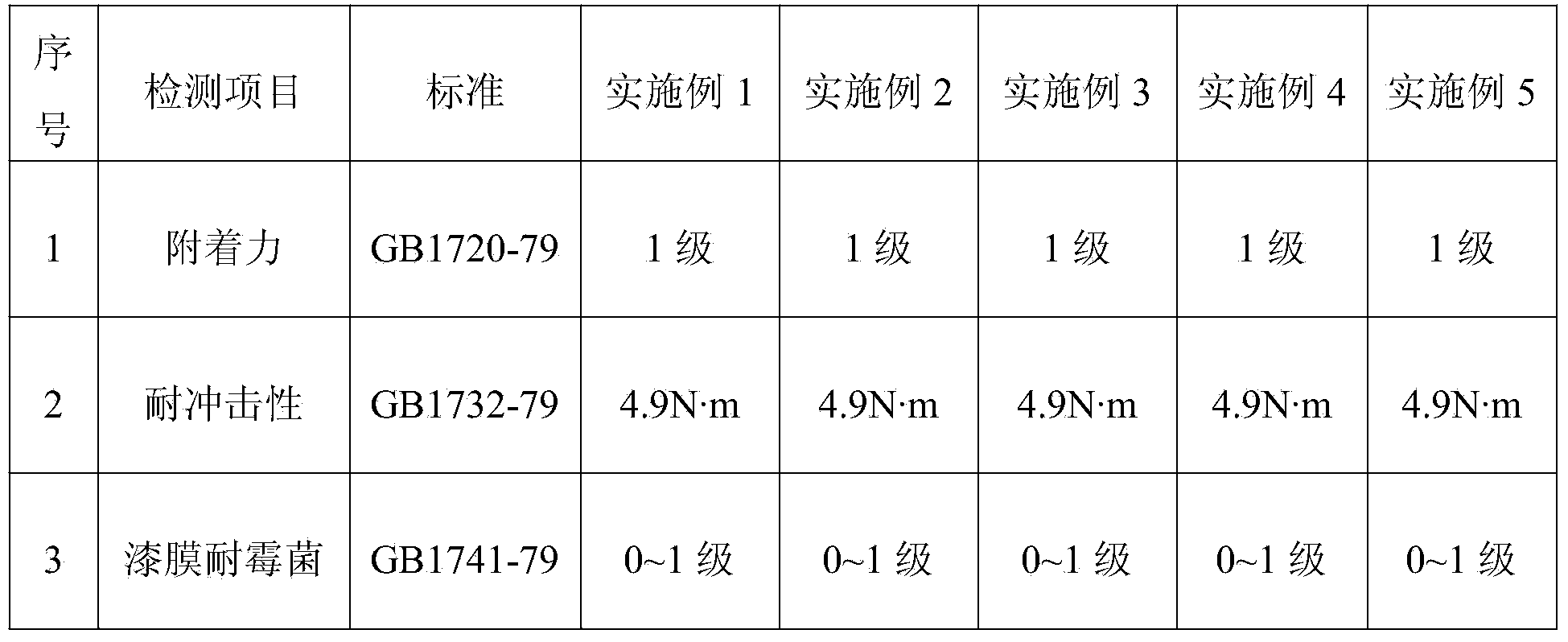

Non-toxic water-based microcapsule mold-proof heat insulation coating and preparation method thereof

ActiveCN104017453AGood antifoulingImprove mildew resistanceAntifouling/underwater paintsPaints with biocidesWater basedEpoxy

The invention provides a non-toxic water-based microcapsule mold-proof heat insulation coating and a preparation method thereof and relates to the field of mold-proof heat insulation coatings. The mold-proof heat insulation coating mainly consists of organosilicone modified acrylate self-emulsifying emulsion, non-toxic mildew preventive microcapsules, fillers, aids and deionized water, wherein in the non-toxic mildew preventive microcapsules, epoxy menadione and other oleophilic anti-fouling compositions are taken as capsule cores, and polyacrylate serves as a capsule wall; the mildew preventive uniformly and effectively diffuses for a long time. The water-based microcapsule mold-proof coating adopts a non-toxic environment-friendly mold-proof heat insulation material, is non-toxic, has obvious mold-proof heat insulation effects, has service life longer than that of a traditional mold-proof coating and has excellent physical performances such as high washing resistance, high adhesive force and high impact resistance.

Owner:DALIAN XINE TECH

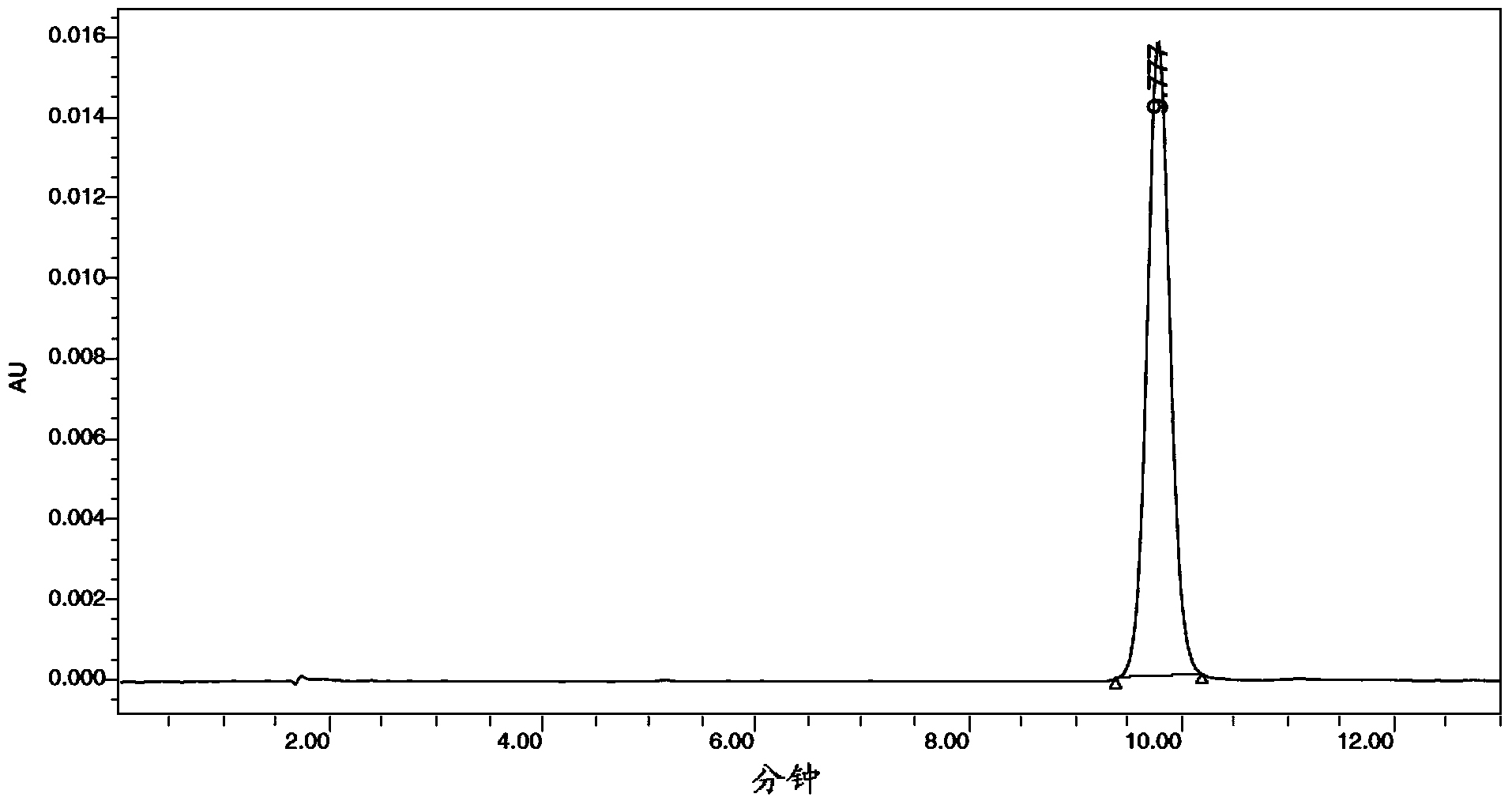

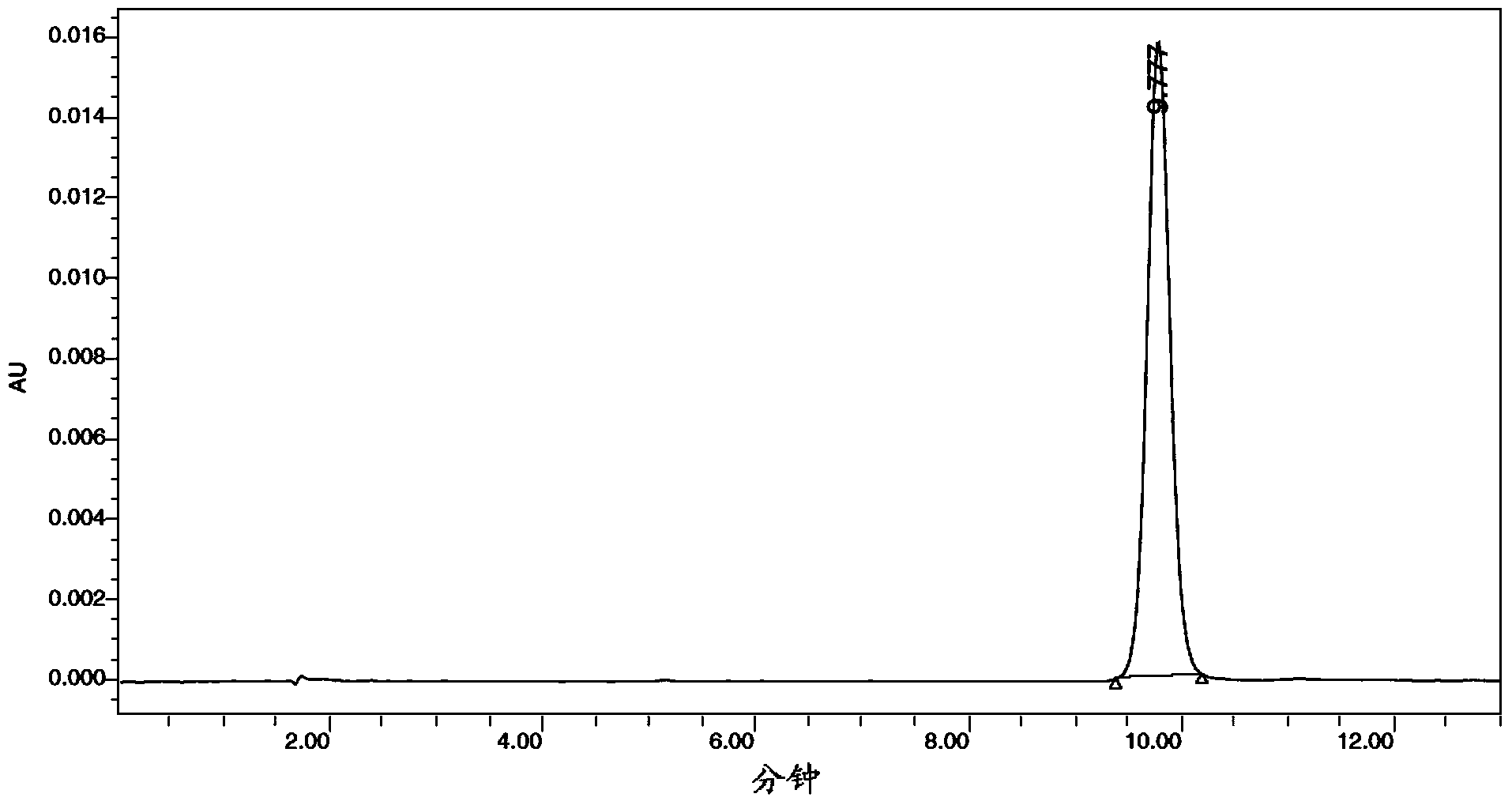

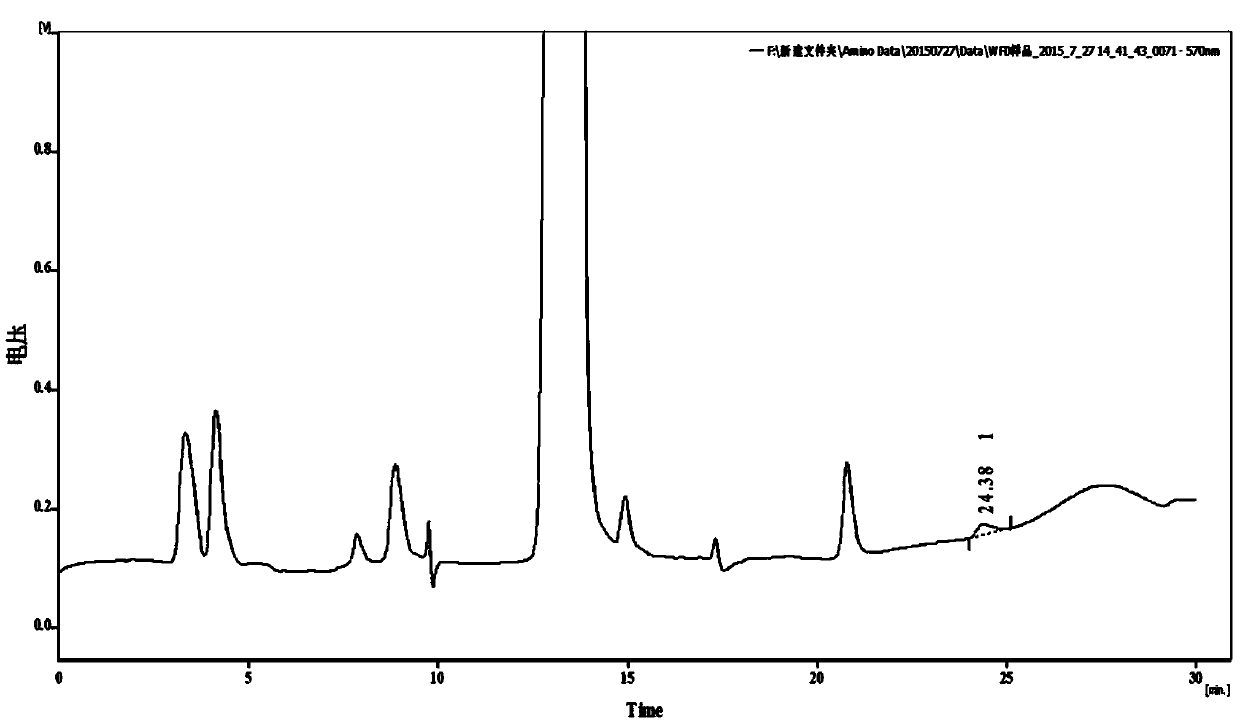

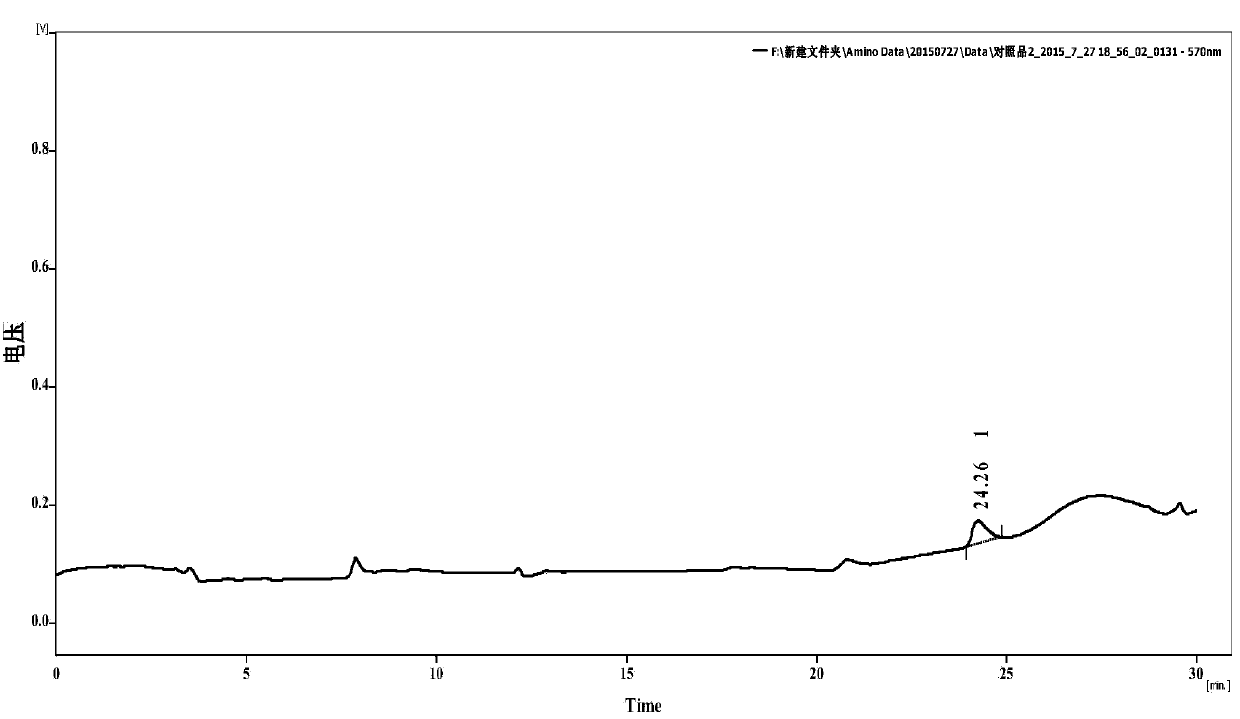

Bacillus subtilis natto and method for purifying vitamin menadione-7 by using bacterial strain

InactiveCN103898175AProtection from high temperature damageHigh yieldBacteriaQuinone separation/purificationIsocratic elutionMenadione

The invention provides bacillus subtilis natto ST188 with CGMCC No. 8400 and a high-yield method for purifying vitamin menadione-7 by using the bacterial strain. The high-yield method comprises the following steps: (1) carrying out spray drying on natto fermentation liquor, and extracting or leaching bacillus natto fermentation liquor spray drying powder by using a solvent so as to obtain a leaching solution; (2) concentrating the leaching solution obtained in the step (1) so as to obtain extract; (3) carrying out column chromatography on the extract obtained in the step (2), carrying out gradient or isocratic elution, and concentrating collected liquid, thus obtaining a menadione-7 crude product; and (4) crystallizing and purifying the menadione-7 crude product obtained in the step (3), thus obtaining the pure vitamin menadione-7 product.

Owner:SUNGEN BIOSCIENCE CO LTD

Nanometer vitamin complex for breeding laying hens, preparing method therefor and usage thereof

InactiveCN102626190APromote growthIncrease egg productionAnimal feeding stuffAnimal scienceAdditive ingredient

The invention discloses a nanometer vitamin complex for breeding laying hens, a preparing method therefor and usage thereof. The content of nutrients in per kilogram of the complex is as follows: 15 million IU of vitaminA, 5 million IU of vitaminD3, 25000 IU of vitaminE , 4000 mg of vitaminK3 (in terms of menadione), 2000 mg of vitaminB1, 10000 mg of vitaminB2, 3000 mg of vitaminB6, 75 mg of vitaminB12, 500 mg of folic acid, 100 mg of d-biotin, 20000 mg of nicotinamide, 10000 mg of D-calcium pantothenate, 10000 mg of vitaminC, and 50000 mg of methionine, with the balance being a carrier. The nanometer vitamin complex for breeding laying hens provided in the invention can significantly improve growth and laying rate of the laying hens, lower feed-to-egg ratio and improve quality of eggs.

Owner:陕西金冠牧业有限公司

Method for preparing chromium sulfate basic by utilizing residual liquor obtained during menadione production

The invention discloses a method for preparing chromium sulfate basic by utilizing residual liquor obtained during menadione production. The method comprises the following steps: uniformly mixing the concentrated residual liquor with industrial sugar according to a certain molar ratio, and reacting in a pressure reactor for 0.5-4 hours at the temperature of 100 to 300 DEG C under the pressure of 0 to 4MPa; completely reducing a small amount of unreacted hexavalent chromium in the feed liquid into trivalent chromium by using a reducing agent after the reaction is ended; regulating the basicity of the feed liquid by using an alkaline solution, filtering, performing spray drying on the filtrate, thus obtaining the chromium sulfate basic product. According to the method disclosed by the invention, a pressure-conditioned curing reaction is adopted, residual organic matters in the menadione residual liquor can be effectively removed, and the quality of chromium powder is improved. The method disclosed by the invention is simple in process, high in reaction rate, low in energy consumption, clean and environment-friendly.

