Patents

Literature

237 results about "Gln - Glutamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

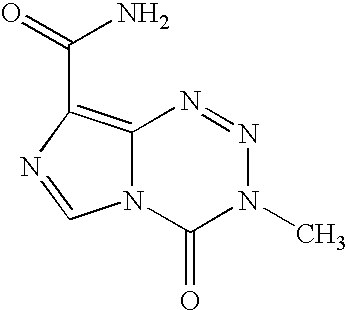

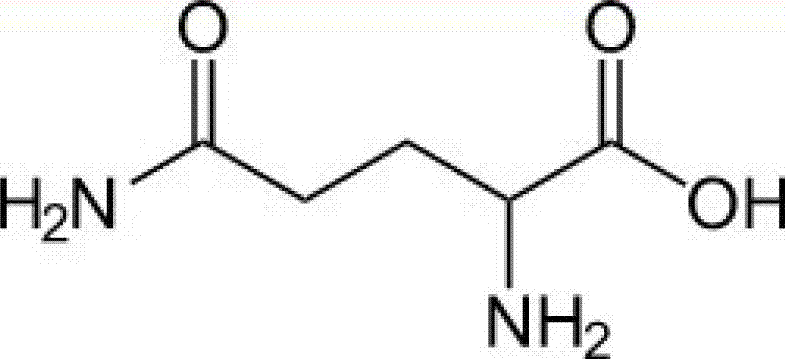

Glutamine (symbol Gln or Q) is an α-amino acid that is used in the biosynthesis of proteins. Its side chain is similar to that of glutamic acid, except the carboxylic acid group is replaced by an amide.

Polypeptide production in animal cell culture

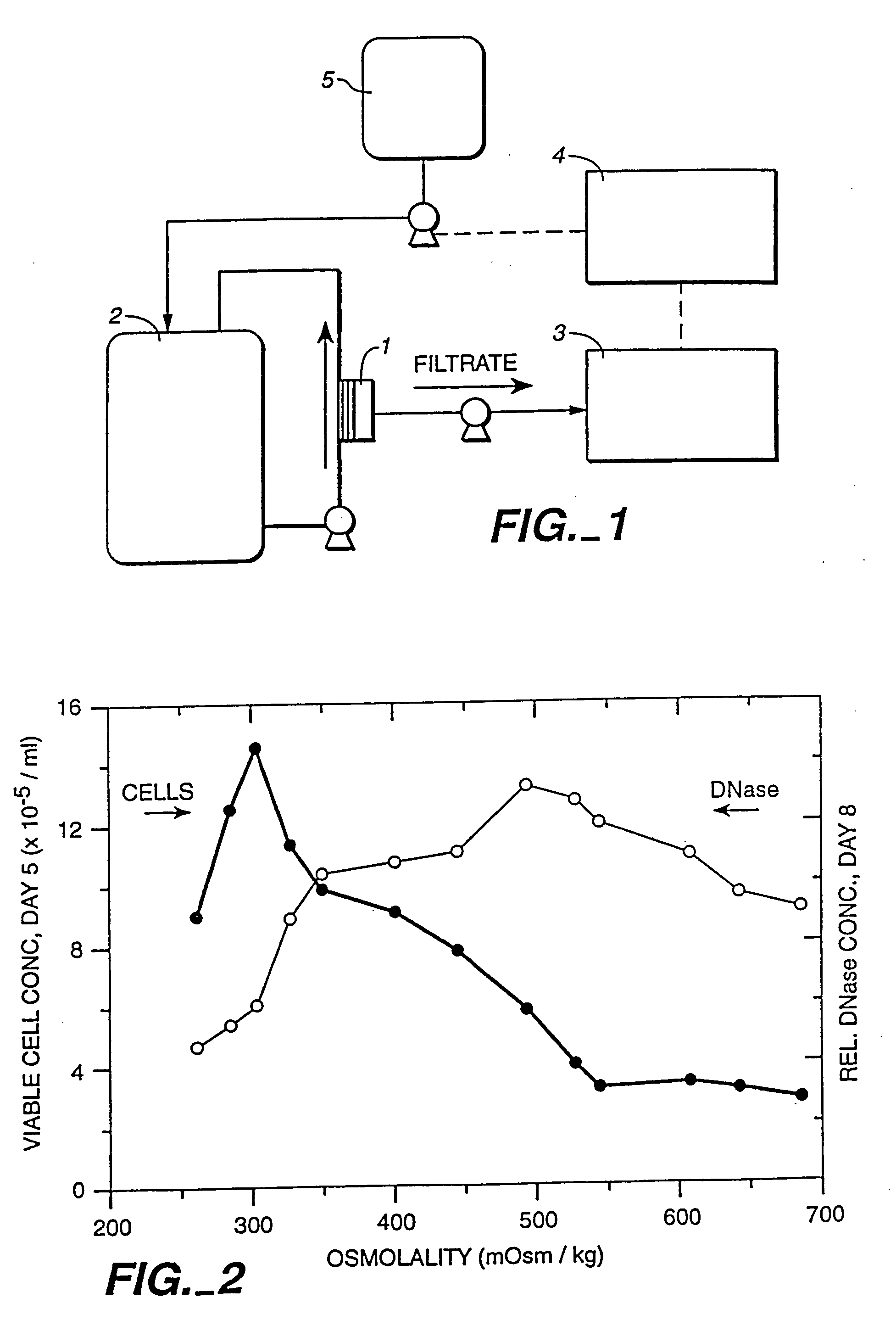

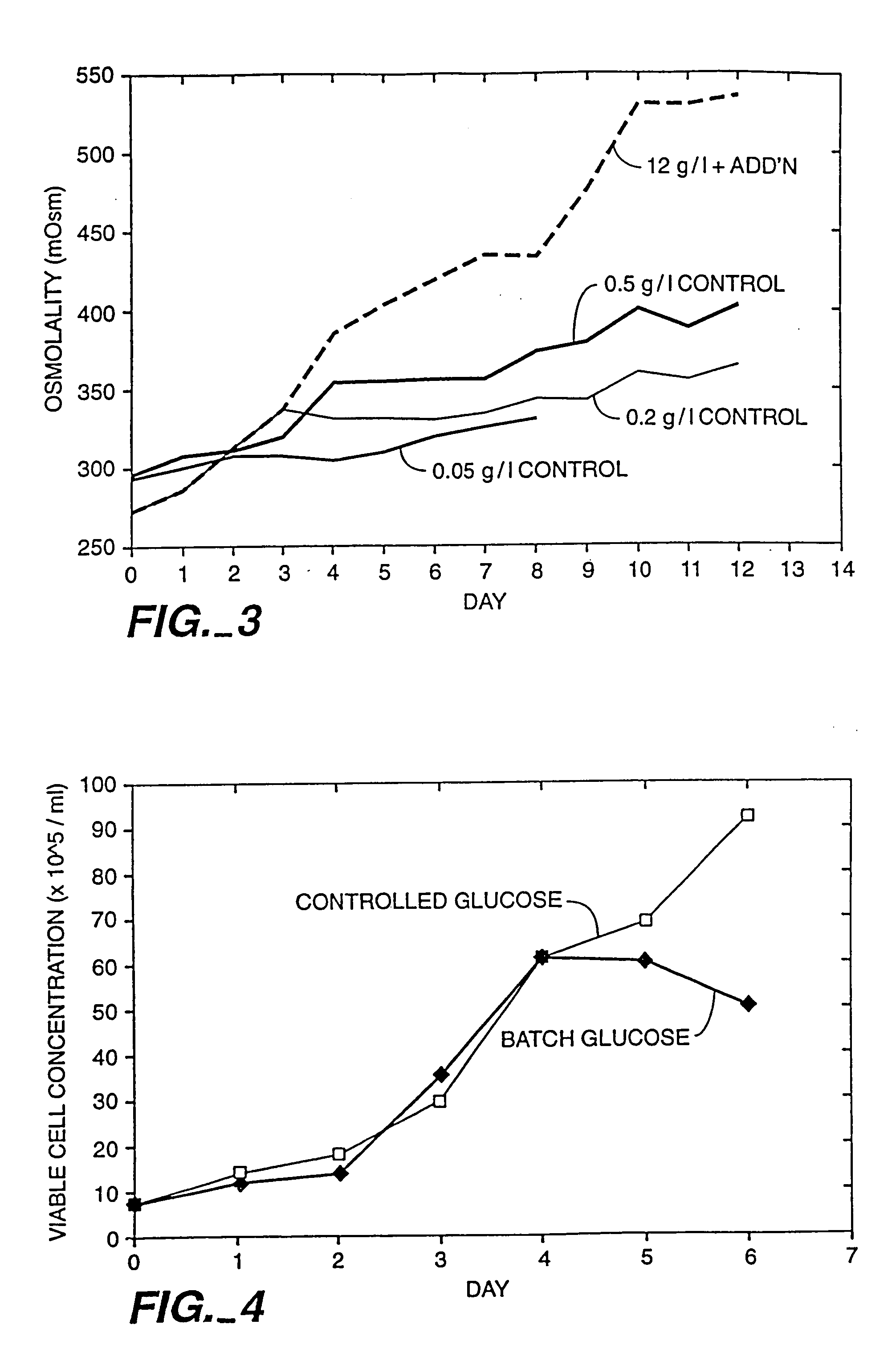

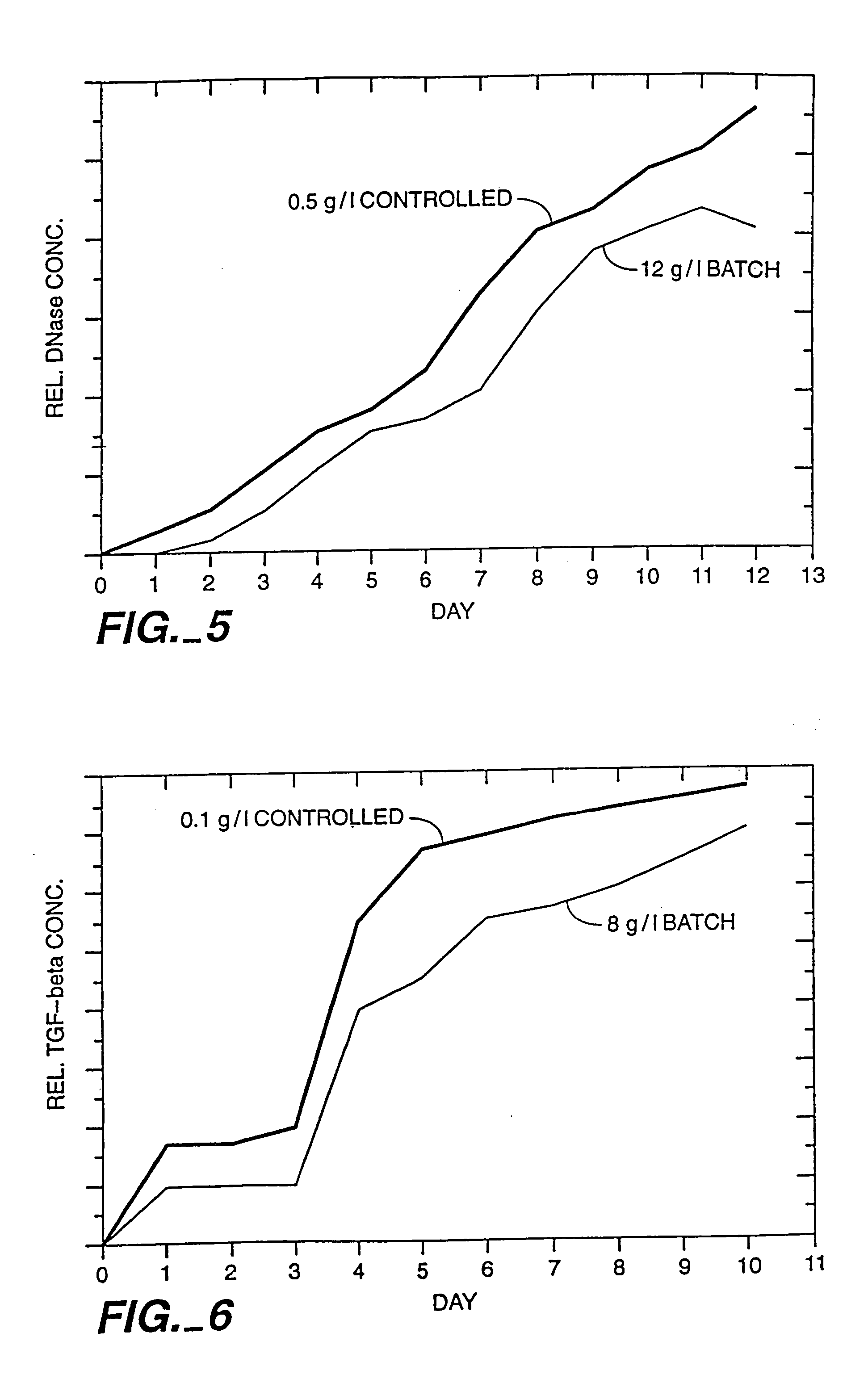

InactiveUS20050272124A1Promote cell growthHigh protein yieldGenetically modified cellsCulture processBiotechnologyGrowth phase

