Method for separating chloro phenol reaction solution

A technology for reaction liquid and chlorinated phenol, applied in the field of continuous separation of chlorophenol reaction liquid, can solve the problems of low production capacity and high energy consumption, and achieve the effects of large production capacity, low energy consumption and few by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

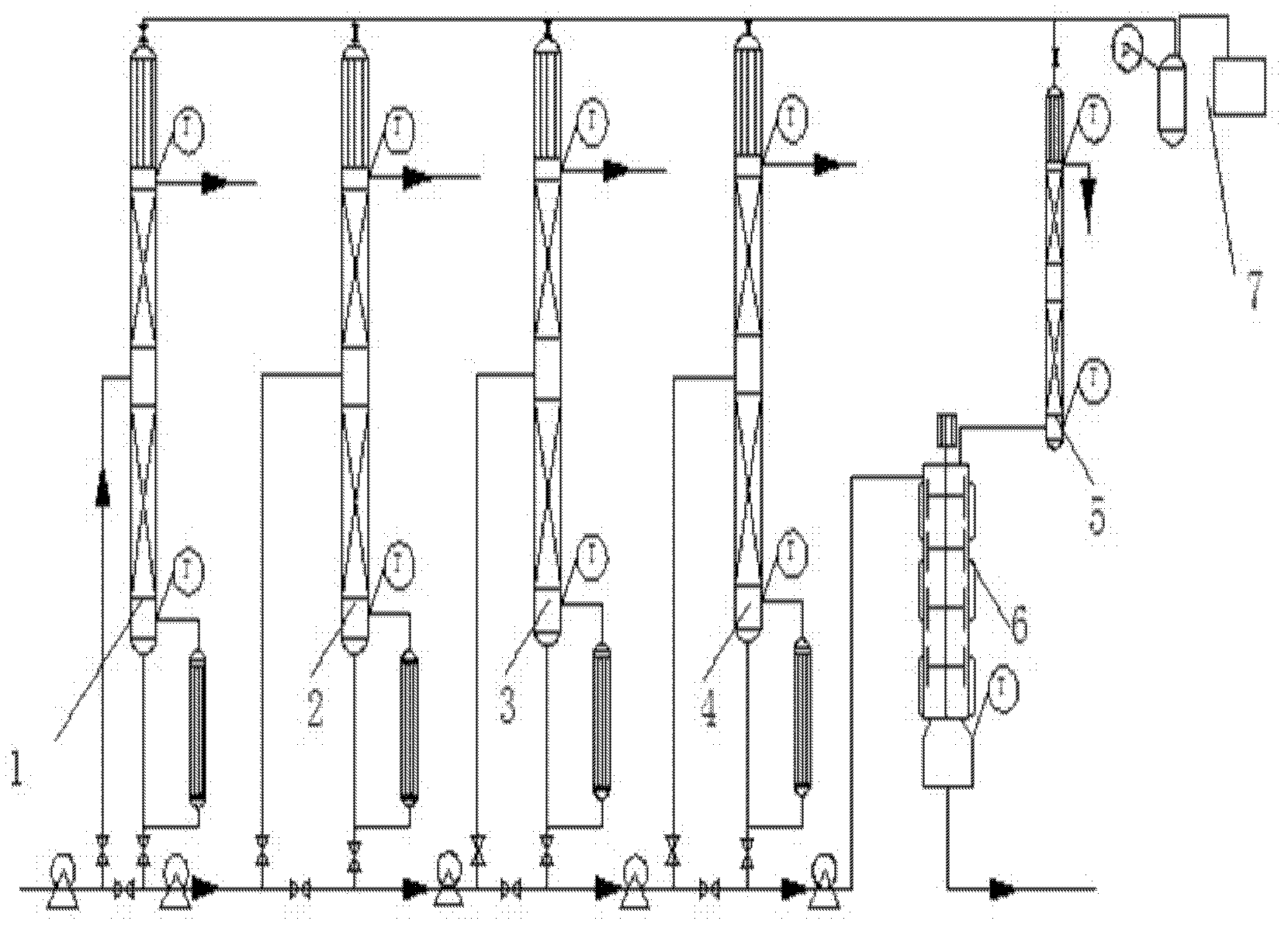

Image

Examples

Embodiment 1

[0024] [Example 1] This method is used to separate chlorophenols, and the components and contents of the reaction solution are: o-chlorophenol (27-30%), p-chlorophenol (20-23%), 2,4-dichlorophenol (15-18%), 2,6-dichlorophenol (10-12%), phenol (1-3%), 2,4,6-trichlorophenol (8-12%) and tar (0.1-2 %). The vacuum degree of each rectification tower is controlled by a decompression device to be 2Kpa. The material of each rectification tower is titanium. The inner diameters of No. 1-5 rectification towers are 800mm, 200mm, 600mm, 1000mm, 500mm, respectively; the heights are 5m, 5m, 20m, 8m, 5m; the heating area of the scraper film evaporator is 10m 2 ; The heating medium of No. 1, 2, and 3 rectification towers is 1.0Mpa saturated steam; the heating medium of No. 4 tower and scraped film evaporator is 210°C heat transfer oil. The corresponding temperature of each tower is: the top temperature of No. 1 tower is 85°C, the bottom temperature of the tower is 190°C, and o-chlorophenol ...

Embodiment 2

[0025] [Example 2] This method is used to produce p-chlorophenol, and the components and contents of the reaction solution are: o-chlorophenol (30-33%), p-chlorophenol (50-55%), 2,4-dichlorophenol (1-4%), 2,6-dichlorophenol (0.1-2%), phenol (8-13%) and tar (0.1-2%). According to each component and the corresponding content, it can be completed only through 4 sets of towers: the vacuum degree of each rectification tower is controlled to 5Kpa through the decompression device, the material of each rectification tower is enamel, and the inner diameters of No. 2-5 rectification towers are respectively 400mm, 400mm, 500mm, 500mm; the heights are 8m, 10m, 10m, 15m; the heating area of the scraper film evaporator is 10m 2 ; The heating medium of No. 2 and No. 3 rectification towers is 1.0Mpa saturated steam; the heating medium of No. 4 tower and scraped film evaporator is heat transfer oil at 210°C. The corresponding temperature of each tower is: the top temperature of No. 2 tower ...

Embodiment 3

[0026] [Example 3] This method is used to produce 2,4-dichlorophenol, and the components and content of the reaction solution are: o-chlorophenol (0.5-2%), 2,4-dichlorophenol (70-76%) , 2,6-dichlorophenol (16-22%), 2,4,6-trichlorophenol (6-8%) and tar (0.1-2%). According to each component and corresponding content, it only needs to pass through 3 sets of towers, and the vacuum degree of each rectification tower is controlled to 3Kpa by a decompression device. The material of each rectification tower is carbon steel, and the inner diameter of No. 3-5 rectification towers 1000mm, 1000mm, 1200mm respectively; heights are 10m, 18m, 8m respectively; the heating area of the scraper film evaporator is 25m 2 ; The heating medium of No. 3 rectification tower is 1.2Mpa saturated steam; the heating medium of No. 4 tower and scraped film evaporator is heat transfer oil at 230°C. The corresponding temperatures of each tower are: the top temperature of tower No. 3 is 92°C, the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com