Patents

Literature

120 results about "P-Chlorophenol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

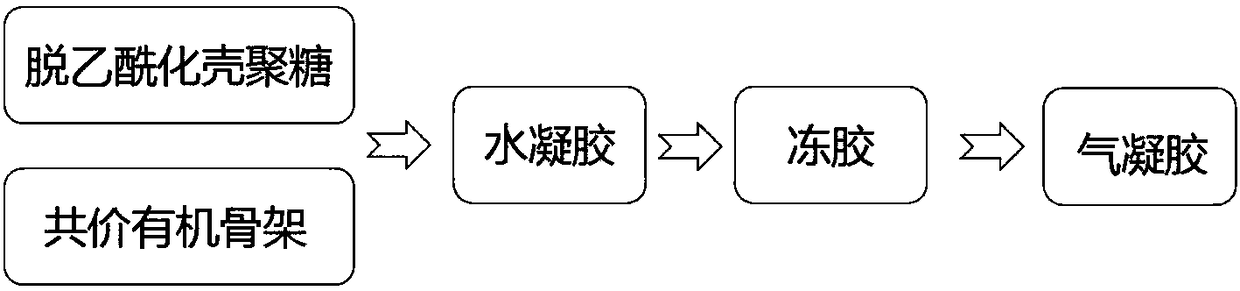

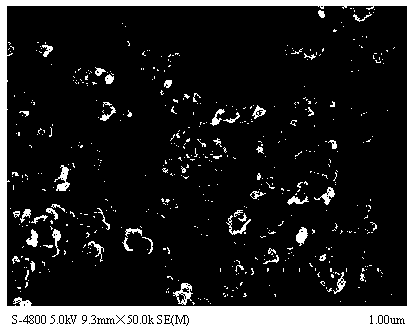

COF (covalent organic framework)-chitosan composite aerogel material supported with metal nanoparticles, preparation method and application

InactiveCN108355713ADeviceizationRealize functional integrationOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsP-ChlorophenolMetal particle

The invention relates to a COF (covalent organic framework)-chitosan composite aerogel material supported with metal nanoparticles and a preparation method of the composite aerogel material. The COF-chitosan composite aerogel material supported with metal nanoparticles is prepared from, in parts by weight, 0-2.16 parts of metal particles, 27.84-50 parts of a COF material and 50-70 parts of chitosan, wherein the content of the metal particles is not zero. Firstly, metal salt is supported in the COF material, metal salt is reduced, the palladium-supported COF material is obtained and then formsan aerogel material with chitosan; the COF material and chitosan are composited, and the composite aerogel material with stable structure and good property is prepared; device production of the COF material and function integration of the COF material and the device are realized; flowing type efficient catalysis of a dechlorination reaction of chlorine-containing aromatic compounds is realized through dechlorination reactions of p-chlorophenol, o-chlorophenol, m-chlorophenol and the like.

Owner:SHANDONG NORMAL UNIV

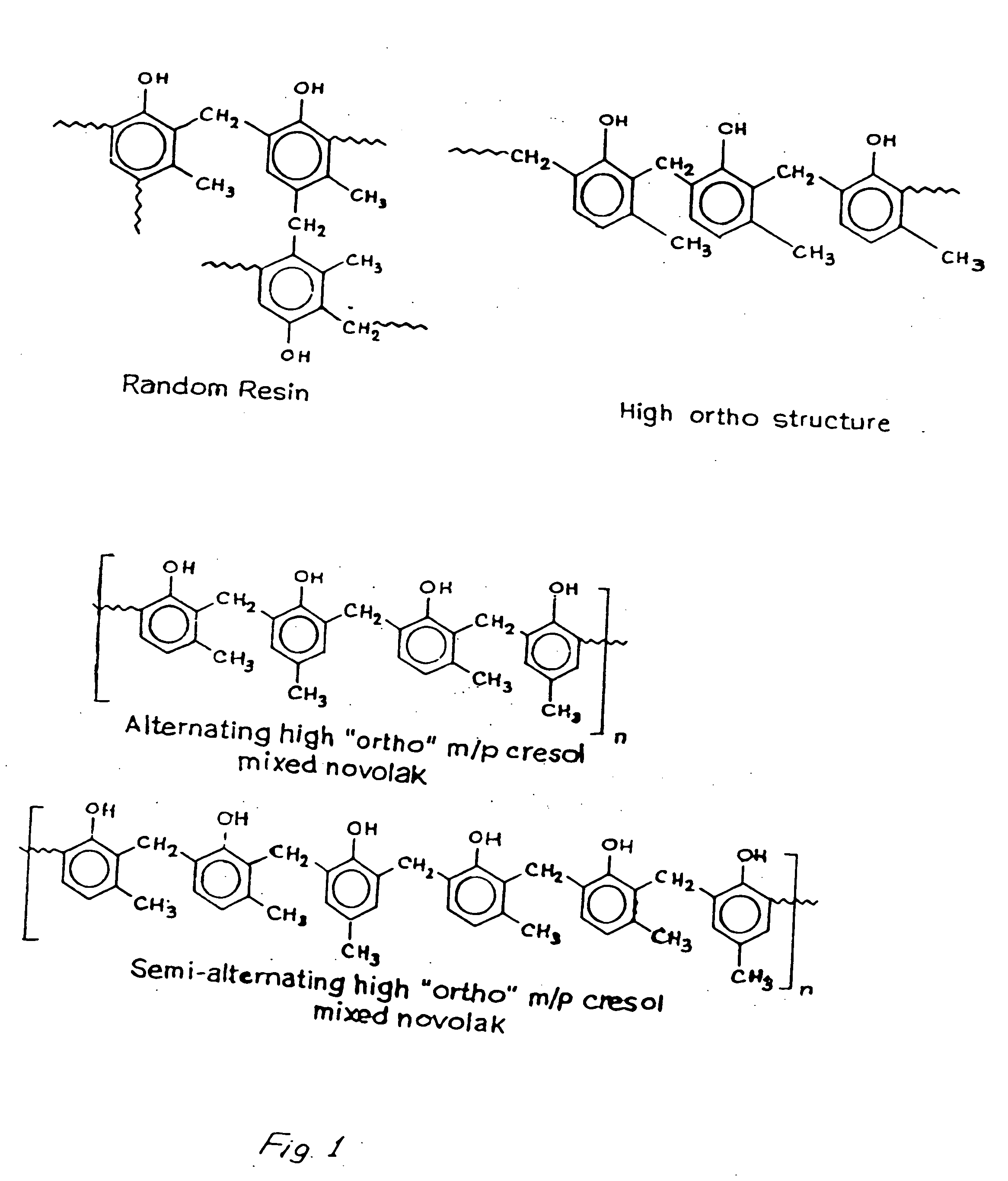

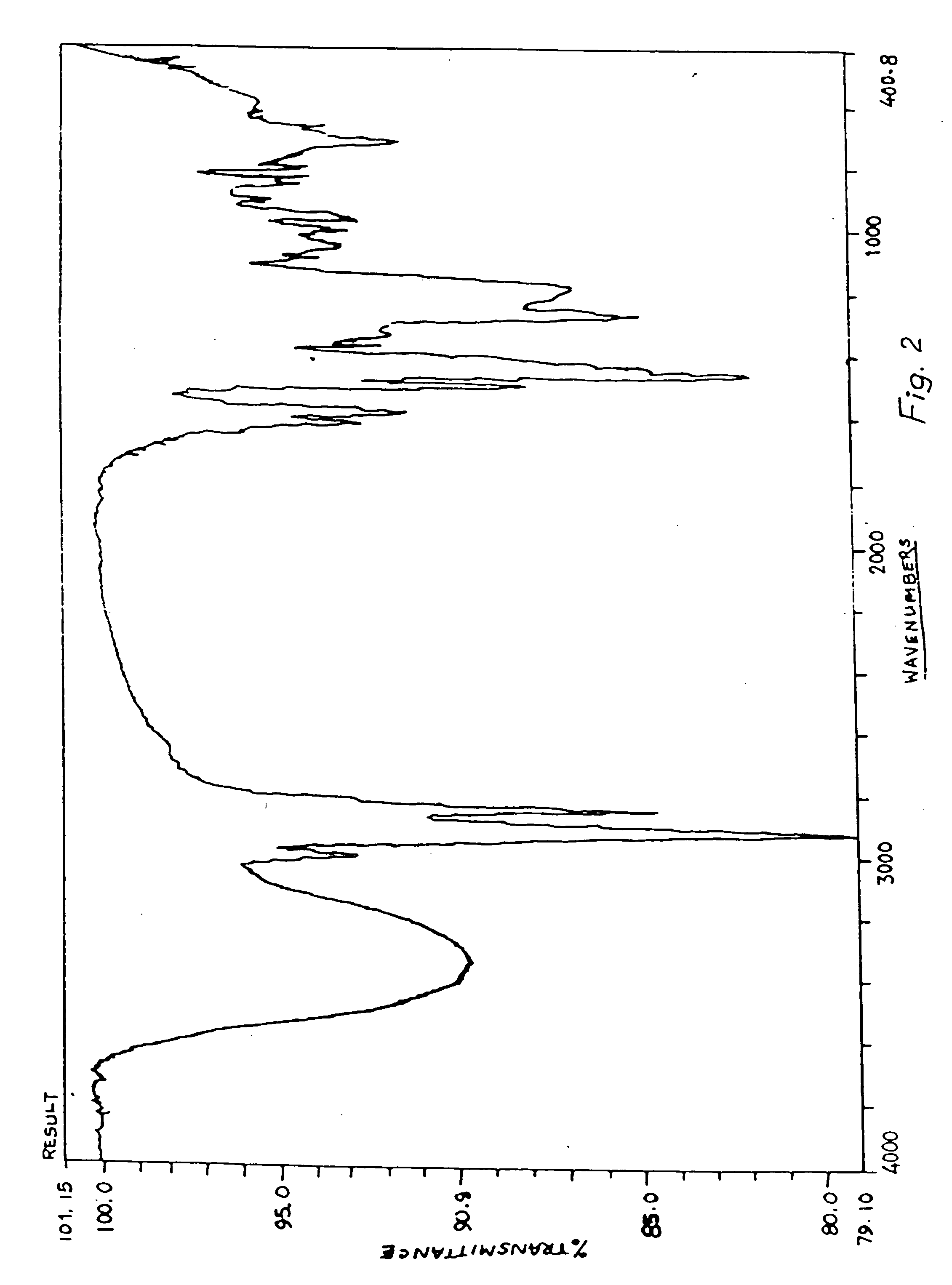

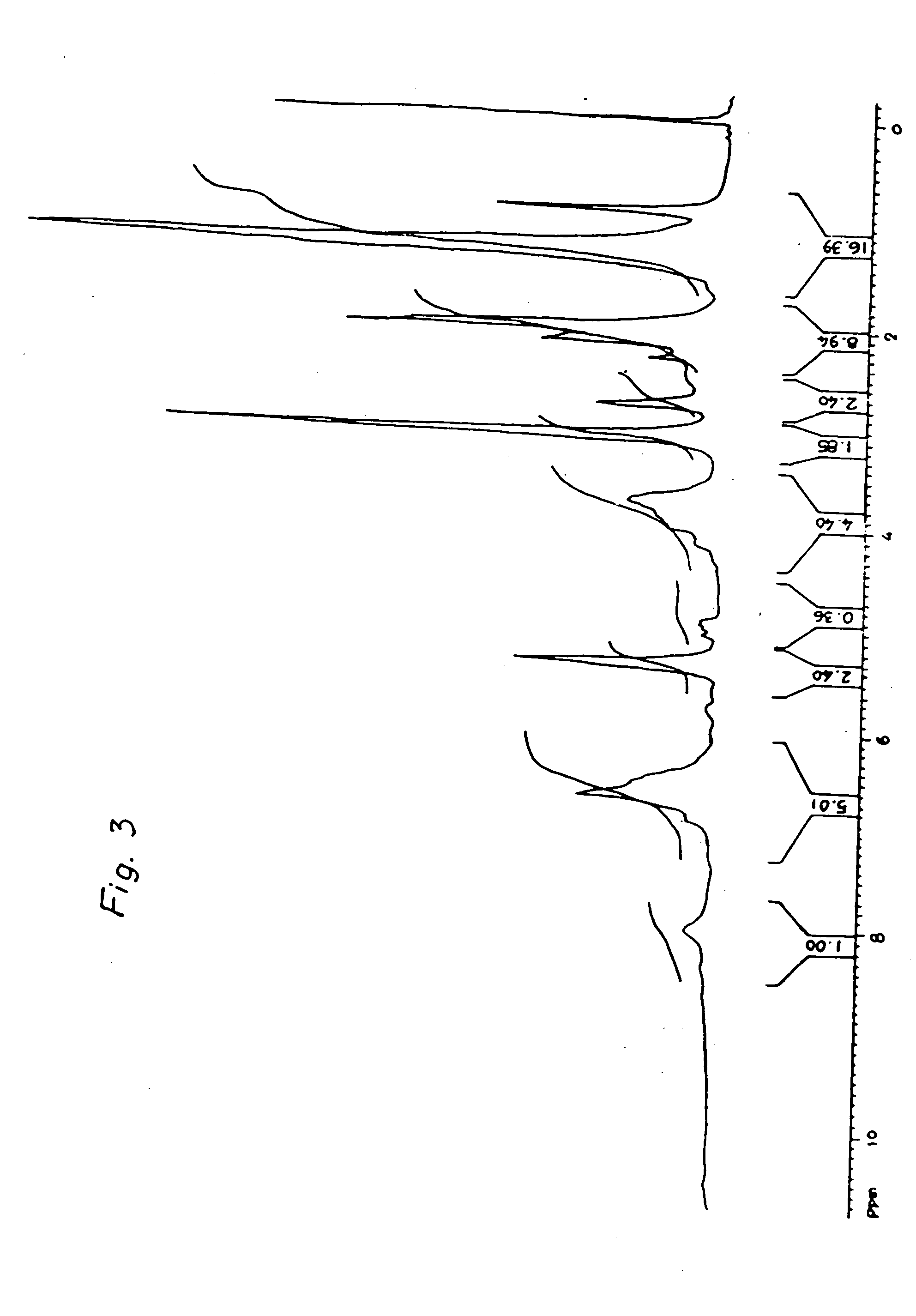

"High ortho" novolak copolymers and composition thereof

InactiveUS20050014086A1UsedPhotomechanical apparatusPhotosensitive material auxillary/base layersResistM-Cresol

A two step process for preparation of “high ortho” novolac resins. A first step involving reaction of phenolic component with formaldehyde carried out at room temperature, which ensures that all the formaldehyde used in the reaction is in liquid state, which almost completely reacts with phenolic compound, leaving no unreacted formaldehyde as effluents. The process uses CNSL or CNSL based phosphorylated prepolymer, or CNSL based monomeric Cardanol or hydrogenated Cardanol or vicinally hydroxylated Cardanol with formaldehyde and other phenolic compounds like m-cresol or p-cresol or o-cresol or 3.5-dimethylphenol or p-chlorophenol or resorcinol or t-butylphenol the positive and negative photoresists are made by mixing these polymers with appropriate photoactive components. For preparation of e-beam photoresist, these novolac resins are fist derivatised by t-BOC and then mixed with photoacid generator.

