Method for selective oxidation of o-chlorophenol in alkaline wastewater

An o-chlorophenol, selective technology, applied in the field of selective oxidation of o-chlorophenol, can solve problems such as inability to remove well, limited reaction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Weigh 6.04875g of Na 2 MoO 4 The solid was dissolved in 100 mL of distilled water to prepare 0.25M Na 2 MoO 4 solution;

[0029] 2) Pipette 200 μl o-chlorophenol with a pipette gun, and dilute it in a 250mL volumetric flask to prepare a 1g / L o-chlorophenol stock solution;

[0030] 3) Take Na 2 MoO 4 Add distilled water (a solution) to the stock solution to have a final molybdate concentration of 2 mM, and adjust the pH to 8; add o-chlorophenol to distilled water (b solution), adjust the pH to 8, and mix the two solutions;

[0031] 4) Mix a and b solutions in step 2) and wrap the reaction bottle with a black bag to make the reaction under dark reaction conditions, add hydrogen peroxide to the system at a concentration of 500 mg / L, and place the reaction system on a constant temperature shaker;

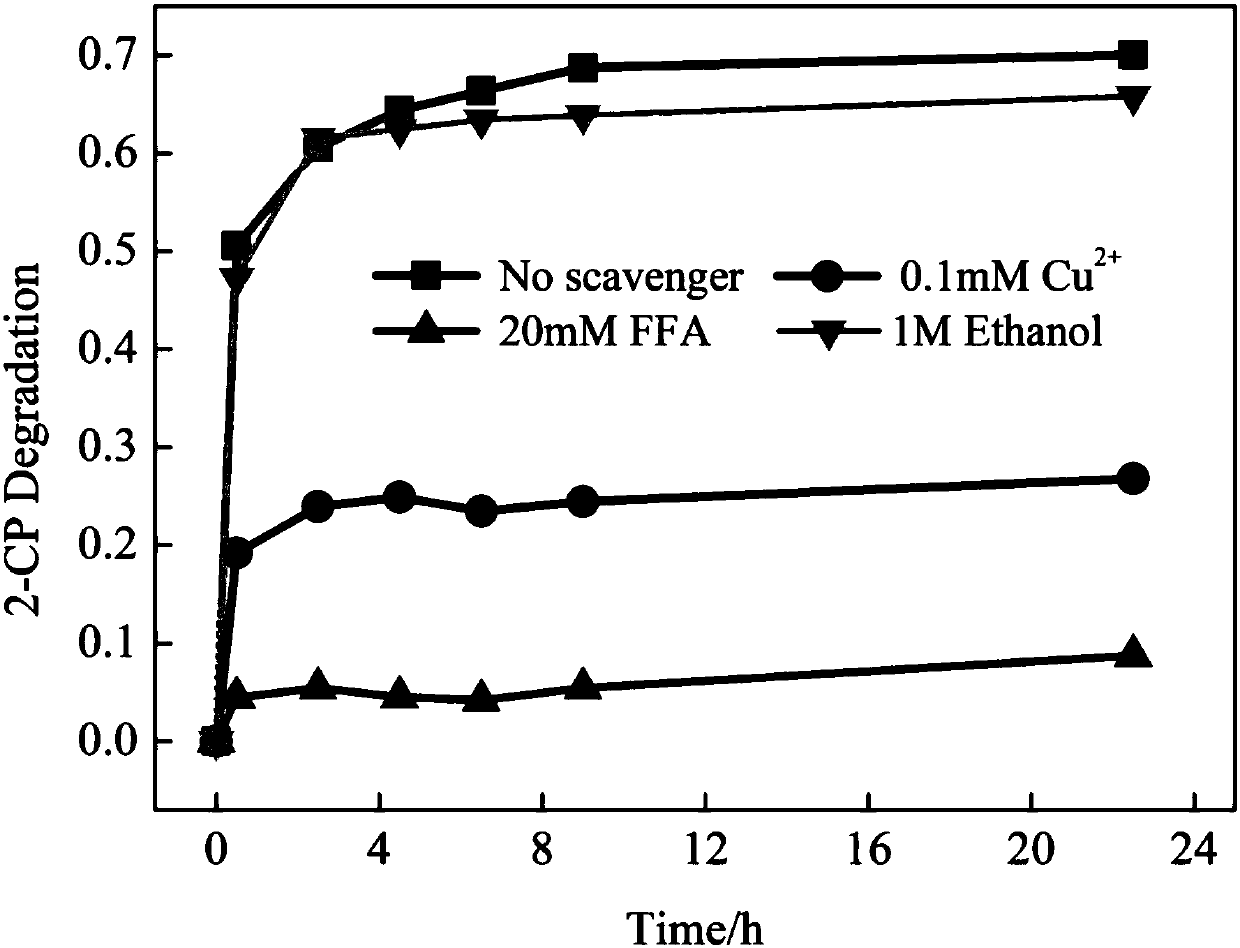

[0032] When the concentration of hydrogen peroxide is 500mg / L at pH 8, the degradation of p-chlorophenol is as follows Image 6 shown. The basic reaction reached equilib...

