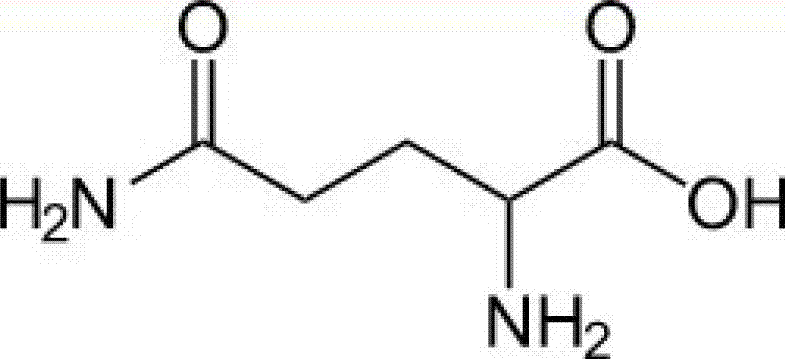

Method for extracting glutamine from fermentation liquor

An extraction method and glutamine technology, applied in the field of fermentation, can solve problems such as large amount of exchange resin, high acid-base consumption, environmental pollution, etc., and achieve the effects of improving yield, reducing energy consumption and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

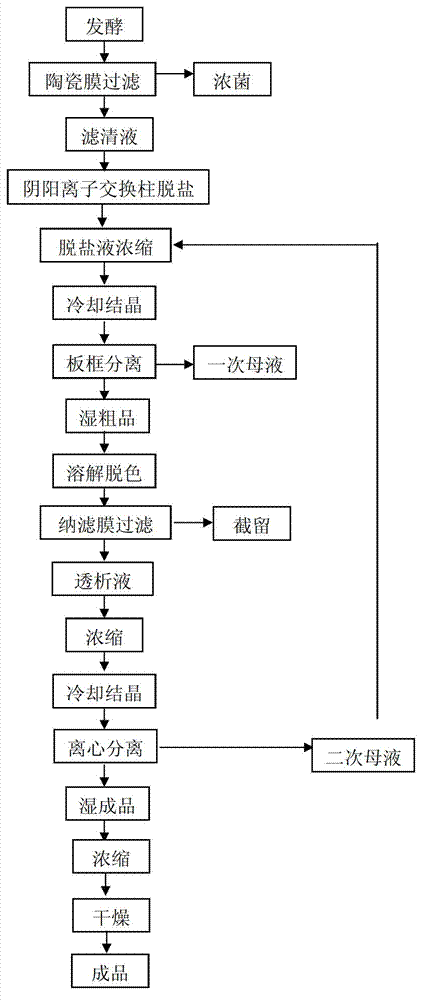

[0061] Embodiment 1: The method for extracting glutamine from fermentation broth described in the present invention extracts glutamine

[0062] Take 27L of glutamine fermentation broth (glutamine content is 78mg / mL), filter with a molecular weight cut-off of 30kDa ceramic membrane to obtain the filtrate, the filtrate is concentrated in vacuum until the glutamine content is 30%, then slowly cool down to 7°C, cool and crystallize After 10 hours, centrifuge to obtain 2302.6 grams of primary crystallization crude product, add 1064 mL of water to wash the crystal, and obtain 2201.8 g of washed crystal crude product after separation, add water to dissolve until the glutamine content is 3.9%, add 856 mL of cation exchange resin to the solution and stir for 2 hours , filter, then add 1150mL of anion exchange resin, stir for 2 hours, filter to obtain 29.08L of filtrate, the filtrate is passed through a nanofiltration membrane with a molecular weight cut-off of 1000Da to obtain the nanof...

Embodiment 2

[0063]Embodiment 2: the method for extracting glutamine from fermentation broth described in the present invention extracts glutamine

[0064] Take 28L of glutamine fermentation broth (glutamine content is 76mg / mL), and filter it with a ceramic membrane with a molecular weight cut-off of 30kDa to obtain the filtrate. hours, centrifuged to obtain 2250.1 grams of primary crystallization crude product, added 1070mL water to wash the crystal, and separated to obtain 2133.3 grams of washed crystal crude product, added water to dissolve until the glutamine content was 3.7%, first added 890mL cation exchange resin to the solution, and stirred for 2 hours , filter, then add 1190mL of anion exchange resin, stir for 2 hours, filter to obtain 32L of filtrate, the filtrate is passed through a nanofiltration membrane with a molecular weight cut-off of 1000Da to obtain the nanofiltration, add 88.8 grams of injection charcoal for decolorization, filter, and the decolorization solution is conc...

Embodiment 3

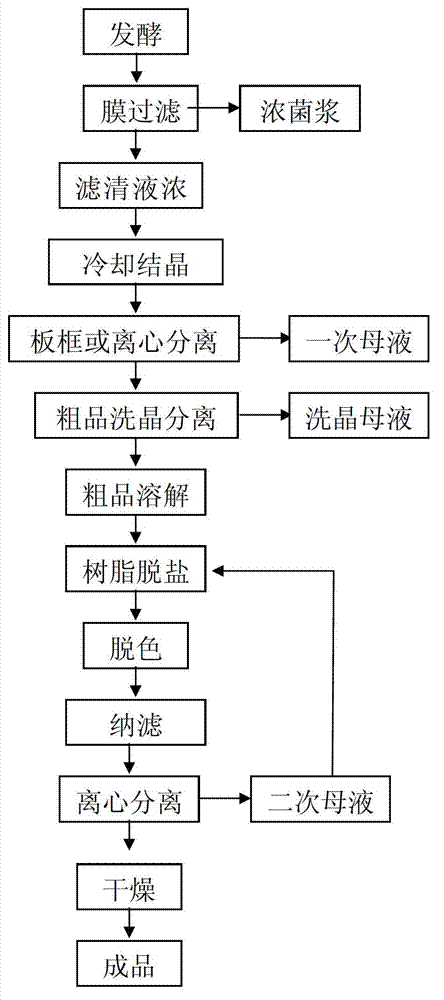

[0065] Embodiment 3: Existing method for extracting glutamine extracts glutamine

[0066] Take 32L of glutamine fermentation broth (glutamine content is 75.2mg / mL), filter the filtrate with a molecular weight cut-off of 30kDa ceramic membrane, pass through an anion and cation exchange column, the volume of the cation resin is 9L, and the volume of the anion resin is 9L, and the resulting The desalted solution was concentrated in vacuo until the glutamine content was 25%, slowly cooled to 7°C, cooled and crystallized for 10 hours, and centrifuged to obtain a crude product of 1 g of crystals, which was dissolved in water until the glutamine content was 4.5%, and 120 g of charcoal for injection was added. Decolorization, filtration, the decolorization liquid obtained by filtration is passed through a nanofiltration membrane with a molecular weight cut-off of 800Da to obtain a nanofiltration liquid, concentrated to a glutamine content of 40%, the concentrated liquid is cooled to be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com