Owner:DEFENCE RES & DEV ORG GOVERNMENT OF INDIA

Preparation process of chlorinated phenol

ActiveCN105777499AHas a positioning effectReduce consumptionOrganic chemistryOrganic compound preparationChlorinated phenolsEthyl Chloride

The invention discloses a preparation process of chlorinated phenol; phenol is used as a raw material, a mixture of arbitrary one of diphenyl sulfide and dimethyl sulfide, arbitrary one of acetic acid and toluene sulfonic acid and arbitrary one of aluminum trichloride and ferric trichloride is used as a catalyst, a chlorinated phenol crude product is generated through sulfuryl chloride chlorination, and a target product is obtained by melt crystallization. The mixed catalyst used in the reaction has a positioning function, the content of p-chlorophenol in the monochlorophenol mixture generated from the reaction is greater than 83%, the content of 2,4-dichlorophenol in dichlorinated phenol generated from the reaction is greater than 98%, the amount of trichlorinated phenol impurities generated from the reaction is reduced, and 2,4,6-dichlorophenol with the content greater than 99% and the total yield more than or equal to 98% is obtained without purification treatment; moreover, energy consumption is greatly reduced, and high-content p-chlorophenol and high-quality 2,4-dichlorophenol can be produced at the same time.

Owner:兰州诚胜化工科技有限公司

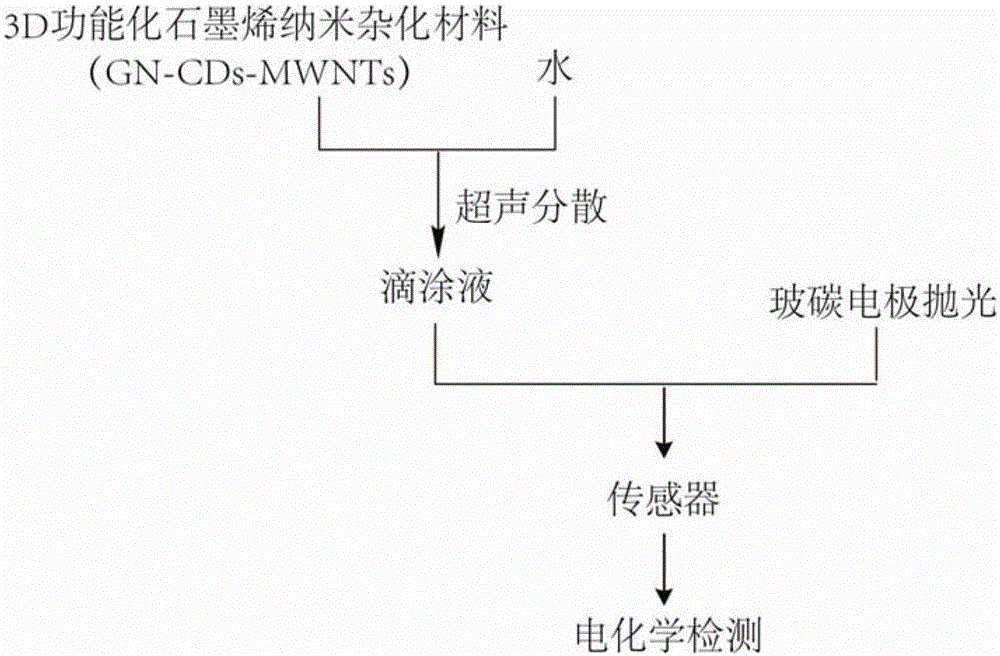

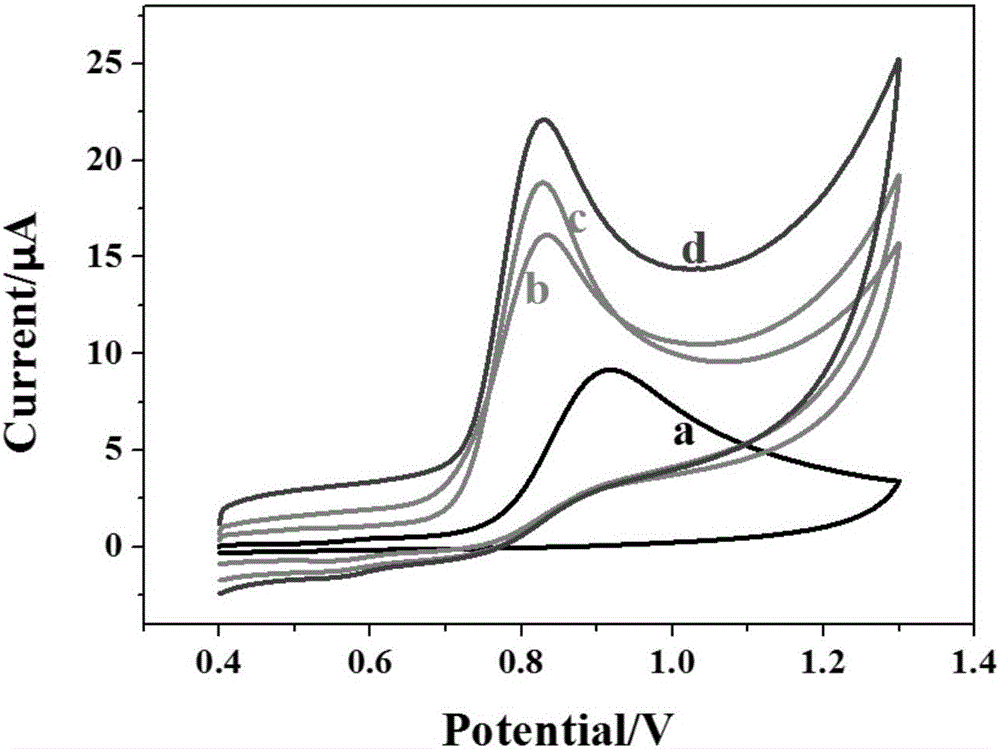

High-sensitivity phenol electrochemical sensor and preparation method thereof

InactiveCN105842307AFast response timeImproved electrocatalytic detectionMaterial nanotechnologyNanosensorsP-AminophenolCarbon nanotube

The invention discloses a high-sensitivity phenol electrochemical sensor and a preparation method thereof. The preparation method comprises the following steps: subjecting a prepared multi-walled carbon nanotube-bridged 3D graphene conductive network to ultrasonic dispersion in water, dispensing an obtained solution on a polished glassy carbon electrode and carrying out drying so as to obtain the sensor. The nanometer sensor prepared from a 3D functionalized nano-material can realize electrochemical detection of p-aminophenol, p-chlorophenol, p-nitrophenol and the like in a complex environment containing other interference substances, and effectively overcomes the defect that CDs are easy to shed; non-covalent bridging of carboxylated carbon nanotubes substantially improves conductivity of the system and selectivity of CDs; and the method is higher in economic performance, better in feasibility and higher in sensitivity.

Owner:NANJING UNIV OF SCI & TECH

R-1-(3-methylphenyl)ethanol and synthesis of ester thereof

InactiveCN104262093AOvercoming the problem of low yieldEasy to realize industrial productionOrganic compound preparationOrganic chemistry methodsP-ChlorophenolKinetic resolution

The invention discloses R-1-(3-methylphenyl)ethanol and a synthetic method of an ester thereof. The preparation method of R-1-(3-methylphenyl)ethanol comprises the following steps: taking 1-(3-methylphenyl)ethanol as a raw material, lipase as a biologic resolution catalyst, acidic resin as a racemization catalyst, and p-chlorophenol ester as an acyl donor, conducting dynamic kinetic resolution to obtain R-1-(3-methylphenyl)ethanol ester, and then conducting LiOH hydrolysis to obtain R-1-(3-methylphenyl)ethanol. The R-1-(3-methylphenyl)ethanol and the synthetic method of the ester thereof disclosed by the invention have the advantages of mild conditions, environment friendliness, good product yield, high selectivity and cheap price and good feasibility of the adopted racemization catalyst, so that the technology has a high application value in industrial production.

Owner:王同俊

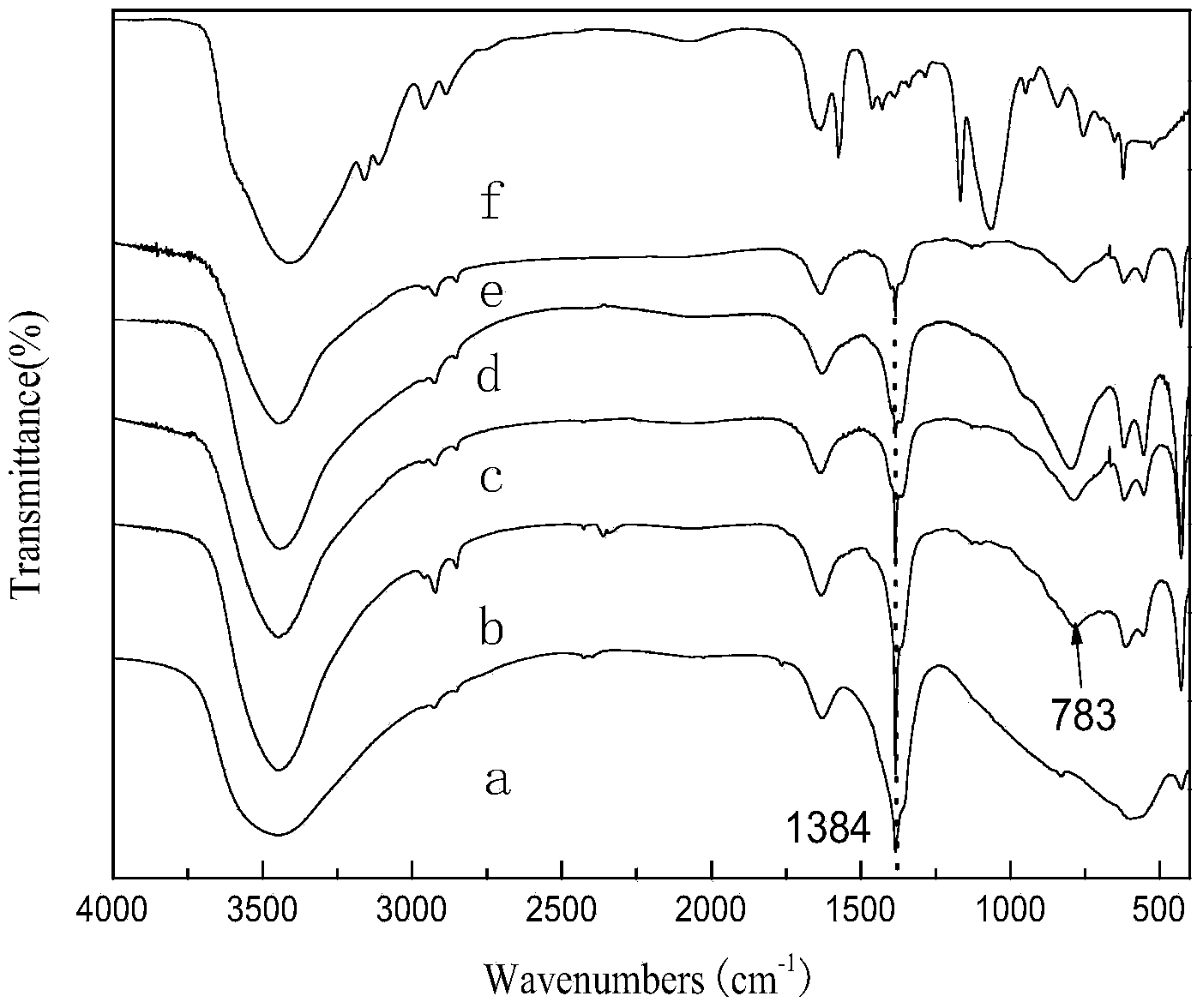

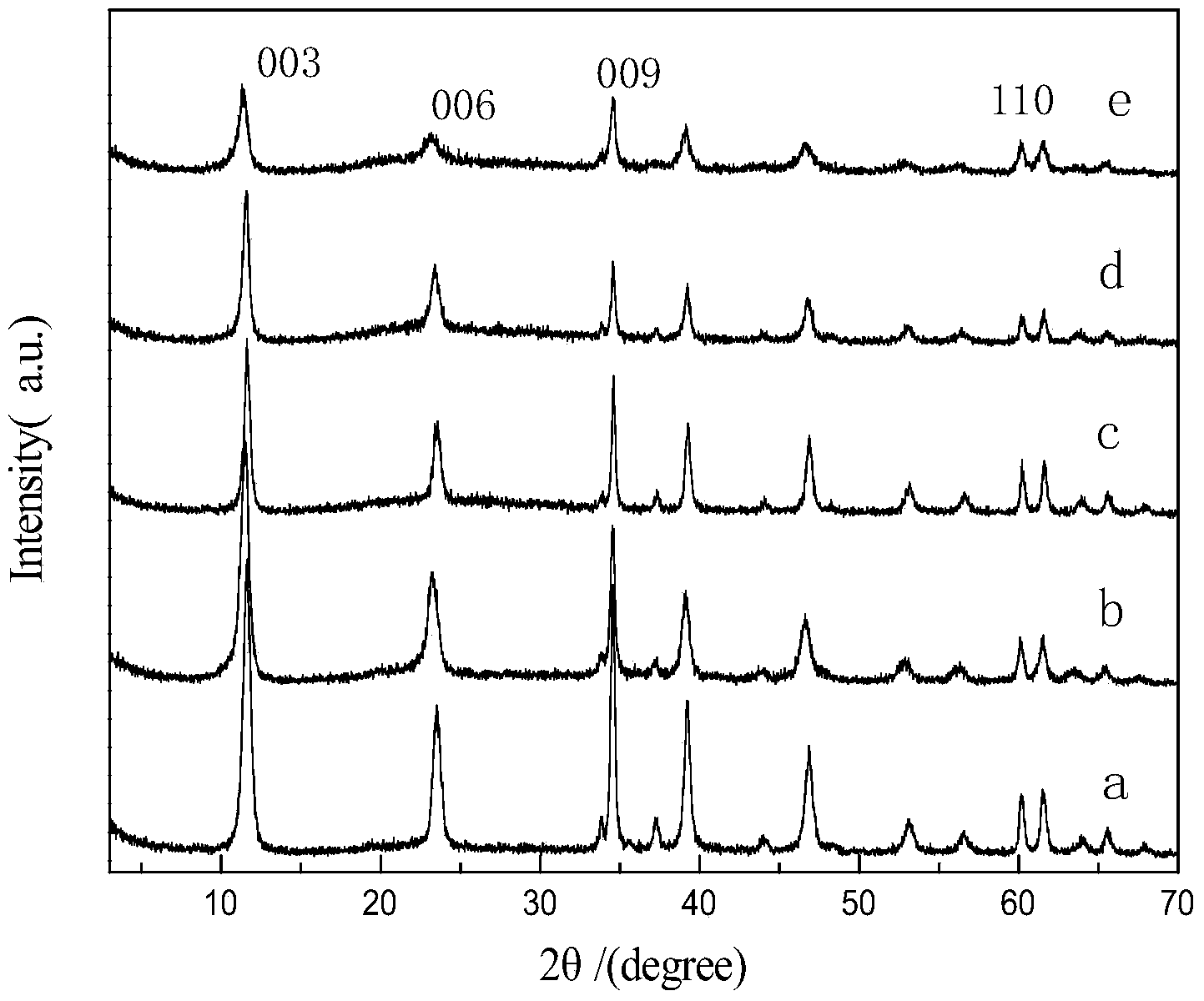

Amino functionalized ionic liquid/hydrotalcite-like compound composite material, and preparation method and application thereof

The invention discloses an amino functionalized ionic liquid / hydrotalcite-like compound composite material, and a preparation method and an application thereof. The preparation method comprises: firstly synthesizing an amino functionalized ionic liquid, then taking amino functionalized ionic liquid with different molar masses, employing a coprecipitation method to load the ionic liquid on the surface of the hydrotalcite-like compound, to prepare the amino functionalized ionic liquid / hydrotalcite-like compound composite material with a lamellar structure. The prepared organic-inorganic composite material has the structure and performance advantages of the functionalized ionic liquid and the hydrotalcite-like compound; the composite material, as an absorbent, shows good adsorption removal capability on pollutions such as o-chlorophenol , m-chlorophenol or p-chlorophenol in water, and has substantially better adsorptivity performance than the hydrotalcite-like compound; and the synergy advantage of the amino functionalized ionic liquid and the hydrotalcite-like compound is given a full play.

