Preparation method and application of novel perovskite photocatalyst containing bismuth

A perovskite type, photocatalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve good photocatalytic activity, simple operation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

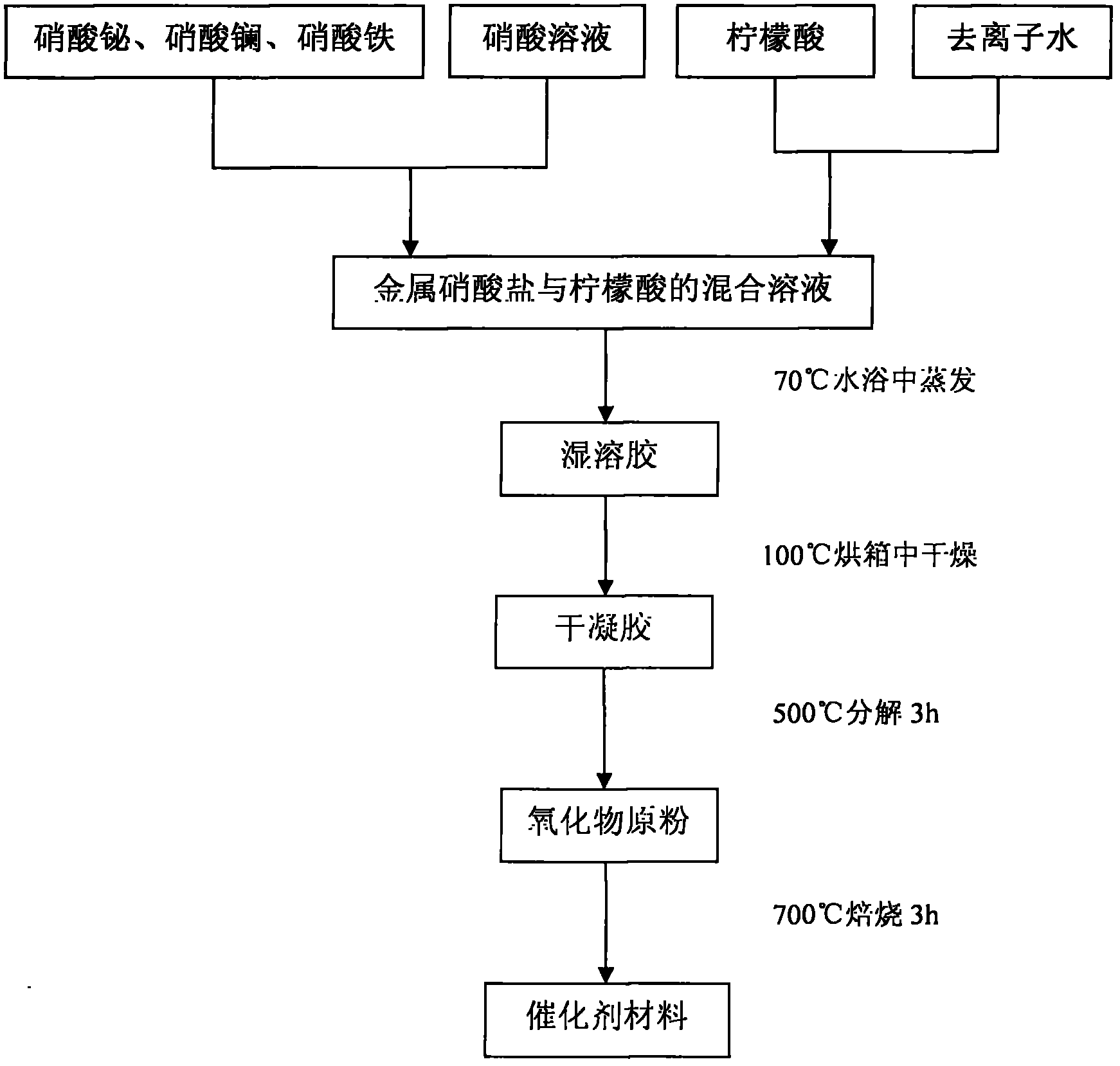

Method used

Image

Examples

Embodiment 1

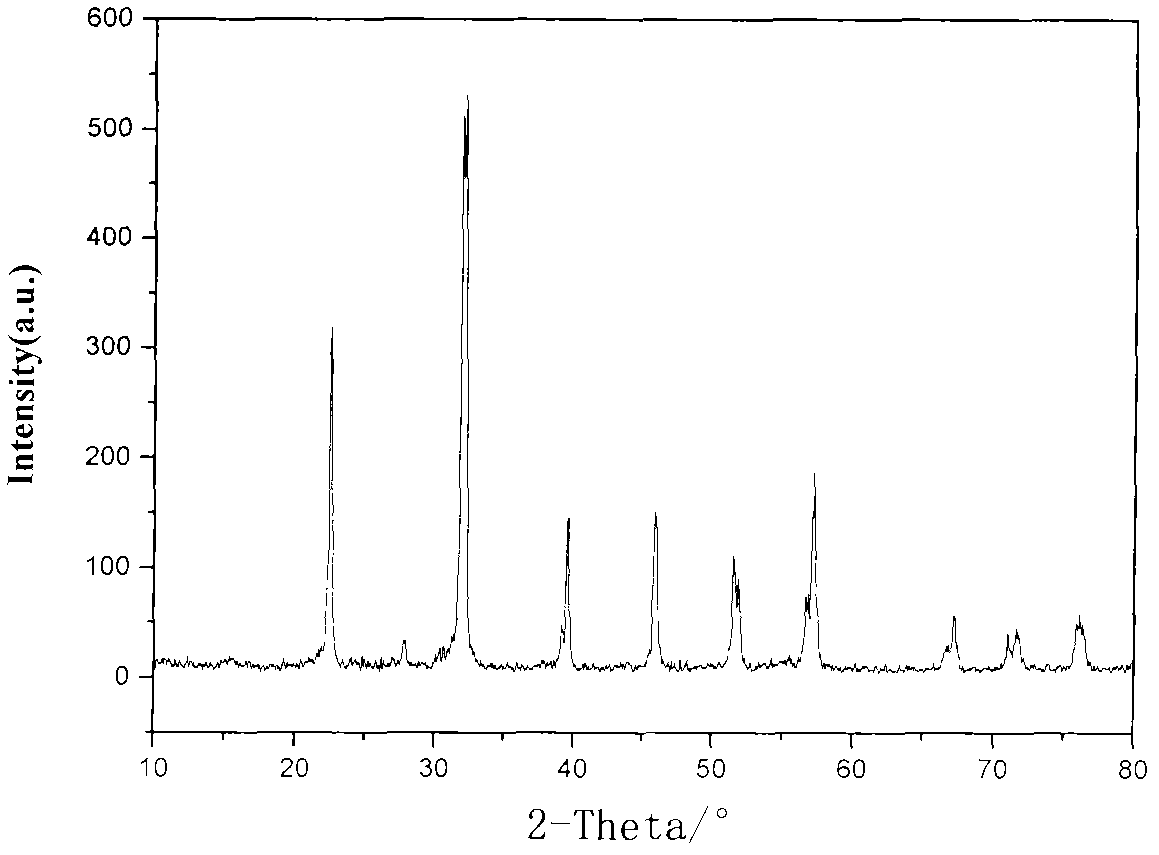

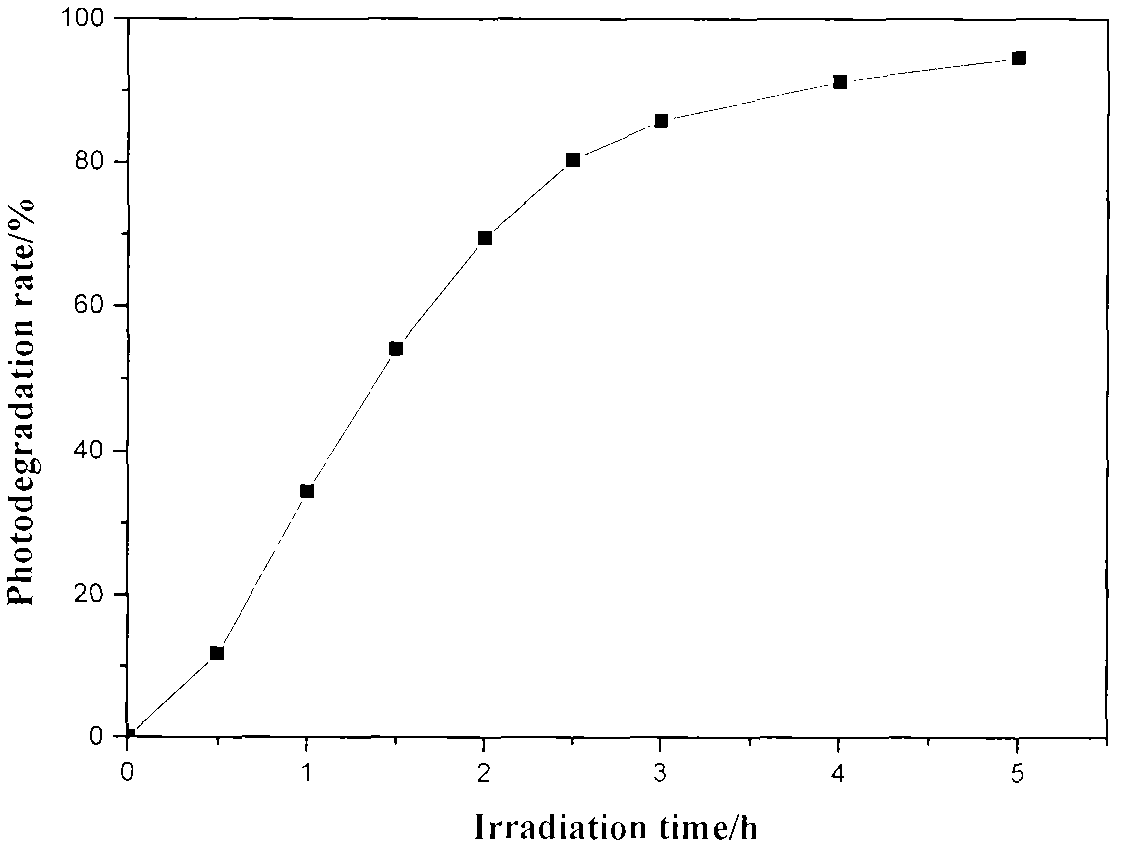

[0027] Embodiment 1: take by weighing 8.7313g Bi(NO 3 ) 3 ·5H 2 O, 0.6498g La(NO 3 ) 3 ·nH 2 O and 8.08g Fe(NO 3 ) 3 9H 2 O was dissolved in 200mL 2mol / L nitric acid solution to obtain a transparent solution; 16.8112g of citric acid was weighed and dissolved in 160mL deionized water, dissolved and added to the transparent solution, and stirred in a constant temperature water bath at 70°C to evaporate the water to obtain a transparent solution