Patents

Literature

67results about How to "Suitable for industrial production needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Synthesis method of sulfobutyl ether-beta-cyclodextrin with specific average substitution degree

The invention discloses a synthesis method of sulfobutyl ether-beta-cyclodextrin with a specific average substitution degree. The synthesis method comprises the following steps: (1) dissolving beta-cyclodextrin into NaOH solution while stirring, wherein the use amount of NaOH solution is 1.6-6.5 times as much as the molar quantity of beta-cyclodextrin; (2) dropwise adding 1,4-butyl sultone and performing reflux etherification; when pH value drops to 8.8, adding NaOH solution to adjust the pH value to be between 8.80-9.70 until the pH value does not change; and then adding all residual NaOH aqueous solution into a reaction container from a sample injector; and (3) when detecting that the mass of residual beta-cyclodextrin in the reaction container is 1% or below, adding NaOH solution, wherein the use amount of NaOH solution is 0.4-1.5 times as much as the molar quantity of beta-cyclodextrin. By the synthesis method, a sulfobutyl ether-beta-cyclodextrin product with a specific average substitution degree can be obtained and the yield is high; in addition, the specific average substitution degree range of the synthesis product is concentrated and the composition of the product is in strict normal distribution; the reaction conditions are mild and post-treatment is simple.

Owner:TIANJIN UNIV

Preparation method of in-situ halogen-free flame-retardant expandable polystyrene

The invention provides a preparation method of in-situ halogen-free flame-retardant expandable polystyrene. The preparation method is characterized by adding halogen-free flame retardants in situ in a suspension polymerization process to obtain expandable polystyrene and prepare a halogen-free flame-retardant foamed polystyrene material with a flame-retardant grade which reaches the grade B. The halogen-free flame retardants are insoluble in water and can be dissolved or be fully dispersed in styrene monomers. The method comprises the following steps: firstly adding the halogen-free flame retardants into the styrene monomers, fully dispersing and dissolving the flame retardants to prepare a halogen-free flame retardant dispersion solution, then adding the halogen-free flame retardant dispersion solution into water phase to carry out polymerization reaction and obtain final reaction products which are flame-retardant-containing expandable polystyrene resin particles; the flame retardants are uniformly distributed in the polystyrene particles, so that the high flame-retardant efficiency can be implemented.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Glutamic acid decarboxylase mutant with enhanced pH stability and application thereof

ActiveCN105296456AImprove the stability of enzyme activitySuitable for industrial production needsFermentationVector-based foreign material introductionGlutamate decarboxylaseRecombinant escherichia coli

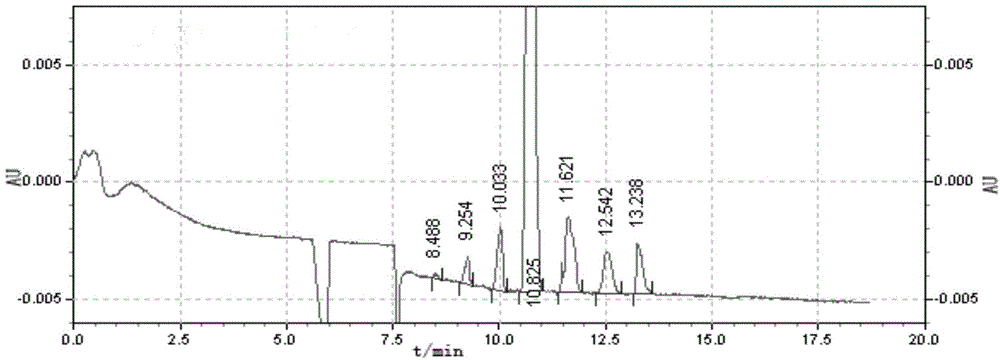

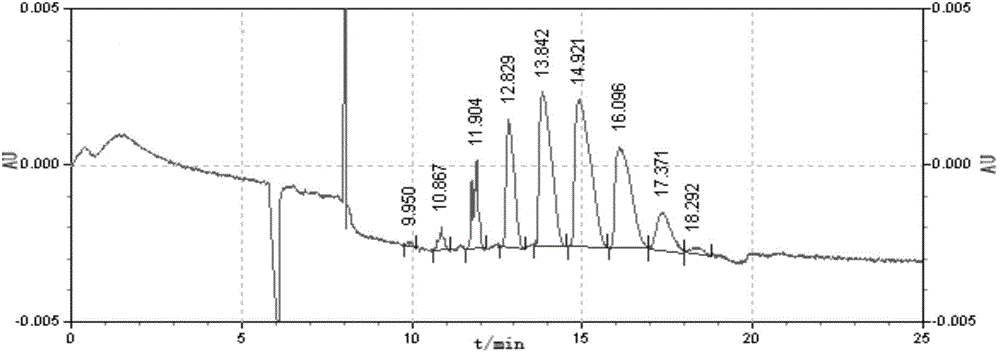

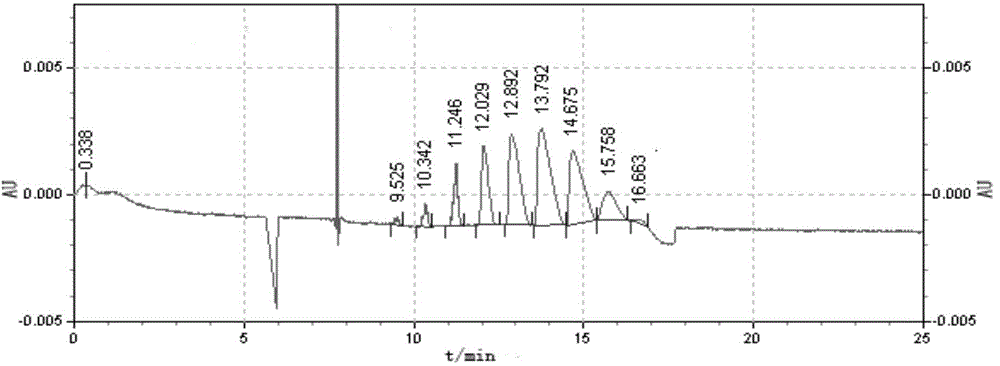

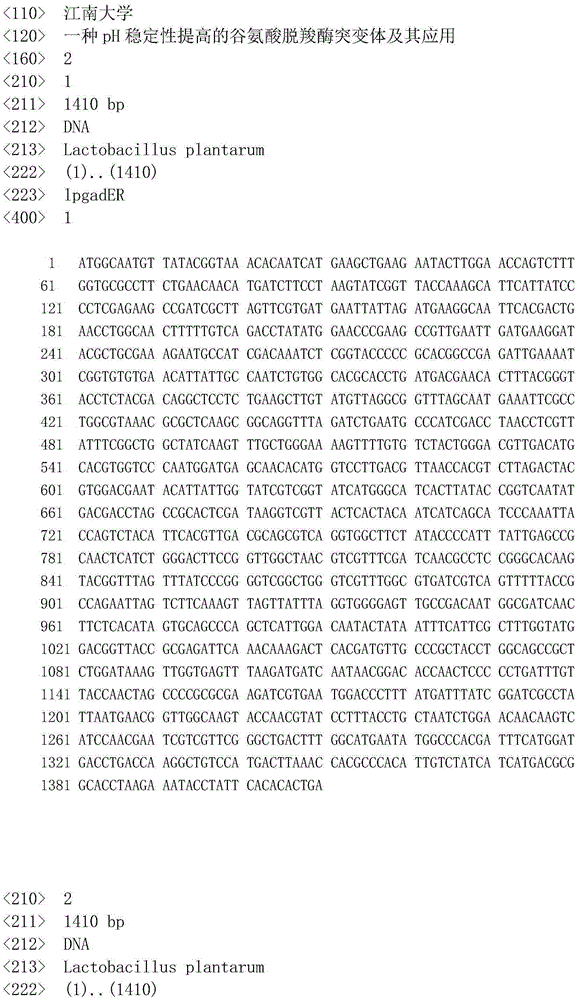

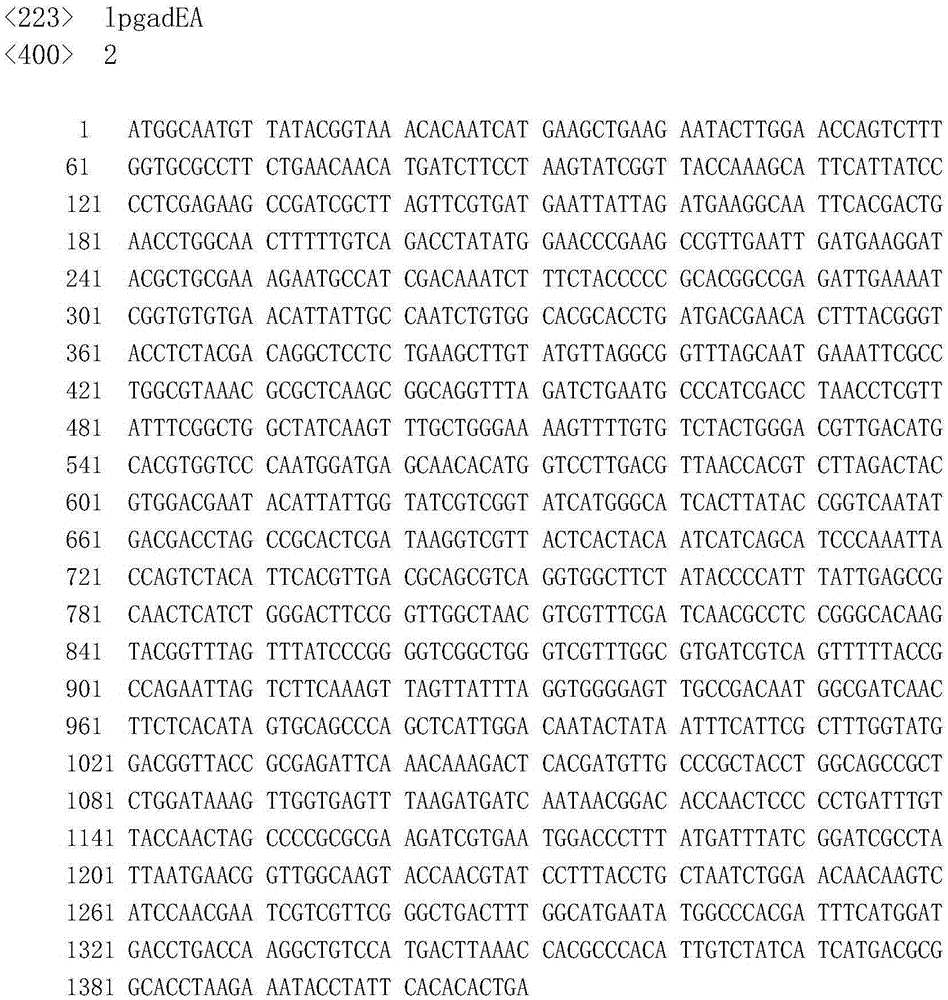

The invention discloses an acid-stable glutamic acid decarboxylase (GAD) mutant with pH stability migrating to neutral range, and belongs to the field of biological engineering. The encoding gene of glutamic acid decarboxylase derived from actobacillus plantarum GB01-21 glutamic acid decarboxylase is subjected to site-specific mutagenesis, and the glutamate E on the 89th site is mutated to arginine R or alanine A. The glutamic acid decarboxylase mutant has relative enzyme in pH value of 6.5 increased from the original 38% up to 72% or 84%, and the enzyme activity stability in the neutral pH range is increased significantly. For the transformation with a glutamic acid decarboxylase mutant synthesized by recombinant escherichia coli, the GABA yield reaches 260 g / L, and the yield is 99.6%; and for the transformation with a glutamic acid decarboxylase mutant synthesized by recombinant Corynebacterium glutamicum, the GABA yield reaches 116 g / L, and the yield is 99.5%. The invention reduces the fermentation equipment loss under acidic conditions, and lays foundation for the efficient synthesis of gamma-aminobutyric acid.

Owner:JIANGNAN UNIV

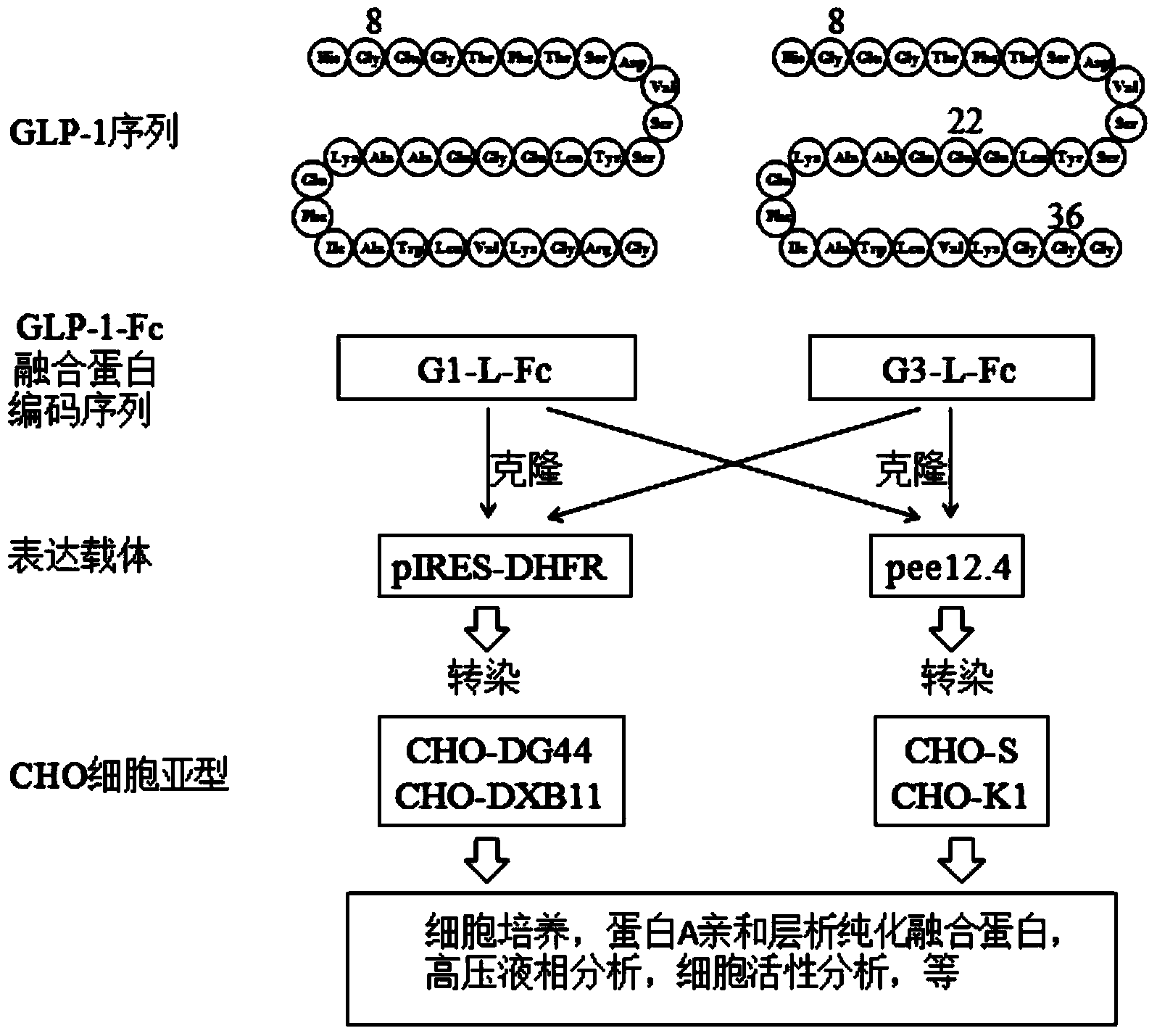

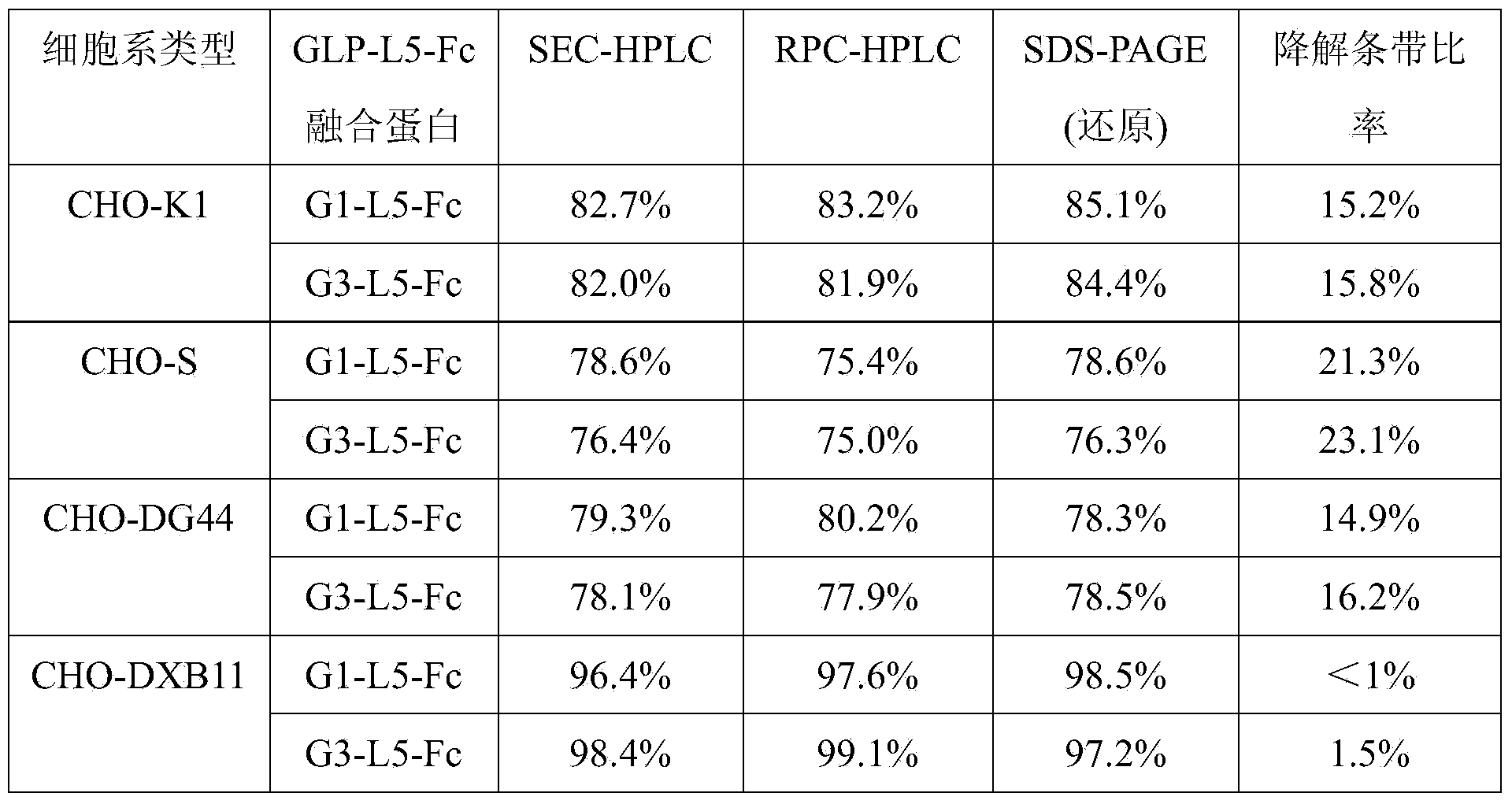

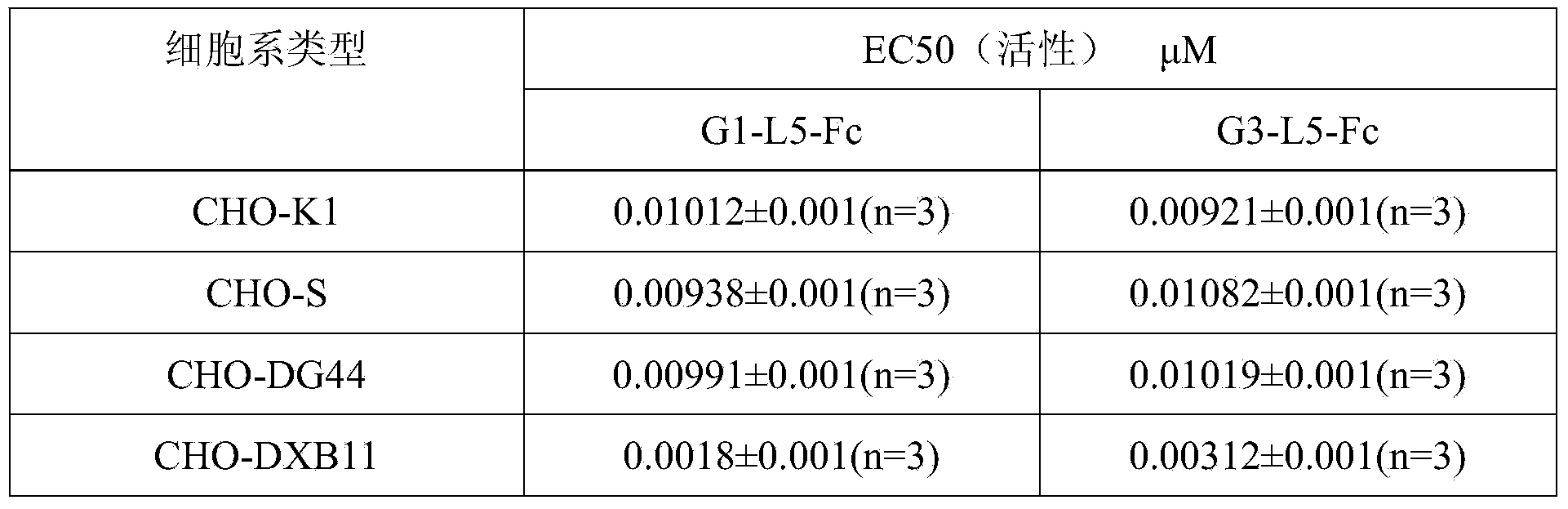

Preparation method of GLP (Glucagon-Like Peptide) -1 or analogue thereof and antibody Fc fragment fusion protein

ActiveCN104293834AReduce quality problemsIncrease the difficulty of purificationPeptide/protein ingredientsMetabolism disorderCell strainDrug biological activity

The invention relates to the technical field of biology and particularly relates to a preparation method of a GLP (Glucagon-Like Peptide) -1 or analogues thereof and an antibody Fc fragment fusion protein. The preparation method of the GLP-1 or the analogues thereof and the antibody Fc fragment fusion protein comprises the following steps: cloning sequences for encoding the GLP-1 or the analogues thereof and the antibody Fc fragment fusion protein into an expression vector; transfecting the expression vector with CHO-DXB11 cells, culturing and screening a positive cell strain; expressing the obtained cell strain and purifying to obtain the fusion protein. By virtue of the preparation method provided by the invention, when the GLP-1-Fc molecule is expressed in DXB11 of the CHO cell line, the problem of degradation cannot be caused, the subsequent purification yield is greatly improved, the biological activity is not decreased and thus the preparation method is very suitable for the requirement of industrial production.