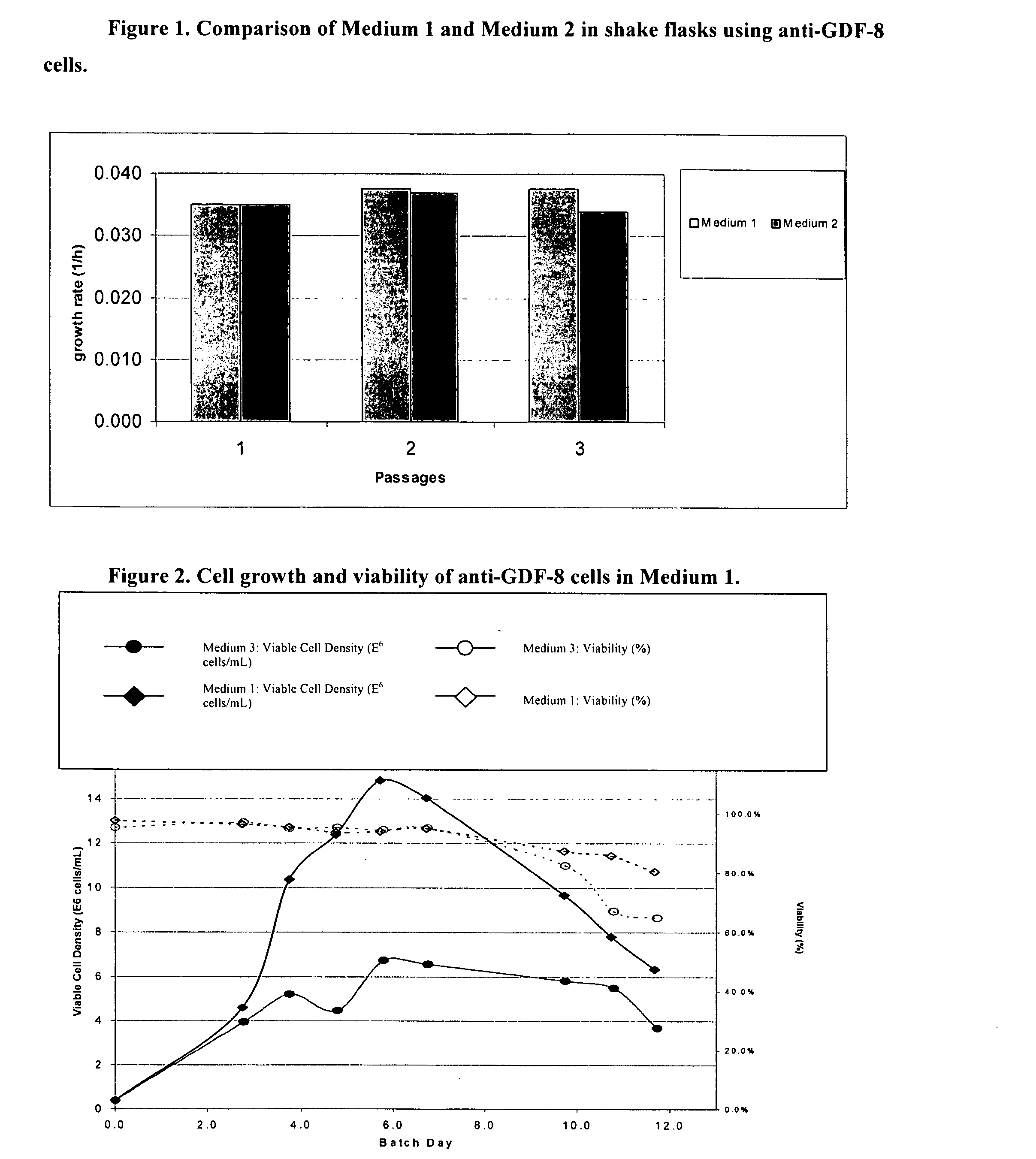

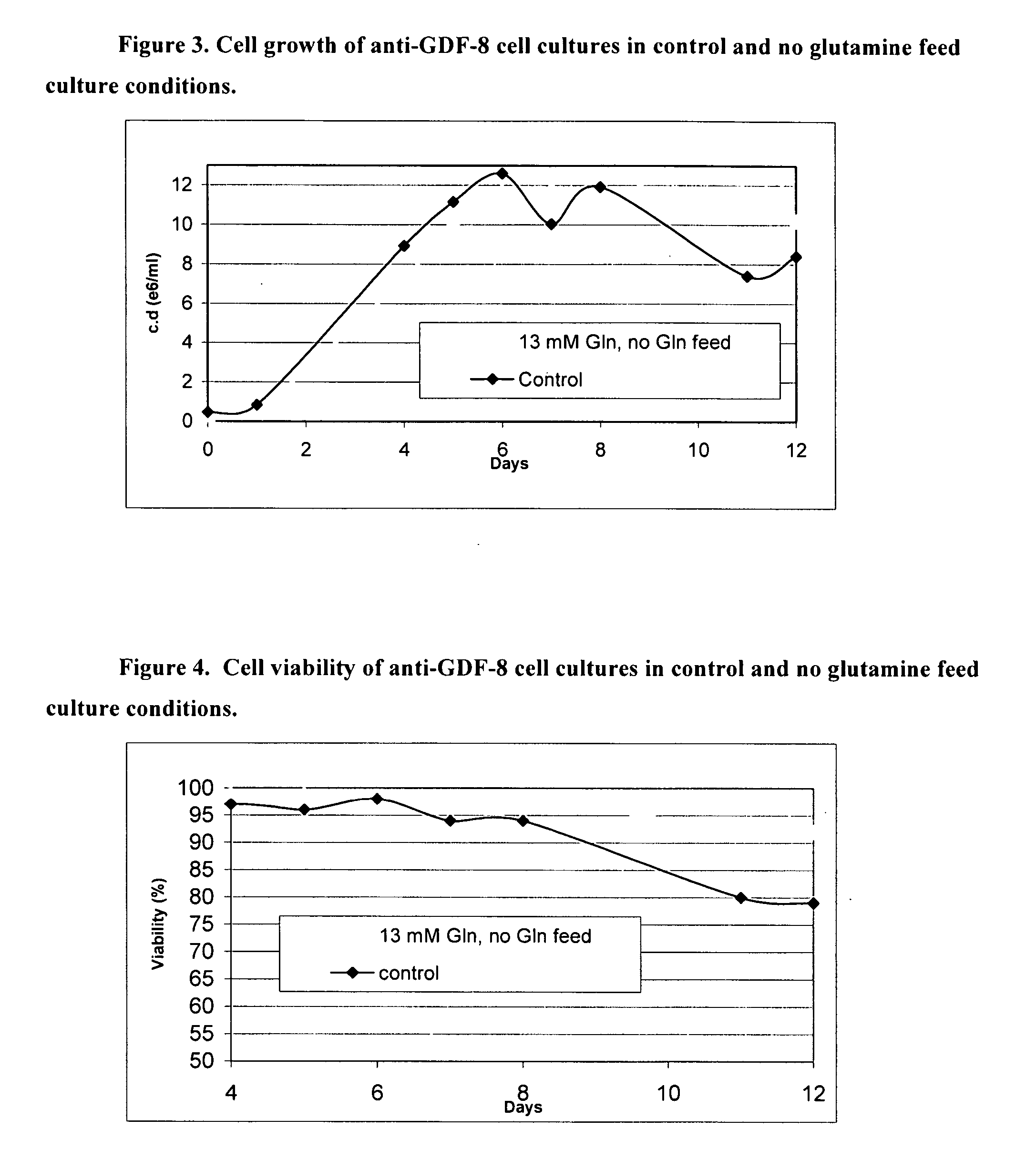

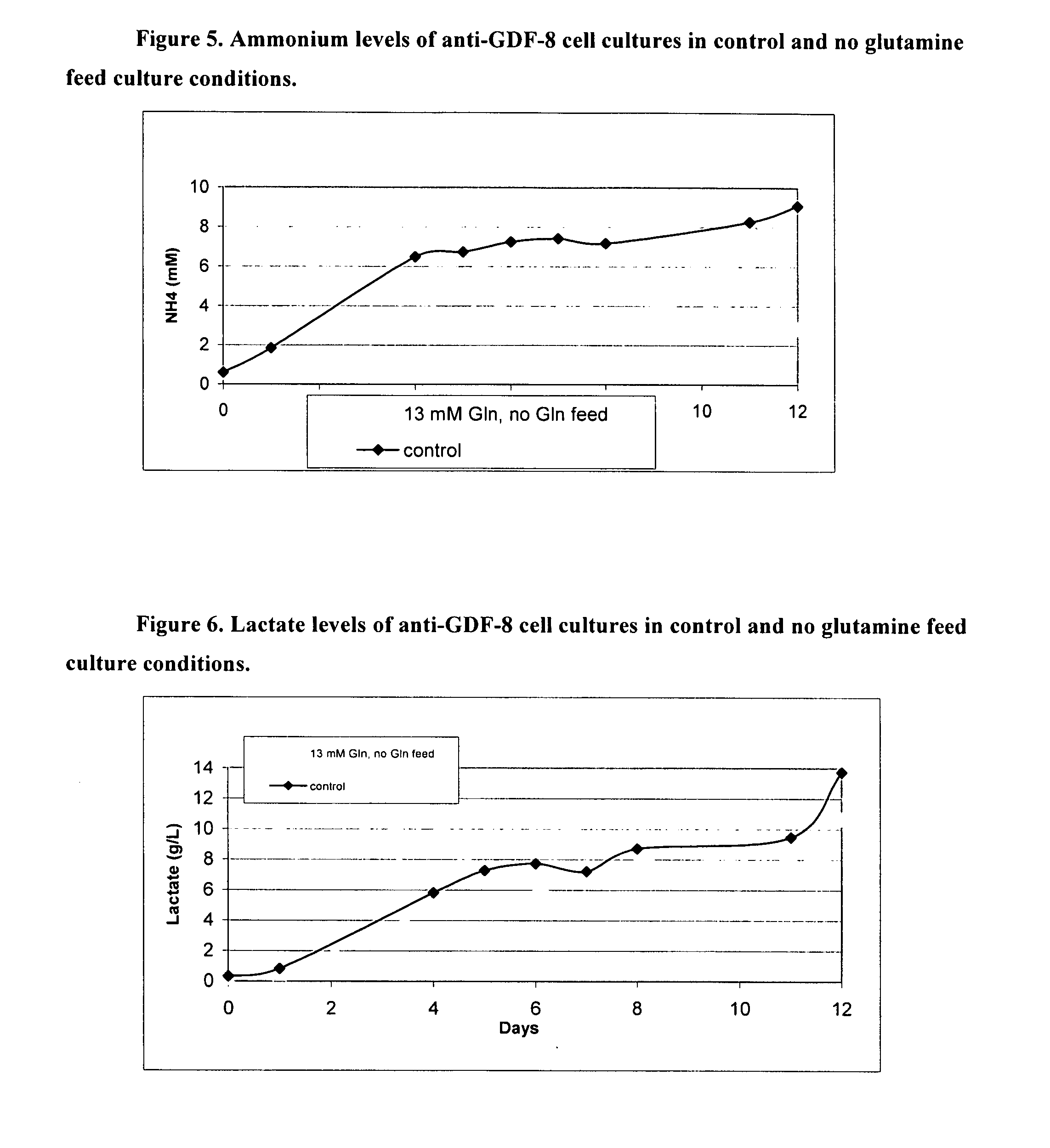

A method of producing a polypeptide in fed batch cell culture is provided which involves an initial cell growth phase and a distinct production phase. In the initial growth stage, animal cells having nucleic acid encoding the polypeptide are cultured at a starting osmolality of about 280-330 mOsm in the presence of a concentration of glucose controlled throughout the culturing to be within a range between about 0.01 and 1 g / L. This is followed by a production phase, where the cultured animal cells of the growth phase are inoculated at a cell seed density of at least 1.0×106 cells / mL and the cells are cultured at a starting osmolarity of about 400-600 mOsm in the presence of a concentration of glucose controlled throughout the culturing to be within a range between about 0.01 and 1 g / L. Preferably, the glutamine concentration in the cell culture medium is simultaneously controlled in order to curtail production of lactic acid and ammonia which result from unnecessarily high glutamine concentrations. During the growth phase, production of potentially detrimental metabolic waste products, such as lactic acid, is controlled thereby curtailing the increase of osmolality due to accumulation and neutralization of waste products. Thus, the cell growth can be improved. In the production phase, the cell culture conditions are modified in order to arrest or reduce cell growth and thereby direct nutrient utilization toward production, as opposed to cell growth. Overall, it is intended that the method results in an improvement in specific productivity, reduction in production run times and / or an increase in final product concentration.

Owner:GENENTECH INC

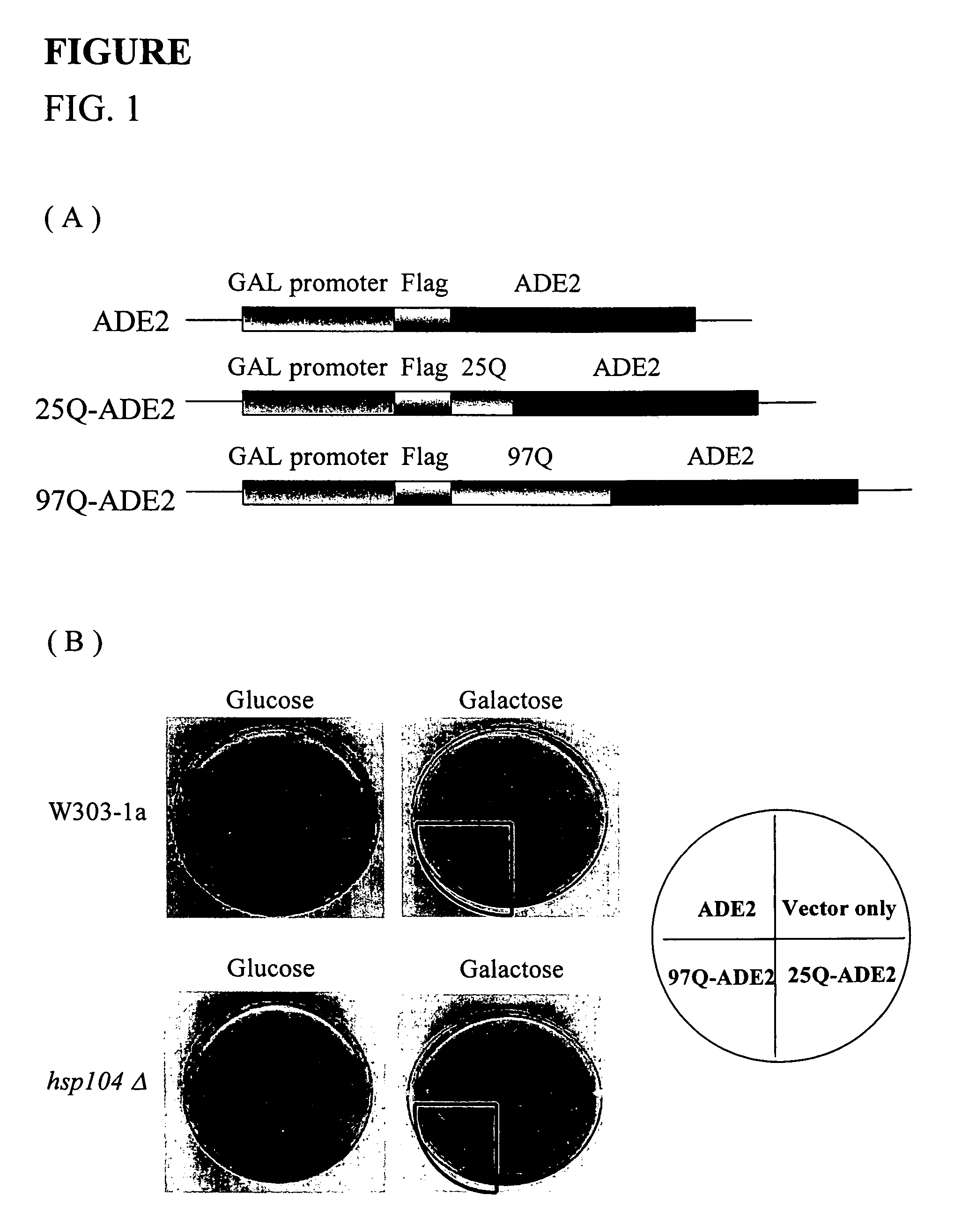

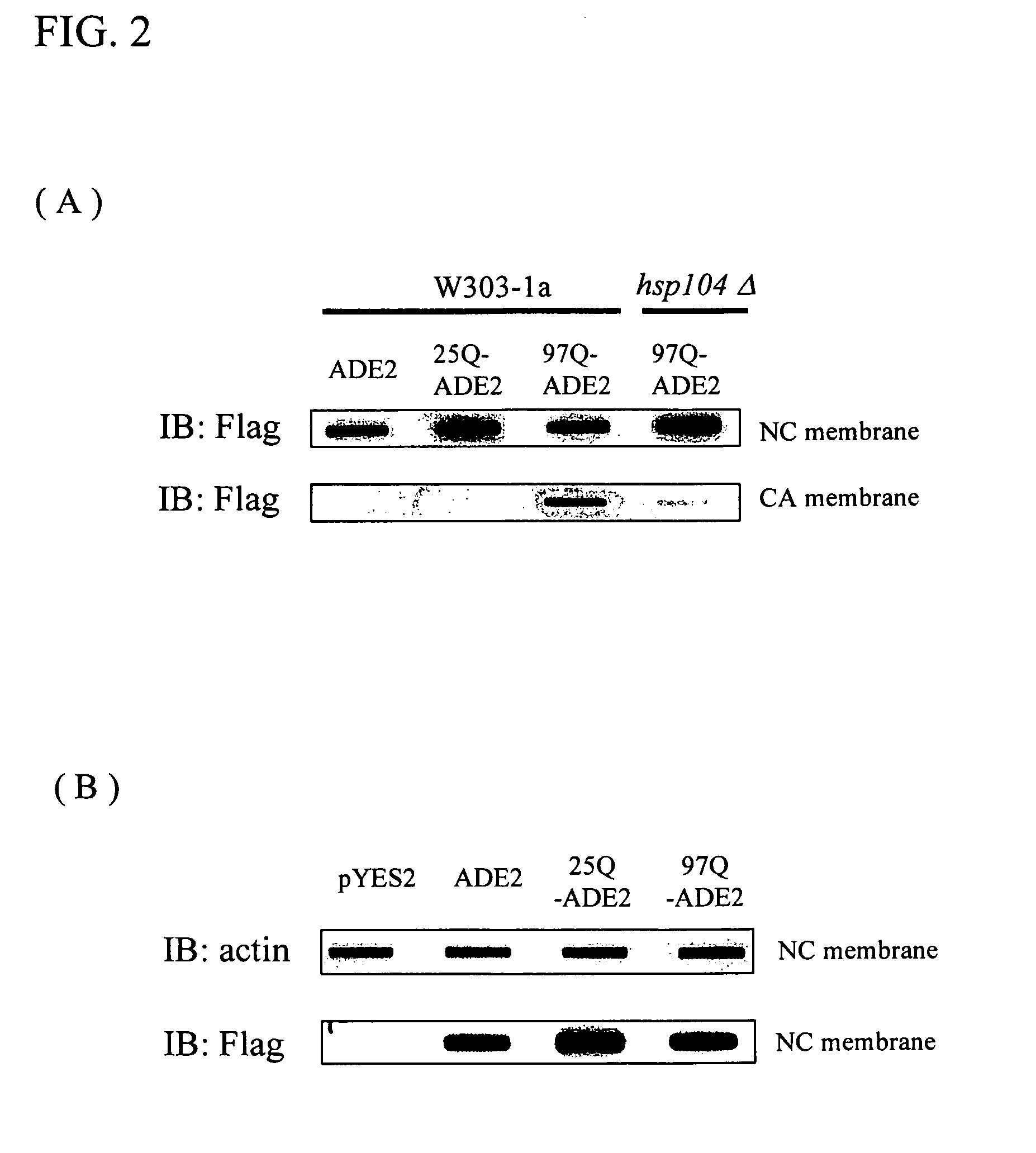

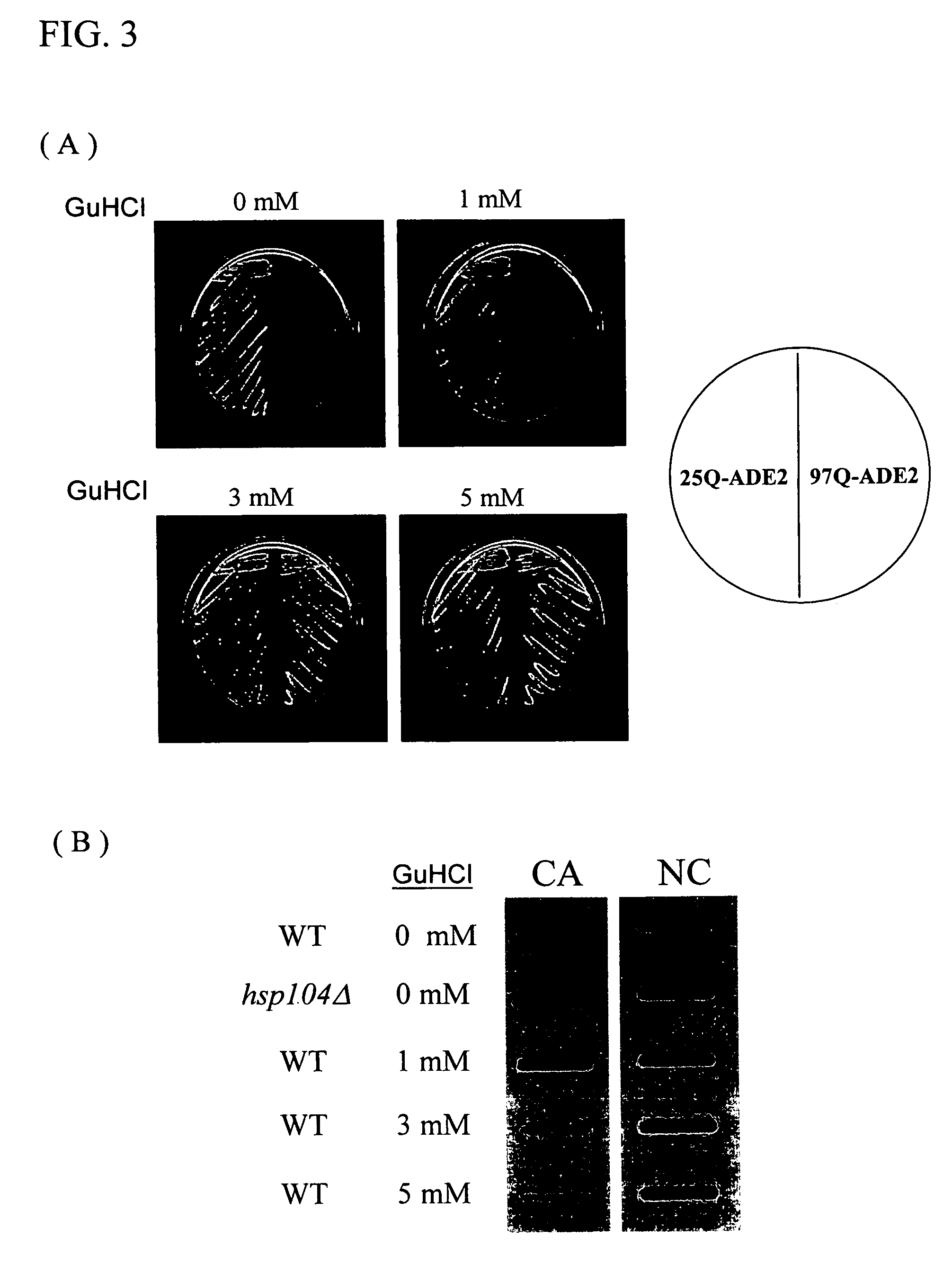

Recombinant protein and method of screening for agents that modulate polypeptide aggregation