Owner:日照经济技术开发区客商服务有限公司

Preparation method for 3,4'dichloro diaryl ether

InactiveCN102516044ARaise the ratioSimple wayOrganic chemistryOrganic compound preparationDiphenyl etherPtru catalyst

A preparation method for 3,4'dichloro diaryl ether is disclosed, which comprises the following steps of: (1) preparation for potassium alkoxide or sodium alkoxide; (2) preparation for potassium p-chlorophenolate; (3) preparation for active cuprous chloride; and (4) preparation for 3,4'dichloro diaryl ether. The preparation method has the following advantages that: side reactions are greatly reduced, reaction speed is fast, the pollution caused by the volatilization of benzene solvents is reduced, the utilization rate of equipment and the like are increased, the quality of product is improved, as well as yield and chilling efficiency are increased by using p-chlorophenol waterless salifying process, using newly-prepared catalyst, optimizing the ratio and pouring method of materials, and protecting by inert gas.

Owner:HUBEI XINGHUO CHEM

Aromatic polyester and manufacturing process thereof

To provide an aromatic polyester which is formed into a film having excellent heat resistance, color, mechanical properties, dimensional stability and gas barrier properties and a manufacturing process thereof;the aromatic polyester comprises a dicarboxylic acid component and a diol component, wherein(i) the dicarboxylic acid component contains 50 to 100 mol % of a recurring unit represented by the following formula (A):wherein R is an alkylene group having 2 to 10 carbon atoms,(ii) the aromatic polyester has an intrinsic viscosity measured at 35° C. by using a mixed solvent of P-chlorophenol and 1,1,2,2-tetrachloroethane (weight ratio of 40 / 60) of 0.4 to 3.0;(iii) the aromatic polyester has a content of a recurring unit represented by the following formula (D) of less than 10 mol %:—O—CH2CH2—O—CH2CH2—O— (D)(iv) the aromatic polyester has a terminal carboxyl group concentration of 200 eq / ton or less; and(v) the aromatic polyester has an alkali metal content of 300 ppm or less.

Owner:TEIJIN LTD

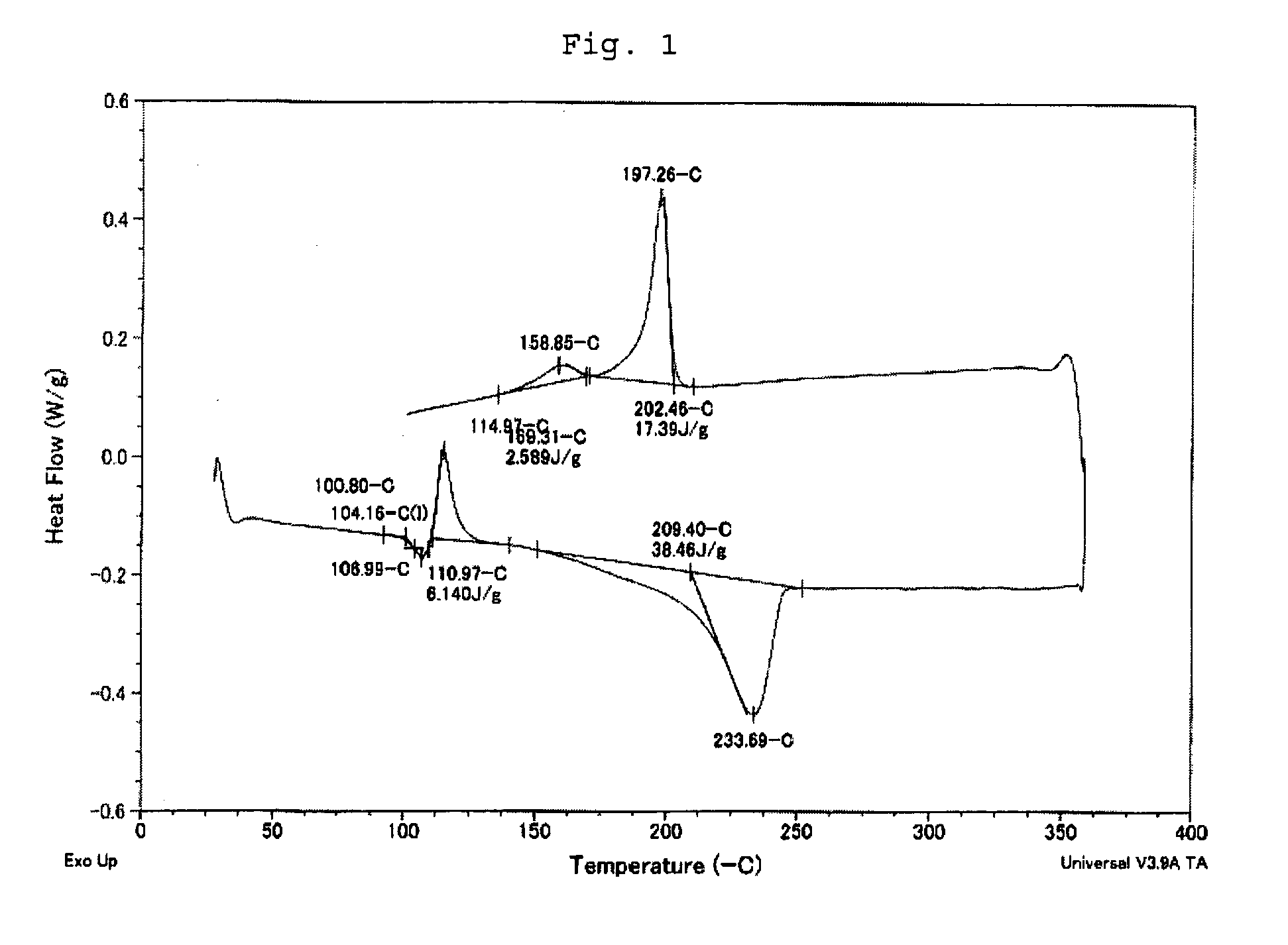

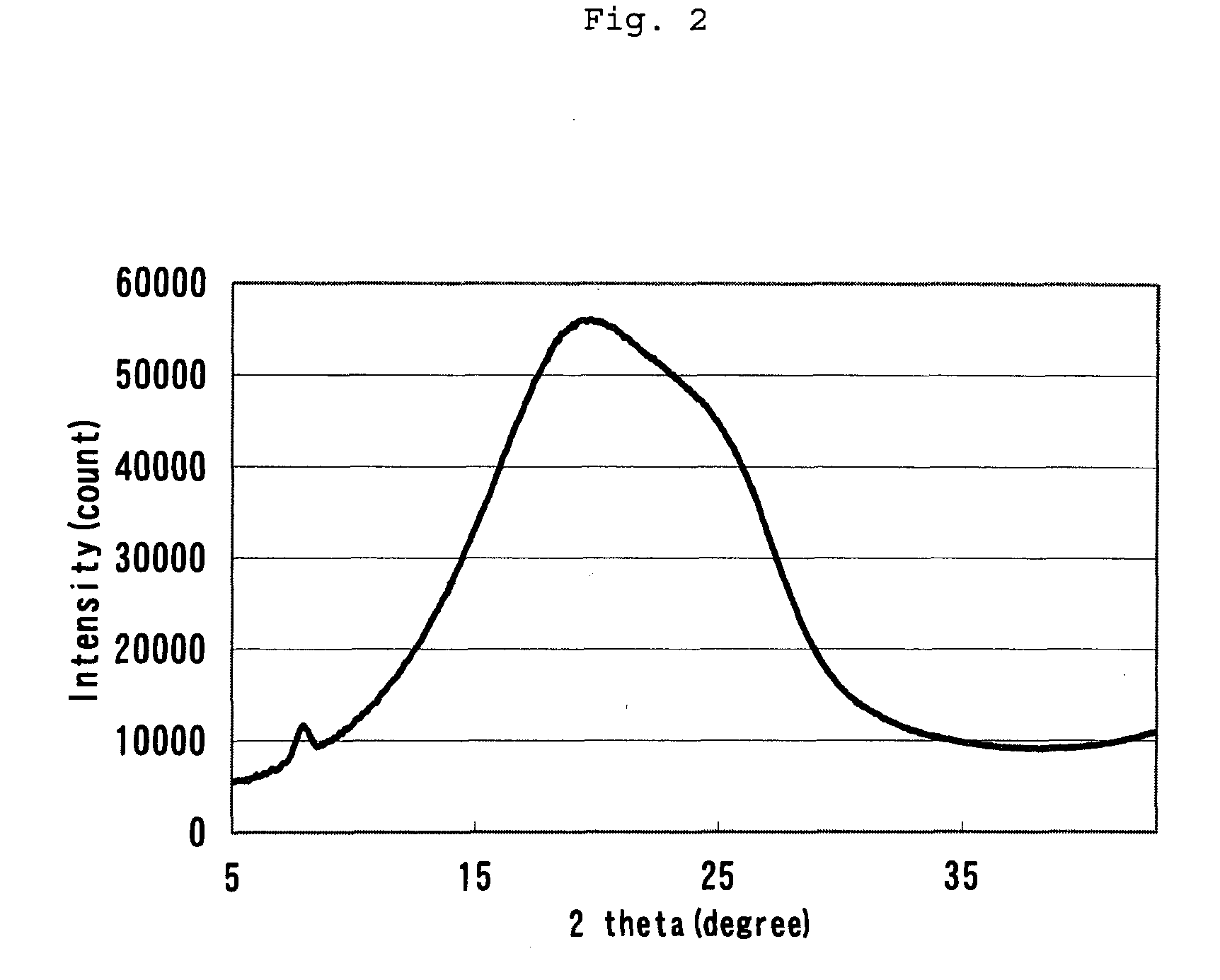

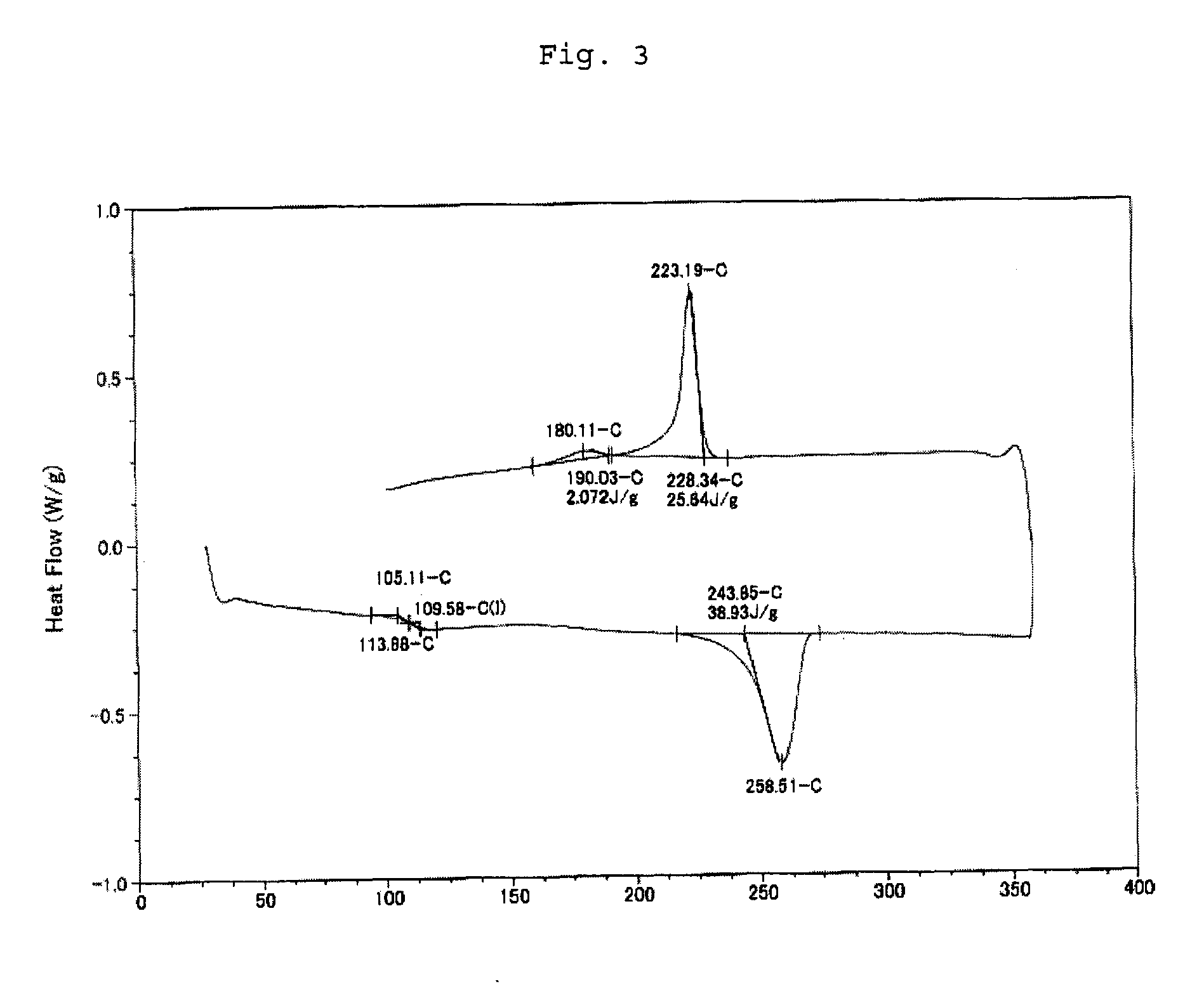

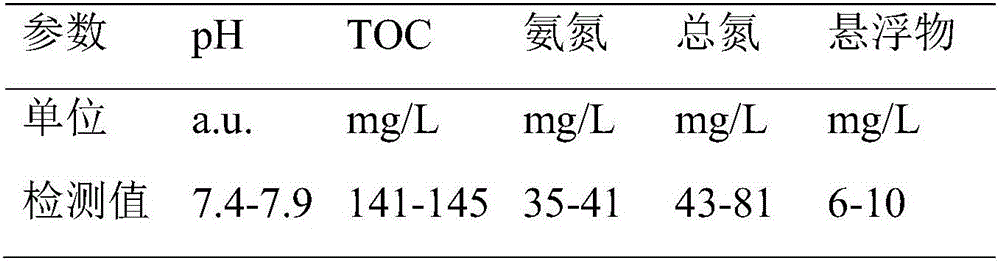

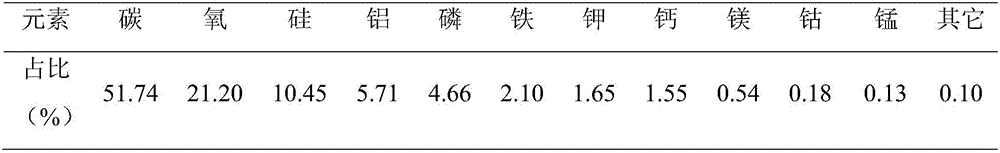

Application of sludge biochar in adsorption to organic pollutants or ammonia nitrogen in sewage and preparation of sludge biochar

