Patents

Literature

103 results about "Empagliflozin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

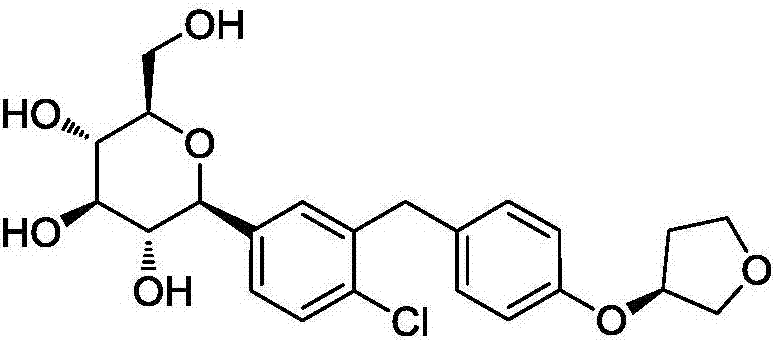

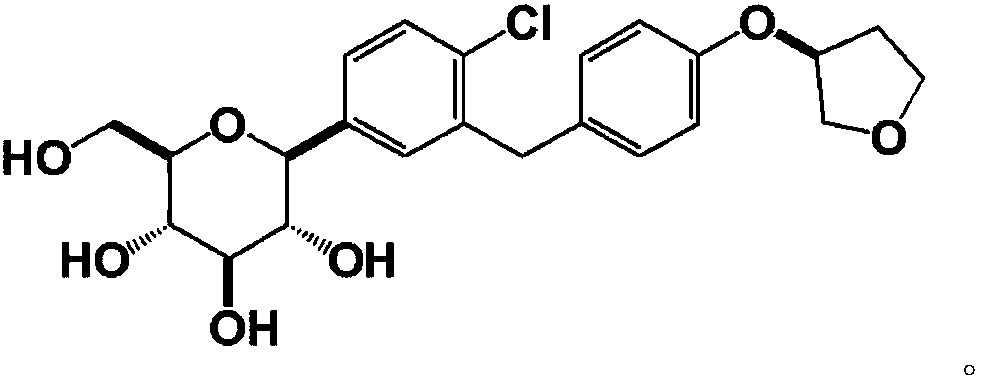

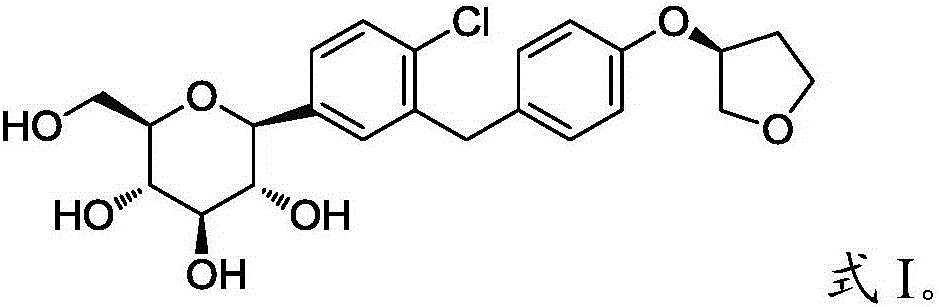

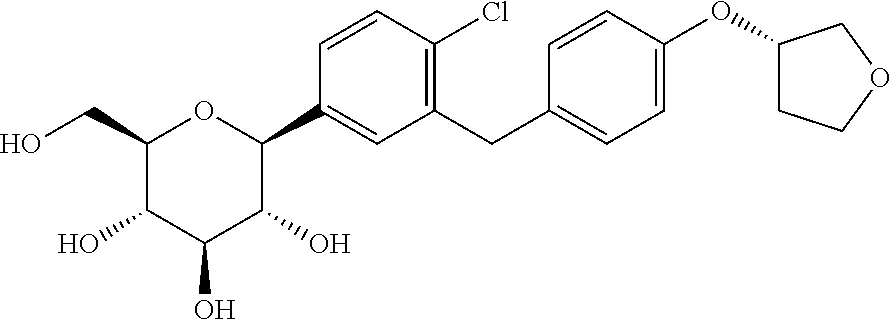

Empagliflozin is used with a proper diet and exercise program to control high blood sugar in people with type 2 diabetes.

