Preparation method of CdS/GE/Fe2O3 composite photocatalyst

A technology of catalyst and composite light, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low photocatalytic performance and limited application range, and achieve convenient magnetic separation and reuse, excellent The effect of visible light catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Ultrasonic disperse 10mg of PB in 40mL of deionized water, add 2mL of PAH (1g L -1 ) solution, stirred for 3h; then sequentially added 1mL 5mg mL -1 GO solution; 5mL 0.11M CdCl 2 solution, stirred for 3h; finally added 5mL of 0.11M Na 2 S solution, stirred for 3h. After washing with deionized water, the obtained sample was placed in an argon atmosphere at 2 °C min -1 The temperature was raised to 350°C and kept for 2h to obtain the final product.

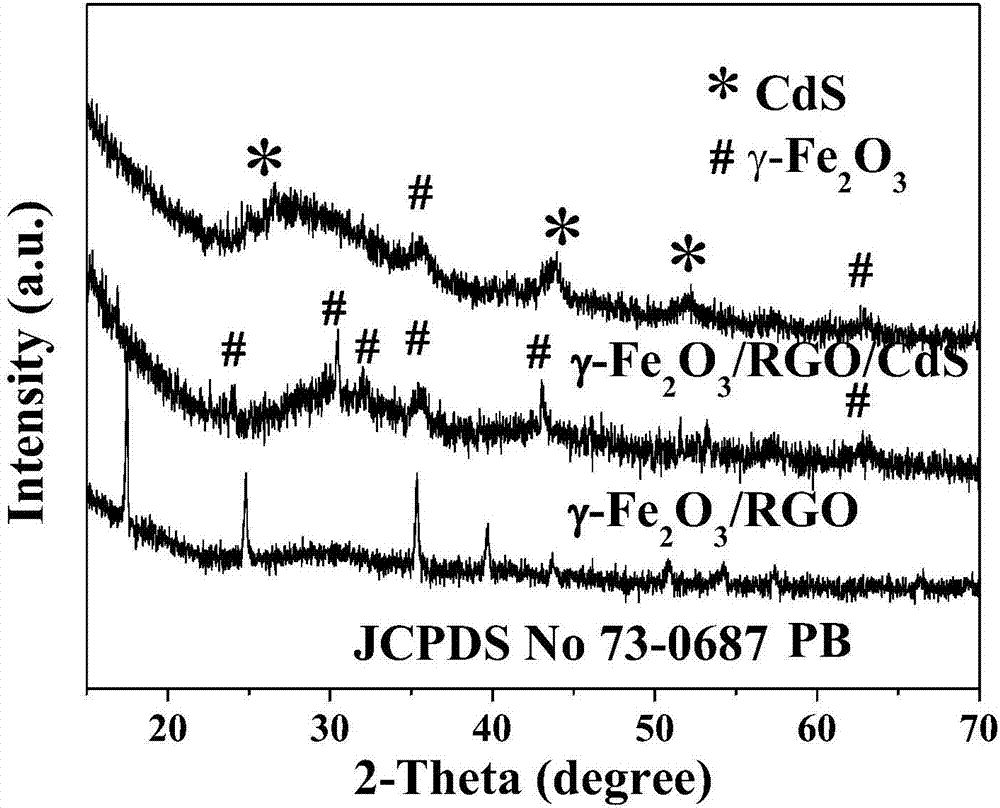

[0024] figure 1 It is the XRD pattern of the product, and all the diffraction peaks in Figure PB are consistent with JCPDS No.73-0687, corresponding to the cubic phase of Fe 4 [Fe(CN) 6 ] 3 . For γ-Fe 2 o 3 In the XRD pattern of / RGO, the diffraction peaks at 30.24, 35.63, 43.28, 53.73, 57.27, 62.925 and 62.499° correspond to (022), (311), (400), (422), (511), and (440) Crystal faces, with γ-Fe 2 o 3 The standard card (JCPDS No 39-1346) matches. In γ-Fe 2 o 3 / RGO / CdS XRD patterns, except for γ-Fe 2 o 3 The ...

Embodiment 2

[0028] Ultrasonic disperse 5 mg of PB in 40 mL of deionized water, add 2 mL of PAH (1 g L -1 ) solution, stirred for 3h; then sequentially added 1mL 5mg mL -1 GO solution; 5mL 0.11M CdCl 2 solution, stirred for 3h; finally added 5mL of 0.11M Na 2 S solution, stirred for 3h. After washing with deionized water, the obtained sample was placed in an argon atmosphere at 2 °C min -1 The temperature was raised to 350°C and kept for 2h to obtain the final product.

Embodiment 3

[0030]Ultrasonic disperse 15mg of PB in 40mL of deionized water, add 2mL of PAH (1g L -1 ) solution, stirred for 3h; then sequentially added 1mL 5mg mL -1 GO solution; 5mL 0.11M CdCl 2 solution, stirred for 3h; finally added 5mL of 0.11M Na 2 S solution, stirred for 3h. After washing with deionized water, the obtained sample was placed in an argon atmosphere at 2 °C min -1 The temperature was raised to 350°C and kept for 2h to obtain the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com