InactiveCN106116090ALarge specific surface areaRich in compositionOther chemical processesSludge treatment by pyrolysisHigh concentrationSludge

The invention discloses application of sludge biochar in adsorption to organic pollutants or ammonia nitrogen in sewage and preparation of the sludge biochar. The sludge biochar is obtained by pyrolyzing dry sludge in a nitrogen environment at the temperature of 300 DEG C to 500 DEG C for at least 2 hours and applied to adsorption to the organic pollutants or ammonia nitrogen in the sewage. By improving the key sludge treatment conditions such as sludge pretreatment, the pyrolysis temperature and the pyrolysis environment in a preparation method, the sludge disposal problem is effectively solved, and meanwhile the prepared sludge biochar has a good adsorption effect on the organic matter (such as p-chlorophenol) and ammonia nitrogen in the sewage (particularly the high-concentration sewage such as landfill leachate) by controlling the usage amount of the sludge biochar.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation process of 2,4-dichlorophenol

InactiveCN106349025AHas a positioning effectIncrease contentOrganic chemistryOrganic compound preparationChlorinated phenolsEthyl Chloride

The invention discloses a preparation process of 2,4-dichlorophenol. The preparation process comprises the following steps: chloridizing phenol or o-chlorophenol serving as a raw material and a mixture which is prepared from boric acid, phenyl sulfide and ferric trichloride and serves as a catalyst to generate a 2,4-dichlorophen coarse product, and rectifying the coarse product to obtain a target product. The mixed catalyst used in the reaction has a positioning effect, so that the content of p-chlorophenol in a chlorinated phenols mixture generated by the reaction is greater than 65 percent, the content of the 2,4-dichlorophenol in di-chlorophenol generated in the reaction is greater than 95 percent, the number of di-chlorophenol impurities generated in the reaction is reduced, and the 2,4-dichlorophenol with the content greater than 99.5 percent and the total yield of 95 percent or above can be obtained by rectification treatment; furthermore, the reaction yield is greatly increased, and the yield of the p-chlorophenol is also increased.

Owner:LIANYUNGANG ZHICHENG CHEM

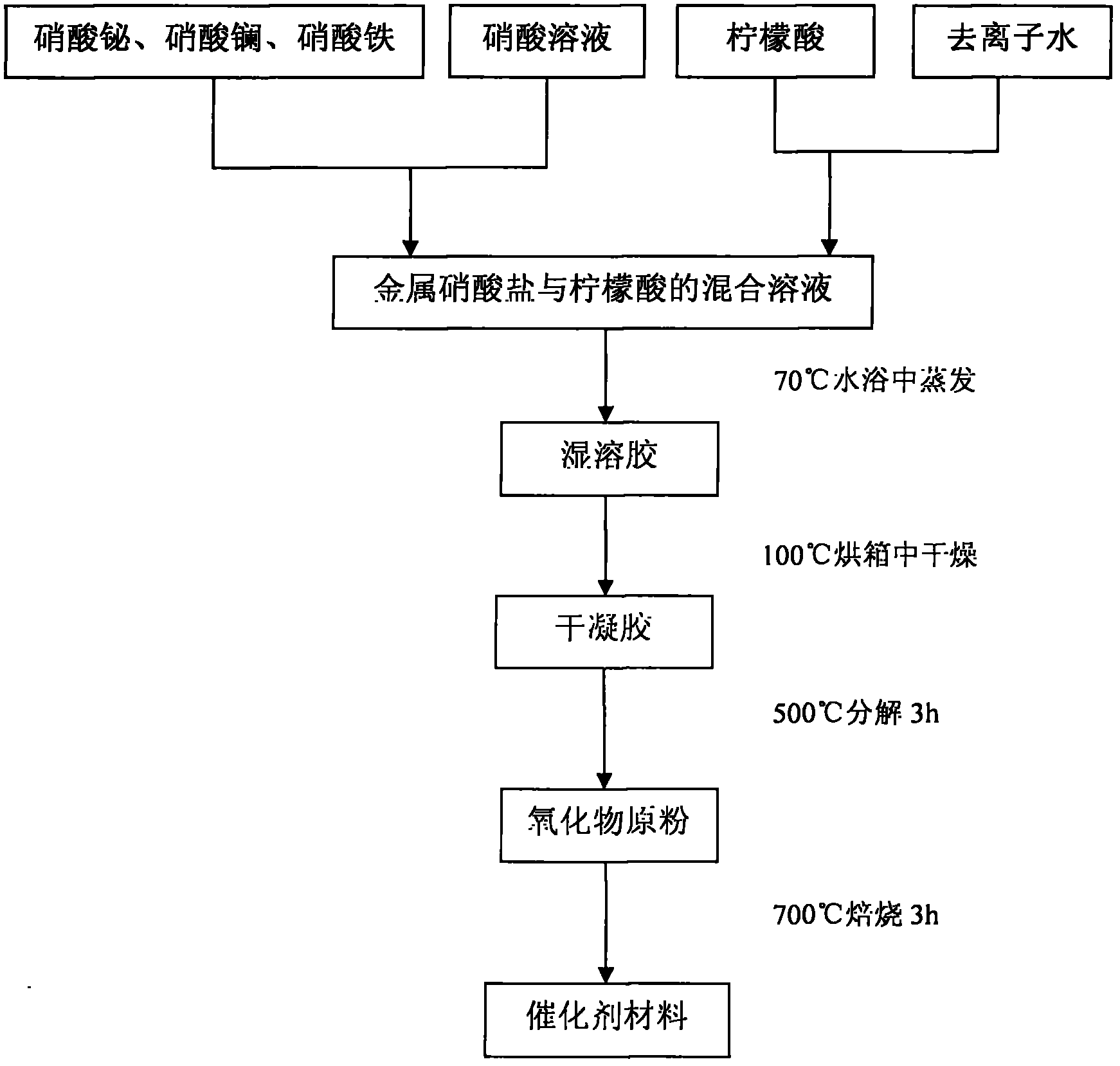

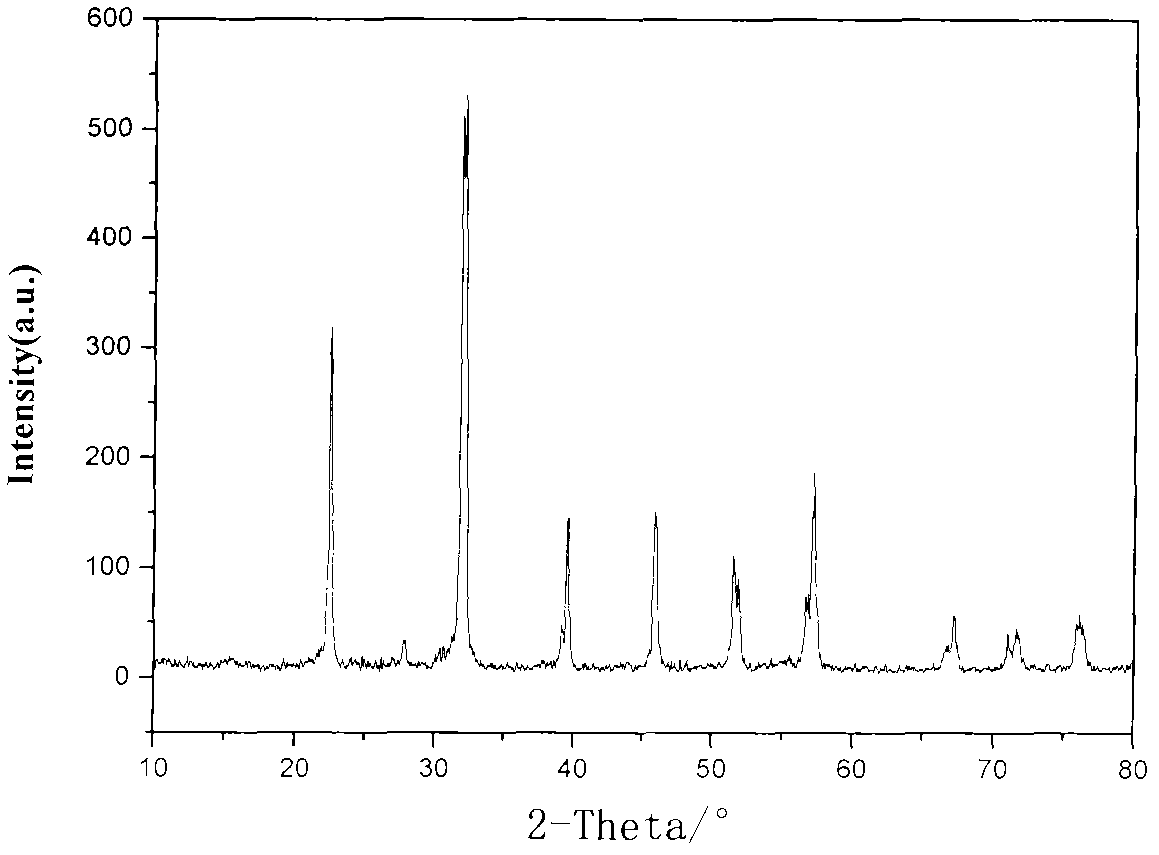

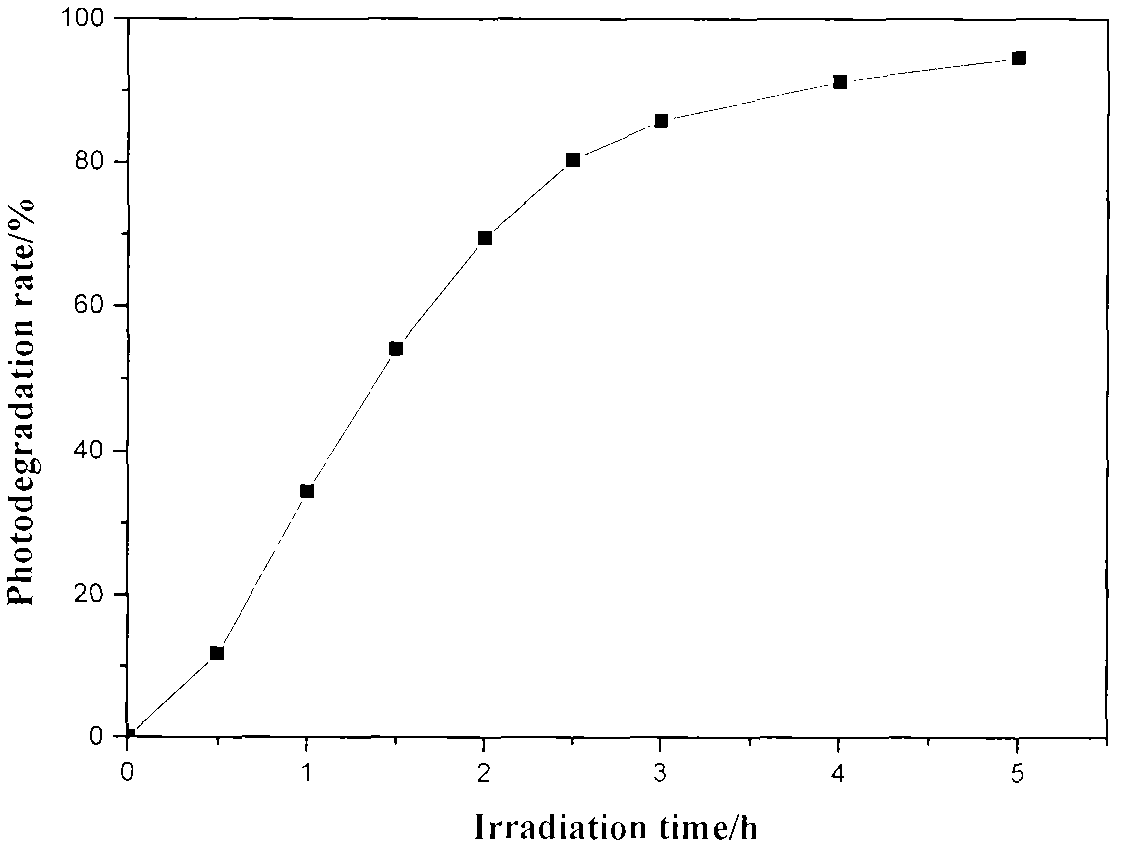

Preparation method and application of novel perovskite photocatalyst containing bismuth

InactiveCN102019184ASimple processLow costWater/sewage treatment by irradiationWater contaminantsPhotocatalytic reactionPtru catalyst

The invention discloses a preparation method and an application of a degradation phenolic wastewater perovskite photocatalyst containing bismuth. The main preparation technology comprises the following steps: dissolving Bi(NO3)3.5H2O, La(NO3)3.nH2O and Fe(NO3)3.9H2O in nitric acid, then adding citric acid to fully mix, performing thermostatic stirring to obtain transparent viscous gel, placing the transparent viscous gel in a drying oven to dry and obtain dried gel; decomposing the dried gel in a muffle furnace, and roasting with a high temperature furnace to obtain Bi1-xLaxFeO3 catalyst. The preparation method has simple technology and low cost. The catalyst is used in the photocatalytic reaction and is characterized in that the degradation activity of the catalyst to parachlorophenol is high under visible-light irradiation.

Owner:INNER MONGOLIA UNIVERSITY

Preparation method of R-3, 5-bis (trifluoromethyl) phenyl ethanol

InactiveCN104230667AEasy to operateHigh yieldOxygen-containing compound preparationOrganic compound preparationPtru catalystP-Chlorophenol

The invention discloses a preparation method of R-3, 5-bis (trifluoromethyl) phenyl ethanol. According to the preparation method disclosed by the invention, 3, 5-bis (trifluoromethyl) phenyl ethanol is taken as a raw material, chlorophenol acetate is taken as an acyl donor, Novozym435 is taken as a resolution catalyst, acidic resin is taken as a racemic catalyst, and then dynamic kinetic resolution is performed to obtain R-3, 5-bis (trifluoromethyl) phenyl ethanol acetate. Then, ester is hydrolyzed to obtain R-3, 5-bis (trifluoromethyl) phenyl ethanol, the final product yield can be more than 90%, and the ee value of the product is more than 99%. The method is simple to operate, the used racemic catalyst has the characteristics of low price, easiness in obtainment, reusability, high product yield, good optical purity and the like, and the method further has great guide and application values in production and preparation processes of R-3, 5-bis (trifluoromethyl) phenyl ethanol.

