MOFs-rGO supported Pd nano-catalyst as well as preparation and application thereof

A nano-catalyst, catalyst technology, applied in the field of catalysis, to achieve the effect of small particle size, good dispersion and stability, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] NH 2 - Preparation of MIL-101 (Cr): Weigh 800mg of chromium nitrate nonahydrate (2mmol), 360mg of 2-aminoterephthalic acid (2mmol) and 200mg of sodium hydroxide (5mmol), and add to 15mL of deionized water. Ultrasonic treatment at room temperature to make it evenly mixed, then transferred to a 50mL polytetrafluoro reactor, reacted at 160°C for 16h, cooled to room temperature, and filtered with a water-based filter membrane with a pore size of 0.22μm to obtain a grass-green solid . Finally, reflux the grass-green solid in 95% ethanol for 12 hours to wash away unreacted 2-aminoterephthalic acid to obtain NH 2 -MIL-101(Cr). The obtained solid powder was dried and activated in a vacuum oven at 100° C. for 12 hours before use.

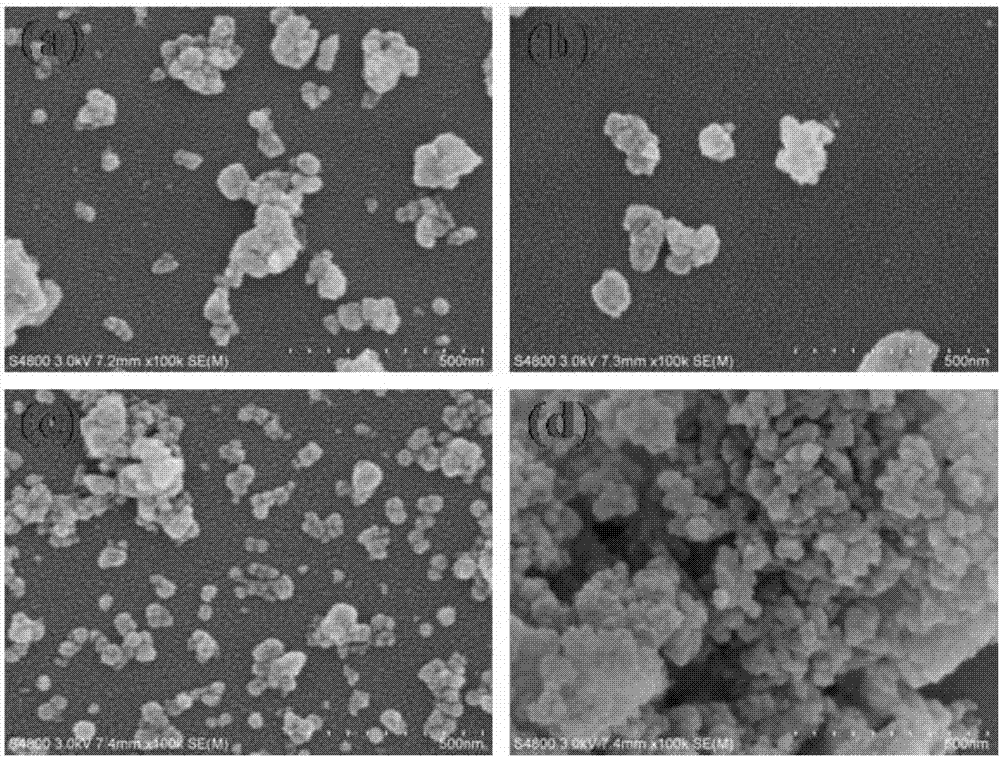

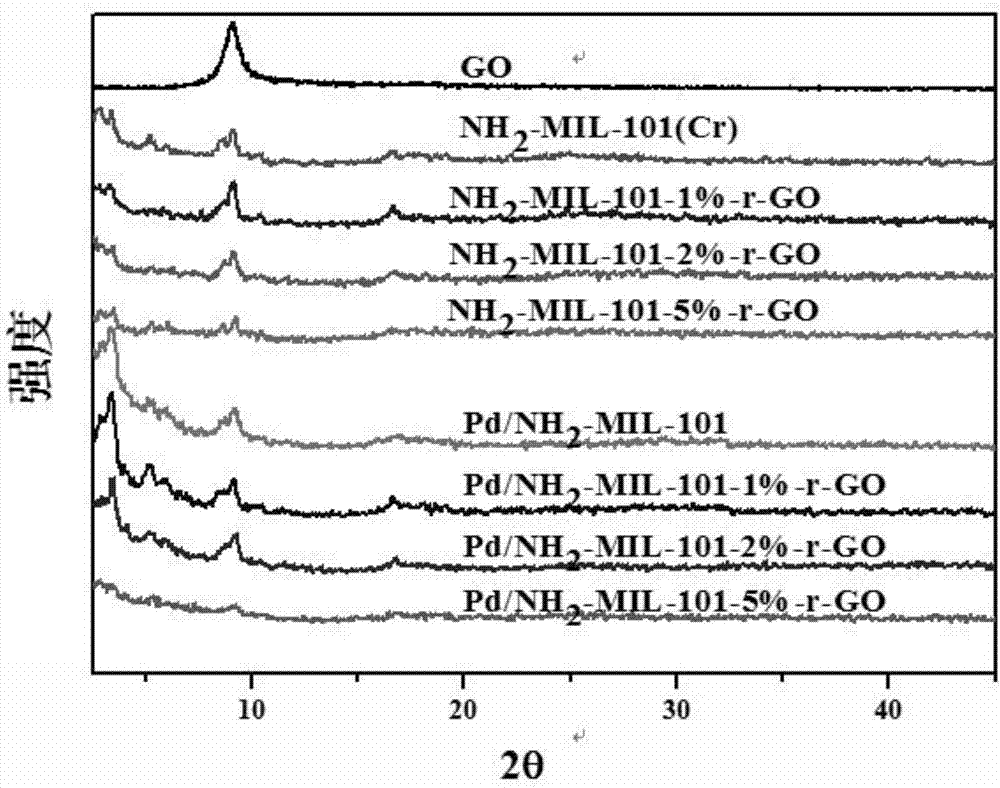

[0029] NH 2 -MIL-101(Cr)-rGO-1, NH 2 -MIL-101(Cr)-rGO-2, NH 2 -The synthesis method of MIL-101(Cr)-rGO-3 and NH 2 - The synthesis method of MIL-101 (Cr) is the same. The difference is that 1%, 2% or 5% GO is added to the solution by mass rati...

