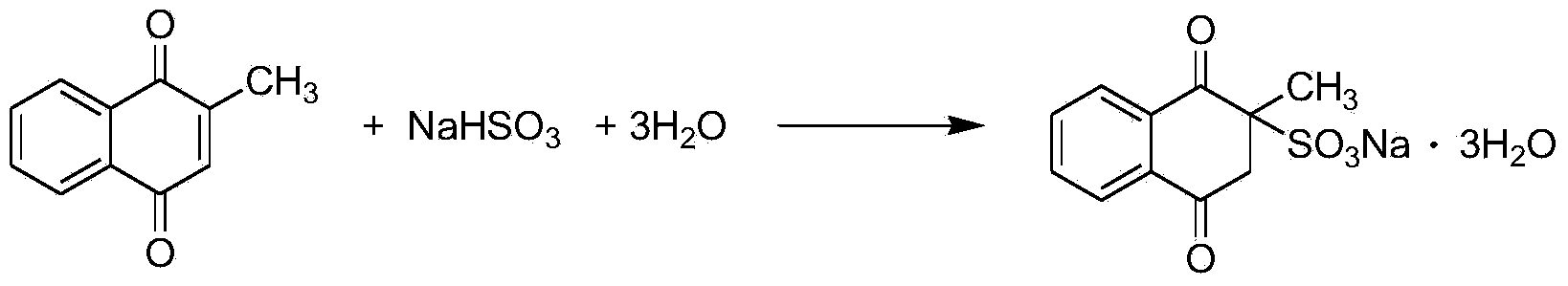

Method for preparing menadione sodium bisulfite continuously in tubular type reactor

A technology of menadione sodium bisulfite and sodium pyrosulfite, which is applied in the field of continuous production of menadione sodium bisulfite using tubular reactors, and can solve the problems of long production auxiliary time, unstable product quality, and low production efficiency, etc. problems, to achieve the effect of large-scale production, easy automation control, and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