Owner:NATIONAL YANG MING UNIVERSITY

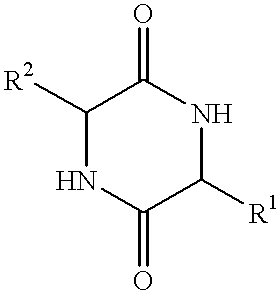

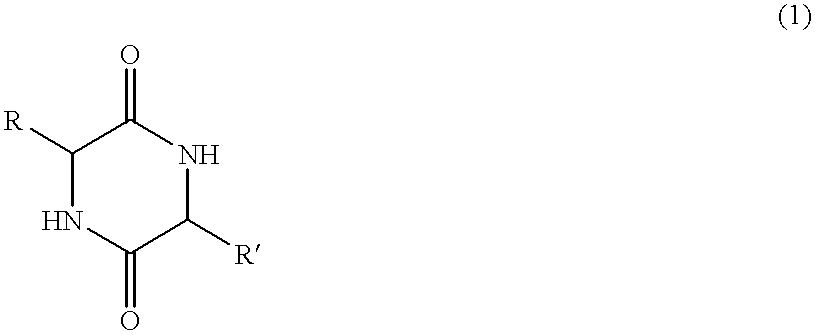

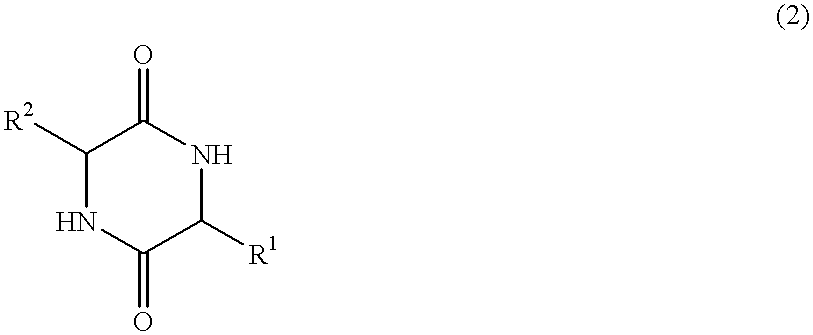

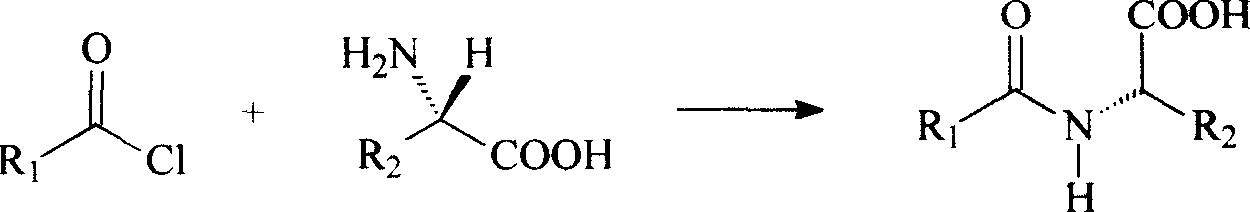

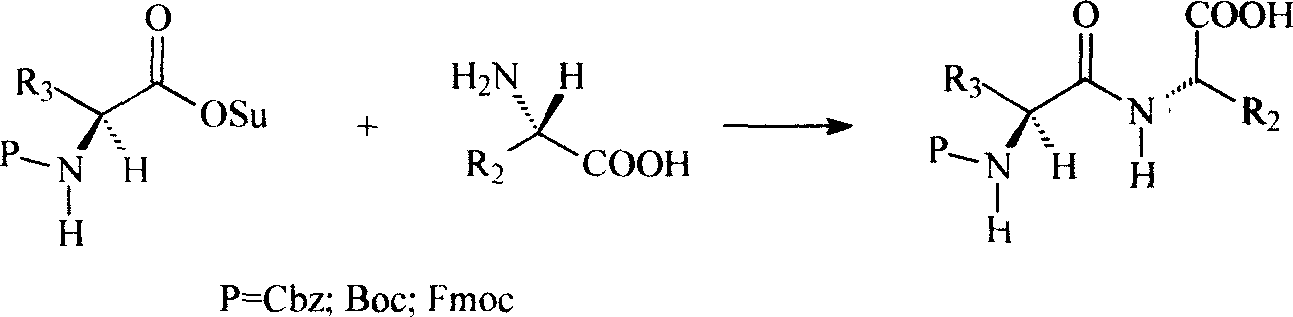

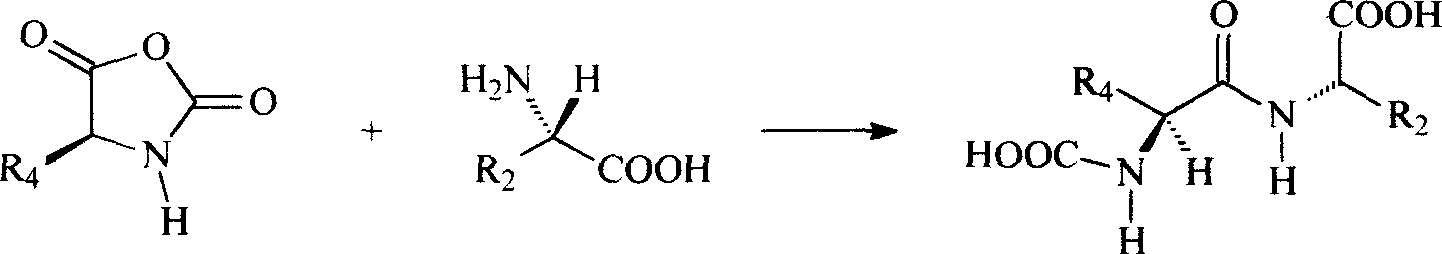

Method of synthesizing diketopiperazines

InactiveUS6967202B2Prevent unwanted side reactionInhibit side effectsOrganic active ingredientsDipeptide ingredientsSide chainTyrosine

The invention provides a method of synthesizing a diketopiperazine of the formula: wherein:R1 is —CH2COR3, or —CH2CH2COR3;R2 is the side chain of an amino acid selected from the group consisting of glycine, alanine, valine, leucine, isoleucine, serine, threonine, aspartic acid, asparagine, glutamic acid, glutamine, lysine, hydroxylysine, histidine, arginine, phenylalanine, tyrosine, tryptophan, thyroxine, cysteine, methionine, norvaline and ornithine;R3 is —OH, —NH2, —OR4, —NHR4, or —NR4R4; andeach R4 is independently an alkyl, aryl, alkylaryl, or arylalkyl.

Owner:AMPIO PHARMA

Production of alpha-ABeta

InactiveUS20060160180A1Reduce accumulationHigh level of proteinAntibody mimetics/scaffoldsImmunoglobulins against growth factorsTotal amino acidsInorganic ions

An improved system for large scale production of proteins and / or polypeptides in cell culture, particularly in media characterized by one or more of: i) a cumulative amino acid concentration greater than about 70 mM; ii) a molar cumulative glutamine to cumulative asparagine ratio of less than about 2; iii) a molar cumulative glutamine to cumulative total amino acid ratio of less than about 0.2; iv) a molar cumulative inorganic ion to cumulative total amino acid ratio between about 0.4 to 1; or v) a combined cumulative glutamine and cumulative asparagine concentration between about 16 and 36 mM, is provided. The use of such a system allows high levels of protein production and lessens accumulation of certain undesirable factors such as ammonium and / or lactate. Additionally, culture methods including a temperature shift, typically including a decrease in temperature when the culture has reached about 20-80% of it maximal cell density, are provided. Alternatively or additionally, the present invention provides methods such that, after reaching a peak, lactate and / or ammonium levels in the culture decrease over time.

Owner:PFIZER IRELAND PHARM CORP

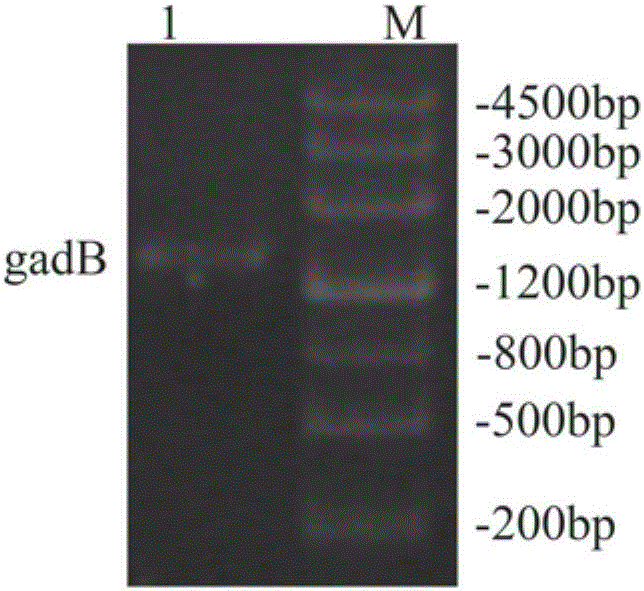

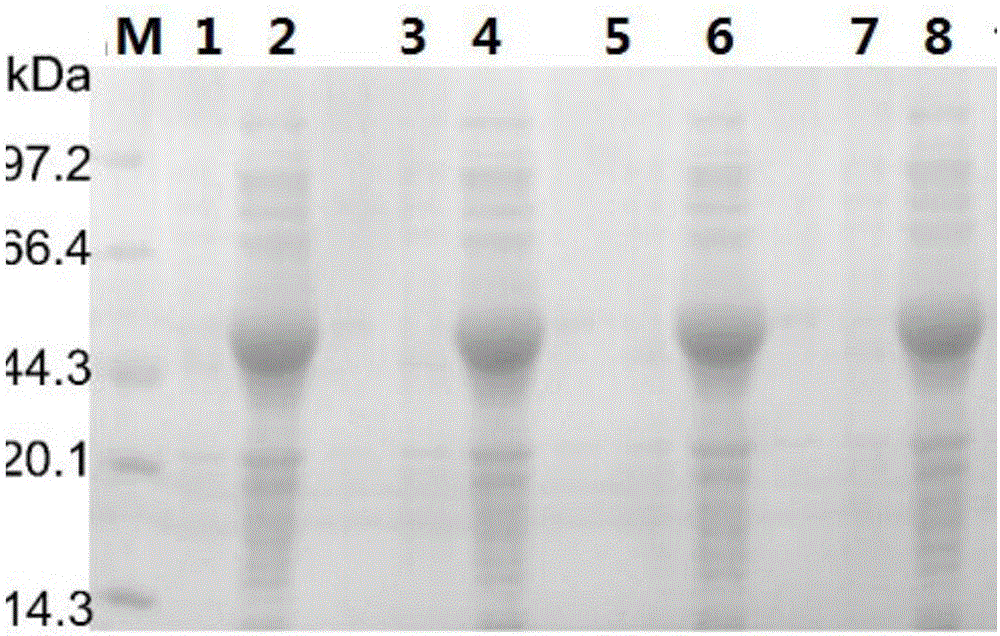

Glutamate decarboxylase mutant with improved thermal stability and application thereof

ActiveCN106754850AImprove the stability of enzyme activitySuitable for industrial production needsFermentationGenetic engineeringEscherichia coliGlutamate decarboxylase

The invention relates to a glutamate decarboxylase mutant with improved thermal stability and an application thereof, belonging to the field of bioengineering. The mutant is prepared primarily by the following steps: performing saturated mutation of glutamine Q, valine V and threonine T on the sites 5-7 of the amino acid sequence of glutamate decarboxylase, and screening to obtain high-stability mutants Q5E / V6S / T7V, Q5Y / V6R / T7K and Q5N / V6Y / T7V. In the glutamate decarboxylase mutant prepared in the invention, the half-inactivation temperature is 45-50.5 DEG C which is 4.9-10.2 DEG C higher than that of wild type mutant; and the half-life period at 45 DEG C is 76-129min, which is 3.2-4.3 times higher than 24min of wild type mutant. By transforming glutamic acid for 12h with the whole cell of glutamate decarboxylase mutant synthesized from recombinant escherichia coli, 260-350g / L gamma-aminobutyric acid (GABA) can be obtained, and the molar yield is 76.6-97.8%. In the glutamate decarboxylase mutant prepared in the invention, the thermal stability is obviously improved, the production of gamma-aminobutyric acid is facilitated, and a foundation is laid for efficient synthesis of gamma-aminobutyric acid.