Owner:SICHUAN YINHE CHEM

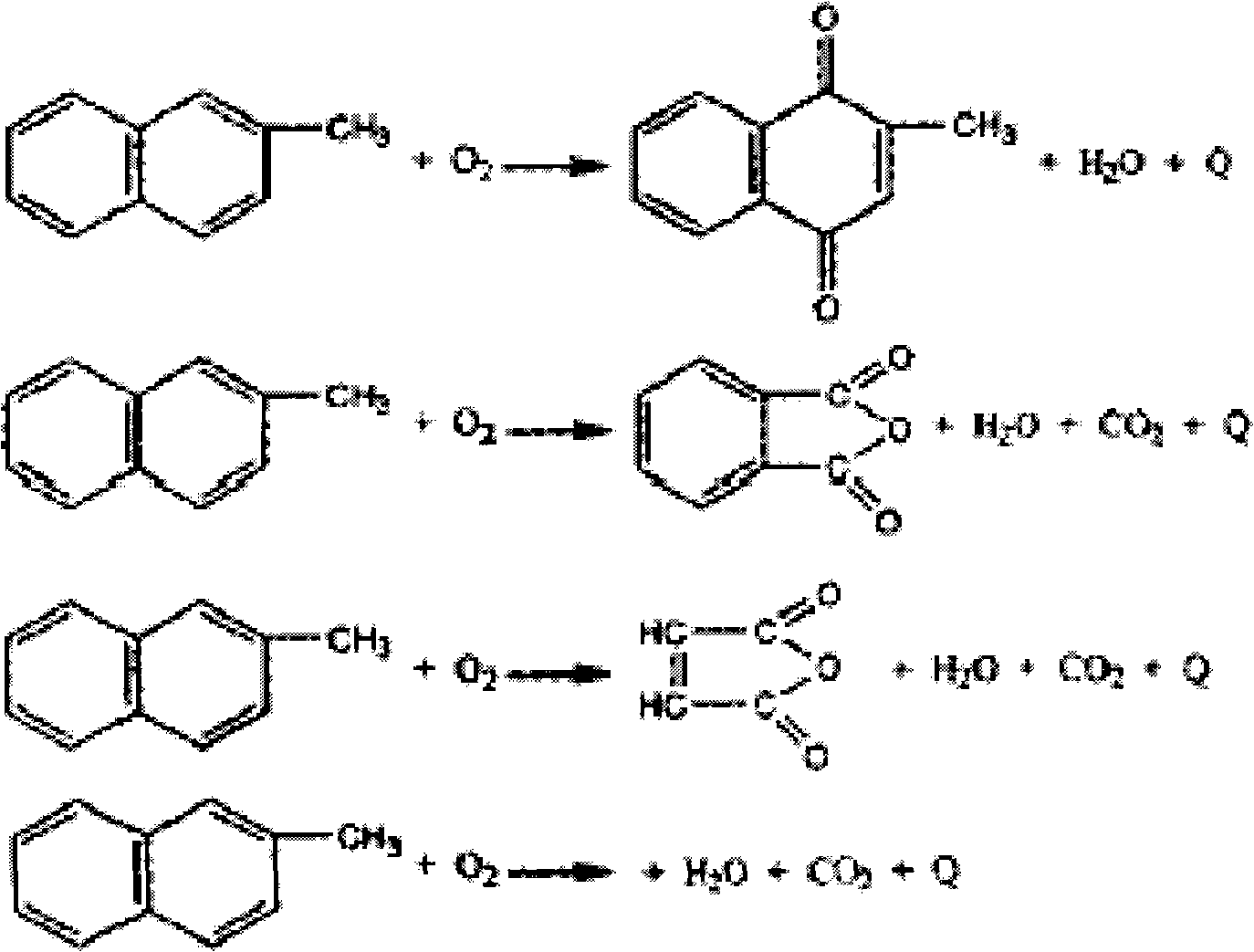

Tubular continuous method for preparing beta-menadione

ActiveCN105481673AImprove production continuityHigh yieldQuinone preparation by oxidationAutomatic controlRetention time

The invention discloses a tubular continuous method for preparing beta-menadione, which comprises the following steps: preparing a beta-methylnaphthalene emulsion, heating the beta-methylnaphthalene emulsion, metering the beta-methylnaphthalene emulsion and an oxidation solution respectively by a measuring pump, adding into a tubular reactor provided with an ultrasonic generator, and carrying out ultrasonic reaction, wherein the retention time of the reactants in the tubular reactor is 1-300 minutes; supplementing dilute sulfuric acid to the outlet of the tubular reactor, adding into a curing tank, and curing for 1-10 hours while keeping the temperature; after finishing curing, filtering, washing, carrying out centrifugal dehydration and drying to obtain the beta-menadione finished product. By using the tubular reactor to produce the beta-menadione, the method has the advantages of high production continuity and short period; and the product has the advantages of high yield, low impurity content and stable quality. The reaction process is easy to control, simple to operate and high in automatic control degree; the material performs forced flow in the tubular reactor to substitute mechanical stirring, thereby implementing industrialized continuous production; and thus, the method has the characteristics of low input cost and short reconstruction period, and can perform large-scale industrial production.

Owner:SICHUAN YINHE CHEM

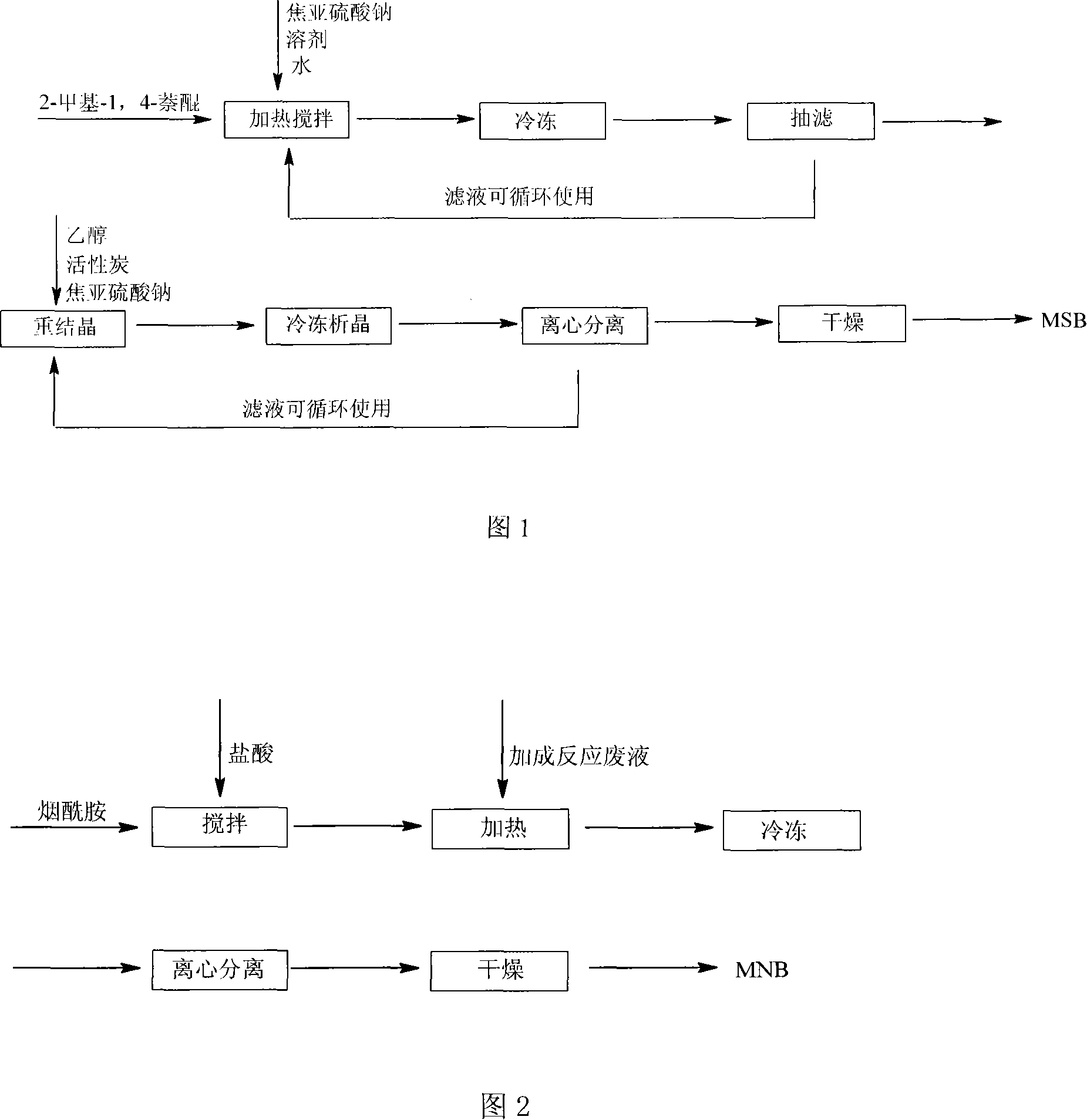

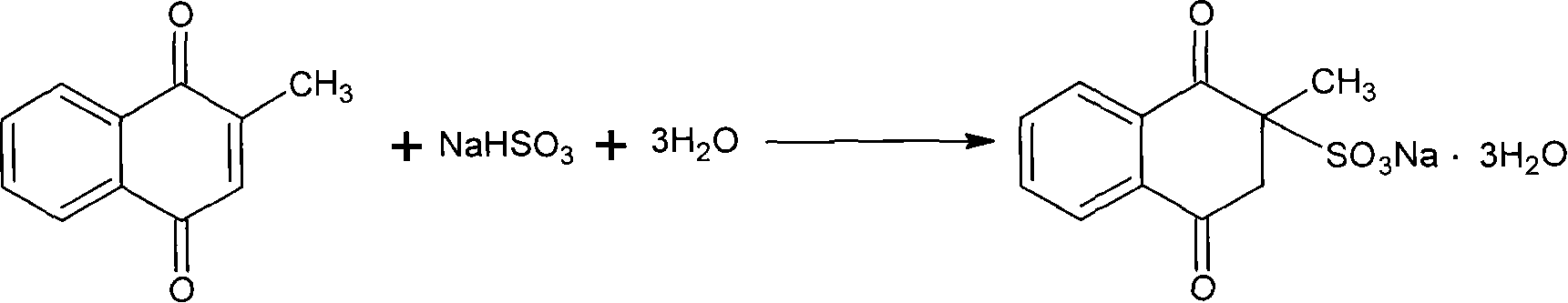

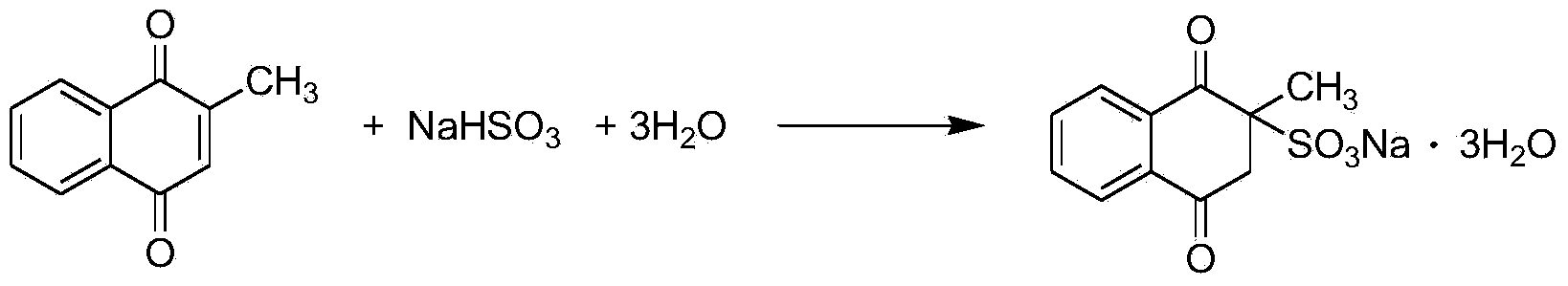

Method for producing vitamin K3

The invention relates to a method of synthesizing fiber K3 (menadione sodium bisulfite) in a new solvent system, which comprises the following steps: (1) adding 2-methyl-1, 4-naphthoquinone and sodium bisulfite into the solvent and heating and stirring the solution and carrying out addition reaction; (2) cooling the reactants which goes through the addition reaction to less than 10 DEG C and carrying out centrifugal separation to get an MSB crude product; (3) adding ethanol, activated carbon and the sodium bisulfite into the MSB crude product, heating and dissolving the mixture, carrying out immediate filtration when the mixture is still hot, cooling the filtrate to less than 10 DEG C, and carrying out centrifugal separation, crystallization and drying to obtain an MSB purified product. The method of synthesizing fiber K3 has the advantages of fast reaction, high product yield and good quality; the method avoids the consumption of the ethanol, improves product yield, reduces side products, avoids the waste of resource and improves the purity of the product.

Owner:QILU UNIV OF TECH

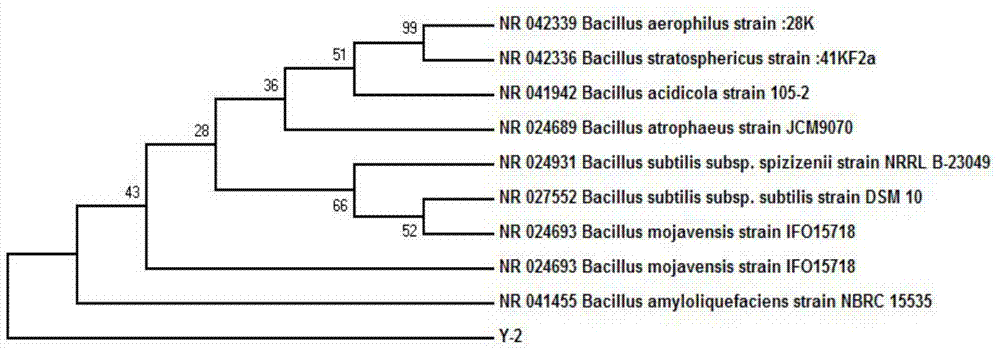

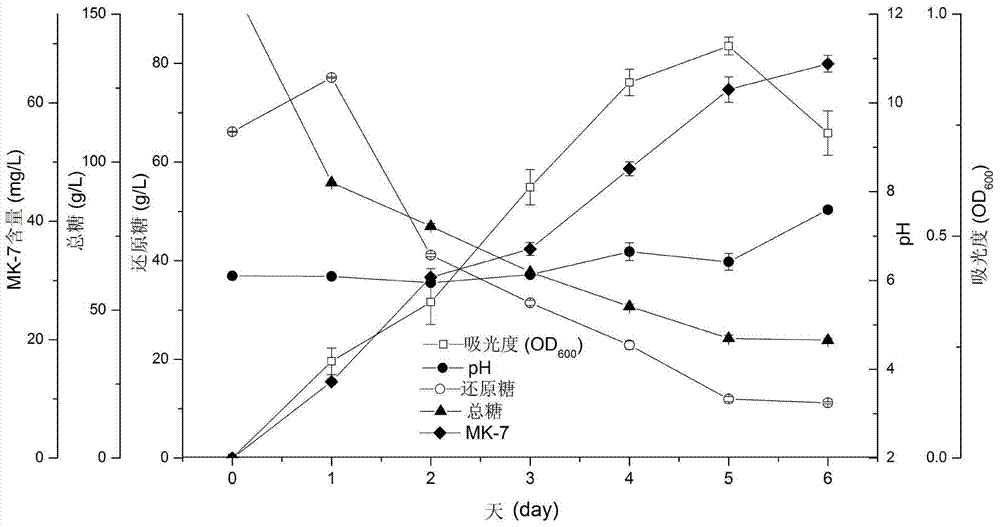

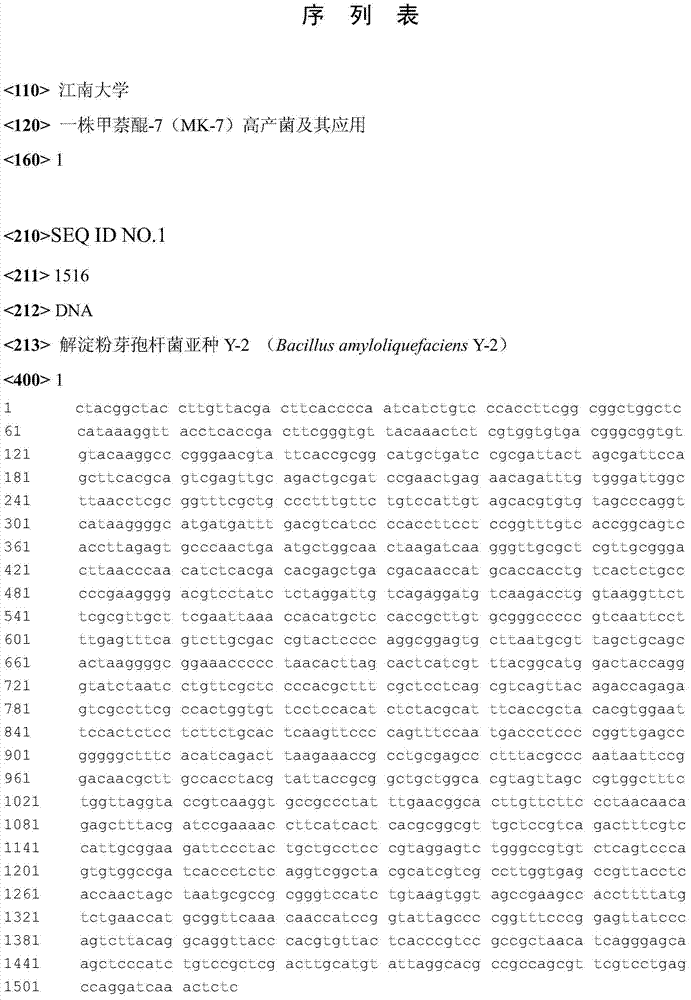

Menadione-7(MK-7) high-yielding strain and application thereof

InactiveCN103865835AHigh production of MK-7BacteriaMicroorganism based processesVitamin K2Industrial fermentation

The invention relates to a strain of bacillus amyloliquefaciens capable of generating a great amount of MK-7 (menadione-7) in a culture process and a culture method thereof. The name of the strain is Y-2, and the class name is bacillus amyloliquefaciens. The obtained strain has stable hereditary character and stable yield trait, is suitable for industrial popularization, and is collected in the China Center for Type Culture Collection (CCTCC), with the collection number CCTCC No.M2013493. The invention also discloses a method for producing MK-7, which comprises the following steps: with 5% of seed inoculation amount, inoculating a seed solution into a fermentation medium; culturing for 2 hours at a rotation speed of 100r / min and a temperature of 37 DEG C; performing stationary culture for 6 days, wherein the highest yield of vitamin K2 (MK-7) reaches 66.62mg / L. According to the MK-7 high-yielding strain and production method provided by the invention, the production cycle is short, the yield is high, and feasibility is provided to the production of MK-7 through industrial fermentation.

Owner:JIANGNAN UNIV

Method for coproduction of chrome tanning agent and menadione

InactiveCN101348425AEmission reductionHigh technical contentQuinone preparation by oxidationChromium sulfatesResource utilizationMenadione

The invention discloses the production of menadione, in particular disclosing a method for manufacturing menadione through combining with a chrome tanning agent. The method is characterized in that the method comprises the following (1) a step of preparing menadione, during which, methylnaphthalene, water and EL series emulsifying agents are added in a first reaction bulb; moreover, sodium bichromade and water are added in a second reaction bulb, and concentrated sulfuric acid is added slowly while stirring for cooling down; then prepared red liquor is slowly dripped into the first reaction bulb while stirring, and is filtered and dried so as to obtain bright yellow crystallized menadione powder; and (2) a step of preparing basic chrome sulphate, during which, the mother liquor obtained during preparing menadione is taken out, and sodium bichromade and dextrose solution are added in order; and chrome tanning agent basic chrome sulphate is obtained after spray drying. Through adopting a chrome tanning agent basic chrome sulphate production device to carry out joint production for menadione, the method realizes maximization of resource utilization; moreover, the method greatly reduces production cost for both sides and the release of waste liquids.

