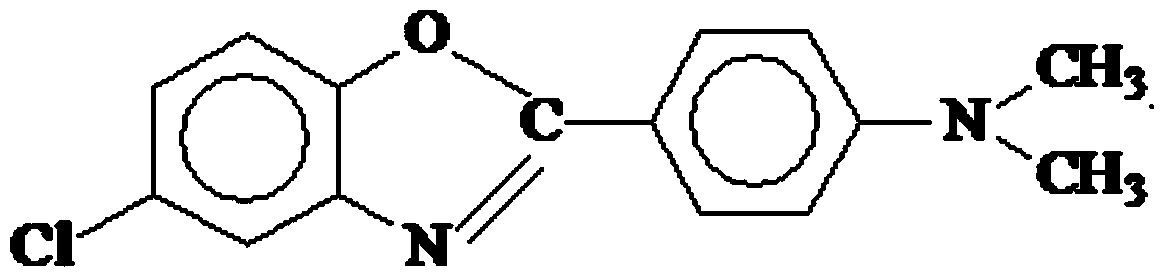

Preparation method of fluorescent whitening agent

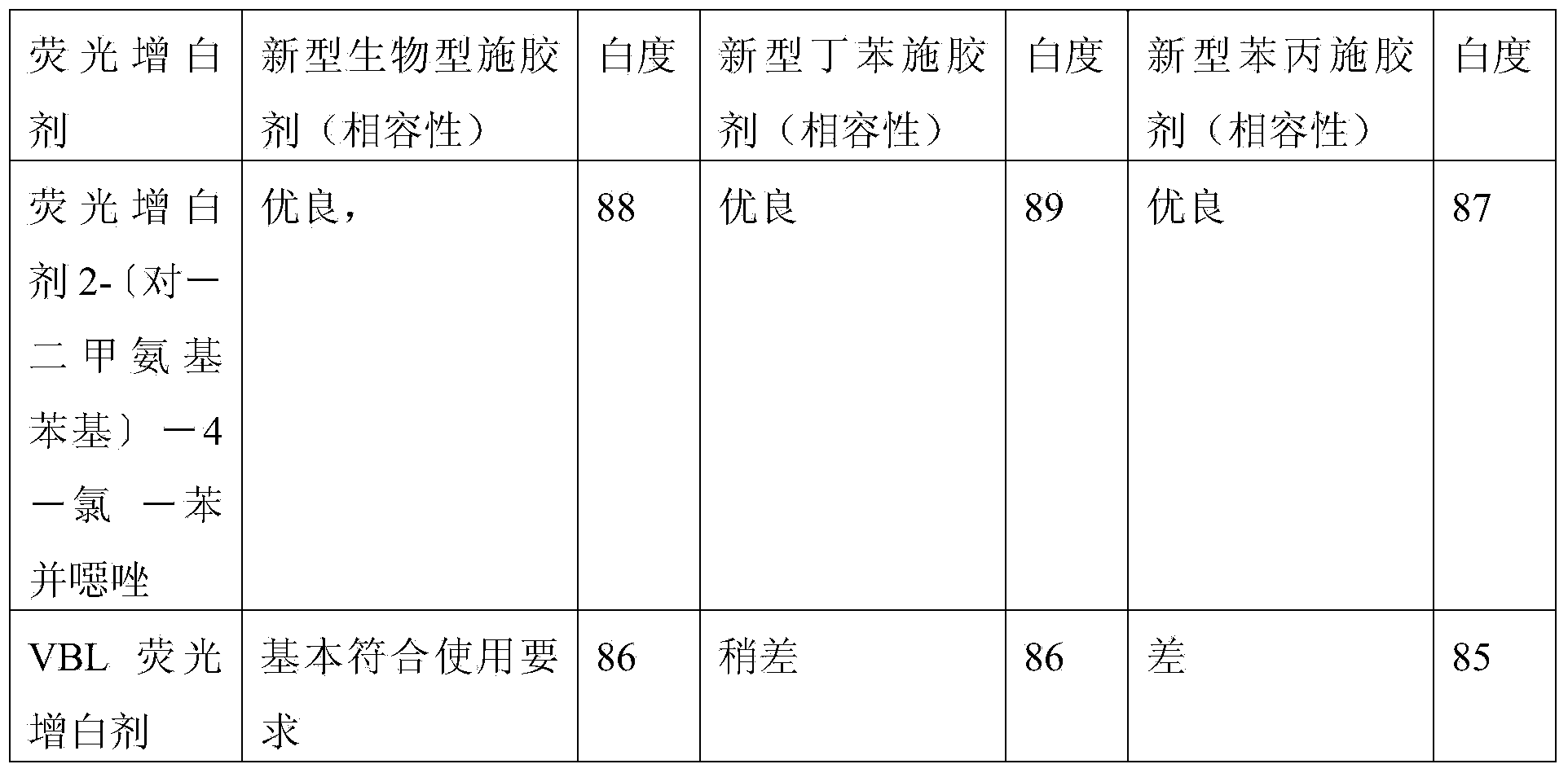

A fluorescent whitening agent and catalyst technology, applied in chemical instruments and methods, addition of luminescent/fluorescent substances, luminescent materials, etc., can solve problems such as poor compatibility of fluorescent whitening agents, achieve good whitening effect, convenient operation, The effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] One, fluorescent whitening agent, its characteristic is prepared through the following steps;