Owner:SYNDEGEN SHANGHAI BIOTECH

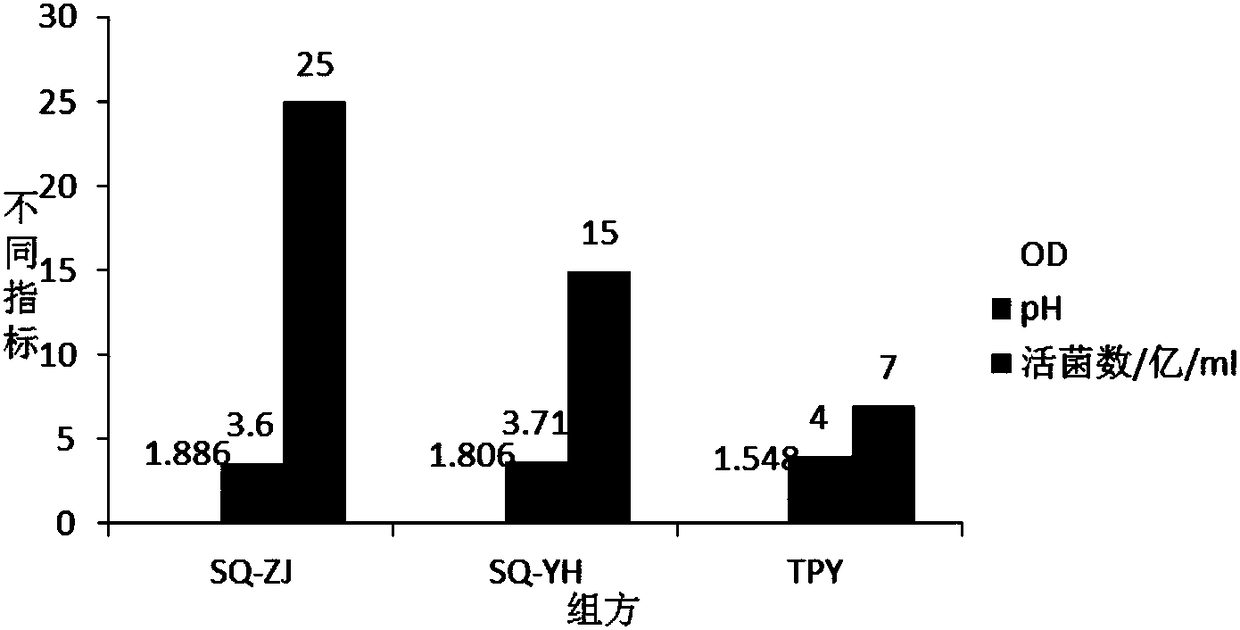

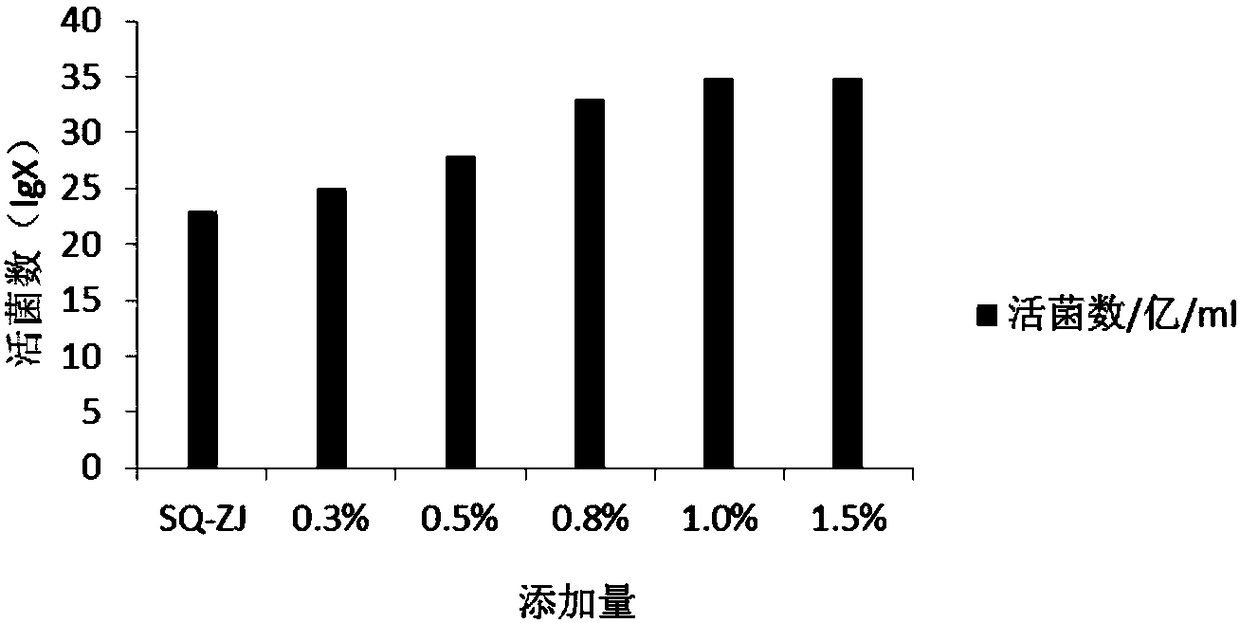

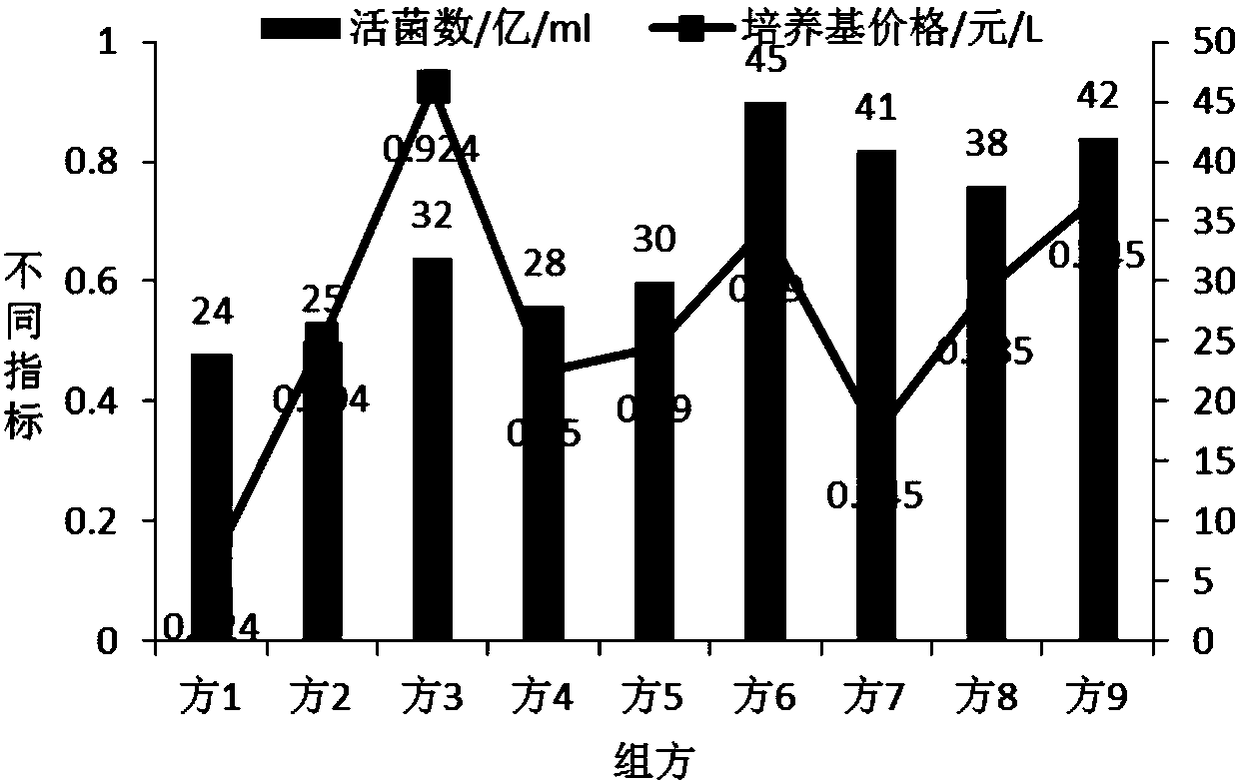

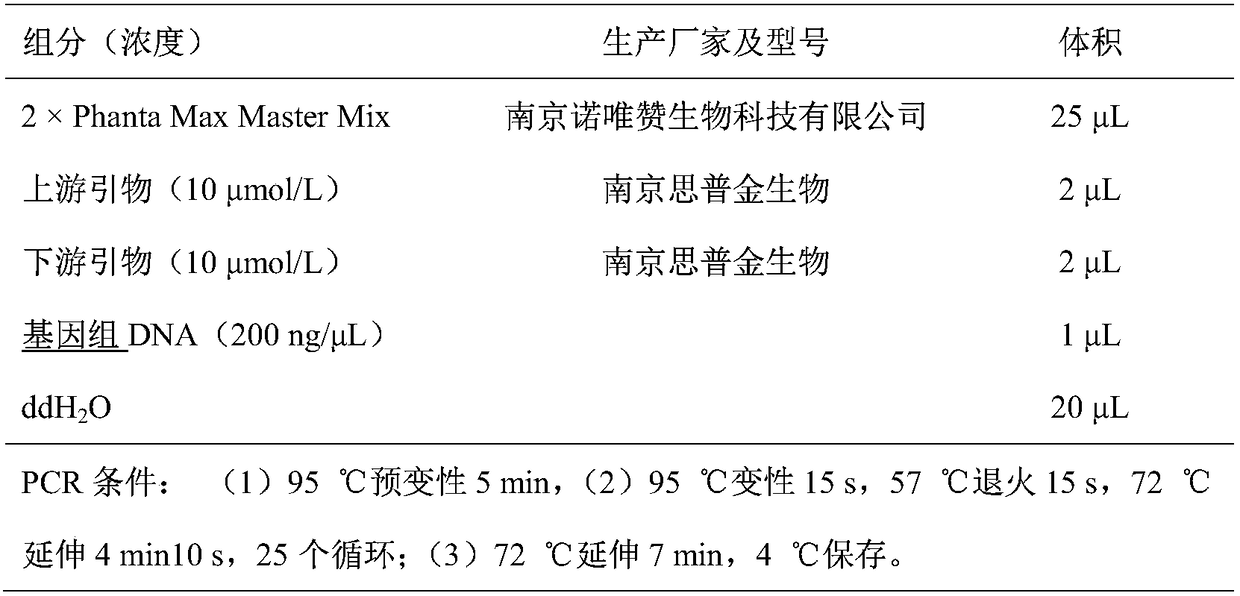

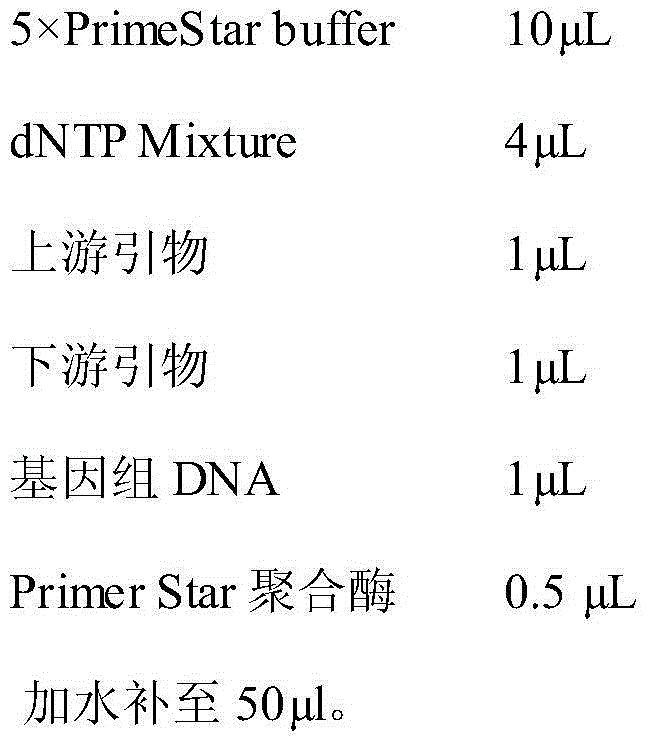

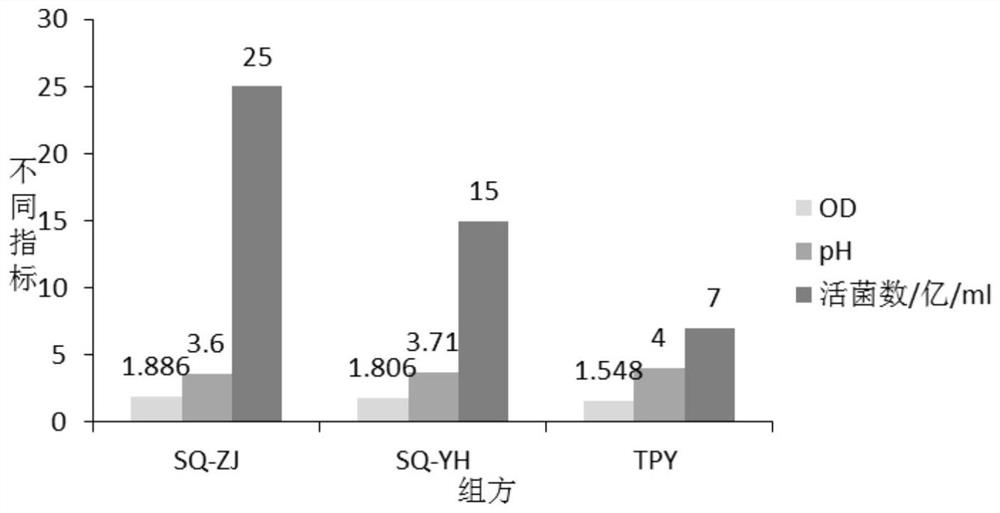

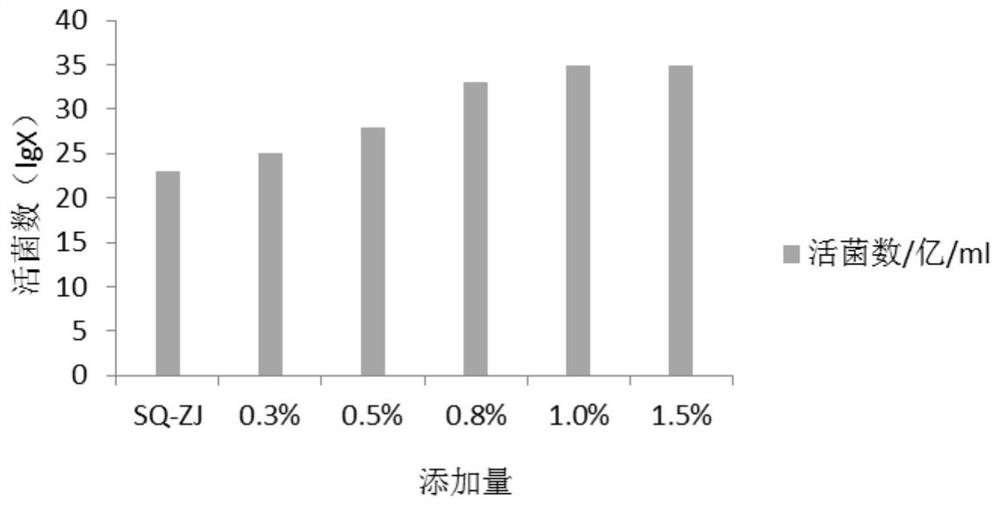

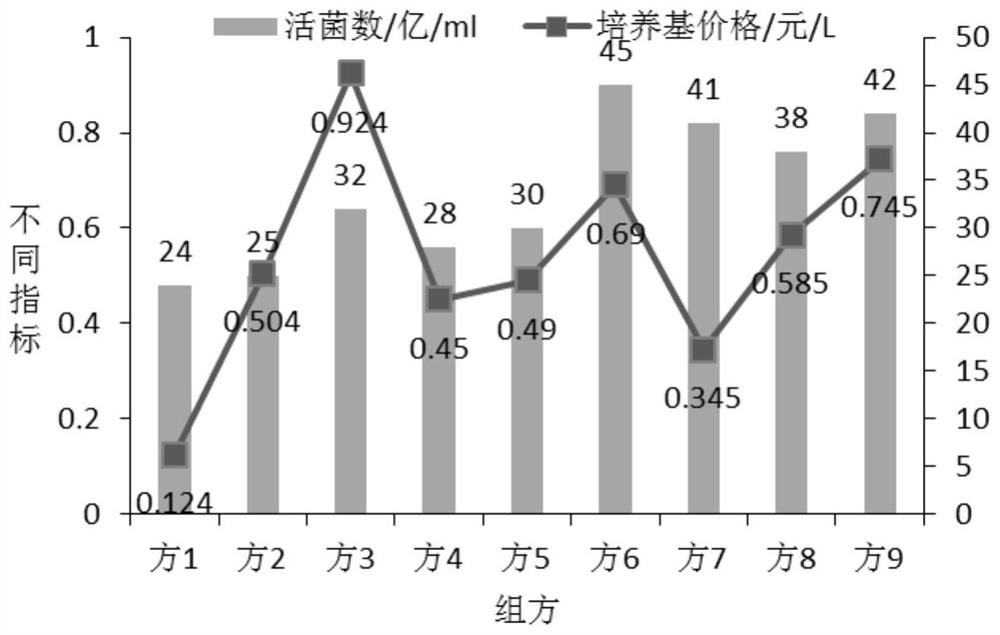

Industrial high-density mixed fermentation culture medium of bifidobacterium and lactobacillus, fermentation culture method and fungus powder embedding method

The invention provides an industrial high-density mixed fermentation culture medium of bifidobacterium and lactobacillus, a fermentation culture method and a fungus powder embedding method. The fermentation culture medium is prepared from the following components: 0.3 to 1.5 percent of corn slurry dry powder, 0 to 1.8 percent of soya peptone, 0 to 1 percent of fructooligosaccharide, 0.5 to 1 percent of glucose, 0.4 to 1.35 percent of dipotassium phosphate, 0.4 percent of potassium dihydrogen phosphate, 0.015 to 0.02 percent of magnesium sulfate, and 0.05 percent of L-cysteine hydrochloride; orthe fermentation culture medium is prepared from the following components: 0.3 to 1.5 percent of the corn slurry dry powder, 0 to 1 percent of beef extract, 0 to 1 percent of the fructooligosaccharide, 0.5 to 1 percent of the glucose, 0.4 to 1.35 percent of the dipotassium phosphate, 0.4 percent of the potassium dihydrogen phosphate, 0.015 to 0.02 percent of the magnesium sulfate and 0.05 percentof the L-cysteine hydrochloride; the fermentation method comprises strain activation and culture, first-grade strain culture, second-grade seed solution preparation, 200L small tank culture in a workshop and 1T large tank culture in the workshop. Comparing the relatively traditional TPY culture medium, the viable count improves 10 times or more and the cost is reduced by 60 percent, meanwhile, according to the formula, raw materials are easy to obtain and the components are simple, so that the fermentation culture medium is suitable for industrial production requirements. The fungus powder embedding method is adopted so that the human body and external environment tolerance capability of strains is greatly improved.