Owner:SHANDONG DAHUA GUANGJI BIOCHEM ENG

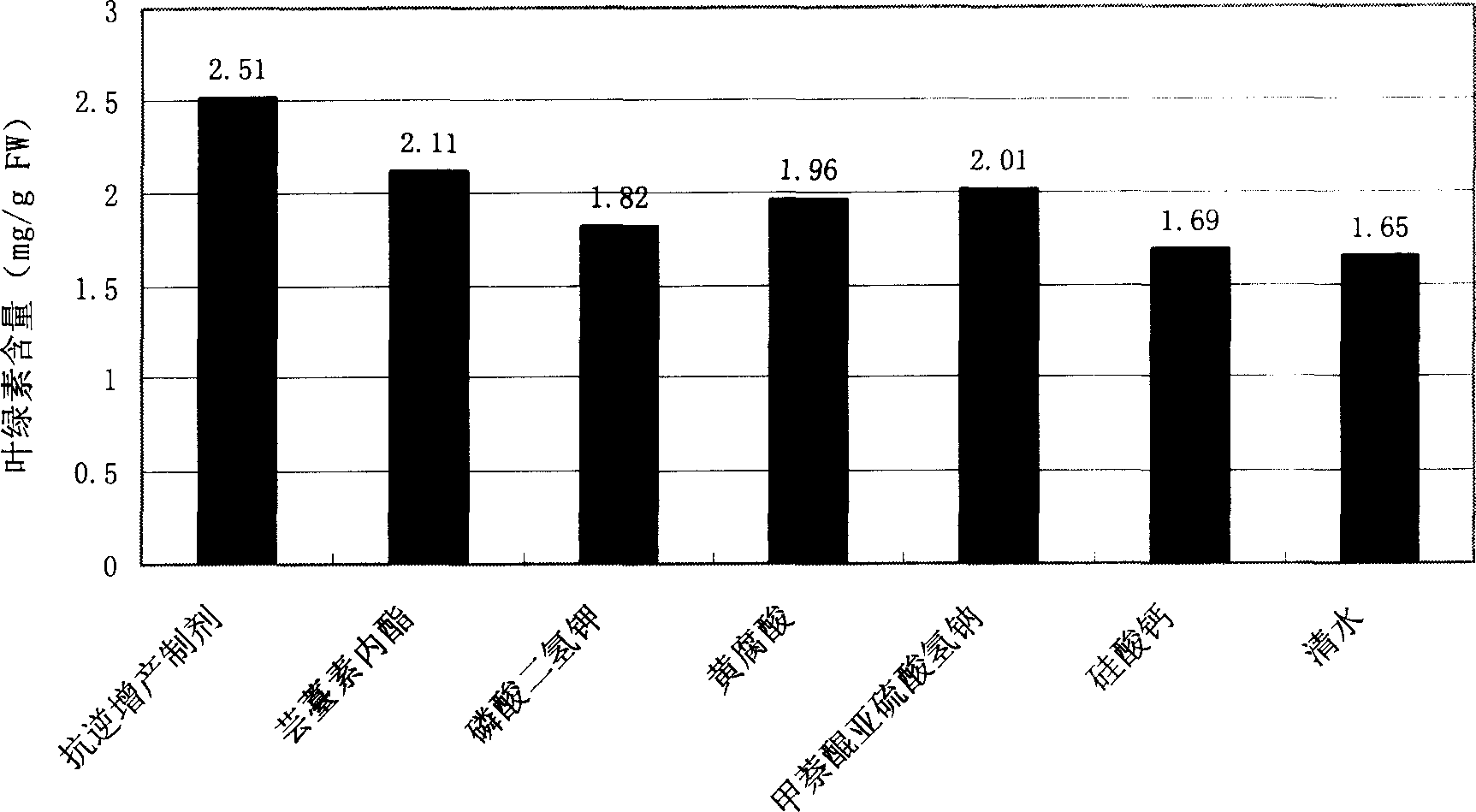

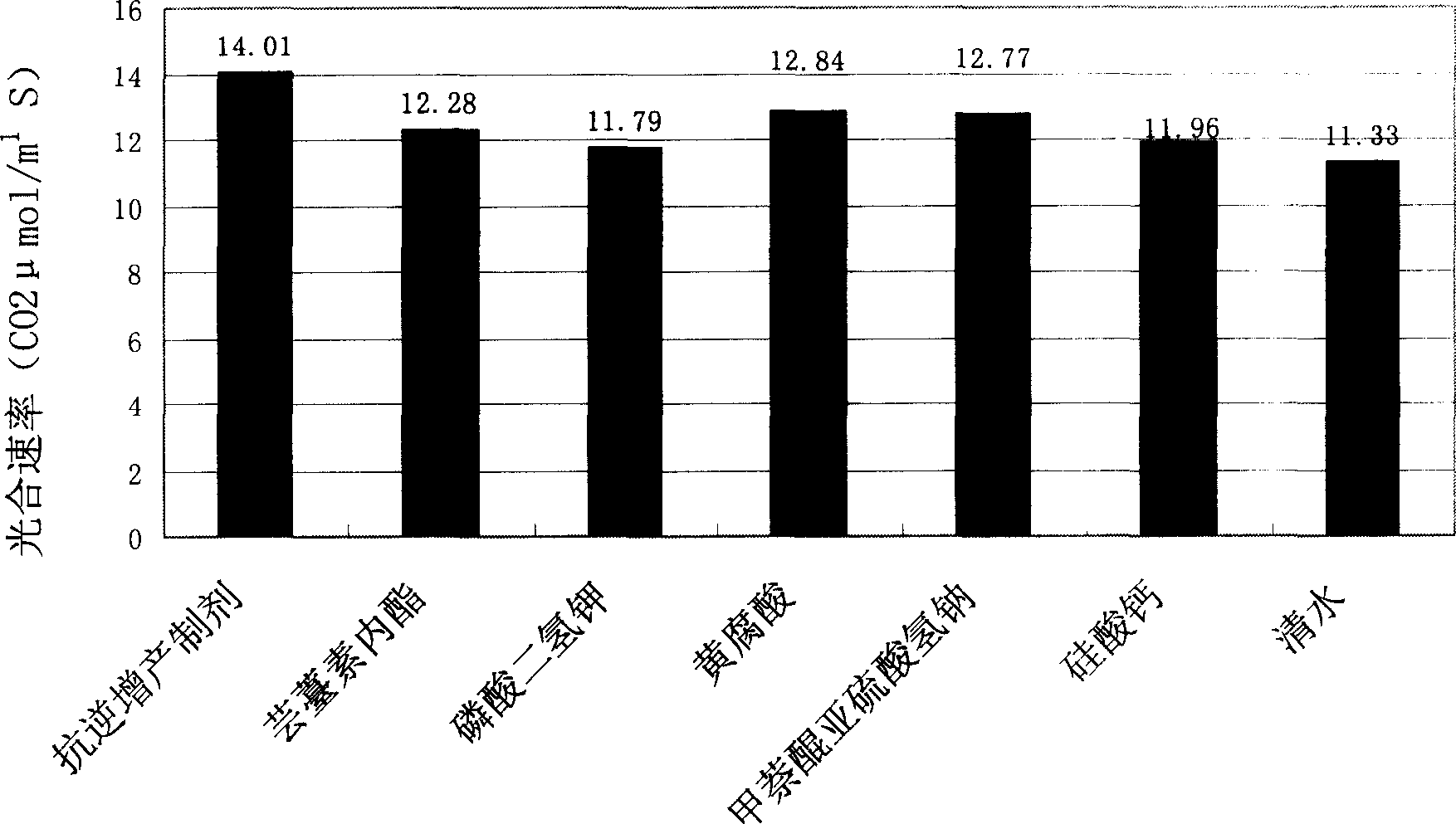

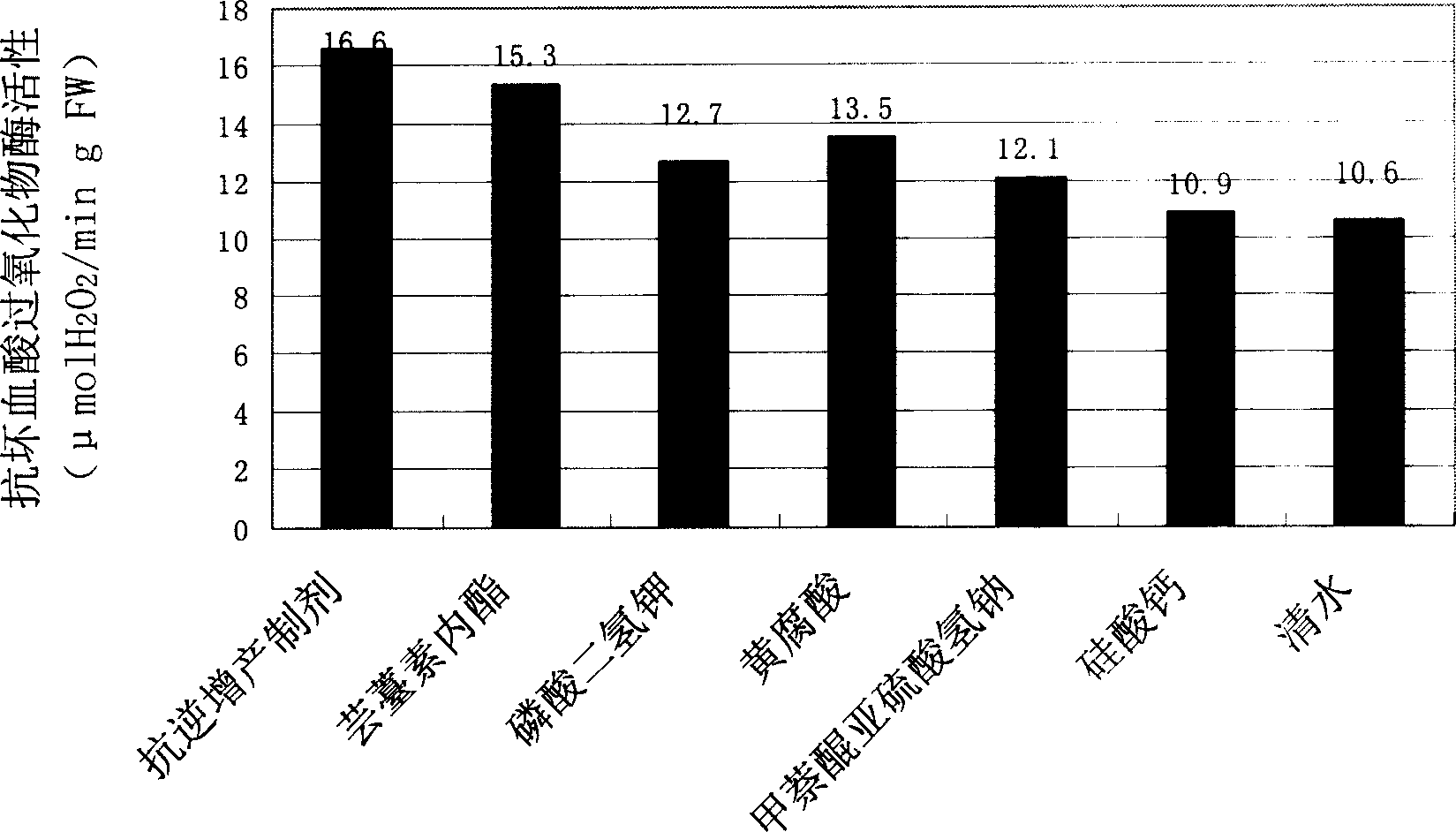

Vegetable adversity resisting and production increasing preparation

InactiveCN1907033AIncrease resistanceImprove developmentBiocidePlant growth regulatorsCalcium silicateVitamin C

Disclosed is a preparation for increasing yield of vegetable, which comprises (by weight ratio) fulvic acid 5-10 parts, Brassinolide 0.001-0.1 part, menadione sodium bisulphate 0.5-1 part, vitamin C 5-10 parts, calcium silicate 20-50 parts, and monobasic potassium phosphate 10-20 parts.

Owner:INST OF VEGETABLE & FLOWERS CHINESE ACAD OF AGRI SCI

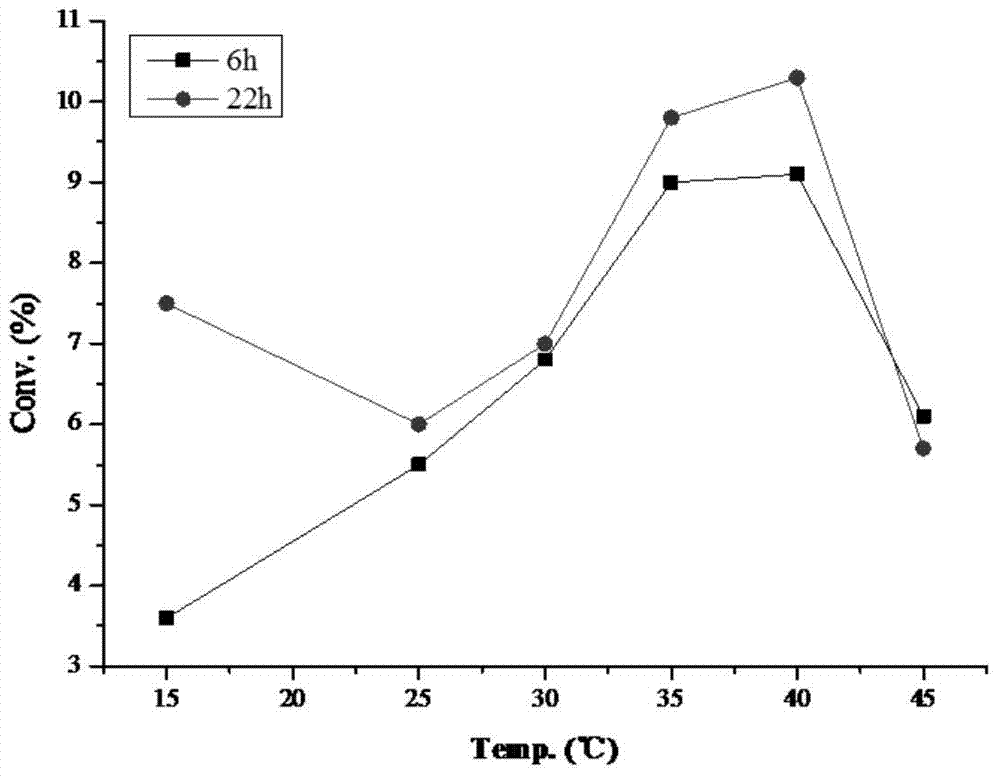

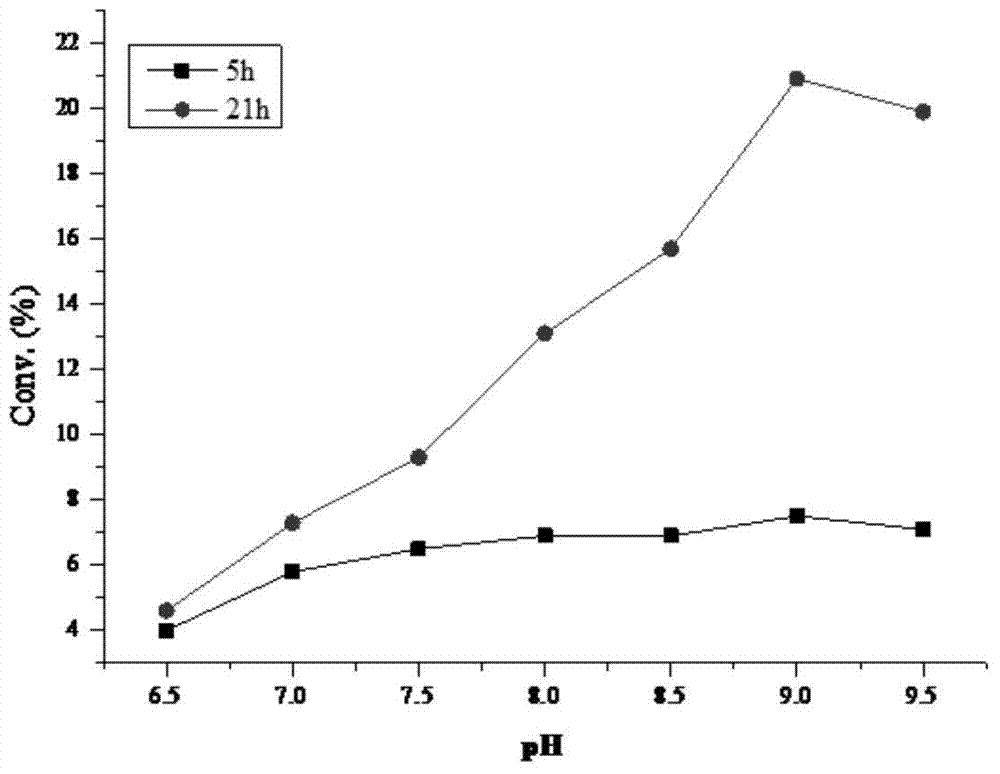

Method for promoting beta-menadione production through ultrasonic waves

ActiveCN103483174AReduce dosageLow reaction temperatureQuinone preparation by oxidationUltrasound - actionMenadione

The invention discloses a method for promoting beta-menadione production through ultrasonic waves. The method includes the steps that oxidation liquid is prepared from sodium bichromate and sulfuric acid, the oxidization liquid is slowly added into mixed mediums containing beta-methyl naphthalene, phase transfer catalysts and water to undergo reaction, and the ultrasonic waves act on the reaction system in the reacting process. Due to the fact that the ultrasonic waves have the promotion effect on the reaction, the temperature of the reaction system can be greatly lowered, side reactions are reduced, the product yield is improved, and the using amount of the oxidization liquid can be greatly reduced.

Owner:SICHUAN YINHE CHEM

Method for preparing 11A, 17A-dihydroxy-pregna-1,4-diene-3,20-dione by enzymatic method

The invention relates to a method for preparing 11A, 17A-dihydroxy-pregna-1,4-diene-3,20-dione by an enzymatic method. The method is characterized by adding a substrate 11A, 17A-dihydroxy-pregna-1-ene-3,20-dione, 3-sterone-1-dehydrogenase, menadione and a cosolvent to an aqueous phase buffer solution with a pH value of 8-11 and stirring to react at a temperature of 30-50 DEG C to obtain 11A, 17A-dihydroxy-pregna-1,4-diene-3,20-dione, wherein the concentration of the substrate is 5-10g / l in an initial reaction system; the feeding amount of 3-sterone-1-dehydrogenase is 0.5-4 times the mass of the substrate; the cosolvent is selected from one of or a composite of more of dimethyl sulfoxide, polyethylene glycol-400 and Tween-60. The method has the advantages that the concentration of the reactive substrate can be 10g / L and the conversion rate within 3 hours can be 99% at most; the product has high yield and good quality; the method is suitable for industrial production.