Owner:EAST CHINA UNIV OF SCI & TECH

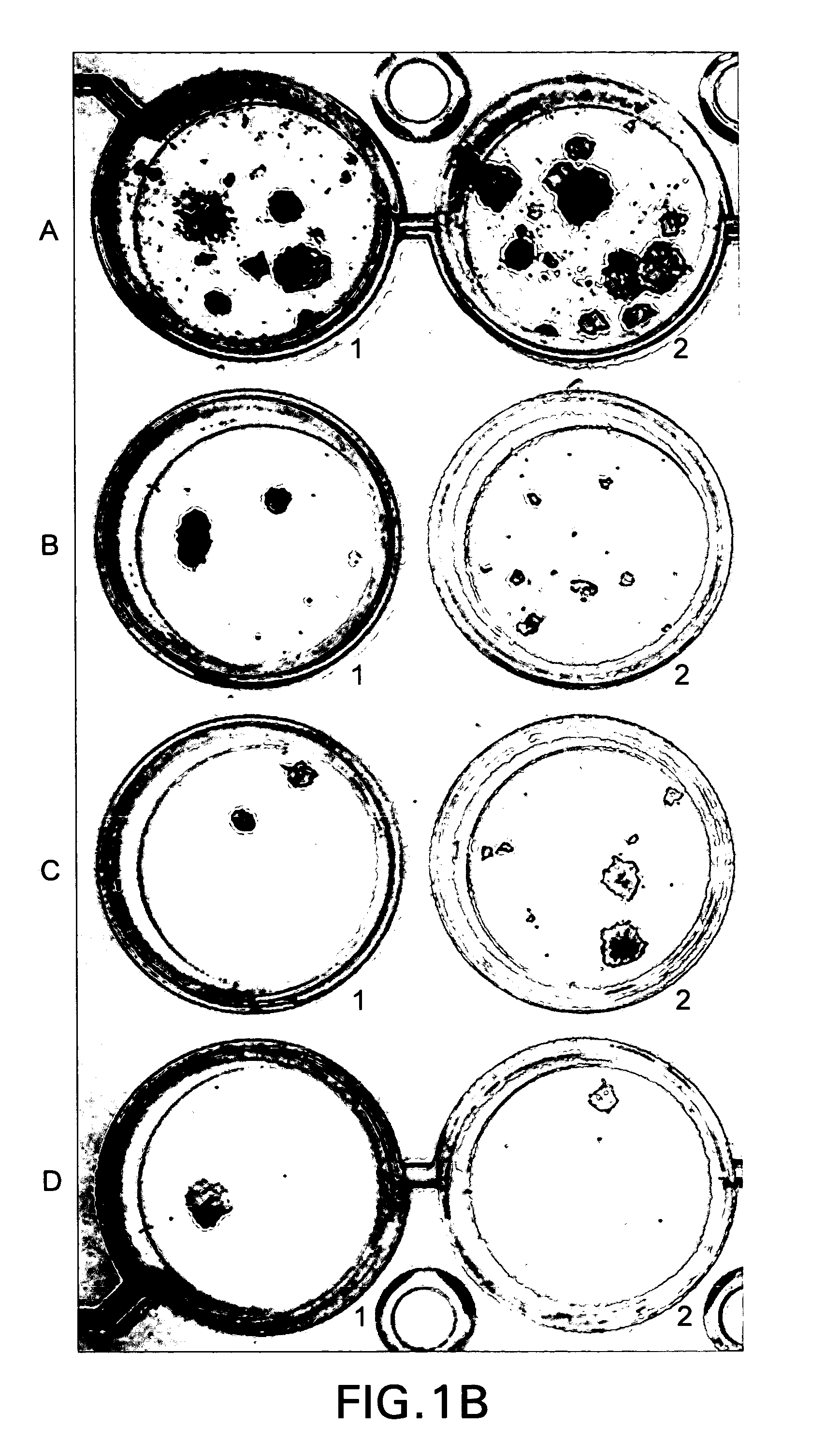

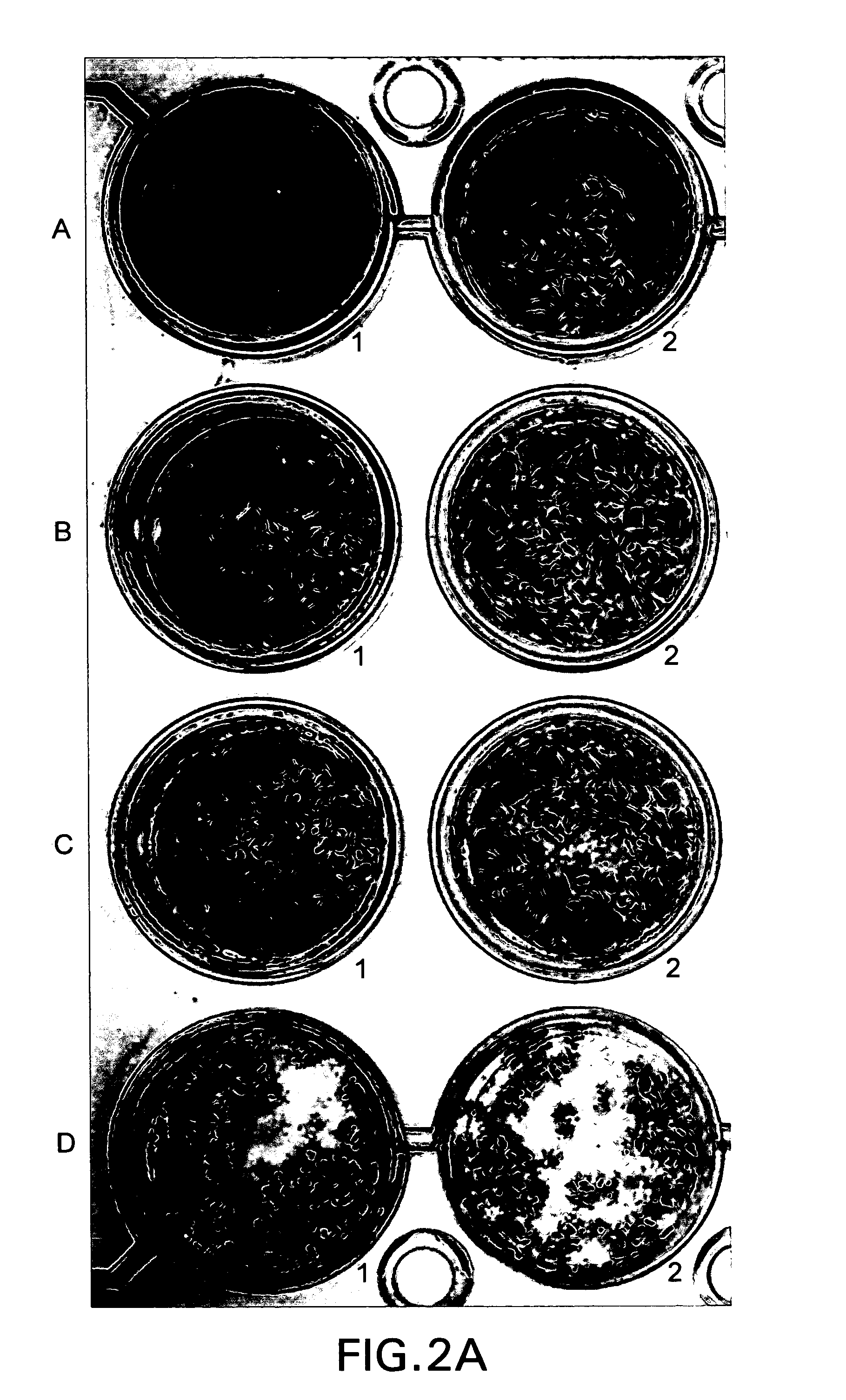

Method for selectively culturing epithelial or carcinoma cells

A method for selectively growing epithelial cells or carcinoma cells in vitro without fibroblast overgrowth comprises (a) suspending a cell pellet comprising digested epithelial or carcinoma cells in a first growth medium, the medium comprising D-valine MEM, methyl cellulose, fetal serum, glutamine and an antibiotic; wherein the methyl cellulose is present in the medium at a concentration sufficient to inhibit growth of fibroblast cells present in the cell pellet; (b) adding the suspension to a cell culture vessel comprising an inner surface which has been at least partially coated with an attachment medium comprising a protein extract, D-valine MEM, glutamine and an antibiotic; and (c) incubating the suspension in the coated vessel to allow selective growth of the epithelial cells or carcinoma cells.

Owner:HEAD JONATHAN F +1

Preparation method of N(2)-L-alanyl-L-glutamine

InactiveCN101062938ASimple processEasy to operatePeptide preparation methodsBulk chemical productionL-alanyl-l-glutamineDipeptide

The invention discloses a preparing method of N(2)-L-alanyl-L-glutamine, which comprises the following steps: producing precursor acid potassium; producing mixed acid anhydride; producing glutamine sodium salt; producing N(2)-L-alanyl-L-glutamine (ala paddy dipeptide); refining. This invention possesses the advantages of simple craft, convenient operation and little contamination.

Owner:福建三爱药业有限公司

L-Amino Acid-Producing Bacterium and a Method for Producing L-Amino Acid

ActiveUS20070254345A1Improved ability to produce L-amino acidsEfficient productionBacteriaFermentationArginineL-Glutamin

Coryneform bacteria are described that have an ability to produce L-amino acids and are modified so that acetyl-CoA hydrolase activity is decreased. The bacteria are used to produce L-amino acids generated by a biosynthetic pathway in which pyruvic acid is an intermediate, such as L-glutamic acid, L-arginine, L-glutamine, L-proline, L-alanine, L-valine, and L-lysine.

Owner:AJINOMOTO CO INC

Intra-intestinal nutrient emulsion for tumor patients

InactiveCN103609933ANutritional balanceRecovery functionMetabolism disorderEmulsion deliveryNutritionTryptophan

The invention belongs to the medicine field, and specifically relates to an intra-intestinal nutrient emulsion for tumor patients. The emulsion is characterized by comprises the following effective components: protein, fat, carbohydrate, total dietary fiber, green tea theine, taurine, L-carnitine, composite vitamins and mineral substances, and water. The protein is provided in an amino acid powder form, the formula of the amino acid powder is adjusted on the basis of 20 kinds of protein amino acids, wherein methionine is replaced by homocysteine, glutamine and glutamic acid are not added, the tryptophan content is low, and the content of branched chain amino acid reaches 35% or more; fat is provided in a saturated aliphatic acid or unsaturated fatty acid form, wherein in the unsaturated aliphatic acid the value of omega-6 / omega-3 is equal to 2-6 / 1; and the carbohydrate is provided in a form of glycerin, glucose, fructo-oligosaccharide or lentinan. Besides one prominent characteristic of the emulsion is that the emulsion is a high-fat and low-sugar type, and the ratio of sugar to fat is 1:1. The emulsion formula is adjusted according to the nutrient and metabolism requirements of tumor patients so as to develop an individualized intra-intestinal nutrient preparation for tumor patients, the preparation can provide balanced nutrients for tumor patients, effectively cures the malnutrition symptom, improves the life quality of patients, and can also be used to assist the tumor treatment.

Owner:湖北一半天制药有限公司

Alpha-amylase variants having an elevated solvent stability, method for the production thereof and detergents and cleansers containing these alpha-amylase variants

ActiveUS20070190632A1Improve instabilityGood limitSugar derivativesBiochemical fibre treatmentSolventChemistry

The present invention relates to α-amylase variants that are stabilized to solvent-exerted hydrolysis, in particular at elevated temperatures or high pH, by point mutagenesis of asparagine (N) or glutamine (Q) residues located on the surface of the molecule to give other amino acid residues. The invention further relates to methods of increasing the stability of an α-amylase to solvent-exerted hydrolysis, in particular at elevated temperatures or high pH, whereby at least one asparagine (N) or glutamine (Q) residue on the surface of the molecule is replaced with a different amino acid residue. The α-amylase variants obtained thereby exhibit better stability to influences of the solvent, increased processivity, and are suited for numerous industrial areas of use, in particular as active ingredients in detergents and cleansers.

Owner:HENKEL KGAA

Bovine oocyte in-vitro fertilization and embryo culture method and transport culture solution

The invention relates to a bovine oocyte in-vitro fertilization and embryo culture method, and a transport culture solution. On one hand, the transport culture solution comprises glycine, alanine, arginine hydrochloride, aspartic acid, cystine dihydrochloride, glutamic acid, L-glutamine, histidine, threonine, tryptophan, tyrosine, valine, ascorbic acid, biotin, choline chloride, calcium pantothenate, folic acid, menadione and the like. The bovine oocyte in-vitro fertilization and embryo culture method comprises the following steps: oocyte collection and in-vitro maturation, in-vitro fertilization, and embryo in-vitro culture and preservation. The method and the related transport culture solution have excellent technical effects as described in the specification.

Owner:天津力牧生物科技有限公司

Pharmaceutical formulations of antineoplastic agents and processes of making and using the same

In its several embodiments, this invention discloses a pharmaceutical formulation comprising at least one antineoplastic agent or a pharmaceutically acceptable salt thereof, and at least one dissolution enhancing agent sufficient to substantially dissolve said at least one antineoplastic agent in at least one aqueous diluent, wherein said dissolution enhancing agent is urea, L-histidine, L-threonine, L-asparagine, L-serine, L-glutamine or mixtures thereof; a lyophilized powder comprising said pharmaceutical formulation, and articles of manufacture thereof.

Owner:MERCK SHARP & DOHME LLC

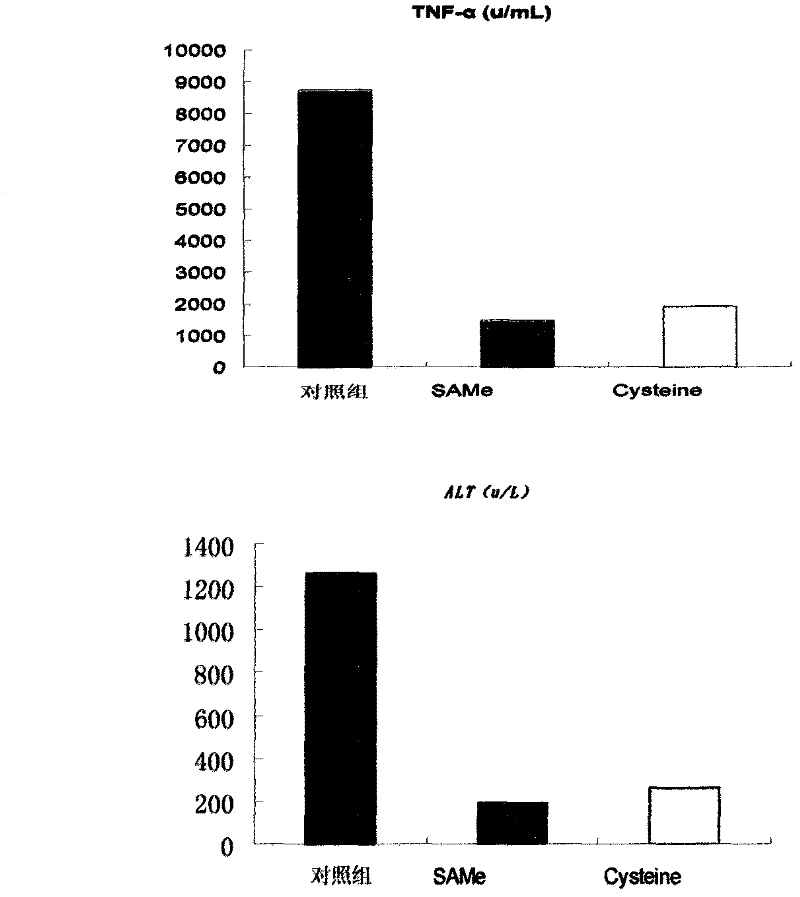

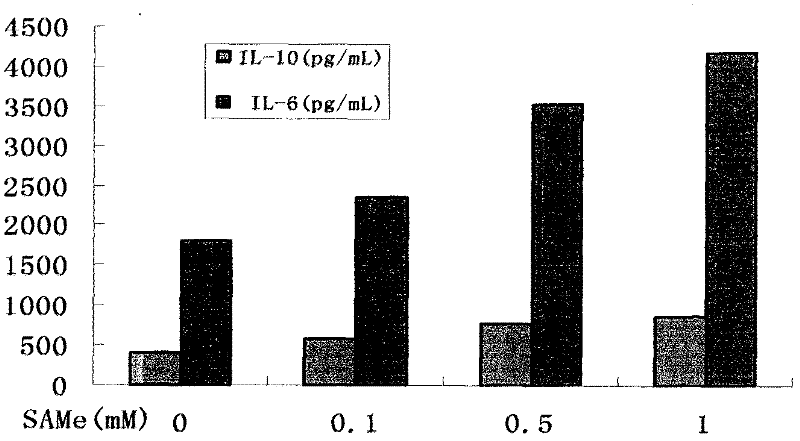

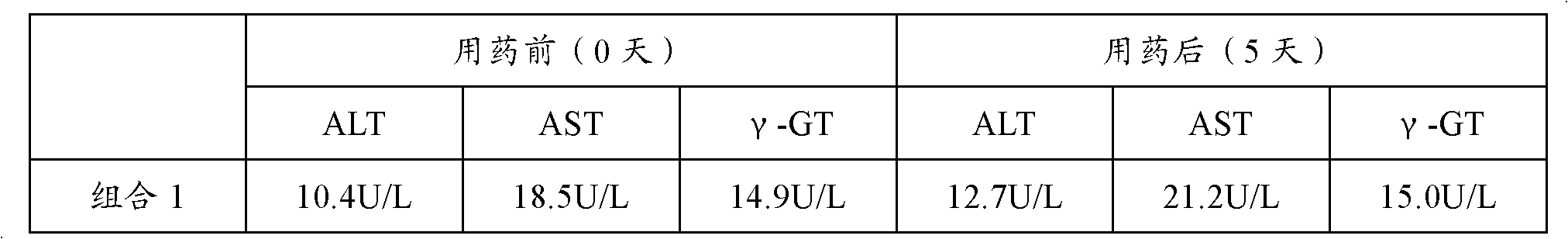

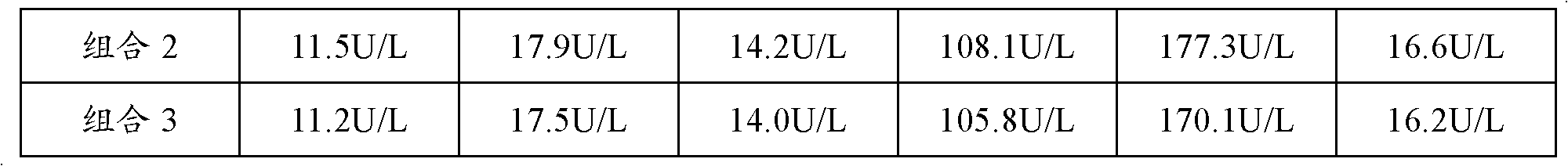

Composite biological preparation with obvious chemical hepatic injury protecting function

InactiveCN102327259AMetabolic Stabilization and RegulationInhibition releaseOrganic active ingredientsDigestive systemS-Adenosyl-l-methionineAdenosine

The invention relates to a composite biological preparation with an obvious chemical hepatic injury protecting function, which consists of the following raw materials in weight ratio: 15-18 parts of glycine, 12-15 parts of arginine, 15-18 parts of cysteine, 16-18 parts of glutamine, 7-10 parts of S-adenosylmethionine and 7-12 parts of alpha-lipoic acid. The composite biological preparation has favorable therapeutic action and prevention action to all hepatic injury caused by various reasons, and has the effective rate (effectual rate) of 98.6% and the cure rate of 76.8%.