Owner:山东凤凰生物科技股份有限公司

Lysine decarboxylase mutant, encoding gene and expression thereof and application

ActiveCN108795916AHigh enzyme activityEnhanced alkali resistance and catalytic performanceBacteriaMicroorganism based processesMutantLysine decarboxylase

The invention discloses a lysine decarboxylase mutant. The lysine decarboxylase mutant is obtained by carrying out site-directed mutation on lysine decarboxylase with an amino acid sequence shown as SEQ ID No: 2 and is any one of (1) and (2): (1) valine at a 12th site of lysine decarboxylase with the amino acid sequence shown as SEQ ID No: 2 is mutated into cysteine and aspartic acid at a 41st site is mutated into the cysteine to obtain the lysine decarboxylase mutant V12C / D41C; (2) leucine at a 89th site of lysine decarboxylase with the amino acid sequence shown as SEQ ID No: 2 is mutated into the cysteine and leucine at a 442nd site is mutated into the cysteine to obtain the lysine decarboxylase mutant L89C / L442C. According to the lysine decarboxylase mutant provided by the invention, the alkali-resisting and catalytic performance is greatly improved and the lysine decarboxylase mutant is more suitable for industrialized production requirements and meets the requirements of social production.

Owner:NANJING UNIV OF TECH

Method for preparing regenerative magnesia-carbon bricks

The invention belongs to the technical field of a refractory material, and discloses a method for preparing regenerative magnesia-carbon bricks. The method comprises the following technical flow steps: piling in classification; sorting; removing impurities; preprocessing; pulverizing; dehydrating; screening; packing; and molding the bricks. Regeneration grains can be used for producing regenerated magnesia carbon bricks, aluminum-magnesium-carbon bricks, aluminum carborundum carbon bricks, tundish dry materials, aluminum-magnesium-carbon fireclay and slag-pot unfired bricks. The regeneration use rate of the carbonic crushed bricks can reach as high as 100 percent. The method saves resources, clears garbage and protects the environment.

Owner:申久祝

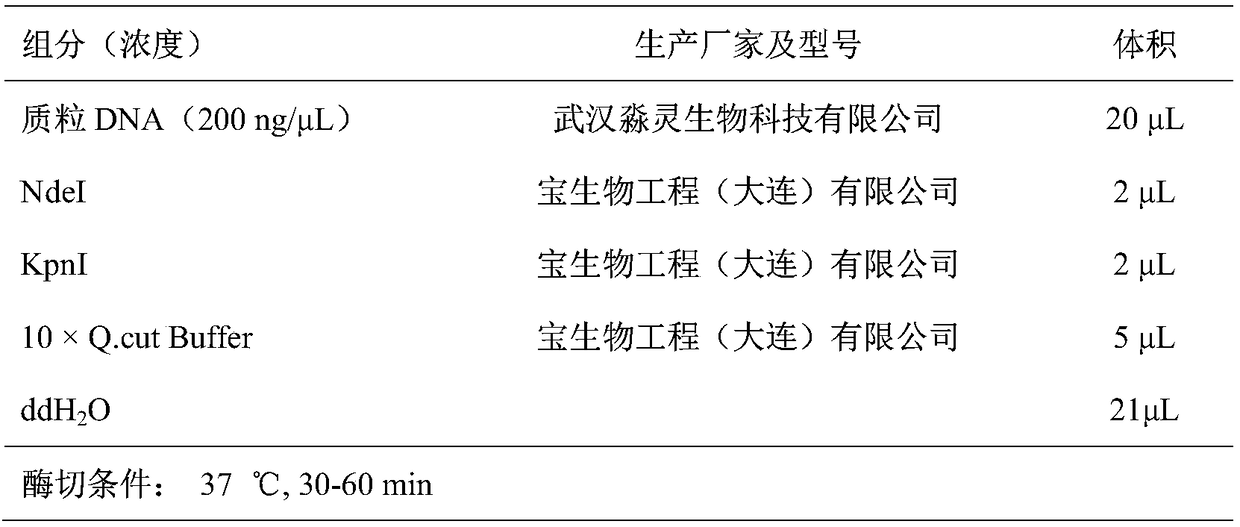

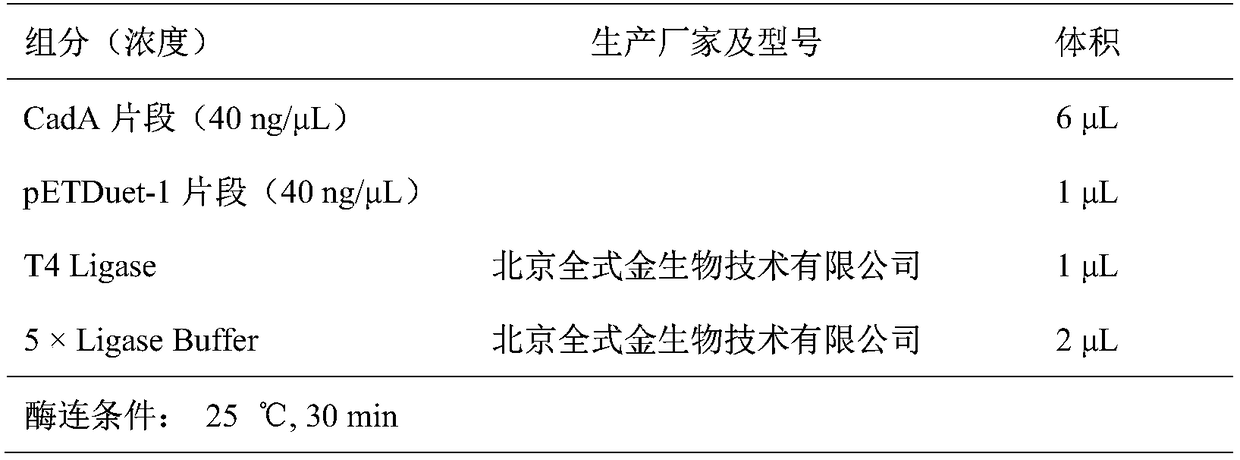

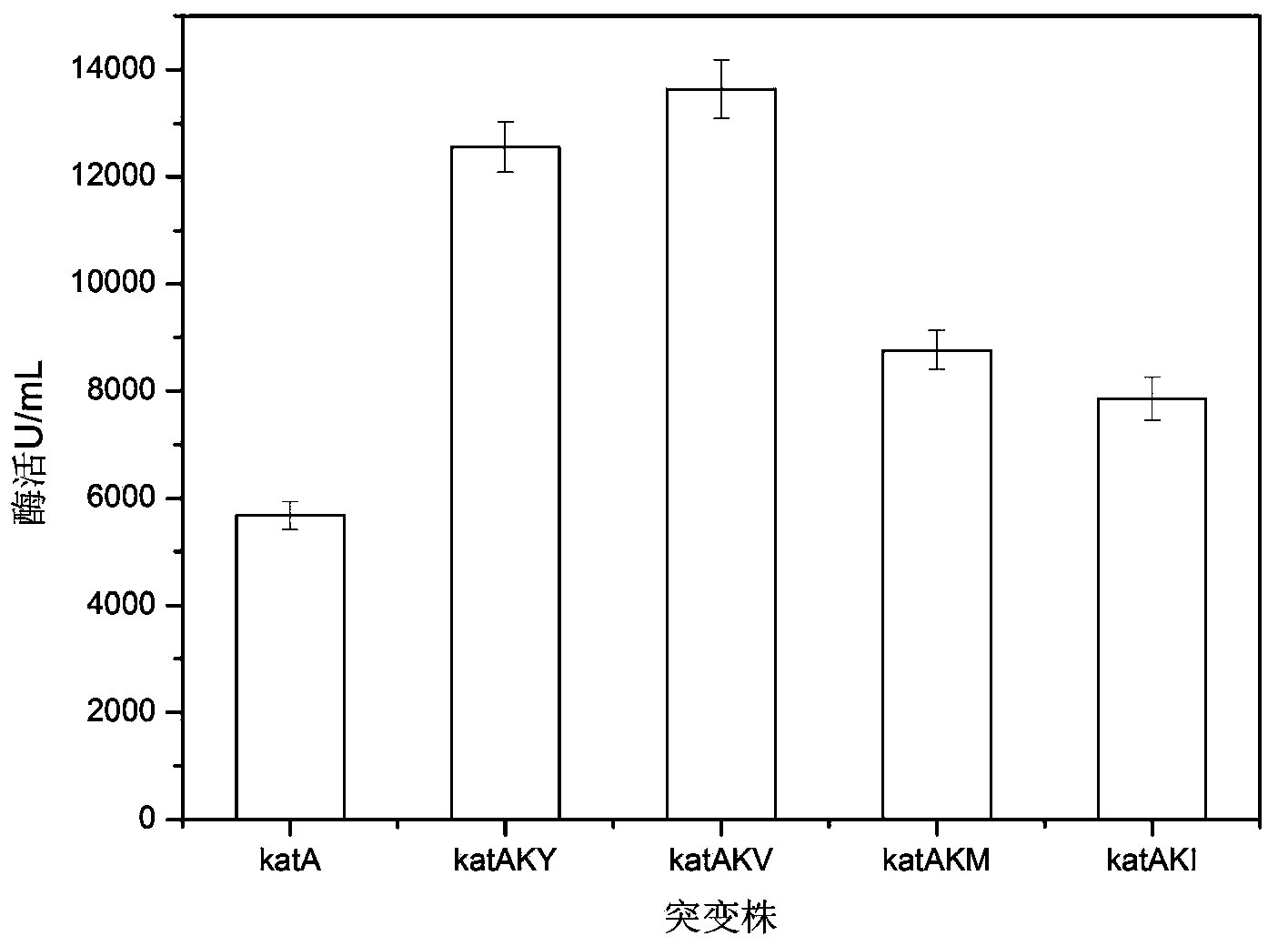

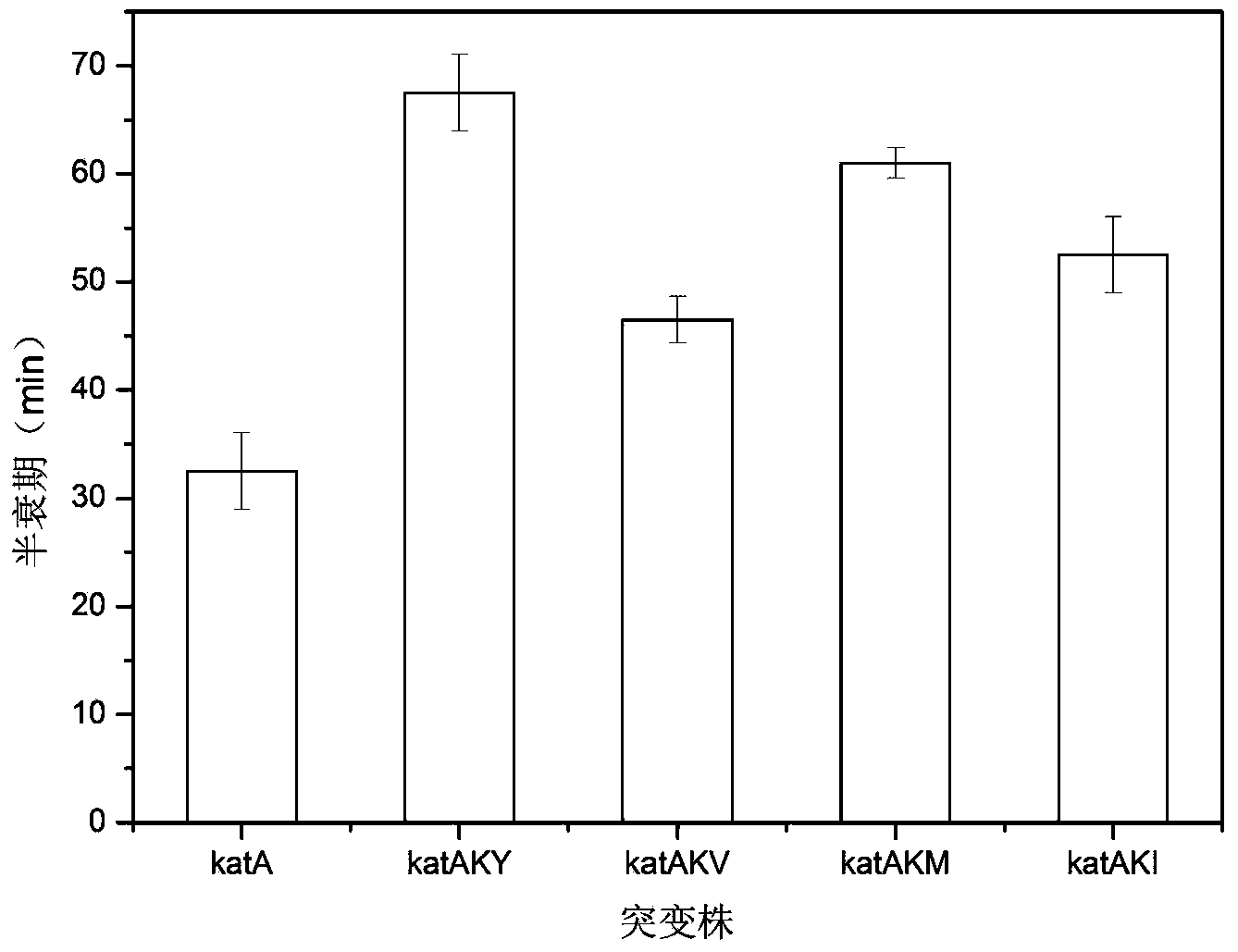

Catalase mutant with improved enzyme activity and heat stability

InactiveCN103451163AIncrease productionGood enzymatic propertiesBacteriaMicroorganism based processesHalf-lifeTyrosine

The invention discloses a catalase mutant with improved enzyme activity and heat stability, and belongs to the field of biological engineering. Catalase derived from bacillus subtilis (B. subtilis WSHDZ-01) is subjected to site-specific mutagenesis, so that a lysine of an amino acid sequence coded by the catalase is respectively mutated into tyrosine Y, valine V, methionine M or isoleucine I at the site 114. The expression quantity of the catalase mutant is respectively 2.23, 2.41, 1.46 and 1.38 times of the expression quantity before mutation, and the half-life period of the catalase after mutation is respectively 2.17, 1.5, 2 and 1.67 times of the half-life period before mutation in the terms of thermal tolerance. The catalase mutant is suitable for industrialization production requirements and has wide application prospect.

