Method for producing vitamin K3

A production method and vitamin technology, applied in the preparation of sulfonic acid, organic chemistry and other directions, can solve the problems of product purity only reaching 94%, difficult to recycle, waste of resources, etc., to achieve product yield and quality improvement, product yield Improve and avoid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

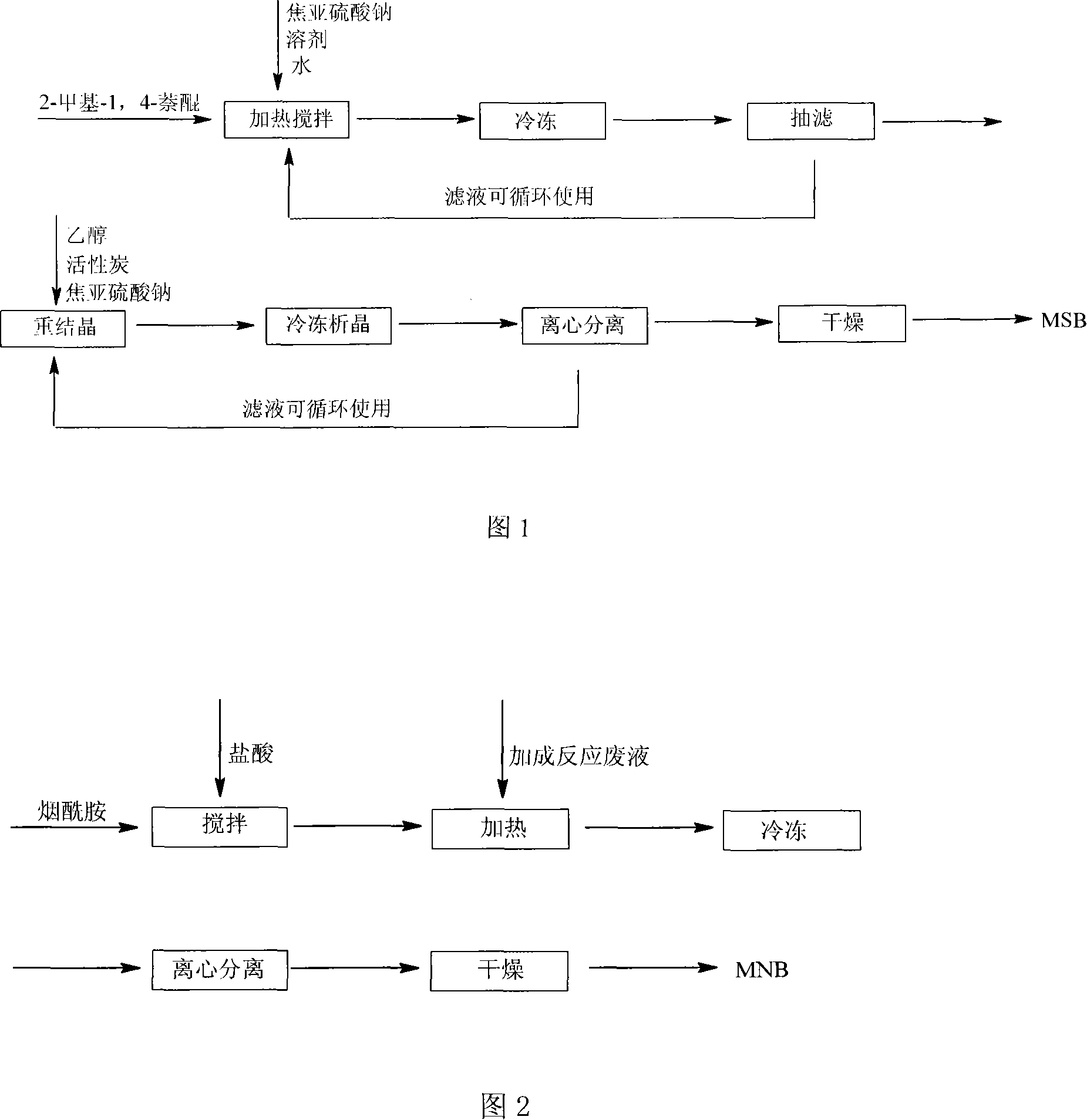

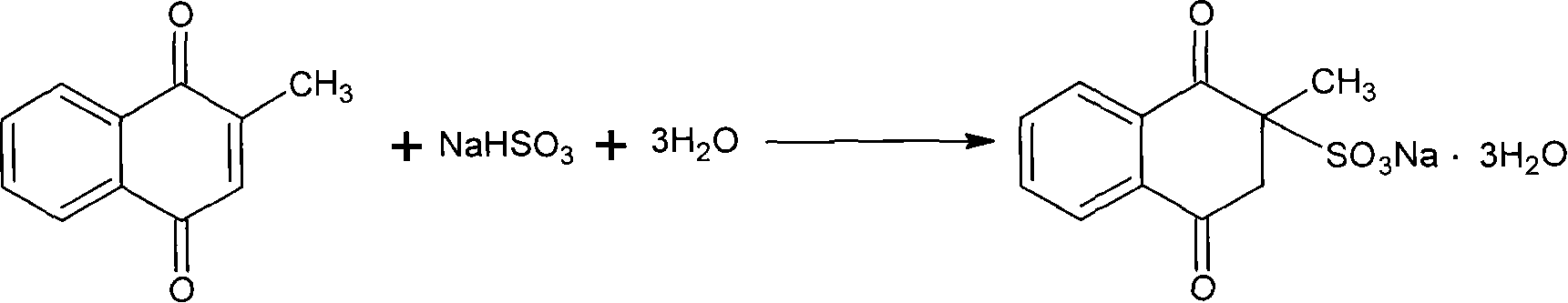

Method used

Image

Examples

Embodiment 1

[0038] Add 500L of solvent water, 250kg of pure 2-methyl-1,4-naphthoquinone, and 225kg of sodium bisulfite into a 1000L reactor, start stirring, raise the temperature to 40-50°C, react for 120 minutes, and feed into the addition crystallization kettle , frozen to below 10°C, incubated for 120 minutes to crystallize, and centrifuged to obtain 390kg of MSB crude wet product. Throw the wet MSB crude product into a 2000L reactor, add 1200L of ethanol, 12kg of activated carbon, and 12kg of sodium bisulfite, heat to 70°C, keep stirring for 30 minutes, filter while it is hot, wash the filter with hot ethanol, and discharge the filtrate and lotion to Refining the crystallization kettle, freezing to below 10°C, insulated for crystallization for 60 minutes, centrifugal separation, washing the crystallization with cold ethanol, centrifugal separation, and drying the crystallization at 50°C to obtain 296kg of MSB product, the yield was 61.7%, and the product purity was greater than or equa...

Embodiment 2

