Bacillus subtilis natto and method for purifying vitamin menadione-7 by using bacterial strain

A technology for vitamin A and natto subtilis, which is applied in the field of purifying vitamin menadione-7, and achieves the effects of simplifying purification steps, improving purity and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Preparation of Bacillus natto fermentation broth:

[0063] Natto (purchased from Japan Biotechnology Co., Ltd.) was dissolved and diluted with sterile water and spread on an agarose-fibrin plate (see: Wei Hua, Zhao Xiangying, Liu Jianjun, Determination of Nattokinase Activity [J]. Shandong Journal of the Institute of Light Industry, 2007, 21(1) 60-63.), after culturing at 37°C for 18 hours, a transparent circle was produced, and colonies with larger transparent circles were selected for multi-generation mutagenesis by ultraviolet light (15s) to obtain Bacillus subtilis natto (Bacillus subtilis natto) ST188 (strains are preserved in the General Microbiology Center of China Microbiological Culture Collection Management Committee, address: No. 3, Yard 1, Beichen West Road, Chaoyang District, Beijing, preservation date: October 31, 2013, and preservation number is : CGMCC No.8400).

[0064] Inoculate 500 mL of the obtained Bacillus subtilis ST188 in natto into 10000 mL of ...

Embodiment 2

[0074]The method of Example 1 was used to purify vitamin MK-7 in Bacillus natto fermentation broth, the difference was that in step (4), the volume ratio of wet packing to dry packing was 2:1.