Owner:JIANGNAN UNIV

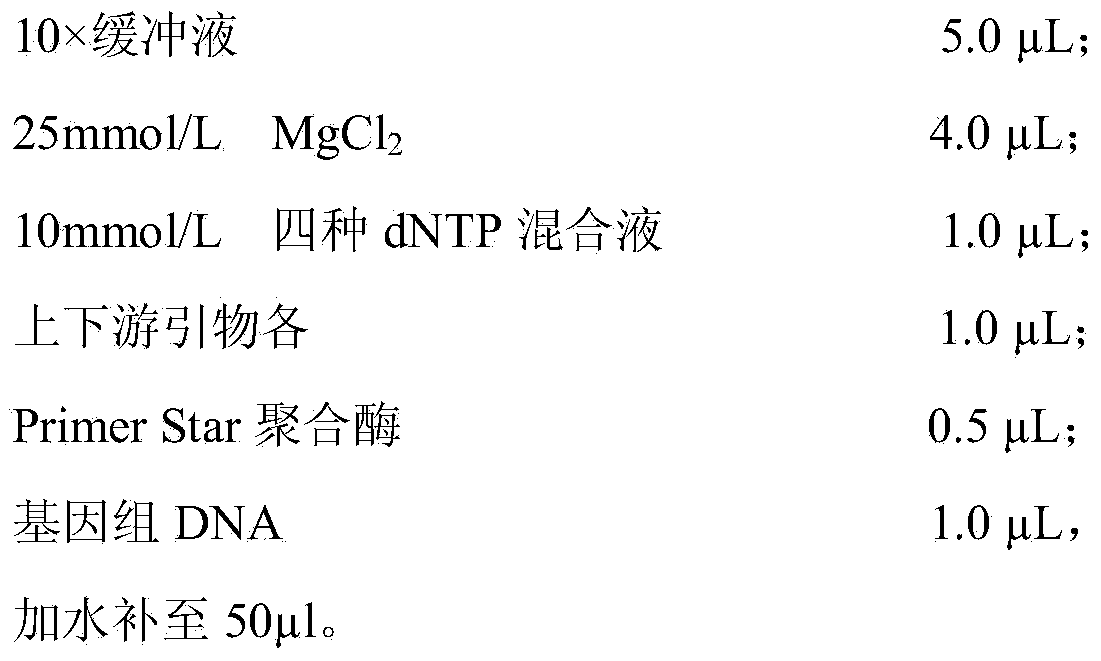

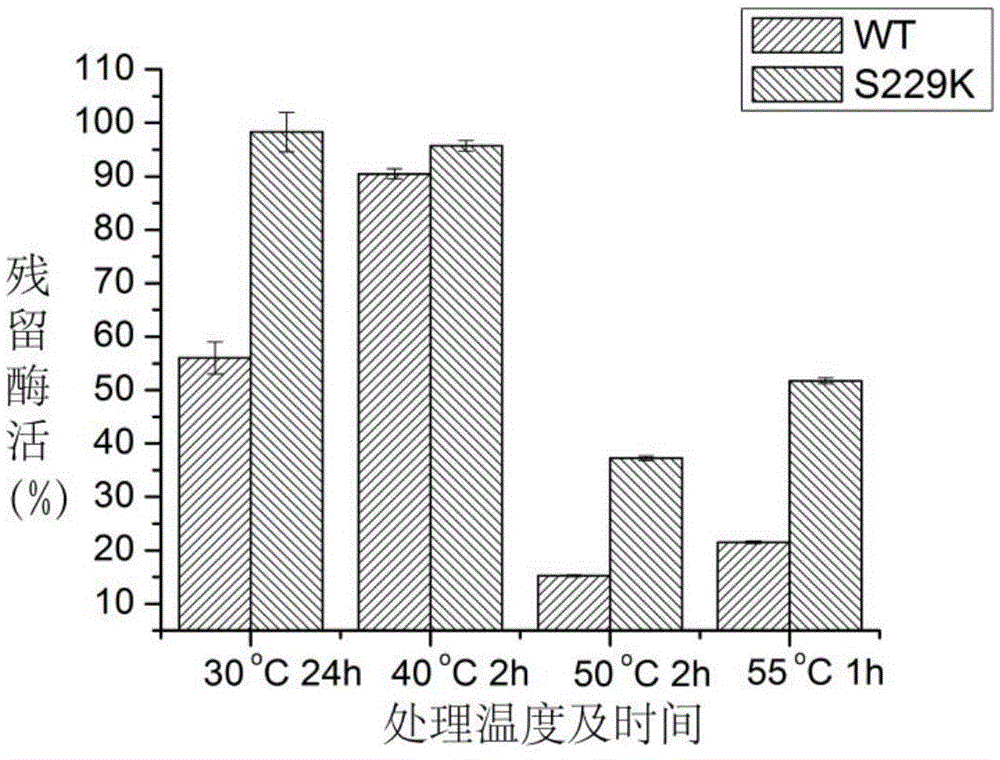

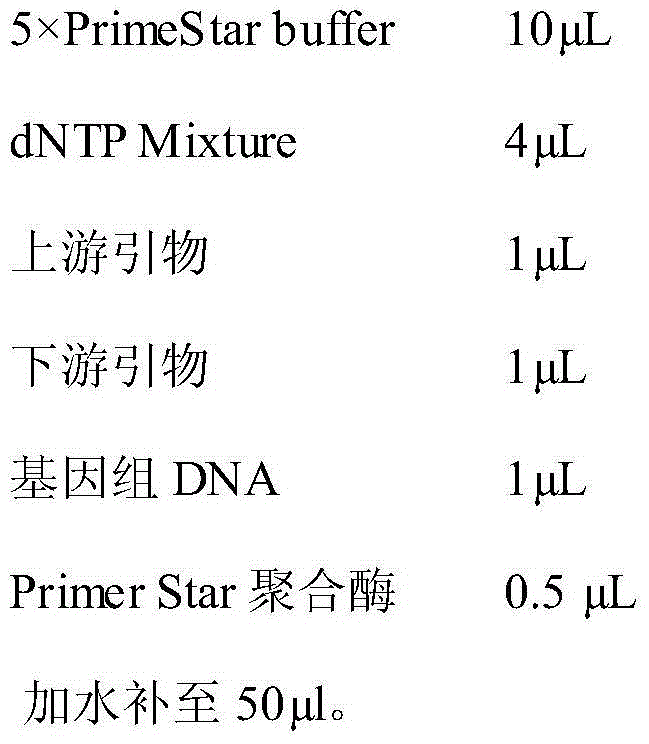

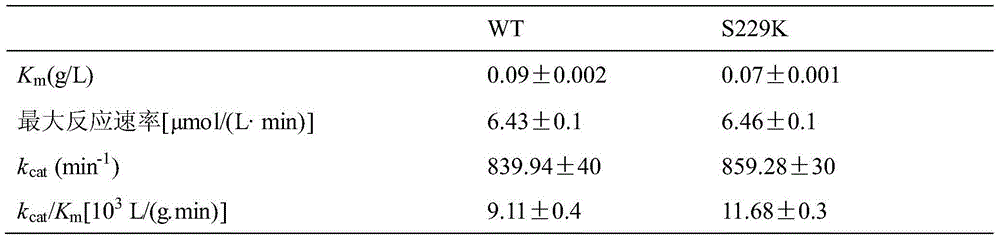

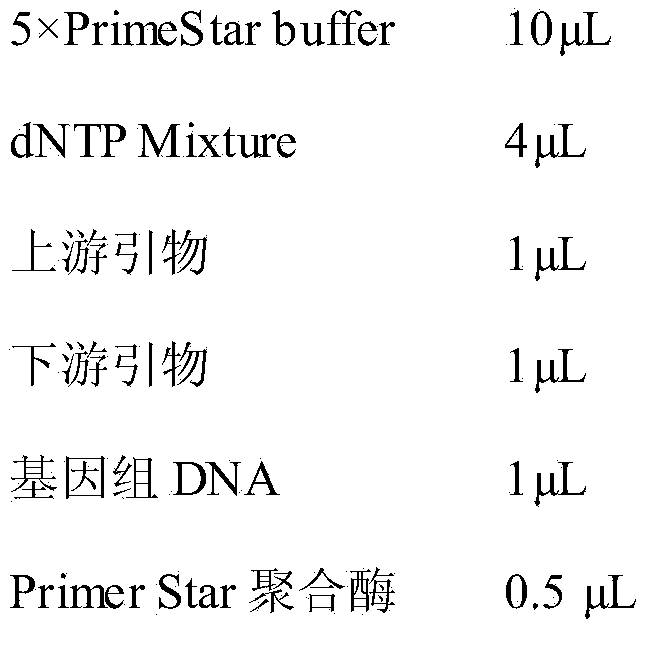

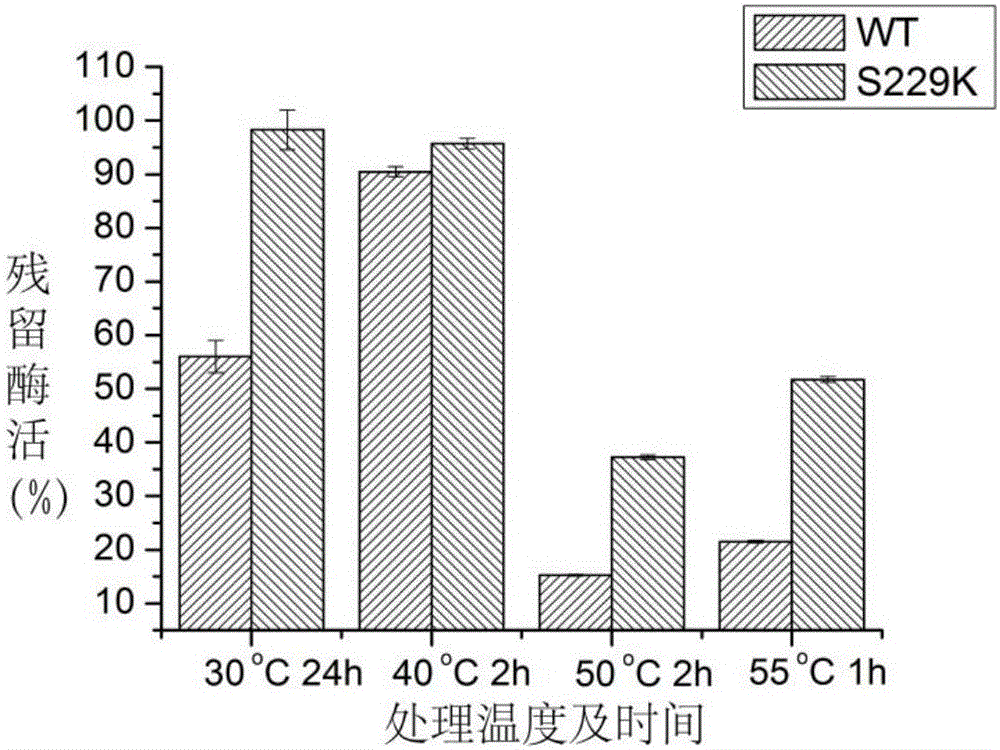

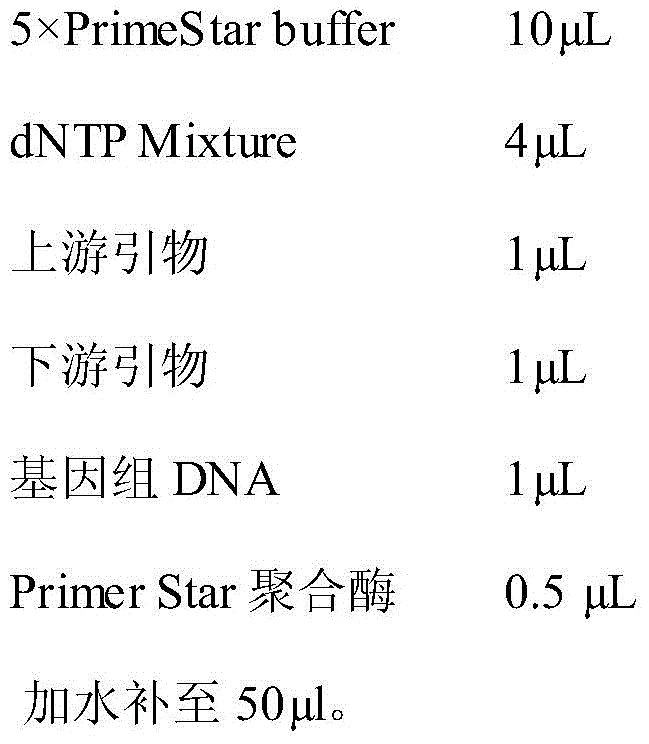

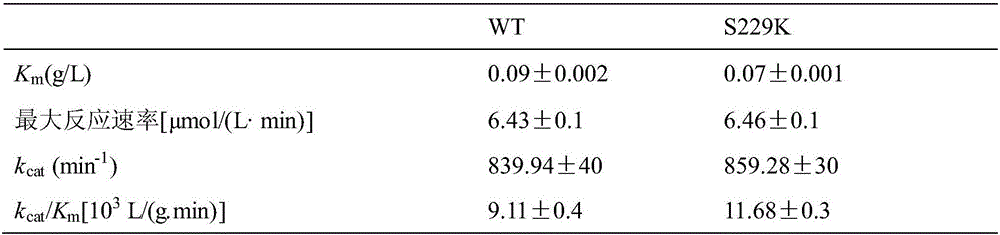

Alkaline pectase mutant with improved heat stability

InactiveCN103981167AImprove thermal stabilityIncreased residual enzyme activityBacteriaFermentationHalf-lifeReaction temperature

The invention discloses an alkaline pectase mutant with an improved heat stability, and belongs to the technical field of bioengineering. The 229th serine S site of an alkaline pectase mutates to lysine K. The heat stabilities of the mutant at 30DEG C, 50DEG C and 55DEG C are respectively obviously higher than the heat stabilities of the alkaline pectase before the mutation. The optimal reaction temperature of the mutant rises by 5DEG C, the half life of the mutant at 55DEG C is 2.10 times the half life of the alkaline pectase, and the Km, Vmax, kcat and kcat / Km are improved. The alkaline pectase mutant provided by the invention is more suitable for industrial production demands, and meets social production requirements.

Owner:JIANGNAN UNIV

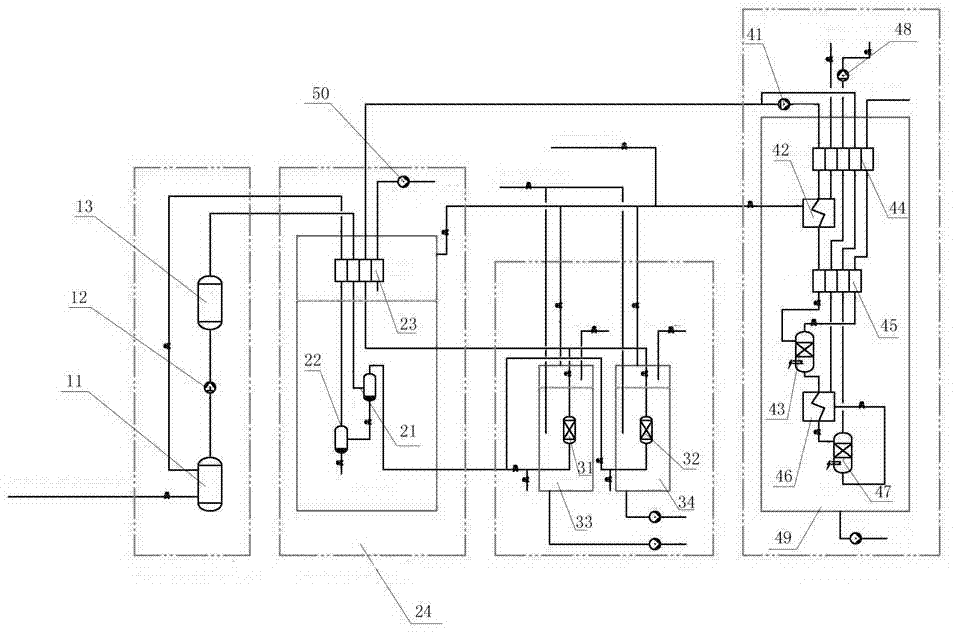

Low-temperature separation and extraction system and method of pure neon

The invention relates to a low-temperature separation and extraction system and a low-temperature separation and extraction method of pure neon. The system comprises a raw material storage and pressurization unit, a condensation separation denitrification unit, an adsorption denitrification unit and a neon purification unit, wherein the raw material storage and pressurization unit, the condensation separation denitrification unit, the adsorption denitrification unit and the neon purification unit are connected in sequence by virtue of pipelines; the raw material storage and pressurization unit comprises a low-pressure buffer tank, a raw material compressor and a medium-pressure buffer tank which communicate in sequence by virtue of pipelines; the condensation separation denitrification unit comprises a first-stage separator and a second-stage separator which communicate in sequence by virtue of a pipeline, and a first heat exchanger is further arranged between the first-stage separator and the medium-pressure buffer tank of the raw material storage and pressurization unit; and the adsorption denitrification unit comprises a first denitrification adsorber and a second denitrification adsorber which communicate in parallel, and the first denitrification adsorber and the second denitrification adsorber are respectively arranged in a second vacuum insulation container and a third vacuum insulation container.

Owner:ZHEJIANG XIN RUI AIR SEPARATION PLANT CO LTD

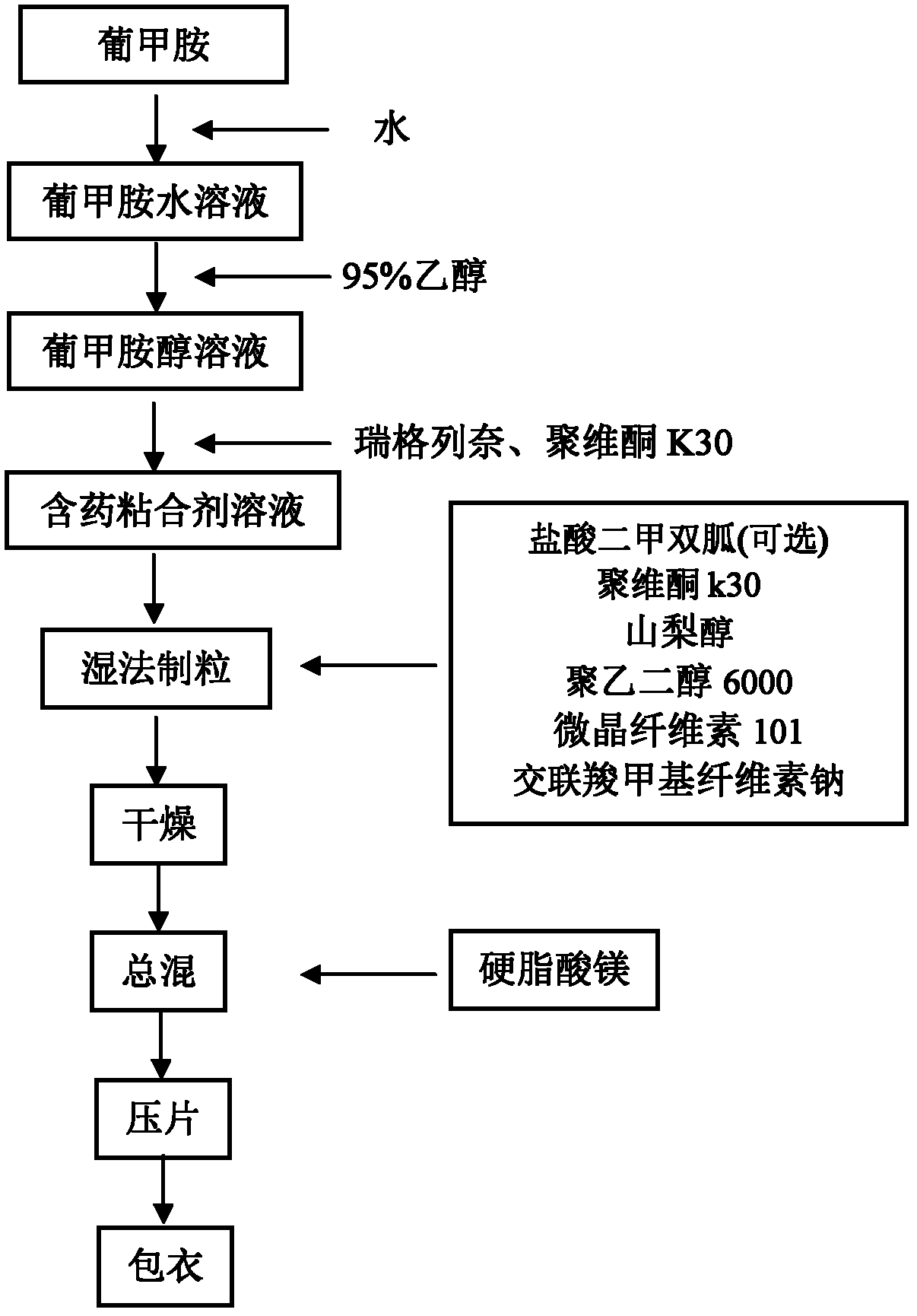

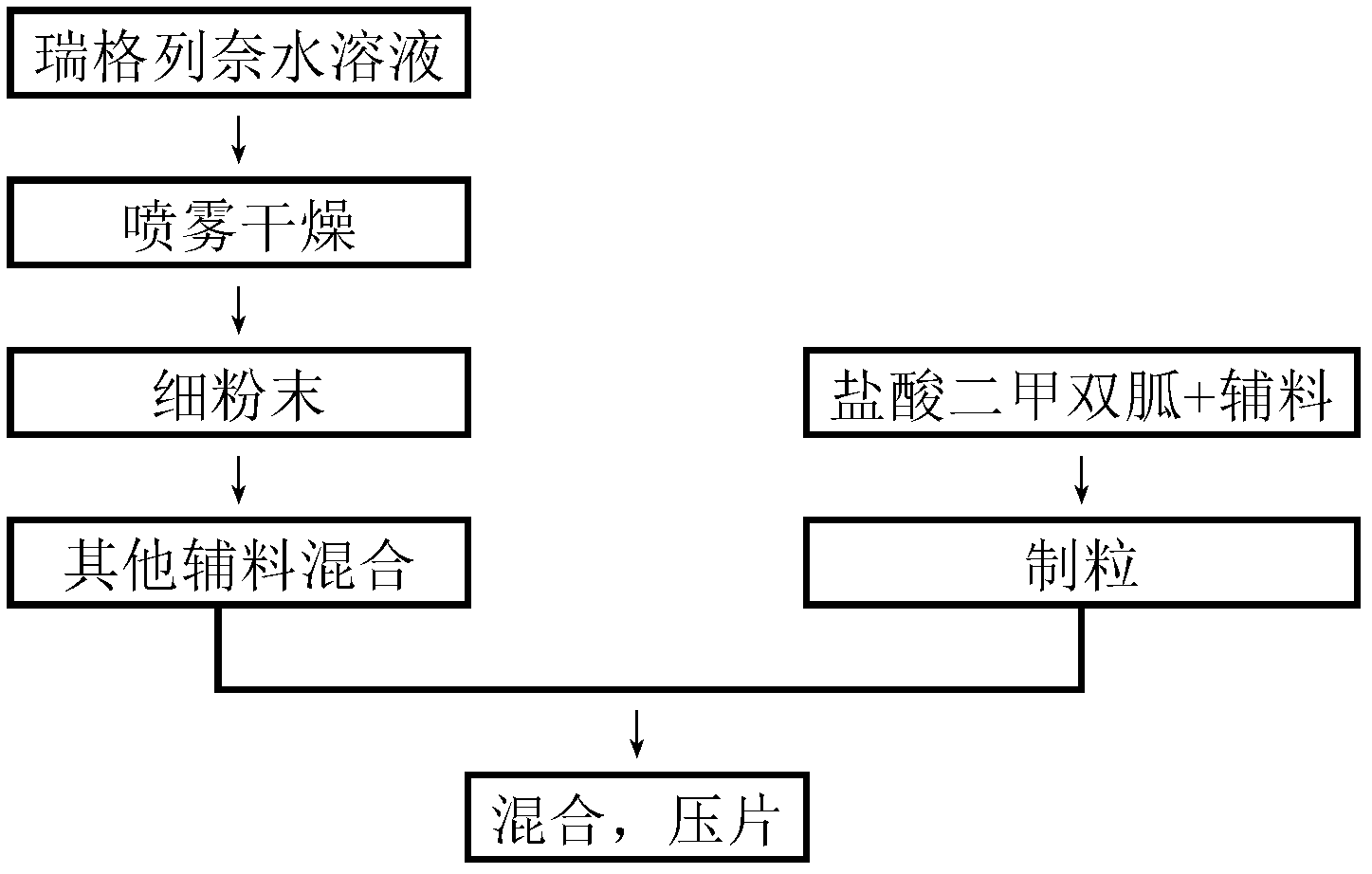

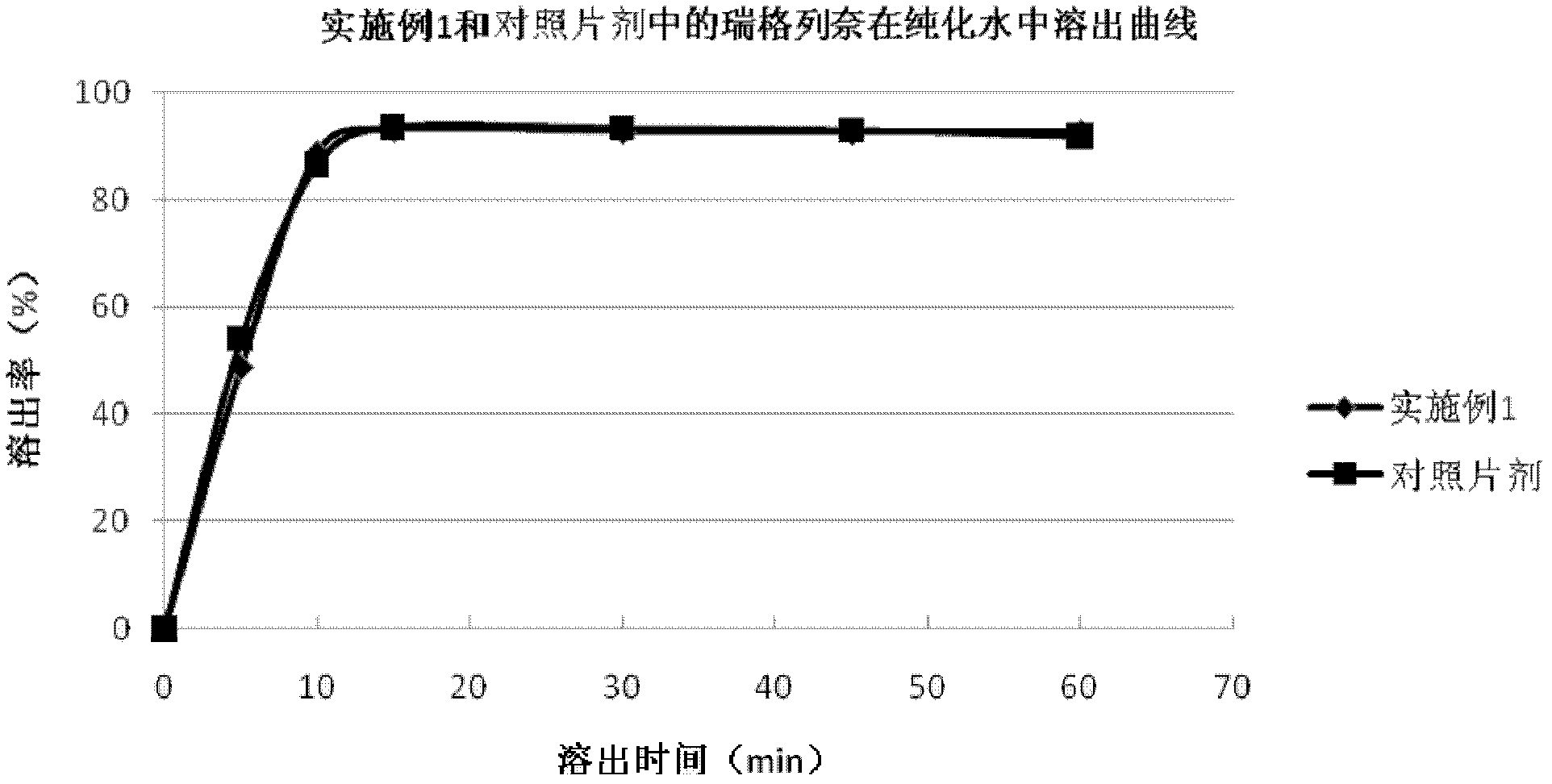

Medicinal preparation containing repaglinide and preparation of medicinal preparation

ActiveCN103181923ASimple processSuitable for industrial production needsOrganic active ingredientsMetabolism disorderAdjuvantAlcohol

The invention relates to a preparation method of a medicinal preparation of repaglinide. The preparation method comprises the following steps: (a) dissolving meglumine and repaglinide in alcohol and water to prepare an adhesive solution; (b) mixing pharmaceutically acceptable adjuvant materials to prepare a mixture; (c) adding the adhesive solution to the mixture obtained in the step b, and performing wet granulation; and (d) preparing the medicinal preparation. The invention further relates to application of meglumine as a repaglinide stabilizer in the medicinal preparation containing repaglinide.

