Preparation method for titanium dioxide-graphene/screen-printed electrode for detecting parachlorophenol

A technology of screen printing electrodes and titanium dioxide, applied in the direction of electrochemical variables of materials, etc., to achieve the effect of improving sensitivity and detection limit, simple process and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

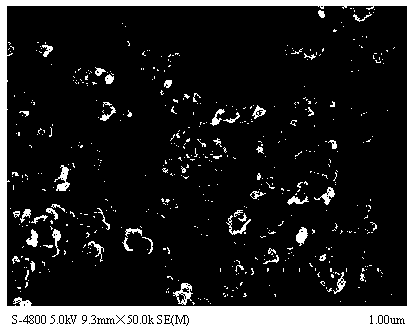

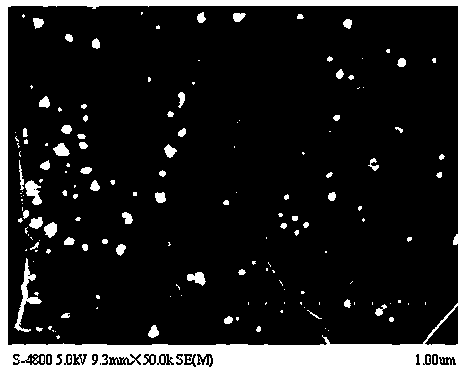

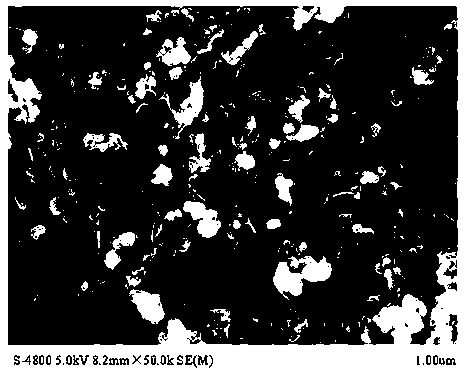

Image

Examples

Embodiment 1

[0034] TiO 2 - Preparation of GO / SPE:

[0035] Activation treatment of SPE: In the electrochemical workstation, the reference electrode of SPE is used as the reference electrode, the working electrode of SPE is used as the working electrode, and the counter electrode of SPE is used as the counter electrode. The 0.5 M sulfuric acid solution was scanned at a sweep speed for 10 cycles, and the activated electrode was left to dry at room temperature.

[0036] Weigh 5 mg of graphene oxide, add 30 mL of deionized water, and react in an ultrasonic reactor (setting frequency 125w) for 30 min until a tan solution is produced, add 40 mL of 0.04 mol / L TiF 4 solution, stirred, and the mixture was placed in a 150mL glass cup, sealed with parafilm and placed in an ultrasonic reactor in a water bath for 50 minutes to ensure better dispersion of the mixed solution. The obtained mixture was heated in an oven at 70°C for 6 hours, and then the mixture was Put it in a polytetrafluoroethylene au...

Embodiment 2

[0048] TiO 2 - Preparation of GO / SPE:

[0049] Activation treatment of SPE: In the electrochemical workstation, the reference electrode of SPE is used as the reference electrode, the working electrode of SPE is used as the working electrode, and the counter electrode of SPE is used as the counter electrode. Scan the 0.1 M nitric acid solution at a sweep speed for 1 cycle, and place the activated electrode at room temperature to dry.

[0050] Weigh 5 mg of graphene oxide, add 40 mL of deionized water, and react in an ultrasonic reactor (setting frequency 125w) for 30 min until a tan solution is produced, then add 55 mL of 0.02 mol / L TiF 4 Solution, stirred, and the mixture was placed in a 150mL glass cup, sealed with a parafilm and placed in an ultrasonic reactor in a water bath for 50min to ensure better dispersion of the mixed solution. The obtained mixture was heated in an oven at 80°C for 5h, and then the mixture Place in a polytetrafluoroethylene autoclave (30ml) with a ...

Embodiment 3

[0056] TiO 2 - Preparation of GO / SPE:

[0057] Activation treatment of SPE: In the electrochemical workstation, the reference electrode of SPE is used as the reference electrode, the working electrode of SPE is used as the working electrode, and the counter electrode of SPE is used as the counter electrode. The 1 M hydrochloric acid solution was scanned at a sweep speed for 20 cycles, and the activated electrode was left to dry at room temperature.

[0058] Weigh 5 mg of graphene oxide, add 50 mL of deionized water, and react in an ultrasonic reactor (setting frequency 125w) for 30 min until a tan solution is produced, then add 70 mL of 0.002 mol / L TiF 4 solution, stirred, and the mixture was placed in a 150mL glass cup, sealed with parafilm and placed in an ultrasonic reactor in a water bath for 50 minutes to ensure better dispersion of the mixed solution. The obtained mixture was heated in an oven at 90°C for 4 hours, and then the mixture was Put it in a polytetrafluoroeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com