Owner:ENZYMEWORKS

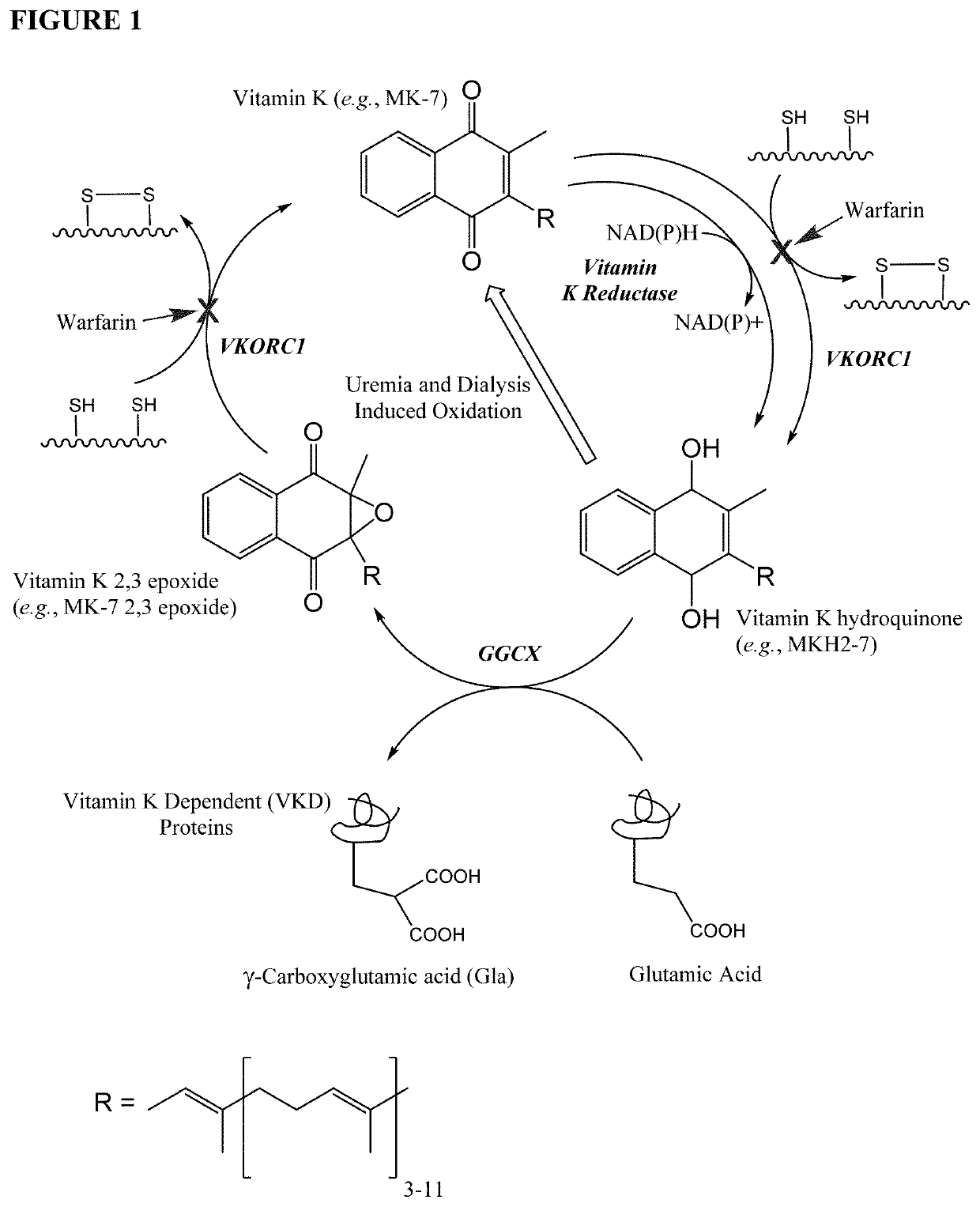

Methods and compositions for preventing or treating tissue calcification

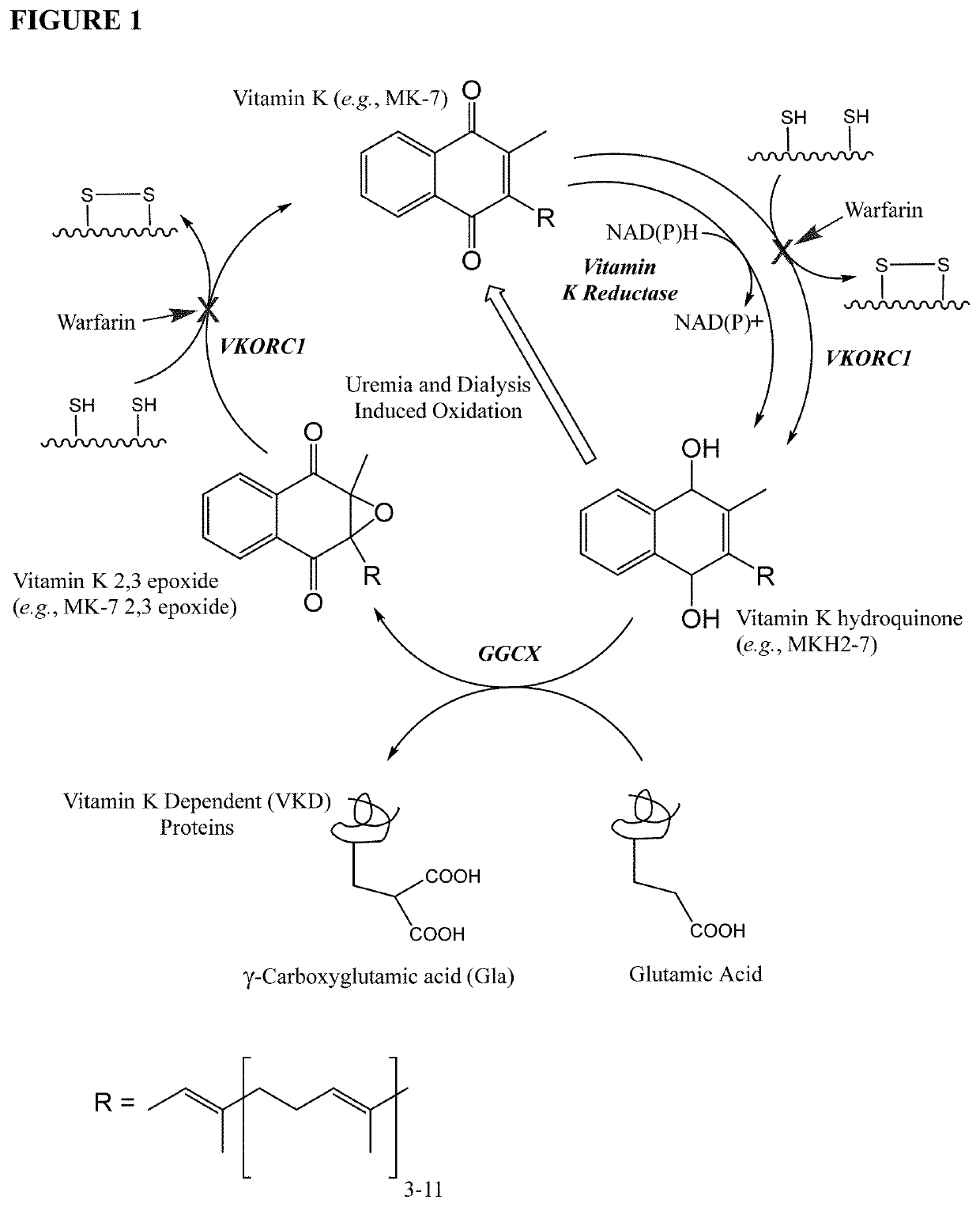

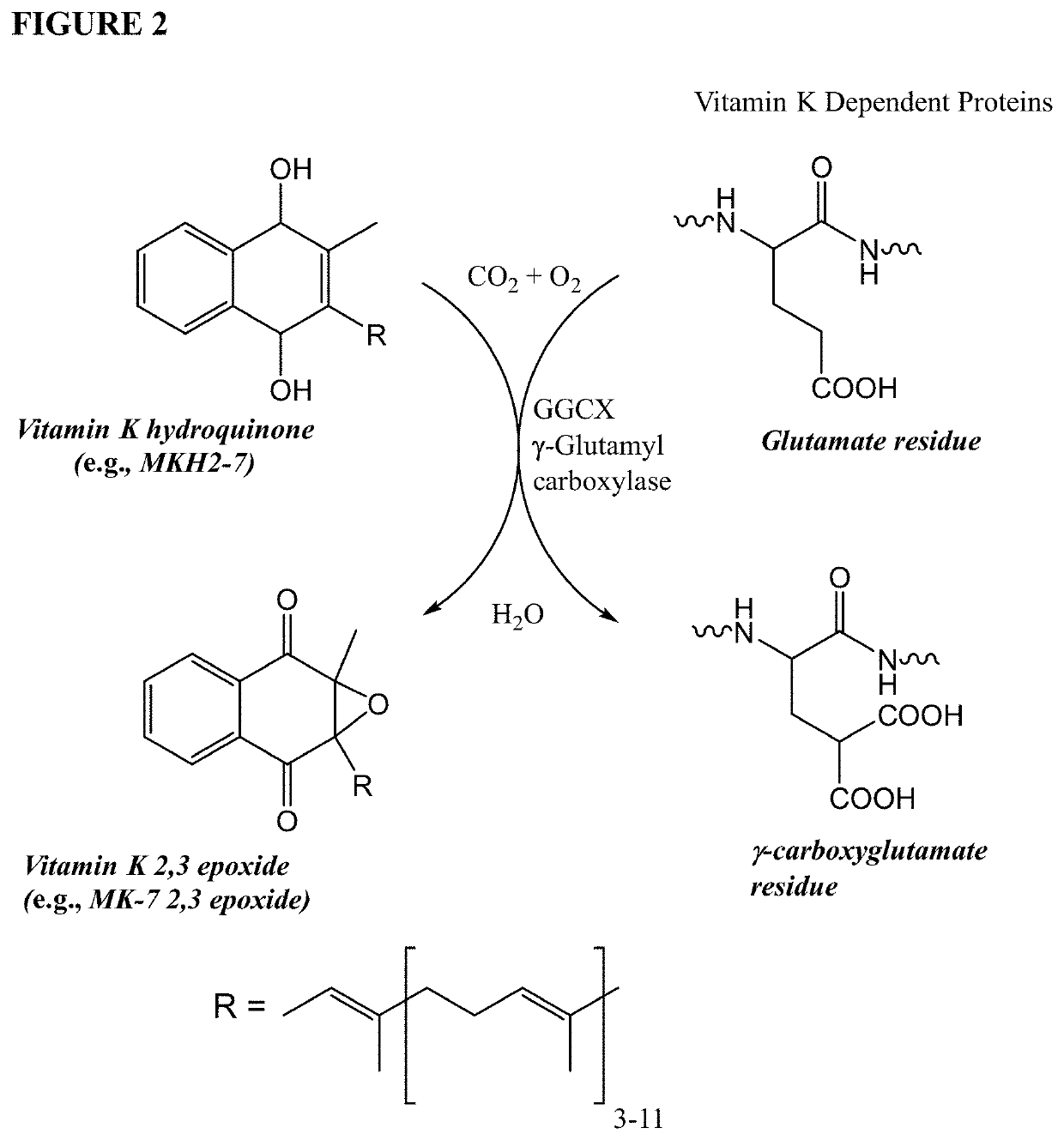

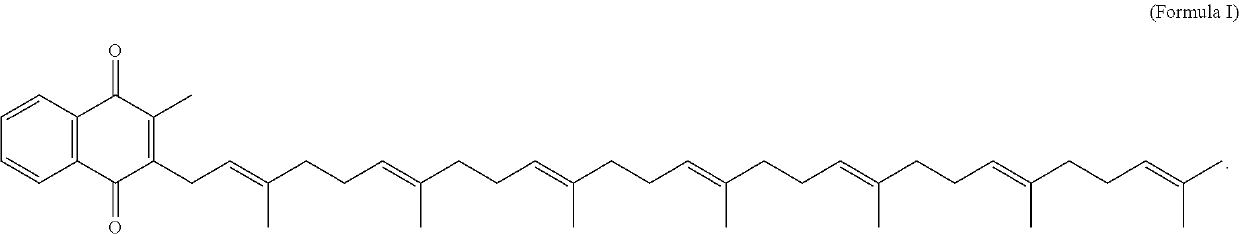

ActiveUS10688064B2Prevent and slow progression of and arrest and reverse tissue calcificationHydroxy compound active ingredientsMetabolism disorderAnti coagulationEnd stage renal failure