Owner:姜国辉

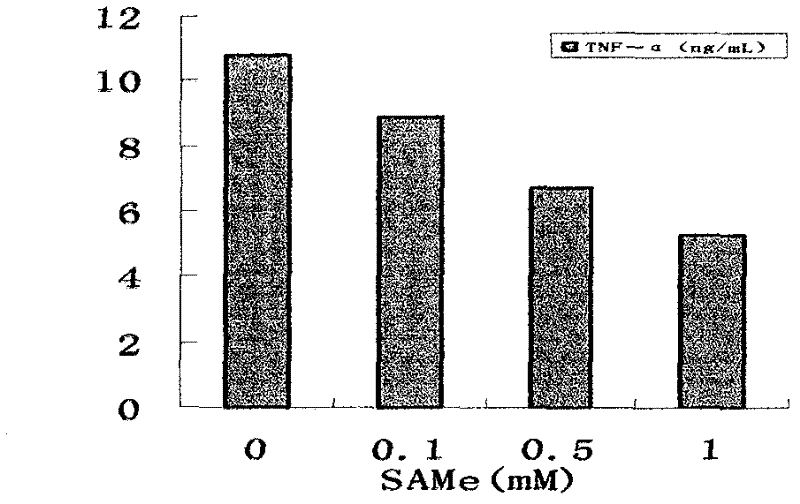

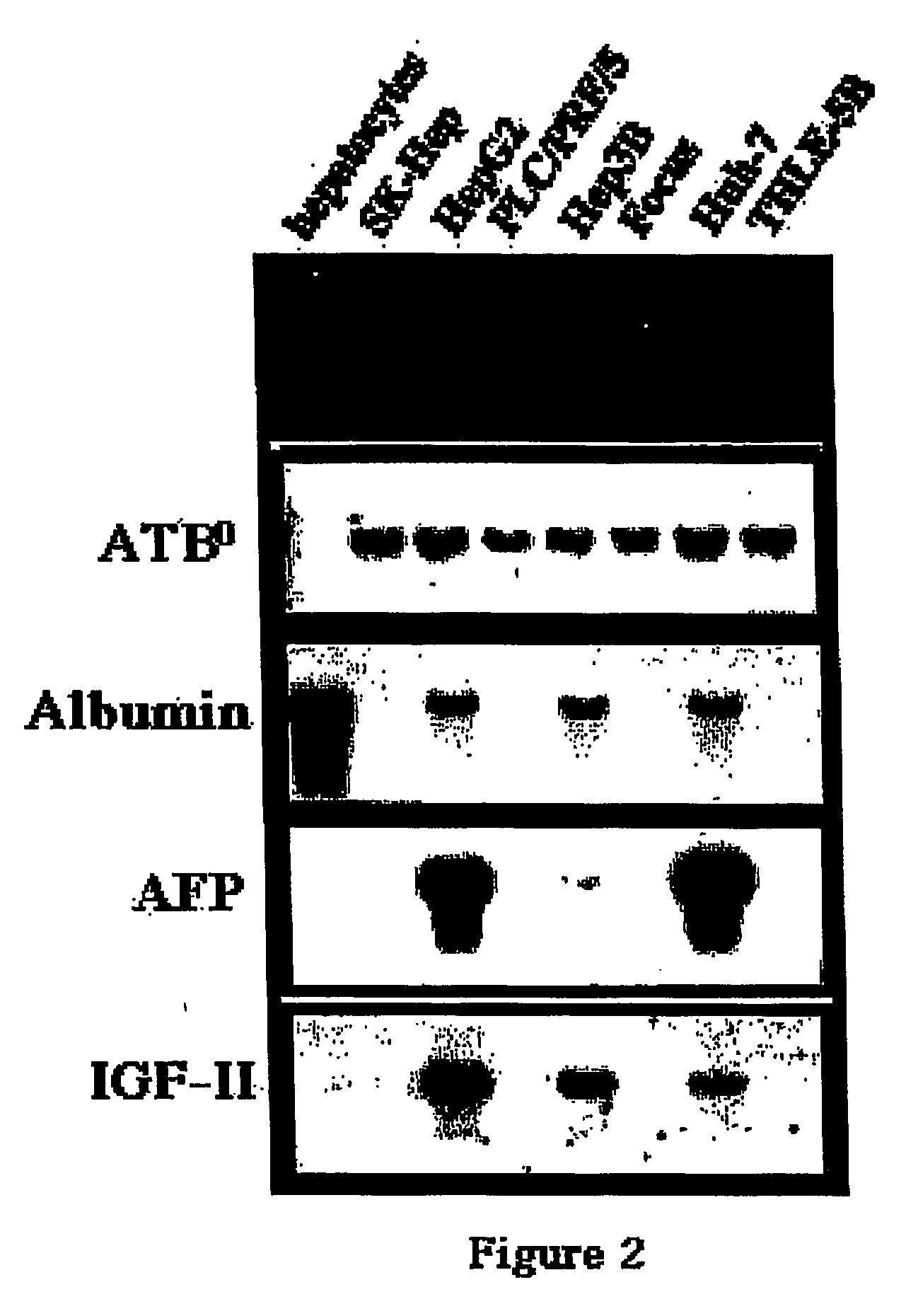

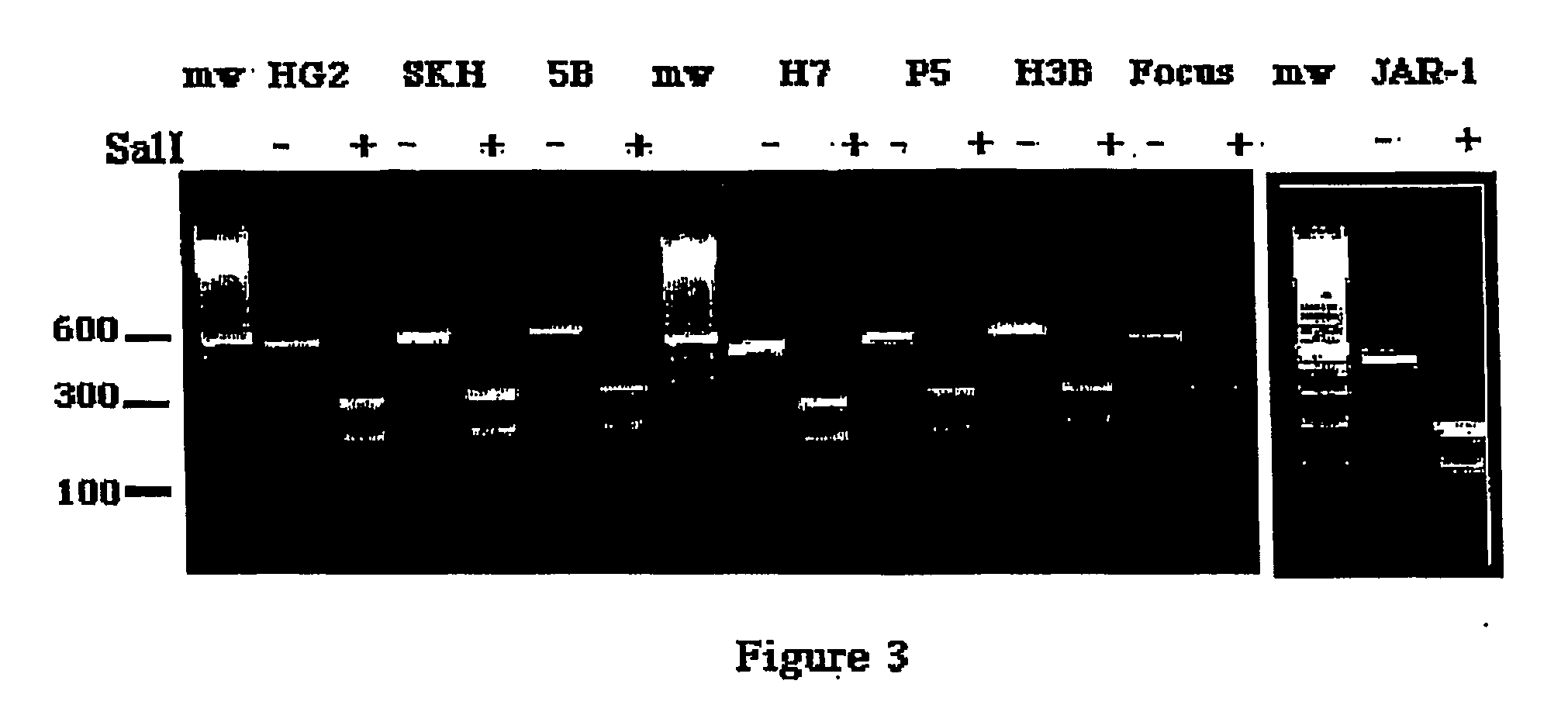

Compositions and methods of treating and diagnosing hepatoma

InactiveUS20060280725A1Reduced uptakeReduces glutamine uptakeBiocideGenetic material ingredientsNucleotideApoptosis

Disclosed are pharmaceutical compositions and methods of treating hepatoma by administering to patients or other populations of cells agents that selectively inhibit the uptake of glutamine by hepatocarcinoma cells, causing the concomitant apoptosis of hepatocarcinoma cells. Preferred agents target the amino acid transporter B0 (ATB0) protein for inhibition. Disclosed are antisense polynucleotides that reduce the expression of ATB0 in hepatocarcinoma cells, causing those cells to reduce the uptake of glutamine and subsequently undergo selective apoptosis.

Owner:SAINT LOUIS UNIVERSITY

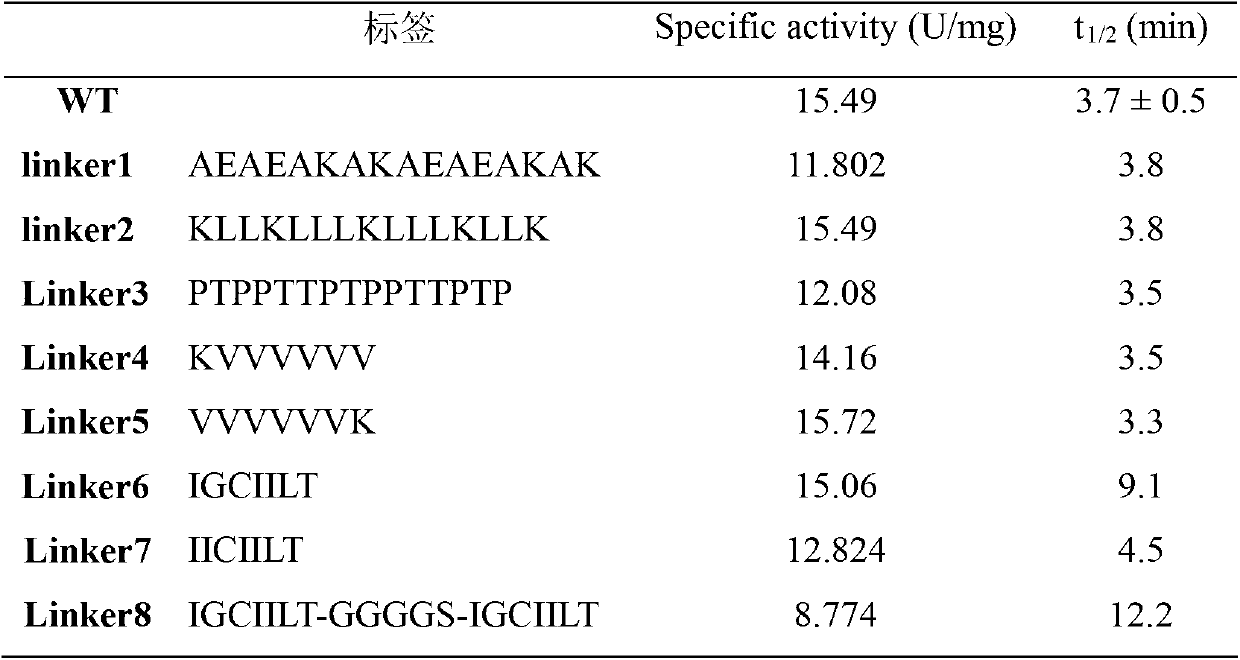

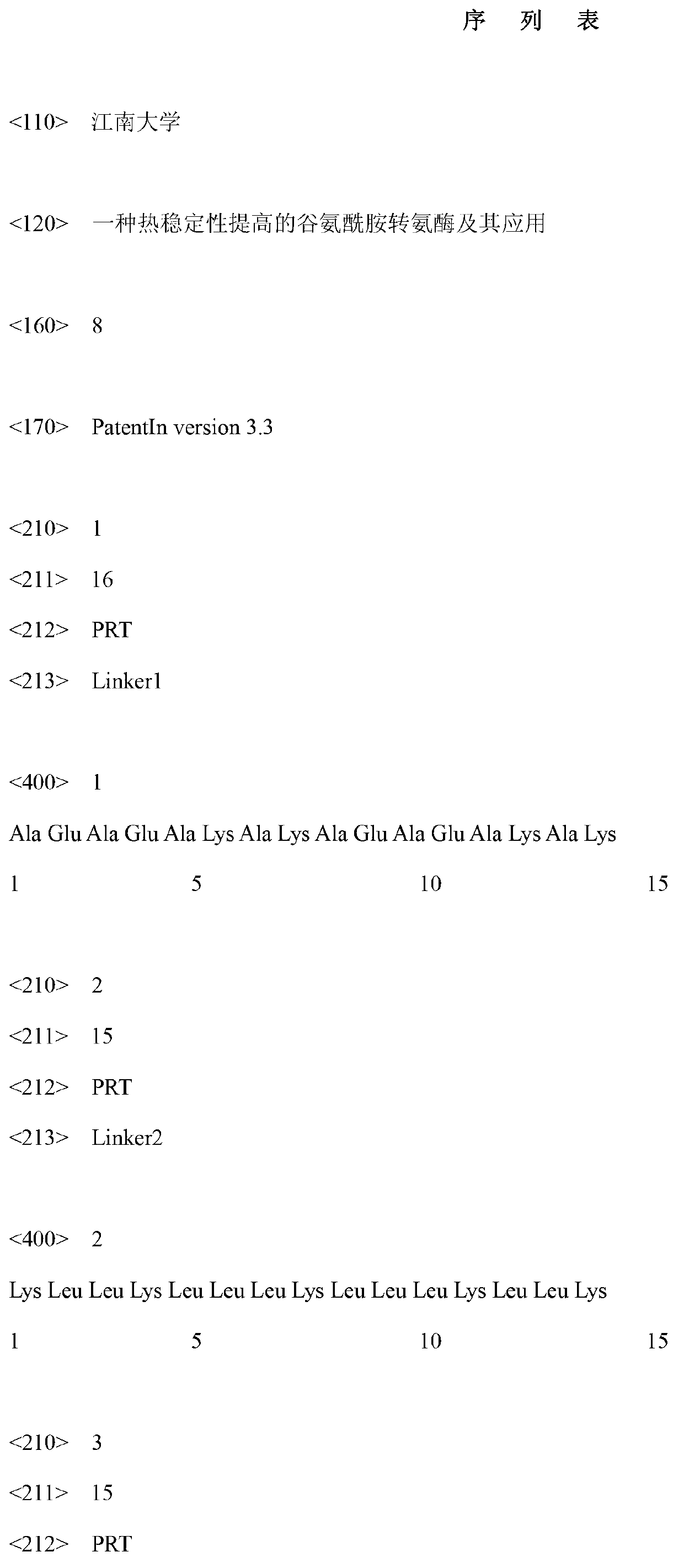

Glutamine transaminase with improved heat stability and application thereof

ActiveCN102994469AGood enzymatic propertiesImprove thermal stabilityBacteriaTransferasesEscherichia coliMicrobial transglutaminase

The invention discloses a glutamine transaminase with improved heat stability and application thereof. High-efficiency expression of microbial transglutaminase (MTG) in escherichia coli serves as a modification platform, a label facilitating improvement of heat stability is added at the C end of MTG maturase, preference is given to IGCIILT to obtain a mutant strain with good enzymatic property, and the heat stability is improved by 2.5 times and 3 times. Modified enzyme is suitable for industrial application, the production cost can be reduced, and the production efficiency can be improved.

Owner:TAIXING YIMING BIOLOGICAL PRODS

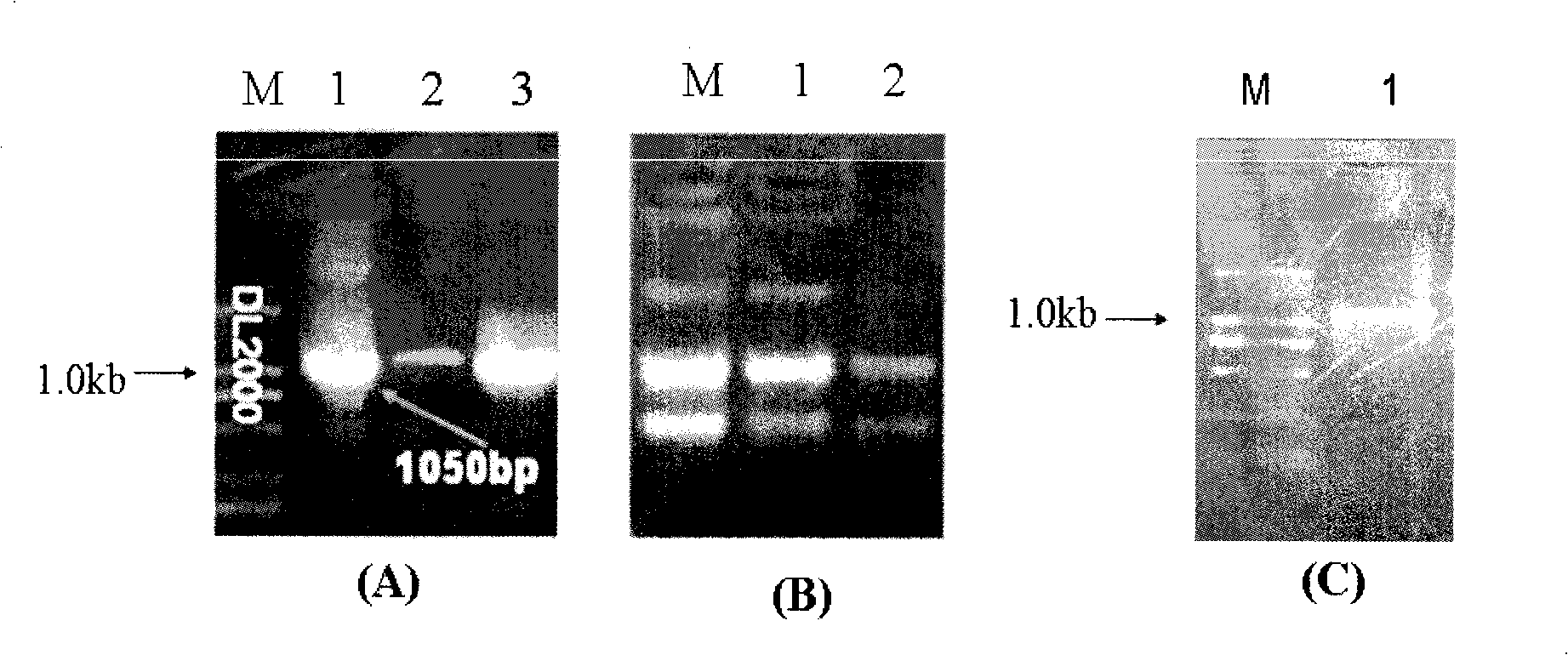

Mutant type Taq DNA polymerase, nucleic acid extraction-free direct PCR amplification kit and application of mutant type Taq DNA polymerase

ActiveCN108130318AHigh activityImprove toleranceMicrobiological testing/measurementTransferasesBiotechnologyWild type

The invention discloses mutant type Taq DNA polymerase, a nucleic acid extraction-free direct PCR amplification kit and an application of the mutant type Taq DNA polymerase. By mutating 709-site glutamic acid of wild Taq DNA polymerase into glutamine, the activity, tolerance and the like of the obtained mutant type Taq DNA polymerase are obviously improved. The mutant type Taq DNA polymerase onlyhas a site, so that the mutation sites are few, and the preparation is easy. Experiment results show that the mutant type Taq DNA polymerase can be applied to a nucleic acid extraction-free direct PCRamplification reaction system, and the nucleic acid extraction-free direct PCR amplification of samples such as blood, foods and soil which contain a large number of inhibiting factors can be realized.

Owner:深圳市艾伟迪生物科技有限公司

Recombined meat adhesive and preparation method and application thereof

The invention discloses a recombined meat adhesive and a preparation method and application thereof, belonging to the field of food processing. The recombined meat adhesive comprises glutamine transaminase, non-meat protein and dietary fiber, has the advantages of low production cost, good adherence effect, great adherence strength to meat slices or meat blocks, little melting loss and boiling loss, great recombined meat tenderness and good flakiness, can effectively ensure the adherence effect, improves the demand of people for dietary fibers and increases the added value of products. The recombined meat prepared by the recombined meat adhesive has the adhesive property higher than or equal to 70g*cm<-2>, decreases the hardness by 62.8 percent and reduces the shearing force by 22.9 percent; the prepared raw and fresh recombined meat or cooked recombined meat has no obvious color difference (p is larger than 0.05) from one-piece meat and has no obvious taste difference (p is larger than 0.05) from the one-piece meat by sensory test.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Heat-resisting and freeze-drying protector for live vaccine and preparation method thereof as well as live newcastle disease vaccine

InactiveCN101947321ALittle change in activityImprove protectionViral antigen ingredientsAntiviralsVitamin CFreeze-drying

The invention discloses a heat-resisting and freeze-drying protector for a live vaccine and a preparation method thereof as well as a live newcastle disease vaccine adopting the freeze-drying protector. The heat-resisting and freeze-drying protector for the live vaccine comprises the following compositions in percentage by weight: 10-15 percent of trehalose, 1-2 percent of polyvinylpyrrolidone (PVP), 1-2 percent of alum, 1-2 percent of glutamine, 2-10 percent of sorbitol, 0.1-0.5 percent of potassium dihydrogen phosphate, 0.5-1 percent of vitamin C and the balance of water. Compared with the traditional vaccine, the heat-resisting and freeze-drying protector for the live vaccine has the advantages of good stability, long preservation time, low preservation condition, little activity damage on the live vaccine, good dissolubility, simple raw material and the like.

