Patents

Literature

44 results about "O-chlorophenol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Optical articles comprising isosorbide polyesters and method for making same

InactiveUS6126992AHigh light transmittanceEasy to copySynthetic resin layered productsPretreated surfacesPolyesterPolymer science

An optical article made of a transparent polymer which includes terephthaloyl moieties, optionally, other aromatic diacid moieties; ethylene glycol moieties; isosorbide moieties; and, optionally, one or more other diol moieties, wherein the polymer has an inherent viscosity of at least about 0.35 dL / g as measured on a 1% solution (weight / volume) in o-chlorophenol at 25 DEG C.

Owner:EI DU PONT DE NEMOURS & CO

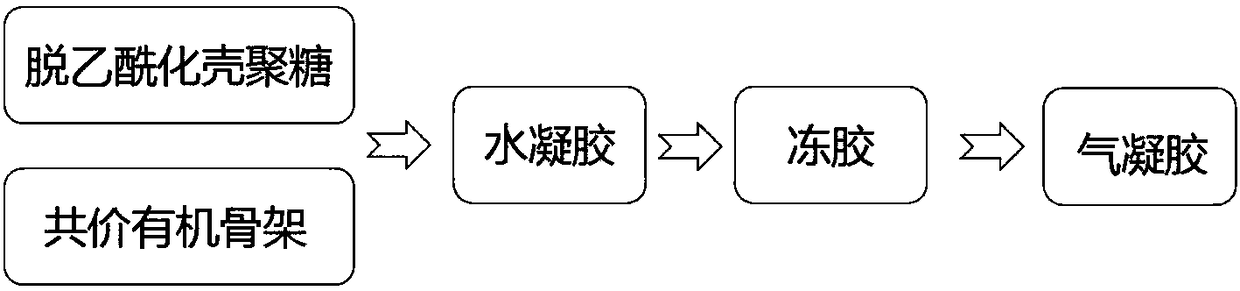

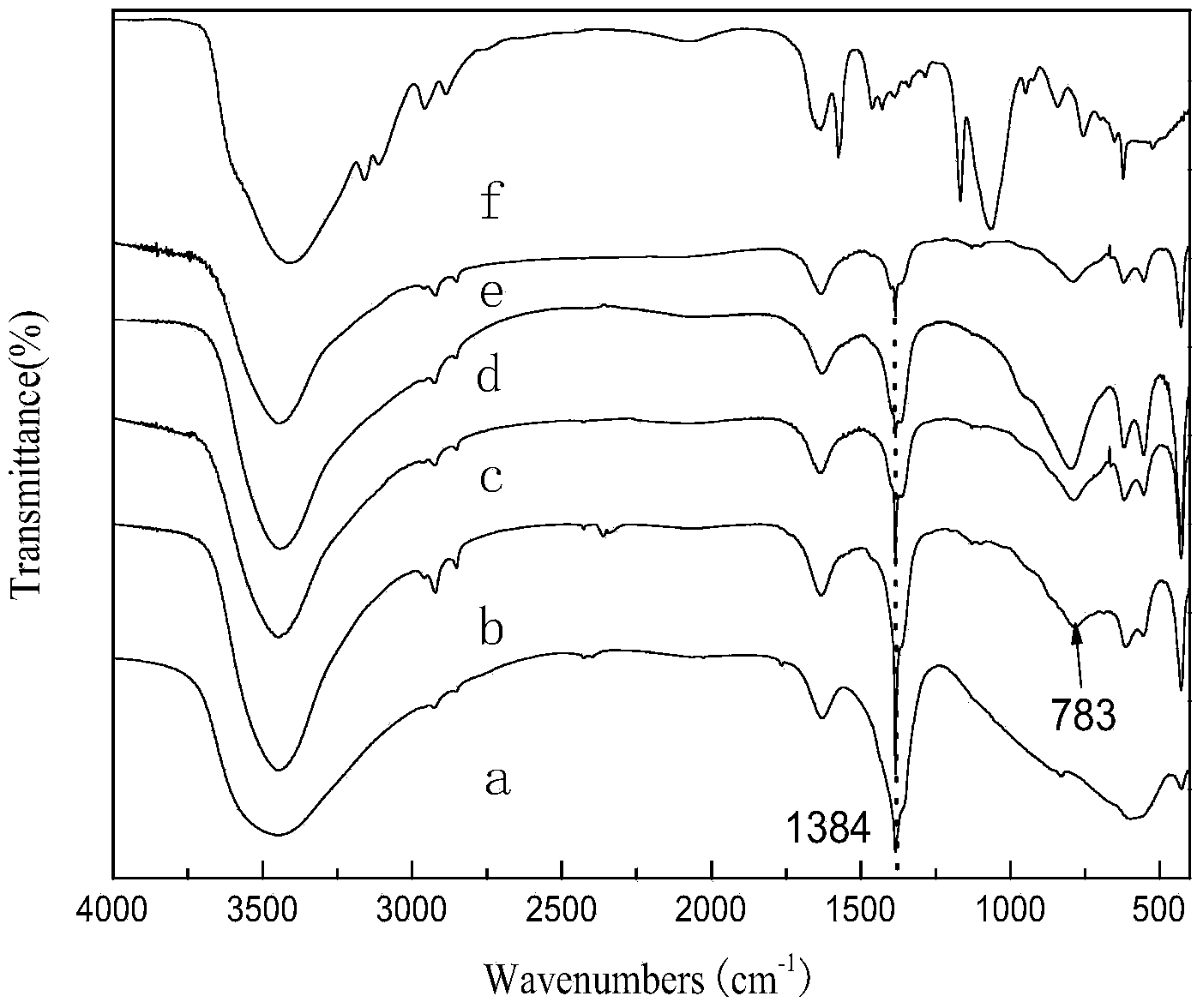

COF (covalent organic framework)-chitosan composite aerogel material supported with metal nanoparticles, preparation method and application

InactiveCN108355713ADeviceizationRealize functional integrationOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsP-ChlorophenolMetal particle

The invention relates to a COF (covalent organic framework)-chitosan composite aerogel material supported with metal nanoparticles and a preparation method of the composite aerogel material. The COF-chitosan composite aerogel material supported with metal nanoparticles is prepared from, in parts by weight, 0-2.16 parts of metal particles, 27.84-50 parts of a COF material and 50-70 parts of chitosan, wherein the content of the metal particles is not zero. Firstly, metal salt is supported in the COF material, metal salt is reduced, the palladium-supported COF material is obtained and then formsan aerogel material with chitosan; the COF material and chitosan are composited, and the composite aerogel material with stable structure and good property is prepared; device production of the COF material and function integration of the COF material and the device are realized; flowing type efficient catalysis of a dechlorination reaction of chlorine-containing aromatic compounds is realized through dechlorination reactions of p-chlorophenol, o-chlorophenol, m-chlorophenol and the like.