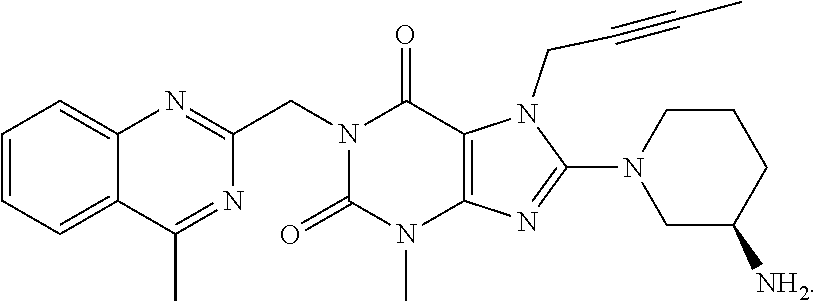

Pharmaceutical composition, methods for treating and uses thereof

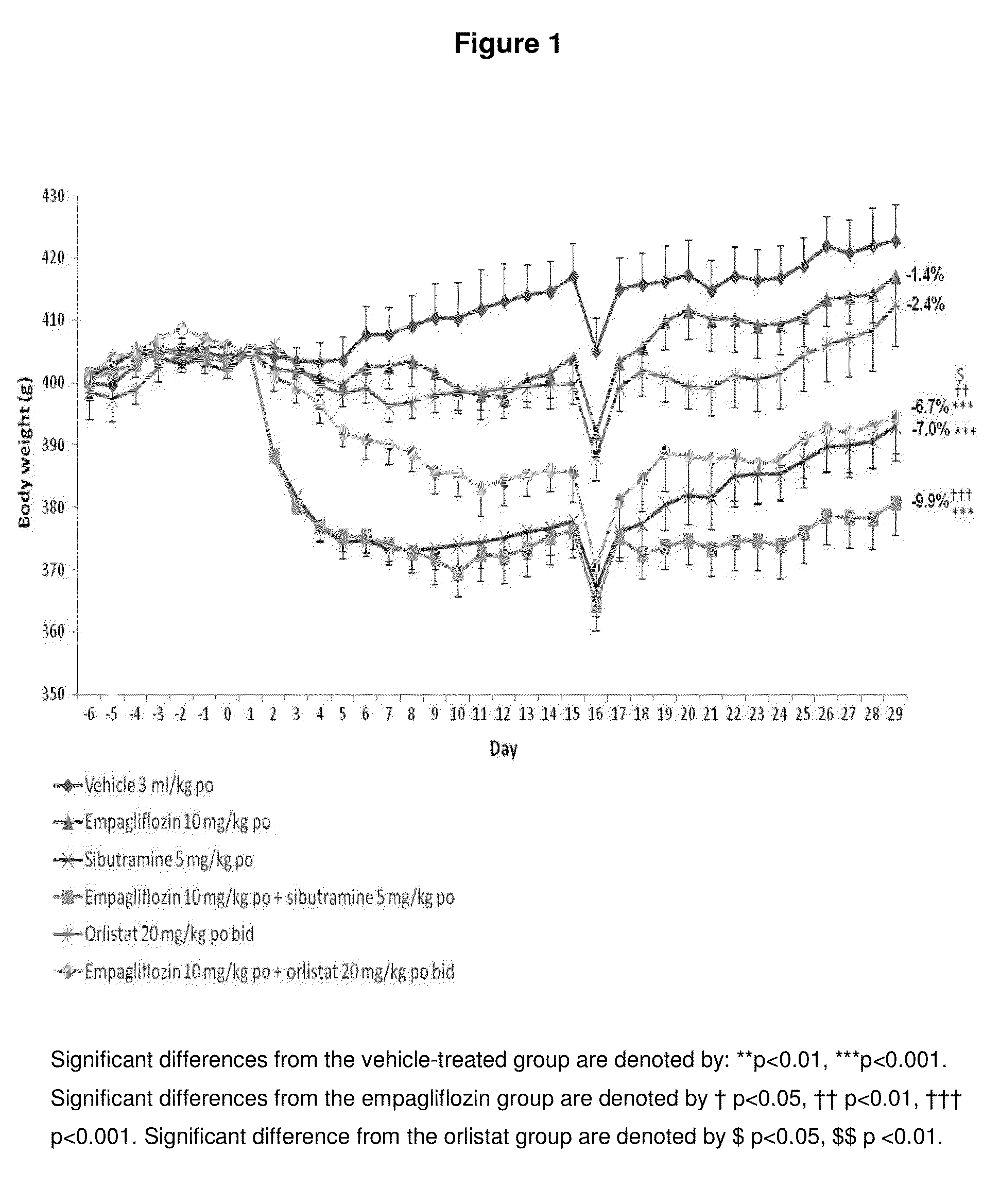

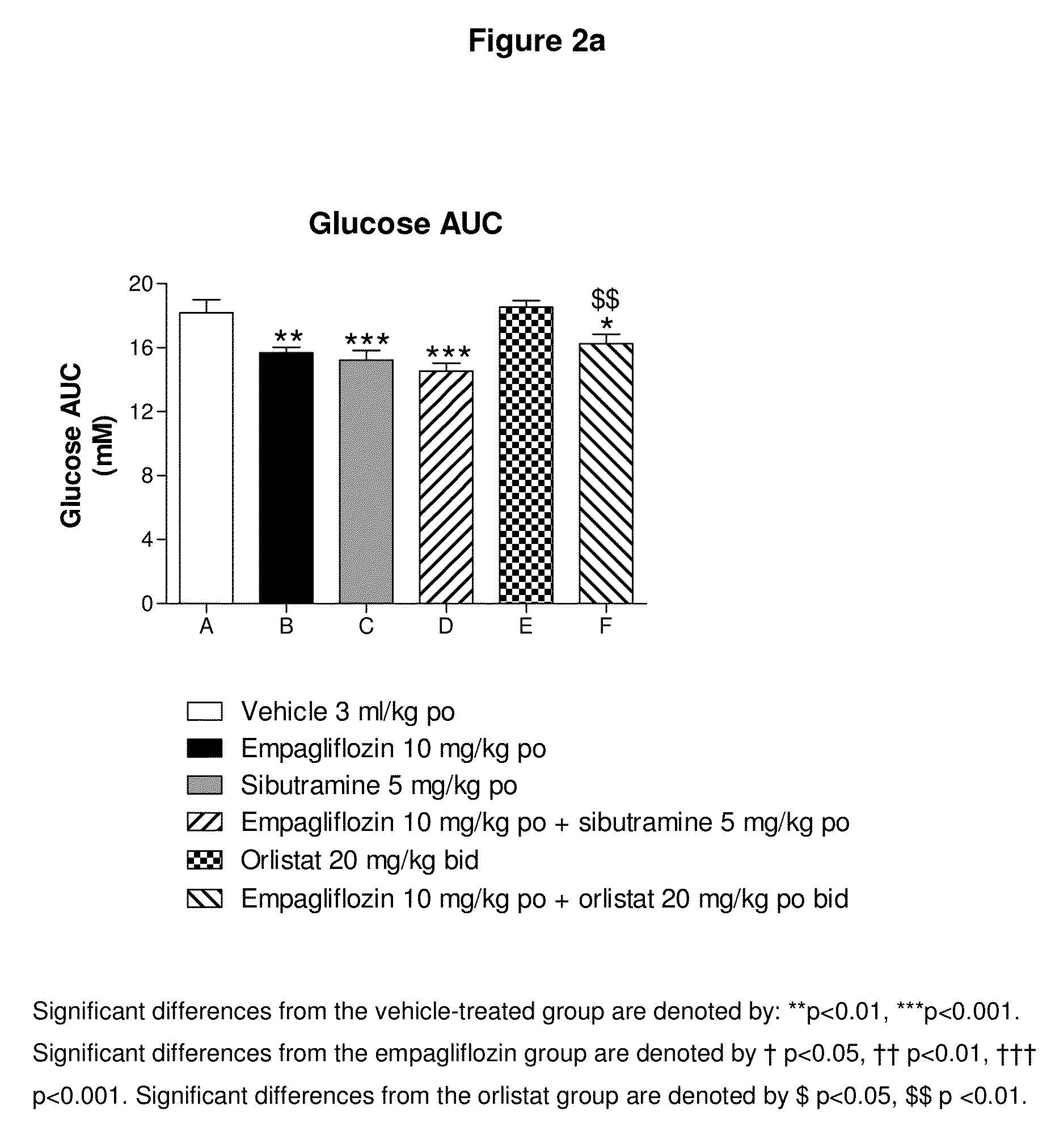

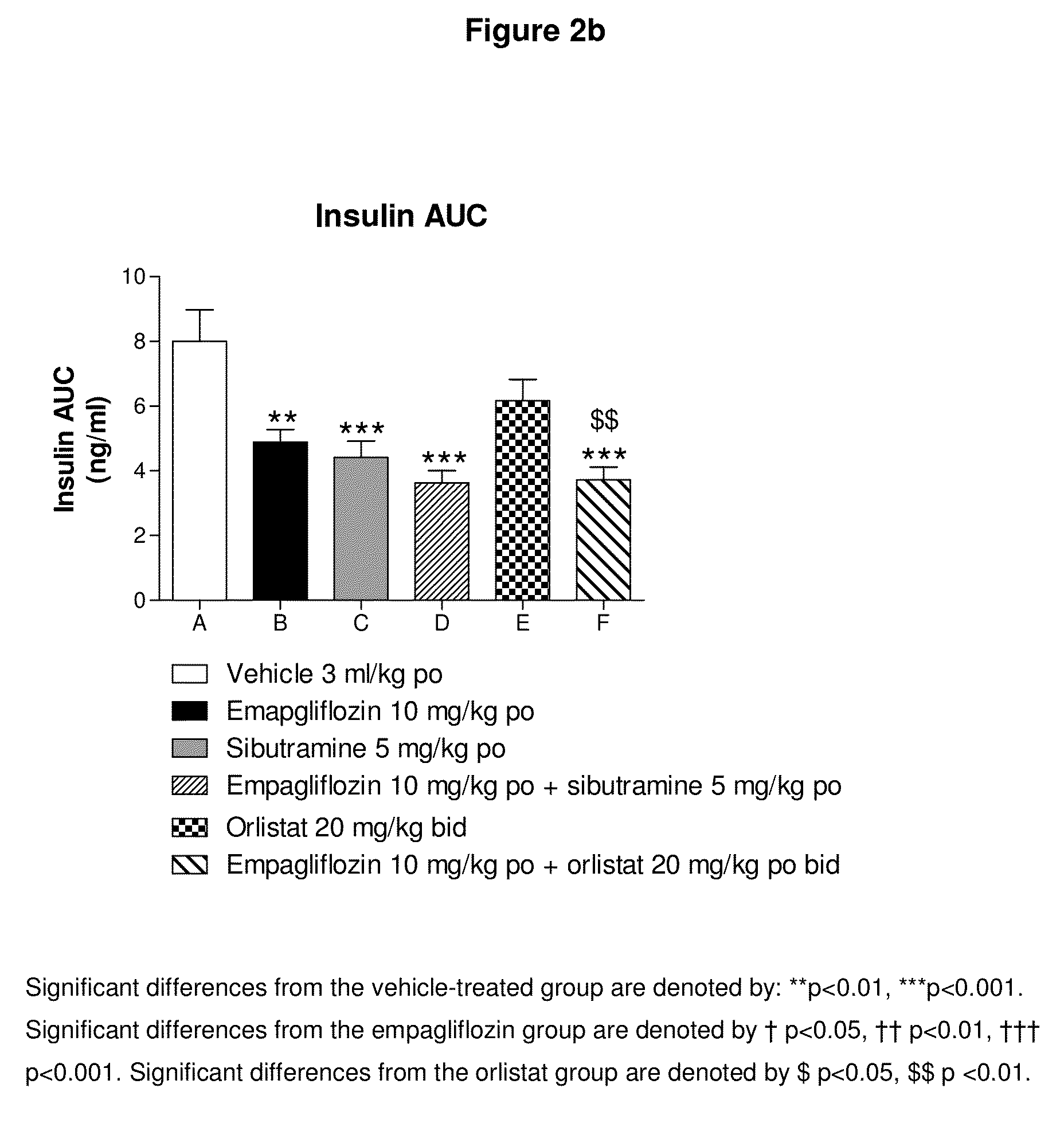

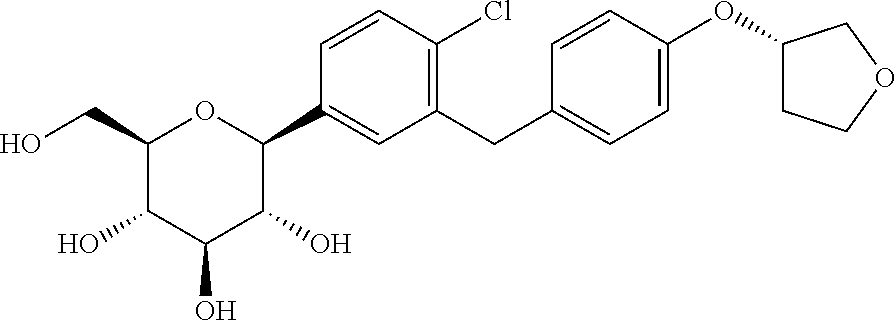

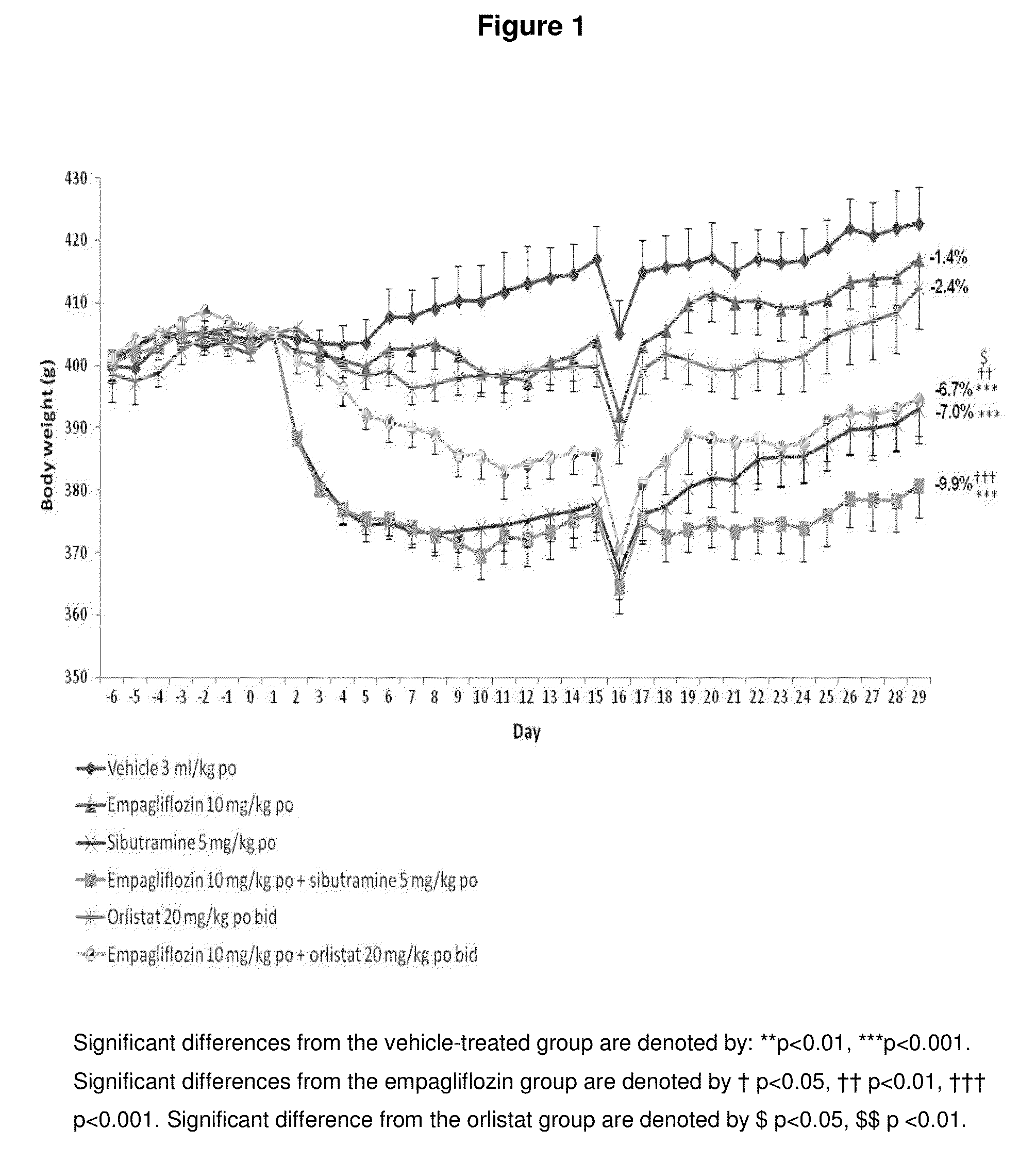

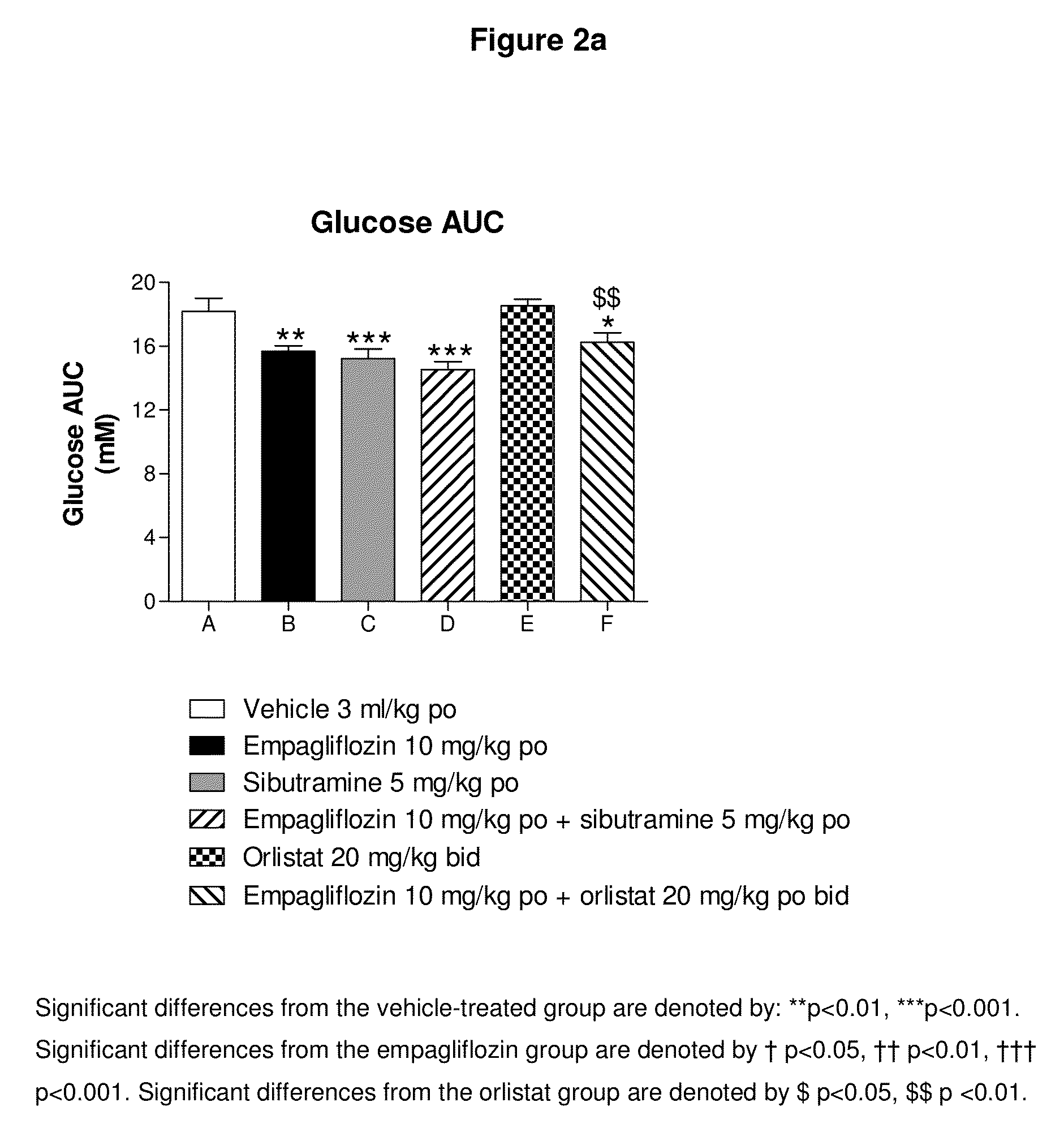

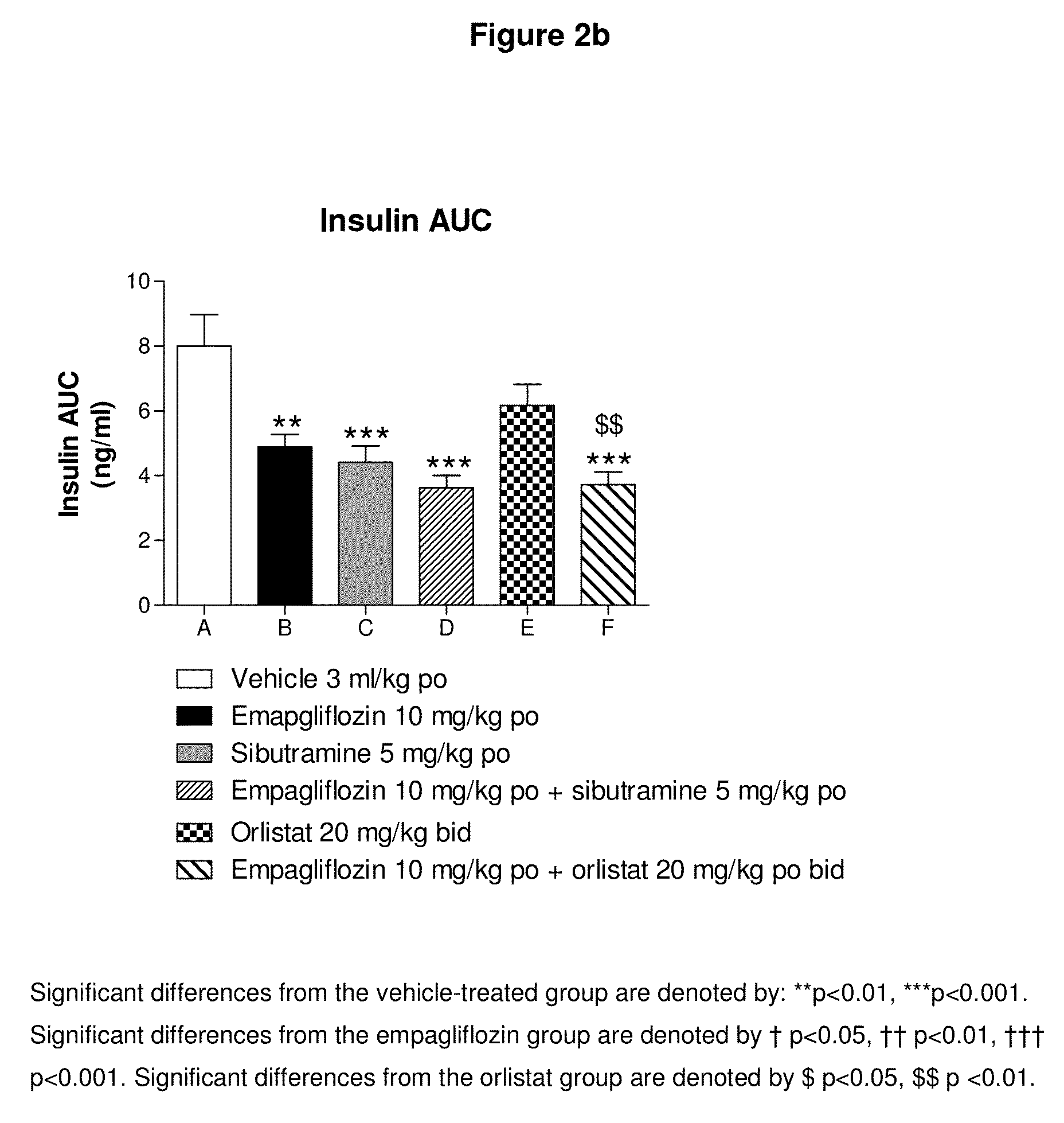

ActiveUS20130252908A1Improve glucose excursionReduce HbA1cBiocideMetabolism disorderAntiobesity drugEmpagliflozin

The invention relates to the treatment of metabolic disorders in an overweight or obese patient characterized in that empagliflozin and one or more antiobesity drugs are administered to the patient.

Owner:BOEHRINGER INGELHEIM INT GMBH

Pharmaceutical composition, methods for treating and uses thereof

InactiveUS20170266152A1Good effectOrganic active ingredientsPill deliveryEmpagliflozinEjection fraction

The present invention relates to methods for preventing or treating acute or chronic heart failure and for reducing the risk of cardiovascular death, hospitalization for heart failure and other conditions in patients with preserved or reduced ejection fraction by administering empagliflozin to the patient.