Owner:河南后羿生物工程股份有限公司

Method for using glutamine aminotransferase catalyzing exogenous protein to clean wool fabric

InactiveCN101302714AGood felt shrinkageReduce COD valueBiochemical fibre treatmentAnimal fibresEcological environmentBiological macromolecule

Owner:JIANGNAN UNIV

Hydrogel applicable to cell adhesion and preparation method of hydrogel

InactiveCN105363070ALower synthesis costSynthesis conditions are easy to controlProsthesisSpecific immunityNon specific

The invention discloses hydrogel applicable to cell adhesion and a preparation method of the hydrogel. The hydrogel is formed by Ac-IIISLGK-NH2 and L-Glutamine (L-Gln) under the action of an enzymatic reaction, wherein the N-terminal of the Ac-IIISLGK-NH2 is acetylated, the C-terminal of the Ac-IIISLGK-NH2 is aminated, the mole ratio of the Ac-IIISLGK-NH2 to the L-Gln is 1:1, reaction temperature is 37-40 DEG C, and reaction time is 24-48 hours. The hydrogel has the advantages that the prepared hydrogel can allow cells to be well adhered to cell surfaces, is low in toxicity and good in biocompatibility, does not cause the non-specific immunity reaction of lymphocyte, is ideal nano tissue engineering material and is significant to human life health.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Pharmaceutical composition of alanyl glutamine injection and compound amino acid injection

InactiveCN102631665AProne to decompositionLittle side effectsOrganic active ingredientsDipeptide ingredientsAmino Acid InjectionPharmacology

The invention relates to a pharmaceutical composition of an alanyl glutamine injection and a compound amino acid injection, in particular to combination application package. The pharmaceutical composition comprises the alanyl glutamine injection and the compound amino acid injection. When the pharmaceutical composition is in use, the alanyl glutamine injection and the compound amino acid injection are jointly utilized and are intravenously dripped. The combination application package greatly facilitates the requirement of clinical application.

Owner:灵康药业集团股份有限公司

Antibacterial mildew-resistant finishing agent for wool caps

InactiveCN107829295AReduce yellowingAvoid yellowingLight resistant fibresWrinkle resistant fibresAminosilochromeGlutaminase

The invention discloses an antibacterial mildew-resistant finishing agent for wool caps. The antibacterial mildew-resistant finishing agent comprises, by weight, 2-10 parts of sodium cyanate, 2-10 parts of hydrogen peroxide, 10-35 parts of modified chitosan, 2-10 parts of eucommia extract, 3-9 parts of bamboo leaf extract, 1-5 parts of cortex dictamni extract, 2-10 parts of pomegranate peel extract, 3-16 parts of radix lithospermi extract, 3-18 parts of beta-cyclodextrin, 0.1-1.2 parts of transglutaminase, 1-5 parts of amino siloxane, 2-10 parts of citric acid and 2-4 parts of hydrophilic surfactant. The antibacterial mildew-resistant finishing agent can endow the wool caps with excellent antibacterial performance and mildew resistance, feltability of the wool caps is lowered, and the woolcaps are enabled to be soft in hand feel and gentle in gloss.

Owner:安徽中福毛纺制帽有限公司

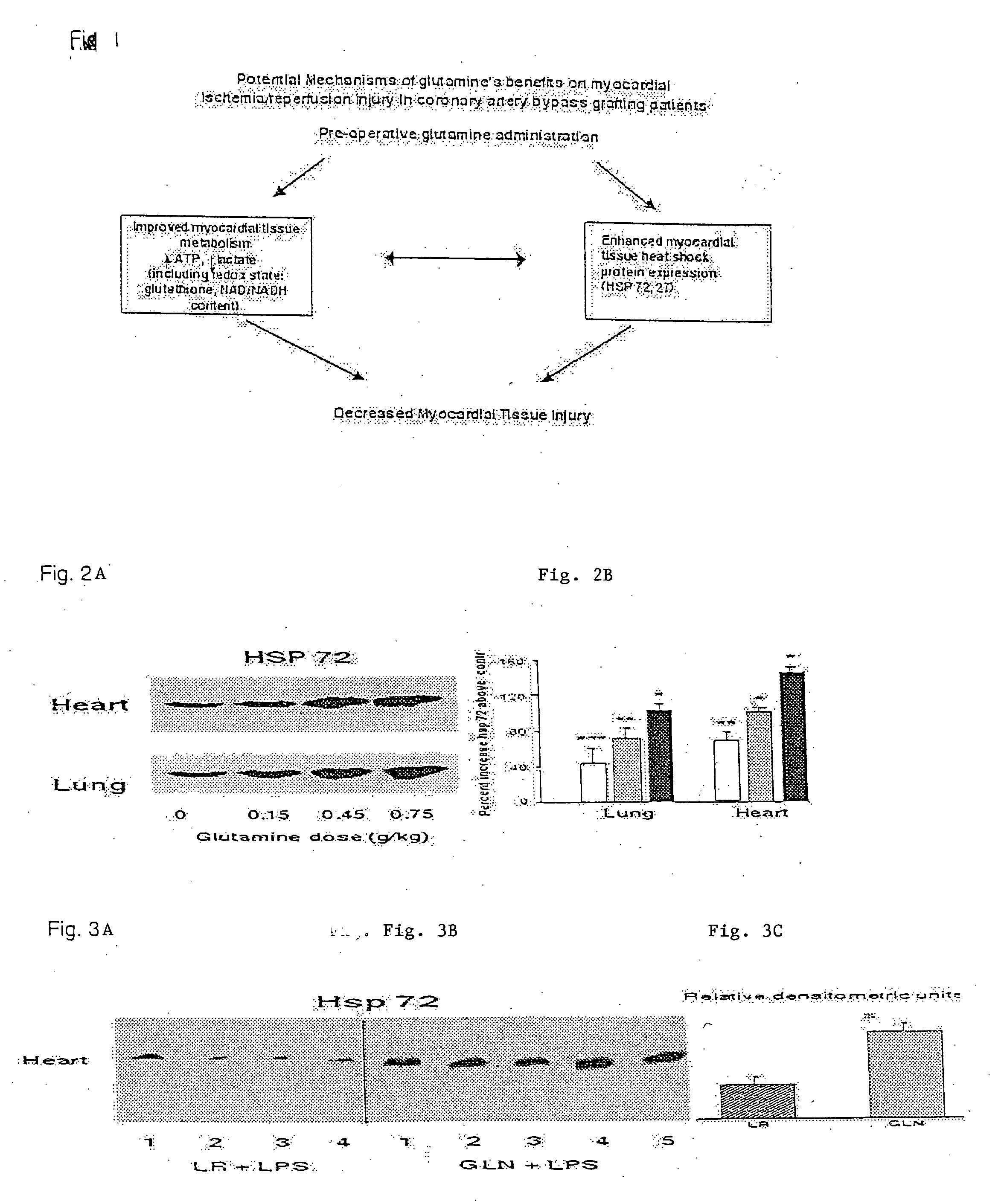

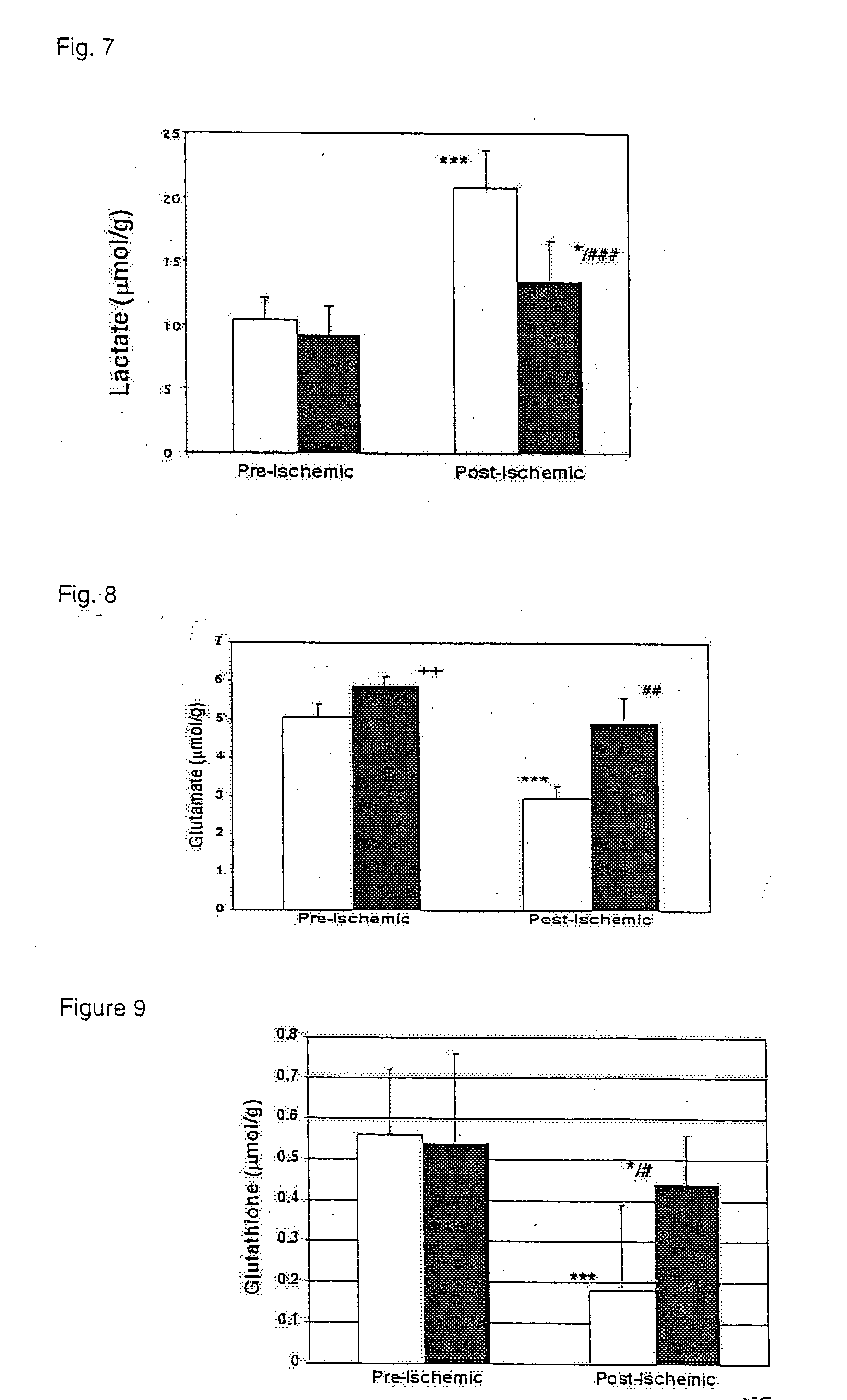

Glutamine for use in treating injury

InactiveUS20050059610A1Increase productionHigh expressionBiocideOrganic active ingredientsHeat shockMedicine

A method of treating a problem relating to tissue metabolism by administering to a patient in need a single dose of glutamine in a pharmaceutically acceptable carrier. Also provided is glutamine for the treatment of an injury relating to tissue metabolism and for preventing cardiac cell damage. A therapeutic composition for treating and preventing cellular metabolic injury, preventing cardiac cell damage, and increasing heat shock protein expression where in the therapeutic includes a single dose of glutamine in a pharmaceutically acceptable carrier is also provided. A method of increasing the expression of heat shock proteins by administering a single dose of glutamine in a pharmaceutically acceptable carrier to a location in need is further provided.

Owner:UNIV OF COLORADO THE REGENTS OF

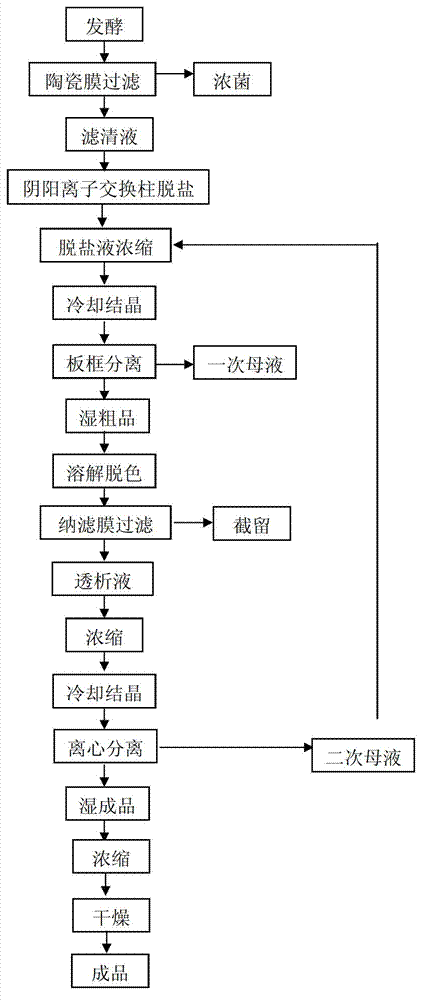

Fermentation production method of high-yield glutamine

ActiveCN104404097AIncreased metabolic fluxReduce generationMicroorganism based processesFermentationBiotechnologyMicrobiology

The invention discloses a fermentation production method of high-yield glutamine. The fermentation production method comprises the following steps: Step One, seed culturing; Step Two, inoculating a fermentation medium with the strain obtained in the Step One for culture; during the fermentation process, controlling the glucose content, temperature, pH, dissolved oxygen and other conditions; Step Three, after the fermentation, extracting and refining glutamine from the fermentation broth. According to the fermentation production method of high-yield glutamine, the raw material is low in cost and easy to realize through control; the acid yield is high through fermentation, and the acid yield can reach 79.8g / L on average.