Owner:SHANDONG NORMAL UNIV

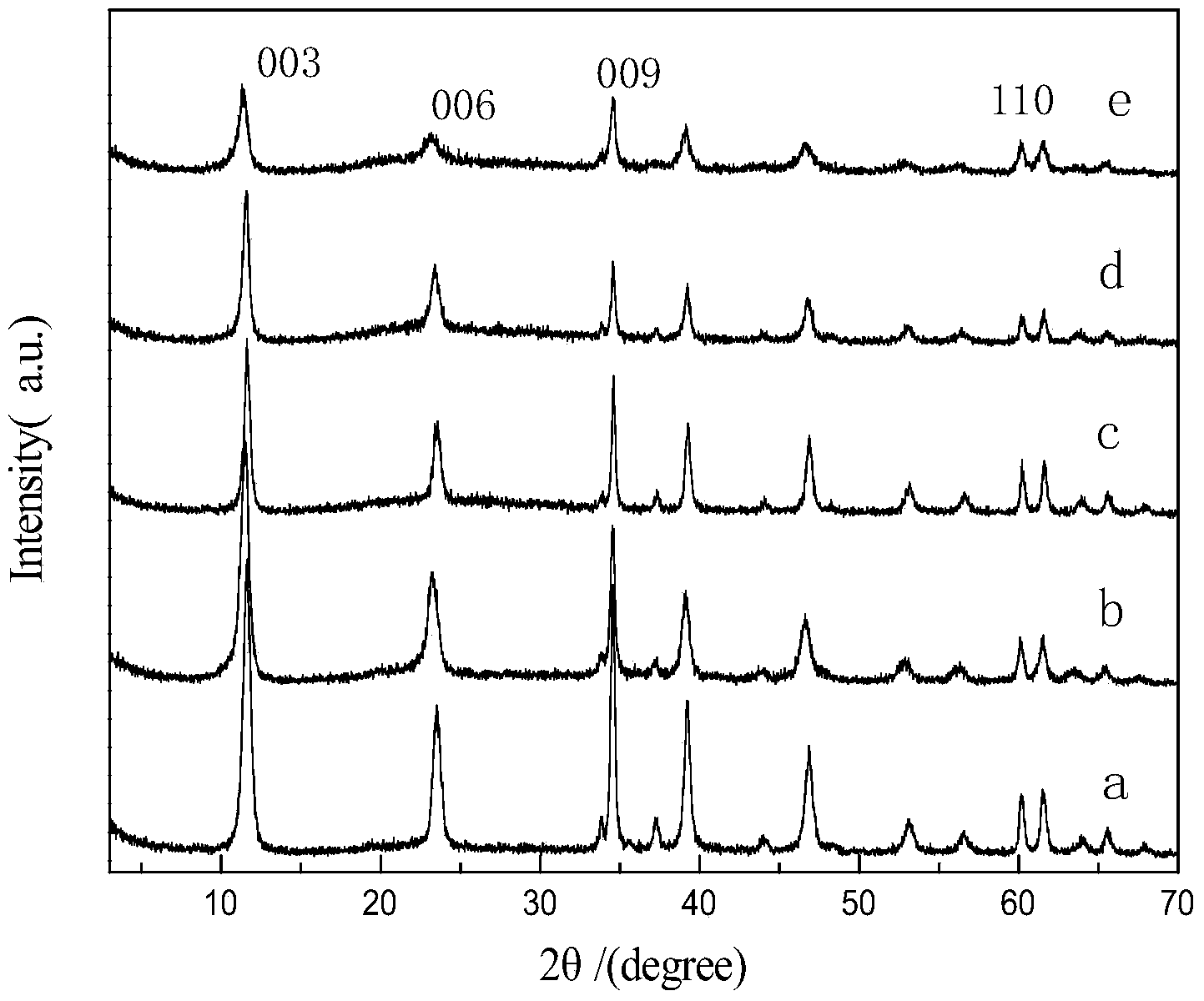

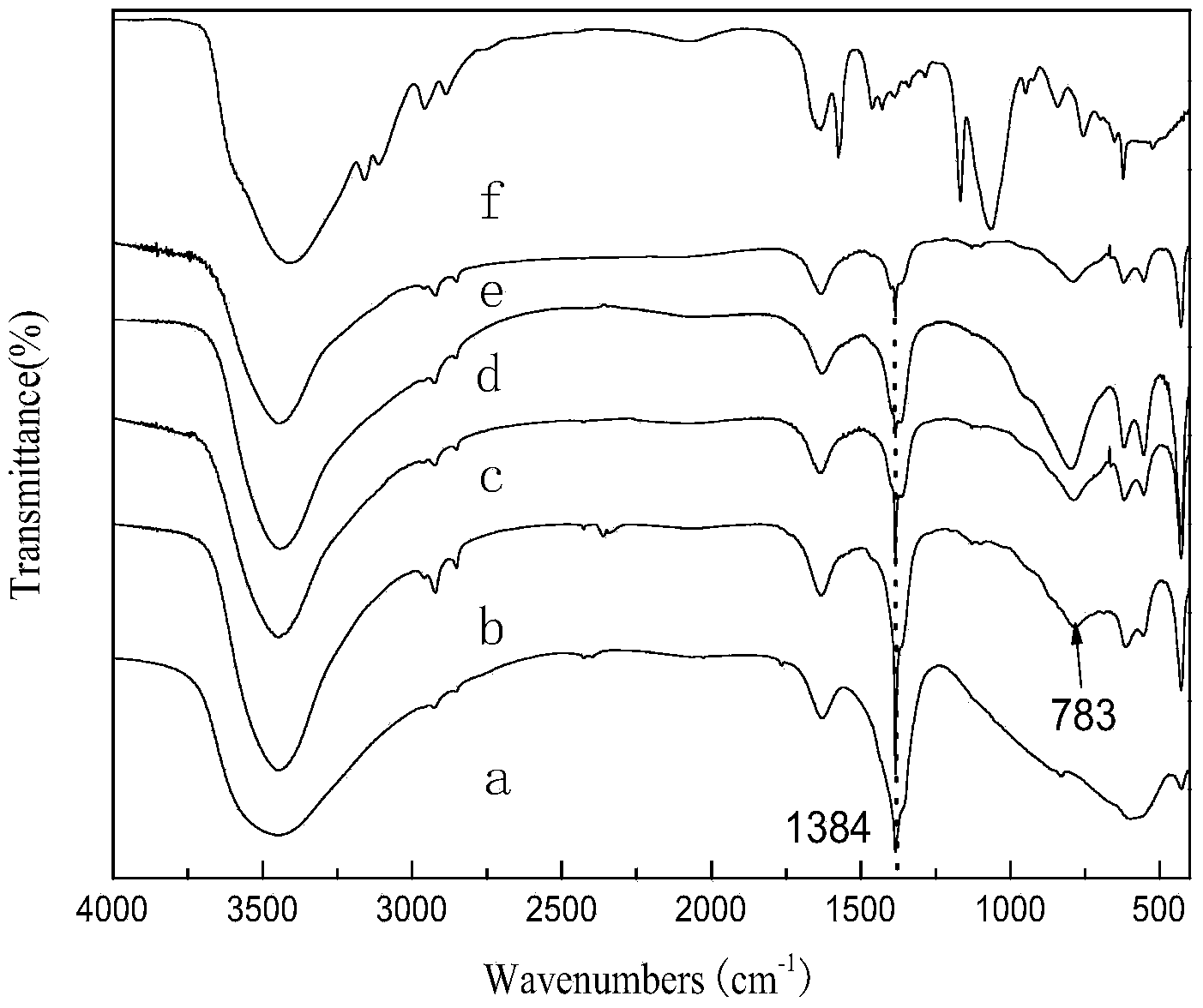

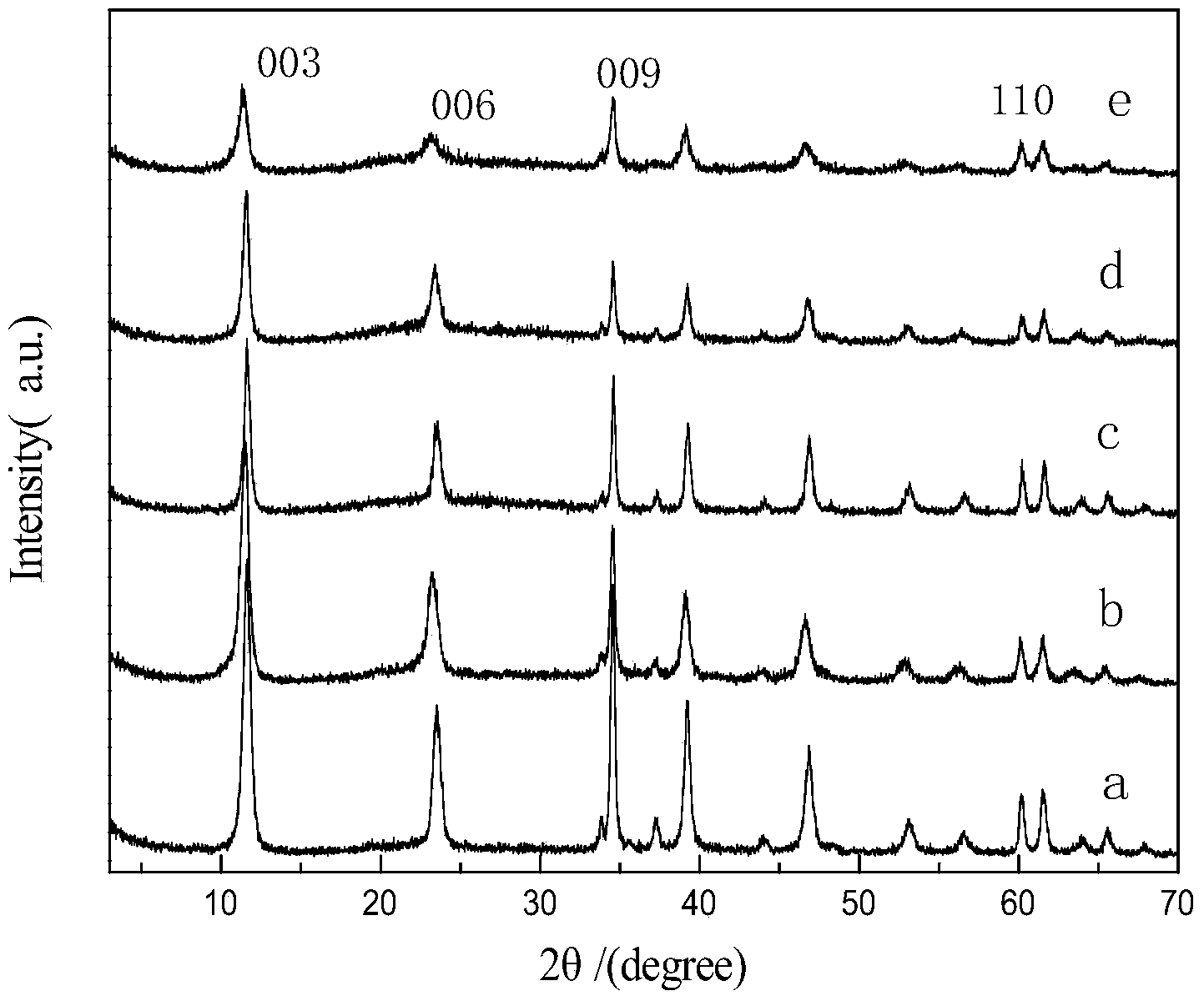

Amino functionalized ionic liquid/hydrotalcite-like compound composite material, and preparation method and application thereof

The invention discloses an amino functionalized ionic liquid / hydrotalcite-like compound composite material, and a preparation method and an application thereof. The preparation method comprises: firstly synthesizing an amino functionalized ionic liquid, then taking amino functionalized ionic liquid with different molar masses, employing a coprecipitation method to load the ionic liquid on the surface of the hydrotalcite-like compound, to prepare the amino functionalized ionic liquid / hydrotalcite-like compound composite material with a lamellar structure. The prepared organic-inorganic composite material has the structure and performance advantages of the functionalized ionic liquid and the hydrotalcite-like compound; the composite material, as an absorbent, shows good adsorption removal capability on pollutions such as o-chlorophenol , m-chlorophenol or p-chlorophenol in water, and has substantially better adsorptivity performance than the hydrotalcite-like compound; and the synergy advantage of the amino functionalized ionic liquid and the hydrotalcite-like compound is given a full play.

Owner:日照经济技术开发区客商服务有限公司

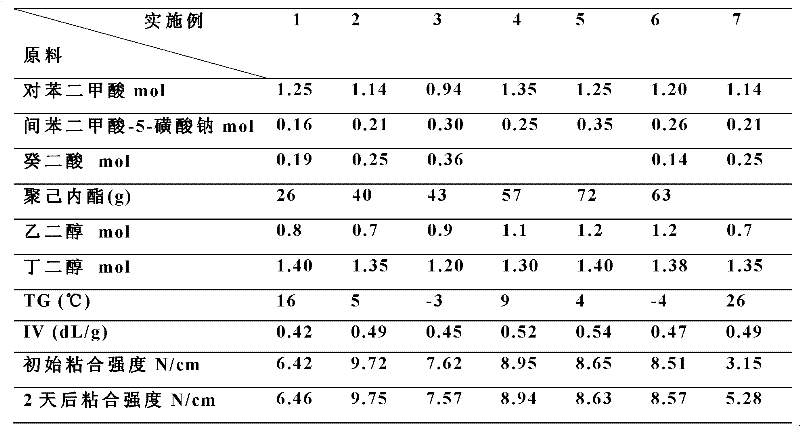

Aqueous copolyester hot melt adhesive and preparation method thereof

InactiveCN102250576AGood water solubilityHigh crystallinityAdhesivesPolymer scienceWater dispersible

The invention discloses an aqueous copolyester hot melt adhesive, which is characterized in that: the adhesive is prepared by using dicarboxylic acid / dicarboxylic acid ester, m-benzene sulfonate and diol as raw materials and by first performing esterification or ester exchange and then adding polycaprolactone to perform polycondensation, wherein the glass transition temperature of the water soluble copolyester is between -10 and 20 DEG C; and at 35 DEG C, o-chlorophenol is used as a solvent, and the inherent viscosity of the copolyester is not less than 0.25 dL / g. The obtained adhesive has high water dispersibility, can crystallize and cure quickly and is environment-friendly.

Owner:苏州瀚海化学有限公司

Preparation process of 2,4-dichlorophenol

InactiveCN106349025AHas a positioning effectIncrease contentOrganic chemistryOrganic compound preparationChlorinated phenolsEthyl Chloride

The invention discloses a preparation process of 2,4-dichlorophenol. The preparation process comprises the following steps: chloridizing phenol or o-chlorophenol serving as a raw material and a mixture which is prepared from boric acid, phenyl sulfide and ferric trichloride and serves as a catalyst to generate a 2,4-dichlorophen coarse product, and rectifying the coarse product to obtain a target product. The mixed catalyst used in the reaction has a positioning effect, so that the content of p-chlorophenol in a chlorinated phenols mixture generated by the reaction is greater than 65 percent, the content of the 2,4-dichlorophenol in di-chlorophenol generated in the reaction is greater than 95 percent, the number of di-chlorophenol impurities generated in the reaction is reduced, and the 2,4-dichlorophenol with the content greater than 99.5 percent and the total yield of 95 percent or above can be obtained by rectification treatment; furthermore, the reaction yield is greatly increased, and the yield of the p-chlorophenol is also increased.

Owner:LIANYUNGANG ZHICHENG CHEM

Polyester film and methods for making same

A polyester film made from a polymer having ethylene glycol moieties, isosorbide moieties and terephthalnoyl moieties, and the method of making the film is described. The polyester film is used to form articles such as films, lacquers, labels, capacitors, insulators, and the like, and has an inherent viscosity of at least 0.35 dL / g when measured as a 1 % (weight / volume) solution of the polyester in o-chlorophenol at a temperature of 25 DEG C.

Owner:EI DU PONT DE NEMOURS & CO

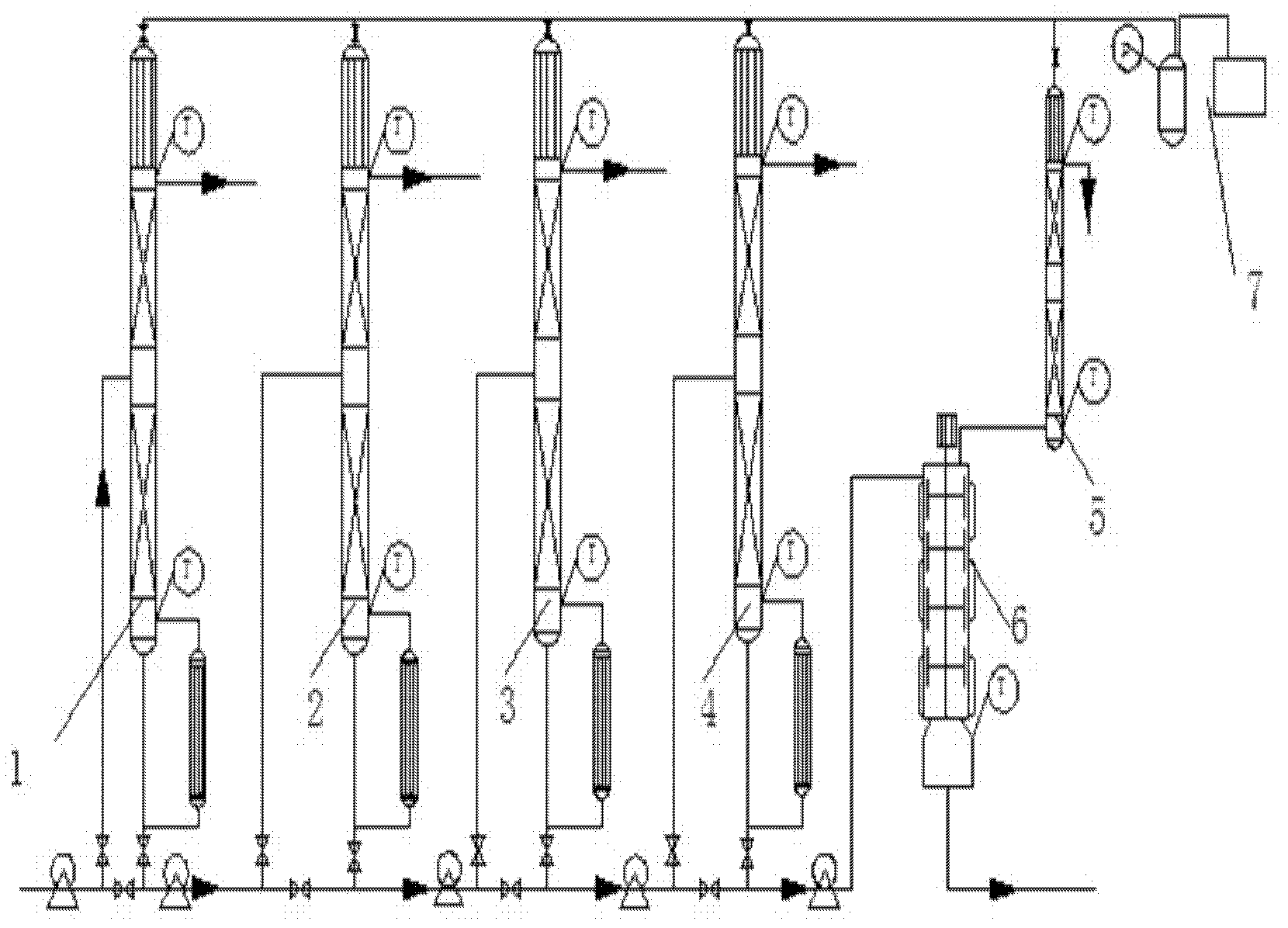

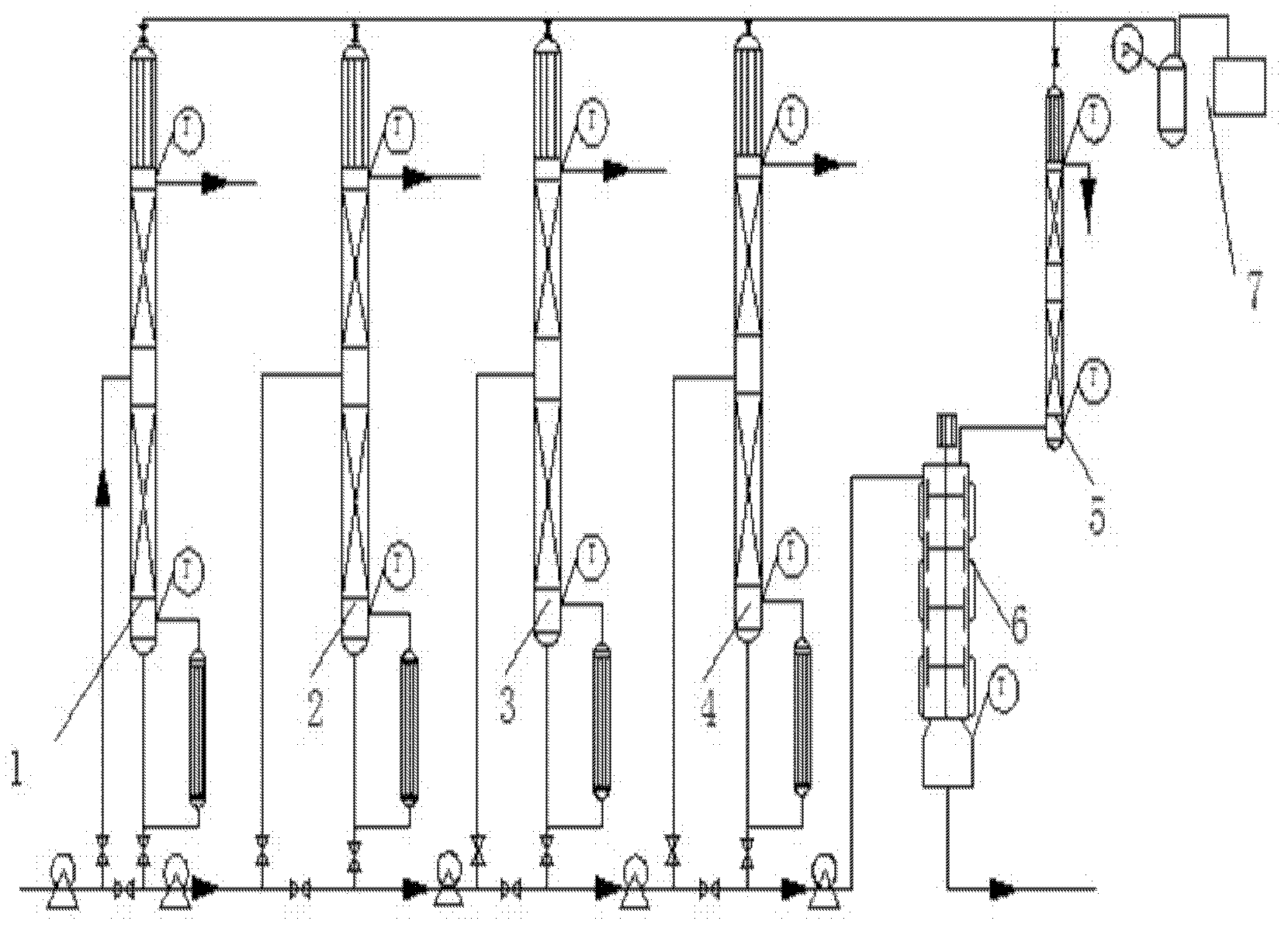

Method for separating chloro phenol reaction solution

InactiveCN102584542AIncrease productionEasy to separateOrganic chemistryOrganic compound preparationPhenolChemistry

A method for a separating chloro phenol reaction solution comprises the specific steps of: enabling the chloro phenol reaction solution (the chloro phenol reaction solution is prepared by phenol and chlorine and comprises such all or part of the main components as phenol, o-chlorophenol, p-chlorophenol, 2,4-dichlorophenol, 2,6-dichlorophenol, 2,4,6-trichlorophenol and a small amount of tar) to continuously flow through a tower 1, a tower 2, a tower 3, a tower 4, a detar device (scraper film evaporator 6) and a tower 5, and controlling the temperatures of tower tops and tower bottoms of rectifying towers according to the different boiling points of the components of the reaction solution so as to separate the components from the tower tops. According to the method, the production capacity is large, the separation effect is excellent, the energy consumption is low, and the chloro phenol reaction solution is applicable to large-scale production.