Owner:BOEHRINGER INGELHEIM INT GMBH

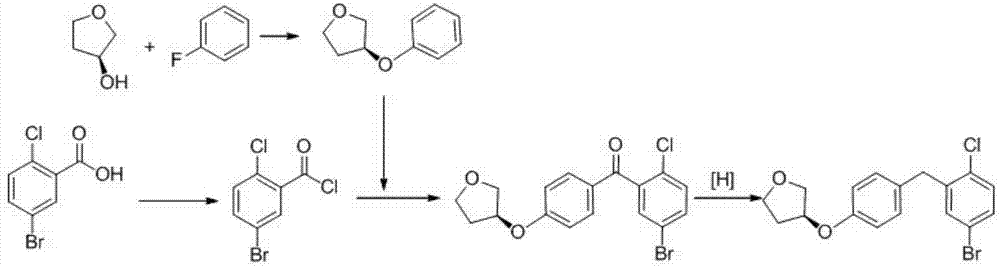

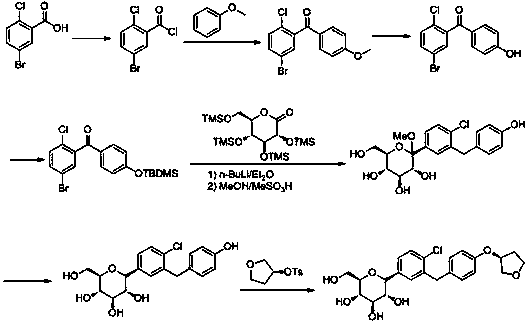

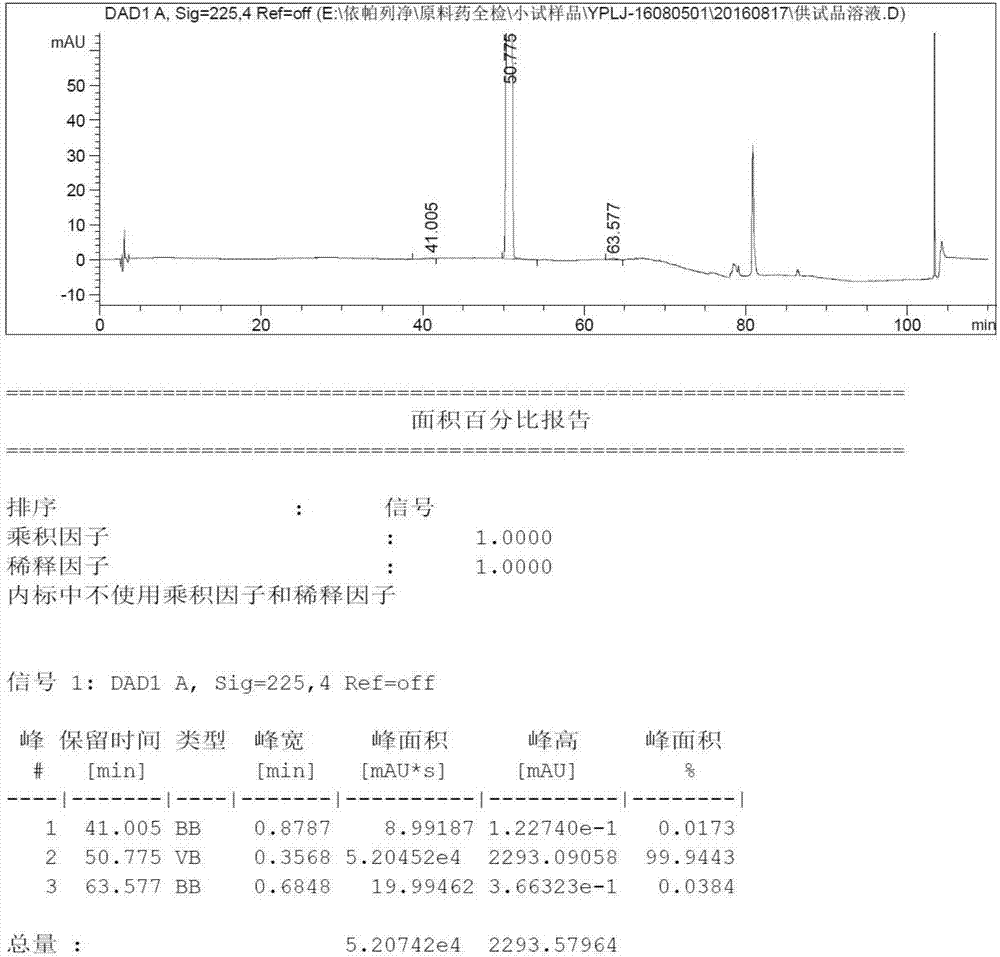

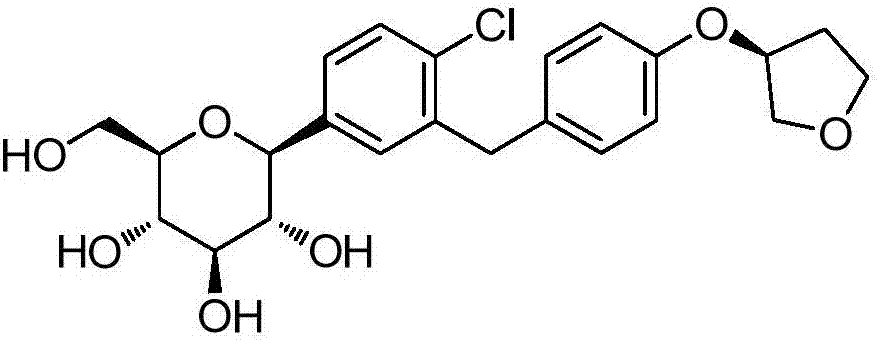

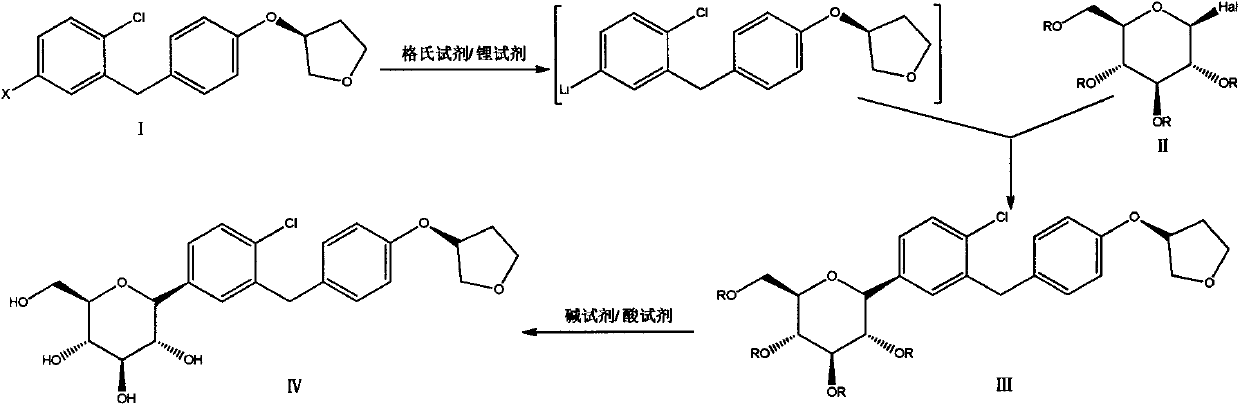

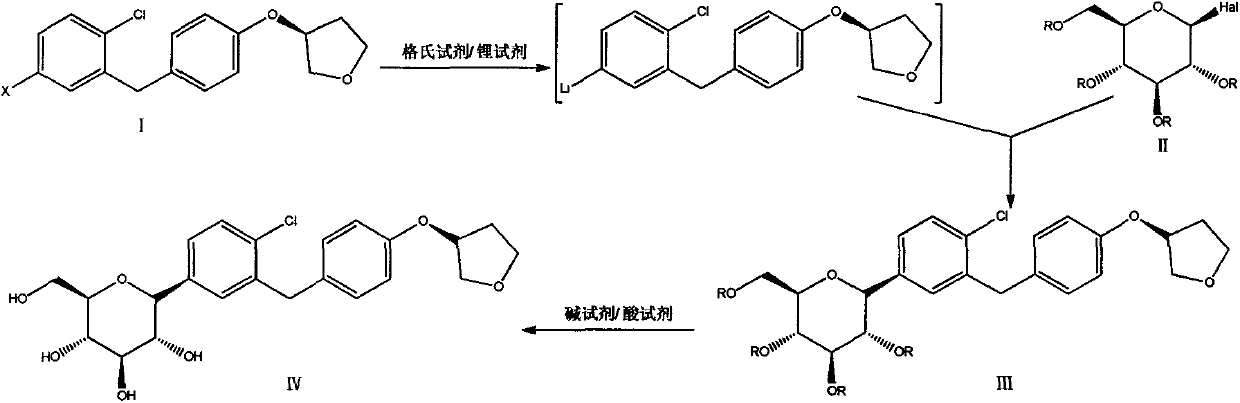

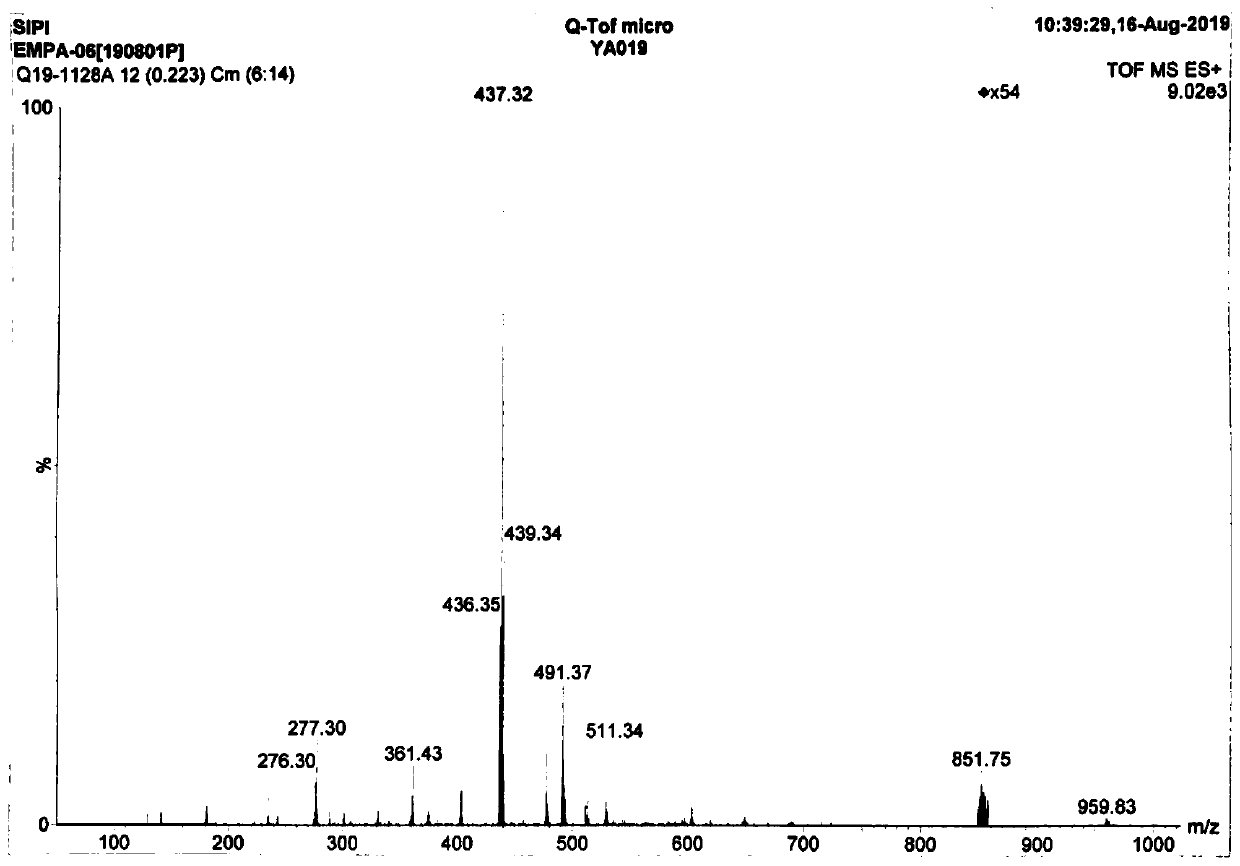

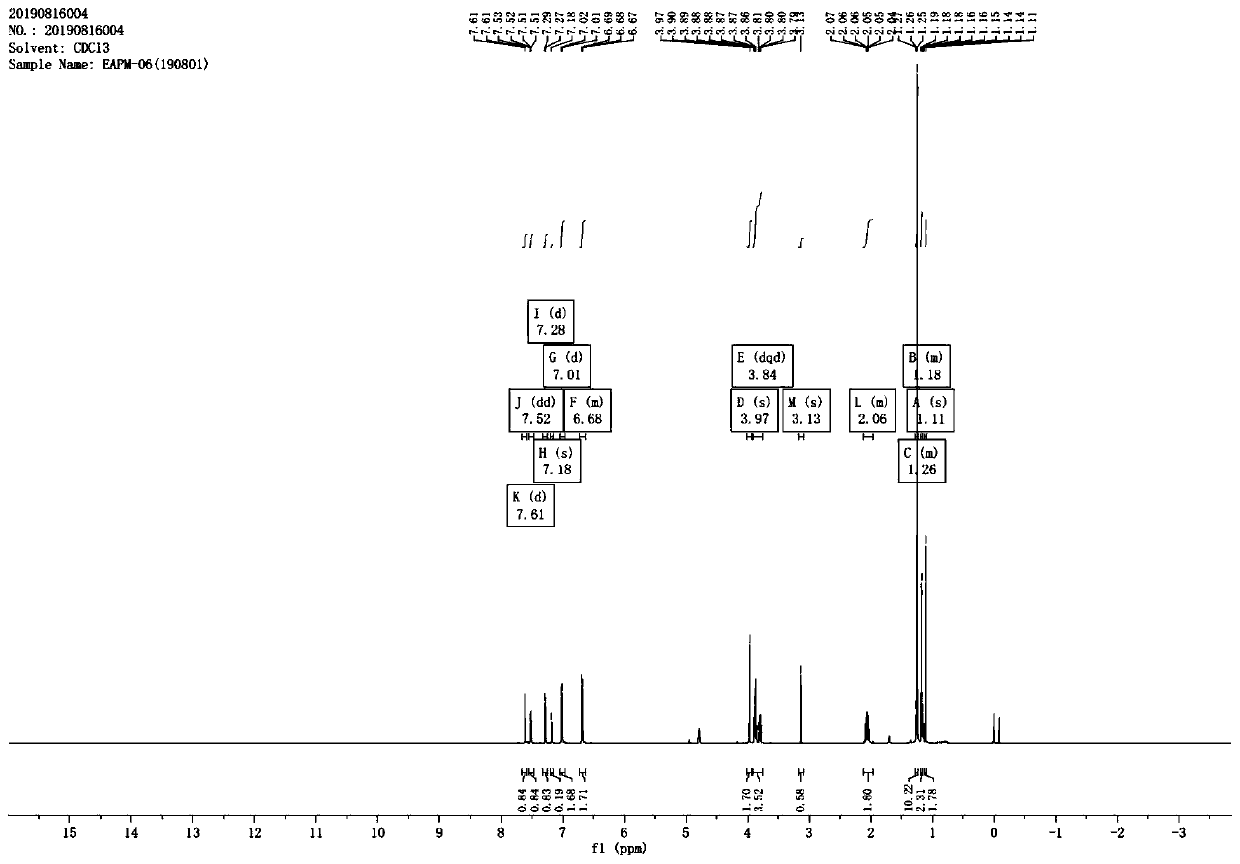

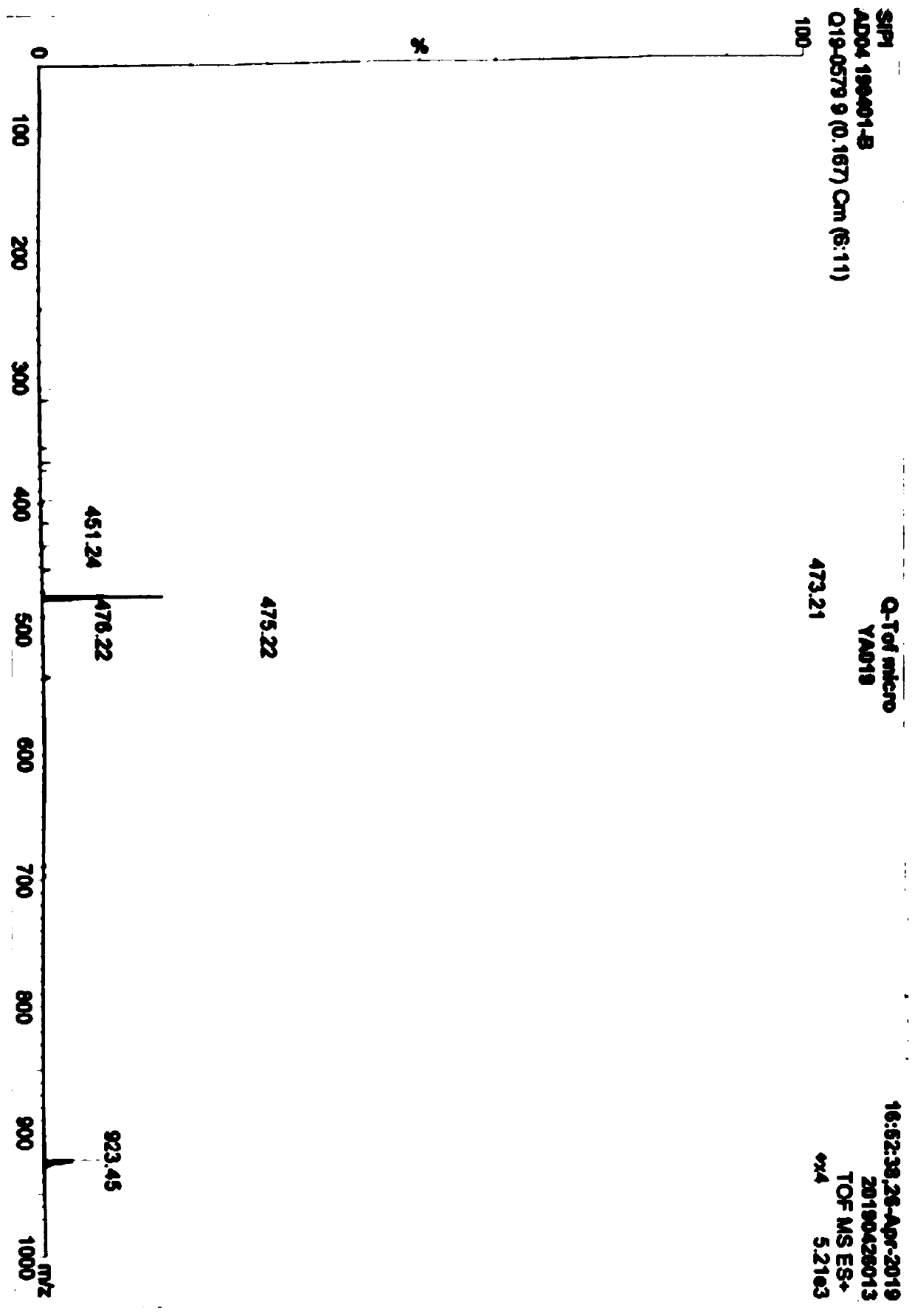

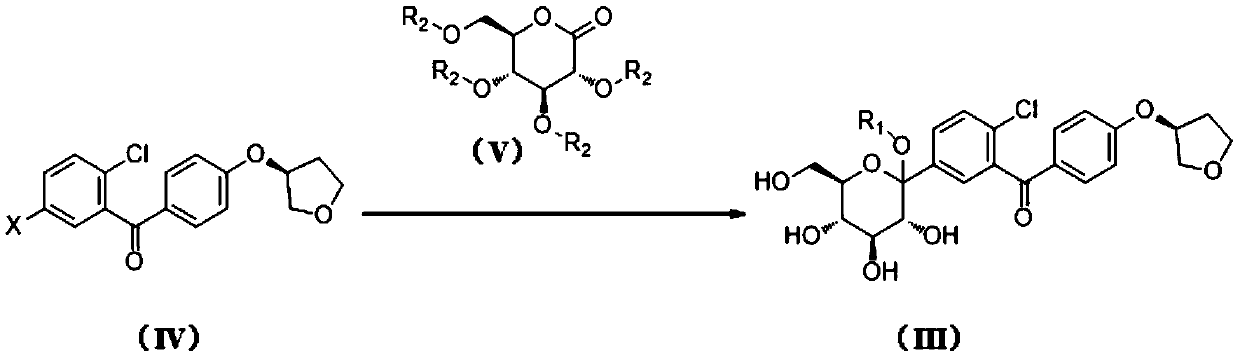

Preparation method of Jardiance

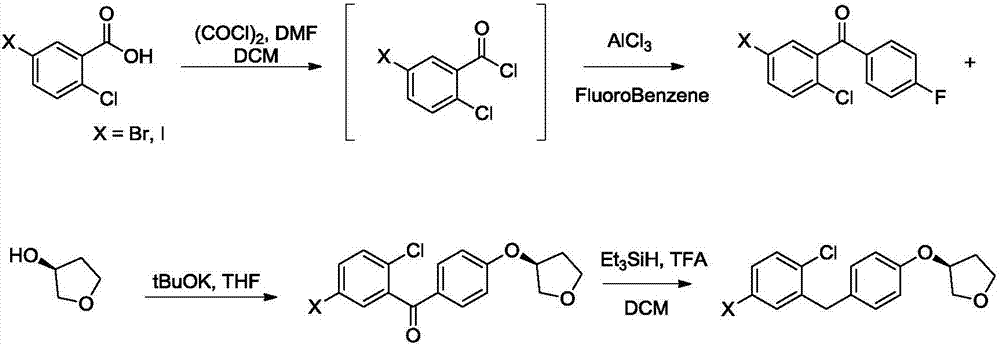

ActiveCN106905305AEasy to operateImprove efficiencyOrganic chemistryBulk chemical productionBromineCombinatorial chemistry

The invention discloses a preparation method of Jardiance. The preparation method comprises the following steps: (1) performing a Grignard exchange reaction on a compound 5, then enabling the compound 5 after the Grignard exchange reaction to react with a glucose lactone derivative 6 so as to obtain a compound 7 (as shown in the description), wherein X is bromine or iodine, LG is chlorine, bromine, mesyloxy or tosyl, and PG is acetyl, tert- butanoyl or benzoyl; (2) under the action of alkali, performing deprotection on the compound 7 so as to obtain a finished product namely an Jardiance type compound 8 (as shown in the description). The preparation route is simple to operate, the reaction steps are reduced, the yield is high, the obtained product is high in purity, and the preparation method is suitable for scaled production.