Owner:王际宽

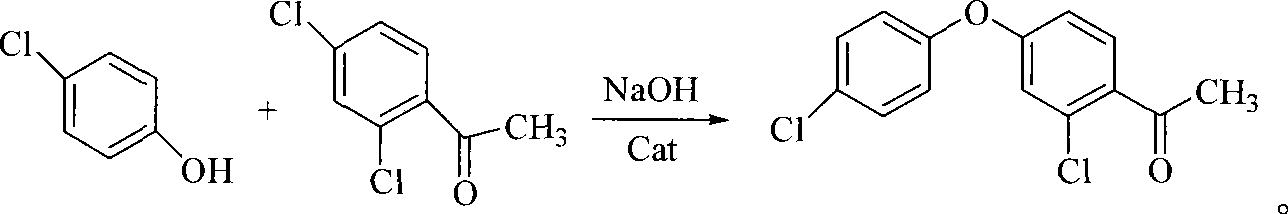

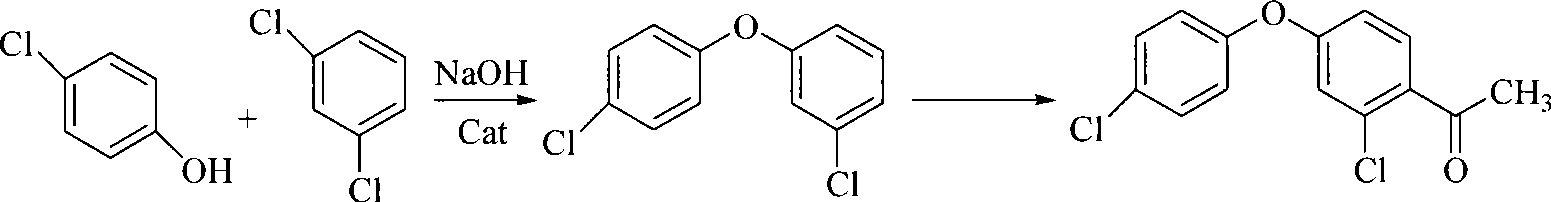

Method for preparing 2-chlorine-4-(4-chlorophenoxy)-hypnone

InactiveCN101434528AOrganic compound preparationCarbonyl compound preparationAcetic anhydrideCopper oxide

The invention discloses a method for preparing 2-chloro-4-(4-chlorophenoxy)-hypnone, which comprises reactions of two steps: firstly, m-dichlorobenzene is adopted as a raw material and the etherification reaction is carried out to p-chlorophenol salt under the catalysis of copper oxide or cupric salt to generate 3, 4'-dichloro-diphenyl ether, and then acylation reaction is carried out between the 3, 4'-dichloro-diphenyl ether and acylation reagent acetic anhydride or acetyl chloride to prepare 2-chloro-4-(4-chlorophenoxy)-hypnone, wherein, the acylation reaction is completed within 1 to 10 hours at the temperature from 0 DEG C to reflux temperature of reaction materials in an organic solvent and with the presence of Lewis acid. When the acetic anhydride is selected as the acylation reagent, mole ratio of materials is that 3, 4'-dichloro-diphenyl ether: acetic anhydride: catalyst is equal to 1:1 to 2:2 to 4; when the acetyl chloride is adopted as the acylation reagent, the mole ratio of the materials is that 3, 4'-dichloro-diphenyl ether: acetyl chloride: catalyst is equal to 1:1 to 2:1 to 2. According to the method, 2-chloro-4-(4-chlorophenoxy)-hypnone which is an important intermediate product of an agricultural fungicide-difenoconazole can be prepared with high yield and high quality.

Owner:中国中化股份有限公司 +1

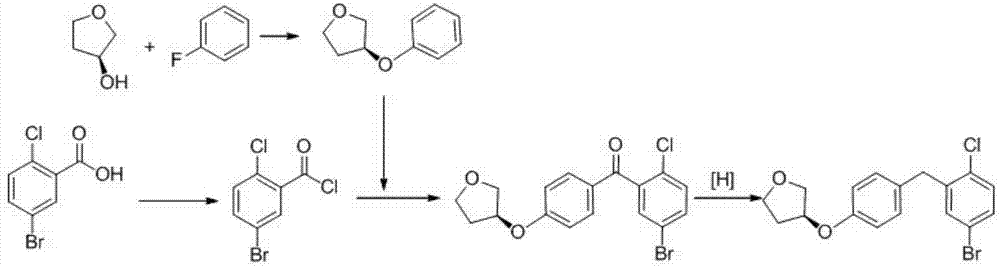

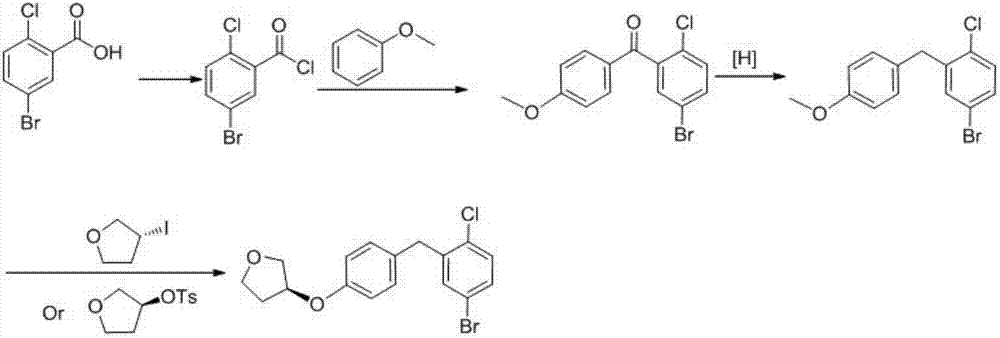

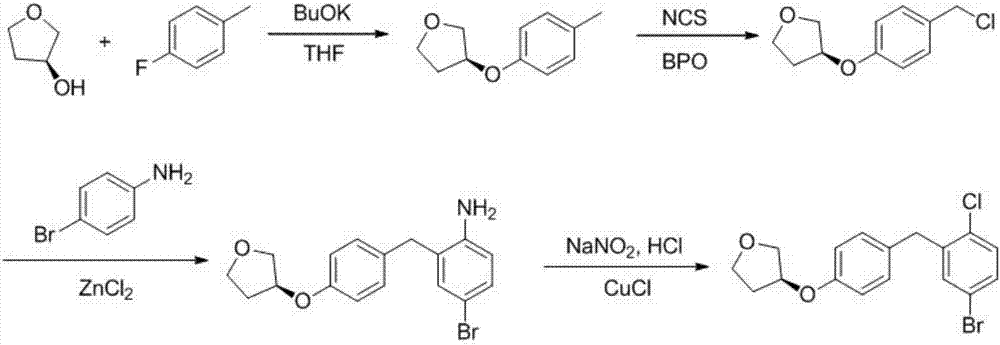

Preparation method of empagliflozin intermediate

The invention provides a preparation method of an empagliflozin intermediate. The preparation method comprises the following steps: 1), taking 4-fluorotoluene and (R)-3-hydroxytetrahydrofuran as raw materials, a polar solvent as a reaction solvent and inorganic alkali as a catalyst, performing a reaction to obtain (S)-3-p-cresyl tetrahydrofuran; 2), with N-chlorosuccinimide and the product obtained in the step 1) as raw materials, a non-polar solvent as a reaction solvent and dibenzoyl peroxide or azobisisobutyronitrile as an initiator, performing a reaction to obtain (S)-3- p-chlorophenol tetrahydrofuran; 3) dissolving 4-bromaniline and the product obtained in the step 2) into ethyl acetate, adding a catalyst Lewis acid, performing a reaction to obtain (S)-3-(4-(5-bromo-2-aminobenzyl)phenoxy) tetrahydrofuran; 4), performing a diazotization reaction on the product obtained in the step 3), and then reacting with cuprous chloride to synthesize (S)-3-(4-(5-bromo-2-chlorobenzyl)phenoxy) tetrahydrofuran. The preparation method has the advantages that the cost is low, the finished product is high in purity and the synthesis route is short.

Owner:安徽省诚联医药科技有限公司

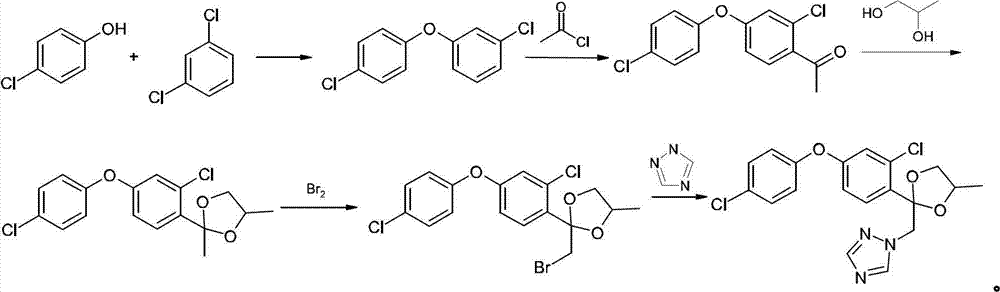

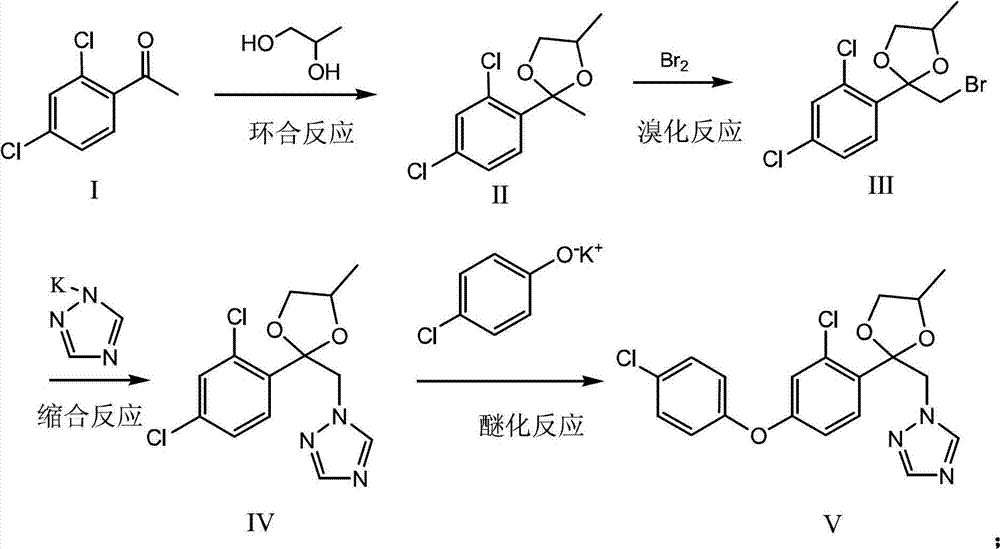

Method for preparing difenoconazole

The invention relates to a method for preparing difenoconazole, which comprises the steps of cyclization reaction, bromination reaction, condensation reaction and etherification reaction in sequence, wherein the cyclization reaction refers to reacting 2,4-dichloroacetophenone with 1,2-propylene glycol in the presence of an acid catalyst in a solvent to form a ketal; the bromination reaction is to drip liquid bromine into a system obtained after cyclization reaction to form brominated ketal; the condensation reaction is to react the brominated ketal with triazole potassium in an N,N-dimethylformamide solvent to form metaconazole; and the etherification reaction is to react the metaconazole with p-chlorophenol potassium in a solvent at 100 to 180 DEG C to form difenoconazole. By the method, the synthesis route is reformed to reduce isomer content, increase product yield, reduce waste gas, water and residue and ensure safe operation and pollution-free production.