Owner:JIANGSU HONGYUAN CHEM

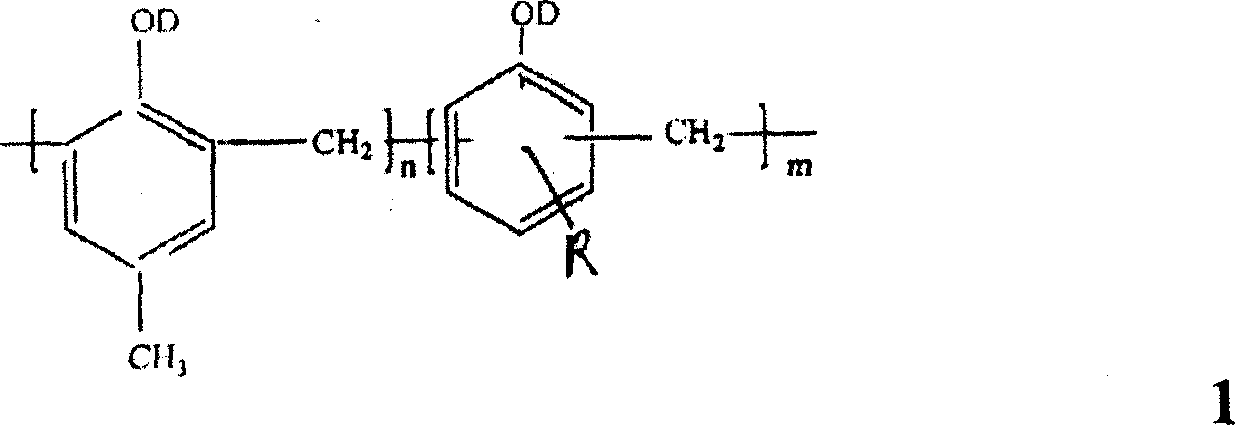

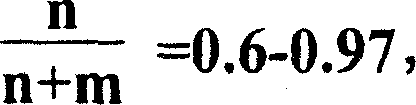

Positive photoresist consumed reactive compound and light sensitive complexes thereof

ActiveCN101158813AIncreased sensitivityImprove development latitudePhotomechanical apparatusSolventPolyphenol

The present invention relates to light-activated compound indicated in below formula 1, wherein, each substituent and symbols are defined by a specification. The light-activated compound of the present invention is obtained from products by reaction and subsequently separation between 2, 1, 4-diazo naphthoquinone sulfonyl chlorine and Ballast in solvent when catalyst exists. The selection of the Ballast is mainly cresol and contains linear phenol resin or polyphenol compound formed by the condensation of at least one of phenol, o-cresol, m-cresol, o-chlorophenol or inter-chlorophenol and formaldehyde. Wherein, the content of the formaldehyde is 60 percent to 97 mol percent and the content of other phenol is 3 percent to 40 mol percent. A PS plate formed by coating of a photosensitive complex prepared by the light-activated compound of the present invention has excellent performance of plate making and imaging, and has better sensitivity and development latitude compared with the traditional PS plate. The light-activated compound of the present invention has favorable matching performance with the linear phenol resin of home and abroad renowned resin manufactures besides having the favorable matching performance with the nine kinds of film forming linear phenol resin of industrialized BTB-21-BTB-29.

Owner:LUCKY HUAGUANG GRAPHICS

Synthesis process for o-chlorobenzaldehyde

InactiveCN106977381AControl generationLow costCarbonyl compound preparation by hydrolysisHalogenated hydrocarbon preparationDistillationReaction temperature

The invention discloses a synthesis process of o-chlorobenzaldehyde. The synthesis process of o-chlorobenzaldehyde comprises the following steps: feeding chlorine in o-chlorotoluene, carrying out catalytic chlorination under the condition of illumination to obtain chlorination liquid, wherein the ratio of the amount of the chlorine to the amount of the o-chlorotoluene is 2-4: 1, the reaction time is 1-2 hours, and the reaction temperature is 100-120 DEG C; distilling the chlorination liquid under reduced pressure, and separating out chlorobenzyl chloride and the o-chlorotoluene to obtain mixed liquid of o-chlorobenzyl dichloride and o-chlorobenzyl trichloride; carrying out hydrolysis reaction on the mixed liquid by using ferric chloride and zinc chloride as catalysts to obtain hydrolysate, wherein the temperature of hydrolysis reaction is 100-120 DEG C, a solvent is water, and the reaction time is 1.5-3 h; and carrying out rectification and purification on the hydrolysate in a vacuum state to obtain o-chlorobenzaldehyde. According to the technical scheme, the cost is further reduced, and the quality of the product is improved. Reasonable catalytic conditions are adopted, the synthesis process is a perfect greening technological synthesis method, generation of by-products is controlled effectively, and the quality of the product is improved further.

Owner:NANJING COLLEGE OF INFORMATION TECH

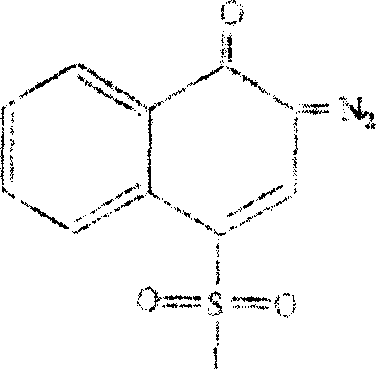

Filtering material and preparation method thereof

ActiveCN102974169ARich varietyIncrease productionOther chemical processesFiltration separationFiberBrute force

The invention discloses a filtering material and a preparation method thereof. The preparation method comprises the following steps of: placing a double-component island fiber into emulsion formed by mixing o-chlorophenol, a surfactant and water; treating under an oscillation condition; washing by pure water; and after carrying out tentering, drying and hot-rolling treatment to obtain the filtering material. An emulsion treating technology is used for completely splitting the island fiber and the specific surface area is enlarged; and an obtained superfine fiber textile has excellent adsorption and separation function, and filtering effect. Compared with a melt-blown non-woven fabric, the island double-component fiber has the advantages of multiple varieties of fibers, large output, developed production process, great brute force and the like; and the filtering material can be applied to an ultra-cleaning filtering and cleaning field and has a popularization and application prospect.

Owner:嘉善泰力蜂窝制品有限公司

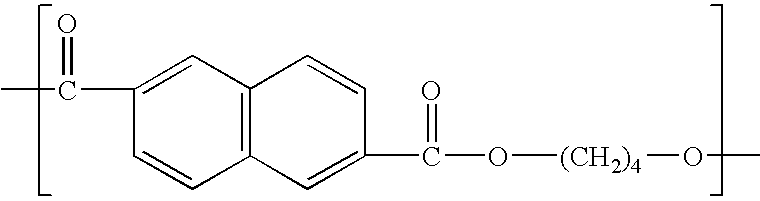

Polybutylene naphthalate filtration media

InactiveUS20070232174A1Easy to processImprove featuresPaper/cardboard layered productsMembrane filtersFiberPolybutylene

This invention is based upon the discovery that polybutylene naphthalate resin (PBN) having an intrinsic viscosity which is within the range of 0.3 to 0.7 dl / g can be easily processed into a nonwoven web of meltblown or spunbond fibers that exhibit excellent characteristics for utilization in making filtration media, such as strength, durability and filtration efficiency. Additionally, such a nonwoven web of meltblown or spunbond fibers offers outstanding resistance to organic liquids, such as gasoline, gasohol, kerosene, diesel fuel, jet fuel, motor oil and the like. Filtration media manufactured utilizing such polybutylene naphthalate also offers excellent heat resistance, chemical resistance, acid resistance, and alkali resistance. The present invention more specifically discloses a filtration media that is comprised of a nonwoven web of fibers having an average diameter which is within the range of about 0.5 microns to about 35 microns, wherein the fibers are comprised of polybutylene naphthalate having an intrinsic viscosity which is within the range of 0.3 to 0.7 dl / g as measured in o-chlorophenol at 35° C.

Owner:TICONA LLC

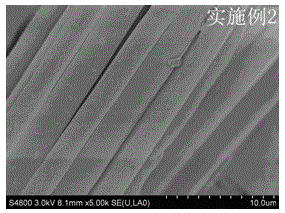

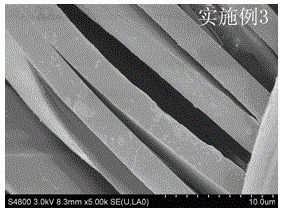

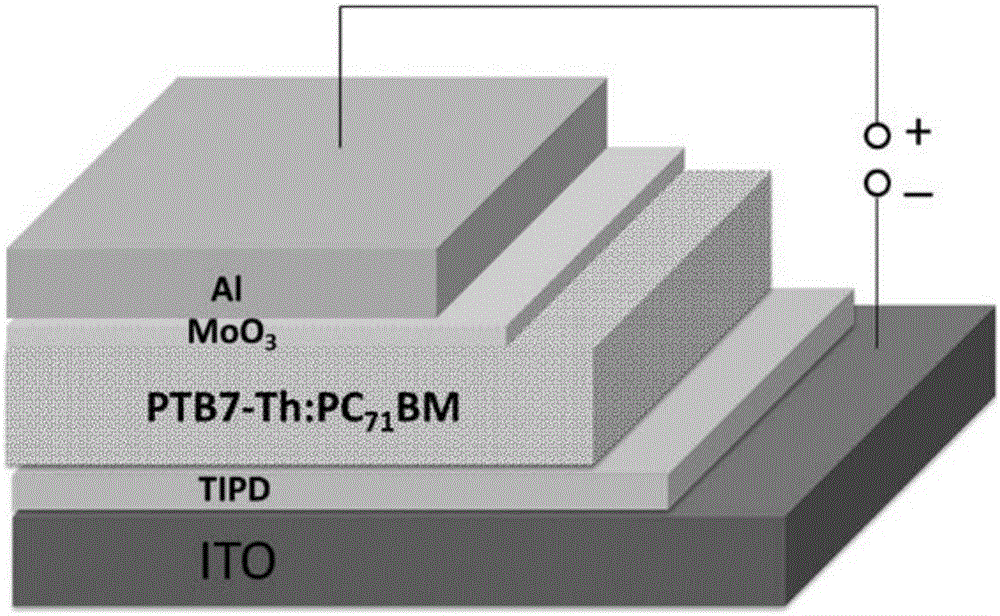

Polymer film and preparation method and application thereof

InactiveCN106410033AImprove conversion efficiencyImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingPolymer sciencePolymer thin films

The invention discloses a polymer film and a preparation method and application thereof and belongs to the technical field of a polymer solar battery. According to the polymer film, the method and the application, through utilization of a feature that chlorophenol selectively dissolves receptors: fullerene derivative and does not dissolve donors: polymer, postprocessing is carried out on conjugated polymer-fullerene derivative blended film by employing o-chlorophenol alcoholic solution, thereby preparing the polymer film with adjustable receptor vertical concentration distribution. After the prepared blended film is applied to a reverse polymer battery, a structure that donors are gathered at an anode side and the receptors are gathered at a cathode side is formed, and relatively independent electron and hole transfer channels are formed in an active layer. Separation of excitons and transfer of charge carriers are effectively improved, thereby clearly improving the short circuit current and conversion efficiency of the battery. The battery with a reverse structure has better stability. Moreover, the polymer film, the method and application have the advantages of simple preparation technology, easy operation, low cost and high repeatability.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method for preparing 2,5-dichlorophenol.

ActiveCN105272828ALow costPromote escapeOrganic chemistryOrganic compound preparationDichlorophenolO-chlorophenol

The invention discloses a method for preparing 2,5-dichlorophenol. In the method, o-chlorophenol is employed as a raw material, a composite catalyst is employed, acidic materials are utilized to protect hydroxys, and then chlorination and hydrolysis are carried out. When the new method for preparing 2,5-dichlorophenol is compared with present production methods in the market, the raw material cost is lower, operation is safer and simpler, the provided method is more friendly to the environment, three wastes (waste gas, waste water and industrial residue) are smaller, the yield is higher, the provided method is suitable for industrial production, and the product quality meets international standards.

Owner:兰州诚胜化工科技有限公司

Preparation process of high-purity p-chlorophenol

ActiveCN108101750AImprove conversion rateHigh yieldOrganic chemistryOrganic compound preparationP-ChlorophenolLiquid state

The invention provides a preparation process of high-purity p-chlorophenol, which includes the steps of: 1) chlorination: heating phenol as a raw material to liquid state, quantitatively pressure-feeding the phenol to an enamel reaction kettle via a pump, feeding chlorine under a normal pressure in a manner of firstly high speed and then low speed to perform the chlorination reaction for 32-38 h,thus producing chlorophenol; 2) rectification: cooling the chlorophenol to 55-60 DEG C and adding a composite extraction agent, uniformly stirring the mixture, and feeding the mixture into a rectification column to perform vacuum distillation, wherein firstly reflux is carried out under vapor pressure of 0.3-0.35 MPa for 3-3.5 h, and then sampling analysis is carried out under the vacuum degree of-0.096 - 0.098 MPa and at temperature of 68-73 DEG C, and receiving o-chlorophenol; 3) regulating the temperature to 115-120 DEG C and vapor pressure to 0.55 MPa, and performing sampling analysis andreceiving p-chlorophenol. In the method, reasonable technical modification is carried out so as to significantly improve conversion rate and yield of the chlorophenol. The method is good separation effect and can reach 99.4% in purities of both the p-chlorophenol and o-chlorophenol. The products have good comprehensive quality. The method is suitable for industrial production.

Owner:HUAIHAI INST OF TECH +1

Polyester resin for weather resistant outdoor waterborne paint and preparation method thereof

ActiveCN106854275AKeep water solubleMaintain paint film propertiesPolyester coatingsEquivalence ratioReaction temperature

The invention provides a preparation method of a polyester resin for weather resistant outdoor waterborne paint. The method includes: firstly taking dicarboxylic acid or its ester and diol as the raw materials, and adding a catalyst to carry out reaction, with the equivalence ratio of alcohol acid reaction being (1.1-2.0):1; in an inert atmosphere, carrying out heat and pressure preservation reaction until the by-product collection amount is greater than a theoretical value by 95%, and controlling the reaction temperature at 180-270DEG C and the pressure at 1-1.5MPa; within 0.5-1h, lowering the pressure to normal pressure, adding a polycondensation catalyst and a stabilizer to carry out polycondensation reaction at a temperature of 210-290DEG C and under a pressure below 500Pa for 1-6h; introducing inert gas to ordinary pressure, and subjecting the melt to extrusion cooling so as to obtain the polyester for weather resistant outdoor waterborne paint. DSC testing finds that the glass transition temperature of the polyester resin for weather resistant outdoor waterborne paint is 20-70DEG C; at a temperature of 35DEG C, o-chlorophenol is solvent, and the inherent viscosity is 0.30-0.70 dL / g; and by means of the hydrophilcity of sulfonate, the polyester resin can be uniformly dispersed in water to form a clear and transparent solution, and the maximum solid content in water can be up to 35%.