Owner:山东科巢生物制药有限公司

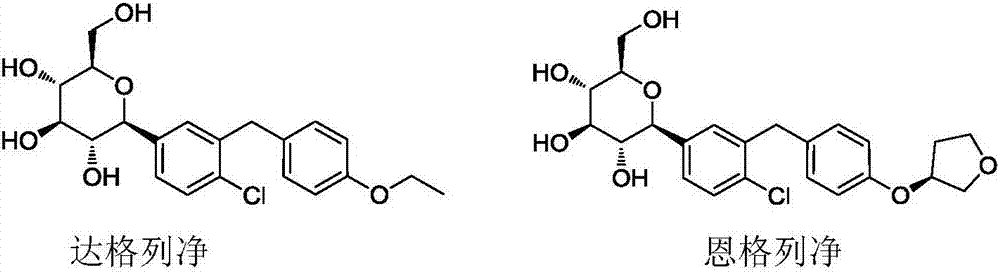

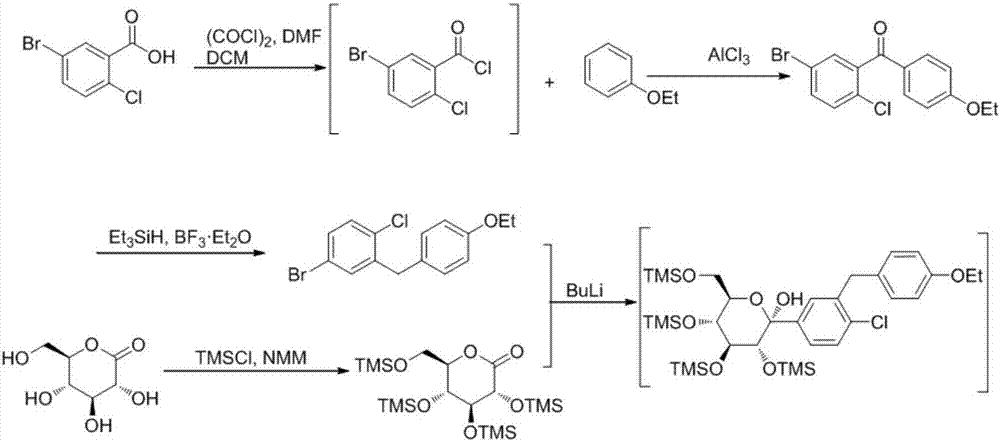

Preparation methods of SGLT-2 diabetes inhibitors and intermediates thereof

ActiveCN107163092AAvoid it happening againLower reaction yieldSugar derivativesSugar derivatives preparationSynthesis methodsCombinatorial chemistry

The invention provides a preparation method of an intermediate compound 7 of an SGLT-2 diabetes inhibitor dapagliflozin and an intermediate compound 8 of a SGLT-2 diabetes inhibitor empagliflozin, and new synthesis method of two final products. The preparation method comprises the following steps: carrying out carbonyl group reduction and hydroxyl group protection on a (5-halo-2-chlorophenyl)(4-ethoxyphenyl)ketone compound 1 used as an initial raw material to obtain a Grignard addition reaction key compound 4, and carrying out Grignard addition and acetylation to obtain the compound 7 and the compound 8. The dapagliflozin and the empagliflozin are respectively prepared from the compound 8. The methods have the advantages of simplicity in operation, high yield, high purity of the obtained products, and suitableness for amplified production.

Owner:山东科巢生物制药有限公司

Pharmaceutical composition, methods for treating and uses thereof

InactiveUS20180344647A1Reduce riskImprove blood sugar controlOrganic active ingredientsMetabolism disorderImmediate releaseMetformin Hydrochloride

The invention relates to solid pharmaceutical dosage forms comprising an extended release core comprising metformin hydrochloride and one or two immediate release coatings comprising linagliptin and / or empagliflozin.

Owner:BOEHRINGER INGELHEIM INT GMBH

Pharmaceutical composition, methods for treating and uses thereof

The invention relates to the treatment of metabolic disorders in an overweight or obese patient characterized in that empagliflozin and one or more antiobesity drugs are administered to the patient.

Owner:BOEHRINGER INGELHEIM INT GMBH

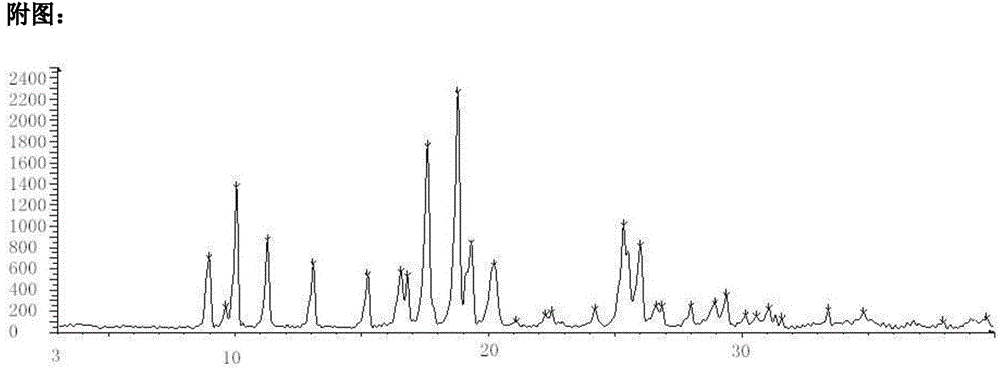

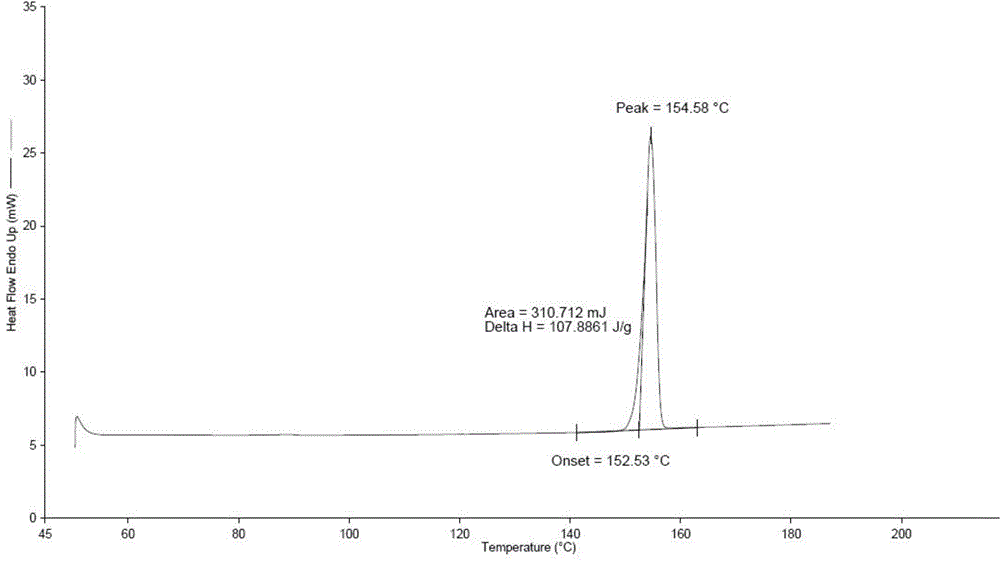

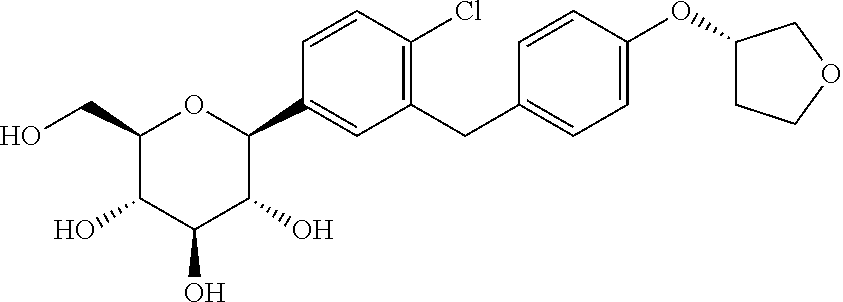

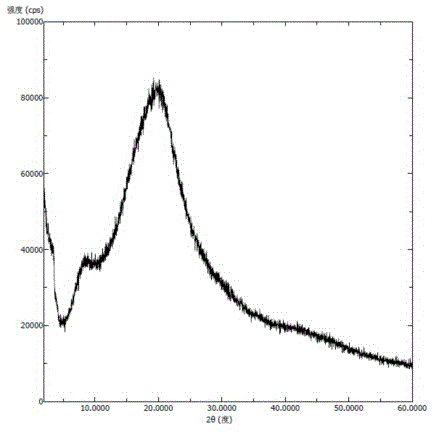

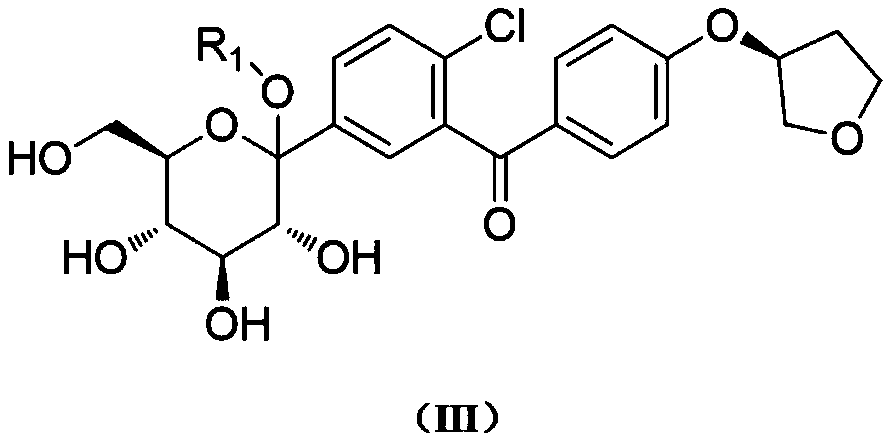

B crystal form of empagliflozin and preparation of B crystal form

The invention relates to a B crystal form of empagliflozin and a preparation method of the B crystal form. The prepared B crystal form of empagliflozin has diffraction peaks when the diffraction angle 2 theta is equal to 8.916 degrees, 10.011 degrees, 11.239 degrees, 17.567 degrees, 18.775 degrees, 19.308 degrees, 25.353 degrees and 26.000 degrees according to characterization of a powder x-ray diffraction pattern, and the powder x-ray diffraction pattern is obtained through CuK alpha rays. The preparation technology of the crystal form is simple, the stability is better, and the medicinal requirements are met.

Owner:JIANGSU LEEWAY BIOLOGICAL TECH

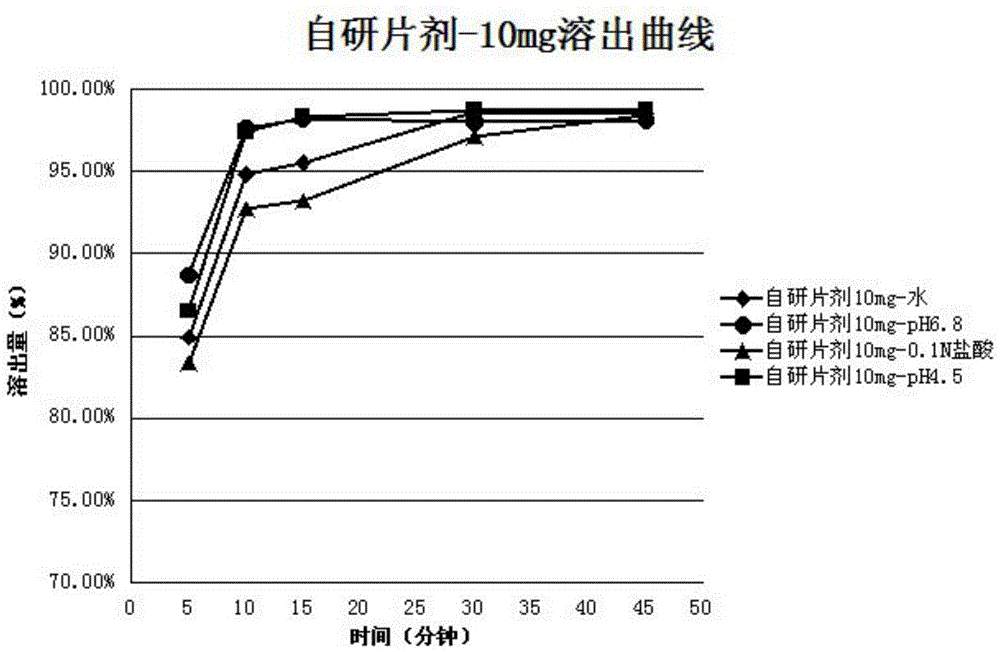

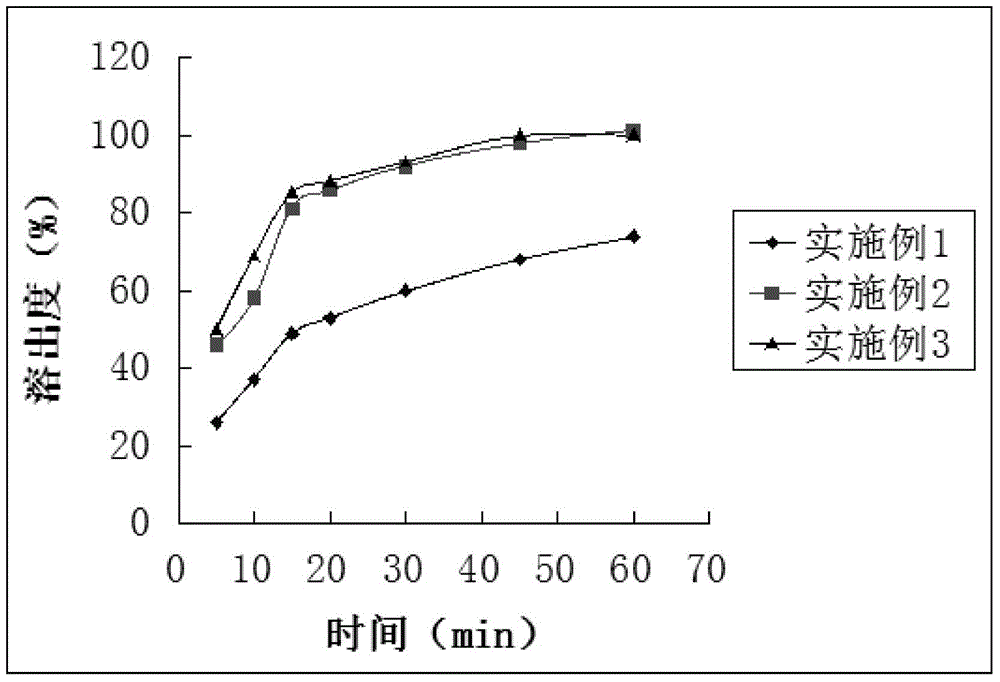

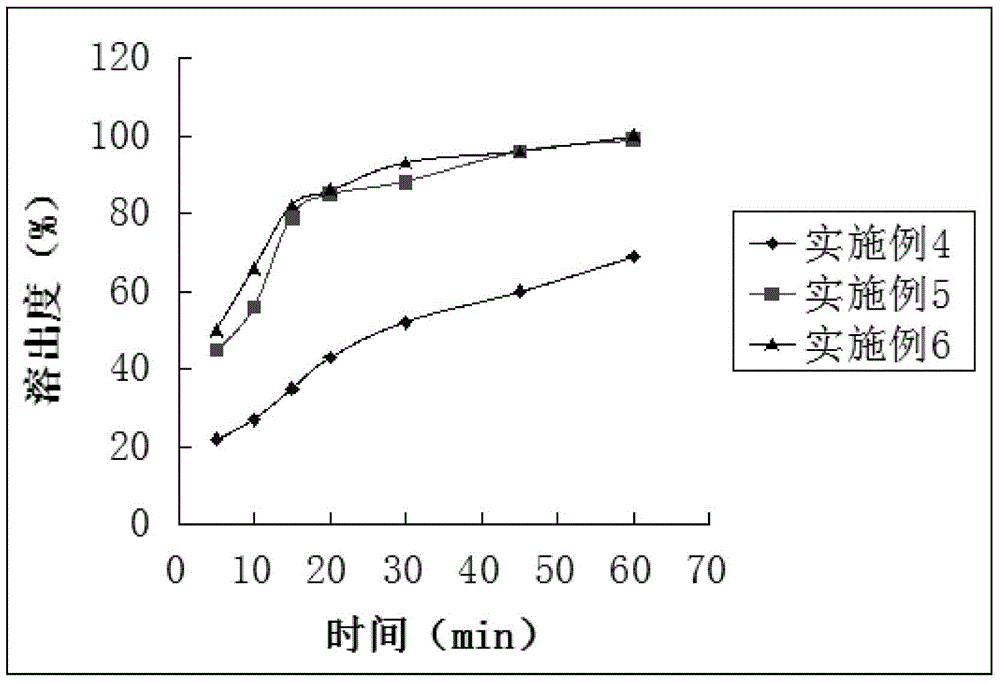

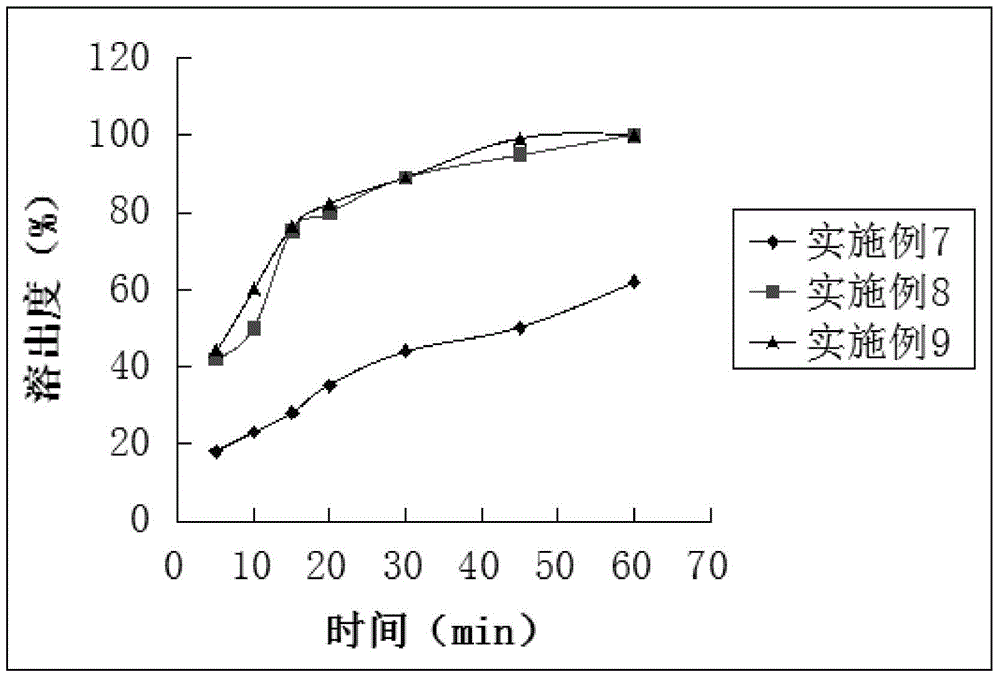

Preparation method of Empagliflozin and mannitol composition

ActiveCN104623684AQuality improvementSimple methodOrganic active ingredientsMetabolism disorderPharmaceutical medicineMannitol