Owner:BEIJING HANMI PHARMA CO LTD

Battery diaphragm, preparation method thereof and lithium ion battery

InactiveCN109473603ADoes not hinder migrationUniform distribution of poresLi-accumulatorsCell component detailsFiberProtection layer

The invention relates to the technical field of battery materials, and discloses a battery diaphragm. The battery diaphragm comprises a base membrane and a spinning layer formed on one surface or twosurfaces of the base membrane, wherein the spinning layer comprises a composite fiber with a core-shell structure; and the composite fiber comprises a fire retardant serving as a core and a high temperature-resistant high polymer material serving as a shell. The battery diaphragm has favorable stability under high temperature and has small high temperature thermal shrinking percentage. Moreover, the spinning layer is provided with a protection layer by the high temperature-resistant high polymer material and is filled with the fire retardant, so as to prevent the fire retardant from being in contact with electrolyte at ordinary time and not influence the performance of the electrolyte under normal state. When the battery is slightly overheated, the protection layer is not damaged, so thatthe performance play space of the battery is increased. When the battery is seriously overheated or suffers thermal runaway to cause the diaphragm to be squeezed out or cause the heat-resistant fibershell to be fused, the fire retardant is released to inhibit the combustion of the electrolyte.

Owner:BYD CO LTD

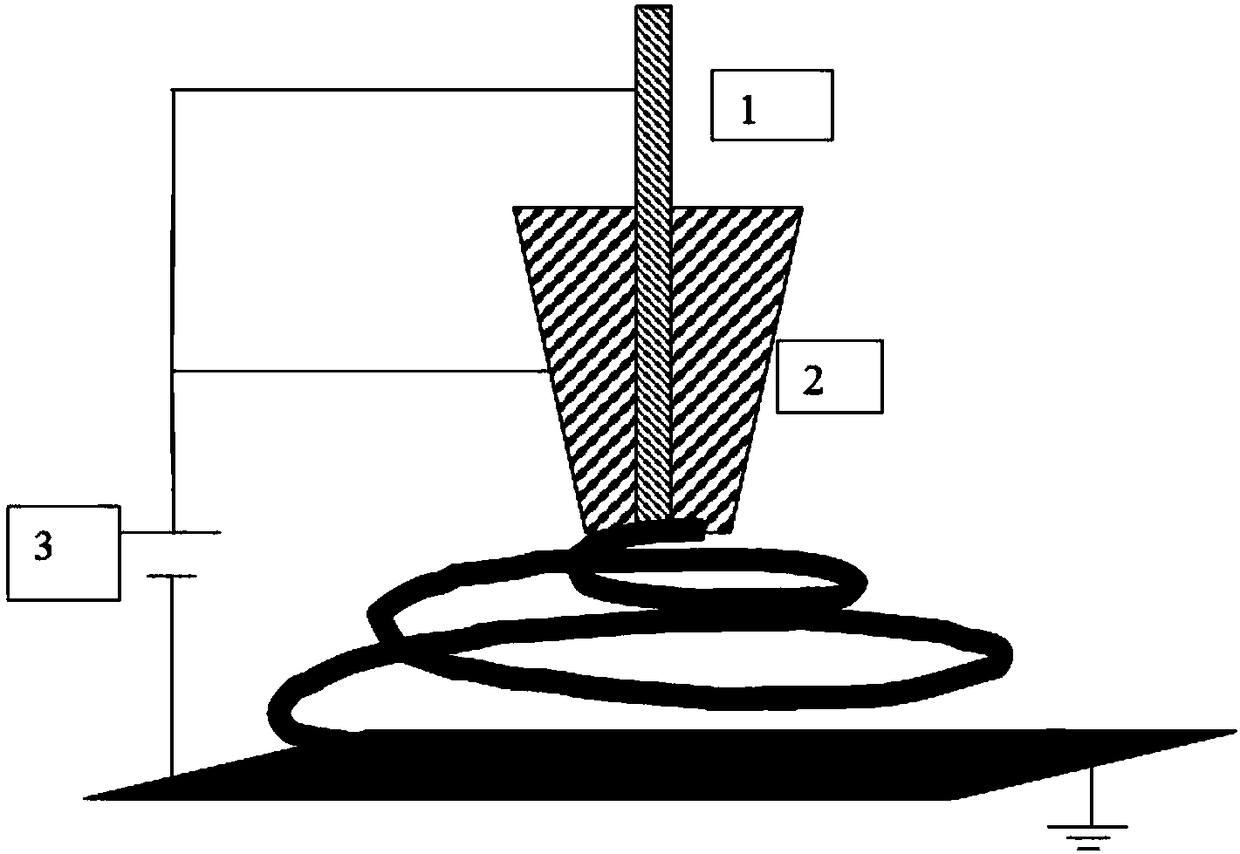

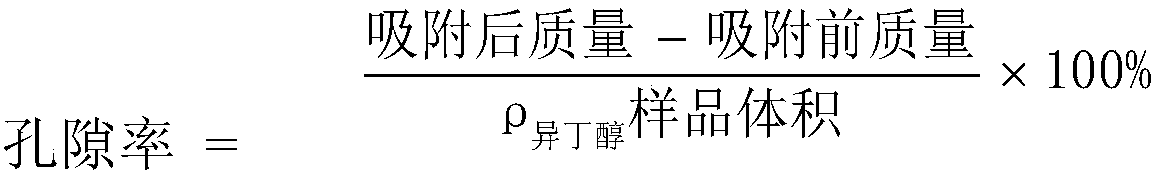

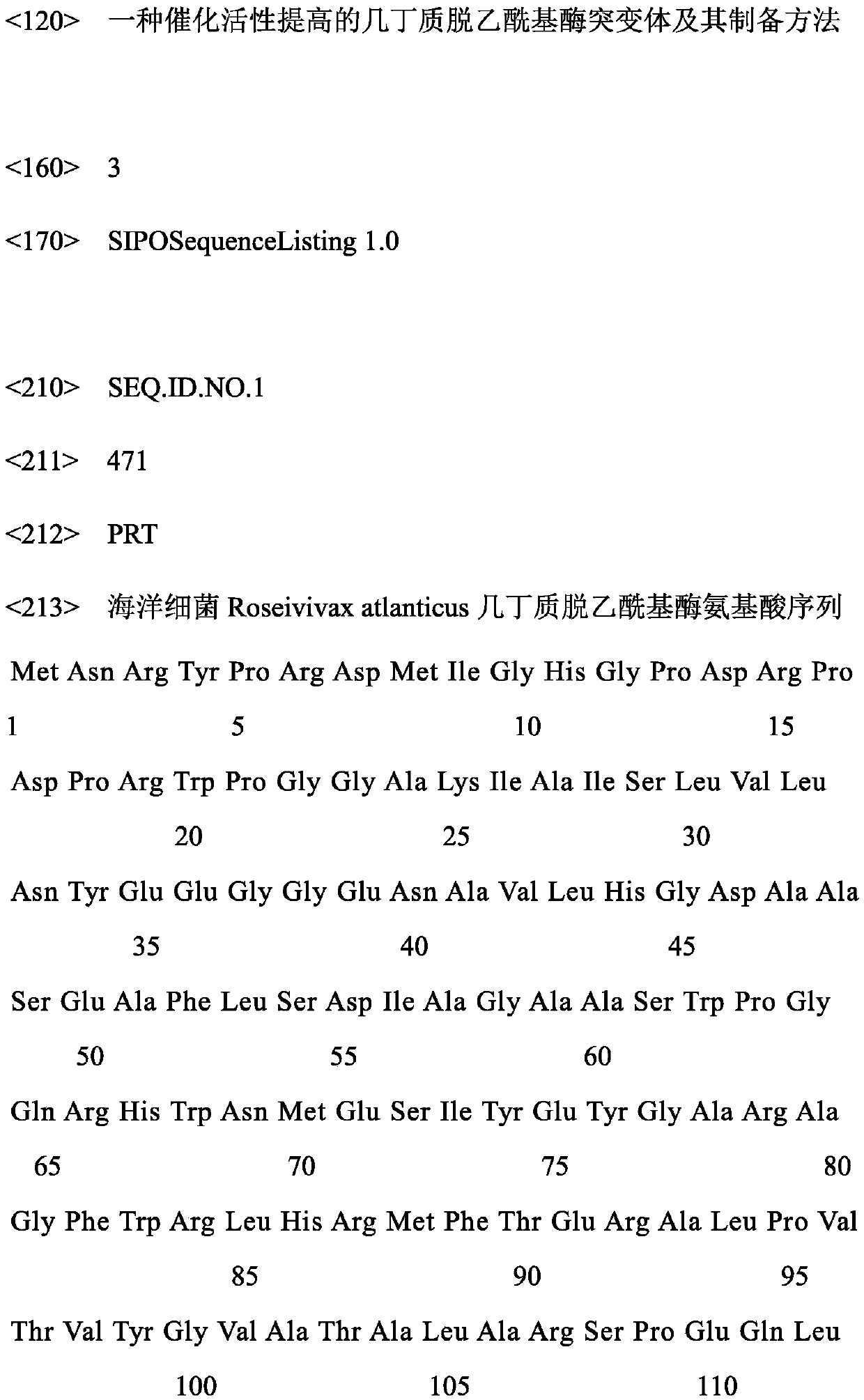

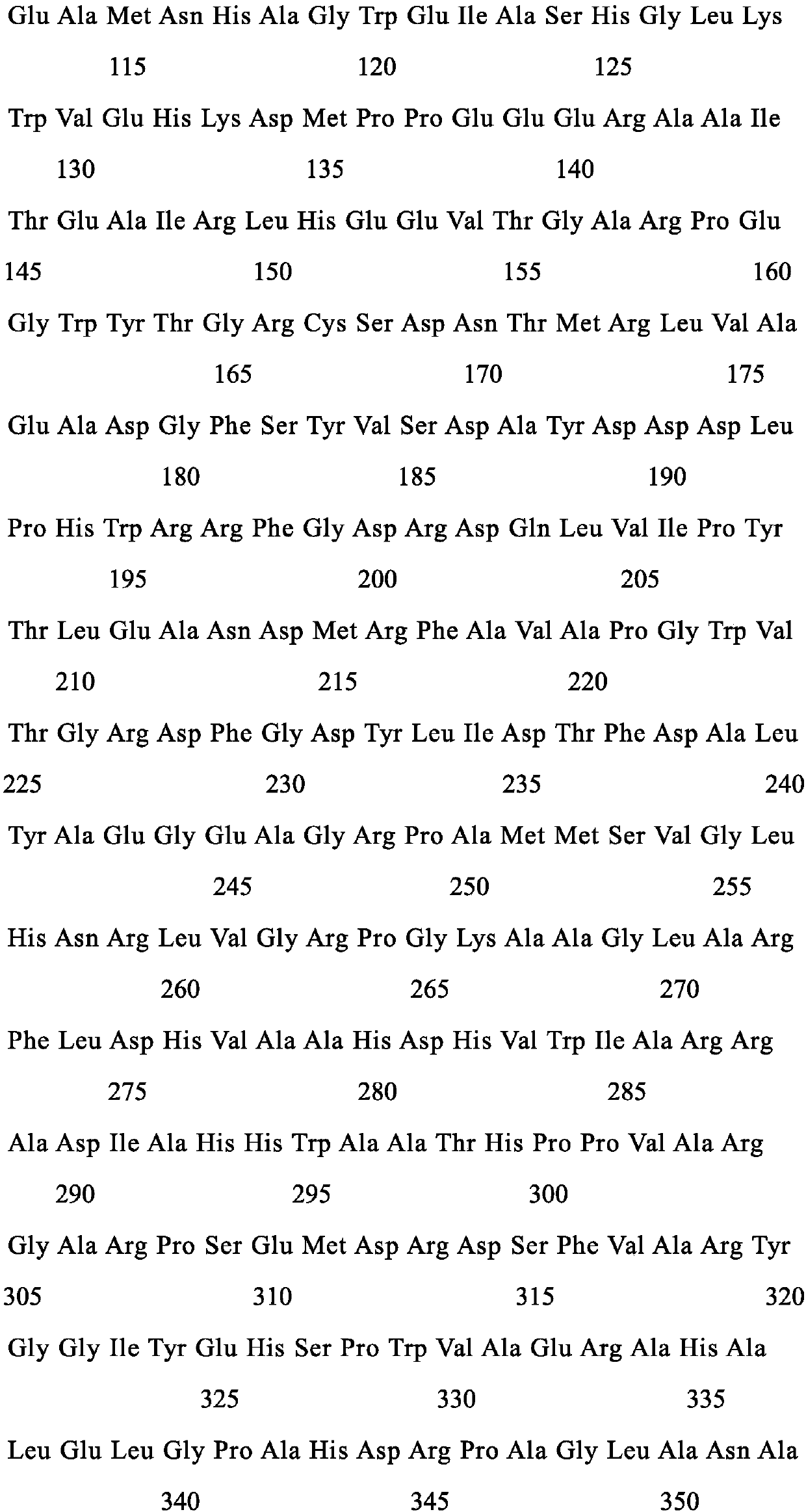

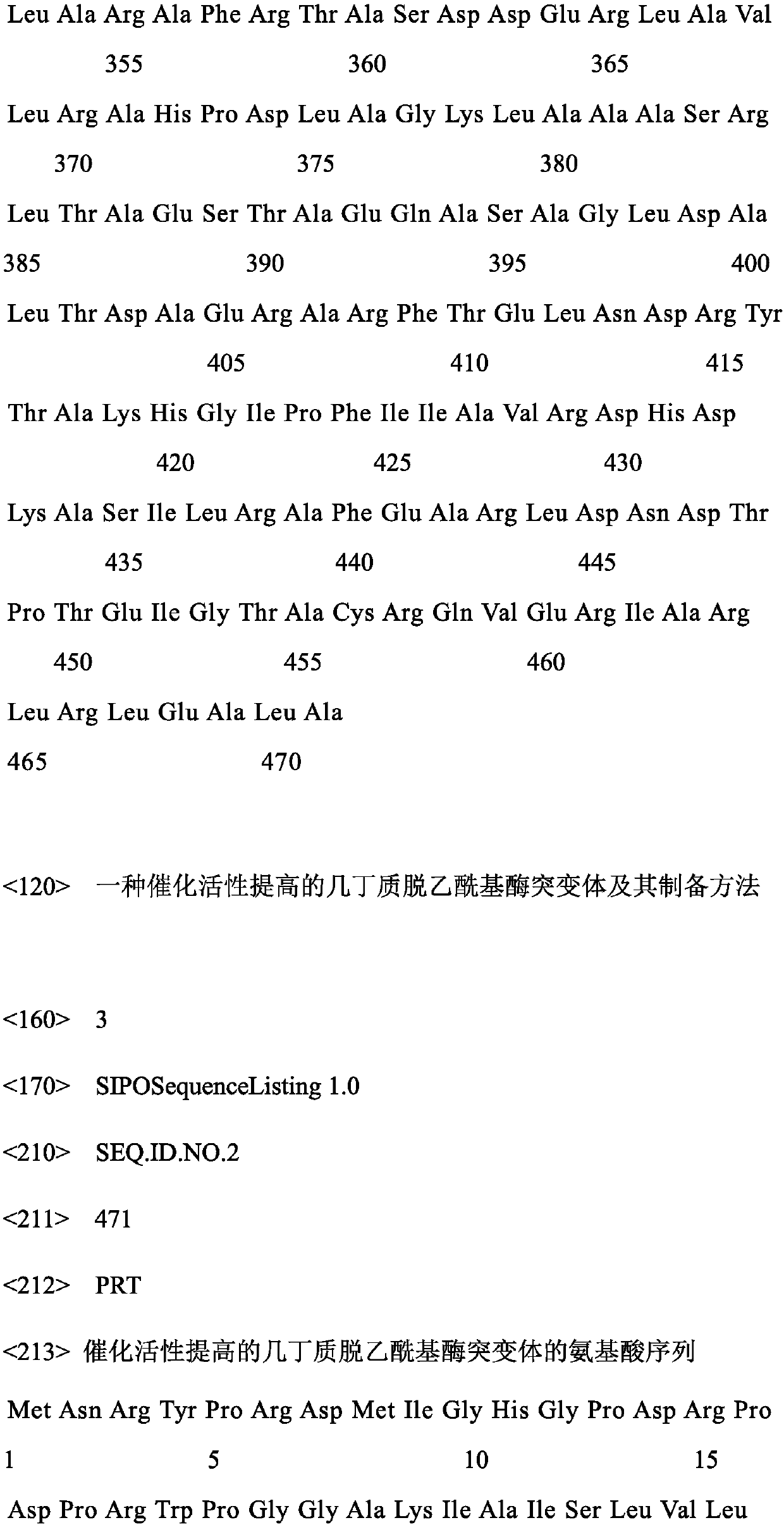

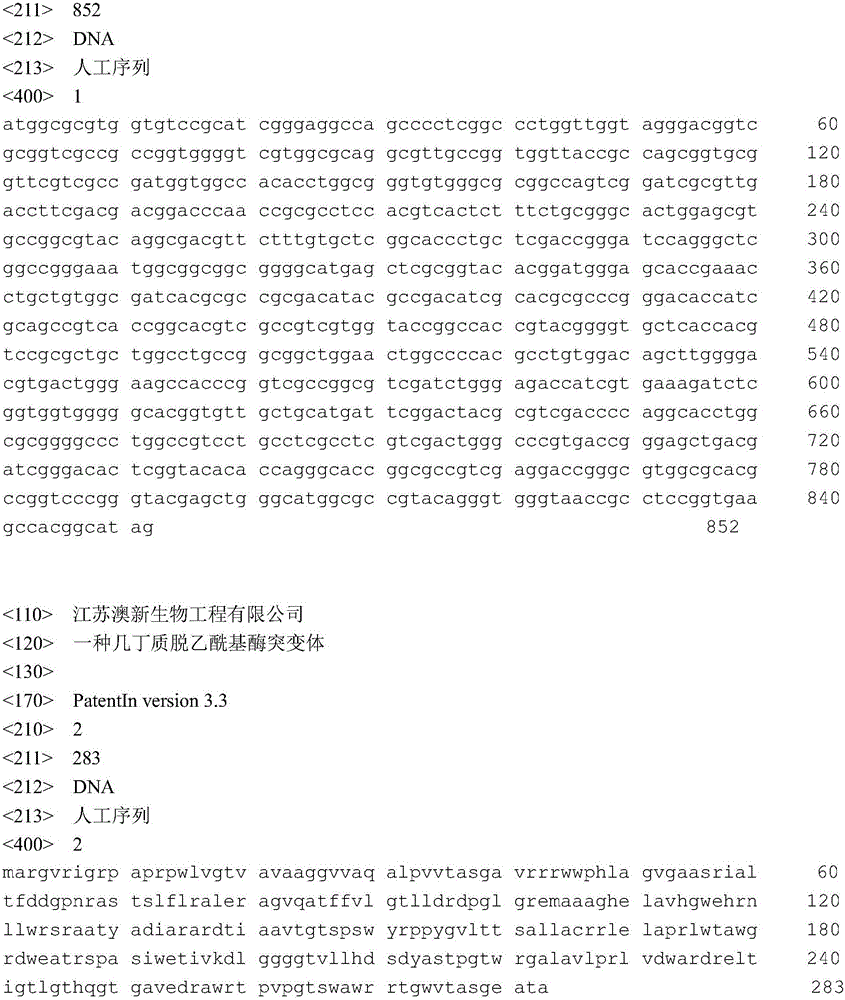

Chitin deacetylase mutant with improved catalytic activity and preparation method thereof

InactiveCN109777796AHigh catalytic activitySuitable for industrial production needsBacteriaHydrolasesBio engineeringRoseivivax atlanticus

The invention discloses a chitin deacetylase mutant with the improved catalytic activity and a preparation method thereof, and belongs to the technical field of bioengineering. Marine bacterium Roseivivax atlanticus chitin deacetylase as shown in SEQ ID NO.1 is mutated as below, 116 asparagine Q is mutated to arginine R, 179 asparagine D is mutated to glycine G, 194 histidine H is mutated to tyrosine Y, 254 valine V is mutated to leucine I, and 282 histidine H is mutated to aspartic acid. Compared with the specific activity before mutation, the specific activity of a mutant enzyme is 2.63 times that of a wild type enzyme. Accordingly, the chitin deacetylase catalytic efficiency is higher, and the mutant is more suitable for industrial production requirements.