Owner:中瀚新材料科技有限公司

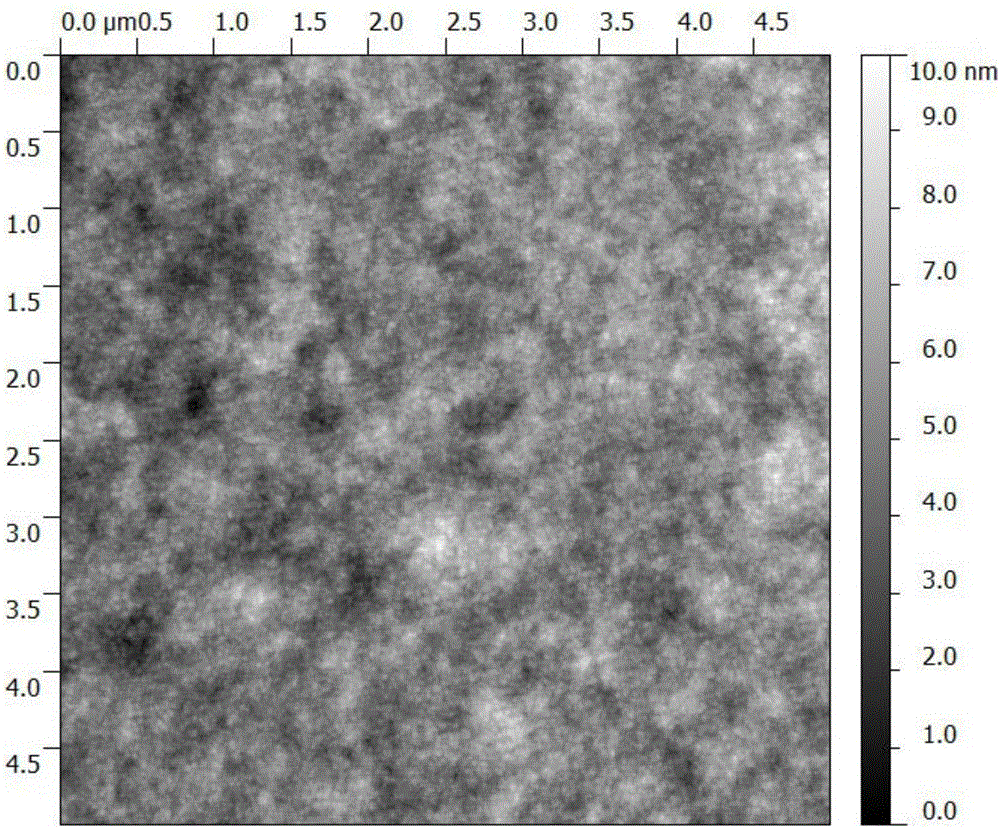

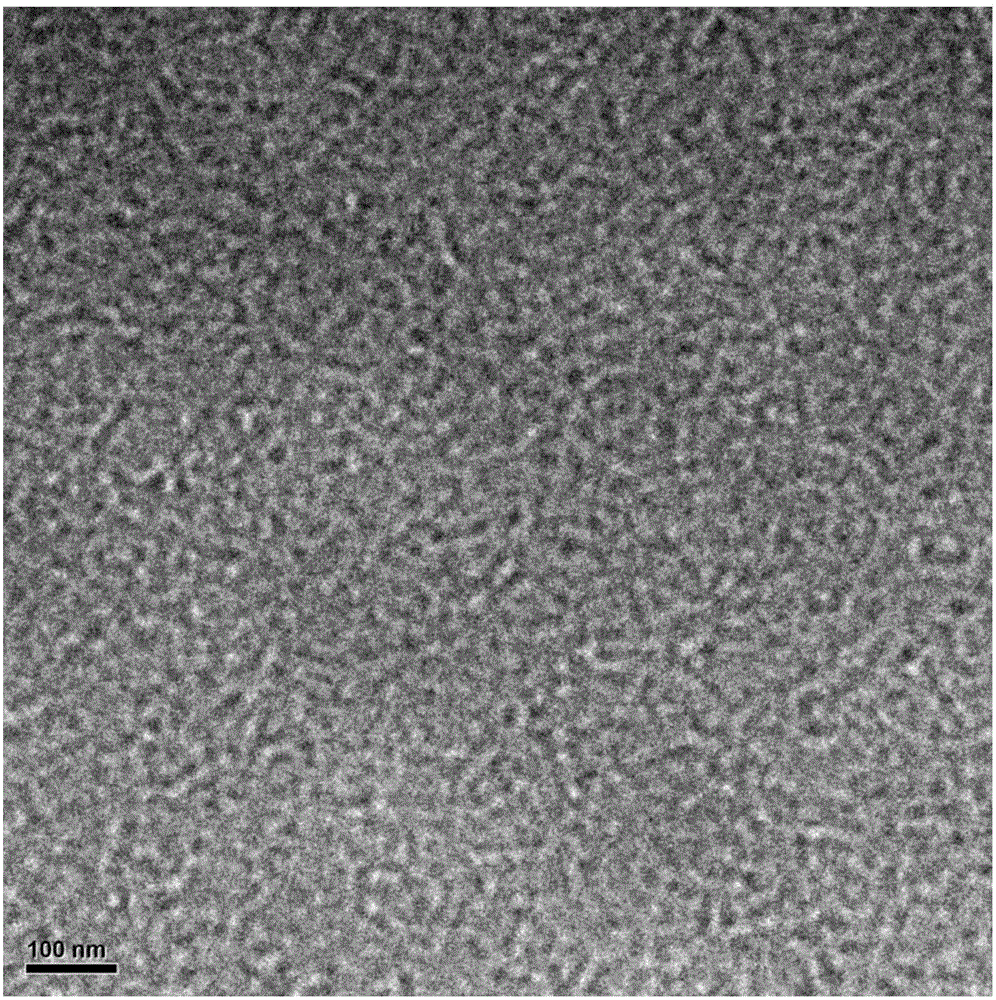

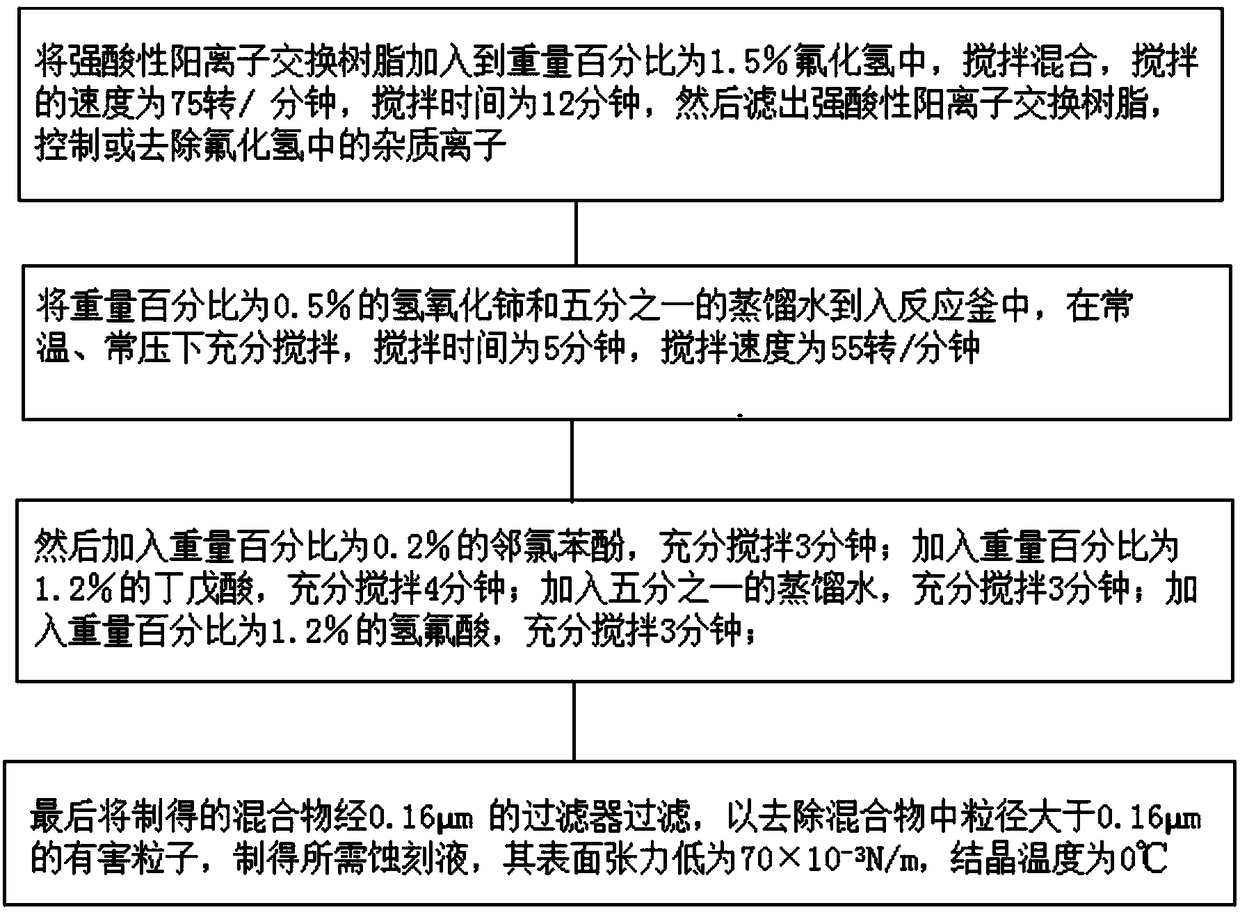

Preparation method for etching liquid for thin film transistor

The invention discloses a preparation method for etching liquid for a thin film transistor. The etching liquid comprises the following compositions in percentage by weight: 0.5%-2.3% of cerium hydroxide, 0.2%-1.8% of o-chlorophenol, 1.2%-2.6% of isobutylglutaric acid, 1.2%-2.6% of hydrofluoric acid, 1.5%-2.3% of hydrogen fluoride, 2.5%-3.3% of a nonionic surfactant, 1.5%-2.6% of a de-foaming agentand the balance of distilled water. Cerium hydroxide, o-chlorophenol, isobutylglutaric acid, hydrofluoric acid and hydrogen fluoride are added on the basis of the original process, so that etching can be performed when penetration of an anti-corrosion coating does not occur, and etching speed of a chromium metal film is remarkably increased, and therefore, the preparation method has controllableetching speed, effectively inhibits degradation of an anti-corrosion protective layer, obtains a chromium metal film assembly line with a flat and smooth surface, and has an important application value.

Owner:佛山杰致信息科技有限公司

Preparation method of 2-chloro-4-bromophonel with high purity

ActiveCN103387484AHigh purityIncrease surface areaOrganic chemistryPhysical/chemical process catalystsCopper chlorideO-chlorophenol

The invention discloses a preparation method of 2-chloro-4-bromophonel with high purity. The preparation method comprises the following steps of mixing and uniformly stirring o-chlorophenol and a locating nanocatalyst, meanwhile, cooling, and adding Br2 to carry out bromination reaction to obtain a product, wherein the locating nanocatalyst is hydrochloride of a transition element. The locating nanocatalyst is a mixture of copper chloride, zinc chloride and silver chloride with the mass ratio of (1-3): (1-8): (1-2). The locating nanocatalyst is used in the preparation method of the 2-chloro-4-bromophonel, so that the purity of the obtained 2-chloro-4-bromophonel is increased from 94% to 97.5%, fewer byproducts are generated, and the yield is very high and can be up to over 97%.

Owner:山东科源化工有限公司

Tower-type continuous chlorination technical process for producing p-chlorophenol

ActiveCN109096057AIncrease conversion rateReduce generationOrganic chemistryOrganic compound preparationDistillationReaction temperature

The invention relates to the field of special environment-friendly coatings, in particular to a tower-type continuous chlorination technical process for producing p-chlorophenol. The process comprisesthe following steps: (1) chlorination: phenol and chlorine in a mole ratio being 1:1-1:1.2 are fed backwards continuously, reaction temperature is 60-100 DEG C, multi-stage continuous chlorination reaction is performed by a tower reactor under normal pressure, and a chlorophenol mixture is obtained and transferred to a chlorophenol receiver; (2) distillation: chlorophenol is transferred to a distillation tower from the receiver for reduced pressure distillation, and fraction o-chlorophenol at 174-176 DEG C, 2,4-dichlorophenol at 208-210 DEG C and p-chlorophenol at 216-218 DEG C are obtained respectively. Reaction selectivity can be improved effectively, generation of byproducts is reduced, and conversion rate of p-chlorophenol is increased effectively.