Embodiment 2

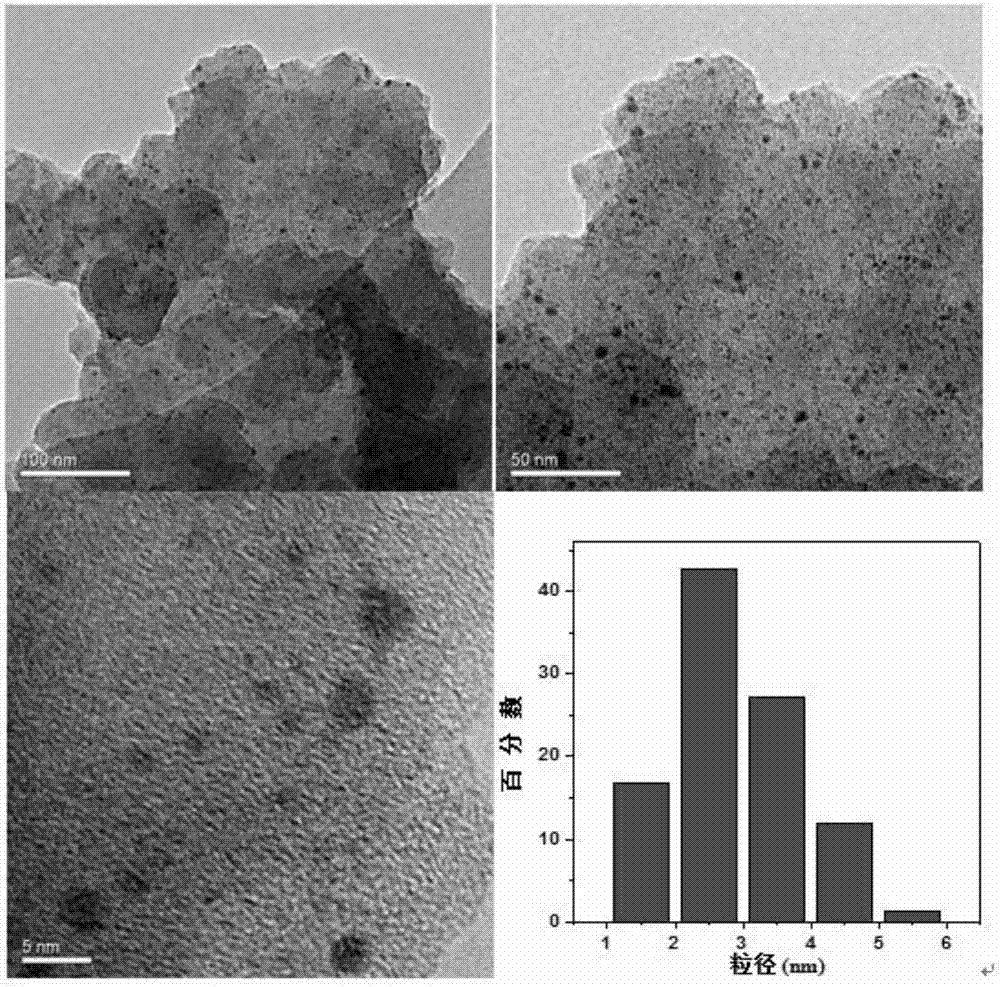

[0031] Four kinds of carriers NH prepared in Example 1 2 -MIL-101(Cr), NH 2 -MIL-101(Cr)-rGO-1, NH 2 -MIL-101(Cr)-rGO-2, NH 2 -MIL-101(Cr)-rGO-3 prepared Pd nanoparticle-supported catalyst carrier, with Pd / NH 2 - The preparation of MIL-101 (Cr) is an example, the specific steps are as follows: Weigh 200 mg of activated solid powder NH 2 - MIL-101 (Cr), ultrasonically dispersed in 20 mL of water. During stirring, 1M HCl solution was added dropwise to the solution to acidify the NH 2 -MIL-101(Cr). After 10 min, 13 mL of 10 mmol of chloropalladium acid solution was added dropwise to the solution, and stirred at room temperature for 6 h. Then use a 0.22 μm pore size water-based filter membrane to carry out suction filtration, wash with 100ml of water and ethanol twice to neutrality, and obtain Pd 2+ / NH 2 - MIL-101 (Cr) solid. Pd 2+ / NH 2 - Disperse MIL-101(Cr) in 20mL water and stir evenly under ice bath. When the temperature of the solution dropped to 2-3° C., an exc...

Embodiment 3

[0033]

[0034] The catalyst prepared in Example 2 was used for the hydrodechlorination reaction of p-chlorophenol and o-chlorophenol. The specific steps are: use a pipette to measure p-chlorophenol or o-chlorophenol solution (18.36mg / mL, 1mmol) into a three-neck flask, dilute to 10mL, add 23mg of catalyst, ultrasonically disperse it, and stir for 10min. After that, 15 mmol of organic base was added to the reaction liquid, and the reaction was stirred under the condition of 30° C. water bath after ultrasonication for 1 min. The mixture was filtered with a needle filter with a pore size of 0.22 μm, and the filtrate was analyzed for its yield by liquid chromatography. The reaction substrates used and the corresponding yields are listed in Table 1. Under the same conditions, Pd / NH 2 -MIL-101(Cr)-rGO-2 and Pd / NH 2 -MIL-101(Cr)-rGO-3 has the best catalytic effect. To further explore the stability of the catalyst, after the reaction, Pd / NH 2 - The loss of Pd in MIL-101(Cr)-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com