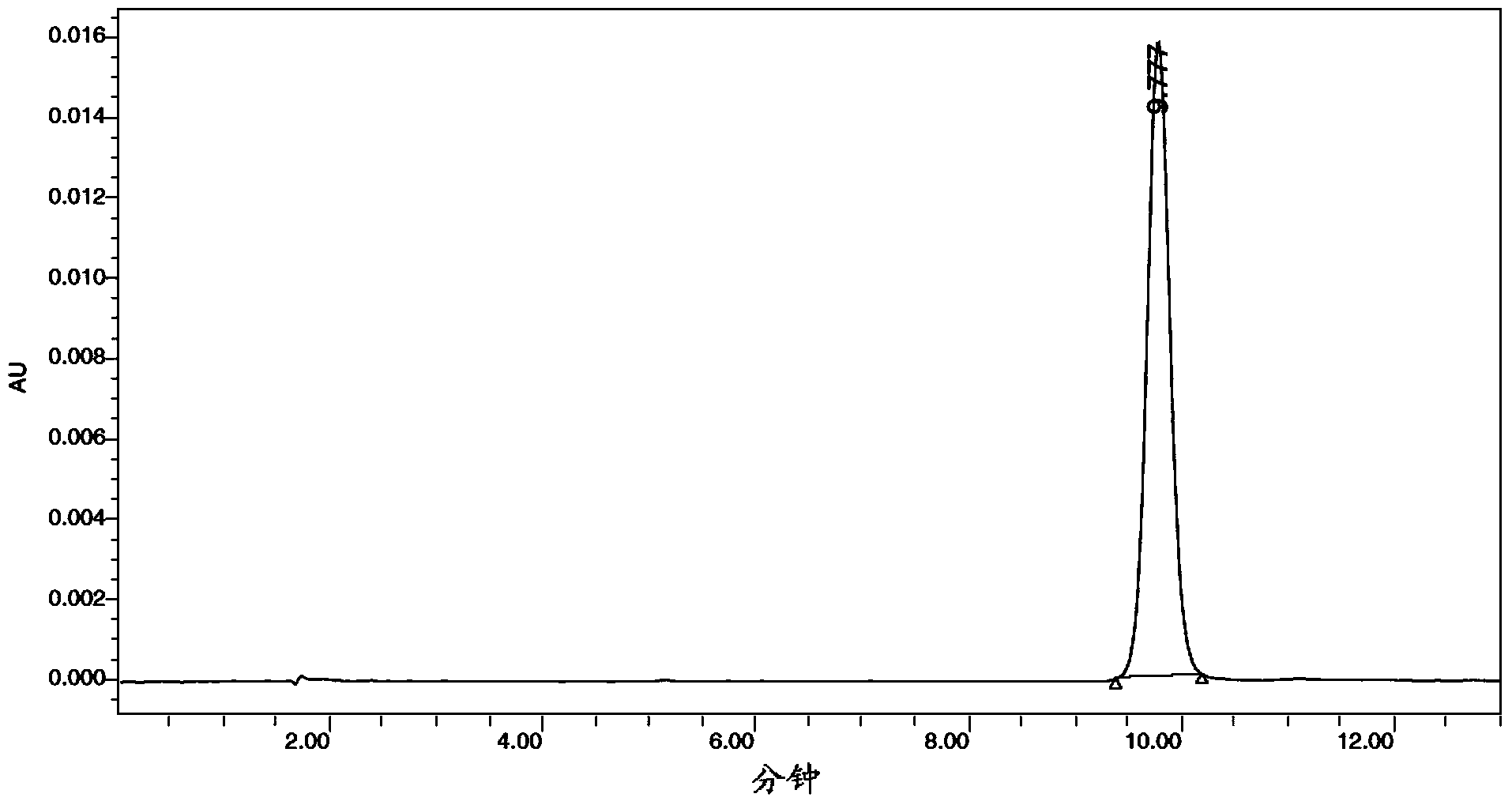

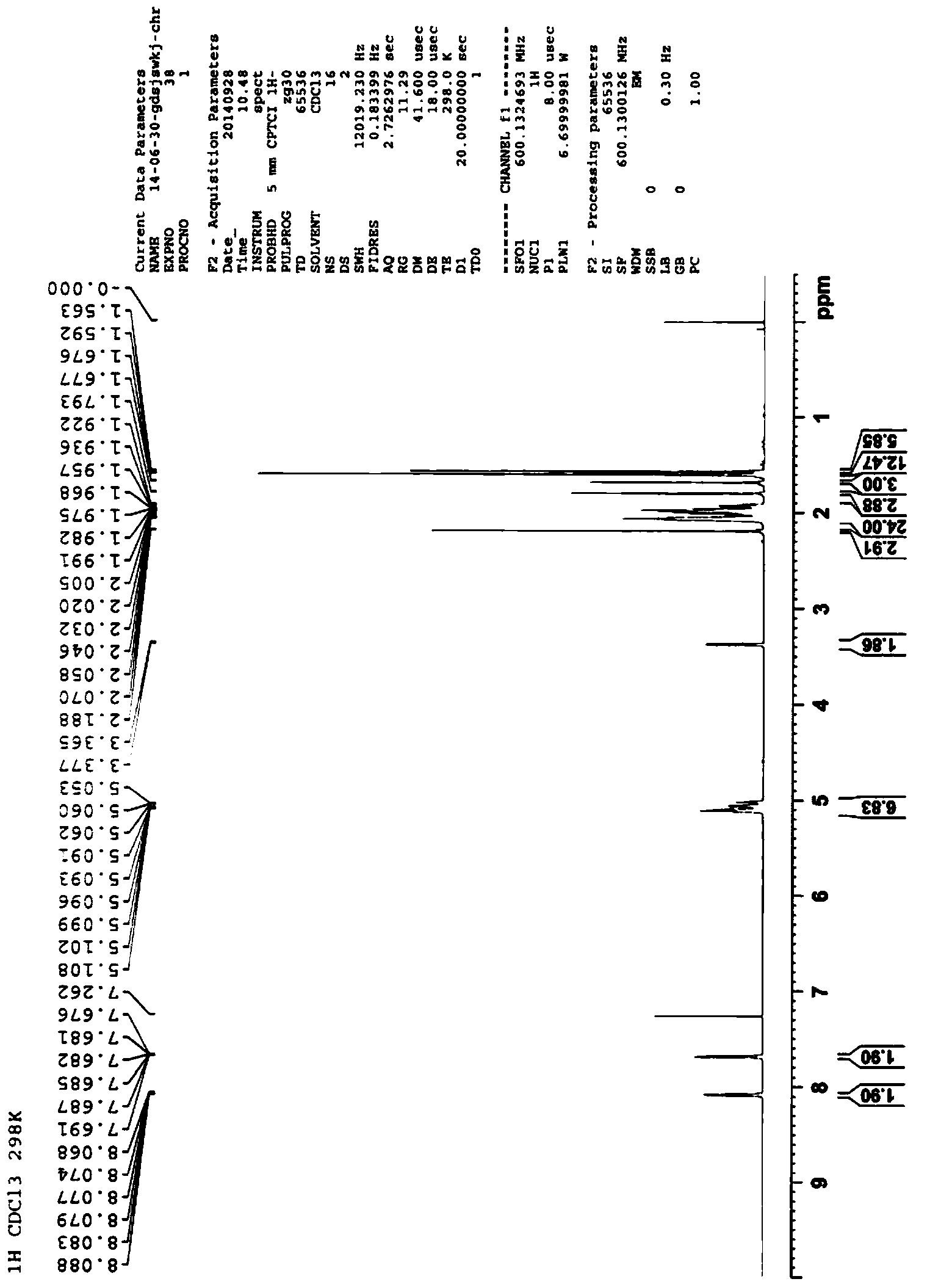

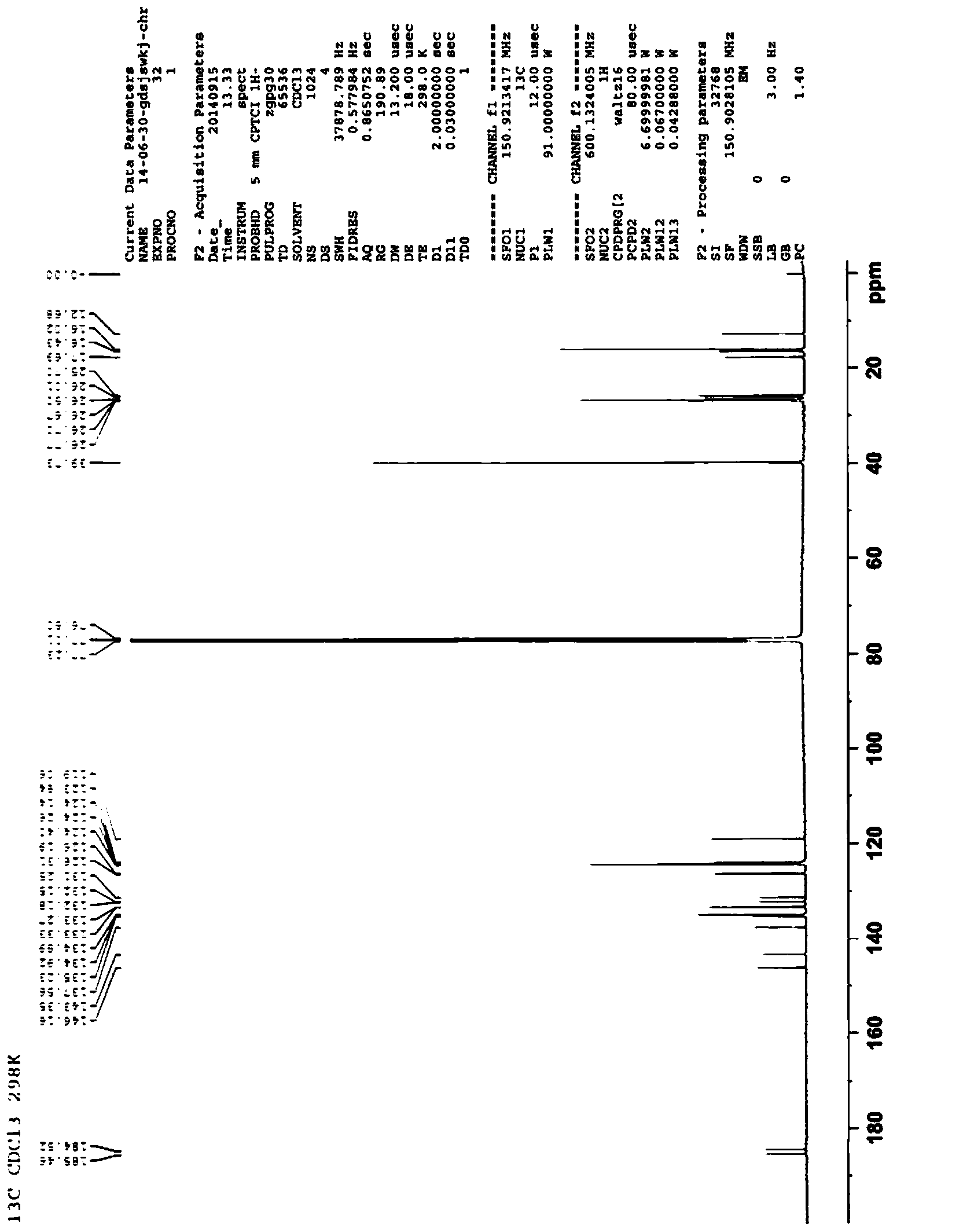

[0075] The H-spectrum, C-spectrum, DEPT135-spectrum, COZY-spectrum, HSQC-spectrum and HMBC-spectrum of the product obtained in Example 1 are consistent, so it can be confirmed that the product is vitamin menadione-7.

[0076] At the same time, the purity of the vitamin MK-7 in the product is determined to be 99% through chromatographic analysis, and the yield of the obtained vitamin MK-7 is 93%.

Embodiment 3

[0078] The method in Example 1 was used to purify vitamin MK-7 in Bacillus natto fermentation broth, the difference was that in step (4), the volume ratio of wet packing to dry packing was 1:2.

[0079] The H-spectrum, C-spectrum, DEPT135-spectrum, COZY-spectrum, HSQC-spectrum and HMBC-spectrum of the product obtained in Example 1 are consistent, so it can be confirmed that the product is vitamin menadione-7.

[0080] At the same time, the purity of the vitamin MK-7 in the product is determined to be 93% through chromatographic analysis, and the yield of the obtained vitamin MK-7 is 92%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com