Owner:浙江新恒贸实业有限公司

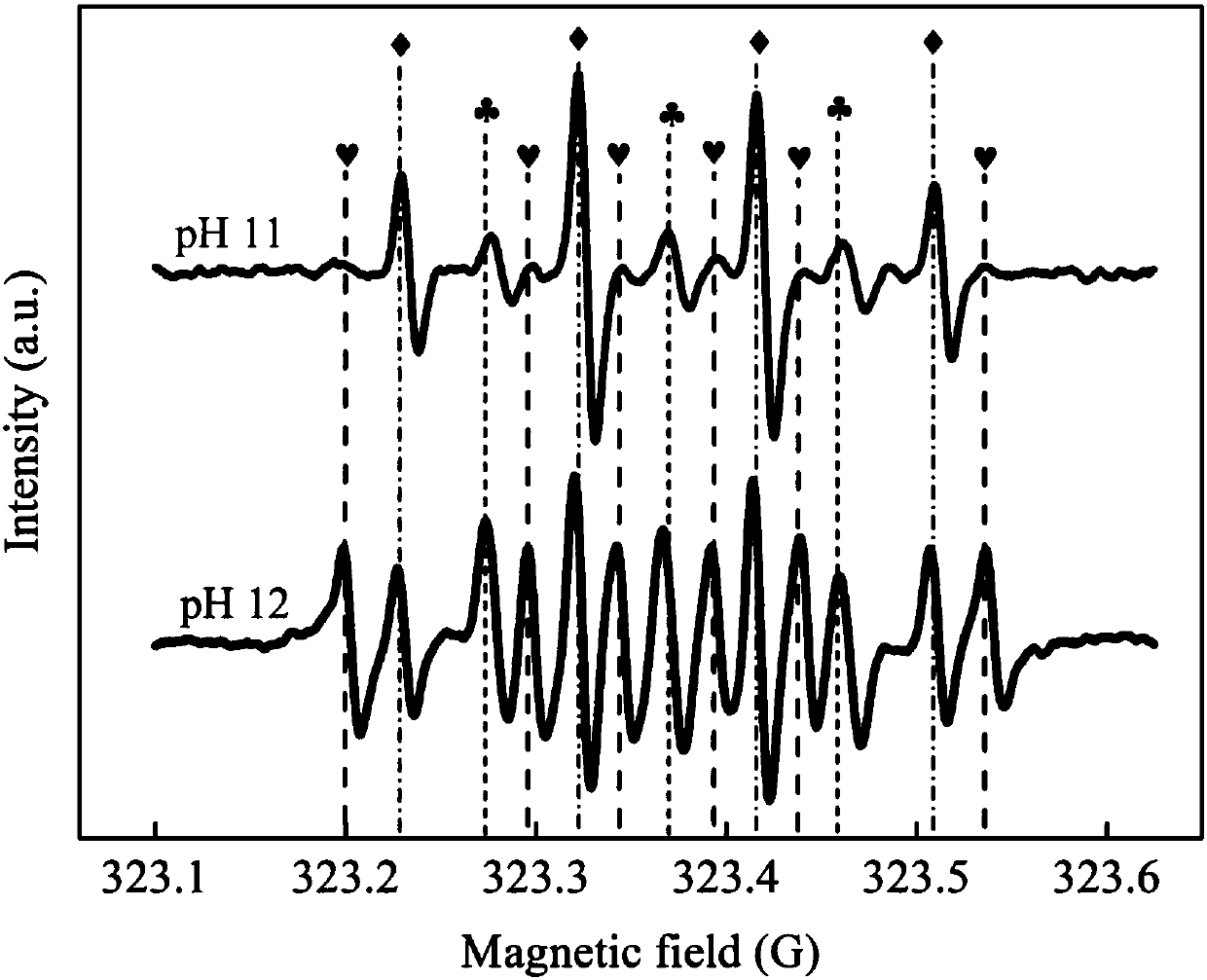

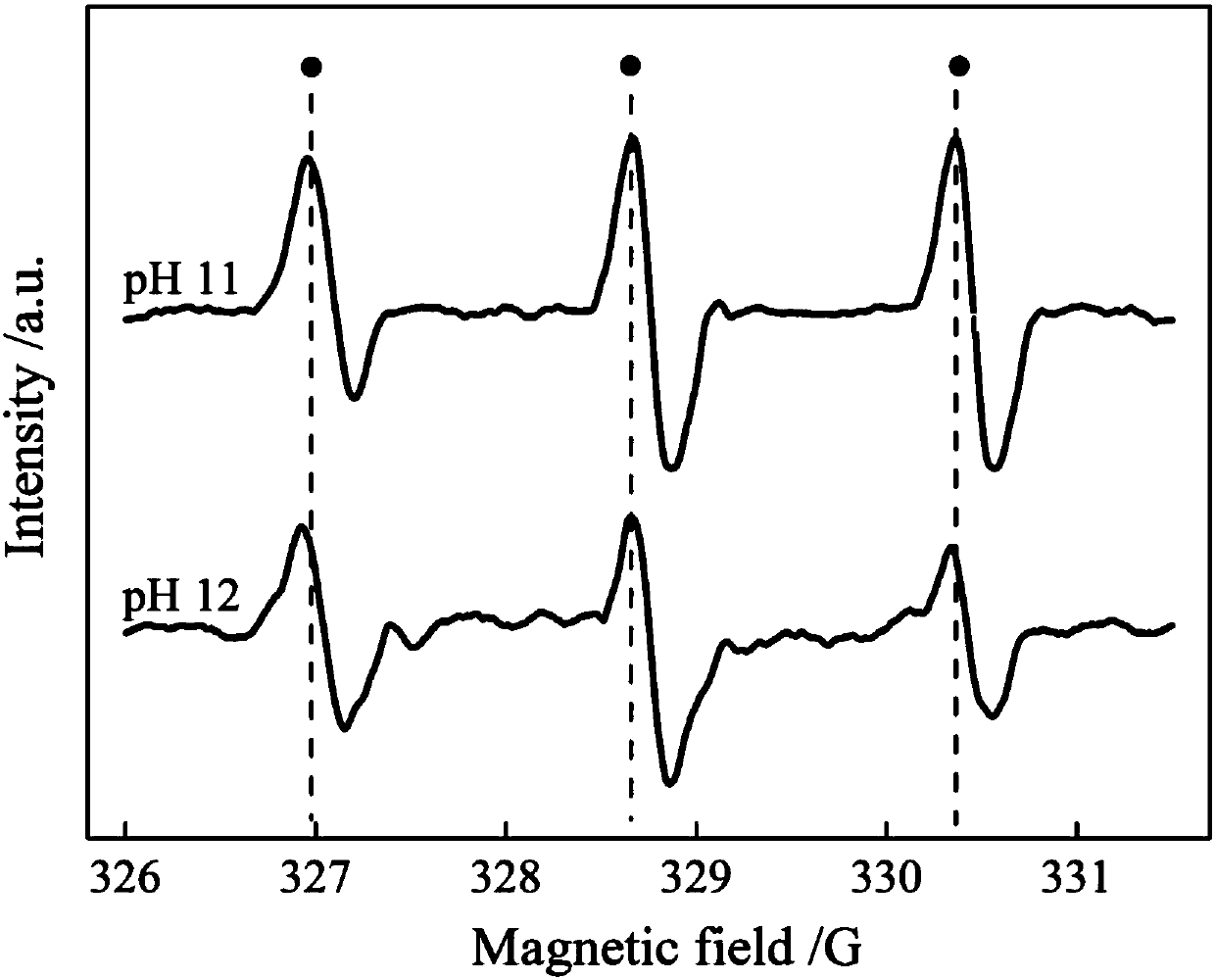

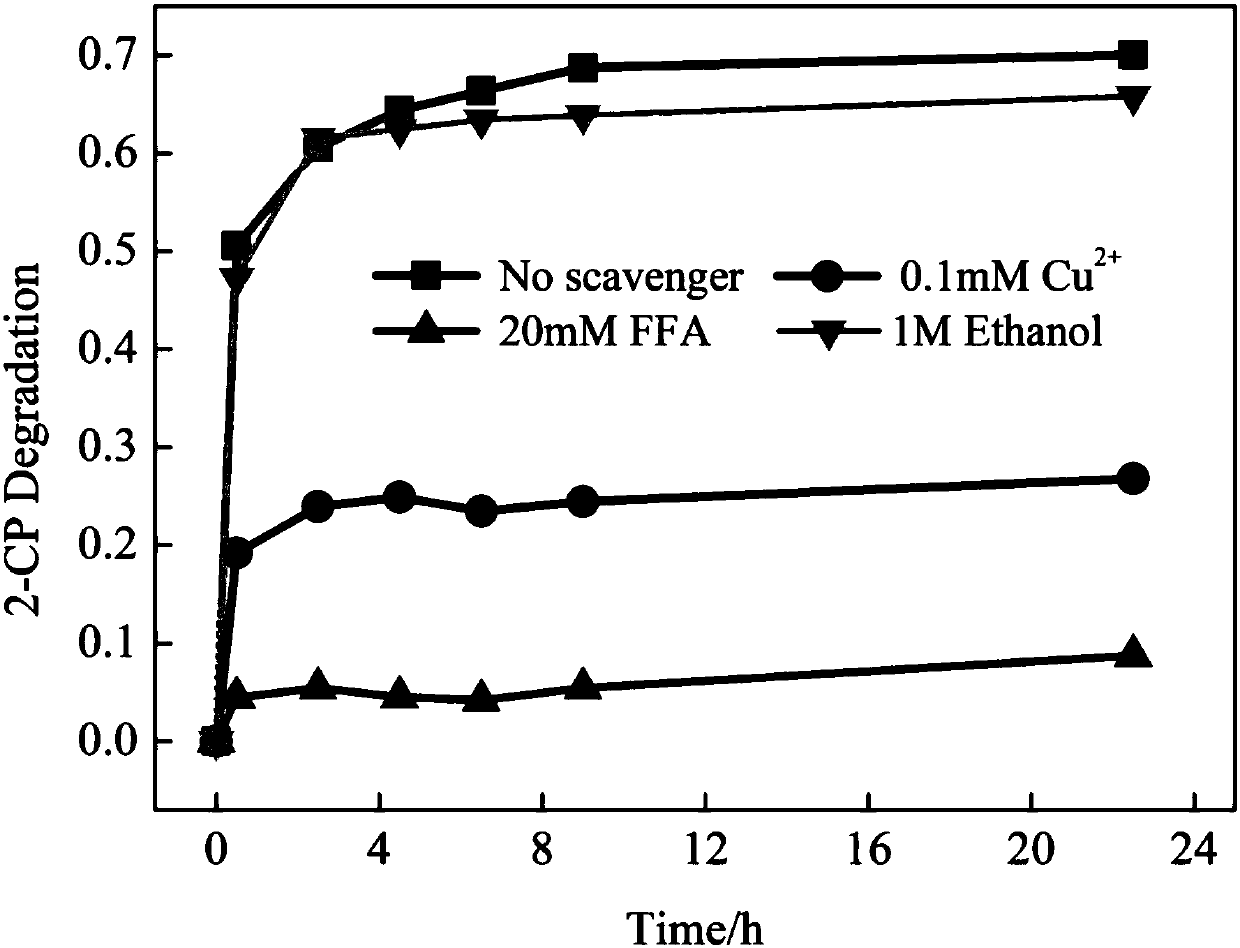

Method for selective oxidation of o-chlorophenol in alkaline wastewater

InactiveCN107902743AAvoid uniform processingWater contaminantsWater/sewage treatment by oxidationWater bathsPhenol

The invention relates to a method for selective oxidation of o-chlorophenol in alkaline wastewater. The method comprises the following steps: weighing solid Na<2>MoO<4>.2H<2>O, dissolving the solid indistilled water to prepare a Na<2>MoO<4> stock solution with a concentration of 0.25 to 0.5 M; transferring the liquid medicine o-chlorophenol with a pipette gun to prepare an o-chlorophenol stock solution with a concentration of 1-2 g / L; adding distilled water into the Na<2>MoO<4> stock solution for dilution and pH value regulation so as to obtain an alkaline solution a; adding the o-chlorophenol stock solution into distilled water until a final concentration is 100 mg / L and regulating the pH value of the obtained solution so as to obtain an alkaline solution b; mixing the solution a with the solution b, keeping the obtained mixture in a dark place so as to allow a reaction to be carried out under dark reaction conditions, adding a hydrogen peroxide solution, and placing the obtained reaction system in a water-bath pot with a temperature of 30 DEG C and a rotation speed of 150 r / min; and reacting molybdate with hydrogen peroxide under alkaline conditions to produce <1>O<2> and O<2><.-> oxidation materials, and the produced <1>O<2> and O<2><.-> have good degradation effect and oxidation selectivity on o-chlorophenol.

Owner:TIANJIN UNIV

Method for synthesizing m-diethylaminophenol

PendingCN112142607AShort production timeEasy to operateOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsXylyleneM-aminophenol

The invention provides a method for synthesizing m-diethylaminophenol. The method comprises the following steps: mixing potassium hydroxide and magnesium oxide, and calcining at 700-800 DEG C to obtain a solid super base catalyst; adding sodium amide and the solid super base catalyst into diethylamine, stirring, keeping the temperature at 3-8 DEG C, dropwise adding o-chlorophenol within 20 minutes, stirring for 10-20 minutes after dropwise adding is finished, starting ultrasonic oscillation, heating, carrying out reflux reaction for 10-30 minutes, carrying out reduced pressure rotary evaporation to recover diethylamine, adding xylene, stirring, cooling to 5 DEG C or below, and adding water to quench the catalyst; and adjusting the pH value of a water layer to be neutral or weakly acidic, and recovering xylene to obtain the m-diethylaminophenol finished product. The method disclosed by the invention not only is short in time and high in efficiency, but also does not use expensive m-aminophenol raw materials, so that the problem of troublesome post-treatment is solved; meanwhile, potential safety hazards caused by using unsafe catalysts can be avoided, so that m-diethylaminophenol production is safer, more economical and more efficient, and industrialization is better facilitated.