Owner:JIANGSU AOXIN BIOTECHNOLOGY CO LTD

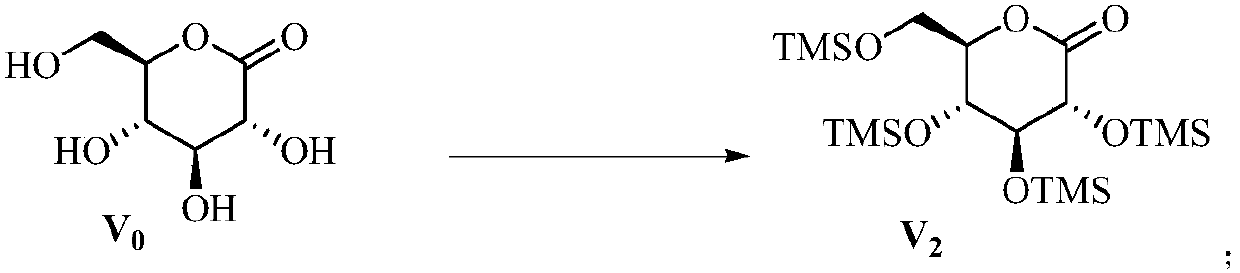

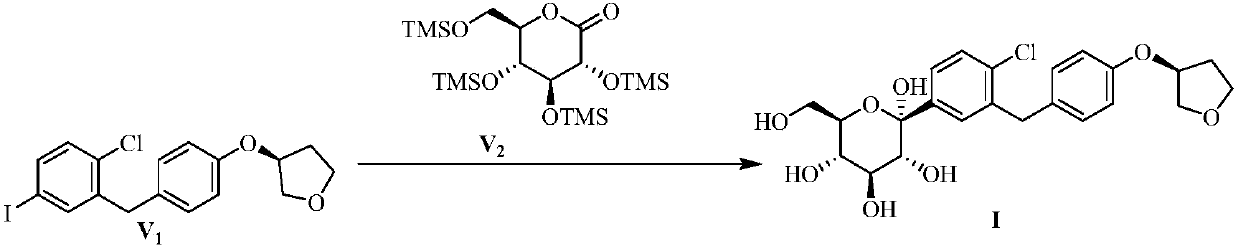

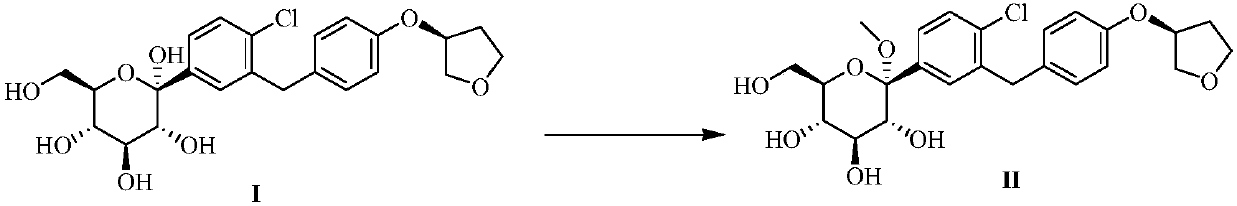

Preparation method suitable for industrial production of empagliflozin

InactiveCN109988161AHigh puritySimple purification methodOrganic chemistryGlucono delta-lactoneOrganic synthesis

The invention belongs to the technical field of organic synthesis route design and medicine and chemical engineering, particularly relates to a synthesis method of a sodium-glucose cotransporter 2(SGLT2) inhibitor, and more particularly relates to a preparation method of empagliflozin. The empagliflozin is synthesized by taking (3S)-3-[4-[(2-chloro-5-iodophenyl) methyl] phenoxy] tetrahydrofuran and glucono delta-lactone as initial raw materials through a series of substep reactions such as protection, addition, substitution, deprotection and reduction. In the synthesis steps disclosed by the invention, a staged target product does not need to be separated and purified after each step of reaction, and the target product is finally obtained by directly subjecting a high-purity reaction intermediate to subsequent steps. The preparation method is simple in process, simple and convenient to operate and good in industrial prospect.

Owner:XUZHOU WANBANG JINQIAO PHARMA +1

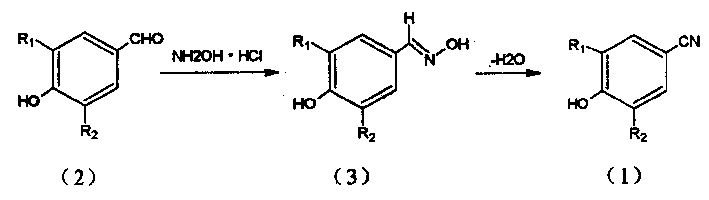

Method of preparing p-cyanophenol like compound

InactiveCN1442404ASolve pollutionSolve the hazardCarboxylic acid nitrile preparationOrganic compound preparationCompound aBenzaldehyde

A process for preparing p-cyanophenol compounds includes such steps as reaction between p-hydroxy benzaldehyde compound and hydroxyamine hydrochloride to obtain p-hydroxy benzaldehyde oxime, separating and dewatering reaction. Its advantage no need of highly toxic raw material, and gentle reaction condition.

Owner:SICHUAN KELUN PHARMA CO LTD +1

Method for preparing chebulagic acid by ethanol reflux method

InactiveCN110724172AImprove securityPromote environmental protectionEsterified saccharide compoundsSugar derivativesMedicinal herbsReflux

The invention provides a method for preparing chebulagic acid by an ethanol reflux method. The method comprises the following steps of (1) preparing an extracting solution: performing reflux extraction on fructus phyllanthi medicinal materials with ethanol so as to obtain the extracting solution; (2) preparing a concentrated solution: concentrating the extracting solution until no ethanol taste exists; (3) preparing a sample feeding solution: adding water to the concentrated solution, performing dispersing, and performing centrifuging or filtration so as to obtain supernatant namely the samplefeeding solution; (4) performing macroporous resin enrichment: enabling the sample feeding solution to be subjected to macroporous resin adsorption, and performing eluting; (5) performing purification: enabling eluent obtained in the step (4) to be subjected to column chromatography; and (6) performing drying: drying the eluent obtained in the step (5). The method is simple and convenient, the content and the transfer rate are high, the amplification technology verification result also indicates that the established preparation technology is stable and feasible, and the method is suitable forindustrial production requirements.

Owner:BEIJING UNIV OF CHINESE MEDICINE

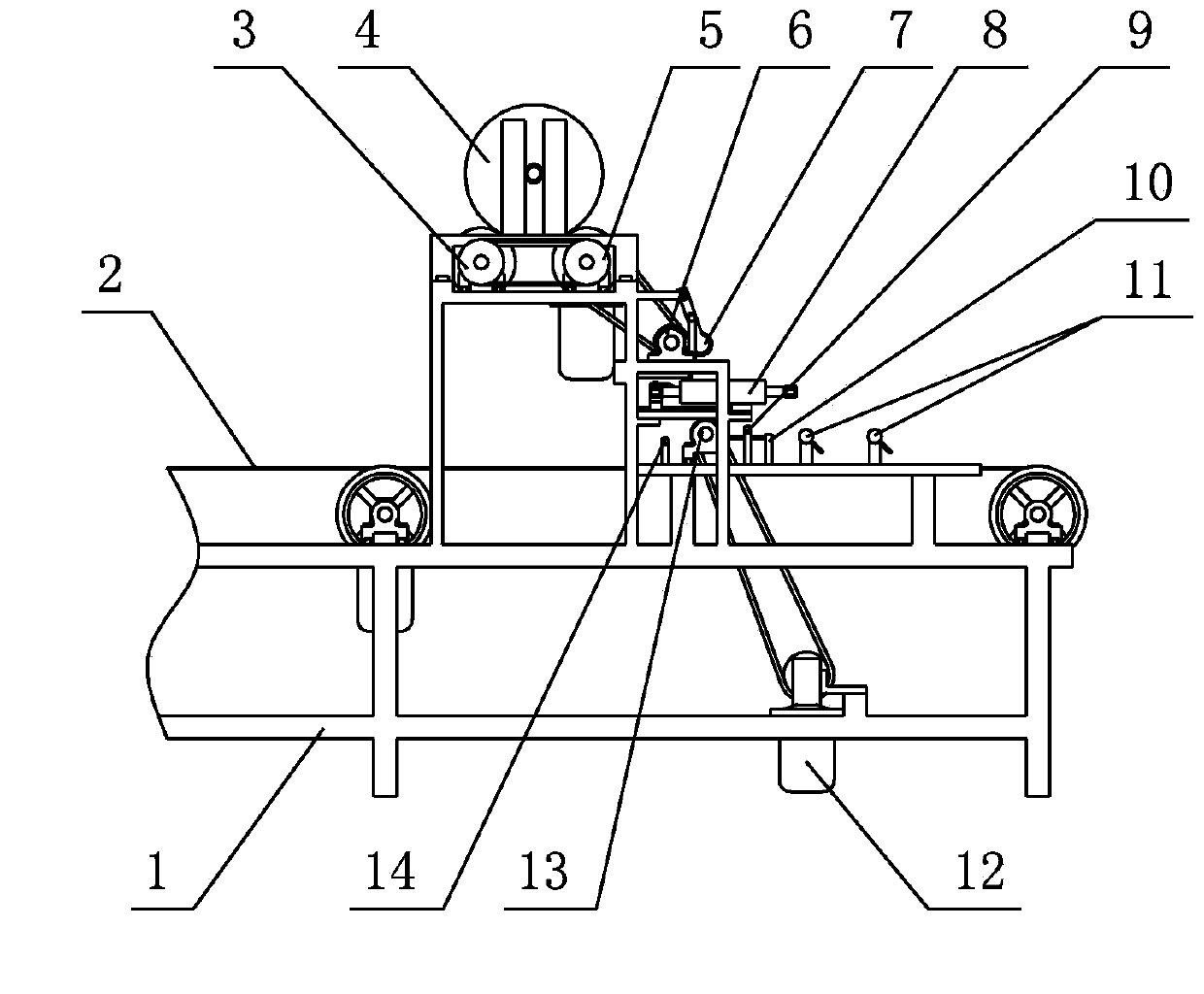

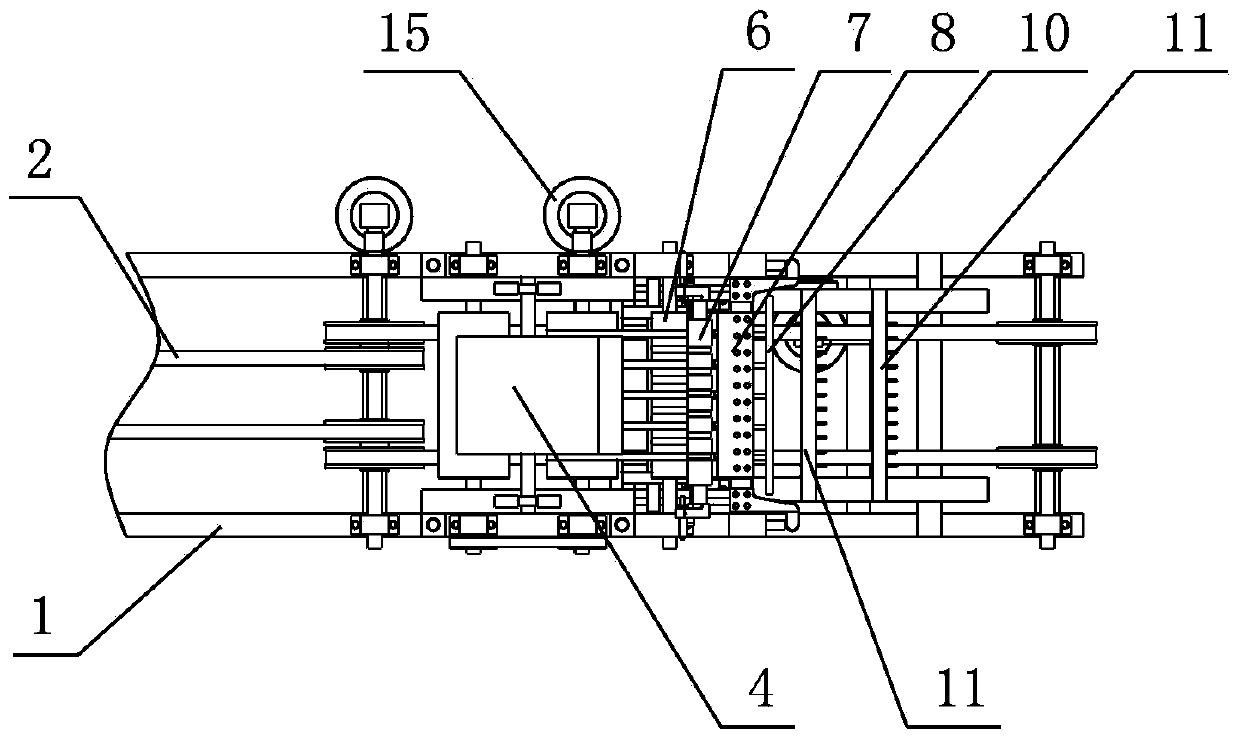

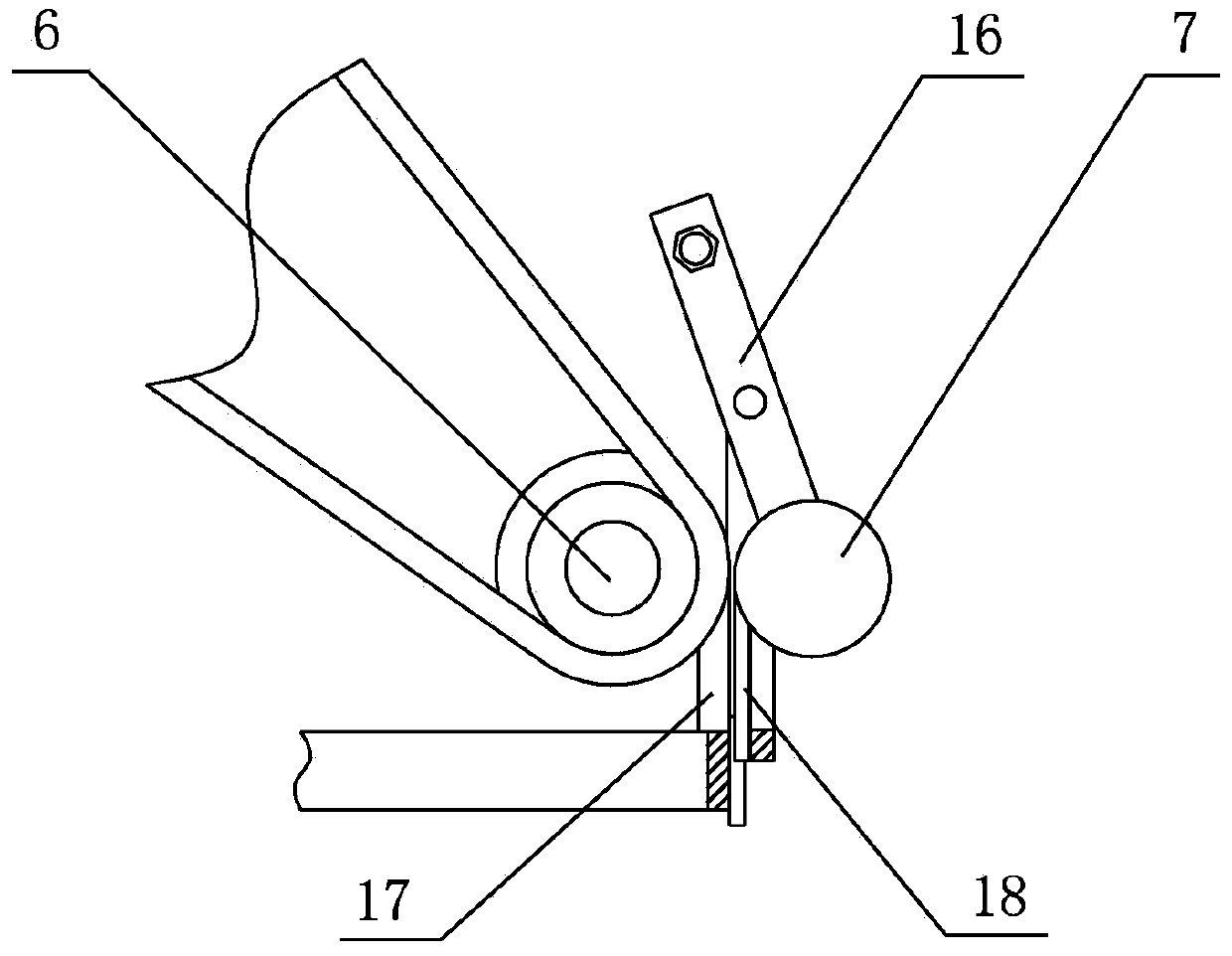

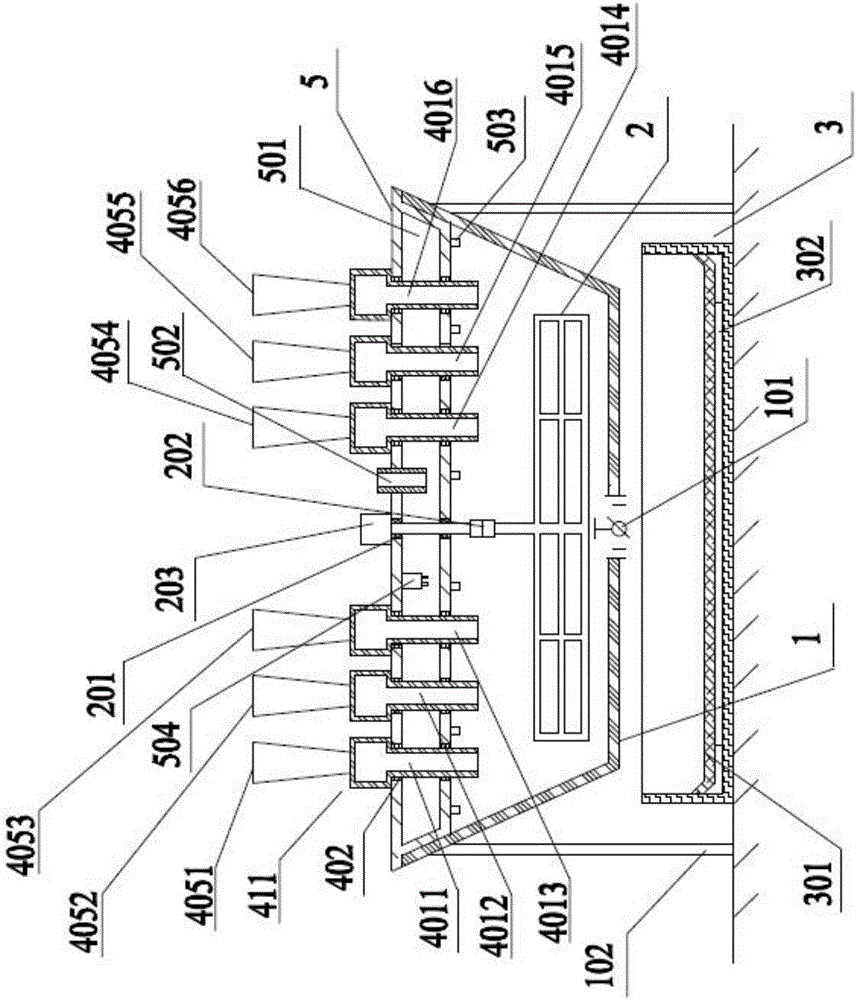

Ceramic tile paper covering machine and paper feeding device

ActiveCN103420197AThe paper feeding process is stableDirection of travel determinedLaminationLamination apparatusCeramic tilesPulp and paper industry

The invention relates to a ceramic tile paper covering machine and belongs to the technical field of ceramic machinery equipment. A paper feeding device comprises a machine frame, a driving wheel and a driven wheel, wherein the driving wheel and the driven wheel are arranged on the machine frame, one end of the driving wheel is connected with a second driving motor, the other end of the driving wheel is connected with the driven wheel through a synchronous transmission device, a paper belt wheel is arranged above the driving wheel and the driven wheel, and a paper belt guide wheel is arranged under the driving wheel. Compared with the prior art, the paper feeding device has the advantages that the rotating paper discharge speed is identical to the paper belt walking speed, the paper feeding process is stable, the paper belt walking direction is definite, and the paper belt conveyance is smooth. The ceramic tile paper covering machine adopting the paper feeding device comprises a ceramic tile conveying belt and also comprises the paper feeding device and a cutter device, wherein the cutter device is arranged under the paper feeding device, and the ceramic tile conveying belt is arranged under the cutter device. The ceramic tile paper covering machine can realize the automatic paper covering on the surfaces of ceramic tiles, the work efficiency is greatly improved and is improved by more than 50 percent through being compared with that of the artificial flow line, and the industrial production requirements are met.