Viscous colloid. The obtained colloid was dried in an oven at 100°C in an air atmosphere for 24 hours to obtain a xerogel, then calcined in a muffle furnace at 500°C for 3 hours to obtain an oxide powder, and then calcined in an air atmosphere at 700°C for 3 hours to obtain Bi 0.9 La 0.1 FeO 3 Catalyst, the catalyst prepared in this example degrades 20mg / L p-chlorophenol simulated wastewater under visible light, and the catalyst dosage is 1g / L, the photocatalytic degradation rate at different times is shown in the following tabl...

Embodiment 2

[0030] Embodiment 2: implementation condition is the same as embodiment 1, and difference is to take by weighing 9.2163g Bi(NO 3 ) 3 ·5H 2 O, 0.3249gLa(NO 3 ) 3 ·nH 2 O and 8.08g Fe(NO 3 ) 3 9H 2 O was dissolved in 200mL 2mol / L nitric acid solution to obtain a transparent solution; finally Bi 0.95 La 0.05 FeO 3 Catalyst, the catalyst prepared in this example degrades 20mg / L p-chlorophenol simulated wastewater under visible light, and the catalyst dosage is 1g / L, the photocatalytic degradation rate at different times is shown in the following table:

[0031] time / h

Embodiment 3

[0032] Embodiment 3: implementation condition is the same as embodiment 1, and difference is to take by weighing 4.8507g Bi(NO 3 ) 3 ·5H 2 O, 3.2492gLa(NO 3 ) 3 ·nH 2 O and 8.08g Fe(NO 3 ) 3 9H 2 O was dissolved in 200mL 2mol / L nitric acid solution to obtain a transparent solution; finally Bi 0.5 La 0.5 FeO 3 Catalyst, the catalyst prepared in this example degrades 20mg / L p-chlorophenol simulated wastewater under visible light, and the catalyst dosage is 1g / L, the photocatalytic degradation rate at different times is shown in the following table:

[0033] time / h

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com