Owner:安徽绿色谷创客空间股份有限公司 +1

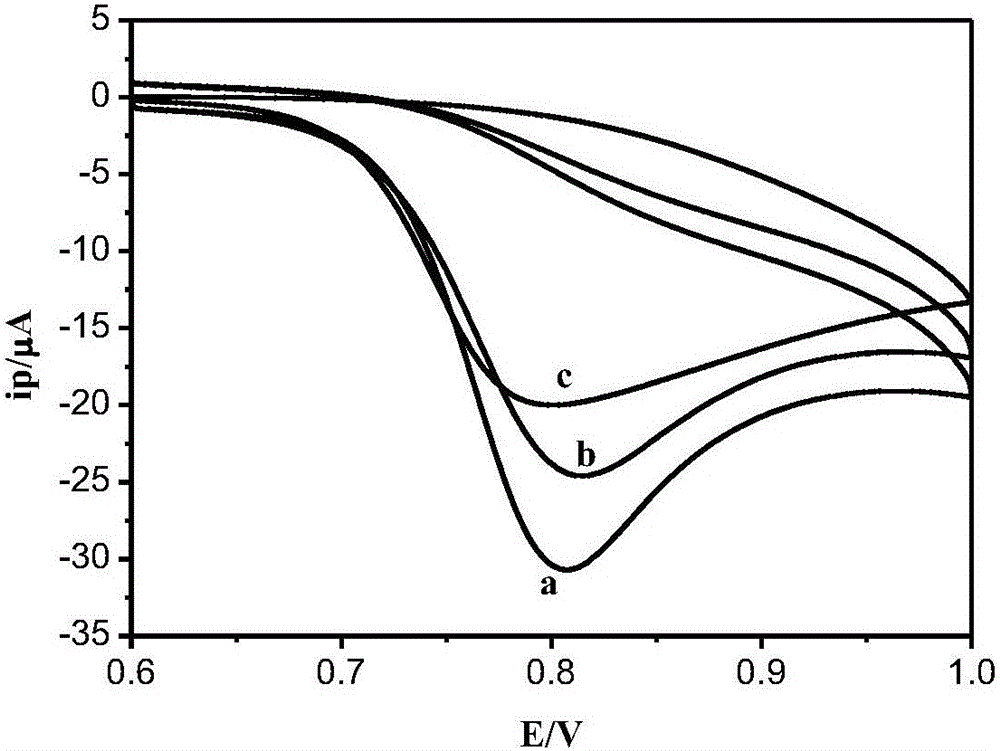

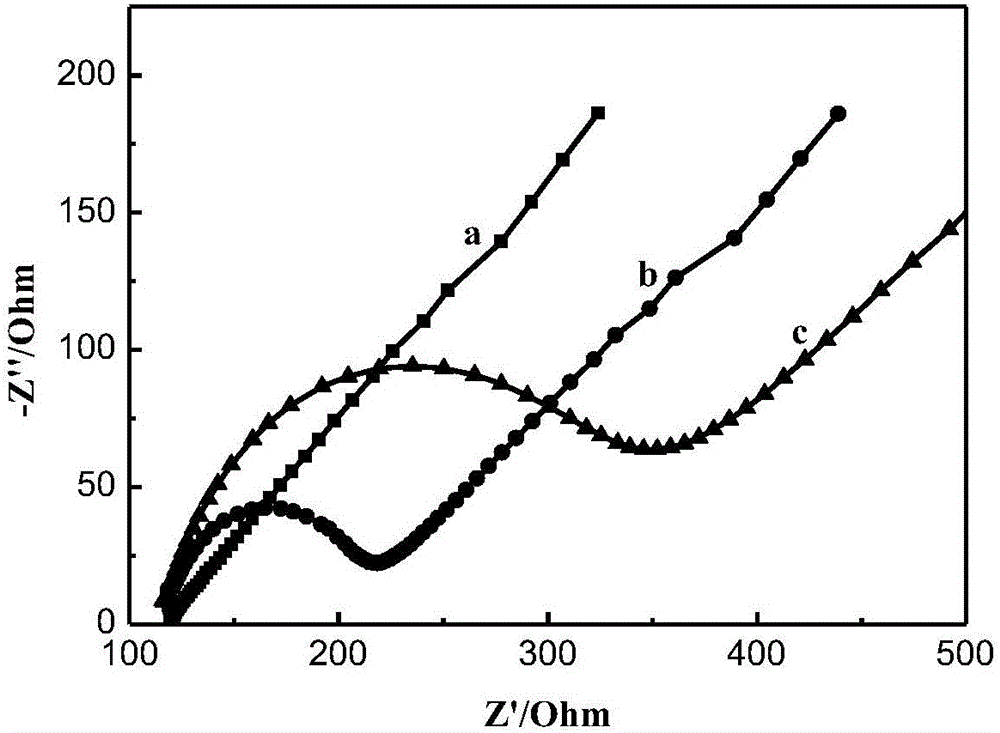

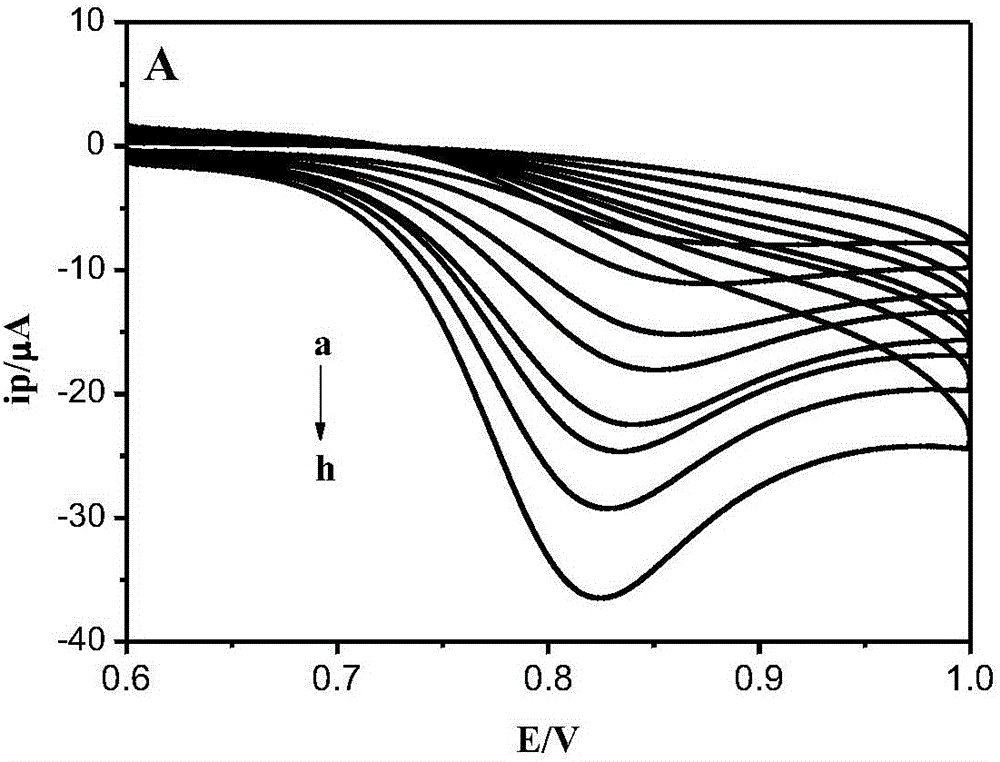

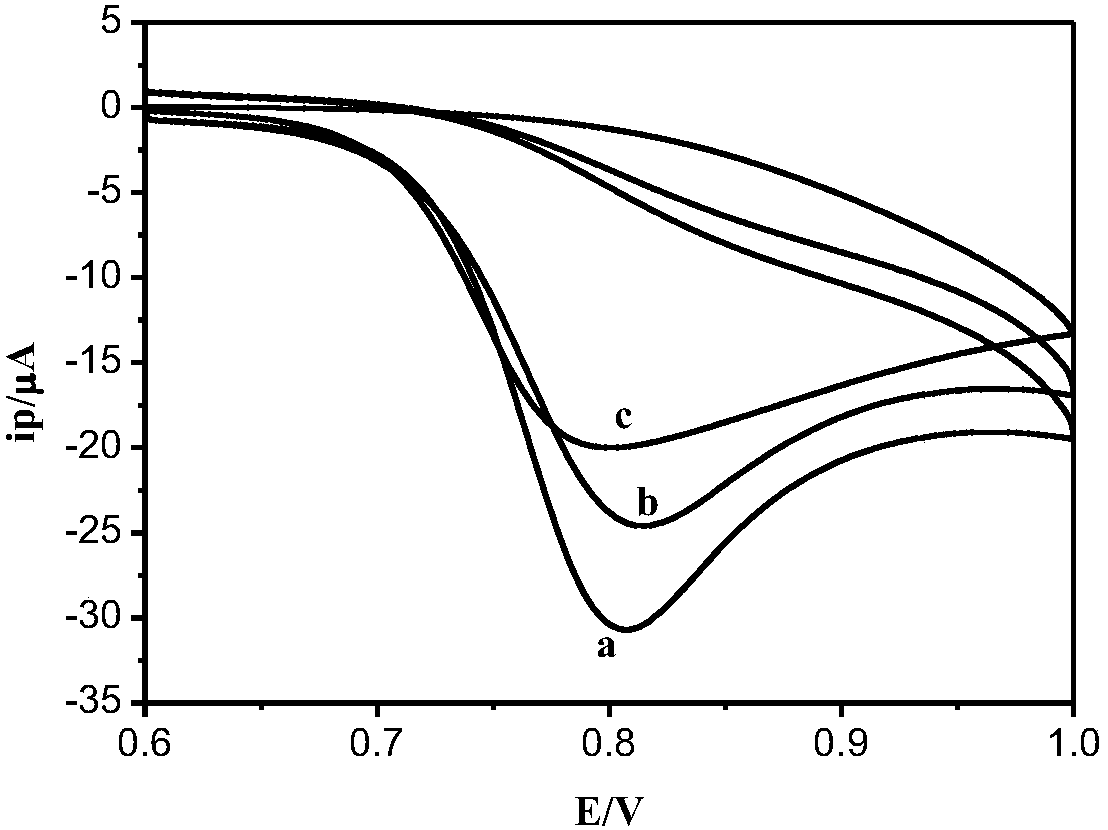

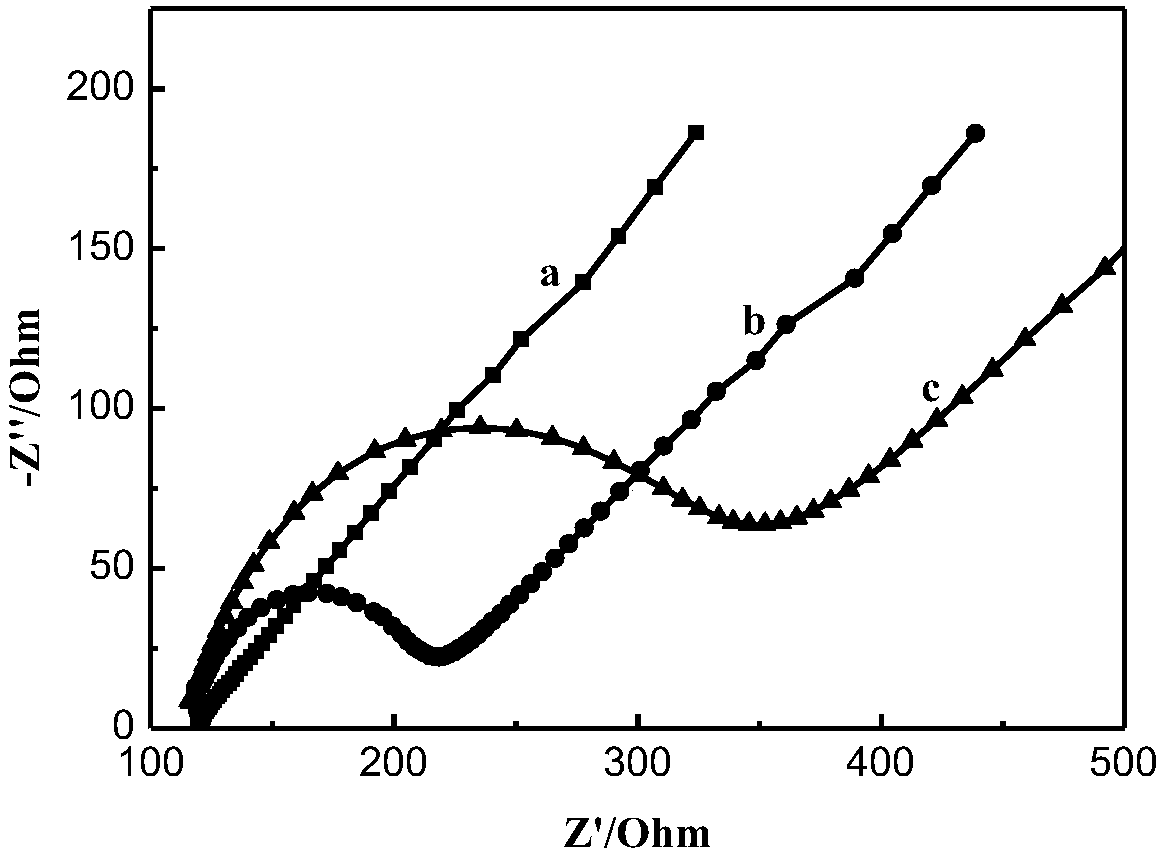

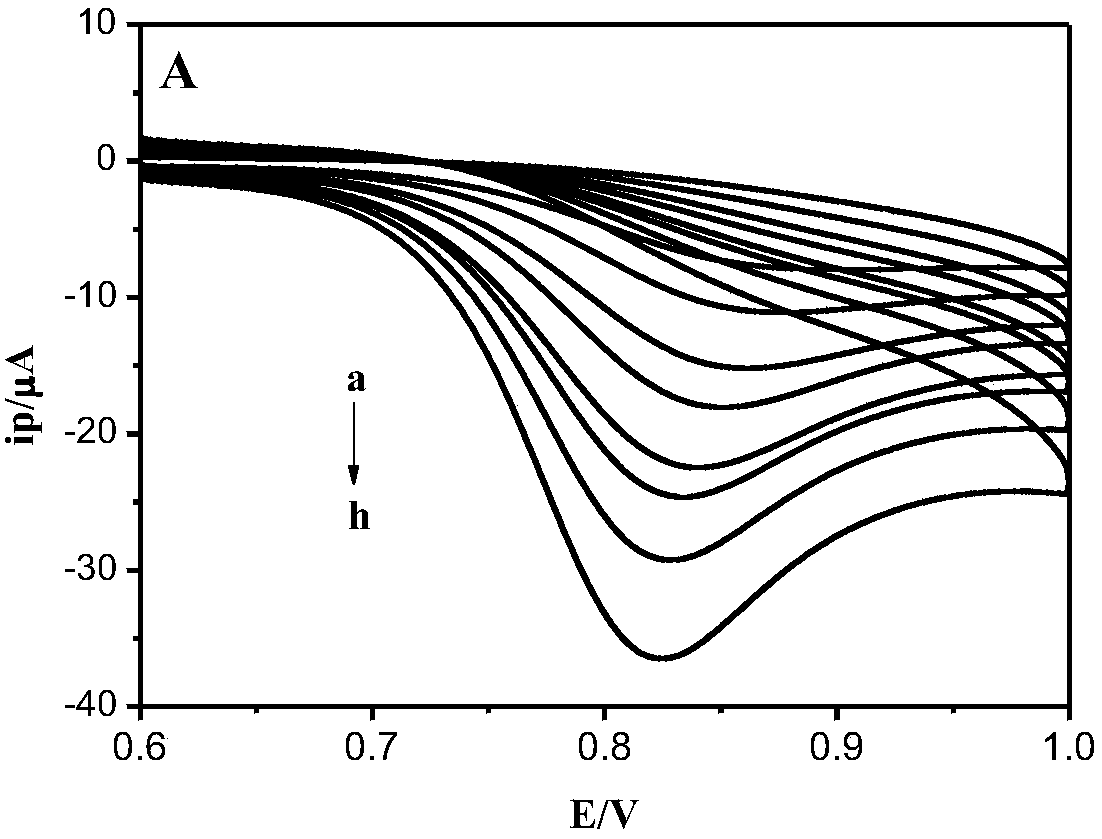

Method for detecting o-chlorophenol based on PEDOT/g-C3N4 electrode

InactiveCN106053581ACatalytic OxidationGood reproducibilityMaterial electrochemical variablesO-chlorophenolDetection limit

The invention discloses a method for detecting o-chlorophenol based on a PEDOT / g-C3N4 electrode. The method comprises the following steps: (1) preparing a standard solution; (2) establishing a standard curve of o-chlorophenol concentrations for detection; (3) detecting the concentration of o-chlorophenol of a sample to be detected. The linear detection range of o-chlorophenol of provided method is in a range of 0.5 to 40 mmol / L. The linear equation of peak current Ipa and o-chlorophenol concentration (c) is Ipa([mu]A)=3.15282+0.57007c(mmol / L) (R2=0.994), and the detection limit is 0.42 mmol / L. At the same time, the provided detection method has a good performance on resisting interference, and has an application prospect on the detection of actual water sample.

Owner:NANJING NORMAL UNIVERSITY

Preparation process and production method of high-strength polyester interlaced yarn

InactiveCN113046847AHigh coloring rateGood moisture absorption and air permeabilityMelt spinning methodsFilament-forming treatmentPolyesterYarn

The invention discloses a preparation process and a production method of a high-strength polyester interlaced yarn, and belongs to the technical field of polyester interlaced yarn preparation. The preparation process comprises the following steps of drying and slicing, melt extrusion, mixing, metering, filtering, spinning, cooling and forming, oiling, winding and UDY. The following technological processes are suitable for conventional spinning, medium-speed spinning, high-speed spinning and ultra-high-speed spinning, and for dry slicing, the simple index [n] of molecular weight is equal to KMa, K-coefficient (when o-chlorophenol or phenol tetrachloroethane is used for determination). The high-strength polyester interlaced yarn has the advantages that the dyeing degree is high and the breathability and hygroscopicity are good, the coloring effect of polyester can be improved when the polyester is dyed, the color of the fabric is brighter and brighter, and the color of the fabric is improved; and meanwhile, the breathability of the polyester fabric is improved, the polyester fabric is more comfortable to wear, the comfort of the polyester is improved, so that quality and effect of polyester preparation are improved, and the delivery and production requirements of people are met.