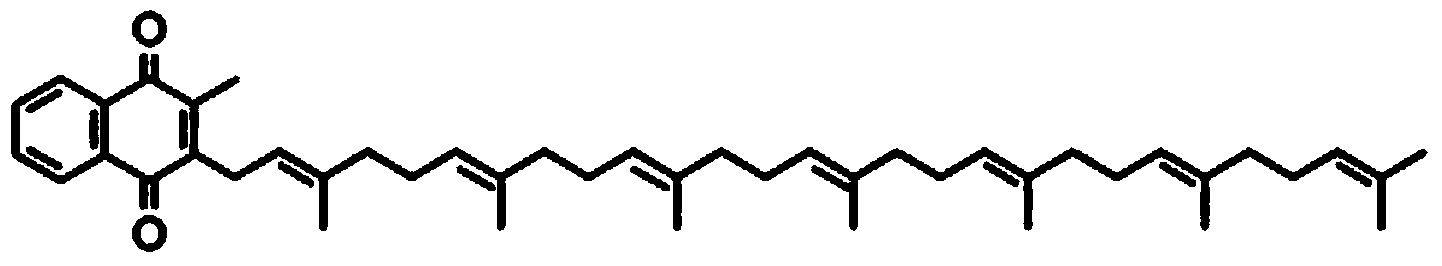

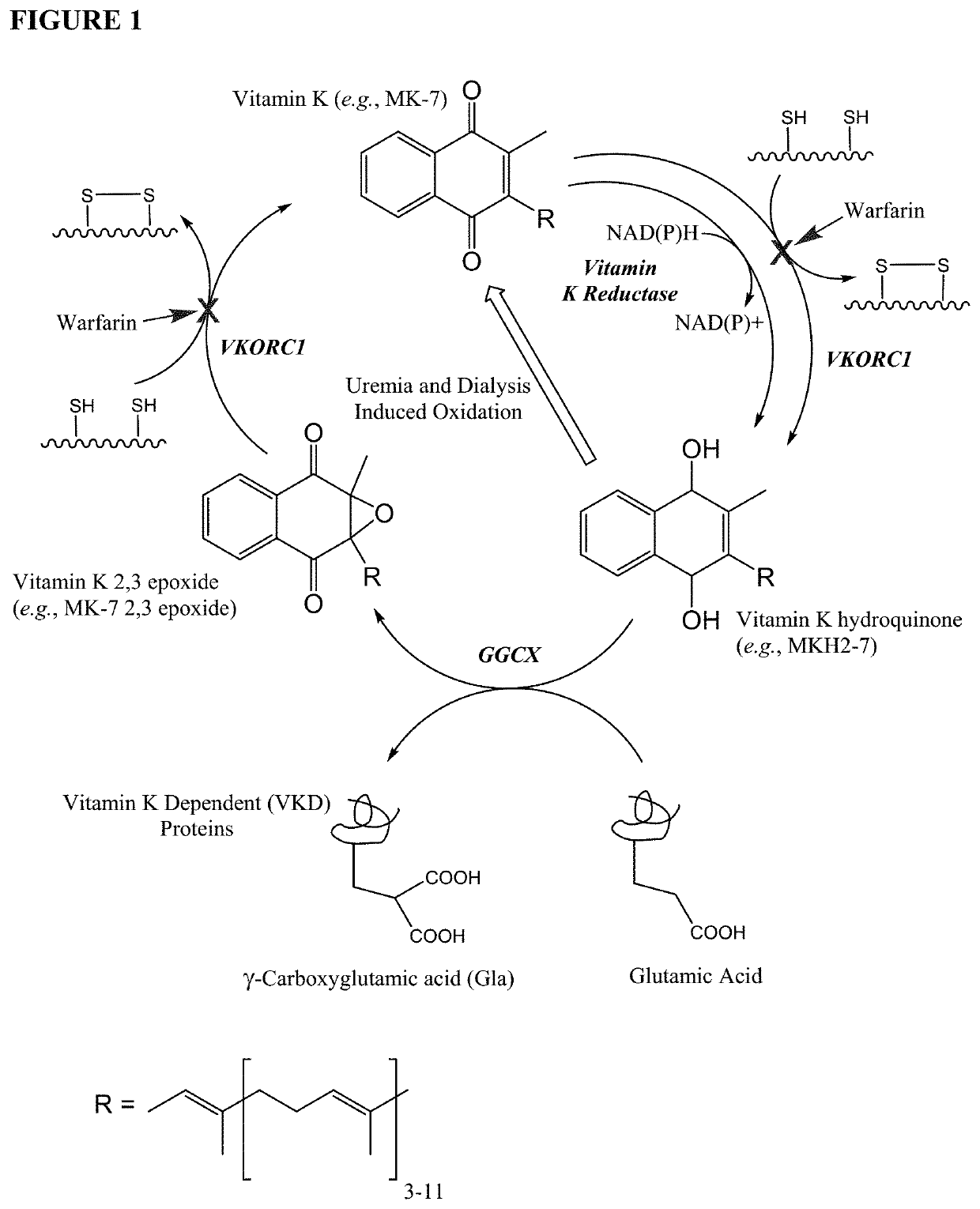

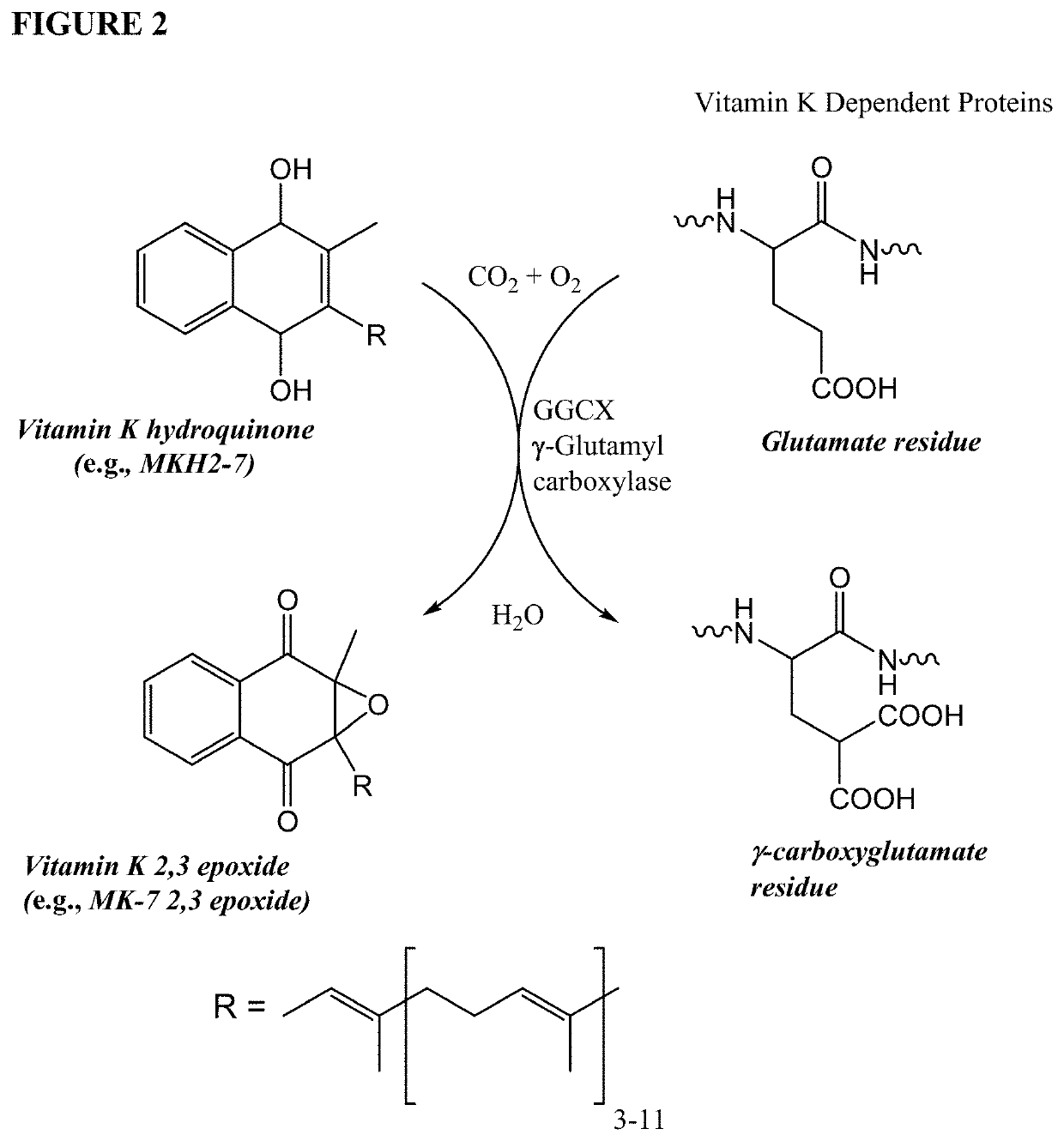

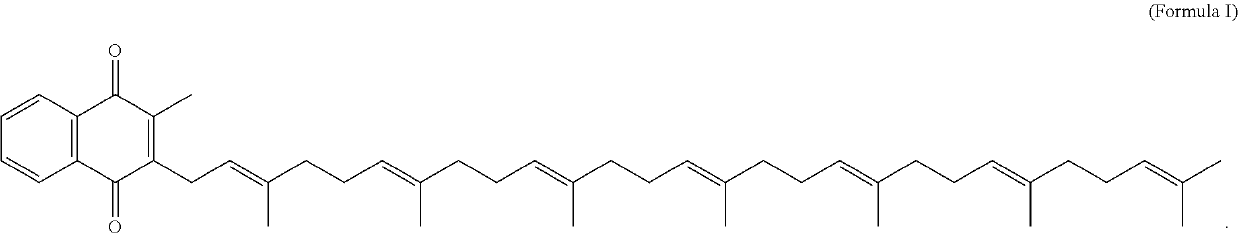

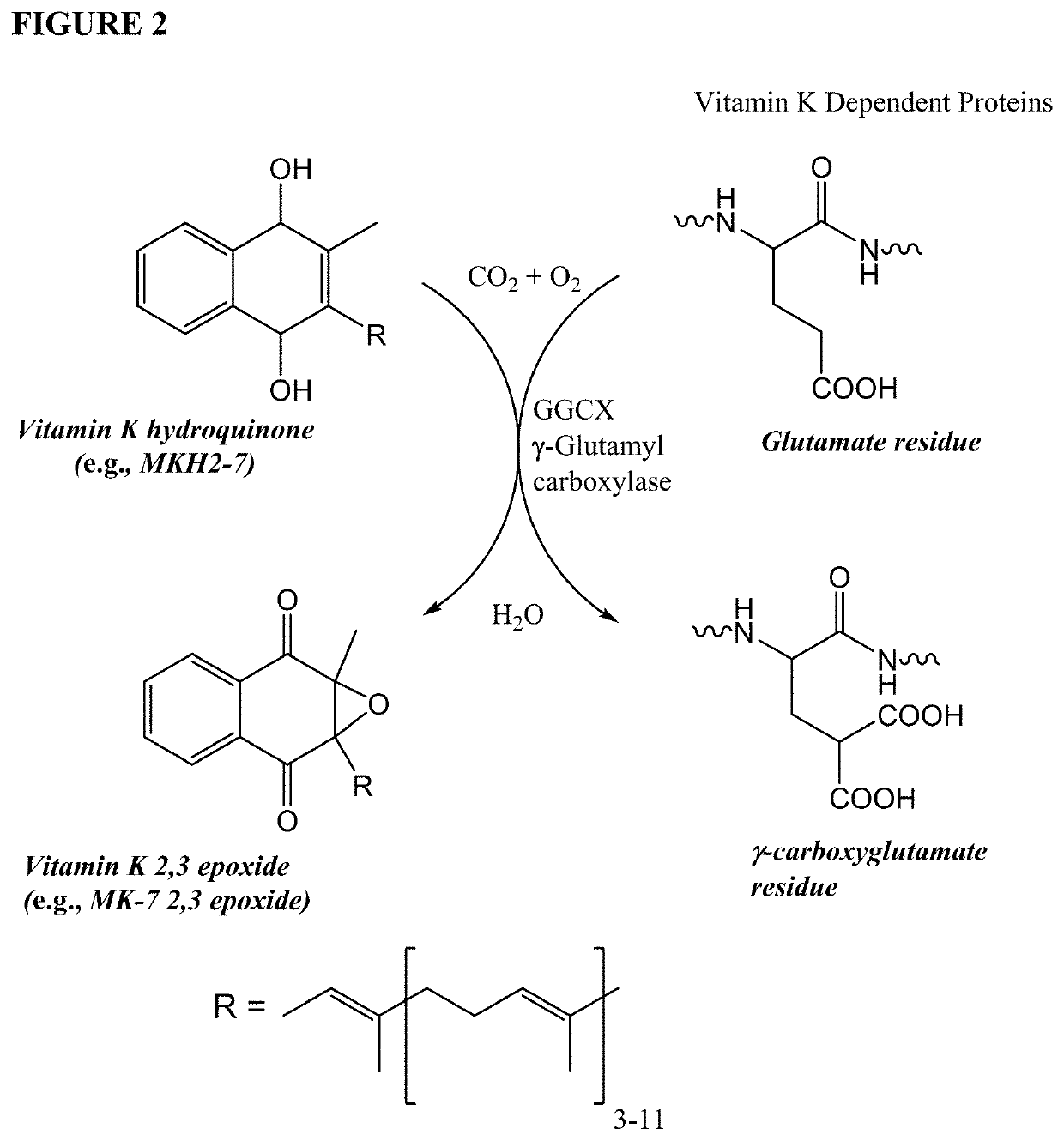

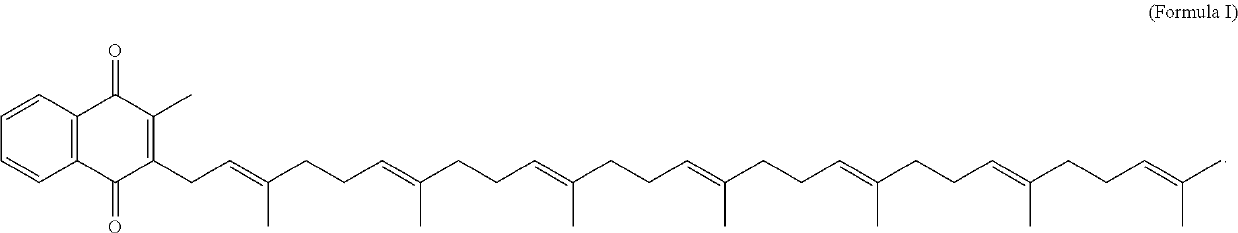

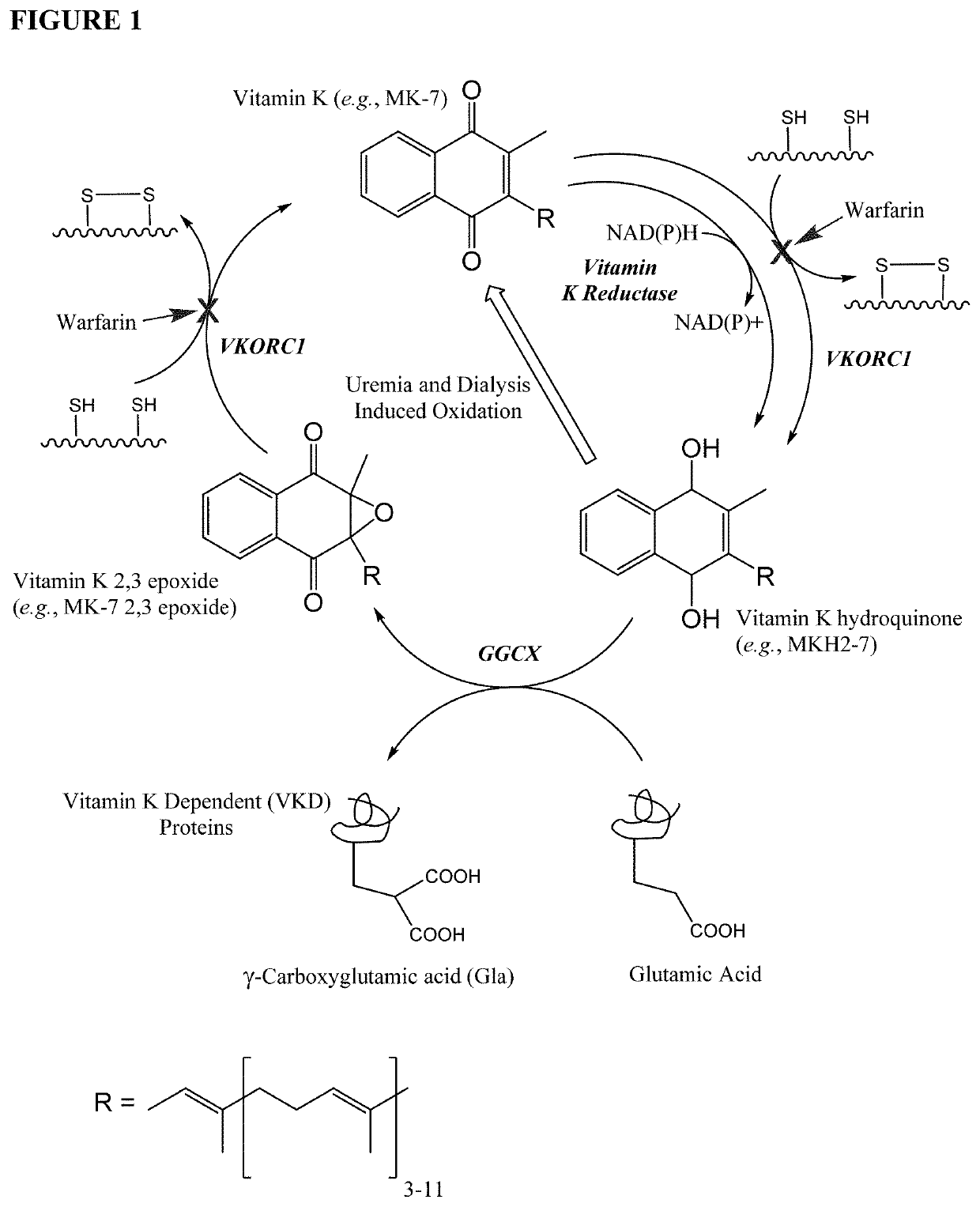

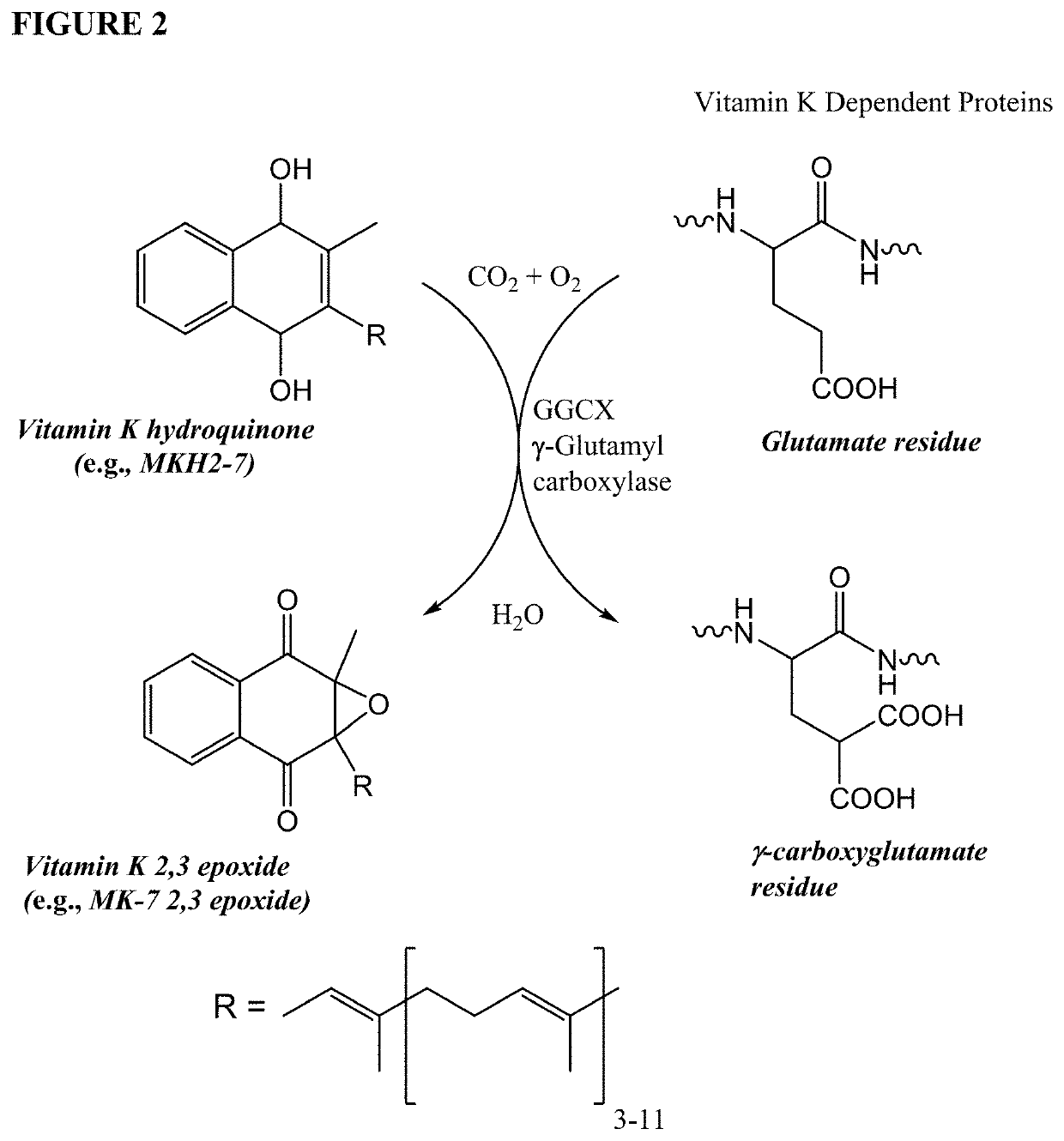

The invention provides methods and compositions for preventing or treating (e.g., slowing the progression of, arresting, and / or reversing) tissue calcification in a subject in need thereof and, more particularly, the invention relates to methods of using menaquinone-7 (MK-7) and / or menaquinol-7 (MKH2-7) for preventing or treating (e.g., slowing the progression of, arresting, and / or reversing) tissue calcification in a subject with diabetes, chronic kidney disease, end stage renal failure, or a subject undergoing hemodialysis and / or receiving anticoagulant therapy. The invention further provides methods and compositions for reducing one or more symptoms of chronic obstructive pulmonary disorder (COPD), including using menaquinone-7 (MK-7) and / or menaquinol-7 (MKH2-7), for preventing or treating (e.g., slowing the progression of, arresting, and / or reversing) one or more symptoms of COPD.

Owner:EPIZON PHARMA INC

Bacillus subtilis natto and method for purifying vitamin menadione-7 by using bacterial strain

ActiveCN104262129AHigh purityHigh yieldBacteriaQuinone separation/purificationIsocratic elutionMenadione

The invention provides bacillus subtilis natto ST188 with CGMCC No. 8400 and a high-yield method for purifying vitamin menadione-7 by using the bacterial strain. The high-yield method comprises the following steps: (1) carrying out spray drying on natto fermentation liquor, and extracting or leaching bacillus natto fermentation liquor spray drying powder by using a solvent so as to obtain a leaching solution; (2) concentrating the leaching solution obtained in the step (1) so as to obtain extract; (3) carrying out column chromatography on the extract obtained in the step (2), carrying out gradient or isocratic elution, and concentrating collected liquid, thus obtaining a menadione-7 crude product; and (4) crystallizing and purifying the menadione-7 crude product obtained in the step (3), thus obtaining the pure vitamin menadione-7 product.