[0040] Put 550L of addition reaction mother liquor, 220kg of 2-methyl-1,4-naphthoquinone, and 195kg of sodium bisulfite into the 1000L reactor, start stirring, raise the temperature to 45°C, react for 120 minutes, and feed until addition The crystallization kettle was frozen to below 10°C, incubated for 120 minutes for crystallization, and centrifuged to obtain 390kg of wet MSB crude product. Throw the wet MSB crude product into a 2000L reactor, add 1200L batch of refined mother liquor, 12kg of activated carbon, and 12kg of sodium bisulfite, heat to 70°C, keep stirring for 30 minutes, filter while it is hot, wash the filter with hot ethanol, discharge the filtrate and Put the washing liquid into a refined crystallization kettle, freeze to below 10°C, insulate and crystallize for 60 minutes, centrifuge, wash the crystals with cold ethanol, centrifuge, and dry the crystals at 50°C to obtain 274kg of MSB product with a yield of 65.0% and a product purity of ≥50% ( Calculated as 2...

Embodiment 3

[0042] Put 255kg of nicotinamide and 215kg of 35% hydrochloric acid into the 2000L reactor, turn on the machine and stir, keep the reaction at 25°C for 30 minutes, put in 700L of MSB addition reaction mother liquor (equivalent to MSB550g), and keep it at 25°C for 120 minutes. Add the material to the crystallization kettle, freeze to below ℃, insulate and crystallize for 120 minutes, centrifuge, wash and crystallize three times, and dry at 50°C to obtain 570kg of MNB with a yield of 91.0% and a product purity of ≥50% (based on 2-methyl-1,4 - Naphthoquinone meter).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com