Owner:JIANGSU SEVENCONTINENT GREEN CHEM CO LTD

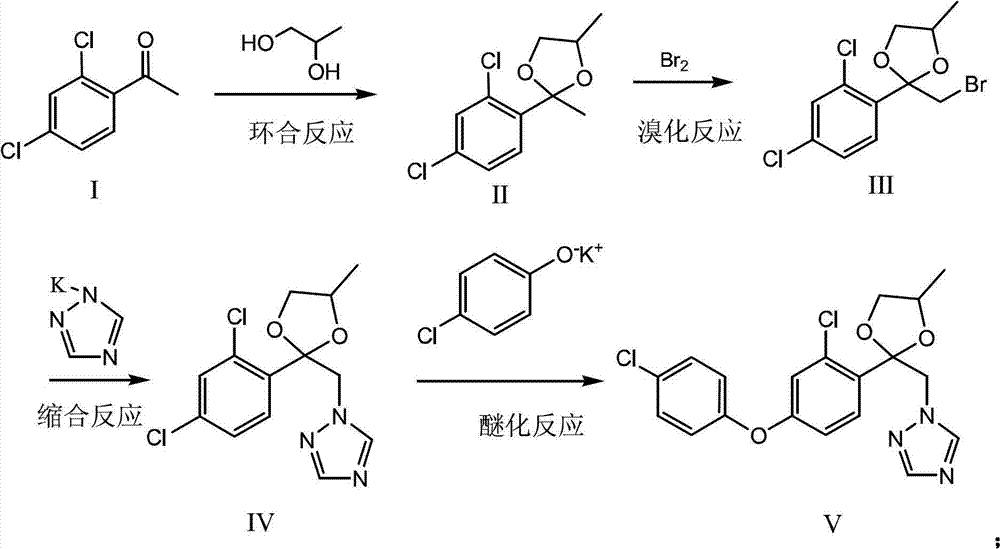

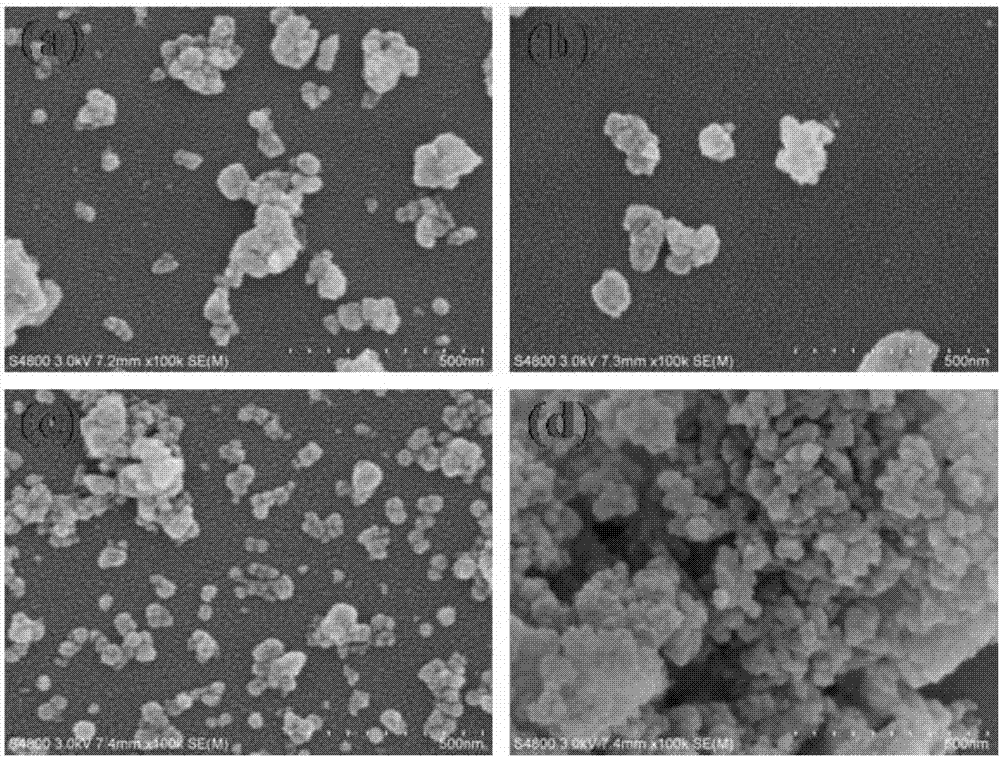

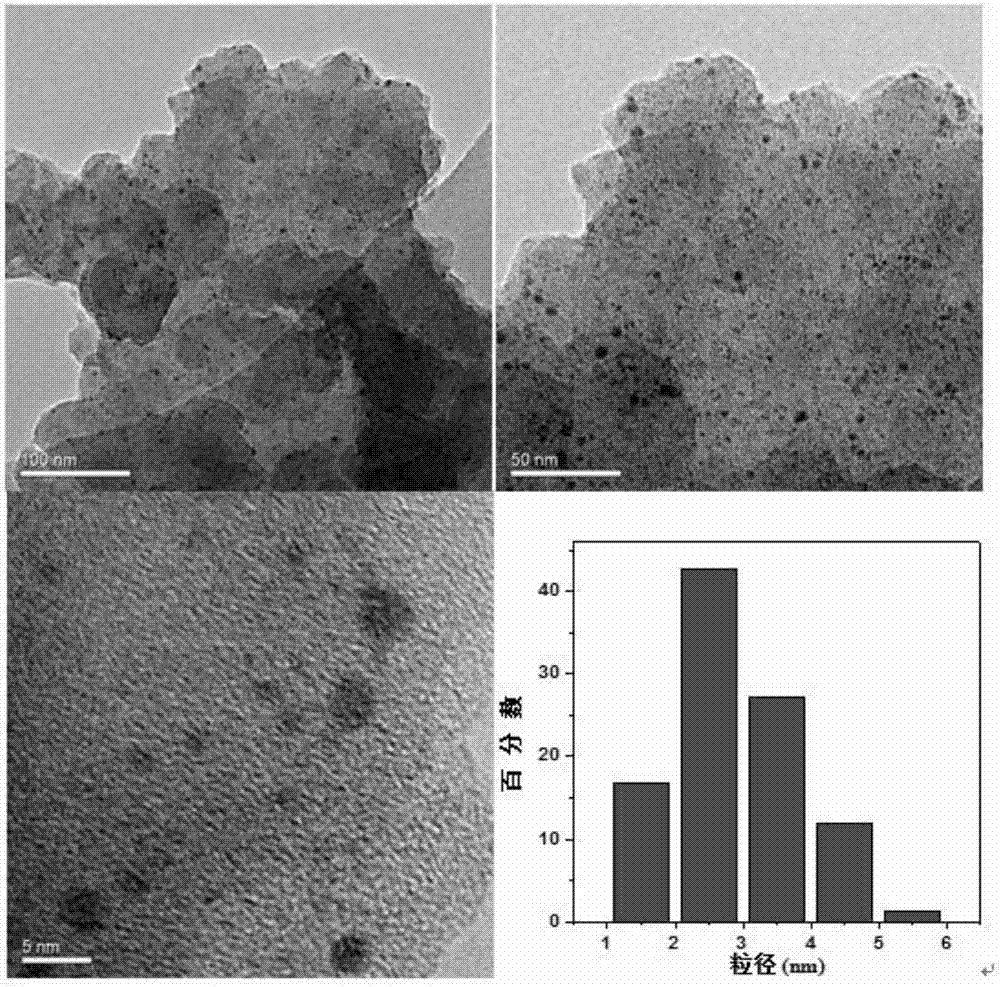

MOFs-rGO supported Pd nano-catalyst as well as preparation and application thereof

ActiveCN107442180AHigh catalytic activityEasy to prepareOrganic chemistryOrganic compound preparationNano catalystPtru catalyst

The invention relates to a MOFs-rGO supported Pd nano-catalyst as well as preparation and application thereof. NH2-MIL-101(Cr)-rGO serves as a carrier, an active ingredient nano-Pd of the catalyst is encapsulated into a cage formed by the carrier, the weight percent of GO in the NH2-MIL-101(Cr)-rGO is 1-5%, and the capacity of the nano-Pd is 4-5wt%. By utilizing the structural characteristics of the MOFs cage, Pd<2+> supported MOFs-rGO is prepared by taking tetrachloroplatinate as a palladium source by utilizing an ion exchange method, and the MOFs-rGO supported Pd nano heterogeneous catalyst is prepared under the action of a NaBH4 reducing agent. Palladium nano-particles are mainly encapsulated in the MOFs-rGO cage, the adsorption performance and stability of the NH2-MIL-101(Cr)-rGO are improved by atomically closely packed rGO, the catalyst has small particle size and excellent dispersity and stability, and the catalytic performance is greatly improved. The catalyst is applied to a dechlorination reaction of parachlorophenol and o-chlorophenol and has high catalytic activity. Moreover, the preparation method of the catalyst disclosed by the invention is simple and easy to operate.

Owner:SHANTOU UNIV

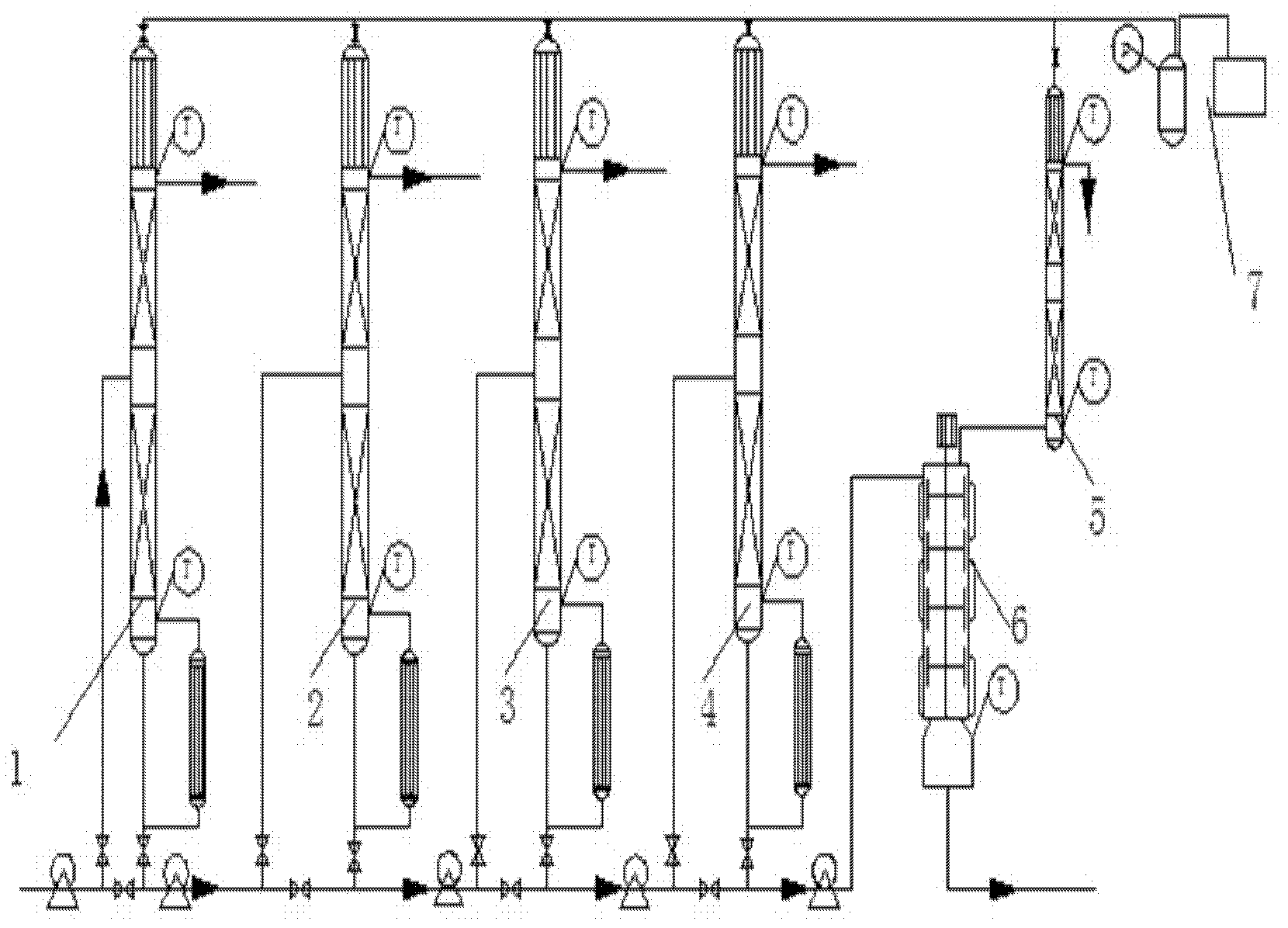

Method for separating chloro phenol reaction solution

InactiveCN102584542AIncrease productionEasy to separateOrganic chemistryOrganic compound preparationPhenolChemistry

A method for a separating chloro phenol reaction solution comprises the specific steps of: enabling the chloro phenol reaction solution (the chloro phenol reaction solution is prepared by phenol and chlorine and comprises such all or part of the main components as phenol, o-chlorophenol, p-chlorophenol, 2,4-dichlorophenol, 2,6-dichlorophenol, 2,4,6-trichlorophenol and a small amount of tar) to continuously flow through a tower 1, a tower 2, a tower 3, a tower 4, a detar device (scraper film evaporator 6) and a tower 5, and controlling the temperatures of tower tops and tower bottoms of rectifying towers according to the different boiling points of the components of the reaction solution so as to separate the components from the tower tops. According to the method, the production capacity is large, the separation effect is excellent, the energy consumption is low, and the chloro phenol reaction solution is applicable to large-scale production.

Owner:JIANGSU HONGYUAN CHEM

Preparation method for titanium dioxide-graphene/screen-printed electrode for detecting parachlorophenol

InactiveCN103969307AStable performance of printed electrodesHigh sensitivityMaterial electrochemical variablesP-ChlorophenolGraphite

A preparation method for titanium dioxide-graphene / screen-printed electrode for detecting parachlorophenol comprises the following steps: preparation of titanium dioxide-graphene composite, preparation of titanium dioxide-graphene dispersion, and preparation of titanium dioxide-graphene / screen-printed electrode. In the invention, the carbon material easy to obtain is used for preparing the electrode-sensitive substance; the prepared titanium dioxide-graphene loaded screen-printed electrode is stable in performance, higher in sensitivity and low in cost, and has a good application prospect; by virtue of a dripping and coating method, the titanium dioxide-graphene dispersion is directly applied to the surface of an electrode to prepare a sensitive film, so that the process is simple and the reproducibility is high. The preparation method adopts the titanium dioxide-graphene composite as a sensitive material to obtain the highly sensitive film, so that the sensitivity and detection limit of the sensor are greatly improved; the screen-printed electrode prepared in the invention can quickly and sensitively detect p-chlorophenol and can be applied to different environmental samples.

Owner:HOHAI UNIV

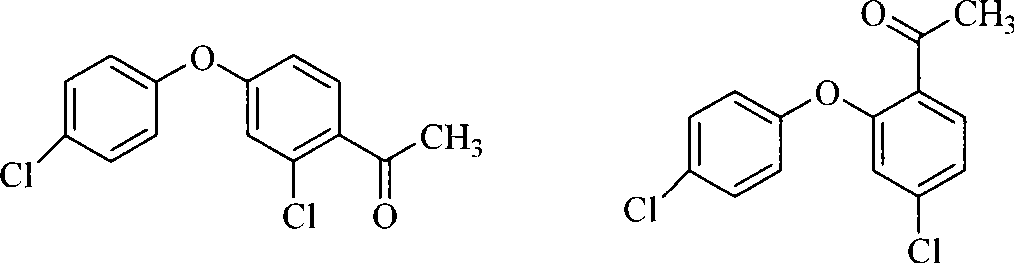

Preparation method of dichlorodiphenylene ether ketone

InactiveCN103073408AImprove recycling ratesMild reaction conditionsCarbonyl compound preparation by condensationKetoneSolvent

The invention discloses a preparation method of dichlorodiphenylene ether ketone. The method includes the steps as follows: (1) condensation reaction: adding p-chlorophenol and a sodium hydroxide solution into a reactor to prepare phenoxide; dehydrating and adding a copper acetate catalyst, assistants and m-dichlorobenzene; and subjecting phenoxide to a condensation reaction with m-dichlorobenzene under the effects of the copper acetate catalyst and the assistants to prepare dichlordiphenyl ether; (2) acylation reaction: dissolving the prepared dichlordiphenyl ether in a solvent, and then subjecting dichlordiphenyl ether to an acylation reaction under the catalysis of an anhydrous aluminum trichloride catalyst to generate dichlorodiphenylene ether ketone. The preparation method has the advantages of short and simple synthetic route, mild reaction conditions, high conversion rate, low production cost, little discharge of three wastes, and high waste liquor recycling rate.