Owner:SUNGEN BIOSCIENCE CO LTD

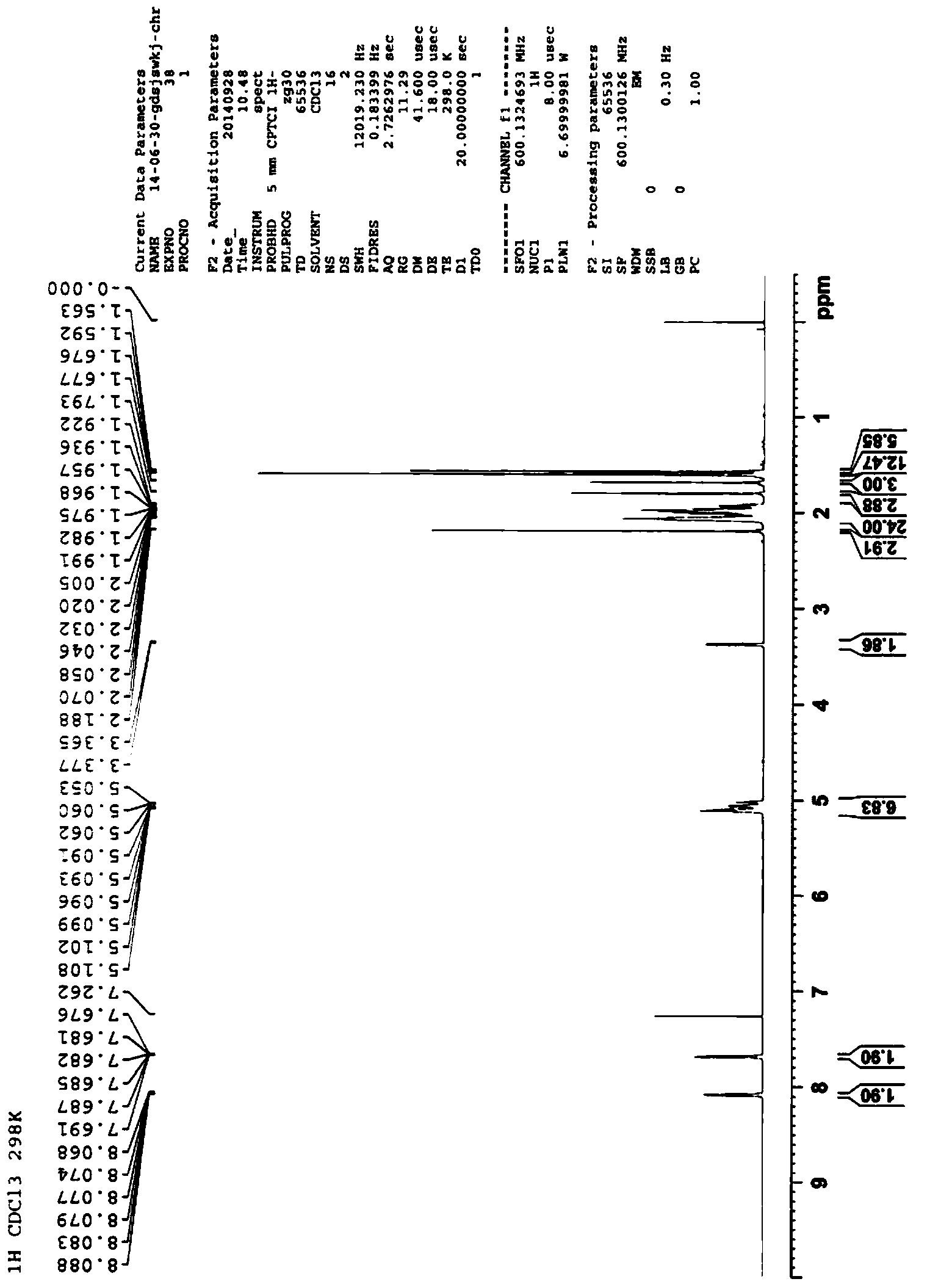

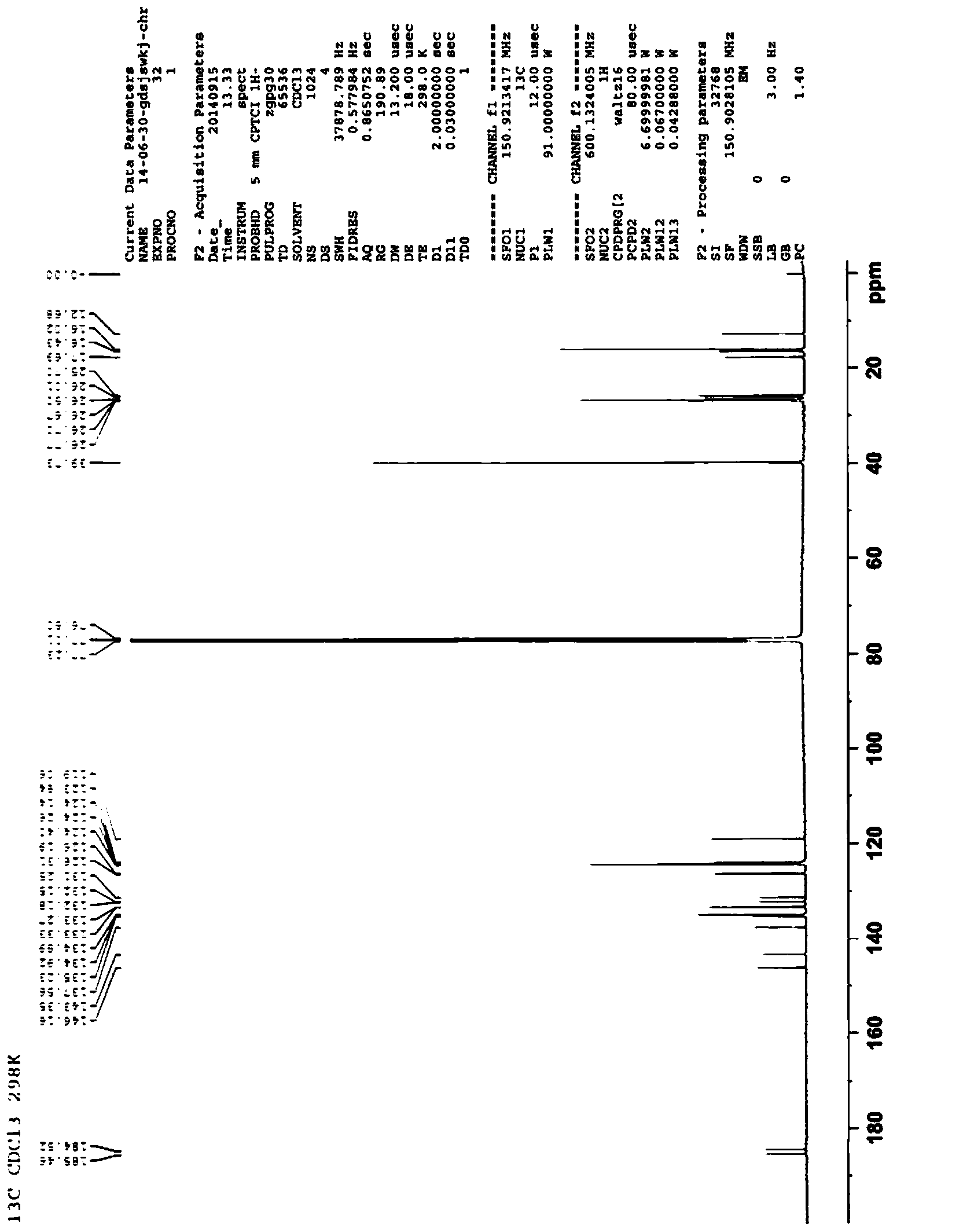

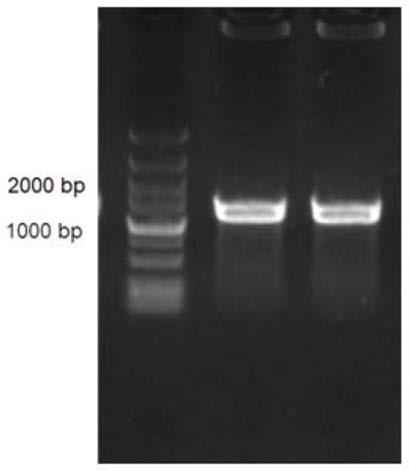

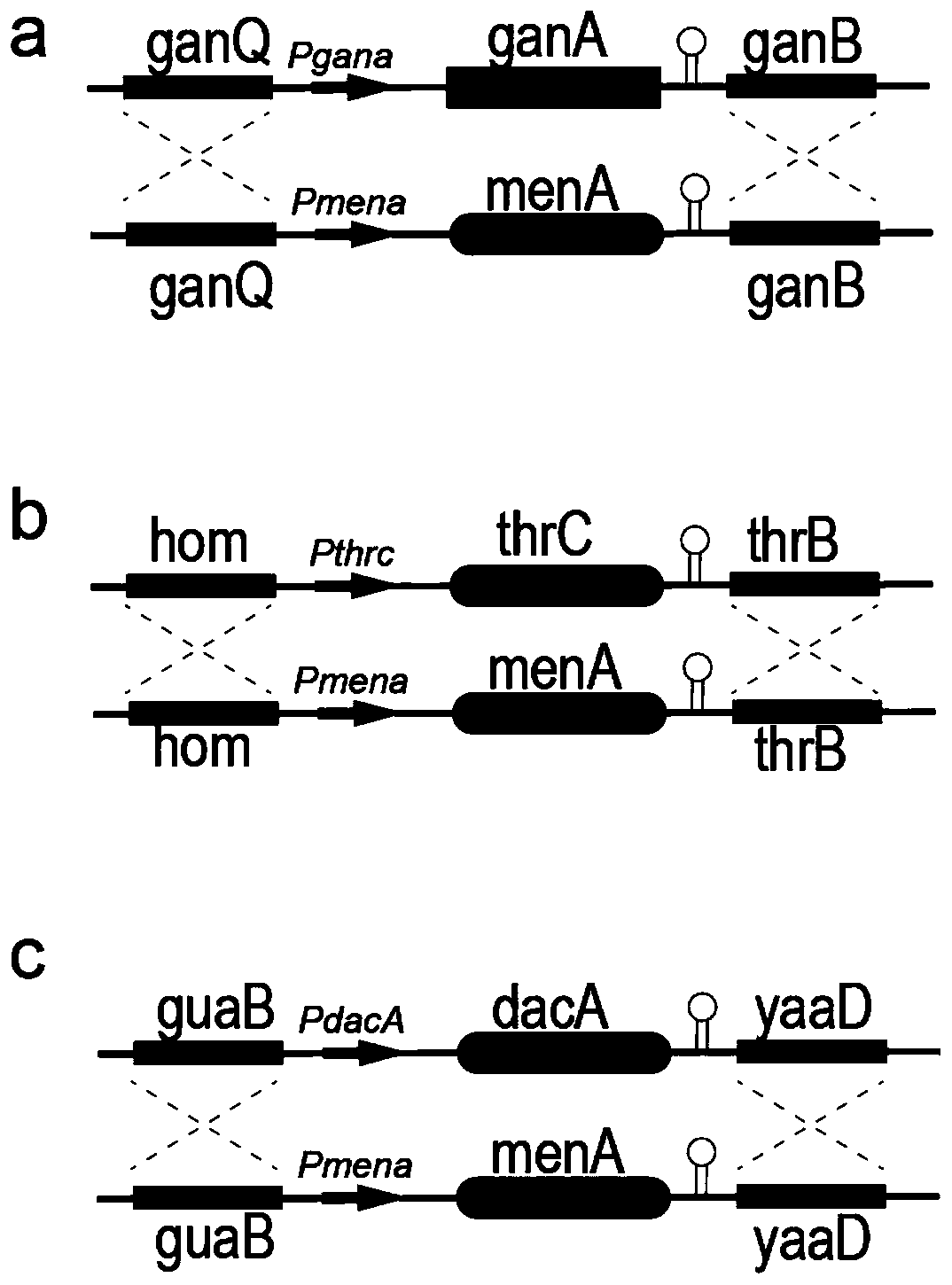

Method for increasing copy number of gene menA and increasing yield of MK-7

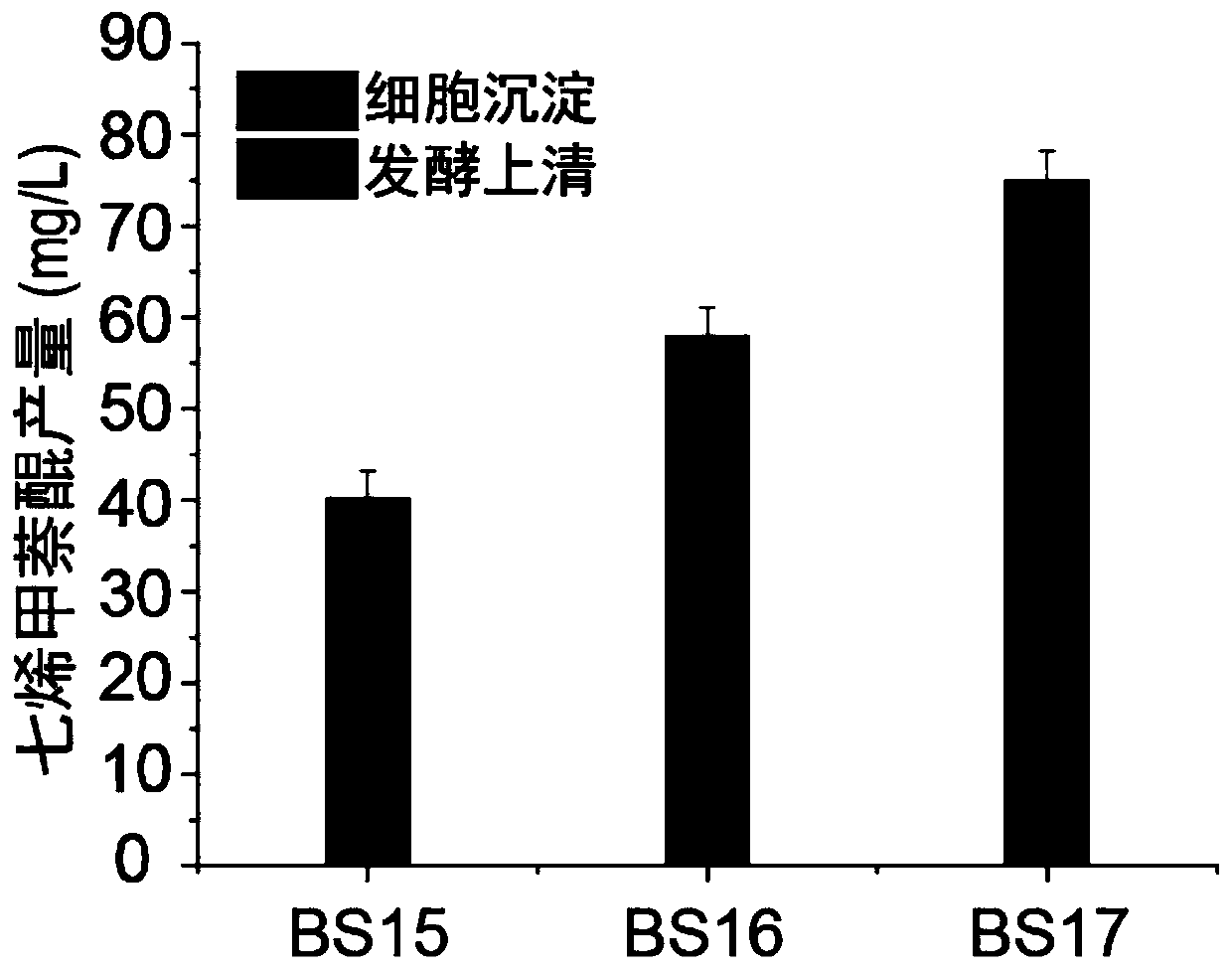

The invention discloses a method for increasing the copy number of gene menA and increasing the yield of MK-7, and belongs to the field of genetic engineering. The method determines that the menA geneis a key gene in the synthetic pathway of heptaene menadione (MK-7), finds out that the self promoter of the menA gene has an important effect on the activity of menA, and replaces a natural promoterof the menA gene on the bacillus subtilis 168 chromosome with P43 promoter, and the yield of MK-7 produced by fermentation of the obtained strain is obviously reduced compared with that of the original strain. The method integrates and expresses the whole open reading frame of menA at the ganA, thrC and dacA sites of a bacillus subtilis genome to respectively obtain recombinant strains BS15, BS16and BS17, so that the yield of MK-7 is increased to 40mg / L, 59mg / L and 75mg / L respectively.

Owner:JIANGNAN UNIV +1

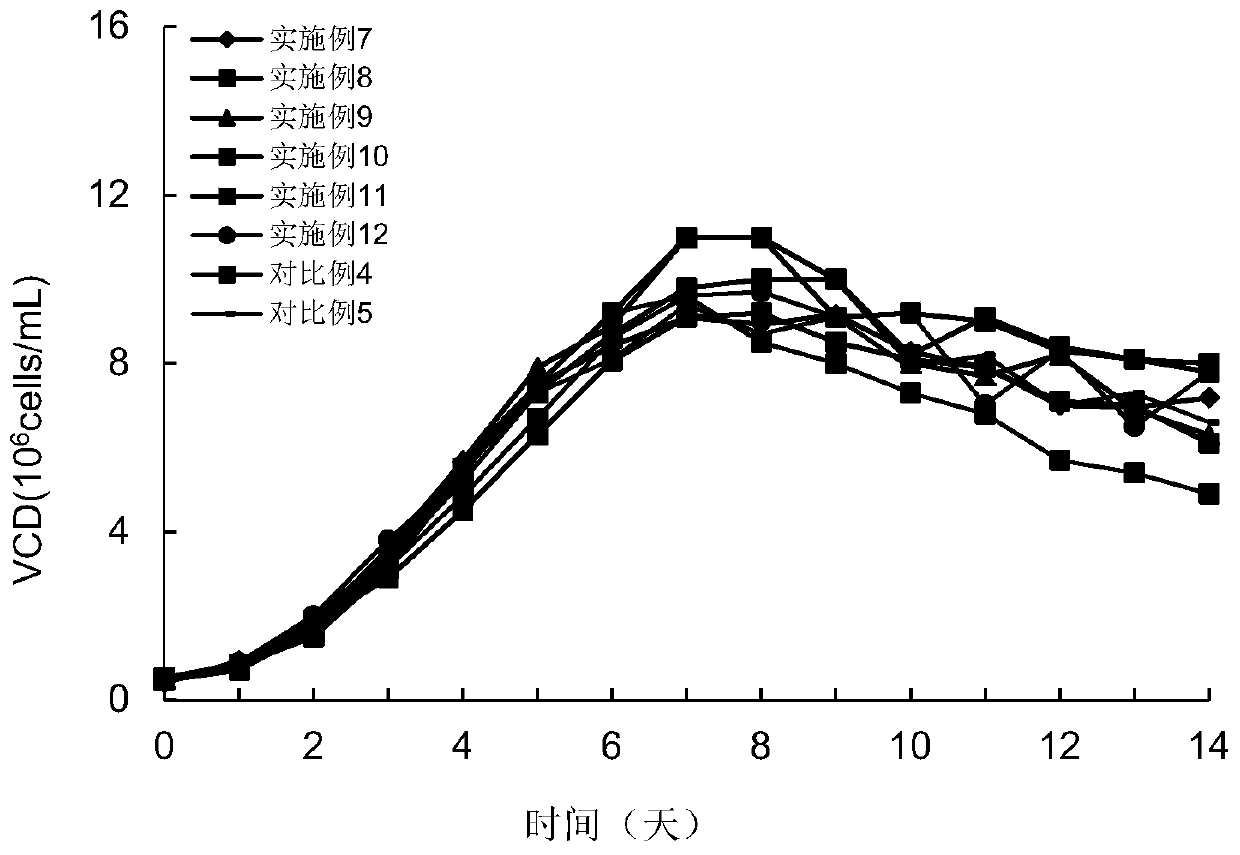

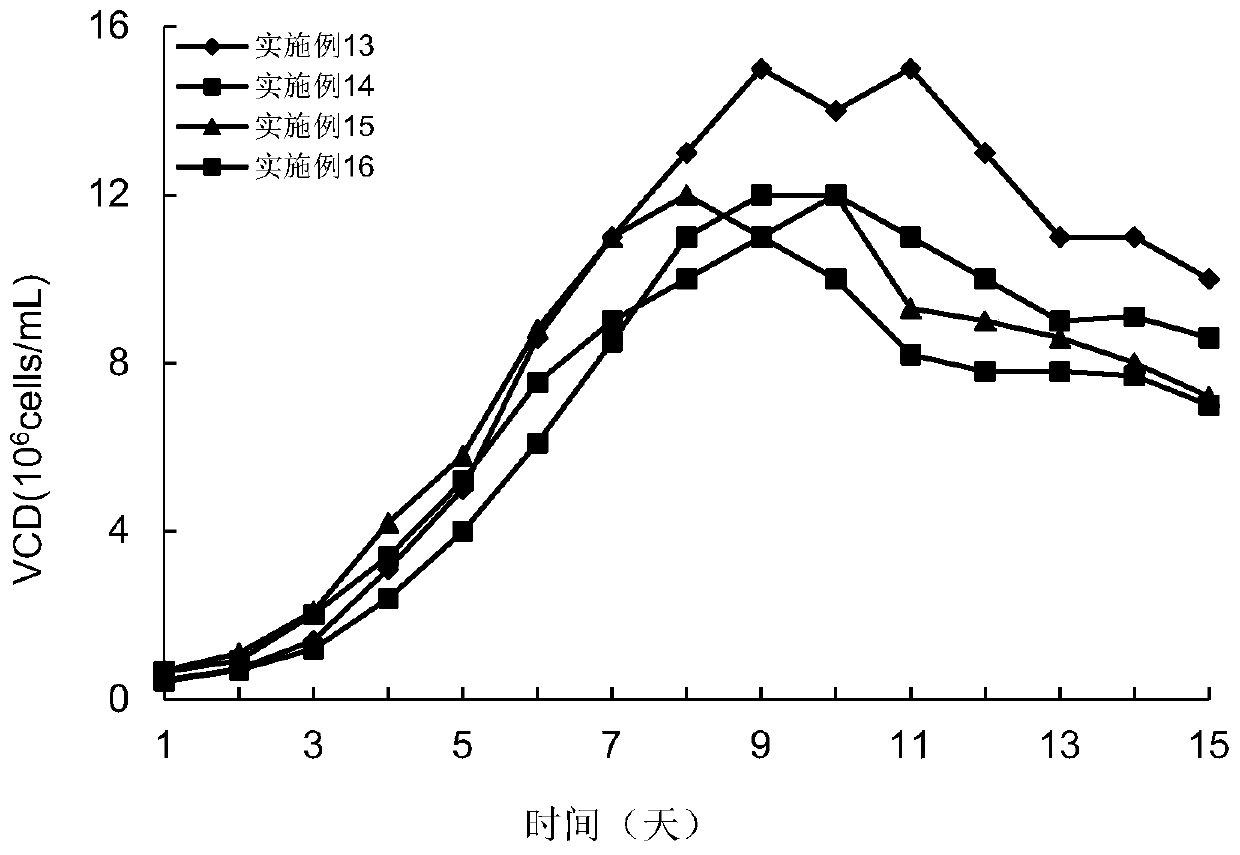

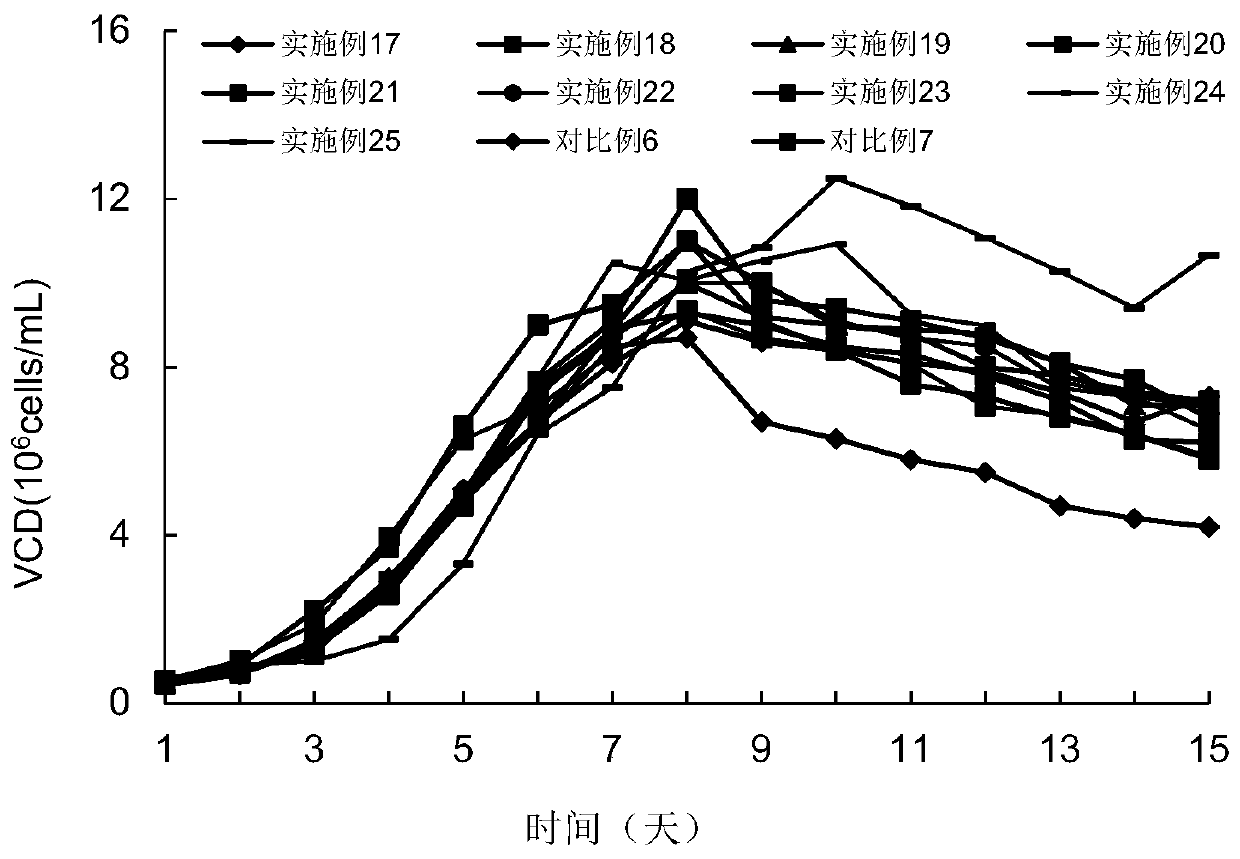

Supplementing culture medium for CHO cell culture and preparing method and application thereof

ActiveCN110343666APromote growthGuaranteed survival rateGenetically modified cellsCulture processThiamine hclTryptophan

The invention relates to a supplementing culture medium for CHO cell culture and a CHO cell culture method. The supplementing culture medium comprises amino acids, vitamins, sodium hydroxide and waterfor injection. According to the total mass of the supplementing culture medium, the supplementing culture medium comprises, by mass, 4.8-19.75% of amino acids, 0.00925-0.13% of vitamins, 1.25-5.5% ofsodium hydroxide and the balance water for injection, wherein the amino acids include L-aspartic acid, L-tyrosine, L-threonine, L-tryptophan and L-glutamic acid, and the vitamins include riboflavin,folic acid, vitamin B12, biotin, menadione sodium bisulfite, thiamine hydrochloride and L-ascorbic acid. By means of the supplementing culture medium and the cell culture method, CHO cell growth can be optimized, and the capacity of cells of expressing target protein can be improved.

