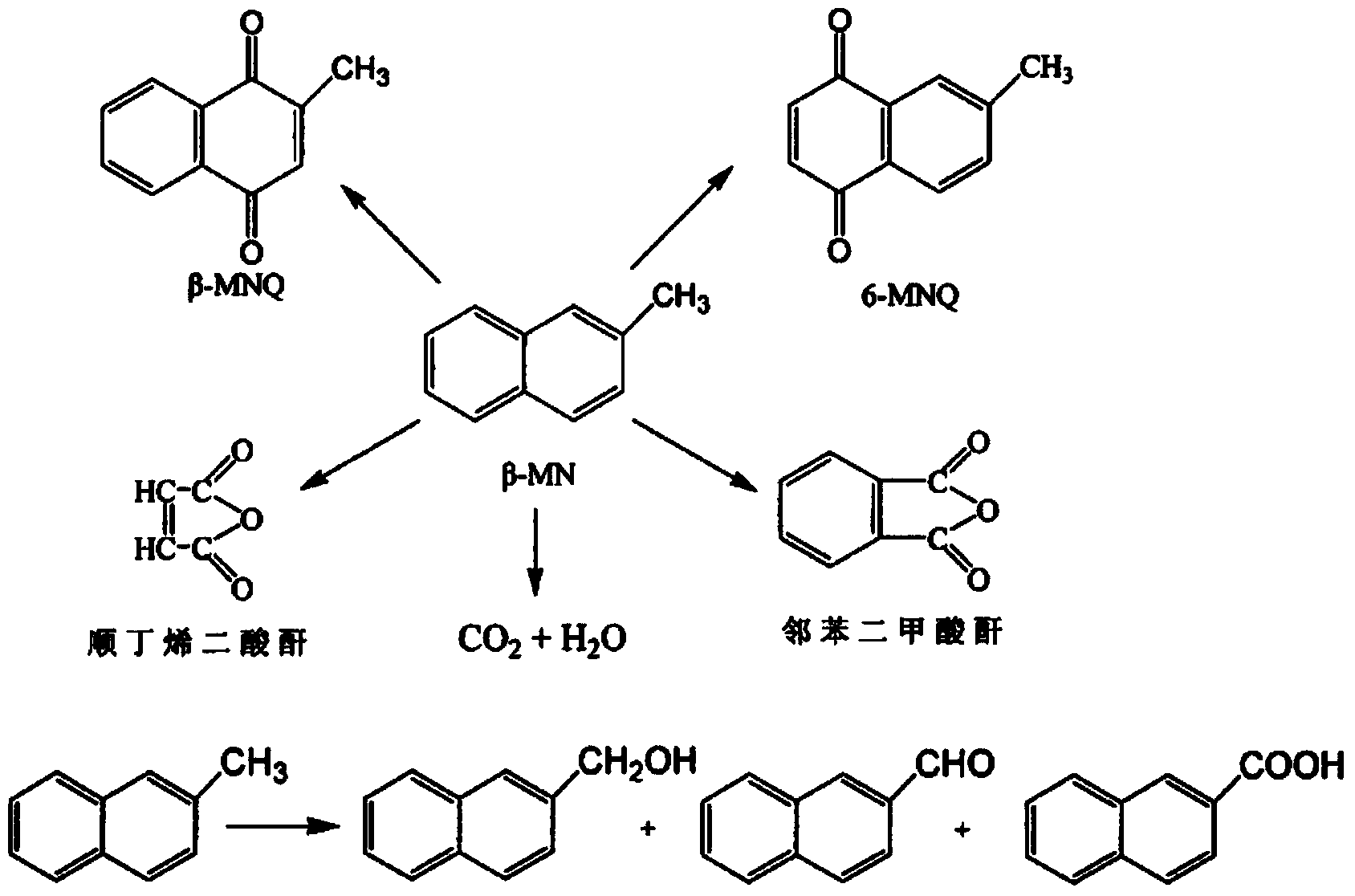

Method for promoting beta-menadione production through ultrasonic waves

A technology of menaquinone and ultrasonic wave is applied in the field of promoting the production of β-menaquinone by ultrasonic wave, which can solve the problems of low molar yield and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Prepare the oxidation solution, which contains 390g / L of sodium rubidin and 550g / L of sulfuric acid in the oxidation solution. Weigh 19.19g of β-methylnaphthalene into a 500mL beaker, add 0.2g of tetrabutylammonium bromide as a phase transfer agent, add 80mL of water, stir and ultrasonicate, the ultrasonic power density is 0.75W / L. At 42°C, 285 mL of the above oxidizing solution was slowly added dropwise into the beaker, and the reaction time was 90 minutes. Filter, wash with water, and dry to obtain 15.13 g of β-menadione. The purity of the product β-menaquinone is 95.34%, and the molar yield is 62.07%. The resulting β-menaquinone crystal had a melting point of 105.6°C.

Embodiment 3

[0045] Prepare the oxidation solution, which contains 360g / L of sodium rubidin and 620g / L of sulfuric acid in the oxidation solution. Weigh 86.54g of β-methylnaphthalene into a 2000mL beaker, add 1.2g of tetrabutylammonium bromide as a phase transfer catalyst, add 240mL of water, stir and ultrasonicate, the ultrasonic power density is 3W / L. At 40°C, 1280 mL of the above oxidizing solution was slowly added dropwise into the beaker, and the reaction time was 90 minutes. Filter, wash with water, and dry to obtain 68.13 g of β-menadione, the product β-menaquinone content is 94.18%, and the molar yield is 61.22%. The resulting β-menaquinone crystal had a melting point of 105.4°C.

Embodiment 5

[0050] Prepare the oxidation solution, which contains 390g / L of sodium rubidin and 550g / L of sulfuric acid in the oxidation solution. Weigh 19.19g of β-methylnaphthalene into a 500mL beaker, add 0.2g of tetrabutylammonium bromide as a phase transfer catalyst, add 80mL of water, stir and ultrasonicate, the ultrasonic power density is 1.3W / L. At 42°C, 285 mL of the above oxidizing solution was slowly added dropwise into the beaker, and the reaction time was 90 minutes. Filter, wash with water, and dry to obtain 14.97 g of β-menadione. The product β-menaquinone has a purity of 94.66% and a molar yield of 61.42%. The resulting β-menaquinone crystal had a melting point of 105.6°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com