Preparation method of photocatalytic net loaded with carbon nitride

A carbon nitride and photocatalysis technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc. problem, to achieve the effect of uniform load, stable load effect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

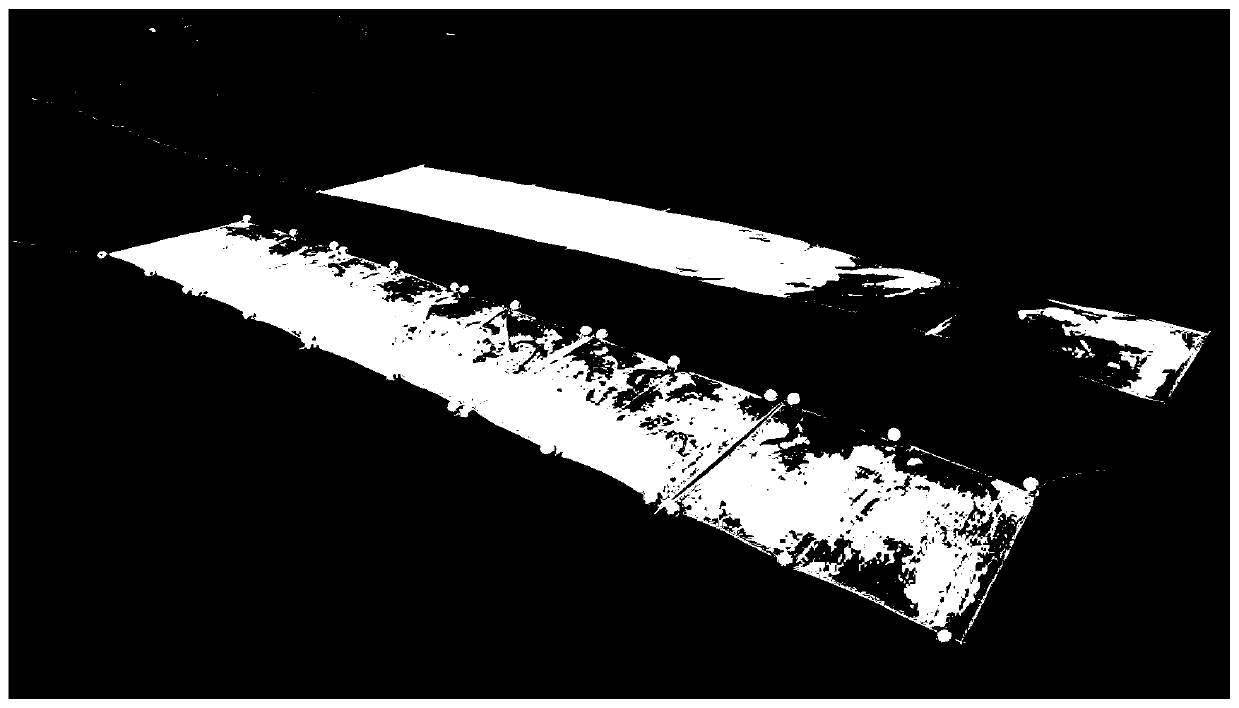

Image

Examples

Embodiment 1

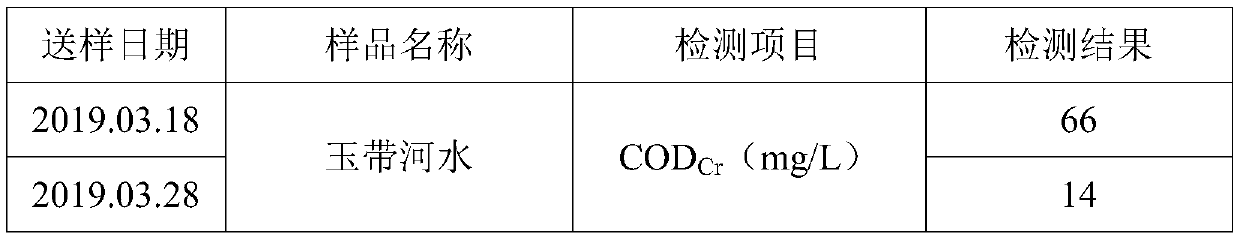

[0024] Example 1: 240g of ultra-thin carbon nitride was weighed, 280g of inorganic binder was added, and ultrasonic treatment was performed for 1 hour. Spray the above solution three times evenly on the 1.2m 2 The 80-mesh cotton fiber net was sprayed three times with 150g, 180g, and 190g respectively, and the interval between each spray was 2.5h, and it was dried at room temperature for 28h to obtain a completely dry photocatalytic net loaded with carbon nitride. The catalytic net is applied to the water purification of the river course (Jiangsu University Yudai River), and the removal rate of COD in the water is 78%.

Embodiment 2

[0025] Example 2: 200g of ultra-thin carbon nitride was weighed, 200g of inorganic binder was added, and ultrasonic treatment was performed for 1 hour. Spray the above solution three times evenly on the 1m 2 The 100-mesh cotton fiber net was sprayed three times with 120g, 150g, and 130g respectively, and the interval between each spray was 2h, and it was dried at room temperature for 24h to obtain a completely dry photocatalytic net loaded with carbon nitride. The catalytic net is applied to water purification in a certain landscape, and the removal rate of COD in water is 91%.

Embodiment 3

[0026] Example 3: 400g of ultra-thin carbon nitride was weighed, 500g of inorganic binder was added, and ultrasonic treatment was performed for 2 hours. Spray the above solution three times evenly on the 1.8m 2 The 50-mesh cotton fiber net was sprayed three times with 300g, 300g, and 300g respectively, and the interval between each spray was 3h, and it was dried at room temperature for 36h to obtain a completely dry photocatalytic net loaded with carbon nitride. The catalytic net is applied to the water quality treatment of the secondary sedimentation tank of a sewage treatment plant, and the COD removal rate in the water is 88%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com