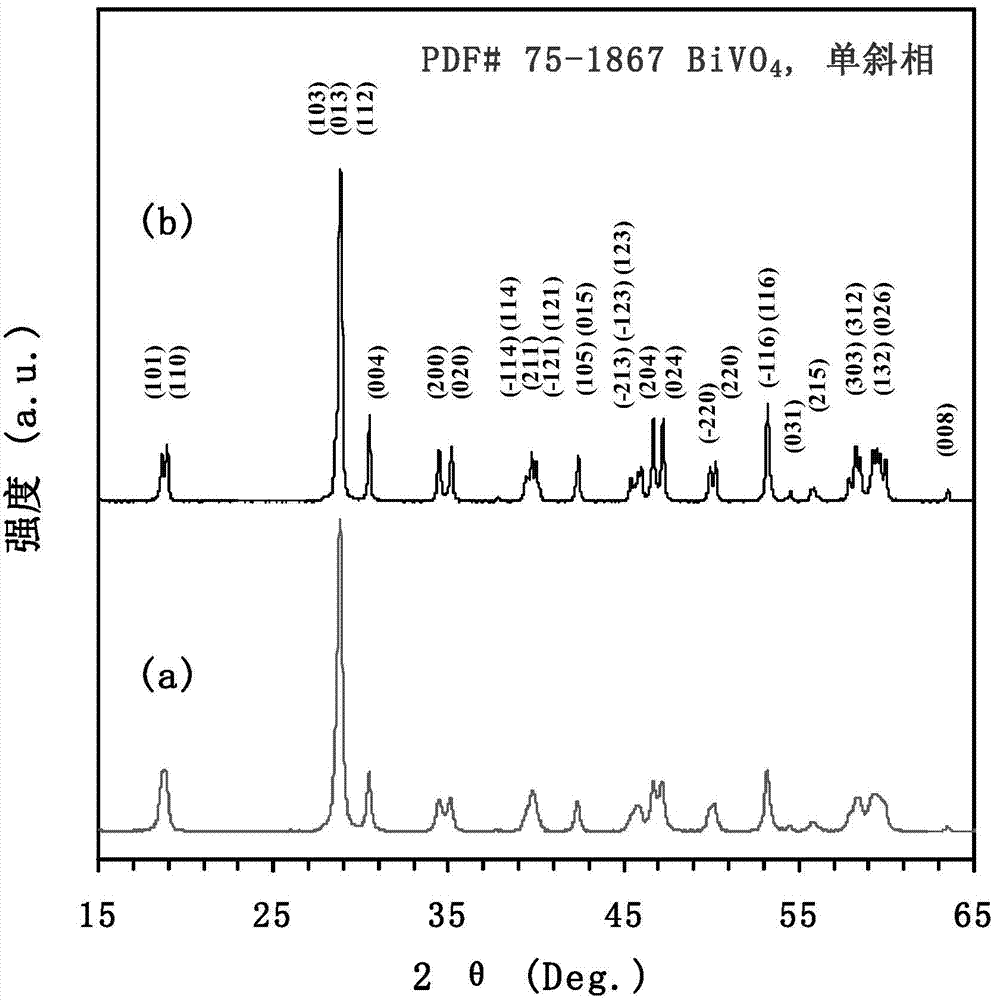

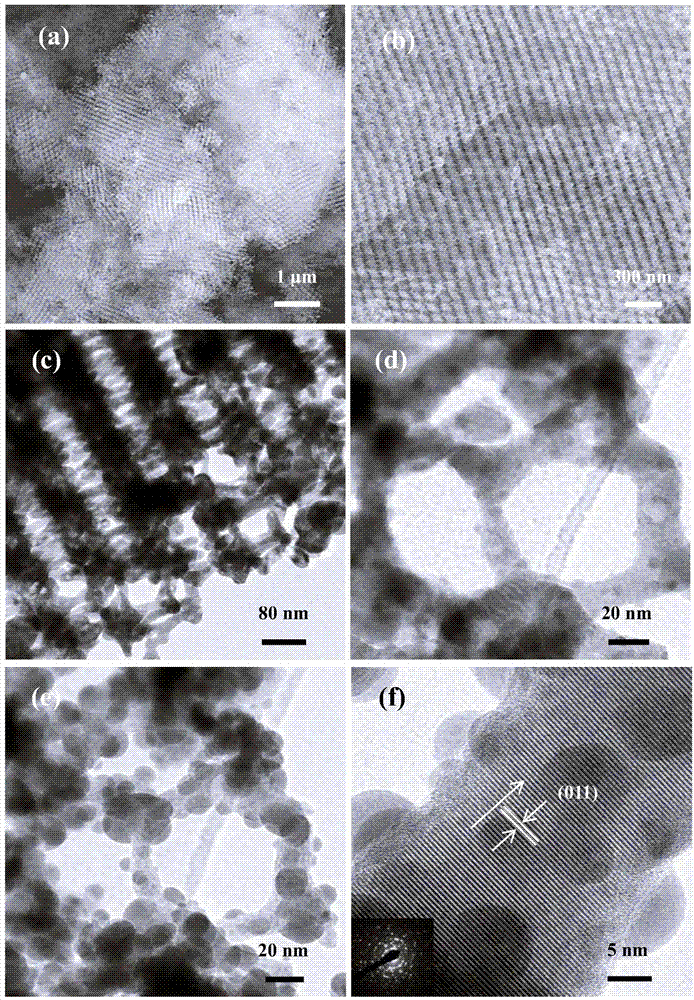

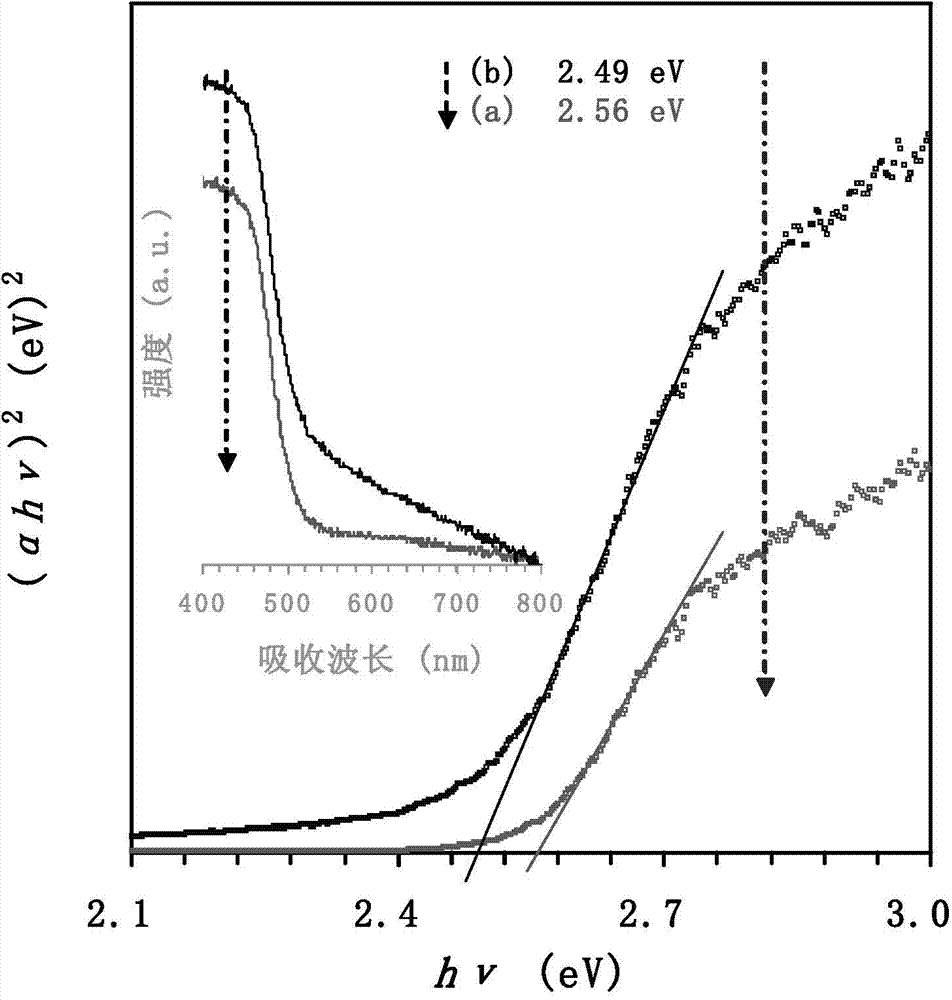

Three-dimensional ordered macroporous (3DOM) BiVO4 loaded AgBr and Pd photocatalyst, preparation and application

A three-dimensional ordered, nano-photocatalyst technology, used in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve good application prospects and high-efficiency visible light catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: (1) Weigh 0.0714g KBr and dissolve it in 246mL deionized water, and dissolve 1.0g3DOM BiVO 4 The carrier was immersed in it, and bubbled in the dark for 2 h under the condition of an ice-water bath, and then 53.3 mL of AgNO with a concentration of 0.01 mol / L was added to it with a constant pressure dropping funnel. 3 The solution (containing the protective agent polyvinylpyrrolidone PVP, the mass ratio of Ag to PVP is 1 / 1.5) was slowly dripped into the above system (the completion time of dripping was about 1h), continued bubbling for 5h and then filtered to obtain a solid precursor. The precursor was dried at 80°C, then placed in an oven at 200°C for 2 hours, washed with deionized water and dried at 80°C to obtain AgBr / 3DOM BiVO 4 ; (2) with PdCl 2 As a precious metal source, polyvinyl alcohol (PVA, 10000g / mol; the molar ratio of Pd to PVA is 1.5 / 1) is used as a protective agent, and Pd is configured 2+ Concentration is the solution of 0.01mol / L; (3) under...

Embodiment 2

[0020] Embodiment 2: 0.05g Pd / AgBr / 3DOM BiVO 4 catalyst sample and 0.6 mL of 30 wt% H 2 o 2 The solution was added to 99.4 mL of an aqueous solution of p-chlorophenol with an initial concentration of 15 mg / L, and then the reaction solution was sonicated in the dark for 0.5 h and then magnetically stirred for 1 h. After the reaction started, take 5mL of the suspension at regular intervals, remove the photocatalyst particles by centrifugation, measure the absorbance of the solution after a certain time (t) of reaction with a UV-Vis instrument and use electrospray ionization mass spectrometry (ESI-MS) To detect residual organic matter in the reaction solution. Figure 4 with Figure 5 It shows that the degradation of p-chlorophenol in the solution is basically completed after 150min of visible light irradiation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com