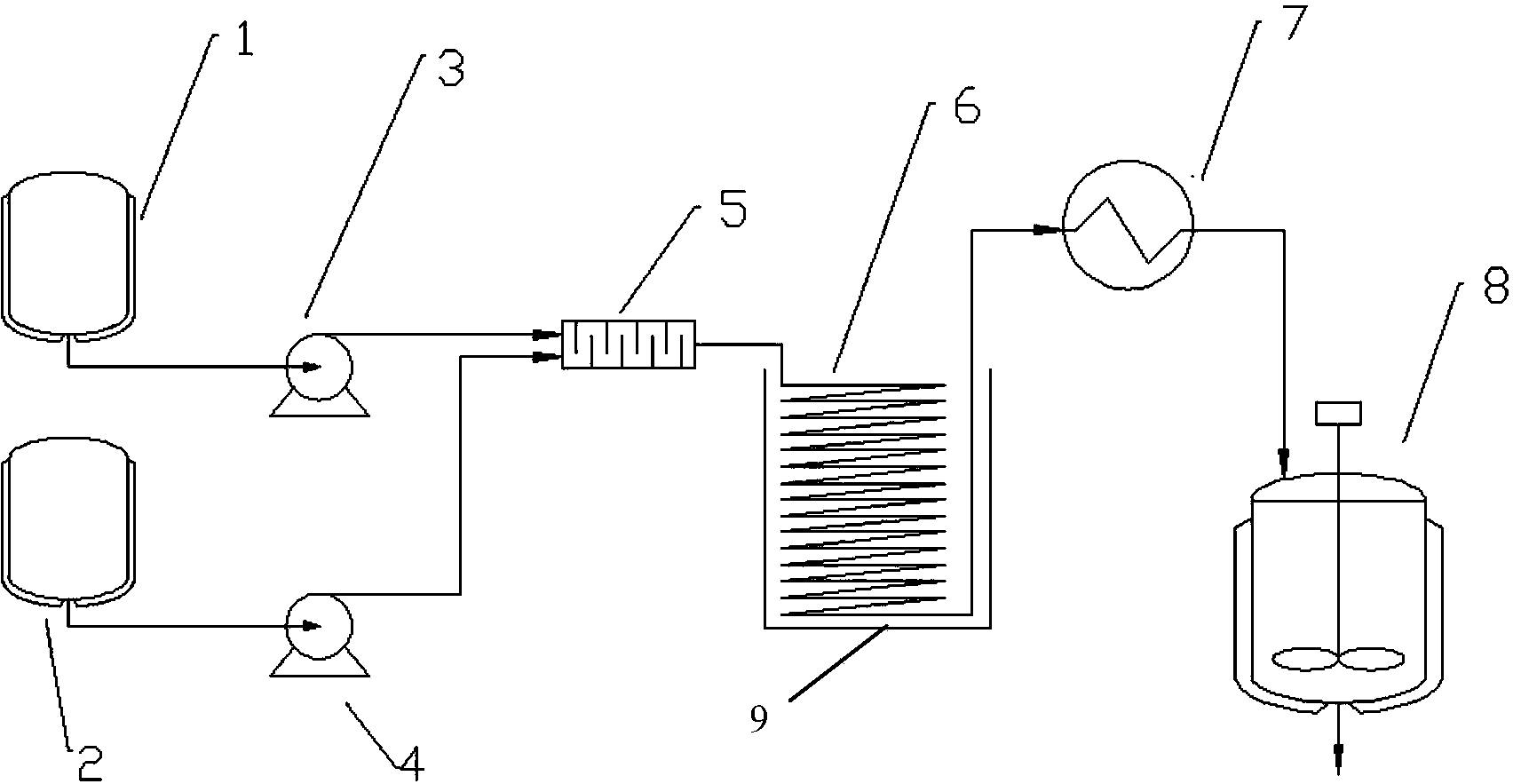

Embodiment 1

[0022] Make β-menadione and ethanol into β-menadione solution at 75°C, add it to storage tank 1, the mass fraction of β-menadione is 10%, add pre-prepared 75°C solution to storage tank 2 The mass fraction is 35% sodium metabisulfite aqueous solution, and the β-menadione solution and sodium metabisulfite solution preheated to 75°C are continuously pumped into the static mixer 5 at a volume flow ratio of 5.6:1. At this time, the β-menadione The molar ratio of quinone and sodium metabisulfite is 1:0.7, the mixed material enters the tubular reactor 6, the temperature of the reaction liquid is controlled at 75°C, and the reaction residence time is 5 minutes. The material at the outlet of the tubular reactor is cooled by the cooler 7 and put into the crystallization kettle 8, frozen to 0°C, heat-preserved and crystallized for 2 hours, centrifuged, washed with cold ethanol for crystallization, and dried to obtain menadione sodium bisulfite. The rate is 70%.

Embodiment 2

[0024] Make β-menadione and ethanol into β-menadione solution at 75°C, add it to storage tank 1, the mass fraction of β-menadione is 22%, add pre-prepared 75°C solution to storage tank 2 The mass fraction is 35% sodium metabisulfite aqueous solution, and the β-menadione solution and sodium metabisulfite solution preheated to 75°C are respectively continuously pumped into the static mixer 5 at a volume flow ratio of 2.5:1. At this time, the β-menadione The molar ratio of quinone and sodium metabisulfite is 1:0.7, the mixed material enters the tubular reactor 6, the temperature of the reaction liquid is controlled at 75°C, and the reaction residence time is 5 minutes. The material at the outlet of the reactor is cooled by the cooler 7 and put into the crystallization kettle 8, frozen to 0° C., heat-preserved and crystallized for 2 hours, centrifuged, washed with cold ethanol to crystallize, and dried to obtain menadione sodium bisulfite. The yield is 74%.

Embodiment 3

[0026] Mix β-menadione and ethanol into β-menaquinone solution at 75°C, add it to storage tank 1, the mass fraction of β-menadione is 18%, add pre-prepared 75°C solution to storage tank 2 The mass fraction is 25% sodium metabisulfite aqueous solution, and the β-menadione solution and sodium metabisulfite solution preheated to 75 ° C are continuously pumped into the static mixer 5 at a volume flow ratio of 2.2:1. At this time, the β-menadione The molar ratio of quinone and sodium metabisulfite is 1:0.7, the mixed material enters the tubular reactor 6, the temperature of the reaction liquid is controlled at 75°C, and the reaction residence time is 5 minutes. The material at the outlet of the reactor is cooled by the cooler 7 and put into the crystallization kettle 8, frozen to 0° C., heat-preserved and crystallized for 2 hours, centrifuged, washed with cold ethanol to crystallize, and dried to obtain menadione sodium bisulfite. The yield is 66%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com