Owner:TONGHUA DONGBAO PHARMA

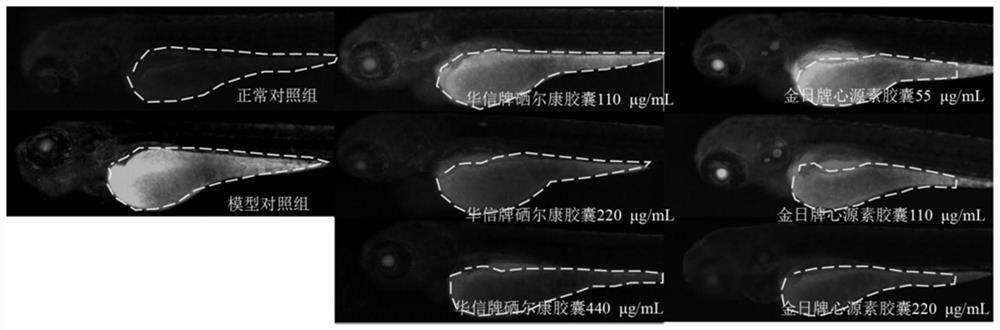

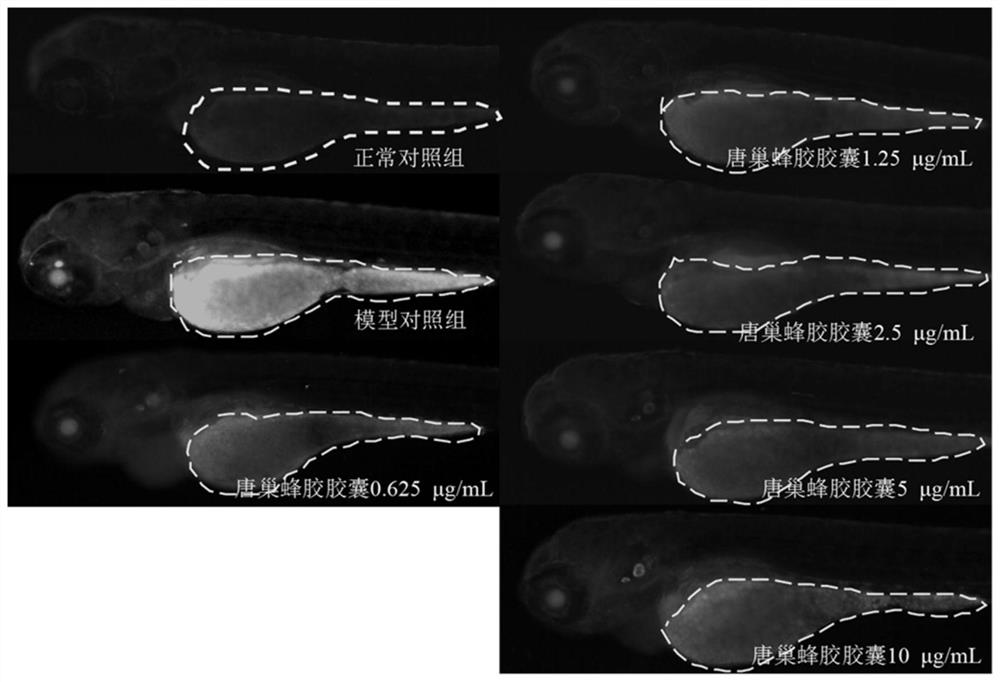

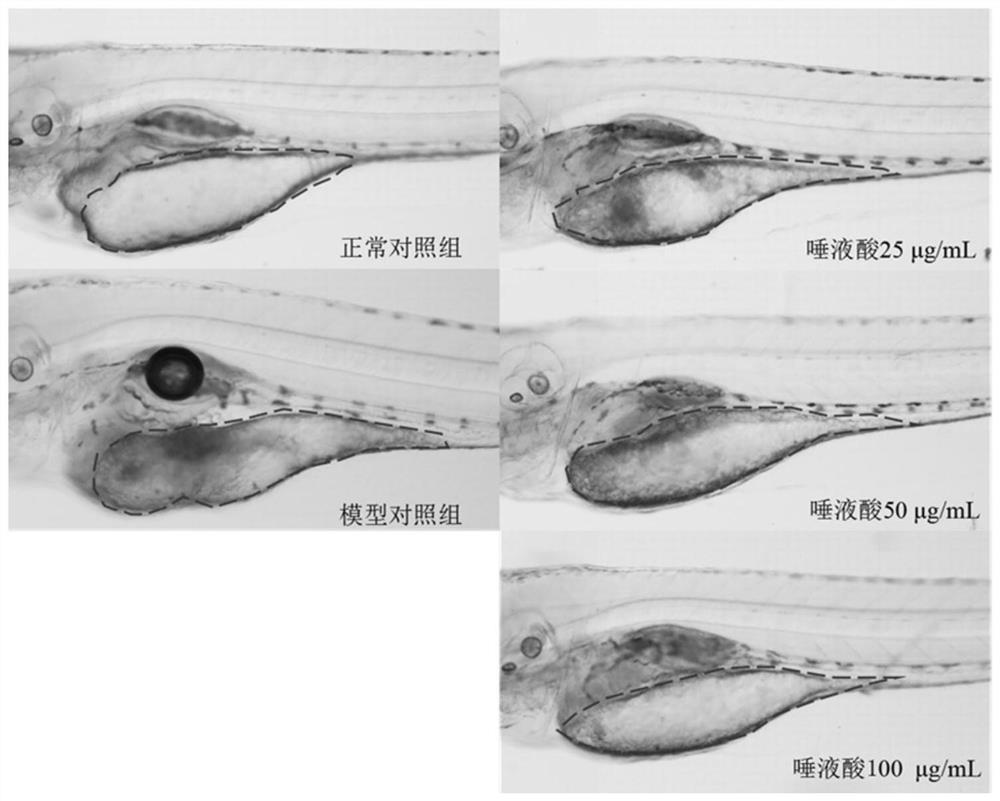

Method for evaluating antioxidant, spot-fading and skin-brightening efficacy by using zebra fish model

ActiveCN112107697AShort experiment cycleCompounds screening/testingClimate change adaptationAnimal scienceMenadione

The invention belongs to the technical field of detection. The invention discloses a method for evaluating antioxidant, spot-fading and skin-brightening efficacy by using a zebra fish model. The method comprises the following steps: carrying out an in-vitro experiment on zebra fish within 3 days after fertilization, taking menadione as a molding agent and an oxidative stress reagent as a dye, andtaking an experimental endpoint as the fourth day after fertilization; collecting a fluorescence picture and a white light picture of zebra fish yolk sacs as data, using yolk sac fluorescence intensity, namely software parameter brightness sum (B), for evaluating an antioxidant efficacy, and using yolk sac pigment intensity, namely software parameter opacity sum (O), for evaluating freckle-fadingand skin-brightening efficacy. The method uses menadione for the first time to establish evaluation of antioxidant, spot-fading and skin-brightening efficacy with the zebra fish model; establishes ananimal model that can evaluate antioxidant, spot-fading and skin-brightening efficacy of both oral health food and applying cosmetics and conforms to a principle of substitution; has a short experimental period, completes efficacy evaluation in 1-2 days, and can screen formulas in batches.

Owner:南京新环检测科技有限公司

Methods and compositions for preventing or treating calciphylaxis

ActiveUS20190374483A1Shorten the progressSmall sizeHydroxy compound active ingredientsMetabolism disorderCOPDHaemodialysis machine

The invention provides methods and compositions for preventing or treating (e.g., slowing the progression of, arresting, and / or reversing) calciphylaxis in a subject in need thereof and, more particularly, the invention relates to methods of using menaquinone-7 (MK-7) and / or menaquinol-7 (MKH2-7) for preventing or treating calciphylaxis in a subject with one or more of the following: diabetes, chronic kidney disease, end stage renal failure, and COPD or a subject undergoing hemodialysis and / or receiving anticoagulant therapy and / or statin therapy.

Owner:EPIZON PHARMA INC

Anti-stress regulator used for promoting growth and improving metabolism of pigs and preparation method thereof

InactiveCN104286542APromote absorptionAnti stressAnimal feeding stuffAdditive ingredientPantothenic acid

The invention discloses an anti-stress regulator used for promoting growth and improving metabolism of pigs. The regulator is prepared from the following ingredients by weight: retinyl acetate, vitamin D3, d1-alpha-tocopheryl acetate, menadione, thiamine hydrochloride, riboflavin, pyridoxine hydrochloride, cyanocobalamin, L-ascorbic acid, d-biotin, nicotinamide, pantothenic acid, folic acid, methionine, lysine, xylooligosaccharide, citric acid, sodium glutamate and glucose as balance. The invention also relates to a preparation method of the anti-stress regulator used for promoting growth and improving metabolism of pigs. The regulator prepared by the method can stimulate the self-metabolism regulation, can improve the feed utilization rate, can improve the food consumption of the growing-finishing pigs and the reproductive performance of the sows, can improve the anti-stress ability, can reduce the death rate and the diarrhea occurrence rate of piglets, has a remarkable growth promotion effect, can improve the growth speed of the weaned pigs, the growing-finishing pigs and the suckling pigs, and has remarkable economic benefit.

Owner:SHANDONG LVDUANTE VETERINARY DRUG IND

Methods and compositions for preventing or treating calciphylaxis

ActiveUS10736858B2Shorten the progressSmall sizeHydroxy compound active ingredientsMetabolism disorderAnti coagulationEnd stage renal failure

The invention provides methods and compositions for preventing or treating (e.g., slowing the progression of, arresting, and / or reversing) calciphylaxis in a subject in need thereof and, more particularly, the invention relates to methods of using menaquinone-7 (MK-7) and / or menaquinol-7 (MKH2-7) for preventing or treating calciphylaxis in a subject with one or more of the following: diabetes, chronic kidney disease, end stage renal failure, and COPD or a subject undergoing hemodialysis and / or receiving anticoagulant therapy and / or statin therapy.

Owner:EPIZON PHARMA INC

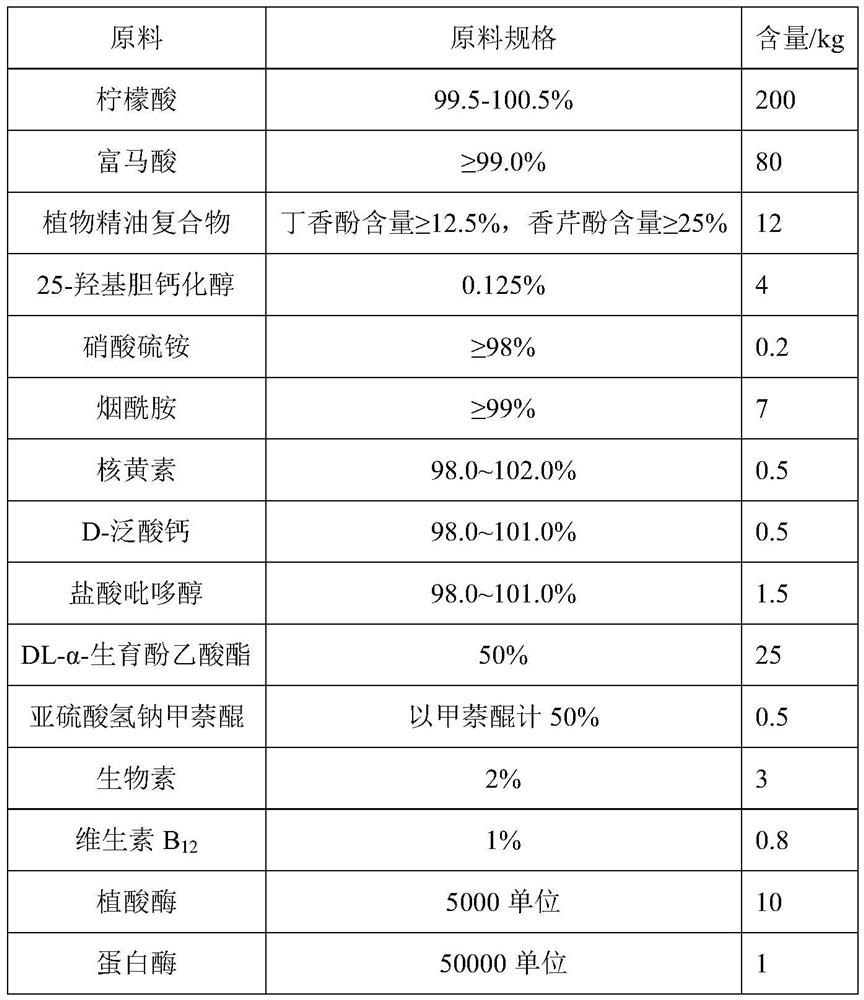

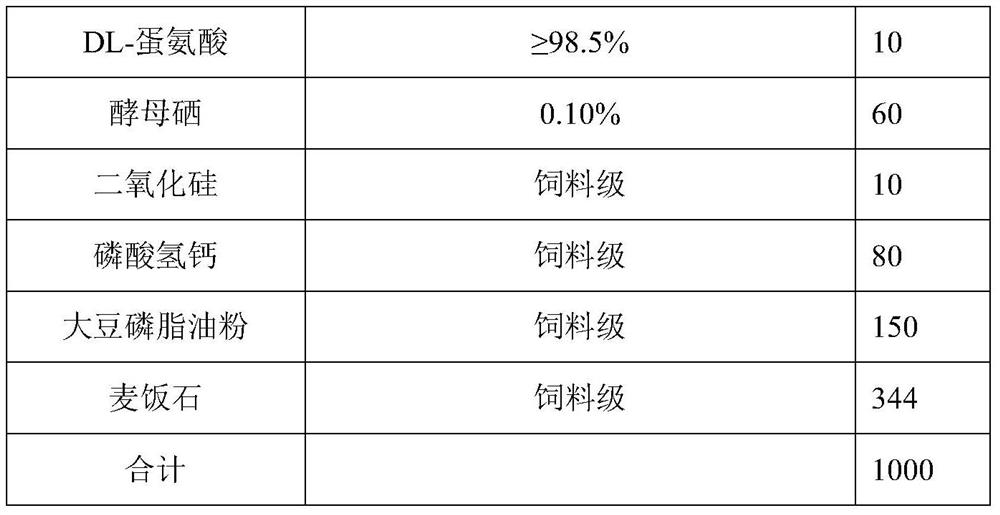

Anti-stress compound premix feed for laying fowls as well as preparation method and application of anti-stress compound premix feed

InactiveCN112568326AInhibition formationRepair and remove damageFood processingAnimal feeding stuffBiotechnologyPhytase

The invention relates to an anti-stress compound premix feed for laying fowls as well as a preparation method and application of the anti-stress compound premix feed. The premix feed is composed of the following raw materials in parts by weight: 160-240 parts of citric acid, 80-160 parts of fumaric acid, 8-15 parts of a plant essential oil compound, 2-5 parts of 25-hydroxy cholecalciferol, 0.15-0.75 part of ammonium sulfate nitrate, 6-15 parts of nicotinamide, 0.2-0.5 part of riboflavin, 0.2-0.5 part of D-calcium pantothenate, 1-2 parts of pyridoxine hydrochloride, 20-36 parts of DL-alpha-tocopheryl acetate, 0.4-0.7 part of menadione sodium bisulfite, 1-4 parts of biotin, 0.3-0.9 part of vitamin B12, 10-30 parts of phytase, 1-5 parts of protease, 2-10 parts of DL-methionine, 20-60 parts ofselenium yeast, 50-150 parts of calcium hydrophosphate and 200-600 parts of a carrier. The premix feed provided by the invention can significantly improve the stress intestinal injury of the laying fowls and improve the digestive absorption capacity, and finally achieves the effects of relieving the stress of the laying fowls, reducing the dirty egg rate, improving the egg laying rate in a stressstate, improving the egg quality and the breeding performance of breeding fowls, reducing the dirty egg rate, improving the fertilization rate and the hatching rate and increasing the economic benefits of farmers.

Owner:QILU ANIMAL HEALTH PROD +1

Methods and compositions for preventing or treating calciphylaxis

ActiveUS20200306208A1Shorten the progressSmall sizeHydroxy compound active ingredientsMetabolism disorderAnti coagulationEnd stage renal failure

The invention provides methods and compositions for preventing or treating (e.g., slowing the progression of, arresting, and / or reversing) calciphylaxis in a subject in need thereof and, more particularly, the invention relates to methods of using menaquinone-7 (MK-7) and / or menaquinol-7 (MKH2-7) for preventing or treating calciphylaxis in a subject with one or more of the following: diabetes, chronic kidney disease, end stage renal failure, and COPD or a subject undergoing hemodialysis and / or receiving anticoagulant therapy and / or statin therapy.

Owner:EPIZON PHARMA INC

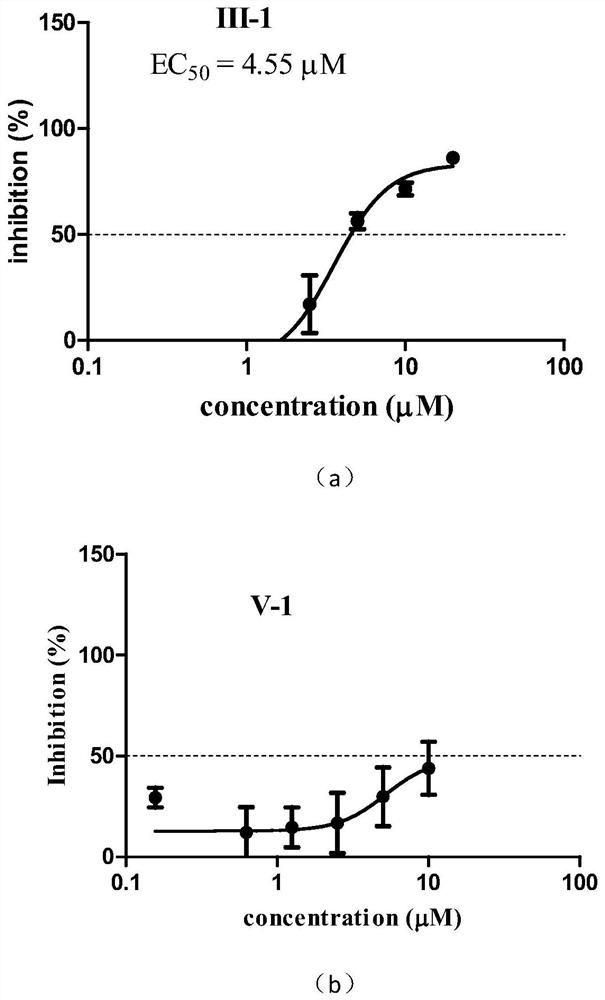

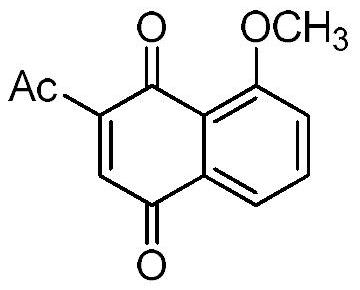

Menadione structure-based novel coronavirus 3CL protease inhibitor

ActiveCN112645809AStrong inhibitory activityHigh yieldOrganic chemistryAntiviralsChemical compoundPharmaceutical drug

The invention discloses a menadione derivative capable of resisting novel coronavirus and medical application of the menadione derivative. The structure of the compound is shown as a formula (I), in the formula, R is a hydrogen atom, methyl, acetyl or hydroxyl, and R1 is hydrogen, methoxy, benzyloxy or benzoyloxy. The compound disclosed by the invention can inhibit the 3CL hydrolase of the 2019-nCoV novel coronavirus, and has the activity of resisting the novel coronavirus. In-vitro activity determination experiments show that the enzyme inhibition rate of part of the compounds reaches 90% or above under the concentration of 1 [mu] M, and is significantly superior to that of a positive control drug alkannin. Cell-level toxicity test experiment results show that the toxicity of menadione and the derivative thereof to host normal cells HSF is significantly lower than that of positive drugs alkannin and juglone, and part of the compounds show relatively strong anti-novel coronavirus activity in vitro, and have an important significance for the development of high-efficiency and low-toxicity new anti-novel coronavirus drugs.