Owner:ZHEJIANG QIULU DRESS

Amino functionalized ionic liquid/hydrotalcite-like compound composite material, and preparation method and application thereof

The invention discloses an amino functionalized ionic liquid / hydrotalcite-like compound composite material, and a preparation method and an application thereof. The preparation method comprises: firstly synthesizing an amino functionalized ionic liquid, then taking amino functionalized ionic liquid with different molar masses, employing a coprecipitation method to load the ionic liquid on the surface of the hydrotalcite-like compound, to prepare the amino functionalized ionic liquid / hydrotalcite-like compound composite material with a lamellar structure. The prepared organic-inorganic composite material has the structure and performance advantages of the functionalized ionic liquid and the hydrotalcite-like compound; the composite material, as an absorbent, shows good adsorption removal capability on pollutions such as o-chlorophenol , m-chlorophenol or p-chlorophenol in water, and has substantially better adsorptivity performance than the hydrotalcite-like compound; and the synergy advantage of the amino functionalized ionic liquid and the hydrotalcite-like compound is given a full play.

Owner:日照经济技术开发区客商服务有限公司

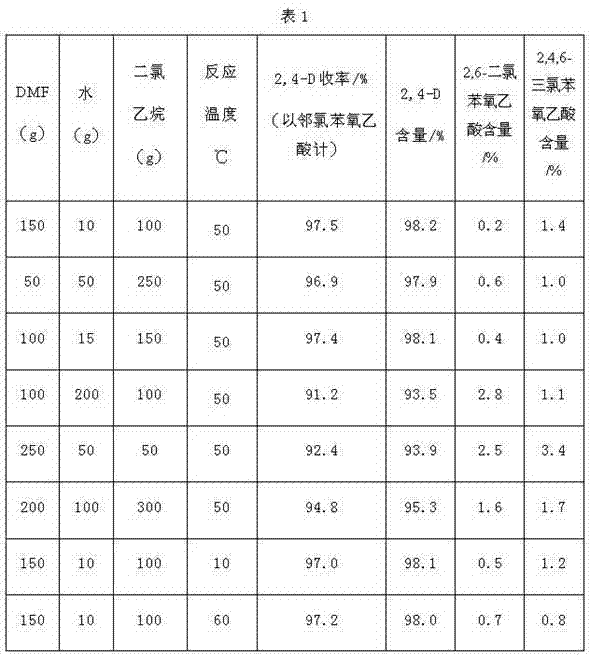

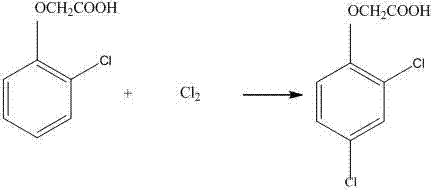

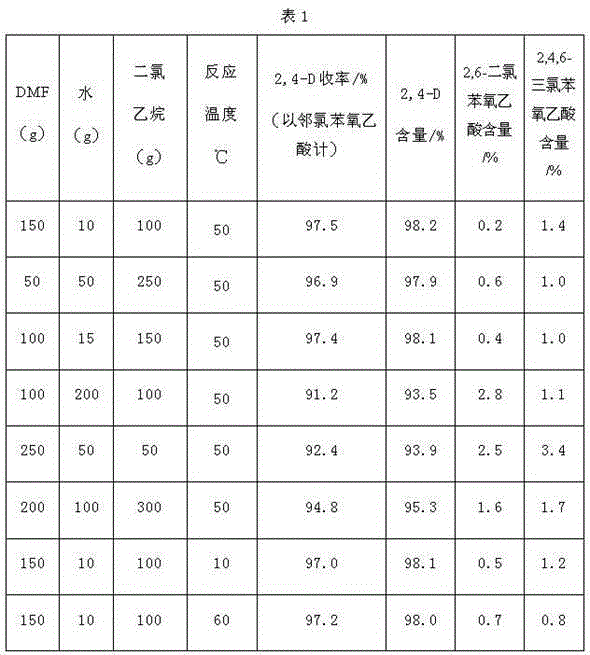

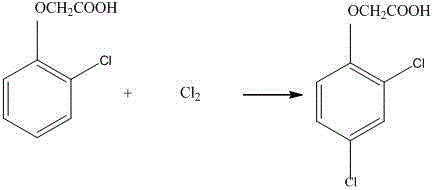

Method for synthesizing 2,4-dichlorphenoxyacetic acid

ActiveCN103145549BRaw materials are easy to getSave raw materialsOrganic compound preparationCarboxylic compound preparationChlorobenzenePtru catalyst

The invention discloses a method for synthesizing 2,4-dichlorphenoxyacetic acid. The method comprises the following steps of: reacting o-chlorophenol which is used as a raw material with chloroacetic acid to generate o-chlorophenoxyacetic acid; and then reacting o-chlorophenoxyacetic acid with chlorine in a mixed solvent to obtain 2,4-dichlorphenoxyacetic acid, wherein the mixed solvent is a mixture of DMF (dimethyl formamide), water and dichlorethane. According to the method, o-chlorophenol is used as the raw material, so that o-chlorophenol can be used, and a new train of thought is provided for the synthesis of 2,4-D; and the raw material is easily available and low in cost, so that the production cost of a product is low. By adopting the mixed solvent, the selectivity of reaction is improved, so that a catalyst is not needed; and through the matching of other conditions, the reaction temperature and other conditions ensure that the yield of the product is improved, the generation of 2,6-dichlorphenoxyacetic acid and 2,4,6-trichlorophenoxyacetic acid is greatly reduced, and the yield of 2,4-dichlorphenoxyacetic acid in a single step can reach over 95%.

Owner:SHANDONG WEIFANG RAINBOW CHEM

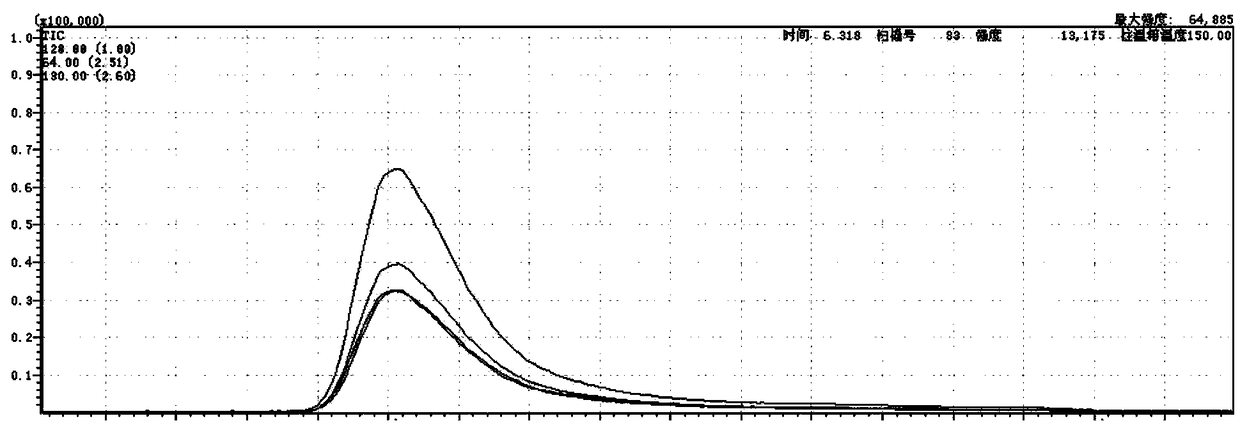

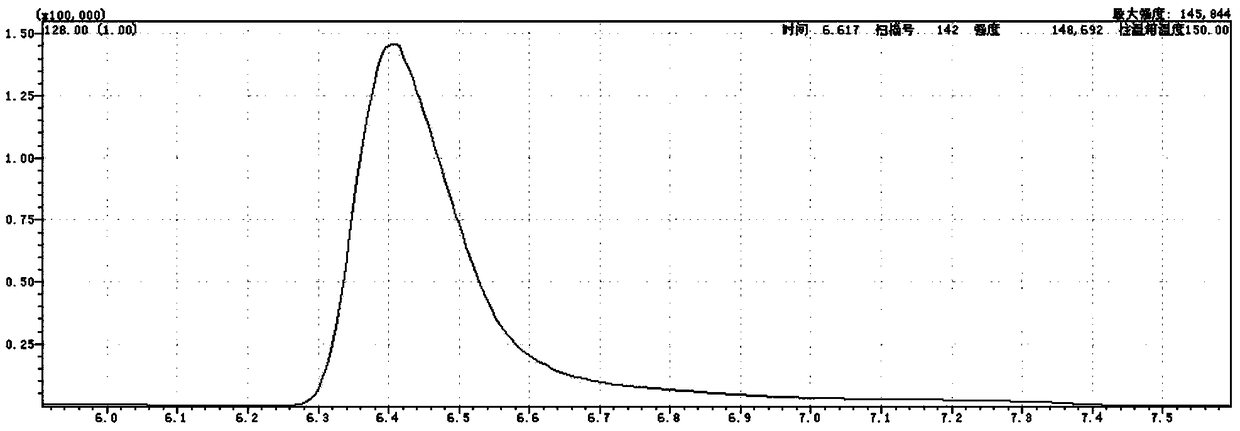

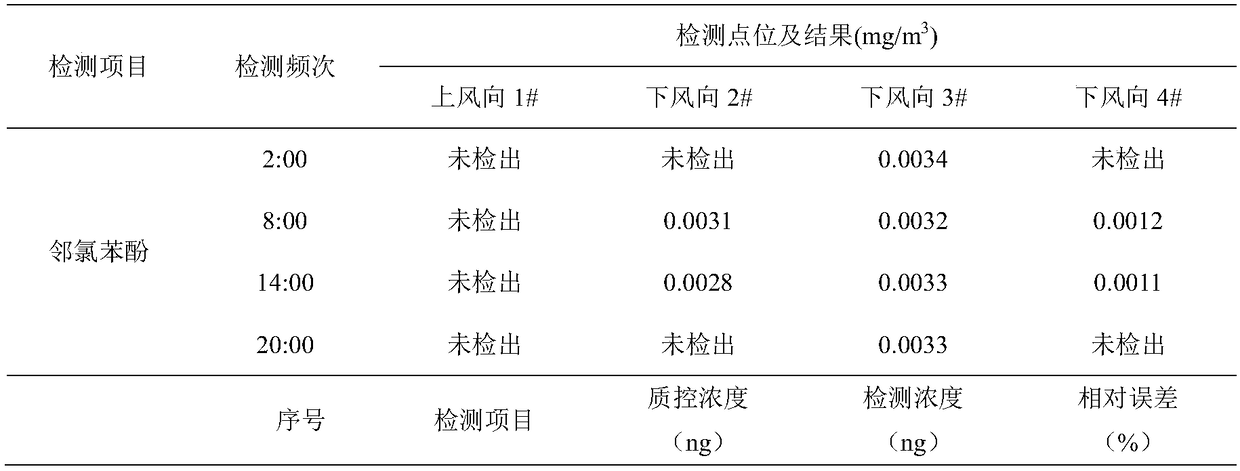

Method for detecting o-chlorophenol in air

The invention relates to the technical field of environmental analytical chemistry, in particular to a method for detecting o-chlorophenol in air. The method comprises the following steps that a sample is collected by using a Tenax sampling tube and a comprehensive atmospheric sampler, the adsorbed sample is thermally decomposed, and GC-MS detects and calculates the content of the o-chlorophenol in the sampling tube to obtain the concentration of the o-chlorophenol in the air; the sampling flow rate is 0.5 L / min and the sampling time is 40 min. The method for detecting the o-chlorophenol in the air has the advantages that the Tenax sampling tube, a thermal desorption instrument and a gas chromatography-mass spectrometry detector are combined with collection and detection of the o-chlorophenol in the air, the operation is simple, an organic solvent is not needed for desorption, the method is safe and environmentally friendly, and the adsorption and recovery efficiencies are high.