Owner:HENAN JULONG BIOLOGICAL ENG CO LTD

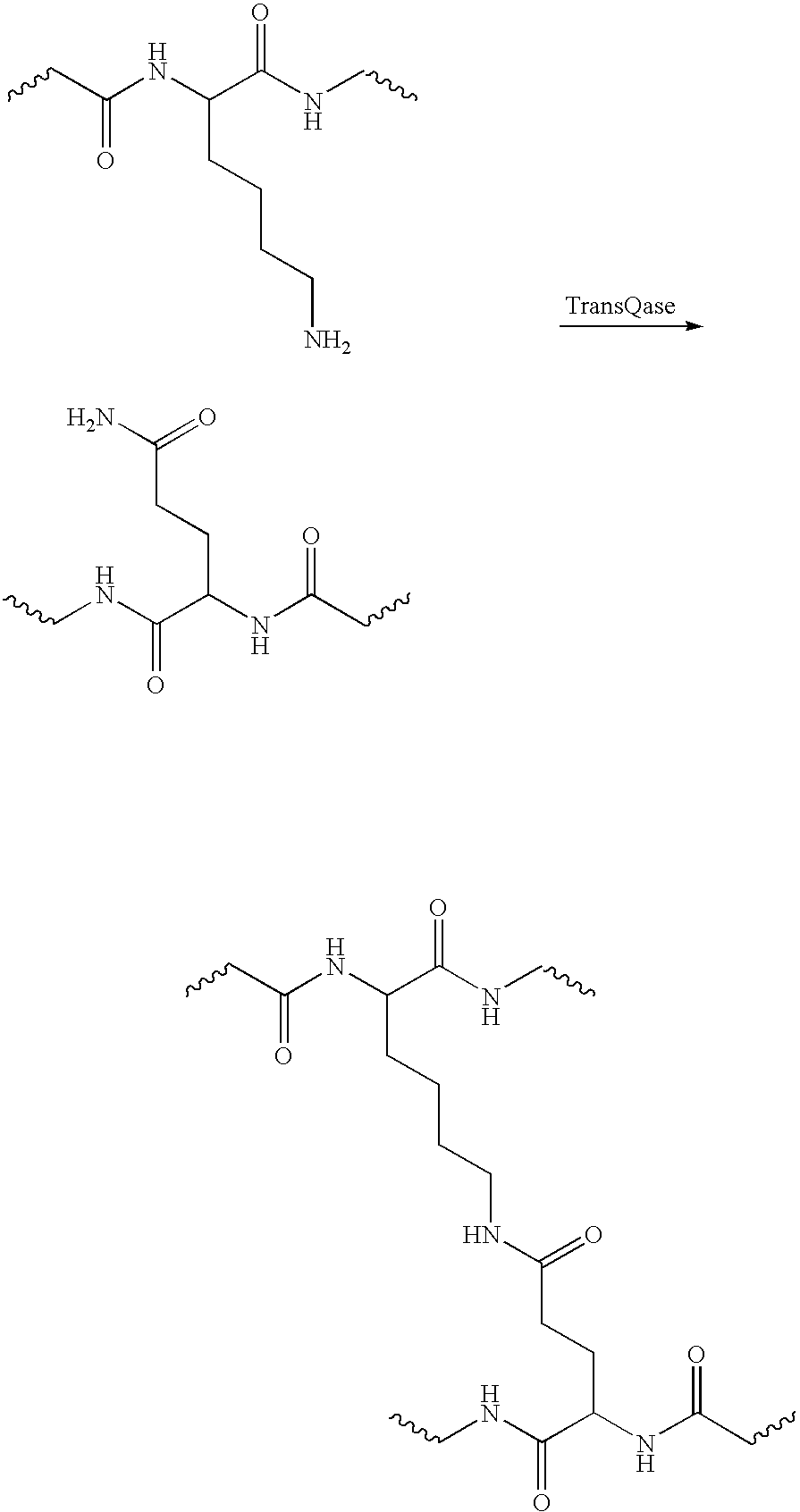

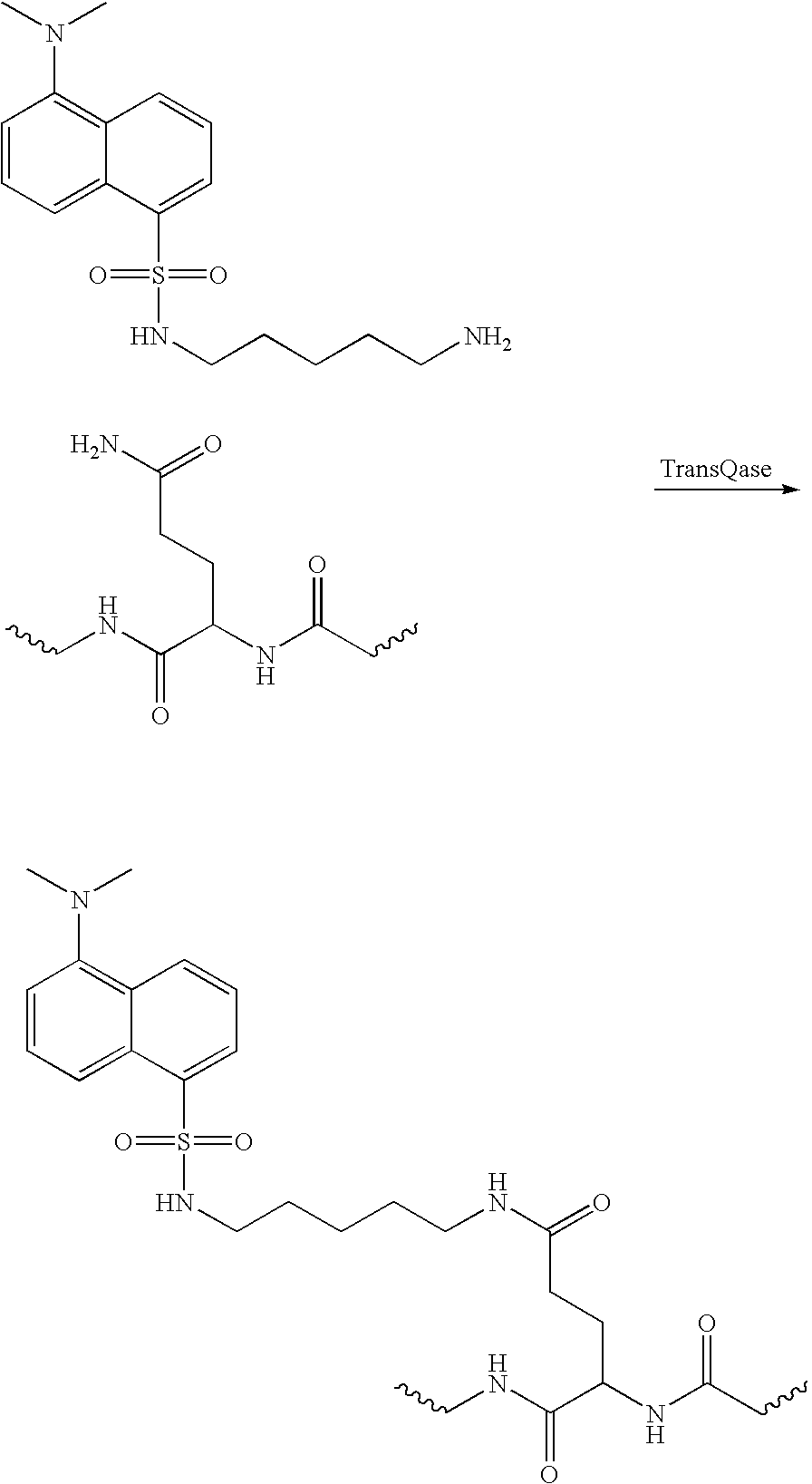

Method of site specific labeling of proteins and uses therefor

InactiveUS20050136491A1Easy to useSuitable for usePeptide/protein ingredientsMaterial analysis by observing effect on chemical indicatorHigh-Throughput Screening MethodsDelivery vehicle

Methods for site-specific modification of protein are provided. These methods modify proteins which have been labeled at a particular site by the reaction of a transglutaminase with a glutamine peptide sequence which has been engineered into the protein. The site-specific modification methods of the invention are useful for producing reagents useful in high throughput screening methods and in producing protein delivery vehicles for specifically targeting cellular and non-cellular targets. Also described are improved biotinylation reagents.

Owner:SMITHKLINE BECKMAN CORP

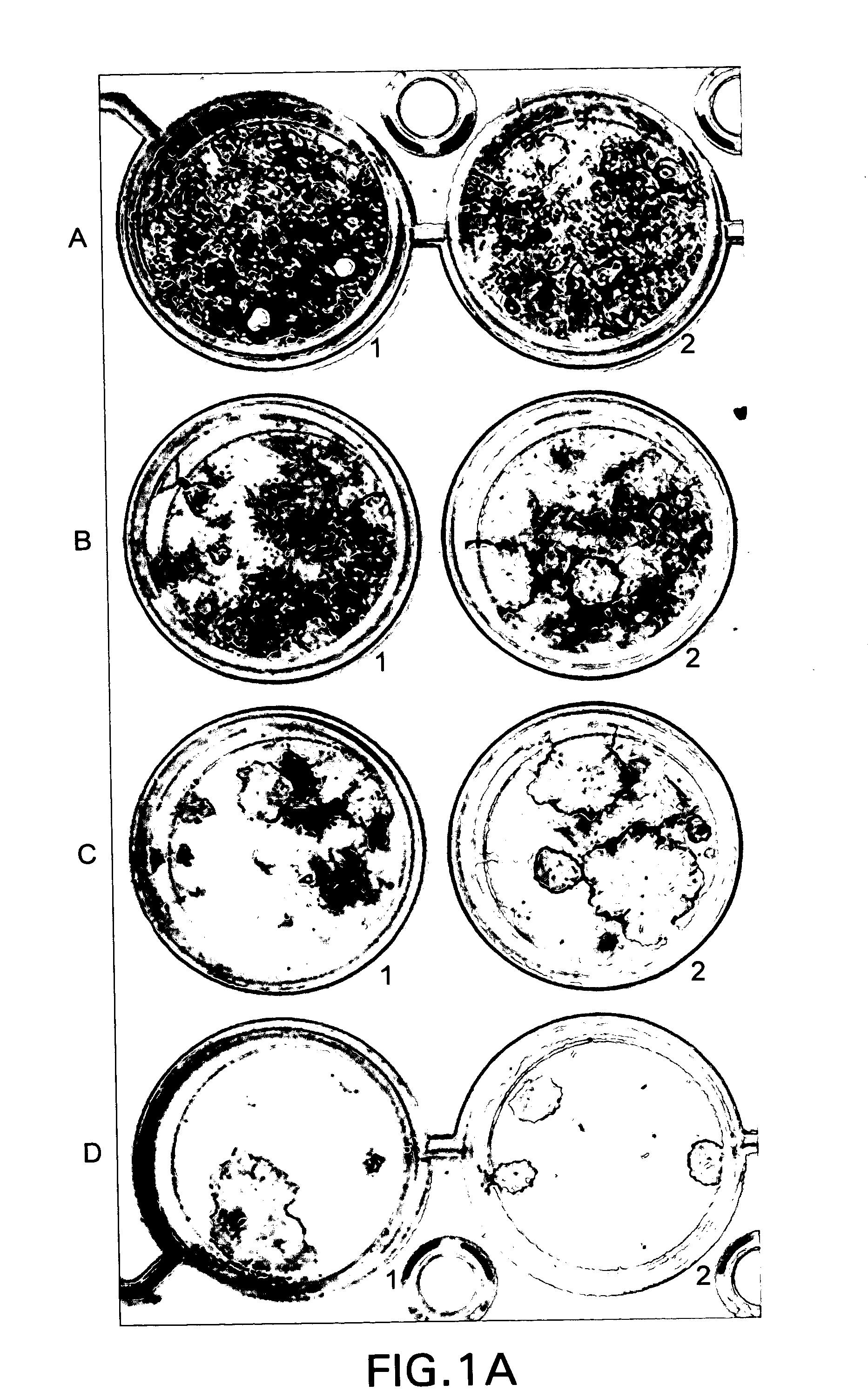

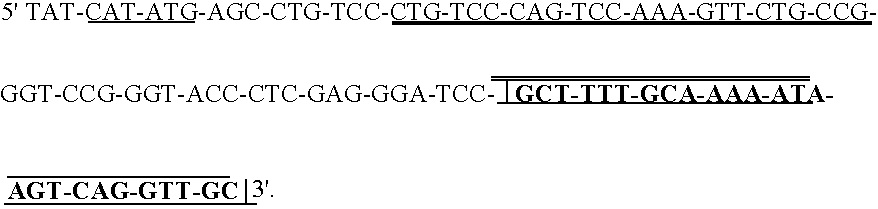

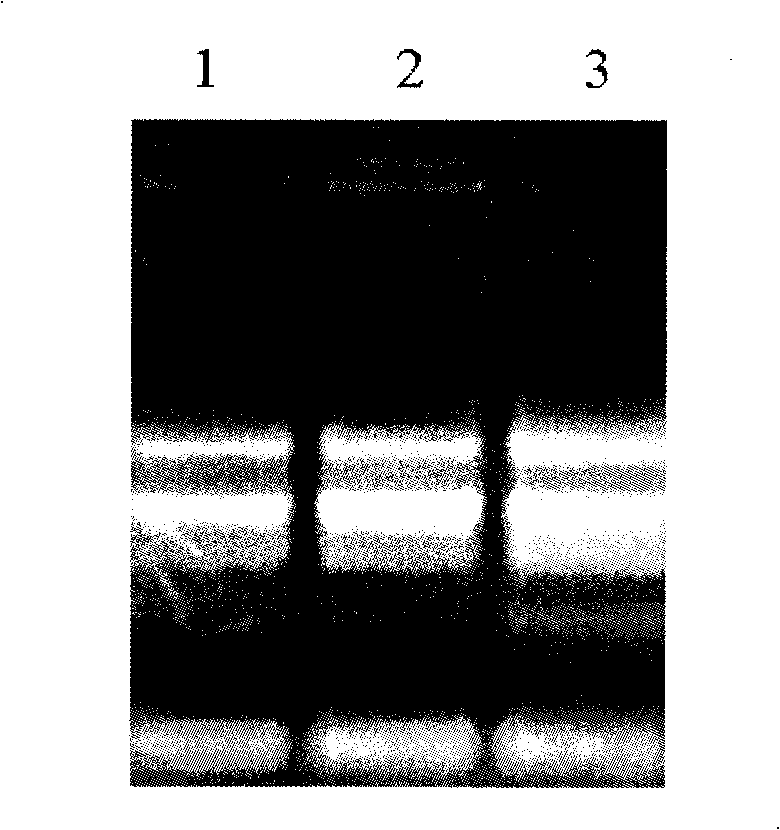

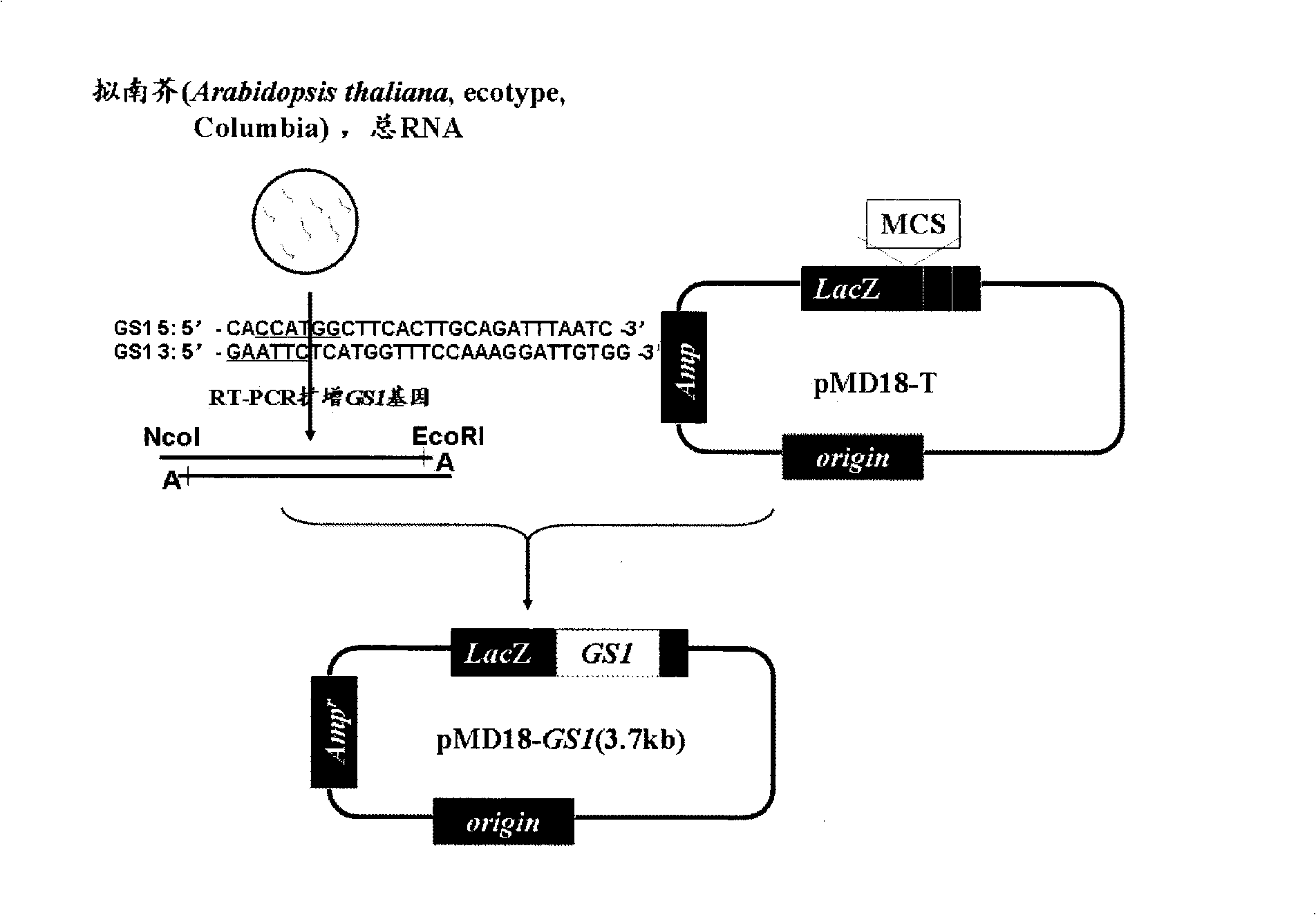

Construction and use of plant expression vector of Arabidopsis thaliana cytoplasm type glutamine synthetase gene

InactiveCN101407824AImprove nitrogen use efficiencyIncreased reassimilation capacityPlant tissue cultureHorticulture methodsNicotiana tabacumLow nitrogen

The invention relates to a special plant expression vector pH2-35S-PrbcS-GS1 which comprises an arabidopsis thaliana cytoplasm glutamine synthetase gene GS1 and can improve the utilization rate of a plant nitrogen element. A method of RT-PCR is used for cloning the GS1 gene from the arabidopsis thaliana of a model plant, a photoinduction type promotor (the promotor of a a small subunit Rubisco) is used for controlling the excessive expression of the GS1 gene in a plant leaf and a leaf disc conversion method is used for transferring the GS1 gene into a pPZP221-PrbcS-Dof1 type transgene tobacco. An experiment result shows that the GS1 gene can be normally transferred in the transgene tobacco; under the nutrition condition of low nitrogen and the growing conditions of indoor irradiation for 24 hours of 2000LUX and 25 DEG C, the growing situation of the plant transferred with the single gene of Dof1 is (the expression of the gene is controlled by the photoinduction type promotor Prbcs) is a little better than that of a contrast tobacco (a wild type without transgene); after being transferred under the natural growing condition of a green house, the growing situation of the tobacco which is simultaneously transferred with the GS1 gene and the Dof1 gene shows remarkable growing advantages than that of the contrast plant; and therefore, simultaneously and excessively expressing the GS1 gene and the Dof1 gene, can improve the efficiency of the GS / GOGAT (glutamine synthetase / glutamic acid synthetase) approaches in the leaf more extensively, thereby improving the utilization rate of the plant nitrogen element. The vector can be broadly applied to the molecule breeding of crops, improving the utilization rate of the plant nitrogen element thereof and the durability to the nutrition condition of low nitrogen and being capable of obtaining a higher yield under the conditions of applying less fertilizers and even not applying the fertilizers.

Owner:KUNMING UNIV OF SCI & TECH

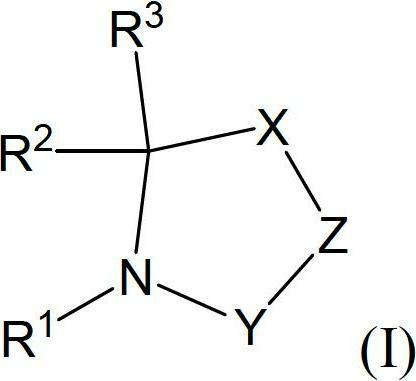

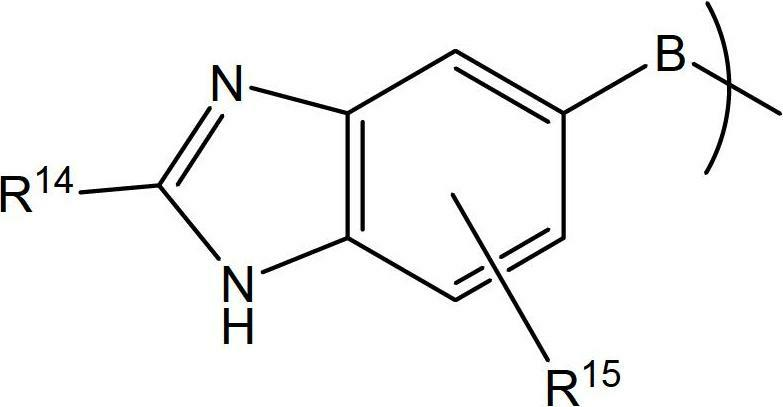

Heterocylcic derivatives as inhibitors of glutaminyl cyclase

ActiveCN102695546ALasting effectOrganic active ingredientsNervous disorderCyclaseL-Pyroglutamic Acid

The invention relates to novel pyrrolidine derivatives of formula (I), wherein R1, R2 and R3 are as defined herein, as inhibitors of glutaminyl cyclase (QC, EC 2.3.2.5). QC catalyzes the intramolecular cyclization of N-terminal glutamine residues into pyroglutamic acid (5-oxo-prolyl, pGlu*) under liberation of ammonia and the intramolecular cyclization of N-terminal glutamate residues into pyroglutamic acid under liberation of water.