The invention provides a preparation method of an Empagliflozin and mannitol composition. The preparation method comprises the following steps: mixing Empagliflozin and mannitol, performing hot-melting granulation, and mixing with other pharmaceutically acceptable carriers to obtain an oral solid preparation. The Empagliflozin and mannitol composition prepared by using the method is stable and controllable in quality and fast to dissolve.

Owner:ZHEJIANG HUAHAI PHARMACEUTICAL CO LTD

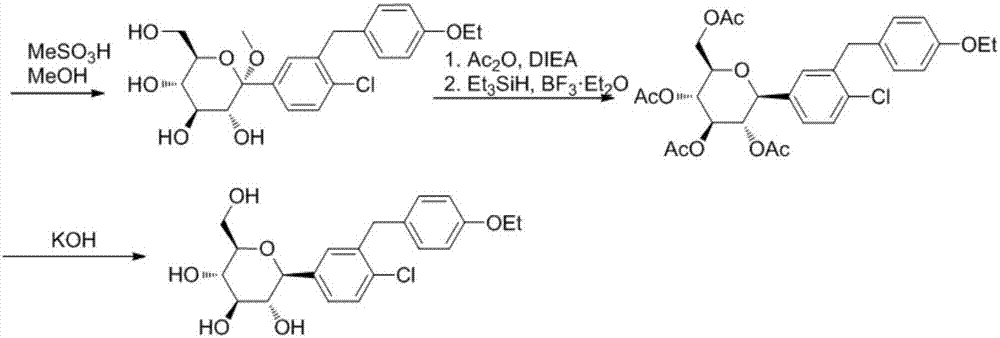

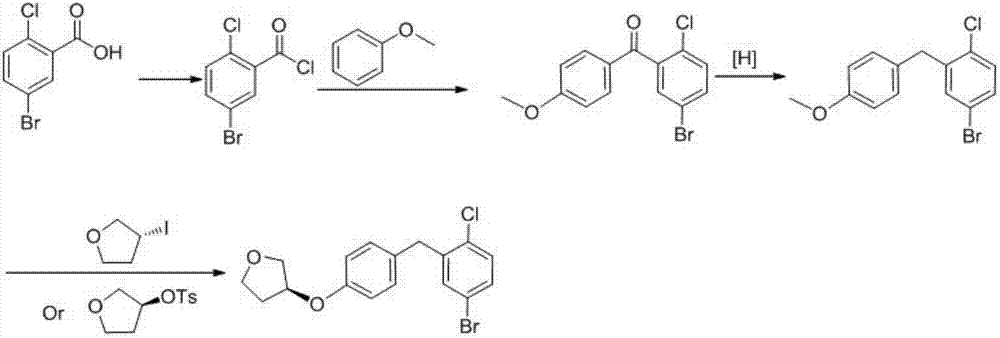

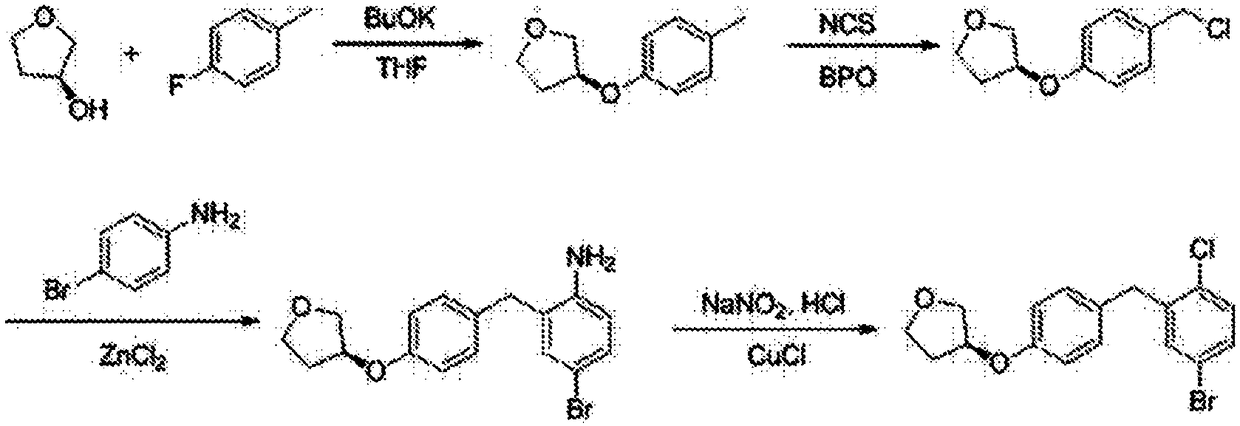

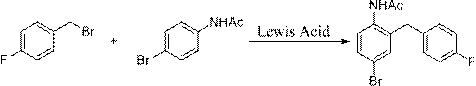

Preparation method of empagliflozin intermediate

The invention provides a preparation method of an empagliflozin intermediate. The preparation method comprises the following steps: 1), taking 4-fluorotoluene and (R)-3-hydroxytetrahydrofuran as raw materials, a polar solvent as a reaction solvent and inorganic alkali as a catalyst, performing a reaction to obtain (S)-3-p-cresyl tetrahydrofuran; 2), with N-chlorosuccinimide and the product obtained in the step 1) as raw materials, a non-polar solvent as a reaction solvent and dibenzoyl peroxide or azobisisobutyronitrile as an initiator, performing a reaction to obtain (S)-3- p-chlorophenol tetrahydrofuran; 3) dissolving 4-bromaniline and the product obtained in the step 2) into ethyl acetate, adding a catalyst Lewis acid, performing a reaction to obtain (S)-3-(4-(5-bromo-2-aminobenzyl)phenoxy) tetrahydrofuran; 4), performing a diazotization reaction on the product obtained in the step 3), and then reacting with cuprous chloride to synthesize (S)-3-(4-(5-bromo-2-chlorobenzyl)phenoxy) tetrahydrofuran. The preparation method has the advantages that the cost is low, the finished product is high in purity and the synthesis route is short.

Owner:安徽省诚联医药科技有限公司

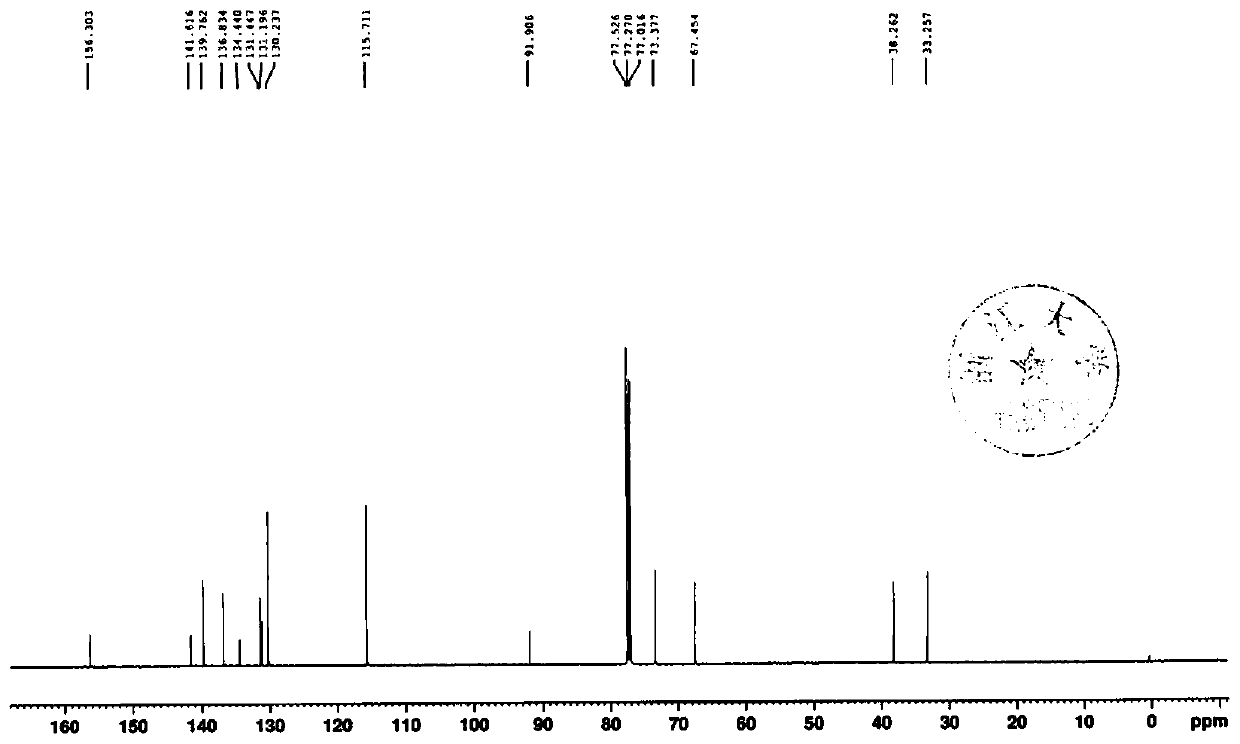

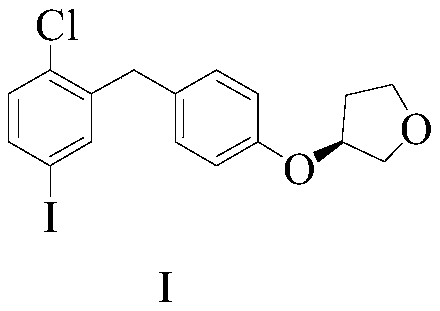

Synthesis method of Empagliflozin intermediate

InactiveCN108178751AHigh yieldImprove responseOrganic chemistry methodsIodine3-Hydroxytetrahydrofuran

The invention discloses a synthesis method of an Empagliflozin intermediate. The synthesis method uses 4-hydroxybenzyl chloride as a starting material to sequentially react with methanesulfonyl chloride and (S)-3-hydroxytetrahydrofuran to obtain compound III, then react with 4-iodoaniline to obtain compound IV, and finally react with cuprous chloride after diazotization to obtain (S)-3-(4-(5-iodine-2-chlorobenzyl)phenoxy) tetrahydrofuran. The raw materials used in the synthesis method are simple and easy to obtain, the operation steps are simple, the post-treatment is simple, the product yieldis high, and the method is suitable for industrial production.

Owner:YANGZHOU POLYTECHNIC INST

Empagliflozin intermediate preparation method

The invention discloses an empagliflozin intermediate preparation method, which comprises: carrying out substitution by using p-methoxybenzyl chloride and p-iodoaniline as starting raw materials to obtain a compound IV, performing diazotization and a Sandmeyer reaction to obtain a compound III, further performing demethylation under the action of boron tribromide to obtain a compound II, and finally performing condensation with (S)-3-p-toluenesulfonyloxy tetrahydrofuran to obtain the target compound I, wherein the product purity is greater than or equal to 99.0%. According to the invention, the preparation method has advantages of simple and easily available raw materials, low cost, simple operation steps, simple post-treatment and high product yield, and is suitable for industrial production.

Owner:ZHEJIANG HUAYI PHARMA CO LTD OF HANGZHOU HUADONG PHARMA GRP +1

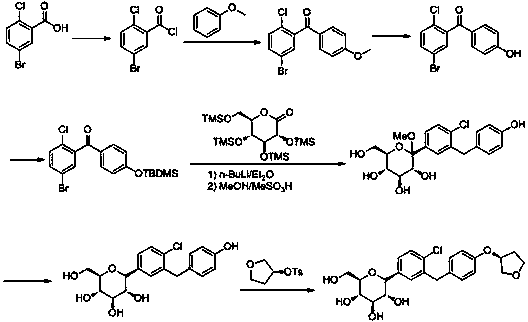

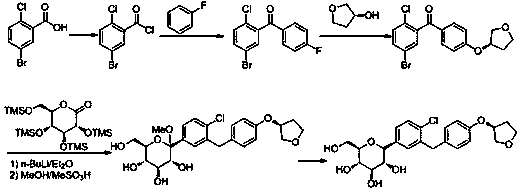

Preparation method of empagliflozin

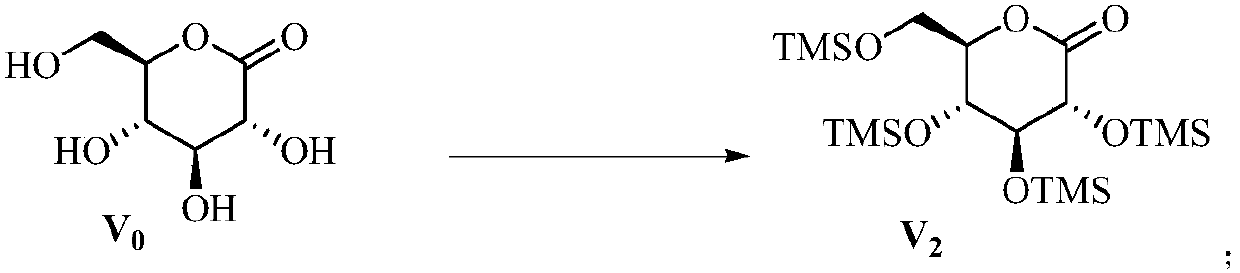

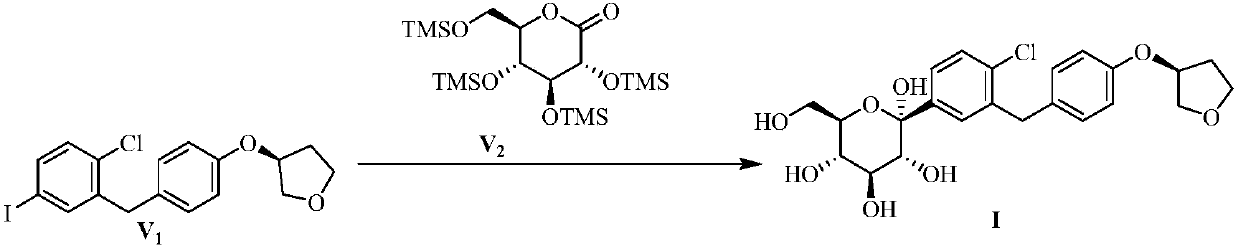

InactiveCN107652277ACheap and easy to getEasy to industrializeOrganic chemistryAlkyl transferTrimethylsilyl

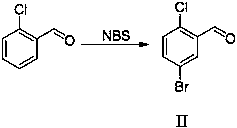

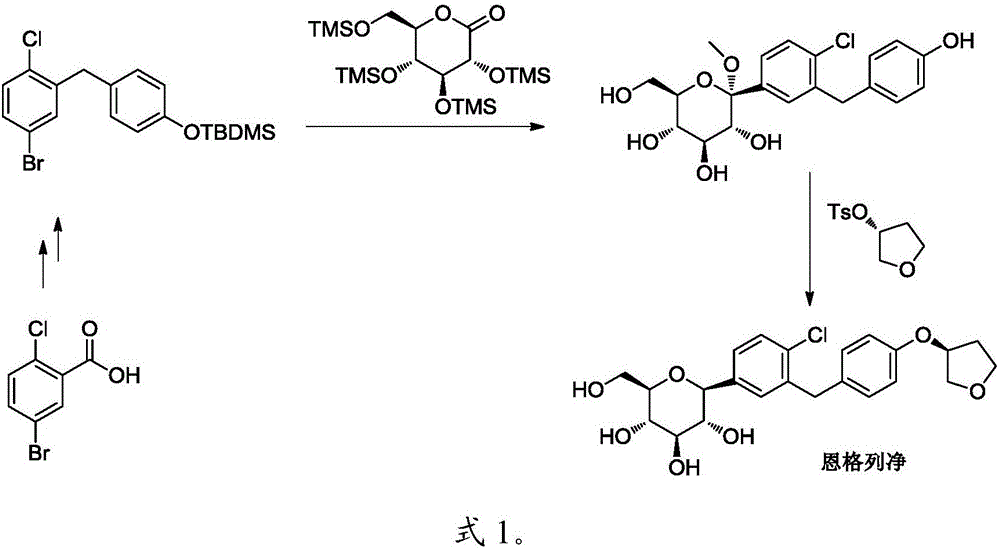

The invention relates to a preparation method of empagliflozin. The preparation method of empagliflozin comprises the following steps: taking 2-chlorobenzaldehyde as a starting material; carrying outbromination reaction, reduction reaction and halogenating reaction on the starting material, and carrying out Friedel-Crafts alkylation reaction on the starting material and (S)-3-phenoxyl tetrahydrofuran to obtain an intermediate which is (S)-3-(4-(5-bromo-2-chlorobenzyl) phenoxyl) tetrahydrofuran; and then carrying out condensation, etherification and methoxyl removal on the intermediate and 2,3,4,6-quadri-O-trimethylsilyl-D-glucolactone to obtain the empagliflozin as a hypoglycemic drug. The preparation method of the empagliflozin has the advantages that compared with an existing synthesisprocess, the preparation method of the empagliflozin takes the 2-chlorobenzaldehyde as the starting material, raw materials are cheap and easy to obtain, industrialization is easy to implement in theprocess, the synthesis route is short, and the method is easy to operate; in a preparation process, various temperature conditions are easy to control, reaction conversion rate is high, and the totalyield can be 75% or above; and moreover, by the preparation method, the product cannot be isomerized easily, impurities are fewer, the purity of the product can be improved, and the purity can be 99%or above.