Owner:SHANGHAI JIAO TONG UNIV

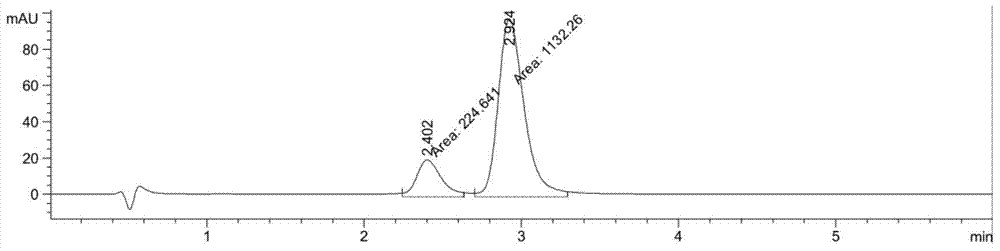

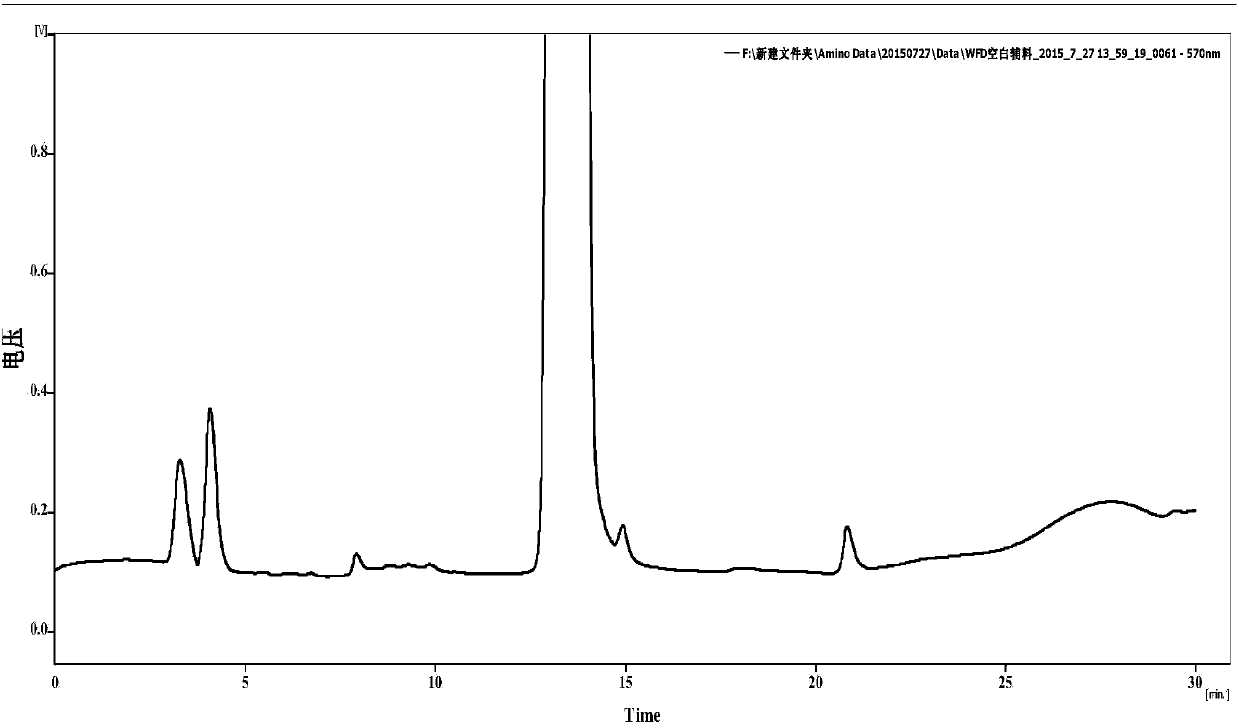

Detection method of multivitamin injection impurities

The invention relates to an analysis and detection method of multivitamin injection impurities, belongs to the field of medicine analysis, and mainly relates to a detection method of oxalic acid, 3-aminopropanol, retinol, alpha-tocopherol, menadione and vitamin K1 cis-isomer impurities in a multivitamin injection.

Owner:北京藏卫信康医药研发有限公司 +1

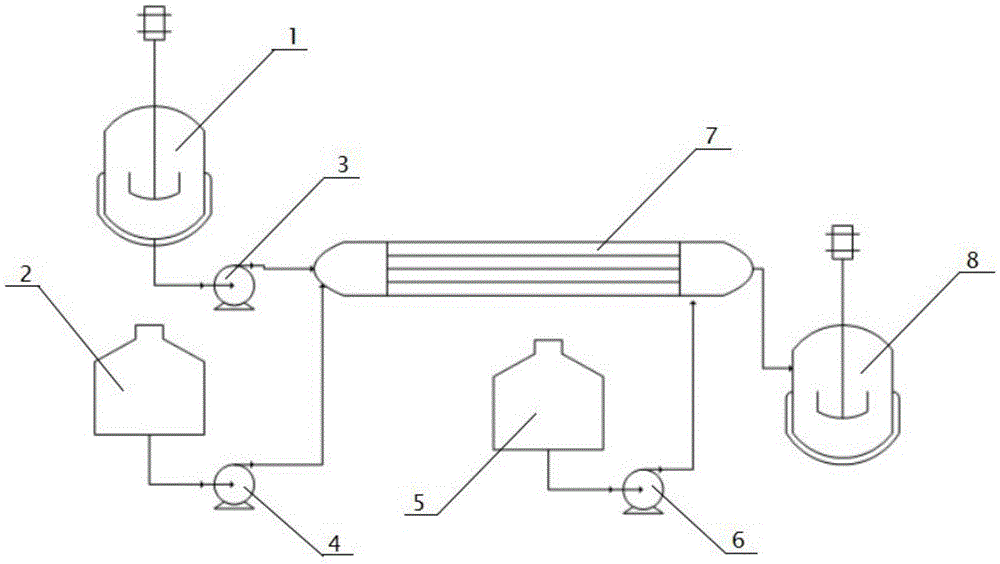

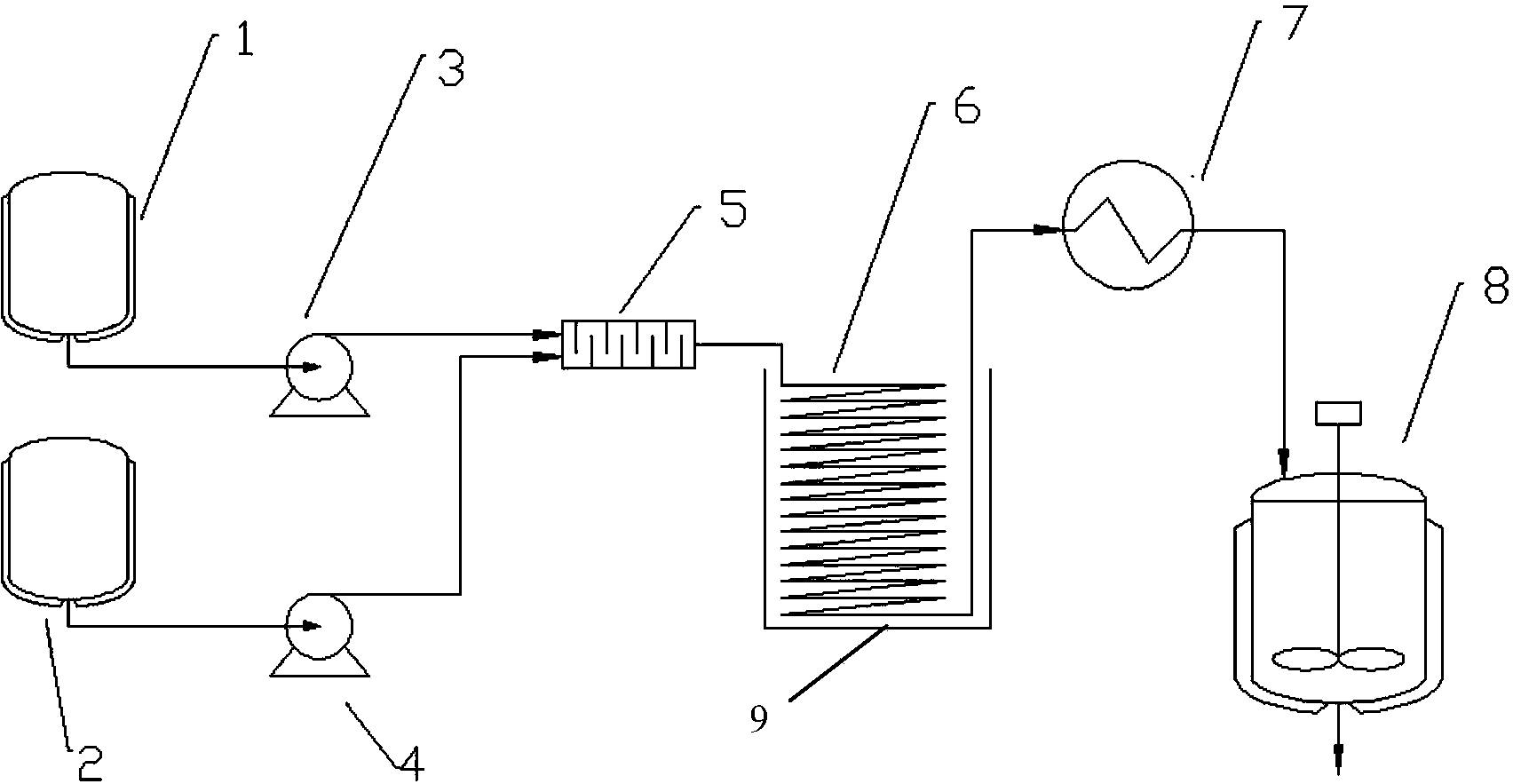

Method for preparing menadione sodium bisulfite continuously in tubular type reactor

ActiveCN104163779AShorten the production cycleHigh yieldSulfonic acids salts preparationRetention timeMixed materials

The invention discloses a method for preparing menadione sodium bisulfite continuously in a tubular type reactor. The method comprises the steps of passing a beta-menadione solution and a sodium metabisulfite solution which are preheated to a temperature of 50-80 DEG C through a metering pump respectively; mixing uniformly through a mixer; introducing the mixed materials into the tubular type reactor to carry out a reaction, controlling a temperature of a reaction solution at 50-80 DEG C and a reaction retention time in the tubular type reactor at 1-15 min; crystallizing the material obtained at a reactor outlet by cooling; separating a solid product by centrifugation; washing and drying to obtain menadione sodium bisulfite. The method takes use of the tubular type reactor to produce menadione sodium bisulfite, has a shortened production period, high product yield, stable quality, easily controllable reaction conditions and convenient and safe operations, can be controlled automatically easily, can realize continuous production, and can realize large-scale production only by a few investment in industry.

Owner:ZHEJIANG UNIV OF TECH +1

One-step addition technique for vitamin K3

InactiveCN101121651AShort processEasy to operateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsVitamin K2Celsius Degree

The invention relates to a novel vitamin K3 one-step processing technology; the technology is a one-step processing method; the reasonable organic solvent and catalyst are chosen to make vitamin K3. The invention reduces the refining, secondary freezing and cooling, and the secondary centrifugal processes of the product; the simple screening process replaces the complex crushing process. The concrete steps are: in the reactor, the beta menadione is put into the ethanol solution; the sodium metabisulfite and catalyst is put according to the proportion; after keeping two hours under the condition of 65 to 75 Celsius system, the solution is put into the crystallizer; the material is put at 0 Celsius system and done with the centrifugal separation; the process is to dry the wet VK3; then screen and get about 319 kilograms of dry VK3, with the content of 101.77 percent. The advantages are: first, the process is short and the operation is simple; secondly, the production rate of the single-kettle is high; thirdly, the collection rate of the product is high; fourthly, the solvent consumption is low; fifthly, the energy consumption is low; sixthly, the product quality is high.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

Method for manufacturing oyster amino acid energy drinks

InactiveCN101536802AHigh nutritional valuePure tasteAnimal proteins working-upFood preparationOysterSolvent

The invention relates to a method for manufacturing oyster amino acid energy drinks, comprising the steps as follows: making the edible part of the oyster into paste shape, adding appropriate amount of water and extracting solvent oil-ethyl acetate miscible liquids for stirring to remove fishy smell; centrifuging to take aqueous solution and precipitate to stir evenly; adding hydrochloric acid to hydrolyze to obtain mixed amino acid aqueous solution, then adding #6 light petrol for stirring to remove fishy smell, centrifuging to collect mixed amino acid aqueous solution for vacuum concentration to obtain mixed amino acid aqueous solution; adding sterile water to dilute mixed amino acid aqueous solution and neutralizing with sodium hydroxide to obtain mixed amino acid mother solution, adding sterile water to dilute to a concentration of 3-5 permillage of amino acid, and adding appropriate amount of calcium lactate and menadione sodium bisulfite D2 to prepare into products. The invention has the advantage that the economic benefit is improved by over 20 times compared with the oysters that are sold with shells; besides, the oyster amino acid energy drinks has pure taste, high nutritional value, simple production method and low cost.

Owner:GUANGDONG OCEAN UNIVERSITY

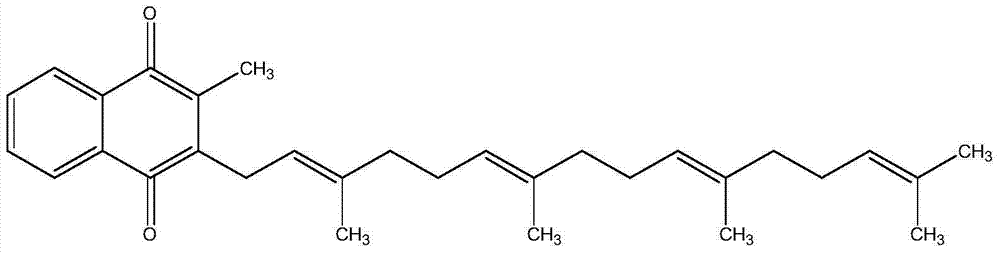

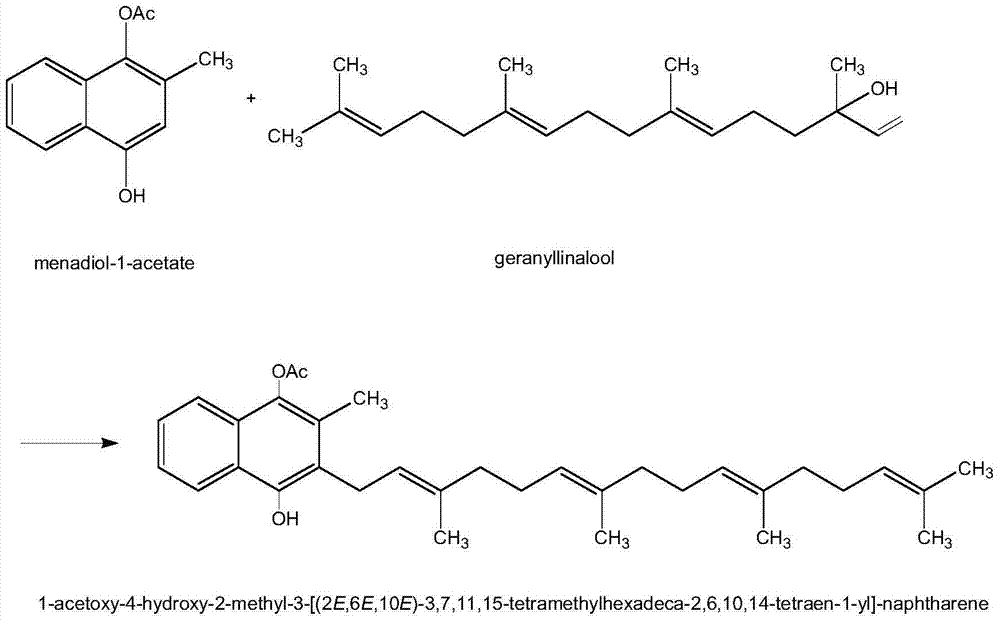

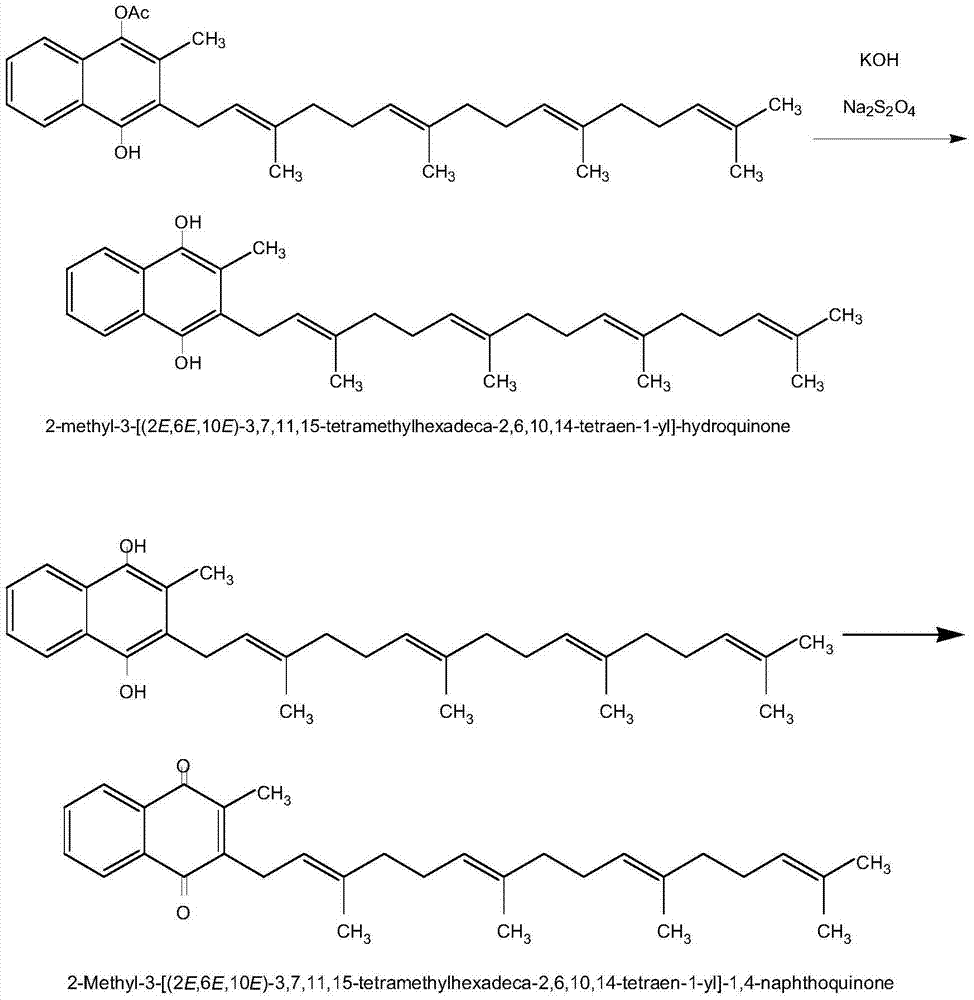

Synthetic method of menatetrenone

InactiveCN104513149AEasy to prepareLow costOrganic compound preparationQuinone preparation by oxidationSodium bicarbonatePotassium hydroxide

The invention provides a synthetic method of menatetrenone, wherein the method includes steps of: (1) a condensation reaction: adding menadione monoacetate, an ether organic solvent, boron trifluoride.diethyl ether, adding geranyl linalool by several times to carry out a reaction, and washing a reaction product successively through water, a 5% sodium bicarbonate solution and a 5% sodium chloride solution after the reaction finished; (2) alcoholysis: adding methylbenzene to the reaction product in the step (1), performing a stirring operation with addition of water, potassium hydroxide, sodium hydrosulfite and methanol; and (3) oxidization: adding water and potassium hydroxide into an organic solvent of the product obtain in the step (2), dropwisely adding a chemical oxidizing agent and performing pressure-reducing concentration to obtain a final product. The invention is advantaged in that through a large amount of experiments, the preparation method of the menatetrenone (vitamin K2) is optimized and preferable solvents and oxidizing agents are determined. The synthetic method is simple, is low in cost and is suitable for large-scale production.

Owner:TIANJIN RUIAN MEDICAL TECH DEV

Efficient antifouling paint for fishing gear

InactiveCN105778696AImprove stabilityEasy to useAntifouling/underwater paintsRosin coatingsSodium PyrithioneDispersity

The invention discloses an efficient antifouling paint for a fishing gear. The antifouling paint is prepared from the following components: methyl methacrylate, vinyltriethoxysilane, butyl acrylate, methyl silicone resin, gramine, epoxy menadione, zinc pyrithione, rosin, nano titanium dioxide, nano zinc oxide, dioctyl phthalate, an initiator and an emulsifier. The antifouling paint for the fishing gear, disclosed by the invention, has the advantages of low toxicity, high efficiency, conformity to environmental protection requirement, high stability, convenience in use, simplicity in application, high cost performance, good adhesion and good antifouling property; through modifying treatment on nano titanium dioxide, the dispersity and stability can be improved while the hydrophobicity is enhanced; by mixing methyl methacrylate and vinyltriethoxysilane through the modified nano titanium dioxide, the ocean antifouling comprehensive performance of the antifouling paint disclosed by the invention is remarkably improved, and the bio-attachment resistance is enhanced; and moreover, the antifouling paint has good surface property, water resistance and mechanical property.

Owner:CHAOHU JUNYE FISHING TACKLE CO LTD

Stable state vitamin K3and method of preparing the same

InactiveCN101347419APromote conversionPromote absorptionOrganic active ingredientsMetabolism disorderVitamin K2Niacinamide

The invention discloses a vitamin K, in particular a steady-state vitamin K3 and a preparation method thereof. The steady-state vitamin K3 is characterized by being made from the following materials: menadione, sodium metabisulfite, niacinamide and sulphuric acid. The preparation method of the steady-state vitamin K3 comprises the steps as follows: the menadione and alcohol water blend are added to a 500ml reaction bottle, fully stirred and pulped, and then the sodium metabisulfite and the niacinamide are added and continuously stirred to facilitate dissolution, the sulphuric acid is slowly added dropwise, and the pH is regulated to 3-5 to obtain a great amount of white crystals, and the white crystals are filtered, washed and dried to obtain the pure K3 with high steady state. The vitamin K3 has high biological activity and maintains vitamin PP efficiency which is the inherent nutritional function of the niacinamide group in MNB structure, that is, a product has the two functions of vitamin K3 and vitamin PP simultaneously, so the vitamin K3 has higher economical efficiency.

Owner:SHANDONG DAHUA GUANGJI BIOCHEM ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com