Owner:维沃永治疗公众有限公司

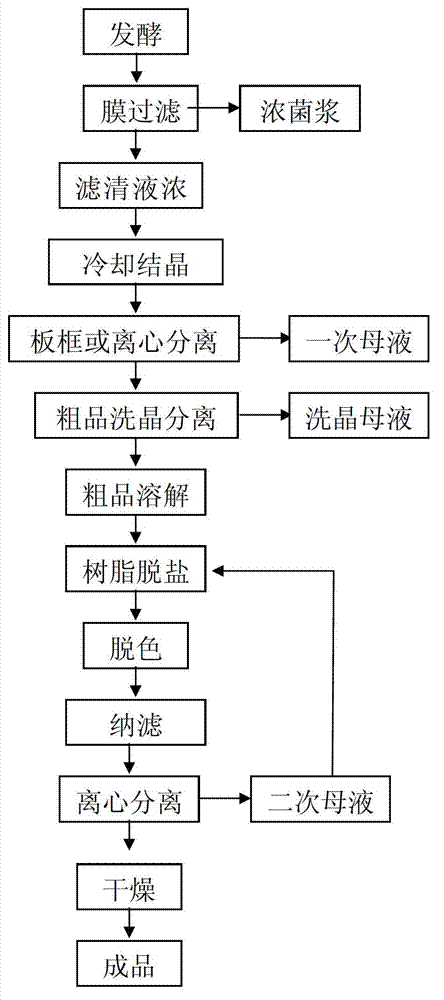

Method for extracting glutamine from fermentation liquor

ActiveCN102924321AHigh purityReduce lossesCarboxylic acid amide separation/purificationSewageIon-exchange resin

The invention belongs to the technical field of fermentation and discloses a method for extracting glutamine from fermentation liquor. The method comprises the following steps of: cooling and filtering glutamine fermentation liquor, concentrating, cooling and crystallizing the obtained filtrate, and separating to obtain a crystallized crude product; adding 30-60 weight percent of water for washing the crystal, and separating to obtain a crude product in which the crystal is washed; and adding water for dissolving, sequentially adding a cation exchange resin and an anion exchange resin for removing salt, and filtering to obtain desalted liquid; performing nanofiltration to obtain nanofiltration liquid, decolorizing and filtering to obtain decolorized solution, concentrating, cooling, crystallizing, separating and drying to obtain glutamine. According to the method, the crude product is washed and crystallized, most of impurities on the surface of the crystallized crude product are removed, and the amount of the desalted resin is reduced, so that the sewage quantity is reduced, the energy consumption is reduced, and the pollution is reduced; and meanwhile, the method of sequentially adding the cation exchange resin and the anion exchange resin into the feed liquid is used for desalting, the glutamine loss caused by long desalting period is greatly reduced, and the yield of the glutamine is improved.

Owner:TONGLIAO MEIHUA BIOLOGICAL SCI TECH CO LTD

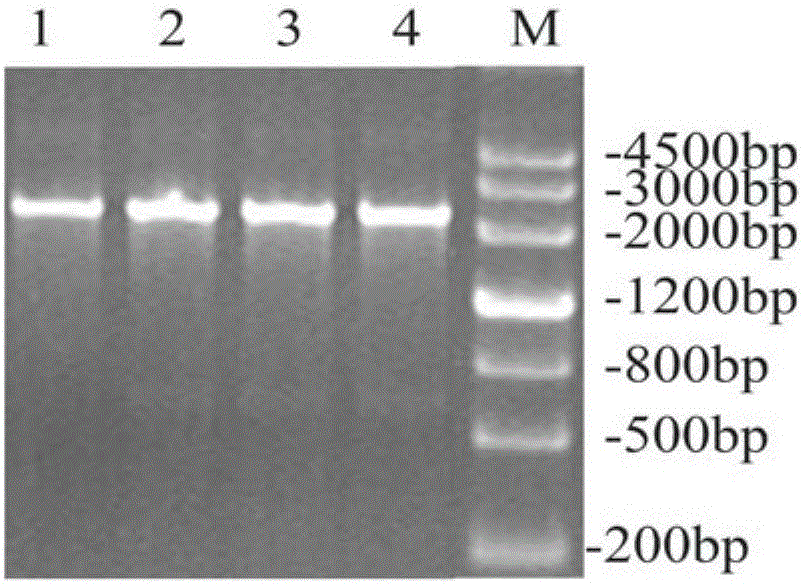

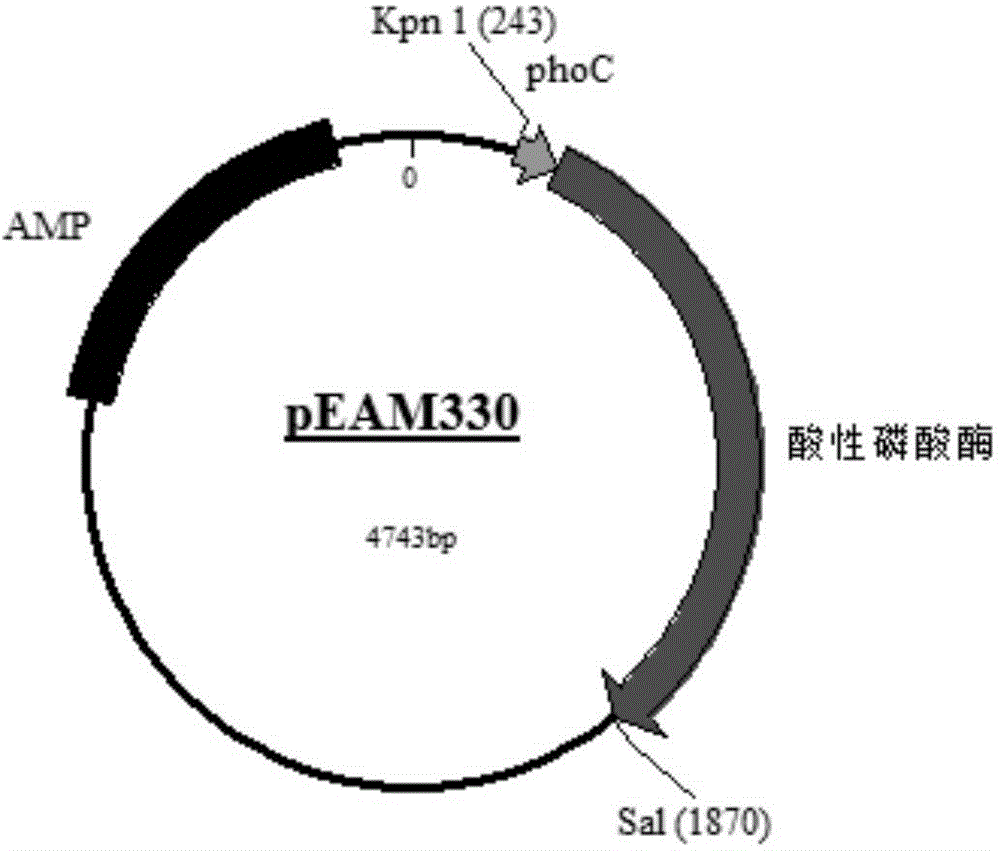

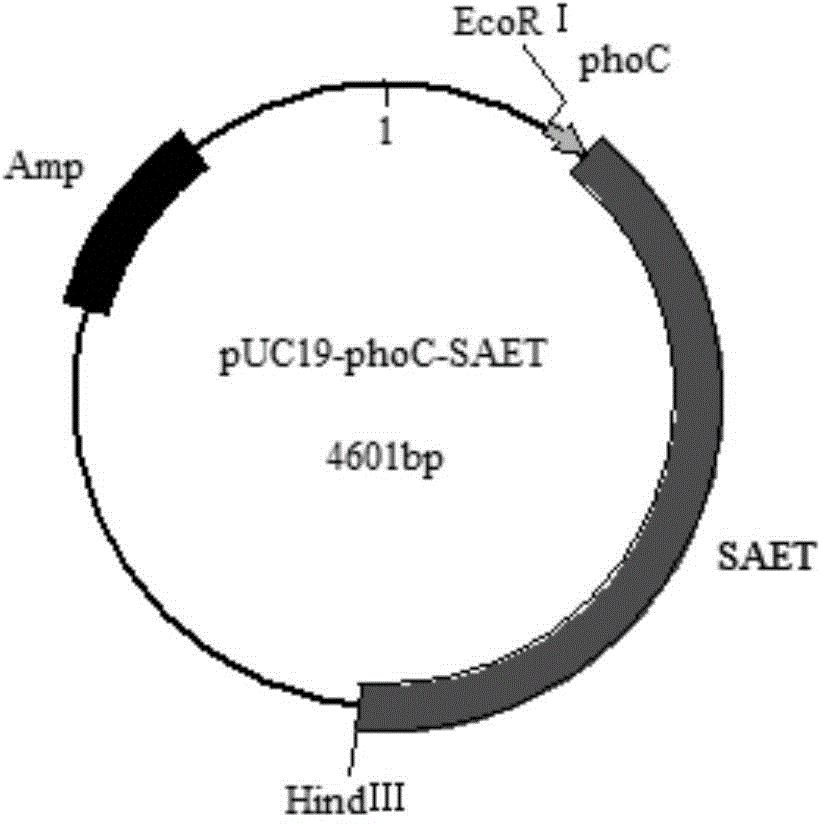

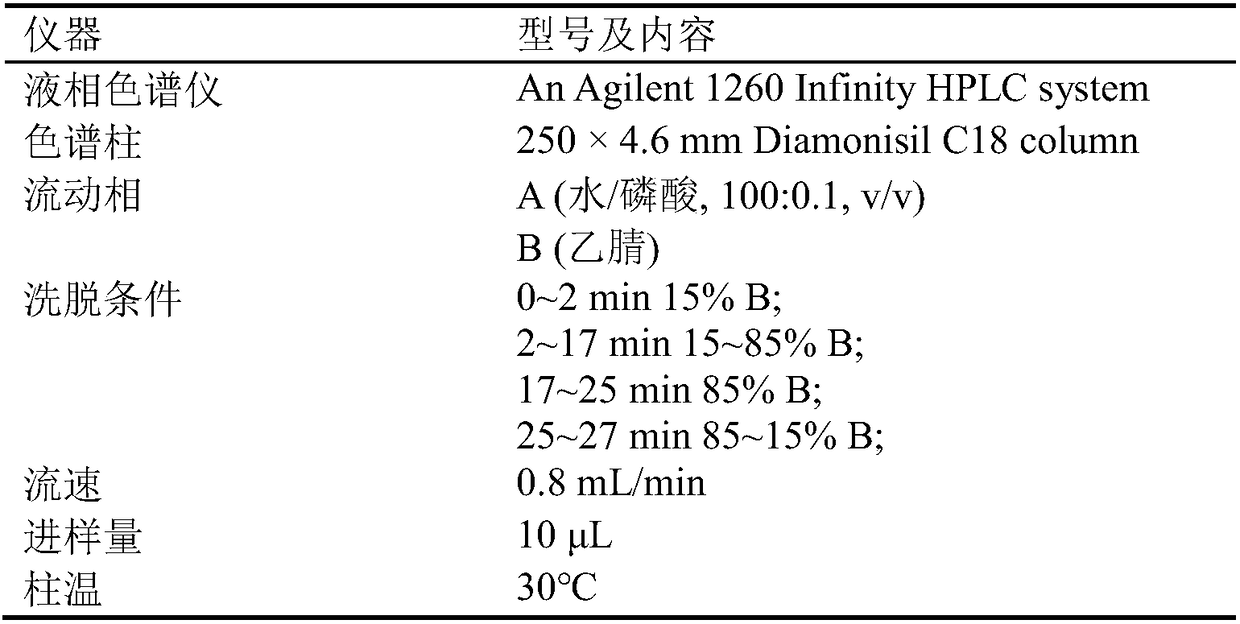

Method of producing L-alanyl-L-glutamine from recombinant escherichia coli

InactiveCN104480172AHigh activityMicroorganism based processesFermentationEscherichia coliL-alanyl-l-glutamine

The invention discloses a method of producing L-alanyl-L-glutamine from recombinant escherichia coli, wherein the method of producing L-alanyl-L-glutamine from recombinant escherichia coli is follows: in an aqueous solution with a determined pH value, acting on free L-glutamine and L-alanine methyl ester hydrochloride to generate L-alanyl-L-glutamine, recombining a gene segment of the protein with the amino-acid ester acyltransferase of the L-alanyl-L-glutamine into a carrier and transferring into host bacteria, thereby obtaining the host bacteria with the recombinant DNA and capable of strengthening the activity of an L-alanyl-L-glutamine biological synthesis system. The method comprises the following steps: (1) culturing a larger number of recombinant escherichia coli cells for expressing the amino-acid ester acyltransferase; (2) excessively expressing the amino-acid ester acyltransferase in the step (1); and (3) taking the amino-acid ester acyltransferase in the step (2) as a crude enzyme source, adding the crude enzyme source into a buffer solution containing L-glutamine and L-alanine methyl ester hydrochloride substrate amino acid to react, thereby realizing efficient production of the L-alanyl-L-glutamine.

Owner:JIANGNAN UNIV

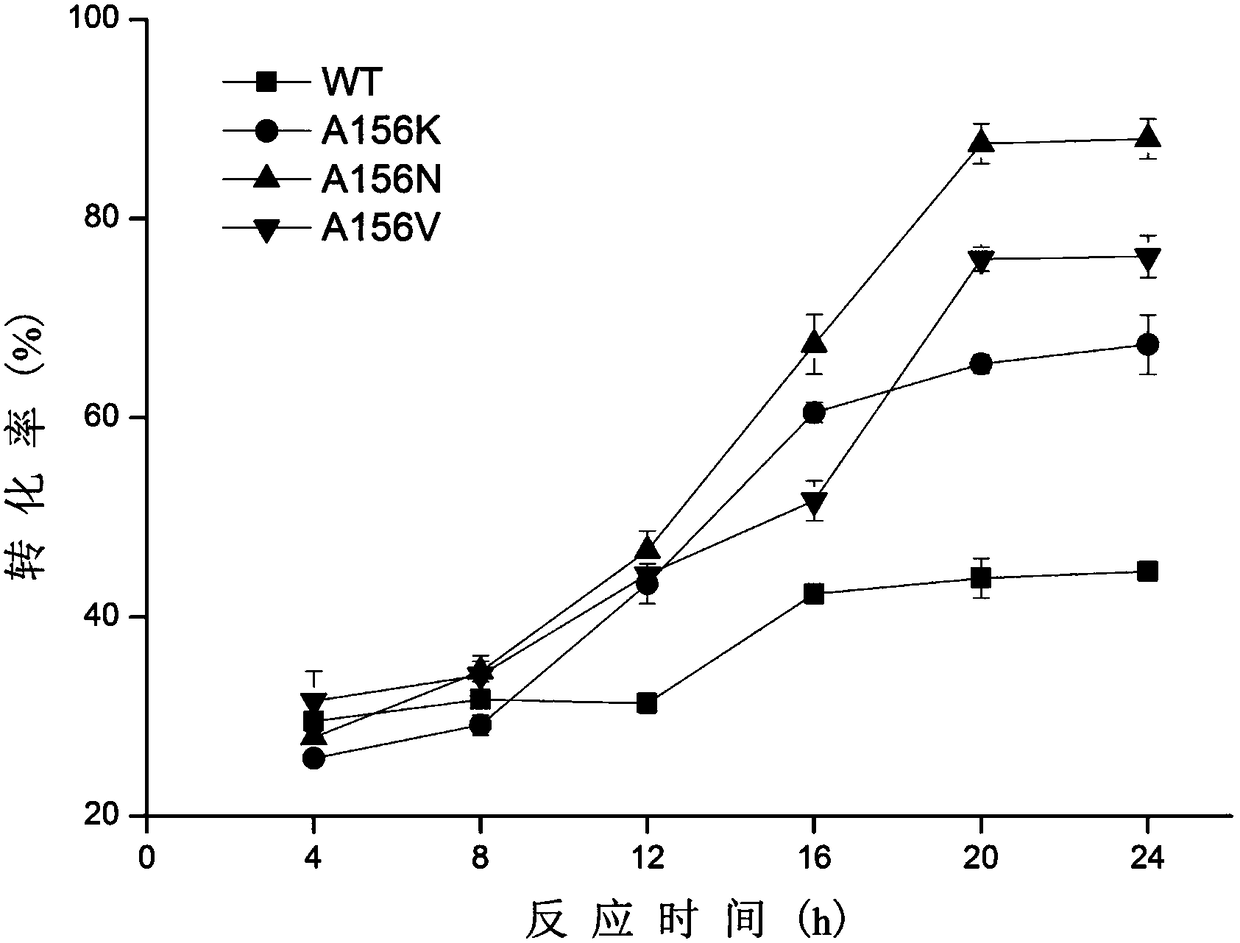

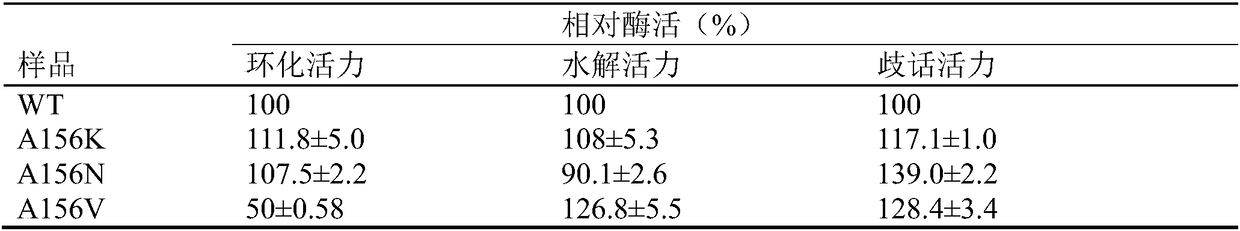

Cyclodextrin glucosyltransferase and preparation method thereof

ActiveCN108486080AImprove glycosylation efficiencyEase of industrial productionBacteriaFermentationCyclodextrinWild type

The invention discloses a cyclodextrin glucosyltransferase and a preparation method thereof, and belongs to the field of genetic engineering and enzyme engineering. The glycosylation efficiency of pigment is improved by 23%, 44% and 32% respectively by replacing alanine (Ala) at the No. 156 site of CGTase of P. Macerans strain JFB05-01(CCTCC NO: M208063) with lysine (Lys), glutamine (Gln) and valine (Val). Those mutant enzymes are more beneficial for catalyzing and producing glycosylated genistein compared with wild type CGTase.

Owner:SHANDONG LONGKETE ENZYME PREPARATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com