Owner:IANGSU COLLEGE OF ENG & TECH

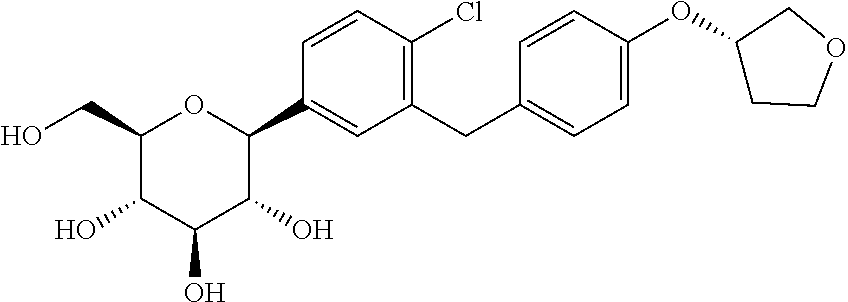

Synthetic method of empagliflozin

ActiveCN106117192AEasy to purifyShort synthetic routeOrganic chemistryBulk chemical productionD-GlucopyranoseCombinatorial chemistry

The invention provides a synthetic method of empagliflozin. The synthetic method comprises the following steps of: by using 2, 3, 4, 6-tetra-O-benzyl-D-glucopyranose acid-1,5-lactone and p-chloroiodobenzene as raw materials, performing a reaction so as to obtain an intermediate as shown in a formula II; performing reduction to eliminate a hydroxyl on anomeric carbon of the intermediate as shown in the formula II, so as to obtain an intermediate as shown in a formula III; by using (S)-3-phenoxy tetrahydrofuran, the intermediate as shown in the formula III, and paraform as raw materials, performing a reaction so as to obtain an intermediate as shown in a formula IV; and removing benzyl of the intermediate as shown in the formula IV, so as to obtain the empagliflozin. According to the synthetic method disclosed by the invention, firstly 1-p-chlorophenyl-2,3,4,6-tetra-O-benzyl-D-glucopyranose is prepared, then the intermediate of the 1-p-chlorophenyl-2,3,4,6-tetra-O-benzyl-D-glucopyranose, the (S)-3-phenoxy tetrahydrofuran and the paraform are used as the raw materials, the empagliflozin protected by intermediate benzyl is prepared, and finally a benzyl protecting group is removed, so that the empagliflozin is obtained. The synthetic route of the synthetic method disclosed by the invention is short, and the total yield is high.

Owner:GANSU CHANGEE BIO PHARMA

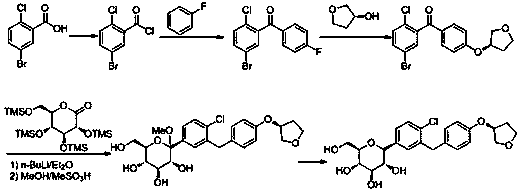

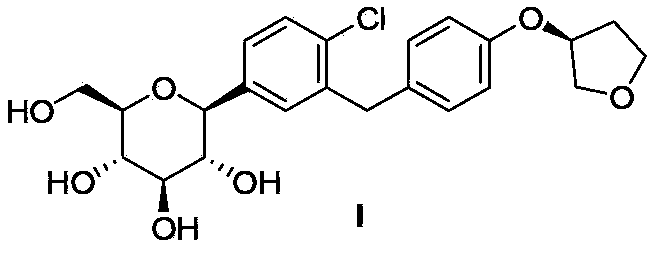

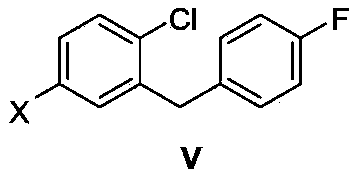

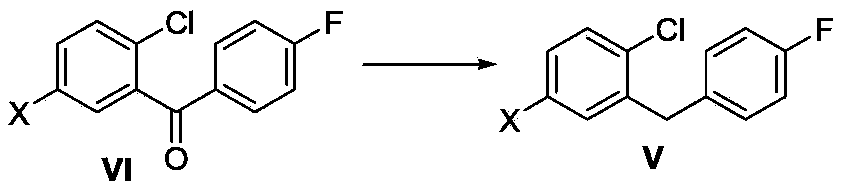

4-substituted-1-chloro-2-(4-fluorobenzyl)benzene, its preparation method and application as intermediate in preparation of anti-type II diabetes drugs

InactiveCN104045513ALow priceReduce pollutionSaccharide with carbocyclic radicalsSugar derivativesBenzeneDiabrezide

The invention discloses a compound 4-substituted-1-chloro-2-(4-fluorobenzyl)benzene shown as formula V, its preparation method and application as an intermediate in preparation of anti-type II diabetes drugs, and especially discloses the compound 4-substituted-1-chloro-2-(4-fluorobenzyl)benzene shown as formula V and its application as an intermediate in preparation of anti-type II diabetes drug Empagliflozin shown as formula I. The method provided by the invention has the advantages of relatively cheap raw material and reagent, low cost, simple and safe operation, good yield, small environmental pollution, and very good economic effect, thus being suitable for industrial production.

Owner:SHANGHAI FANGNAN PHARMA

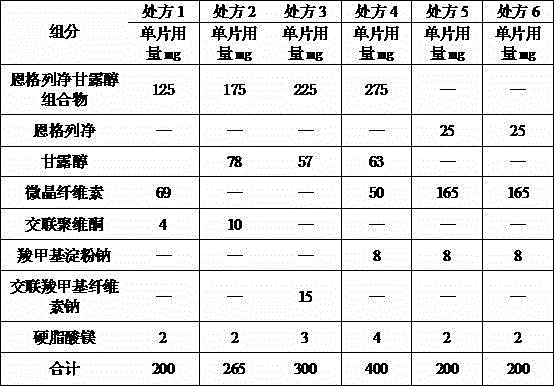

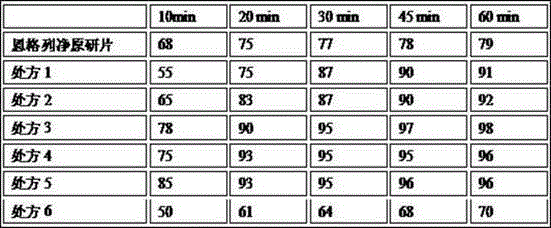

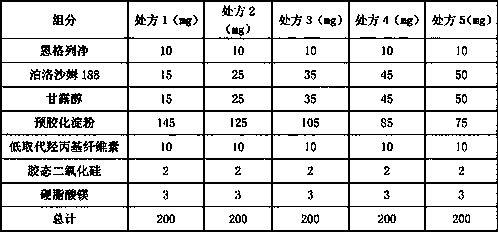

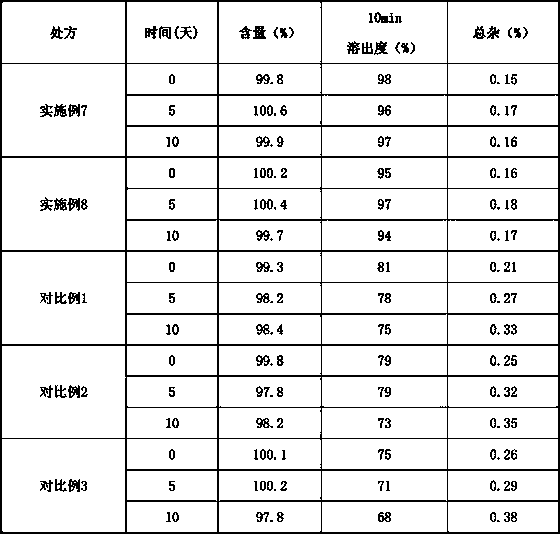

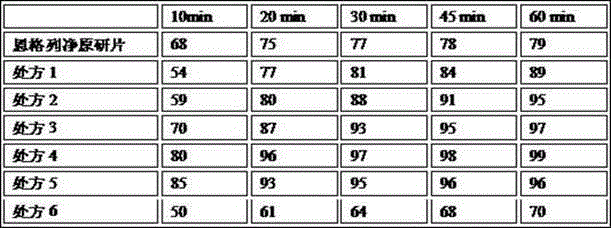

Empagliflozin tablet, and preparation method and application thereof

InactiveCN105769782AReduce demandReduce manufacturing costOrganic active ingredientsMetabolism disorderTreatment effectSolvent

The invention relates to an empagliflozin tablet, and a preparation method and application thereof. The empagliflozin tablet comprises a first component and a second component, wherein the first component is at least one selected from a group consisting of empagliflozin, a pharmaceutical salt thereof and a solvate of empagliflozin, and the second component is microcrystalline cellulose. According to the invention, by controlling the microcrystalline cellulose in a reasonable range, empagliflozin can be better dissolved out in mediums like 0.1 N hydrochloric acid and water, so bioavailability and stability of the empagliflozin tablet are improved. A prescription and the preparation method for the empagliflozin tablet are simple and practicable, save production cost and improve the quality and treatment effect of the empagliflozin tablet.

Owner:WATERSTONE PHARMA WUHAN

Pharmaceutical composition, methods for treating and uses thereof

InactiveUS20180318251A1Good effectOrganic active ingredientsPill deliveryEmpagliflozinEjection fraction

The present invention relates to methods for preventing or treating acute or chronic heart failure and for reducing the risk of cardiovascular death, hospitalization for heart failure and other conditions in patients with preserved or reduced ejection fraction by administering empagliflozin to the patient.

Owner:BOEHRINGER INGELHEIM INT GMBH

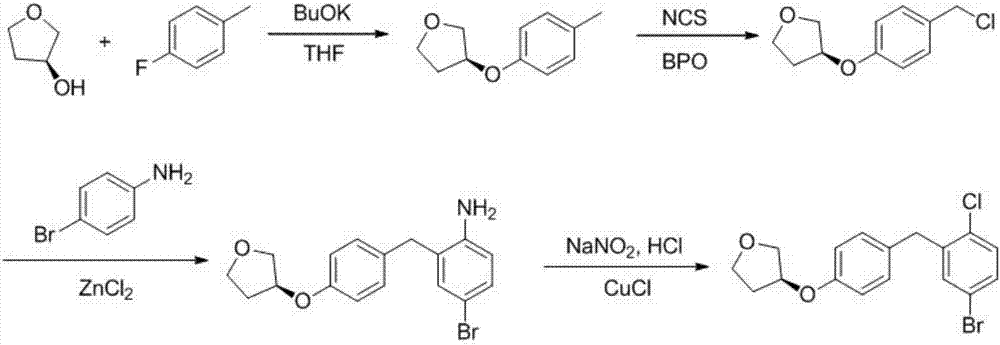

Synthesis process for empagliflozin

InactiveCN107652278ACheap and easy to getEasy to industrializeOrganic chemistry methodsAlkyl transferTrimethylsilyl

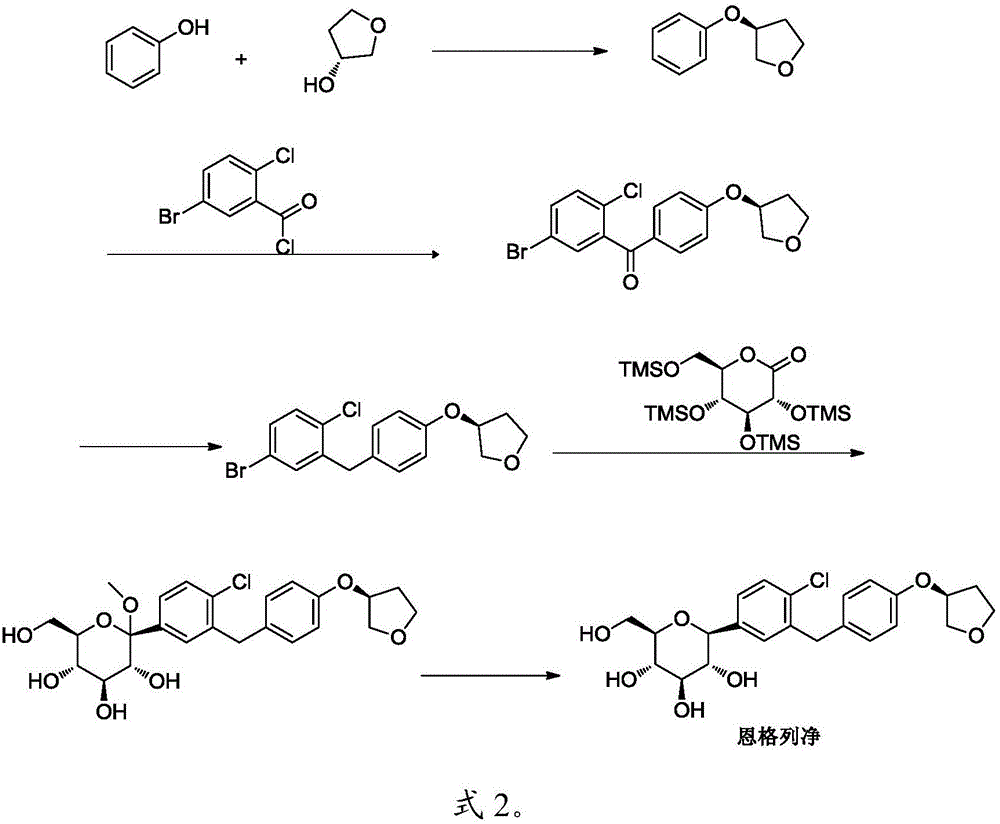

The invention relates to a synthesis process for empagliflozin. The synthesis process for empagliflozin comprises the following steps: taking 4-fluorotoluene as a starting material; carrying out radical bromo reaction, Friedel-Crafts alkylation reaction, deprotection, diazotization chlorination and alkylation reaction to obtain an intermediate which is (S)-3-(4-(5-bromo-2-chlorobenzyl) phenoxyl) tetrahydrofuran; and then carrying out condensation, etherification and methoxyl removal on the intermediate and 2,3,4,6-quadri-O-trimethylsilyl-D-glucolactone to obtain the empagliflozin as a hypoglycemic drug. The synthesis process for empagliflozin has the advantages that compared with an existing synthesis process, the synthesis process for the empagliflozin takes the 4-fluorotoluene as the starting material, raw materials are cheap and easy to obtain, industrialization is easy to implement in the process, the synthesis route is short, and the process is easy to operate; in a preparation process, various temperature conditions are easy to control, reaction conversion rate is high, and the total yield can be 70% or above; and moreover, by the synthesis process, the product cannot be isomerized easily, impurities are fewer, the purity of the product can be improved, and the purity can be 99% or above.