Owner:扬州市天平化工厂有限公司

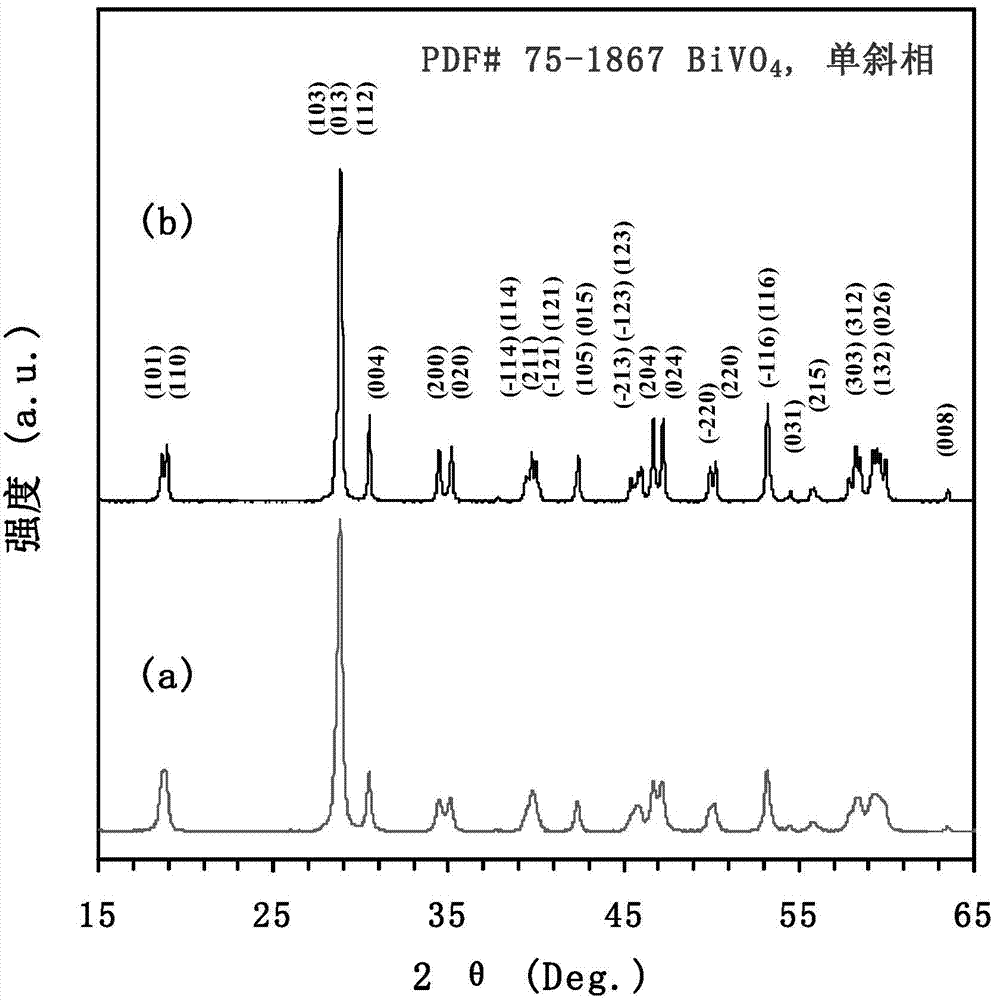

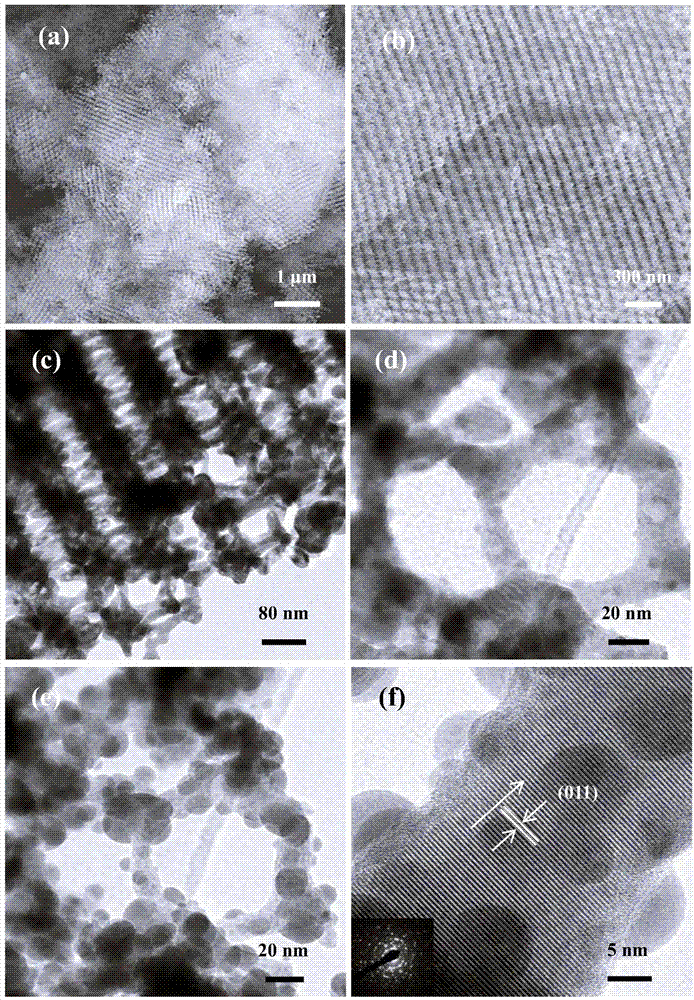

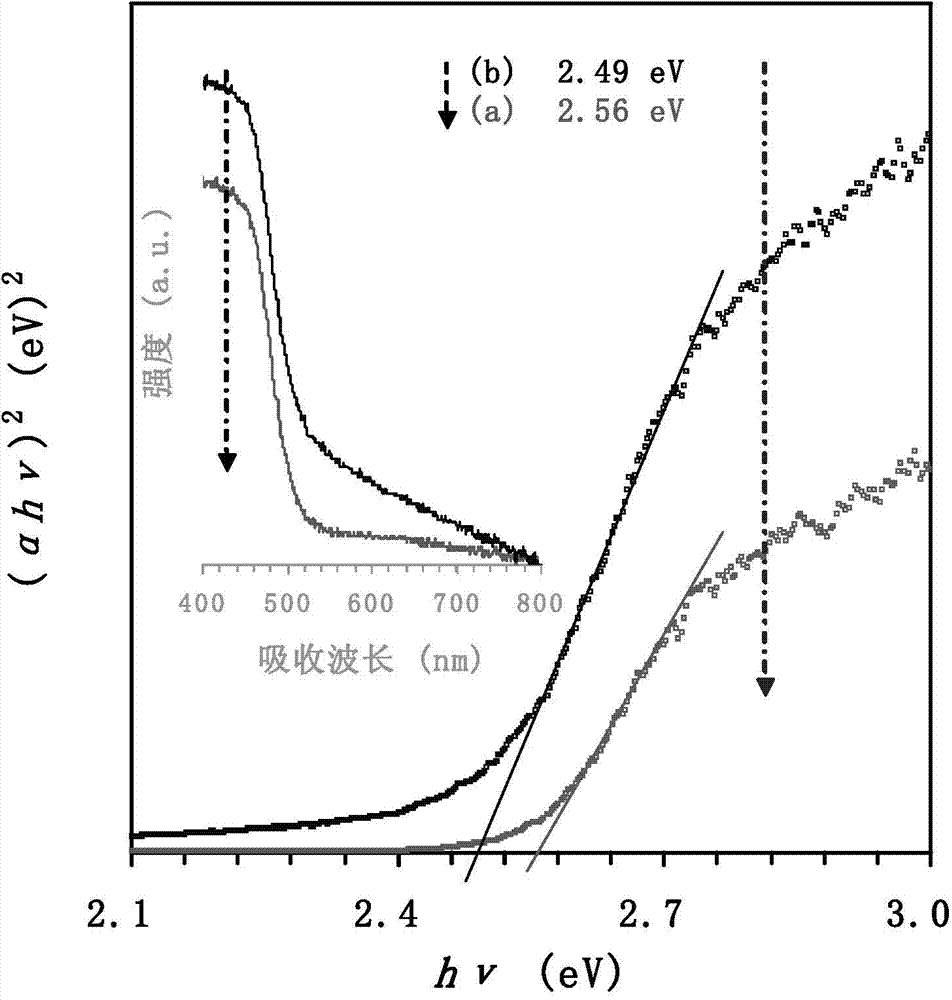

Three-dimensional ordered macroporous (3DOM) BiVO4 loaded AgBr and Pd photocatalyst, preparation and application

InactiveCN104117370AExcellent visible light catalytic activityGood application prospectPhysical/chemical process catalystsWater/sewage treatment by irradiationBand gapMicrosphere

The invention discloses a three-dimensional ordered macroporous (3DOM) BiVO4 loaded AgBr and Pd photocatalyst, preparation and application, belonging to the technical field of visible light response catalysts. A novel 3DOM BiVO4 loaded AgBr substance and Pd efficient visible light response nano hybridization photocatalyst is prepared by taking a 3DOM BiVO4 photocatalysis material as a carrier, adopting a PMMA microsphere hard template method, a low-temperature deposition-sedimentation method and a bubbling reduction method. The catalyst has a 3DOM structure, heterojunction and gradient structure surface as well as plasma resonance effect; AgBr is uniformly spread on the surface of a BiVO4 carrier; Pd is attached to the surface of the 3DOM structure in a nanocluster mode, and the specific surface area is 16m<2> / g, and the band gap energy is 2.49eV; the catalyst shows efficient visible light catalytic activity to degradation of parachlorophenol under the irradiation of visible light, and 4-CP is basically degraded completely after 150 minutes.

Owner:BEIJING UNIV OF TECH

Method for preparing 1,4-dihydroxy anthraquinone

InactiveCN104926636AImprove catalytic performanceReduce dosageOrganic compound preparationQuinone preparationHydroxyanthraquinonePtru catalyst

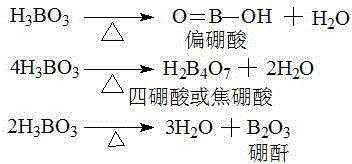

The invention discloses a method for preparing 1,4-dihydroxy anthraquinone by taking a boric acid dehydration compound as a catalyst. The method comprises the following steps: (1) heating boric acid at 100-250 DEG C to prepare the boric acid dehydration compound; (2) adding fuming sulphuric acid, phthalic anhydride, the boric acid dehydration compound and parachlorophenol into a condensation kettle in sequence, and carrying out condensation reaction at 100-250 DEG C; (3) adding a proper amount of water and the materials in the condensation kettle into a hydrolysis kettle, carrying out hydrolysis reaction at 50-115 DEG C, discharging a reactant, filtering the reactant by pressing, washing and drying the reactant to prepare 1,4-dihydroxy anthraquinone. According to the method, the boric acid dehydration compound is used as the catalyst, so that the addition amount of the raw materials including fuming sulphuric acid and phthalic anhydride is reduced; the resource consumption can be reduced; the cost is reduced; the waste emission is reduced; the method is relatively environmentally-friendly and economical.

Owner:JIANGSU YABANG DYE

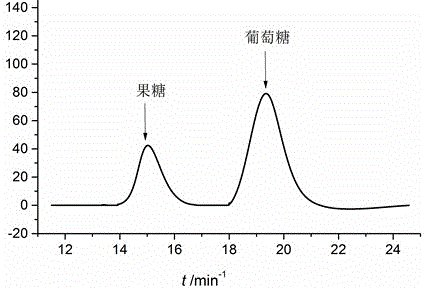

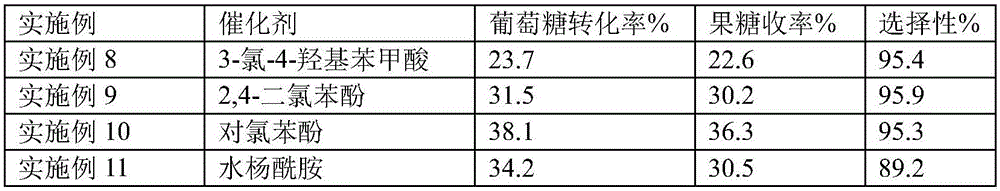

Chemical method of preparing fructose from glucose

InactiveCN106749432AEasy to operateProcess safetySugar derivativesSugar derivatives preparationFructoseP-Chlorophenol

The invention relates to a simple chemical preparation method of preparing fructose from glucose. Under one atmospheric pressure and at a low temperature, one or more of phenol compounds such as p-methoxy phenol, p-chlorophenol, nitrophenol, and the like, is taken as the catalyst to catalyze glucose into fructose. The operation method is simple, the reaction conditions are mild, the cost is low, the yield of fructose is as high as 50%, by product is barely produced, and the selectivity is greater than 96%.