Owner:山东恒诚检测科技有限公司

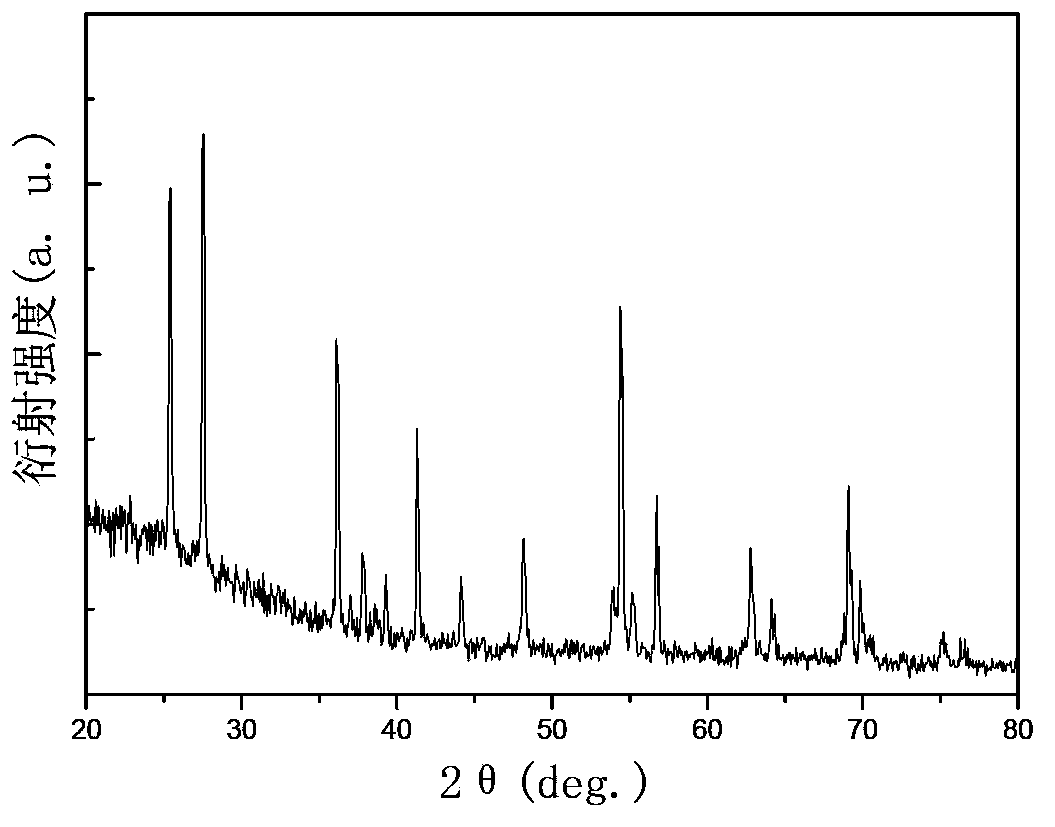

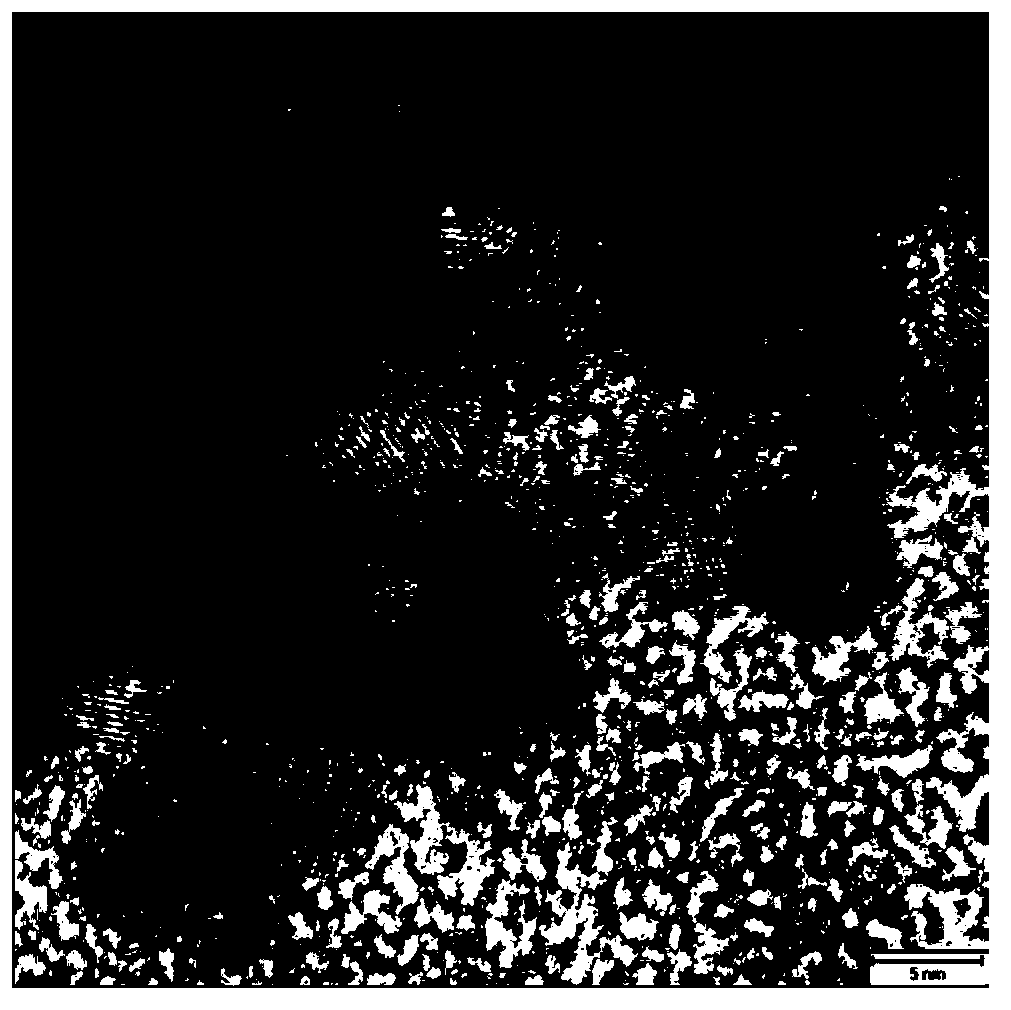

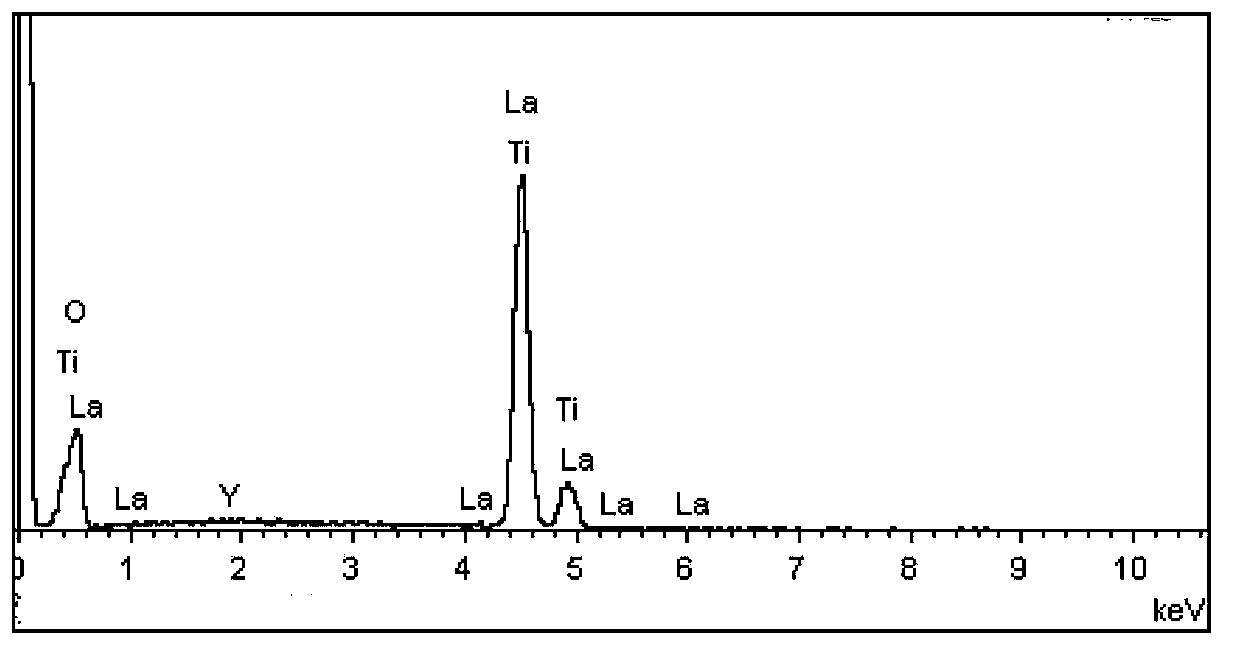

Lanthanum-yttrium-codoped nano-titanium dioxide gas-sensitive material as well as preparation method and application thereof

InactiveCN103159255BQuick checkGood effectMaterial nanotechnologyMaterial analysis by electric/magnetic meansGas detectorYttrium

Owner:QUFU NORMAL UNIV

Method for synthesizing 2,4-dichlorphenoxyacetic acid

ActiveCN103145549ARaw materials are easy to getSave raw materialsOrganic compound preparationCarboxylic compound preparationChlorobenzenePtru catalyst

The invention discloses a method for synthesizing 2,4-dichlorphenoxyacetic acid. The method comprises the following steps of: reacting o-chlorophenol which is used as a raw material with chloroacetic acid to generate o-chlorophenoxyacetic acid; and then reacting o-chlorophenoxyacetic acid with chlorine in a mixed solvent to obtain 2,4-dichlorphenoxyacetic acid, wherein the mixed solvent is a mixture of DMF (dimethyl formamide), water and dichlorethane. According to the method, o-chlorophenol is used as the raw material, so that o-chlorophenol can be used, and a new train of thought is provided for the synthesis of 2,4-D; and the raw material is easily available and low in cost, so that the production cost of a product is low. By adopting the mixed solvent, the selectivity of reaction is improved, so that a catalyst is not needed; and through the matching of other conditions, the reaction temperature and other conditions ensure that the yield of the product is improved, the generation of 2,6-dichlorphenoxyacetic acid and 2,4,6-trichlorophenoxyacetic acid is greatly reduced, and the yield of 2,4-dichlorphenoxyacetic acid in a single step can reach over 95%.

Owner:SHANDONG WEIFANG RAINBOW CHEM

Method for separating chloro phenol reaction solution

InactiveCN102584542BIncrease production capacityHigh yieldOrganic chemistryOrganic compound preparationPhenolChemistry

Owner:JIANGSU HONGYUAN CHEM

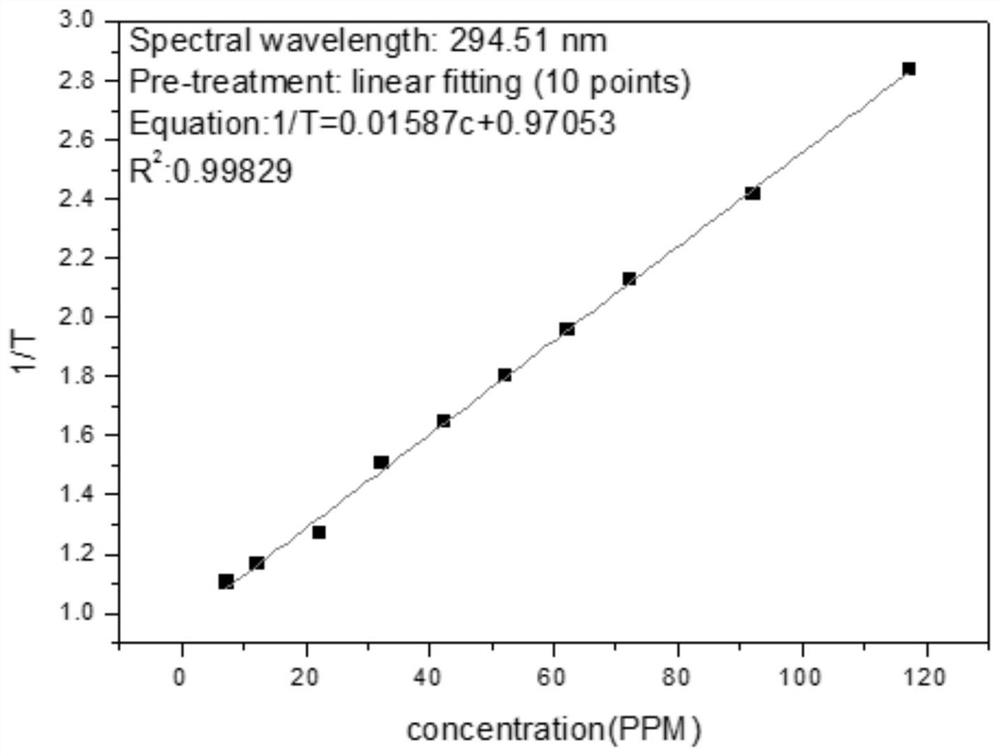

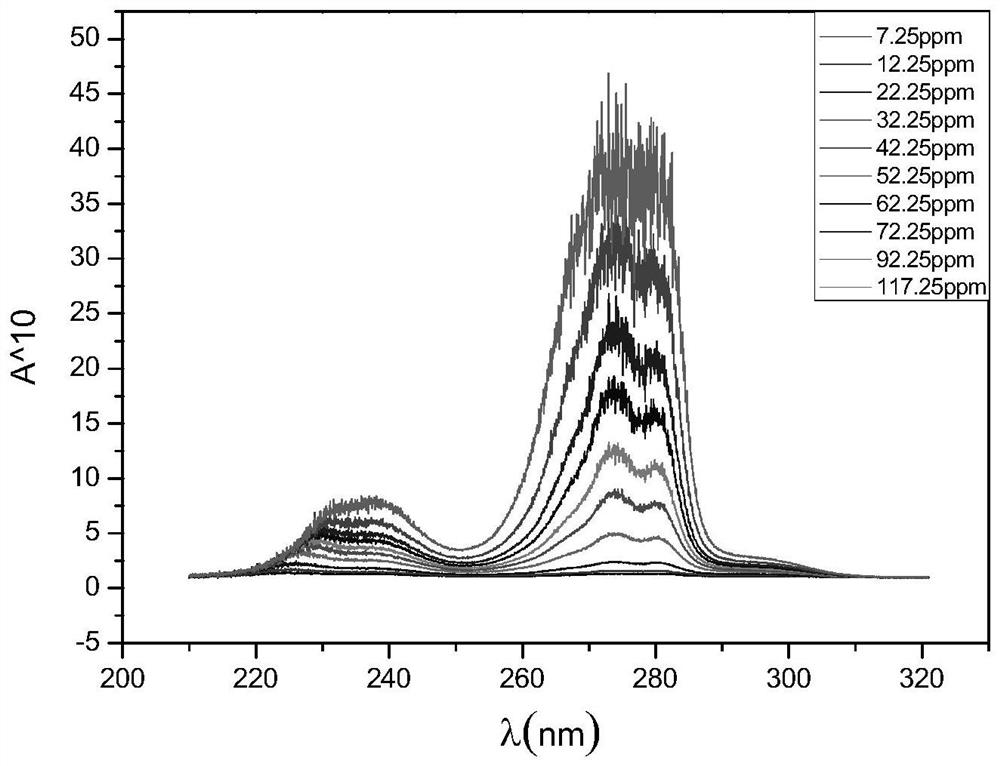

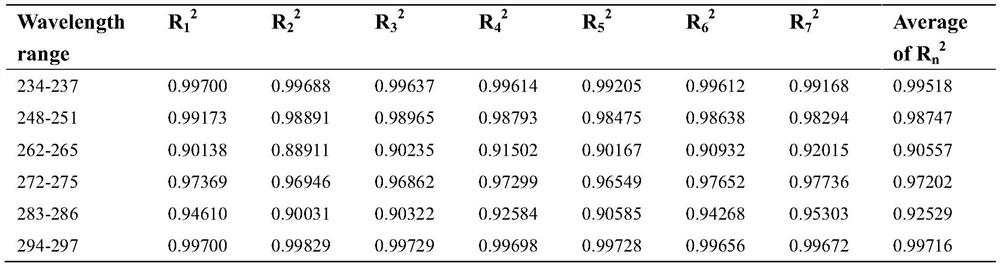

O-chlorophenol concentration measuring method based on ultraviolet spectrum analysis

InactiveCN111624168AWill not polluteHigh precisionPreparing sample for investigationColor/spectral properties measurementsUv spectrumOptical spectrometer

The invention discloses an o-chlorophenol concentration measurement method based on ultraviolet spectrum analysis. The method comprises the following steps: (1) preparing a standard solution; (2) obtaining an ultraviolet spectrum of the standard solution by using an ultraviolet / visible spectrograph; (3) finding the optimal detection wavelength; (4) establishing a standard curve for detecting the concentration of o-chlorophenol; and (5) detecting the concentration of the o-chlorophenol solution to be detected. The linear detection range of the method on o-chlorophenol is 7.25-117.25 PPM, and when the wavelength of ultraviolet light is 294.51 nm, the relationship between the transmittance of o-chlorophenol and the concentration of the solution is as follows: 1 / T(one of the transmittance)=0.01587*C(PPM)+0.97053, R2=0.99829, and the mean square error is 5.427*10<-4>. Meanwhile, compared with other methods, the detection method disclosed by the invention has the advantages of large detection range, high precision, no pollution and the like, and has a certain application prospect in o-chlorophenol concentration detection.

Owner:HOHAI UNIV

A method for detecting o-chlorophenol based on pedot/g-c3n4 electrode

InactiveCN106053581BCatalytic OxidationGood reproducibilityMaterial electrochemical variablesO-chlorophenolDetection limit

The invention discloses a method for detecting o-chlorophenol based on a PEDOT / g-C3N4 electrode. The method comprises the following steps: (1) preparing a standard solution; (2) establishing a standard curve of o-chlorophenol concentrations for detection; (3) detecting the concentration of o-chlorophenol of a sample to be detected. The linear detection range of o-chlorophenol of provided method is in a range of 0.5 to 40 mmol / L. The linear equation of peak current Ipa and o-chlorophenol concentration (c) is Ipa([mu]A)=3.15282+0.57007c(mmol / L) (R2=0.994), and the detection limit is 0.42 mmol / L. At the same time, the provided detection method has a good performance on resisting interference, and has an application prospect on the detection of actual water sample.

Owner:NANJING NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com