Owner:IANGSU COLLEGE OF ENG & TECH

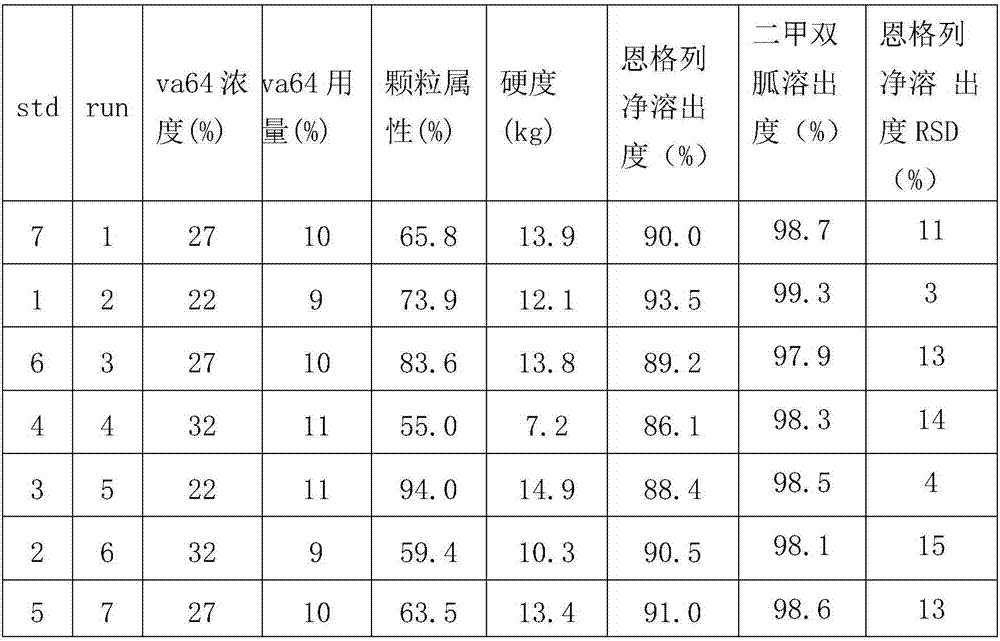

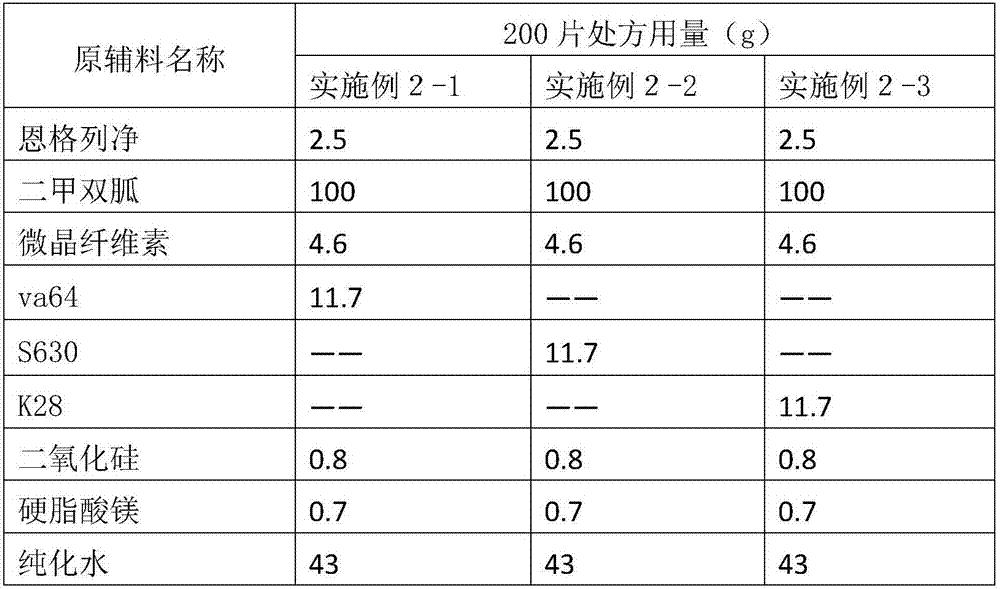

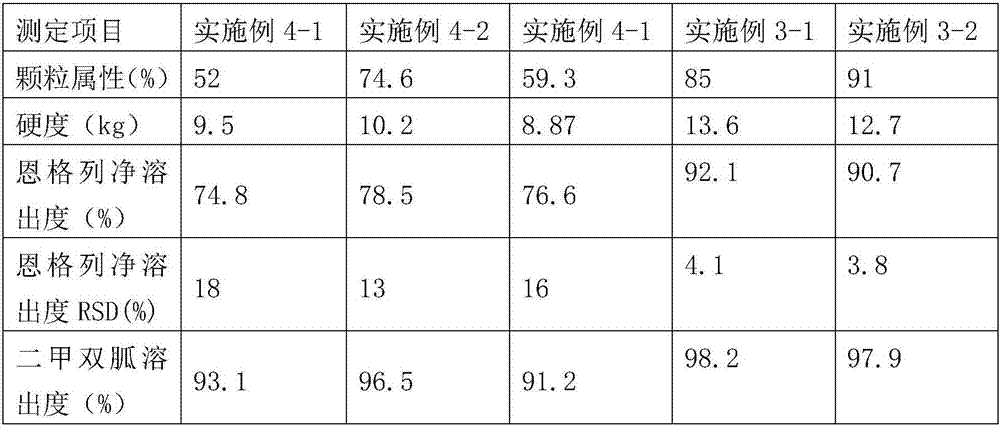

Medicine composition containing empagliflozin and dimethylbiguanide hydrochloride

ActiveCN106924237AHigh hardnessPromote dissolutionOrganic active ingredientsMetabolism disorderDissolutionEmpagliflozin

The invention discloses a medicine composition containing empagliflozin and dimethylbiguanide hydrochloride. The medicine composition contains a filling agent, a binder, a flow aid and a lubricating agent, wherein the content of the binder is 9 to 11 percent .The invention also discloses a method for preparing the empagliflozin and dimethylbiguanide hydrochloride medicine composition. The empagliflozin and dimethylbiguanide hydrochloride medicine composition disclosed by the invention is high in hardness and rapid in dissolution, and an interslice dissolution degree RSD is small.

Owner:HANGZHOU HUADONG MEDICINE GRP PHARMA RES INST

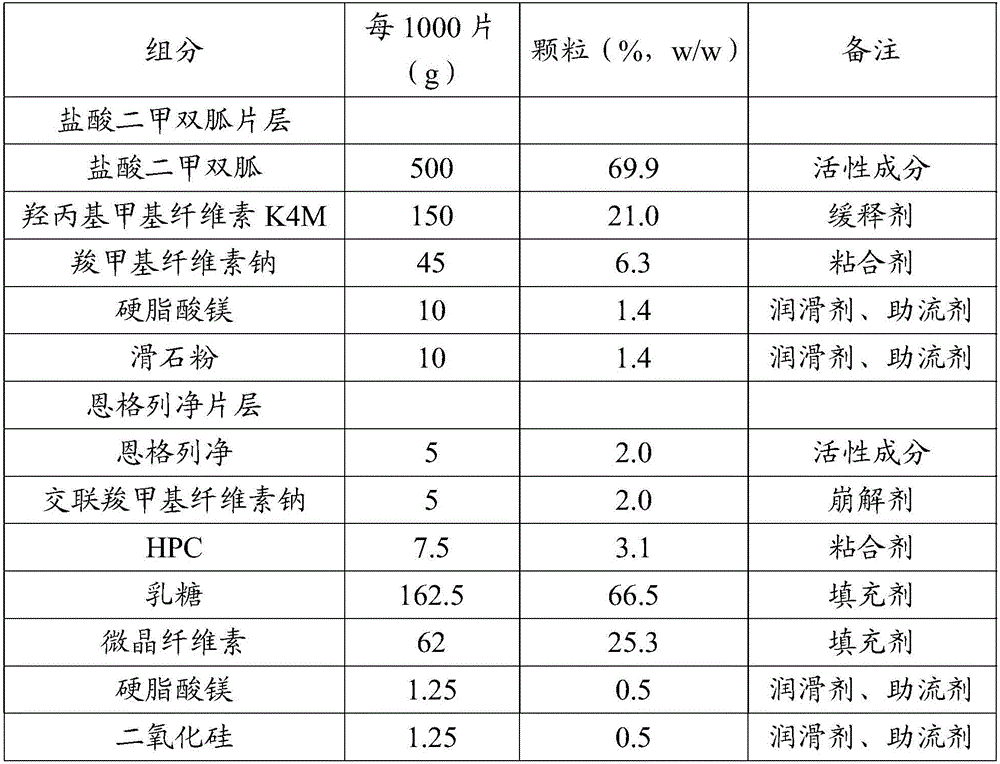

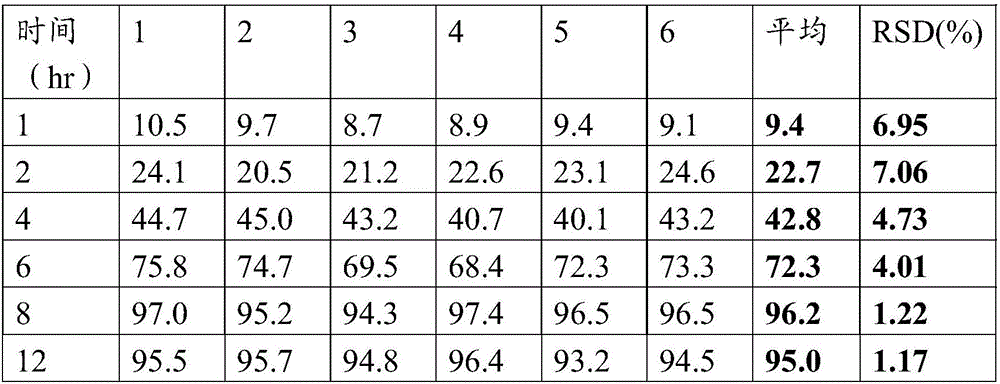

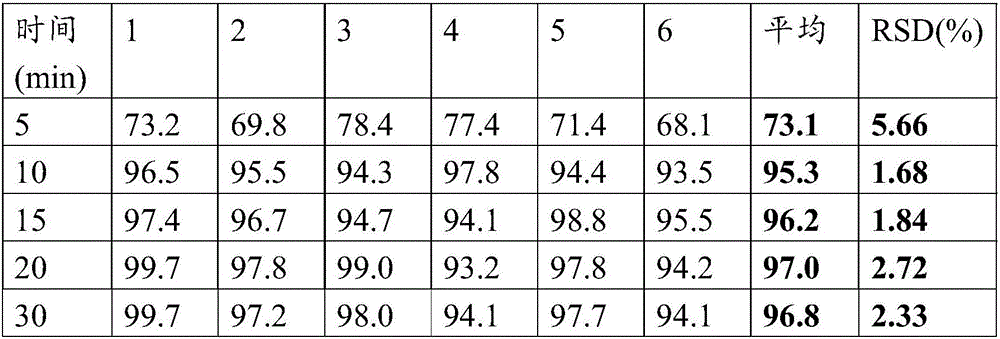

Double-layer tablet containing metformin hydrochloride and empagliflozin, and preparation method thereof

InactiveCN107432869AGuaranteed sustained release propertiesSolution for Rapid DissolutionOrganic active ingredientsMetabolism disorderActive componentMetformin Hydrochloride

The present invention provides a double-layer tablet containing metformin hydrochloride and empagliflozin, wherein the metformin hydrochloride tablet layer is a sustained-release layer, the empagliflozin tablet layer is a rapid-release layer, and the metformin hydrochloride sustained-release layer is 12-24 h sustained-release layer. The invention further provides a preparation method of the double-layer tablet, and uses of the double-layer tablet in preparation of drugs for treatment and / or improvement of type 2 diabetes. According to the present invention, with the double-layer tablet containing metformin hydrochloride and empagliflozin, the sustained release property of the metformin hydrochloride and the rapid dissolution of the empagliflozin are ensured; the double-layer tablet is taken twice a day, and can provide the important significant for the improvement of the clinical treatment of diabetes patients; and the method has advantages of simple preparation process, low production cost and product stability improving, and can ensure the mixing uniformity of the two active components in the production.

Owner:TIANJIN INSTITUTE OF PHARMA RESEARCH

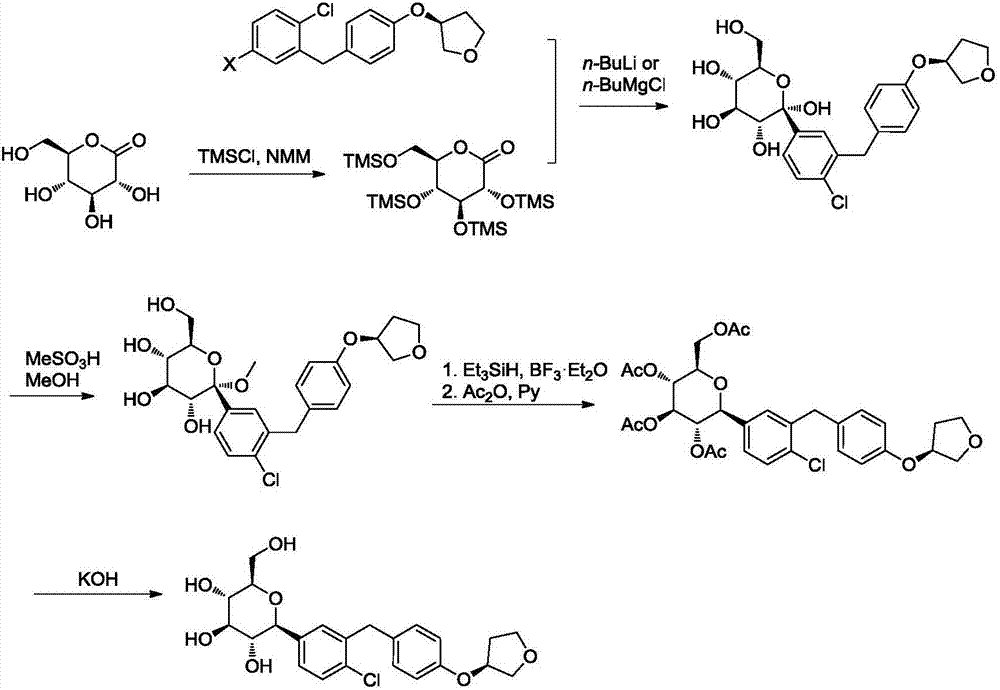

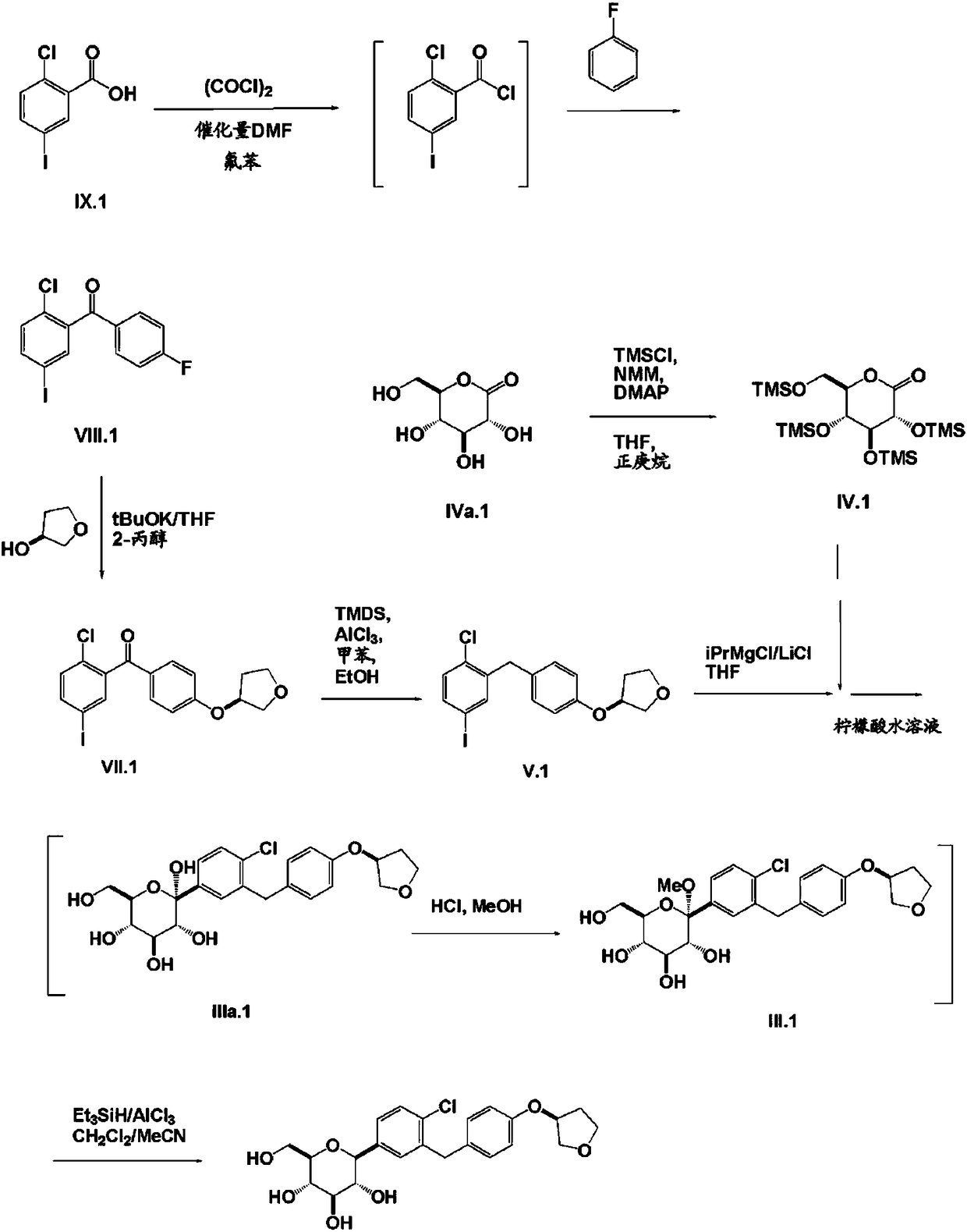

Preparation method suitable for industrial production of empagliflozin

InactiveCN109988161AHigh puritySimple purification methodOrganic chemistryGlucono delta-lactoneOrganic synthesis

The invention belongs to the technical field of organic synthesis route design and medicine and chemical engineering, particularly relates to a synthesis method of a sodium-glucose cotransporter 2(SGLT2) inhibitor, and more particularly relates to a preparation method of empagliflozin. The empagliflozin is synthesized by taking (3S)-3-[4-[(2-chloro-5-iodophenyl) methyl] phenoxy] tetrahydrofuran and glucono delta-lactone as initial raw materials through a series of substep reactions such as protection, addition, substitution, deprotection and reduction. In the synthesis steps disclosed by the invention, a staged target product does not need to be separated and purified after each step of reaction, and the target product is finally obtained by directly subjecting a high-purity reaction intermediate to subsequent steps. The preparation method is simple in process, simple and convenient to operate and good in industrial prospect.