Owner:SICHUAN UNIV

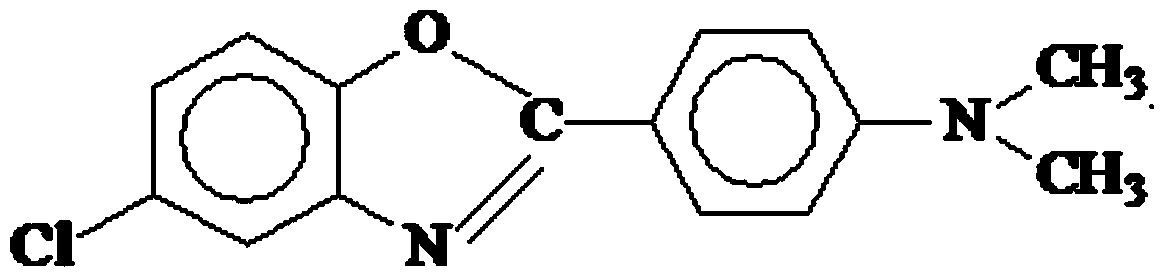

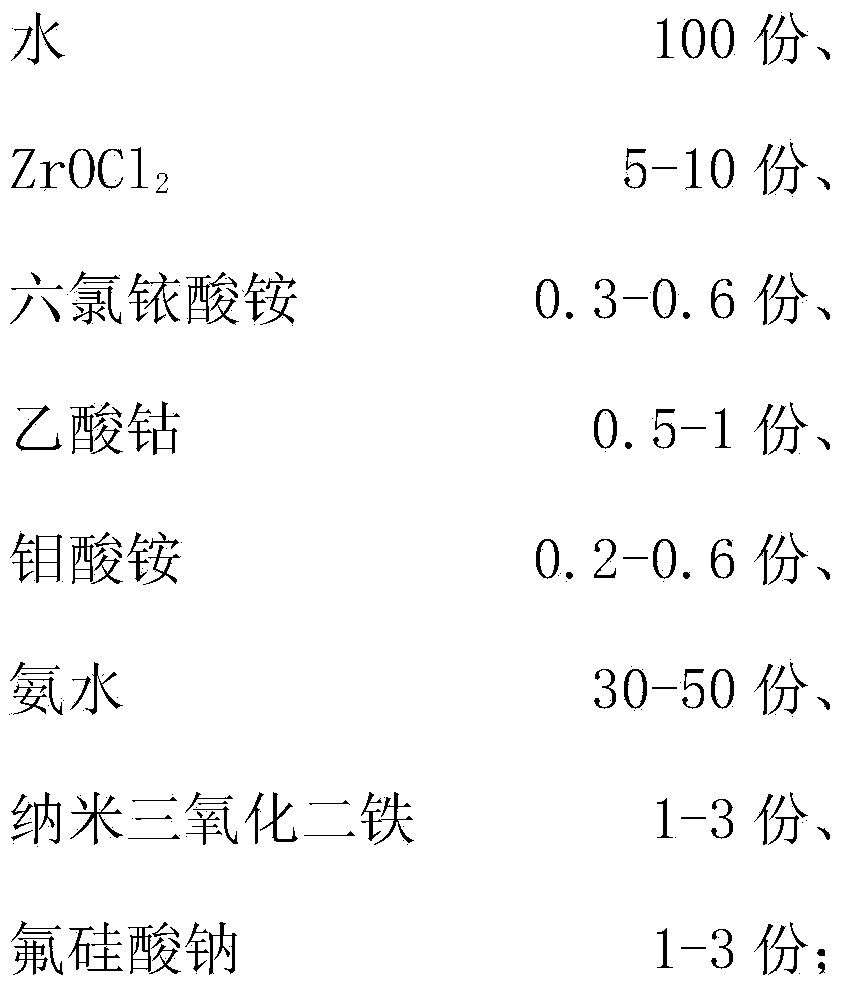

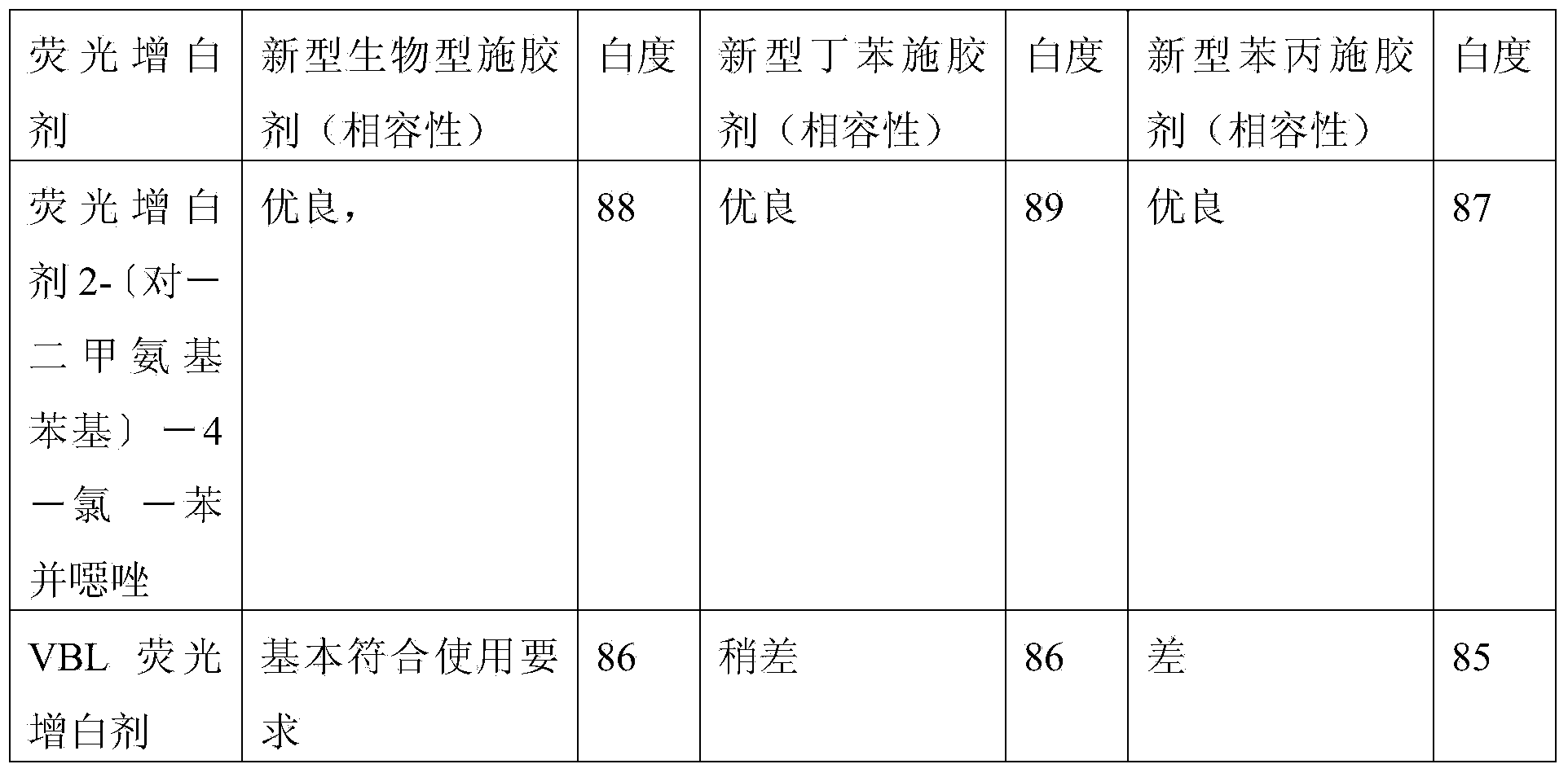

Preparation method of fluorescent whitening agent

ActiveCN103524446AGood compatibilitySimple processOrganic chemistryAzo dyesBenzoxazoleWhitening Agents

The invention provides a preparation method of a fluorescent whitening agent. The preparation method comprises the following steps: mixing 4-dimethylaminobenzoylchloride, p-chlorophenol ortho-aminophenol, doped SO42- / ZrO2-Fe2O3-SiO2 type mixed crystal solid superacid catalyst and ethylene glycol monobutyl ether, heating to 160-180 DEG C, performing reflux reaction for 2-3 hours, standing, separating the catalyst, adding 5-10 parts of sodium hydroxide, rising to 100-120 DEG C, stirring for 1-2 hours, standing, separating and removing the lower solution, distilling off a solvent from an upper reaction product through a decompression method, enabling the reactant to a jelly, adding water below 10 DEG C, washing and filtering, and obtaining the fluorescent whitening agent which is 2-(p-dimethylamino phenyl)-4-chlorine-benzoxazole. The preparation method of the fluorescent whitening agent is simple in process; the use of the strong acid is avoided, so that the corrosion to the equipment is avoided; the use of a large amount of water is avoided; the prepared fluorescent whitening agent is good in compatibility with a surface sizing agent in papermaking and good in whitening effect.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

New technology of synthesizing 4-[2-(cyclo propyl methoxy] ethyl] phenol

InactiveCN1651379AEasy to operateHigh yieldOrganic compound preparationEther preparationP-ChlorophenolPhenol

A process for preparing 4-[2-(cyclopropyl methoxy)ethyl) phenol from P-chlorophenol includes such steps as phenohydroxy protecting, Grignard reacting, etherifying and hydrolyzing for removing protection.

Owner:NANJING UNIV

Sterilizing algicide for circulating cooling water and preparation method of sterilizing algicide

InactiveCN103444760AImprove the bactericidal effectLong duration of actionBiocideDisinfectantsEngineeringDiethyl ether

The invention relates to a sterilizing algicide for circulating cooling water and a preparation method of the sterilizing algicide. The sterilizing algicide comprises the following components in parts by mass: 10-19 parts of chlorophenasic acid, 10-19 parts of parachlorophenol, 3-10 parts of dodecyl dimethyl benzyl ammonium chloride, 0.5-3 parts of dithiocyano-methane, 8-15 parts of sodium dodecyl benzene sulfonate, 1-5 parts of acetone oxime, 2-5 parts of methyl alcohol, 1-3 parts of diethyl ether, 4-8 parts of sodium hydroxide, and 19-37 parts of water. The sterilizing algicide has good sterilizing and algae removal effects, and has a long pesticide effect, the sterilizing rate reaches over 98%, and the pesticide effect time is more than 25 hours.

Owner:SUZHOU KANGHUA PURIFYING SYST ENG

Peelable water-based paint

InactiveCN104263088AHigh mechanical strengthGood weather resistancePolyamide coatingsWater basedCellulose acetate

The invention discloses peelable water-based paint. The peelable water-based paint comprises the following components: cellulose acetate resin, petroleum resin, polyether sulfone resin, polyamide resin, elastic polyurethane emulsion, composite zinc phosphate, water-based silicone acrylic emulsion, wollastonite powder, talcum powder, phthalocyanine blue, titanium dioxide, carbon black, ethylene glycol butyl ether, m-nitrophenol, sodium hexametaphosphate, p-chlorophenol, aromatic hydrocarbon sulfonic acid, an ultraviolet absorber, BYK-300 and deionized water. The peelable water-based paint has the beneficial effects of being high in mechanical strength, good in weather resistance, good in adhesion, good in glossiness, good in acid resistance and peelable.

Owner:QINGDAO JIASHANG CREATIVE CULTURE

Waterborne coating

The invention relates to a waterborne coating. The waterborne coating comprises the following components: epoxy resin, petroleum resin, polyether sulfone resin, butyl acrylate, ethyl acetoacetate, polysorbate, isooctyl acrylate, wollastonite in powder, talcum powder, titanium dioxide, carbon black, mono-epoxy allyl glycidyl ether, m-nitrophenol, 10% silicone oil, p-chlorophenol, arene sulfonate, a diluent, an aid and deionized water. The waterborne coating has the beneficial effects that the raw materials are uniformly dissolved and dispersed; the waterborne coating has high mechanical strength, good impact resistance, good adhesion and good glossiness.

Owner:QINGDAO JIASHANG CREATIVE CULTURE

Preparation process of high-purity p-chlorophenol

ActiveCN108101750AImprove conversion rateHigh yieldOrganic chemistryOrganic compound preparationP-ChlorophenolLiquid state

The invention provides a preparation process of high-purity p-chlorophenol, which includes the steps of: 1) chlorination: heating phenol as a raw material to liquid state, quantitatively pressure-feeding the phenol to an enamel reaction kettle via a pump, feeding chlorine under a normal pressure in a manner of firstly high speed and then low speed to perform the chlorination reaction for 32-38 h,thus producing chlorophenol; 2) rectification: cooling the chlorophenol to 55-60 DEG C and adding a composite extraction agent, uniformly stirring the mixture, and feeding the mixture into a rectification column to perform vacuum distillation, wherein firstly reflux is carried out under vapor pressure of 0.3-0.35 MPa for 3-3.5 h, and then sampling analysis is carried out under the vacuum degree of-0.096 - 0.098 MPa and at temperature of 68-73 DEG C, and receiving o-chlorophenol; 3) regulating the temperature to 115-120 DEG C and vapor pressure to 0.55 MPa, and performing sampling analysis andreceiving p-chlorophenol. In the method, reasonable technical modification is carried out so as to significantly improve conversion rate and yield of the chlorophenol. The method is good separation effect and can reach 99.4% in purities of both the p-chlorophenol and o-chlorophenol. The products have good comprehensive quality. The method is suitable for industrial production.

Owner:HUAIHAI INST OF TECH +1

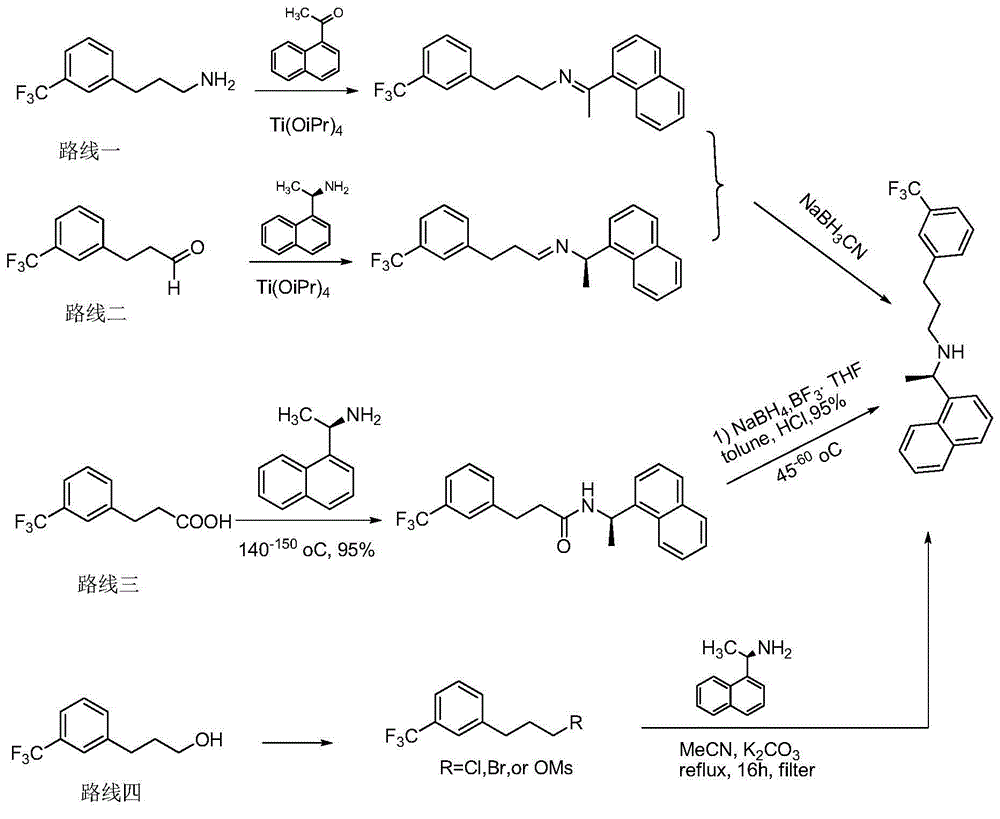

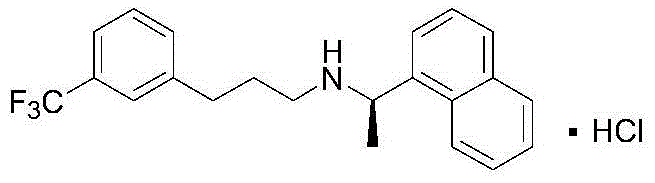

Synthesis method of cinacalcet

ActiveCN104592037AHigh yieldEasy to operateOrganic compound preparationAmino compound preparationP-ChlorophenolSynthesis methods

The invention discloses a synthesis method of cinacalcet. The synthetic route is divided into two parts, namely, (1) preparing a chiral compound as shown in the description from racemic 1-naphthylethylamine as a starting material by virtue of a dynamic kinetic reliquid method in the presence of Pd / LDH-SA serving as a racemic catalyst, p-chlorophenol fatty acyl ester serving as an acyl donor and lipase serving as a biological reliquid catalyst; and (2) reacting m-trifluoromethylbenzaldehyde serving as a starting material and a cheap and easily available material acetaldehyde to obtain m-trifluoromethyl cinnamic aldehyde and carrying out reduced pressure distillation to obtain a pure product; reacting m-trifluoromethyl cinnamic aldehyde and the compound as shown in the description to produce an imine intermediate; dissolving the imine intermediate in ethanol and reacting in the presence of Raney nickel serving as a hydrogenation catalyst to obtain the product cinacalcet. By the synthesis method, the reaction yield and the optical purity of the product are increased, the reaction conditions are milder and the raw materials are easily available.

Owner:ZHEJIANG UNIV

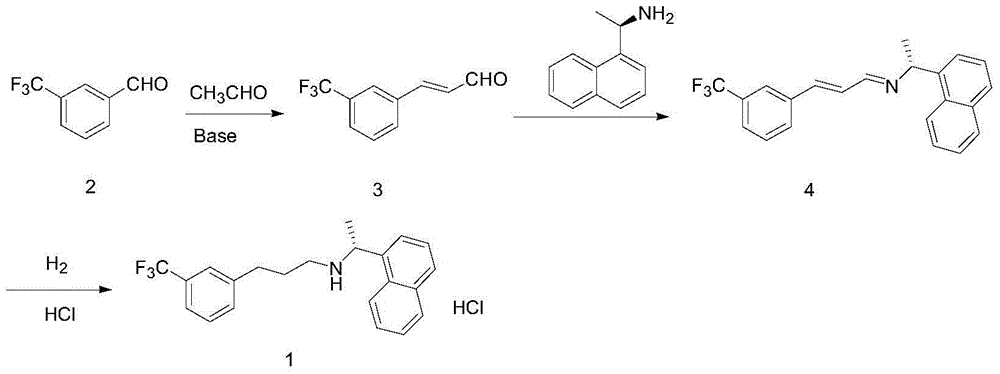

Synthesis method for co-producing p-chloroaniline and p-chlorophenol isocyanate

InactiveCN102617401AAvoid pollutionAvoid poisoningIsocyanic acid derivatives preparationOrganic compound preparationP-chloroanilineReflux

The invention relates to a synthesis method for co-producing p-chloroaniline and p-chlorophenol isocyanate. The method comprises the following steps of: reducing parachloronitrobenzene by using iron powder, separating water, dehydrating, adding a solvent, reacting with a bis(trichloromethyl) carbonate solution, distilling to recover the solvent, and distilling to obtain a p-chlorophenol isocyanate finished product. The method has the advantages that a process is advanced; process conditions are reasonable; the production of p-chloroaniline is organically combined with that of p-chlorophenol isocyanate; the environment pollution and an intoxicating phenomenon which are brought by p-chloroaniline used as an industrial product in the processes of aftertreatment, conveying, carrying and feeding can be avoided; virulent phosgene and diphosgene are avoided during production of p-chlorophenol isocyanate, and production is safe and reliable; the residual bis(trichloromethyl) carbonate is removed by normal-pressure reflux; the improvement on the quality of a product is facilitated; and the method has great implementation value and social and economic benefits.

Owner:象山志华新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![New technology of synthesizing 4-[2-(cyclo propyl methoxy] ethyl] phenol New technology of synthesizing 4-[2-(cyclo propyl methoxy] ethyl] phenol](https://images-eureka.patsnap.com/patent_img/b59de7b9-c511-471c-8612-a0108d4a7bd0/A20041006541600041.PNG)