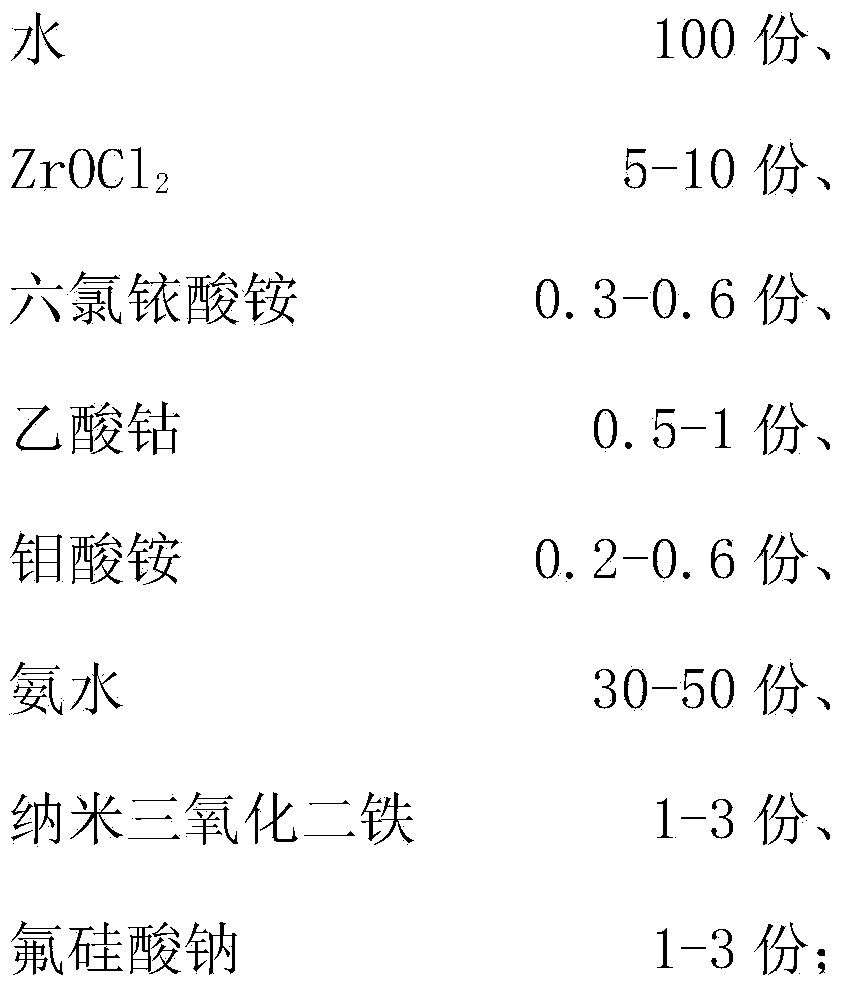

[0018] (a). Chemical composition: 80 parts of 4-dimethylaminobenzoyl chloride, 100 parts of p-chloro-o-aminophenol, doped with SO 4 2- ∕ZrO 2 -Fe 2 o 3 - SiO 2 3 parts of mixed crystal solid superacid catalyst, 150 parts of ethylene glycol monobutyl ether, 5 parts of sodium hydroxide;

[0019] (b) Preparation method: Add 4-dimethylaminobenzoyl chloride, p-chloro-o-aminophenol, doped SO 4 2- ∕ZrO 2 -Fe 2 o 3 - SiO 2 Type mixed crystal solid superacid catalyst, ethylene glycol monobutyl ether, heat up to 160 ° C, reflux for 3 hours, stand still, separate the catalyst, add sodium hydroxide, then heat up to 100 ° C and continue stirring for 60 minutes, stand still, Separate and remove the lower layer solution, distill off the solvent from the upper layer reaction product by decompression method, make the reactant a jelly, add 100 parts of deionized water below 10°C, fi...

Embodiment 2

[0026] One, fluorescent whitening agent, its characteristic is prepared through the following steps;

[0027] (a). Chemical components: 90 parts of 4-dimethylaminobenzoyl chloride, 110 parts of p-chloro-o-aminophenol, doped

[0028] SO 4 2- ∕ZrO 2 -Fe 2 o 3 - SiO 2 Type mixed crystal solid superacid catalyst 4 parts, ethylene glycol monobutyl ether 165 parts, sodium hydroxide 7.5 parts;

[0029] (b) Preparation method: Add 4-dimethylaminobenzoyl chloride, p-chloro-o-aminophenol, doped SO 4 2- ∕ZrO 2 -Fe 2 o 3 - SiO 2 Type mixed crystal solid superacid catalyst, ethylene glycol monobutyl ether, heat up to 160-170°C, reflux for 2.5 hours, stand still, separate the catalyst, add sodium hydroxide, then heat up to 110°C and continue stirring for 60 minutes, stand still , Separation and removal of the lower layer solution, the upper layer reaction product is distilled off the solvent with a reduced pressure method, so that the reactant is a jelly, add 100 parts of deioni...

Embodiment 3

[0032] One, fluorescent whitening agent, its characteristic is prepared through the following steps;

[0033] (a). Chemical composition: 100 parts of 4-dimethylaminobenzoyl chloride, 120 parts of p-chloro-o-aminophenol, doped with SO 4 2- ∕ZrO 2 -Fe 2 o 3 - SiO 2 Type mixed crystal solid superacid catalyst 5 parts, ethylene glycol monobutyl ether part 180 parts, sodium hydroxide 10 parts;

[0034] (b) Preparation method: Add 4-dimethylaminobenzoyl chloride, p-chloro-o-aminophenol, doped SO 42- ∕ZrO 2 -Fe 2 o 3 - SiO 2 Type mixed crystal solid superacid catalyst, ethylene glycol monobutyl ether, heat up to 160-180°C, reflux for 3 hours, stand still, separate the catalyst, add sodium hydroxide, then heat up to 120°C and continue stirring for 60 minutes, stand still , Separation and removal of the lower layer solution, the upper layer reaction product is distilled off the solvent with a reduced pressure method, so that the reactant is a jelly, add 100 parts of deionized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com