Owner:XUZHOU WANBANG JINQIAO PHARMA +1

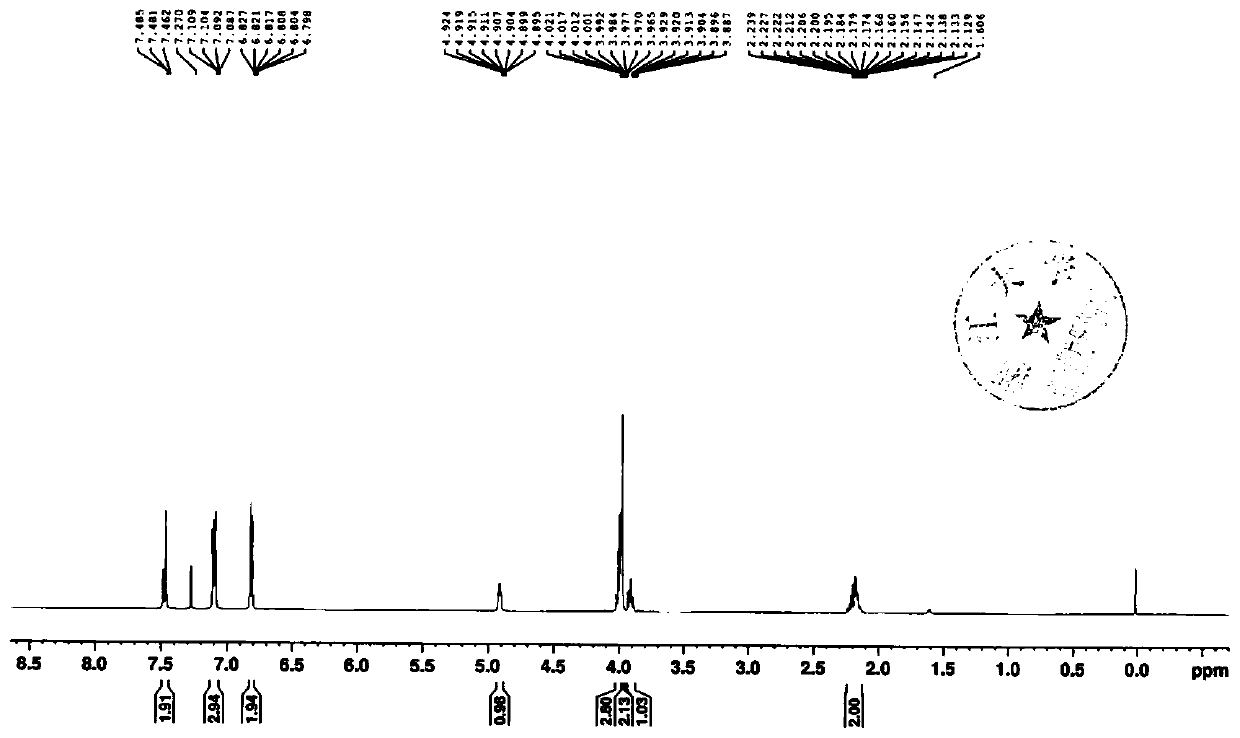

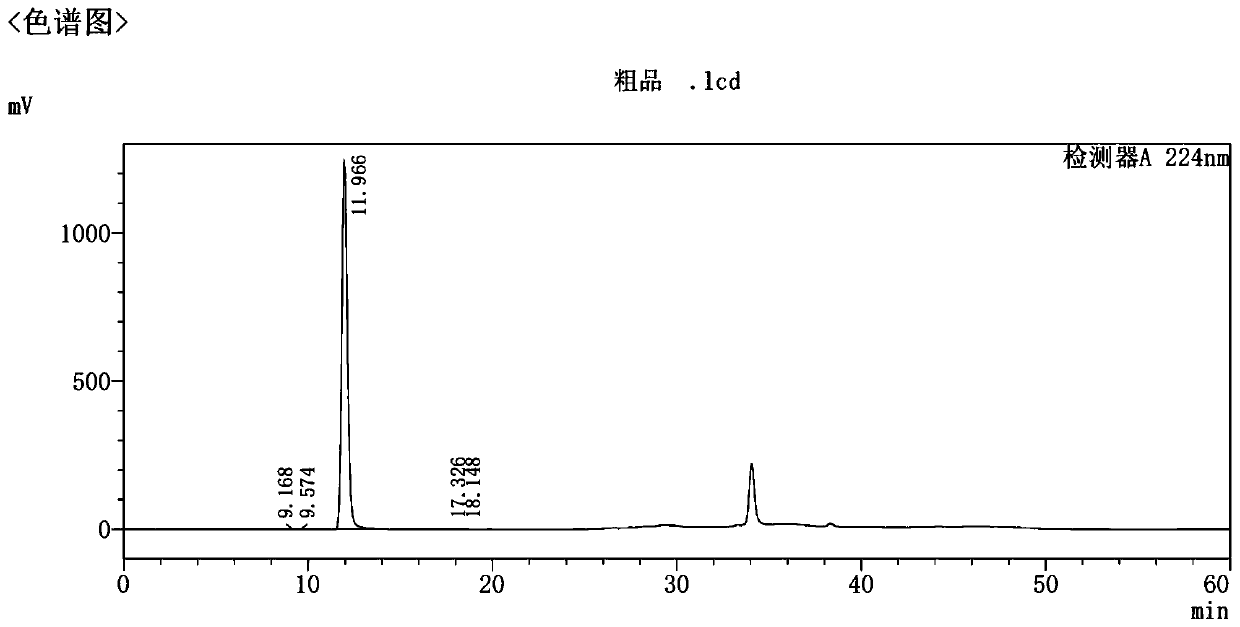

Method for preparing high purity Empagliflozin

InactiveCN107163033ASuitable for industrial mass productionSimple methodOrganic chemistryAluminium chlorideTriethylsilane

The present invention provides an improved method for preparing high purity Empagliflozin, the method includes the following steps: step a. under the protection of nitrogen, performing reaction of compounds 1 and 2 to obtain a compound 3; step b. adding the compound 3 into a reactor, adding methanol, dropwise adding concentrated hydrochloric acid, stirring, dissolving, clarifying, and performing reaction at room temperatur to obtain a compound 4; step c. adding dropwise an acetonitrile and dichloromethane solution of the compound 4 to an aluminium chloride, triethyl silicane, acetonitrile and dichloromethane solution for reaction, after completion of the reaction, adding water for quenching the reaction, stirring until a solid is precipitated, filtering by suction, and collecting a filter cake to obtain a crude product of compound 5, namely Empagliflozin; and d. refining the crude product. The method is suitable for industrial production,and can be used for the preparation of the high purity Empagliflozin.

Owner:YANGTZE RIVER PHARMA GRP BEIJING HAIYAN PHARMA +1

A method for preparing empagliflozin

ActiveCN107556302AHigh purityHigh yieldOrganic chemistryBulk chemical productionCompound organicLithium

A method for preparing empagliflozin is provided. The method includes steps of preparing a composite organometallic reagent to promote condensation of (S)-4-halogen-1-chloro-2-(4-tetrahydrofuran-3-yloxy-benzyl) benzene and halogenated glucose, and then removing a protecting group to obtain a product, wherein the organometallic reagent is a product by mixing a Grignard reagent or a lithium chloridepromoted Grignard reagent with a lithium reagent. The organometallic reagent can allow the temperature of a coupling reaction to be increased from -78 DEG C to -10 DEG C, thus improving process reaction conditions, making operation simple and convenient, reducing byproducts and reducing the production cost. The method reduces process steps, avoids reactions at excessively low temperatures, increases the total yield and has an industrial application prospect.

Owner:CHENGDU UNIV

Pharmaceutical composition, methods for treating and uses thereof

InactiveUS20180125813A1Good effectOrganic active ingredientsUrinary disorderCardio vascular diseaseEmpagliflozin

Owner:BOEHRINGER INGELHEIM INT GMBH

Synthetic method of empagliflozin

ActiveCN110698467AOrganic chemistryMetabolism disorderBiochemical engineeringCombinatorial chemistry

The invention provides a brand-new synthesis process of empagliflozin. According to the process, a boric acid ester is used for halogen removal, and specific reaction conditions are combined, so thatempagliflozin can be prepared with high yield and simplicity and convenience in operation. The synthesis method of empagliflozin has the advantages of mild reaction conditions, high total yield, few side reactions and convenience in operation, thereby being beneficial to industrial production and cost control.

Owner:HUANGGANG LUBAN PHARM

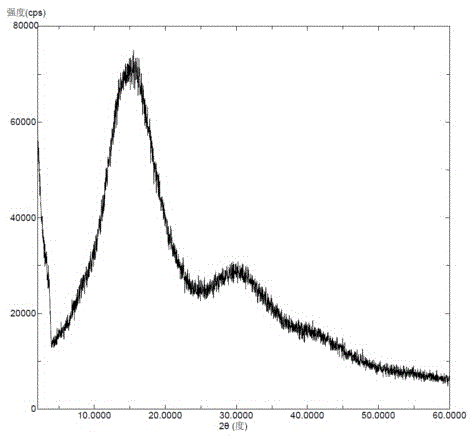

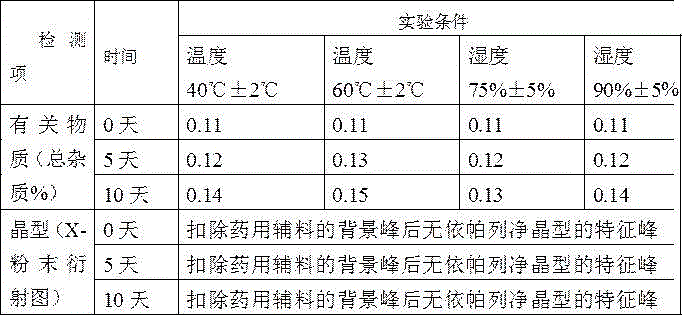

A solid dispersion of amorphous empagliflozin and a preparing method thereof

A solid dispersion of amorphous empagliflozin and a preparing method thereof are provided. The solid dispersion includes empagliflozin and two or more than two medicinal auxiliary materials, and the weight ratio of the empagliflozin to all the medicinal auxiliary materials is 1:0.1-100. The empagliflozin in the solid dispersion is amorphous. An X-ray amorphous powder diffraction spectrum of the solid dispersion does not has a characteristic peak of empagliflozin crystals after deducting background peaks of the medicinal auxiliary materials. The solid dispersion has good stability and dispersibility, and the dissolution rate of the empagliflozin is increased, thus increasing bioavailability of a medicine preparation and medicine absorption by a human body. Under accelerated testing conditions, good physical stability and chemical stability can be maintained. The method has characteristics of simple operation, convenient separation, a low cost, good reappearance and easy implementation and is suitable for industrial production.

Owner:CHANGZHOU FANGNAN MEDICINE TECH CO LTD

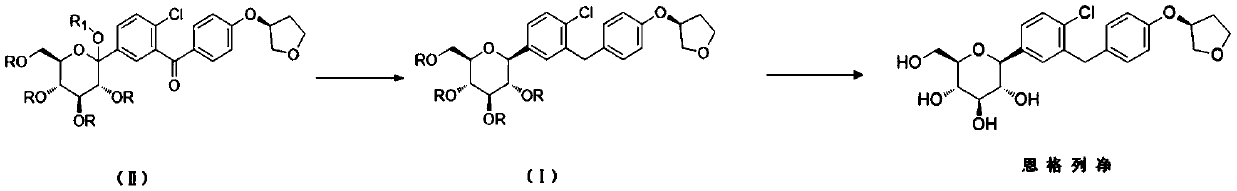

Synthesizing method suitable for industrial empagliflozin production

PendingCN110305118AAvoid repeated useSimple processOrganic chemistryBulk chemical productionCompound (substance)Empagliflozin

The invention discloses a synthesizing method suitable for industrial empagliflozin production. The synthesizing method includes: subjecting a compound as shown in formula (II) to reduction reaction to obtain a compound as shown in formula (I), and removing the protecting groups of the compound as shown in formula (I) to obtain empagliflozin. The synthesizing method has the advantages that the method is simple in process, only needs one-step reduction reaction and can effectively reduce the repeated use of high-toxicity and high-risk chemicals; in addition, the intermediate purified after derivation protection, effective process control is achieved, and product quality is increased; the method is high in practical application value and suitable for industrial production.

Owner:SICHUAN KELUN PHARMA RES INST CO LTD

Empagliflozin tablet and preparation process thereof

ActiveCN111214450AHigh dissolution rateImprove stabilityOrganic active ingredientsMetabolism disorderPharmaceutical medicineMannitol

The invention provides an empagliflozin tablet and a preparation process thereof. The empagliflozin tablet comprises empagliflozin, carrier materials and other pharmaceutically acceptable auxiliary materials, and is characterized in that the carrier materials jointly consist of poloxamer and mannitol. The empagliflozin tablet disclosed by the invention has the advantages that the operation of thepreparation process is simple; and the characteristics of high dissolution rate, good stability and the like are realized.

Owner:SHANGHAI HANSOH BIOMEDICAL +2

Empagliflozin quick-release pellet preparation and preparation method

InactiveCN106727420AOrganic active ingredientsMetabolism disorderMetal ions in aqueous solutionOral medication

The invention discloses an empagliflozin quick-release pellet preparation and a preparation method, and relates to the field of pharmaceutic preparation techniques and applications. An administration mode of the quick-release pellet preparation is oral administration; a blank pellet core is taken as a carrier; an empagliflozin aqueous solution containing a cosolvent and an adhesive is a drug layering solution; the dosage of empagliflozin is 0.0025-0.3wt% of the dosage of the pellet core; and the oral dosage of the empagliflozin is not higher than 50mcg. The empagliflozin quick-release pellet preparation has the characteristics of high drug layering rate, good content homogeneity, quick release, rapid effect in abirritation, good clinic compliance, high safety and the like. In addition, a blank pellet core fluidized bed drug layering method is suitable for preparing a very-low-specification oral empagliflozin preparation.

Owner:FOSHAN TENGRUI MEDICINE TECH CO LTD

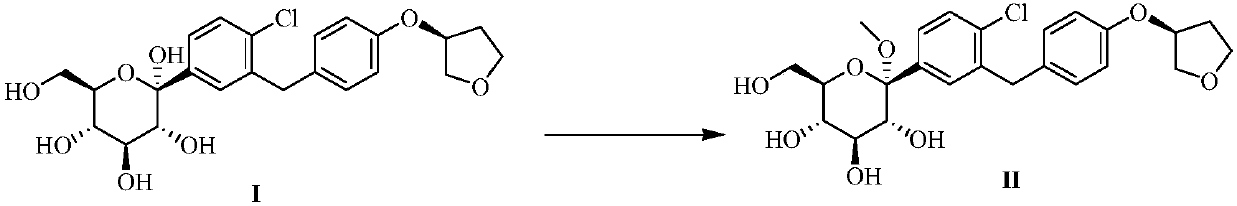

Preparation and refining method of high-purity empagliflozin

ActiveCN110655511APromote crystallizationReduce manufacturing costOrganic chemistryProcess engineeringEmpagliflozin

The invention relates to a crystallization method of a high-purity empagliflozin crude product and a further refining method of the crude product. The refining method is capable of increasing the purity of the crude product with ensured crude product yield, so that the refining and purifying times are obviously reduced; the refining method is further optimized, the refining purity and yield are improved, and high-purity empagliflozin is obtained. The method provided by the invention can reduce the production cost and is more suitable for industrial large-scale production.

Owner:BEIJING LUNARSUN PHARMA

Preparation method of empagliflozin microcrystalline cellulose composition

ActiveCN104586803ASimple processSave costsOrganic active ingredientsMetabolism disorderEmpagliflozinChemistry

The invention provides a preparation method of an empagliflozin microcrystalline cellulose composition. The preparation method comprises the following steps: mixing empagliflozin and microcrystalline cellulose to obtain a mixture of empagliflozin and microcrystalline cellulose; heating the mixture to melt the empagliflozin, and stirring the mixture; and cooling to obtain an empagliflozin microcrystalline cellulose composition. The empagliflozin composition prepared by the method provided by the invention has stable and controllable quality and is quickly dissolved out.

Owner:ZHEJIANG HUAHAI PHARMA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com