Owner:淄博欣科陶瓷机械有限公司

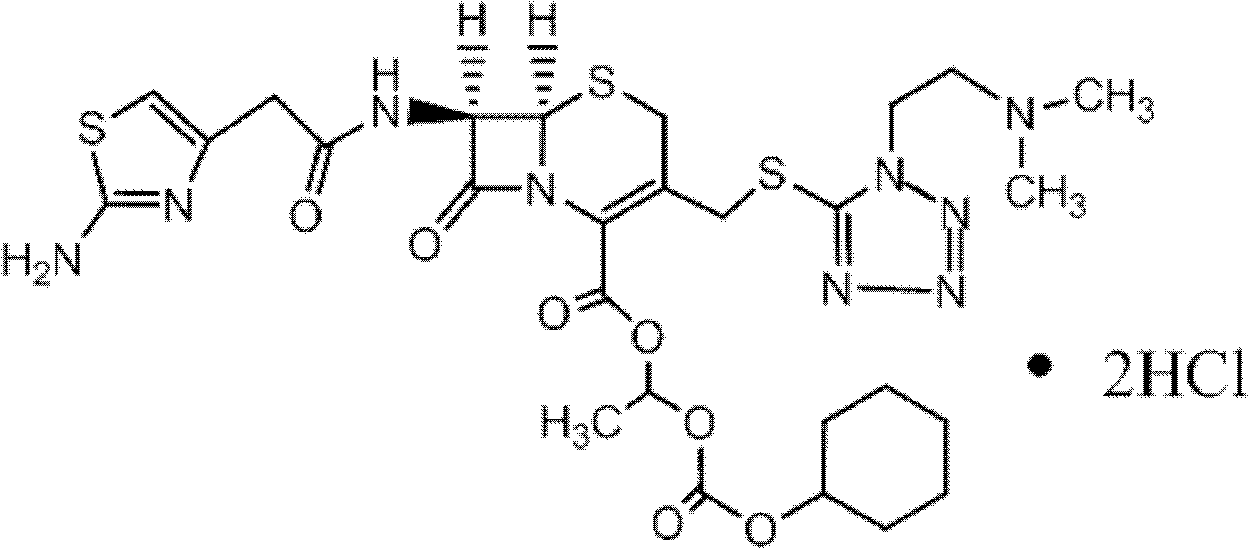

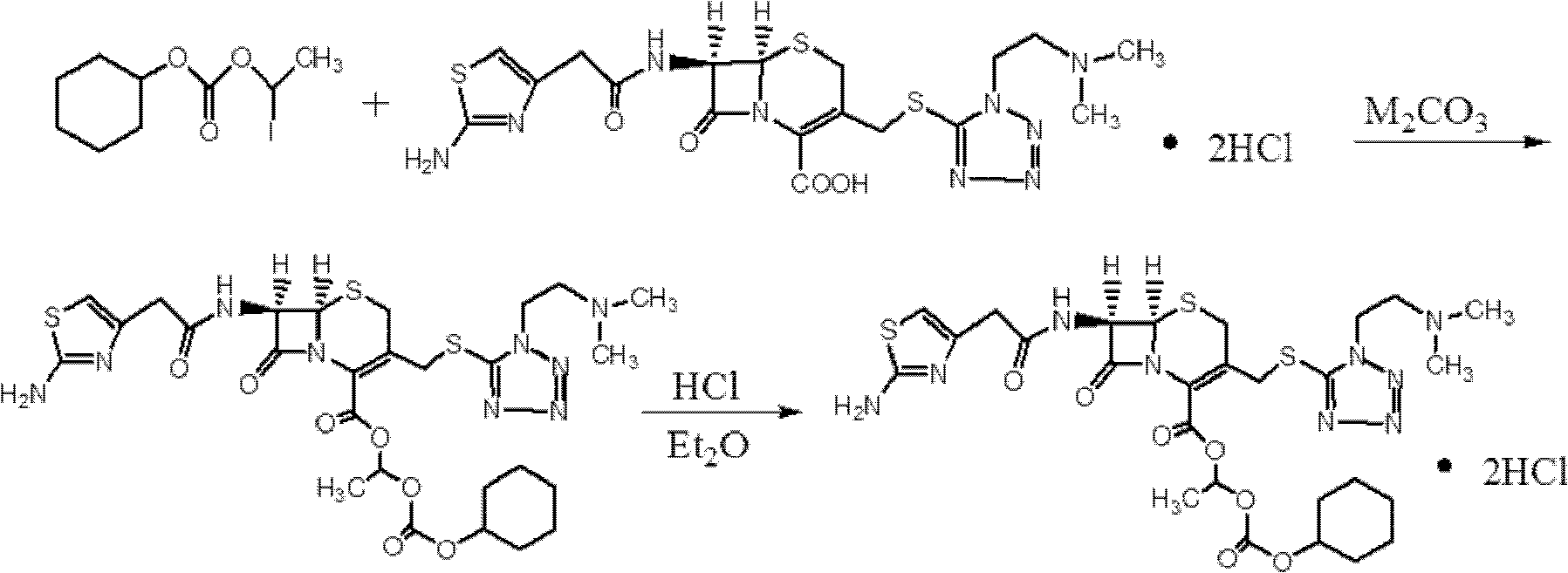

Preparation method of cefotiam hexetil hydrochloride

InactiveCN102424687AReduce usageSimple purification methodOrganic chemistryCefotiam HydrochloridePurification methods

The invention provides a preparation method of cefotiam hexetil hydrochloride. The method comprises: subjecting cefotiam hydrochloride and 1-iodoethyl cyclohexyl carbonate to an esterification reaction so as to obtain a cefotiam hexetil crude product, which is then purified into hydrochloride, thus obtaining cefotiam hexetil hydrochloride. In the esterification reaction, potassium carbonate is added, and cefotiam hydrochloride, potassium carbonate and 1-iodoethyl cyclohexyl carbonate are in a reaction mole ratio of 1:2.2-2.5:2.5-3. The method provided in the invention can reach a yield of 66% and make the isomer ratio less than 2%, or even to 1.3%. Employment of the preparation method in the invention can avoid usage of a chromatographic column and simplify the purification method, so that the method can be more suitable for industrial production needs.

Owner:HUNAN FANGSHENG PHARMACEUTICAL CO LTD

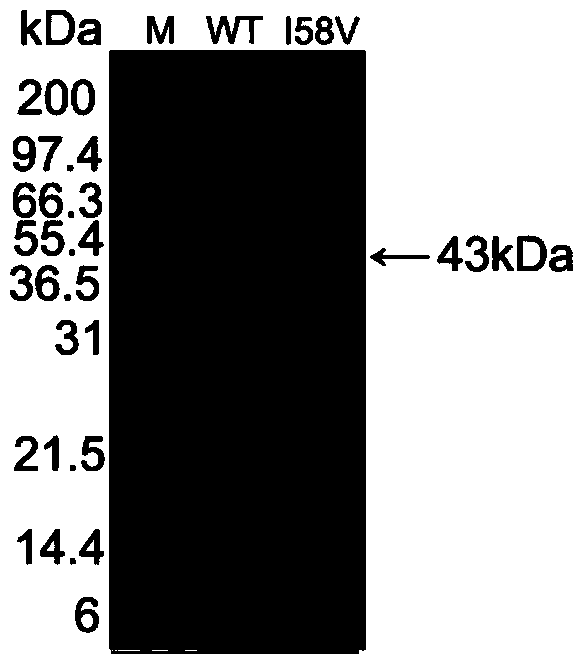

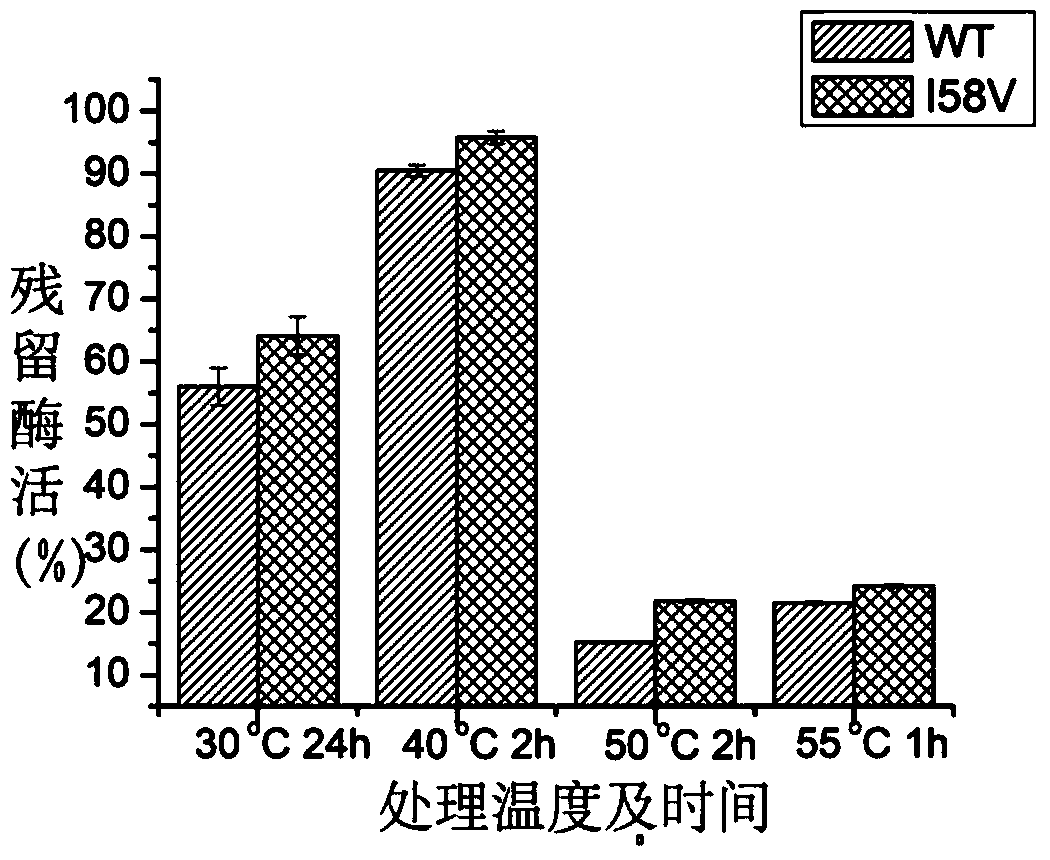

PGL (Polygalacturonate Lyase) mutant capable of improving secretion performance

InactiveCN103966194AIncrease enzyme activityImprove heat resistanceMicroorganism based processesFermentationReaction temperaturePolygalacturonate lyase

The invention discloses a PGL (Polygalacturonate Lyase) mutant capable of improving secretion performance and belongs to the technical field of bioengineering. A 58-th isoleucine I point of PGL deriving from Bacillus sp.WSHB04-02 is mutated into valine V. The extracellular enzyme activity of the mutated PGL is improved to 337.58 U / mL, and is 2.60 times that of the PGL which is not mutated, and the expression quantity of extracellular secretion is obviously increased. In addition, the optimum reaction temperature of the mutant is improved by 5 DEG C, and the optimum enzyme activity can be better shown under the condition of high temperature; Km is obviously improved, the capacity of the mutant in combination with a substrate is improved to be 4.5 times than that of the mutant which is not mutated, and kcat, t1 / 2,kcat / Km and the like are improved. The enzymatic property of the PGL provided by the invention is greatly improved, and requirements for industrial production and social production are met.

Owner:JIANGNAN UNIV

A mutant of alkaline pectinase with improved thermostability

InactiveCN103981167BImprove thermal stabilityIncreased residual enzyme activityBacteriaFermentationPectinaseHalf-life

Owner:JIANGNAN UNIV

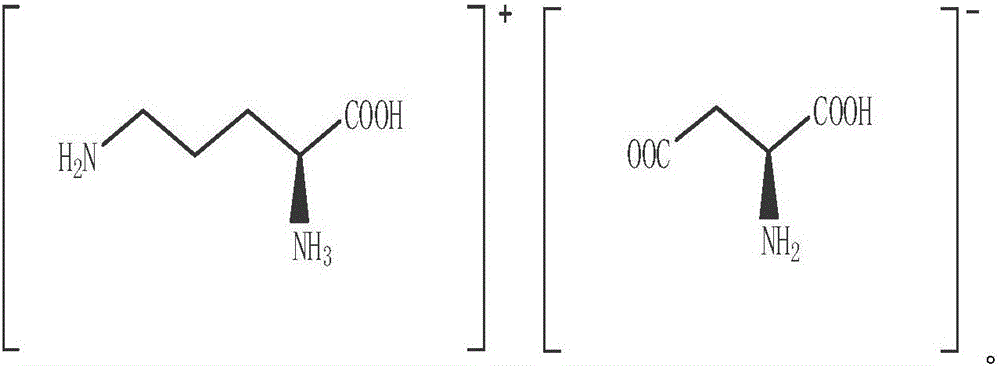

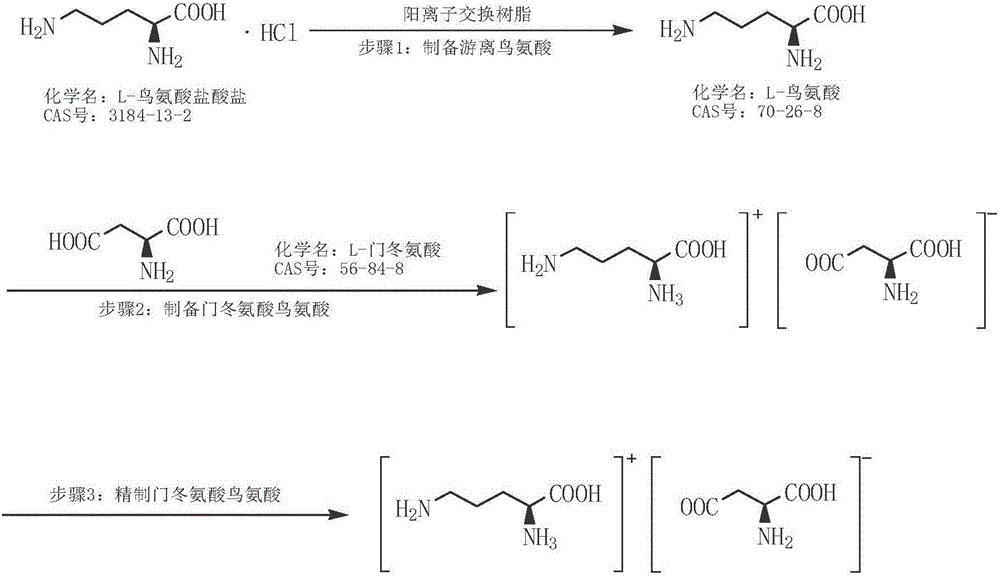

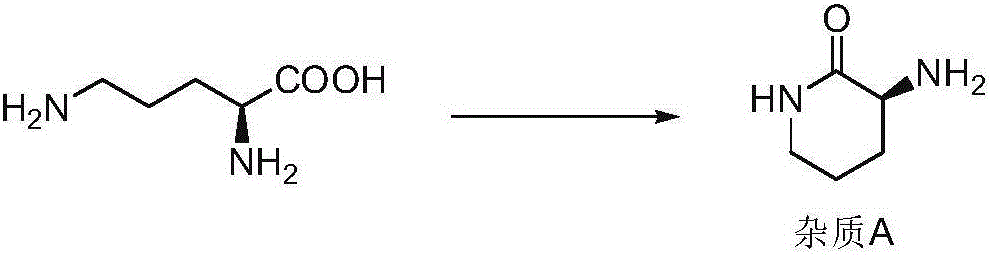

Preparation method of ornithine aspartate

InactiveCN107522629AReduce generationReduce overdependenceOrganic compound preparationAmino-carboxyl compound preparationOrnithine synthesisOrnithine aspartate

The invention provides a preparation method of ornithine aspartate. The method is characterized in that L-ornithine monohydrochloride is used as the raw material, cation exchange resin is utilized, and a free L-ornithine aqueous solution is obtained through absorption, eluting and ammonia removal; the L-ornithine aqueous solution and L-asparaginic acid are subjected to reaction, crystallization and refining, and ornithine aspartate is obtained after drying. The preparation method is simple in reaction conditions, low in cost, and suitable for industrial production; the prepared ornithine aspartate is high in purity, and high in yield.

Owner:福建金山生物制药股份有限公司

Chitin histone deacetylase mutant

ActiveCN105886487AHigh catalytic activitySuitable for industrial production needsNucleic acid vectorFermentationChitin deacetylaseCancer research

The invention discloses a chitin histone deacetylase mutant, and belongs to the technical field of bioengineering. 52nd-bit valine V of chitin histone deacetylase of obligate Salinispora arenicola is mutated to obtain glycine G, and a 66th-bit proline point P is mutated to obtain serine S. The chitin histone deacetylase mutant has the advantages that the specific activity of enzymes of the chitin histone deacetylase mutant is 3.92 times the specific activity of wild type enzymes as compared with the enzymes of the chitin histone deacetylase mutant prior to mutation; the chitin histone deacetylase is applicable to industrial production requirements, and social production requirements can be met.

Owner:JIANGSU AOXIN BIOTECHNOLOGY CO LTD

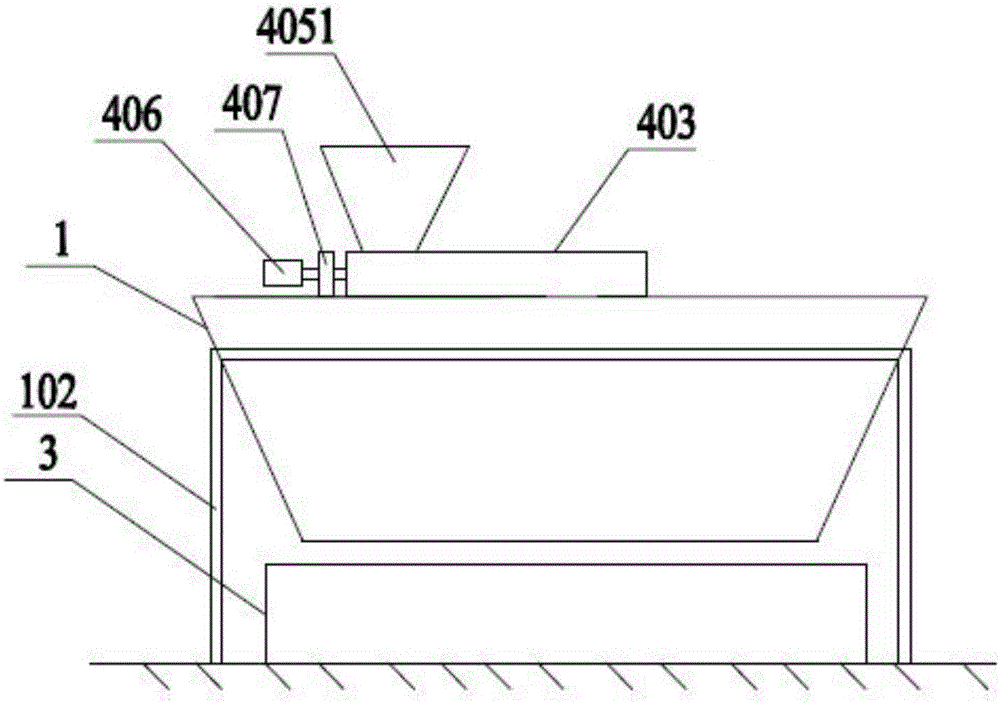

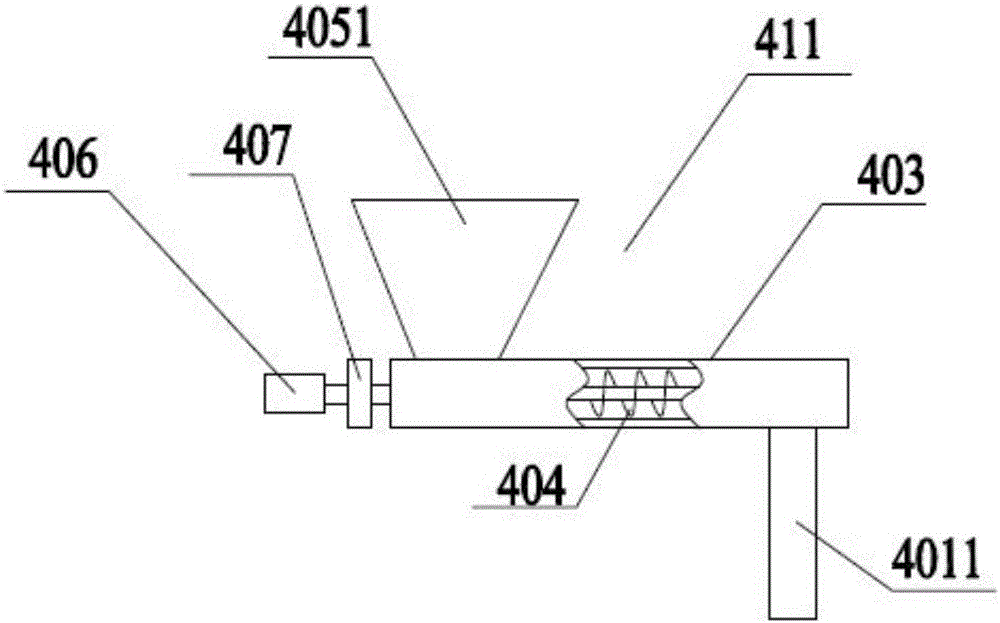

Honeycomb thermal-insulation mortar and production line mixing device thereof

The invention relates to the field of building thermal-insulation materials, particularly a honeycomb thermal-insulation mortar and a production line mixing device thereof. The honeycomb thermal-insulation mortar is prepared from the following raw materials in parts by weight: 110-130 parts of silicon micropowder, 5-6 parts of silicon dioxide aerogel, 13-15 parts of polystyrene granule, 3.8-5.8 parts of dispersible latex powder, 0.12-0.19 part of cellulose hydroxypropyl methyl ether and 3-3.5 parts of foaming agent. The fire resistance of the honeycomb thermal-insulation mortar reaches Grade A; the heat conductivity coefficient is lower than 0.035W / (m.k); and thus, the honeycomb thermal-insulation mortar can substitute the traditional thermal-insulation mortar to increase the fireproof safety performance of the building and enhance the energy-saving effect of the building. The manufacturing and application methods are simple; and the production device is simple in structure, implements intelligent control, is suitable for industrial production, and solves the problems in the prior art in an economical and effective way.

Owner:北京万源恒泰科技有限公司

A kind of lysine decarboxylase mutant, its coding gene and its expression and application

ActiveCN108795916BImprove stabilityIncrease enzyme activityBacteriaMicroorganism based processesSite-directed mutagenesisMutant

The invention discloses a lysine decarboxylase mutant. The lysine decarboxylase mutant is obtained by carrying out site-directed mutation on lysine decarboxylase with an amino acid sequence shown as SEQ ID No: 2 and is any one of (1) and (2): (1) valine at a 12th site of lysine decarboxylase with the amino acid sequence shown as SEQ ID No: 2 is mutated into cysteine and aspartic acid at a 41st site is mutated into the cysteine to obtain the lysine decarboxylase mutant V12C / D41C; (2) leucine at a 89th site of lysine decarboxylase with the amino acid sequence shown as SEQ ID No: 2 is mutated into the cysteine and leucine at a 442nd site is mutated into the cysteine to obtain the lysine decarboxylase mutant L89C / L442C. According to the lysine decarboxylase mutant provided by the invention, the alkali-resisting and catalytic performance is greatly improved and the lysine decarboxylase mutant is more suitable for industrialized production requirements and meets the requirements of social production.

Owner:NANJING TECH UNIV

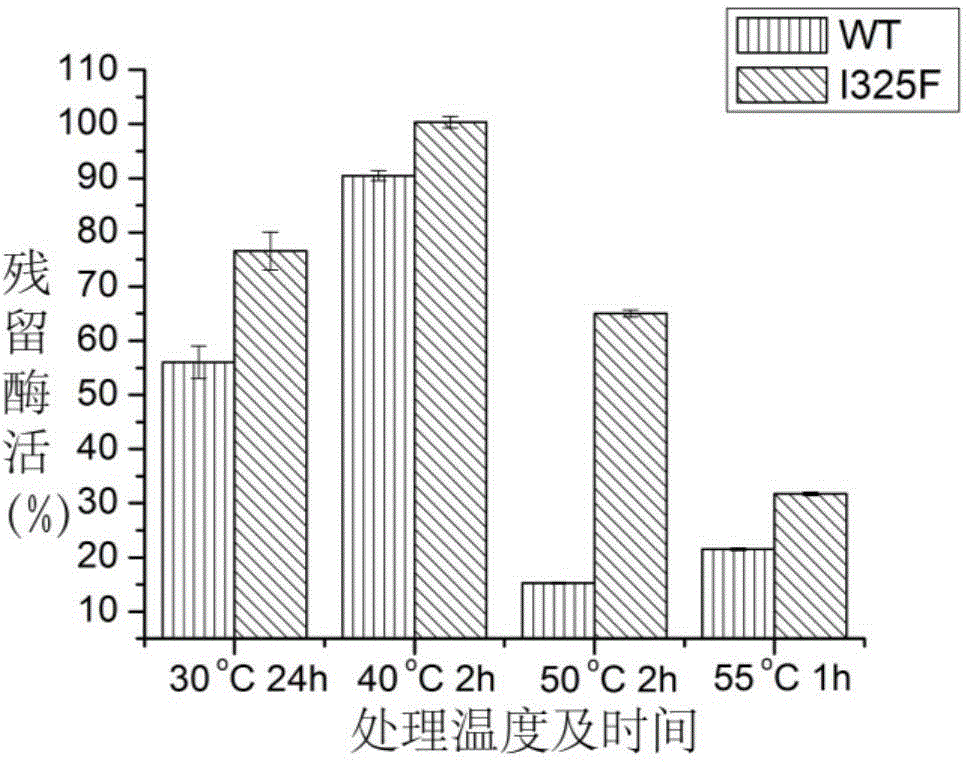

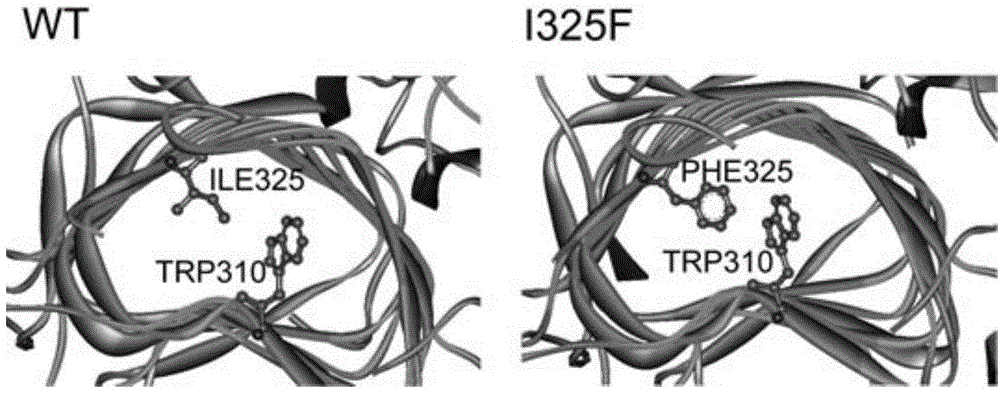

Alkaline pectase mutant with improved heat resistance

InactiveCN103981166AImprove heat resistanceIncreased residual enzyme activityBacteriaFermentationHeat resistanceHalf-life

The invention discloses an alkaline pectase mutant with an improved heat resistance, and belongs to the technical field of bioengineering. The 325th isoleucine I site of alkaline pectase from Bacillus sp.WSHB04-02 mutates to phenylalanine F. The residual enzyme activity of the obtained mutated alkaline pectase undergoing heat insulation at 50DEG C for 2h is 4.27 times that of the alkaline pectase before the mutation; and the above situation shows that the heat resistance of the mutated alkaline pectase I325F at 50DEG C is obviously improved, and the I325F still has a stable structure at 50DEG C for a long time. The half life of the mutated alkaline pectase I325F at 55DEG C is 1.89 times the half life of the alkaline pectase before the mutation; and the Km, Vmax, kcat and kcat / Km are improved. The enzymatic properties of PGL provided by the invention are greatly improved, so the PGL is suitable for industrial production demands, and meets social production requirements.

Owner:JIANGNAN UNIV

An industrialized high-density mixed fermentation culture method of bifidobacteria and lactobacillus and a bacteria powder embedding method

ActiveCN108277178BMake the most of synergiesReduce manufacturing costFood freezingBacteriaBiotechnologyPhosphoric acid

The invention provides an industrialized high-density mixed fermentation medium of bifidobacterium and lactobacillus, a fermentation culture method and a bacterial powder embedding method; the fermentation medium is: corn steep liquor dry powder 0.3-1.5%, soybean peptone 0-1.5% 1.8%, fructooligosaccharide 0‑1%, glucose 0.5‑1%, dipotassium hydrogen phosphate 0.4‑1.35%, potassium dihydrogen phosphate 0.4%, magnesium sulfate 0.015‑0.02%, L‑cysteine hydrochloride 0.05 %; or corn steep liquor dry powder 0.3‑1.5%, beef extract 0‑1%, fructooligosaccharides 0‑1%, glucose 0.5‑1%, dipotassium hydrogen phosphate 0.4‑1.35%, potassium dihydrogen phosphate 0.4%, magnesium sulfate 0.015-0.02%, L-cysteine hydrochloride 0.05%; the fermentation method includes strain activation culture, primary strain cultivation, secondary seed liquid preparation, 200L small tank cultivation in workshop and 1T large tank fermentation in workshop nourish. Compared with the traditional TPY culture medium, the culture medium formula provided by the invention has more than 10 times the number of viable bacteria and 60% lower cost, and the raw materials of the formula are easy to purchase, the ingredients are simple, and it is suitable for industrial production needs. The bacterial strain embedding technology greatly improves the ability of the bacterial strain to tolerate the human body and the external environment.

Owner:山东凤凰生物科技股份有限公司

A mixed regeneration method of inorganic sand and organic sand and its regenerated sand

ActiveCN107008851BHigh recovery rateContribute to embrittlementFoundry mouldsMould handling/dressing devicesEnergy consumptionPollution

The invention relates to an inorganic sand and organic sand mixing regeneration method. Through primary mechanical regeneration, hot regeneration and secondary mechanical regeneration, an inorganic film on the surface of inorganic sand can be fully crushed and stripped; in the hot regeneration process, an organic resin film is fully combusted to provide more uniform heat source energy for mixing regeneration, so that the regeneration energy consumption is reduced, and the embrittlement of an inorganic bonding agent on the surface of the inorganic sand is facilitated; and through two times of mechanical regeneration, covering matters on the surface of the inorganic sand are removed more thoroughly. The recovery rate of regenerated sand in the regeneration method is high up to reach 80-95%, and is far higher than the regeneration rate of below 50% in a general drying method; and the regeneration method is simple in process and equipment, free of secondary environment pollution, suitable for industrial production demands and higher in economical and social values. The performances of the regenerated sand obtained by the regeneration method are near the performances of new sand, and are excellent, so that the regenerated sand can directly serve as facing sand.

Owner:HEFEI RENCHUANG CASTING MATERIAL CO LTD

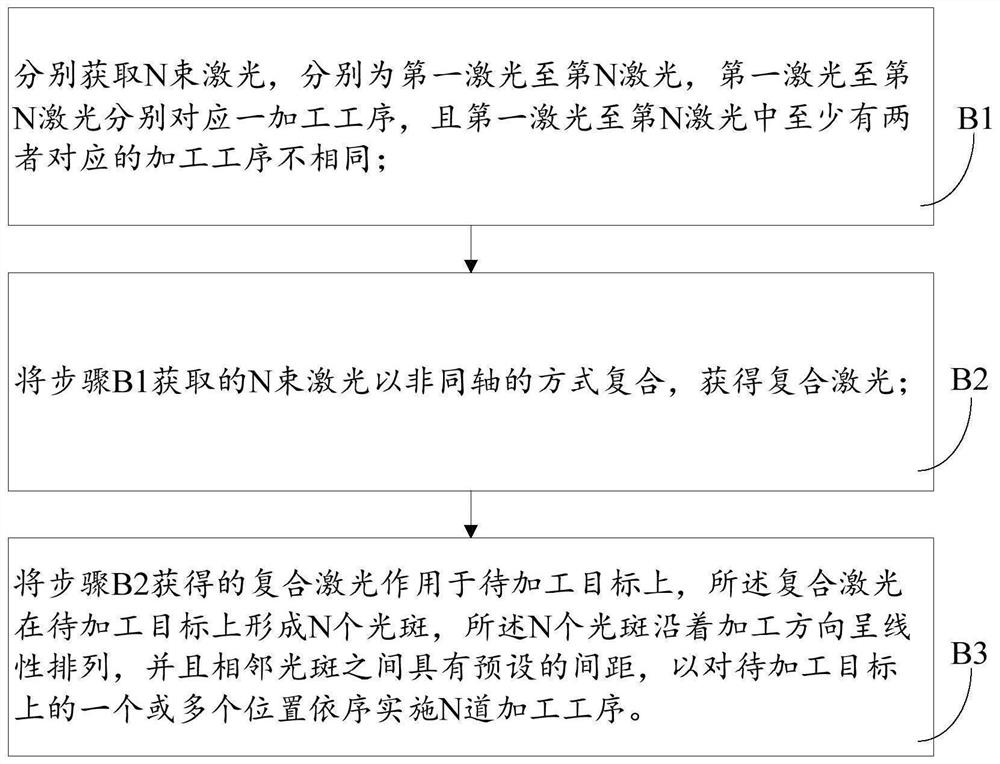

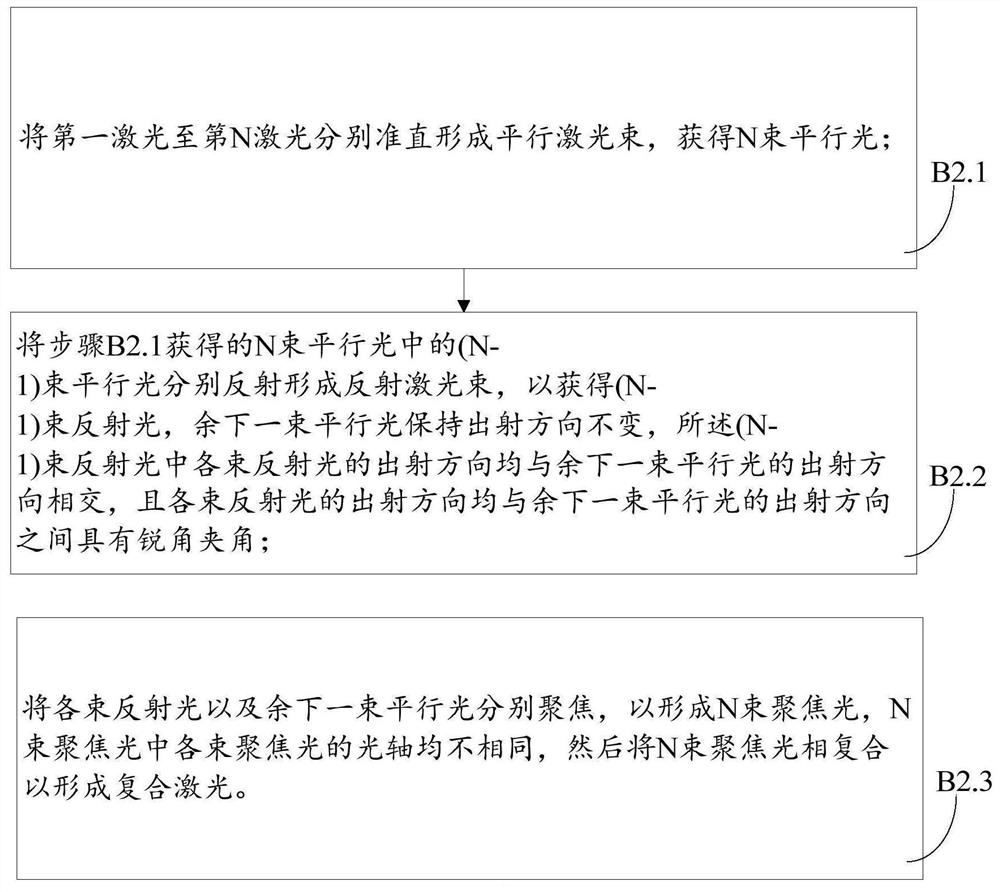

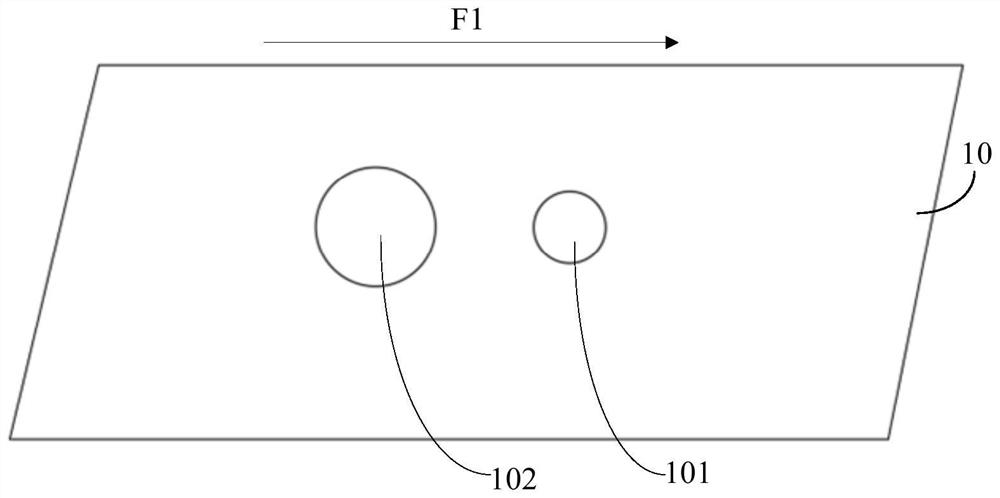

Composite laser processing method and composite laser processing device

ActiveCN113199138AEfficient processingEasy to processLaser beam welding apparatusMaterials scienceFacula

The invention discloses a composite laser processing method and a composite laser processing device. The method comprises the steps that N laser beams are composited in a non-coaxial manner to obtain composite laser, each laser beam in the N laser beams corresponds to one processing procedure, the composite laser forms N light spots on a to-be-processed target, the N light spots are linearly arranged in the processing direction, and a preset distance is formed between every two adjacent light spots, so that N processing procedures are sequentially implemented on one or more positions on the to-be-processed target, wherein N is a positive integer greater than or equal to 2. The method can be used for compositing the N laser beams with any wavelength and any processing characteristic, and the method has the advantage of simplifying the processing procedures. The composite laser processing device disclosed by the embodiment of the invention can be used for processing by adopting the method, and has the advantages of being reasonable in overall structural layout and suitable for industrial production requirements.

Owner:WUHAN RAYCUS FIBER LASER TECHNOLOGY CO LTD

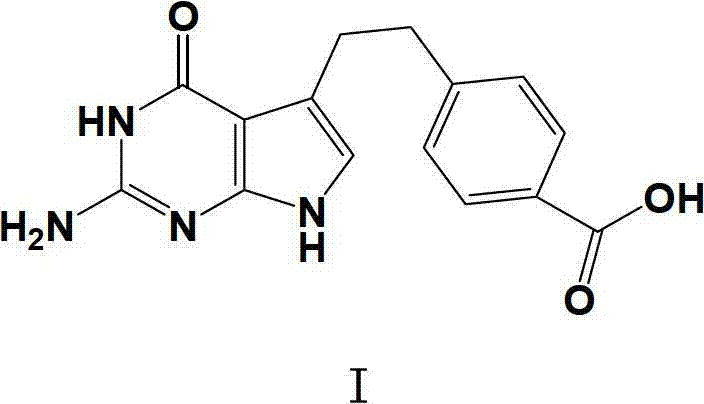

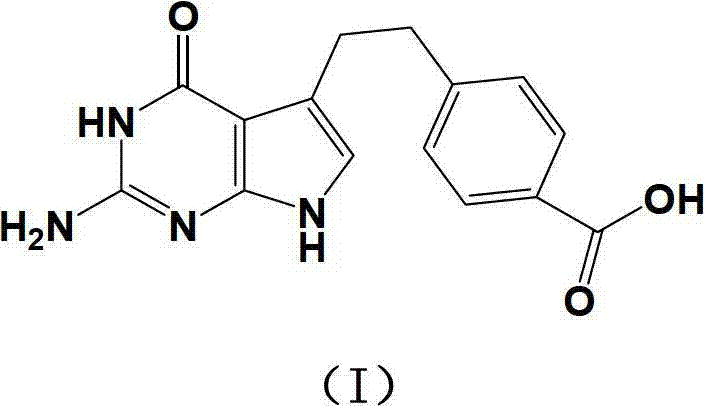

Preparation method of pemetrexed or pemetrexed salt

The invention relates to a preparation method of pemetrexed or a pemetrexed salt. The preparation method comprises the following steps of (a) salifying L-glutamic acid and dissolving in a mixed solvent of N-methyl pyrrolidone and water; (b) reacting a compound of a formula (I) with CDMT (2-chloro-4,6-dimethoxy-1,3,5-triazine) to prepare an active ester; (c) adding the obtained active ester to the L-glutamic acid salt solution obtained in the step (a); and (d) adding acid to adjust a pH value of a reaction mixture of the step (c), and adding water to dilute to obtain pemetrexed. The preparation method of the pemetrexed or the pemetrexed salt disclosed by the invention has the advantages of short process, high product yield and reduced production cost of pemetrexed.

Owner:JIANGSU HANSOH PHARMA CO LTD

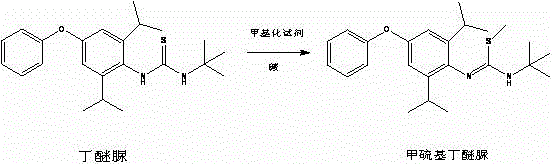

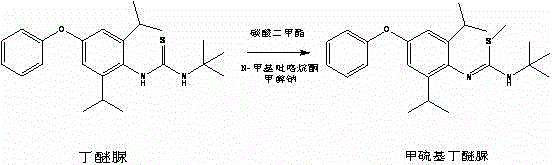

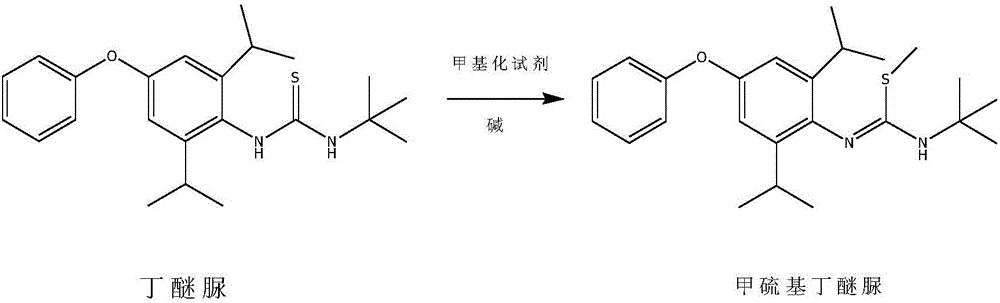

Method for preparing methylmercaptodiafenthiuron

The invention discloses a method for preparing methylmercaptodiafenthiuron. The method comprises the following reaction formula described in the specification, wherein in the formula, a methylation reagent is selected from methyl chloride, methyl bromide, methyl benzenesulfonate, methyl trifluoromethansulfonate, methyl p-toluenesulfonate, dimethyl carbonate, trimethyl phosphate, dimethyl sulfate, diazomethane, methyl trichloroethanimidate, and formaldehyde+formic acid; an alkali is selected from M2CO3, NCO3, MHCO3, MXR1, N(XR1)2, MH, NH2 or NO; M is selected from Li, Na or K; N is selected from Mg or Ca; X is selected from O or S; R1 is selected from H or C1-C6 alkyl. The compound shown in the reaction formula undergoes a reaction with the methylation reagent and the alkali in a proper solvent to prepare the methylmercaptodiafenthiuron. According to the method, the methylation reagent with low price is used, so the product cost is reduced; and the method is mild in reaction condition, simple, convenient and feasible in post-treatment method, economic and effective, and prone to industrialized production.

Owner:HAILIR PESTICIDES & CHEM GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com