Embodiment 2

[0034] 1) Weigh 12.0975g of Na 2 MoO 4 Dissolve the solid in 100 mL distilled water to prepare 0.5M Na 2 MoO 4 solution;

[0035] 2) Pipette 400 μl o-chlorophenol with a pipette gun, and dilute it in a 250mL volumetric flask to prepare a 1g / L o-chlorophenol stock solution;

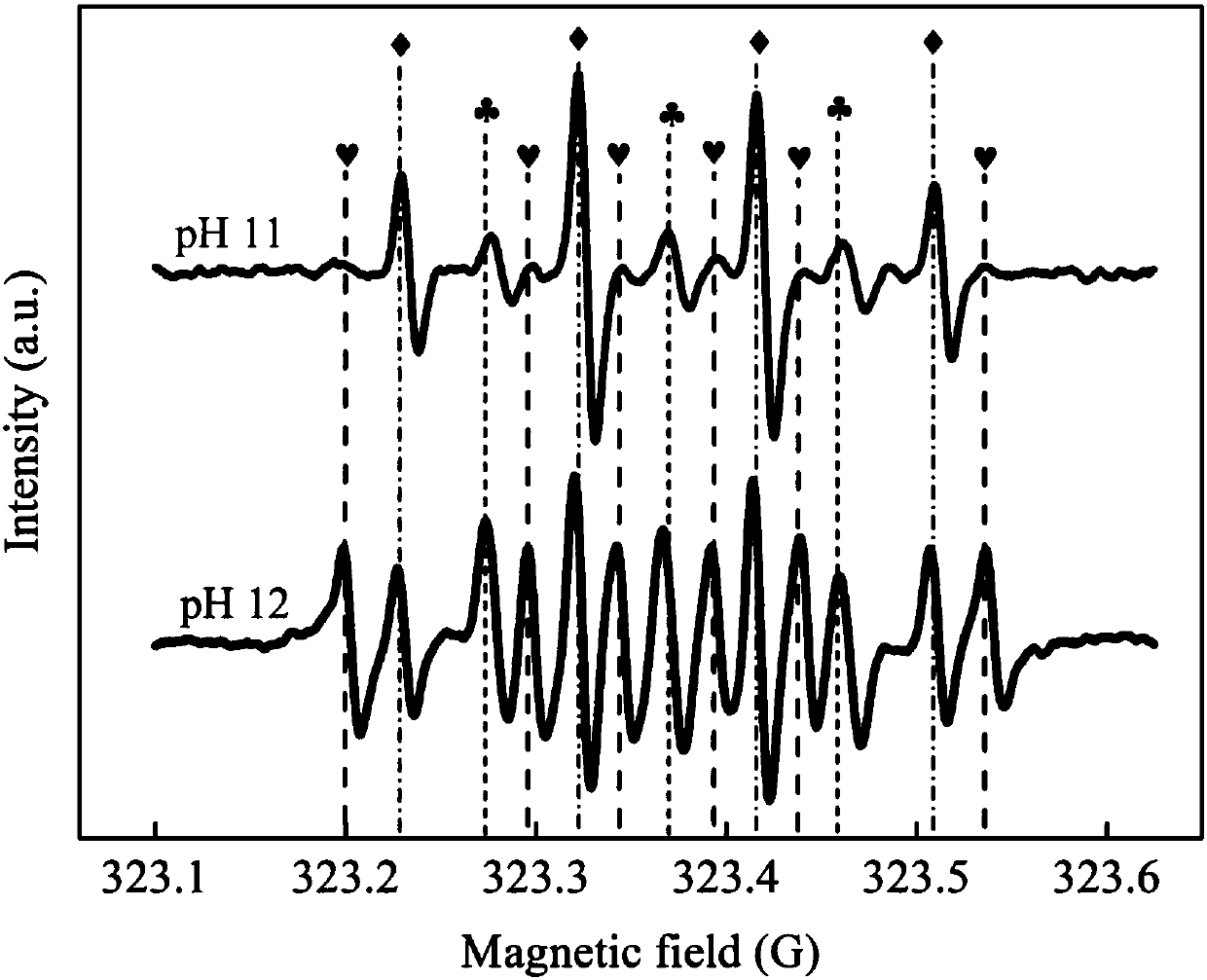

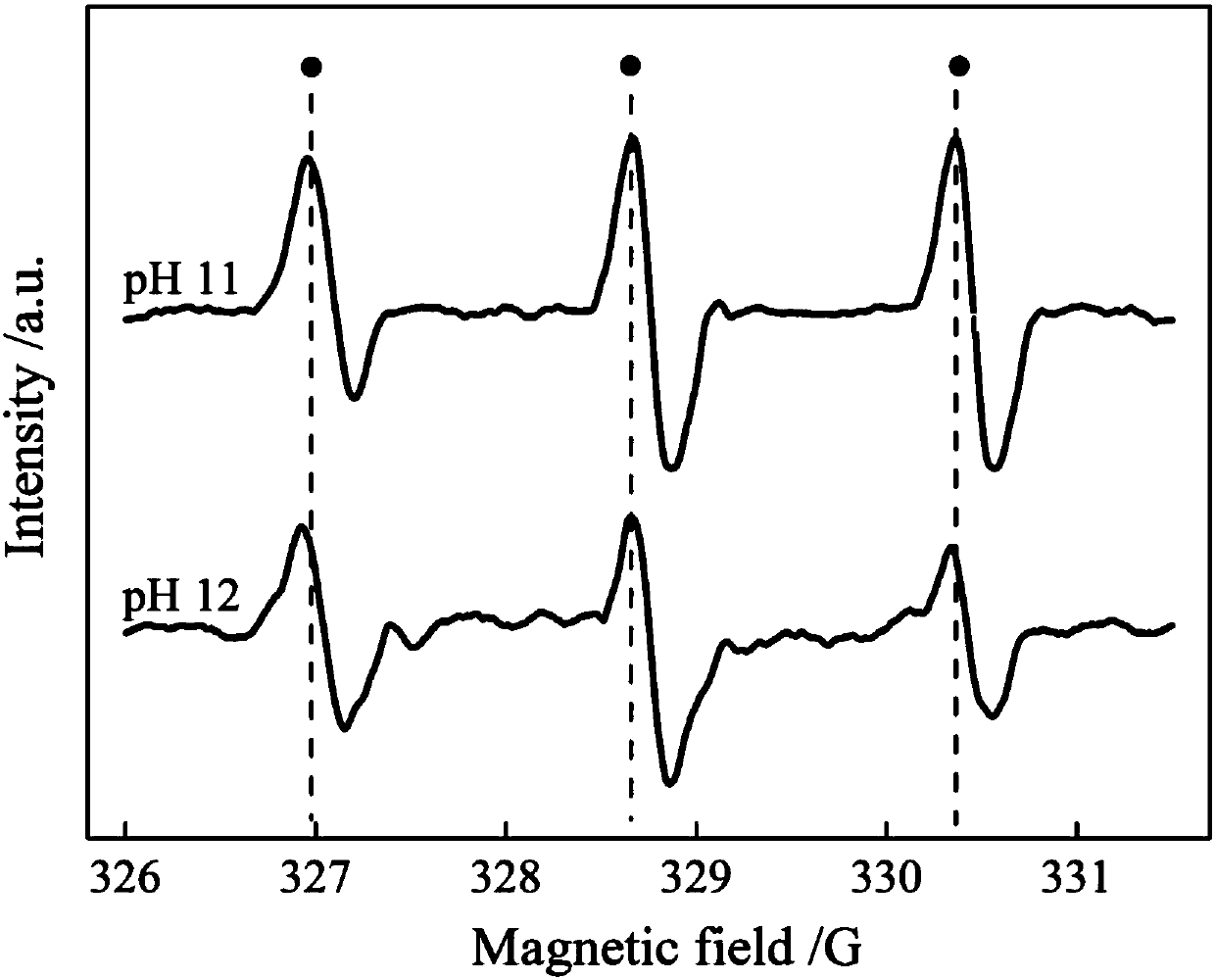

[0036] 3) Take Na 2 MoO 4 Add distilled water (solution a) to the stock solution to make the final concentration of molybdate 0.5mM, and adjust the pH to 11; take o-chlorophenol and add it to distilled water (solution b), adjust the pH to 11, and mix the two solutions;

[0037] 4) Mix a and b solutions in step 2) and wrap the reaction bottle with a black bag to make the reaction under dark reaction conditions, add hydrogen peroxide to the system at a concentration of 1000 mg / L, and place the reaction system on a constant temperature shaker;

[0038] When the hydrogen peroxide concentration rises to 1000mg / L at pH 11, the degradation of p-chlorophenol is as follows Image 6 shown. After 8 hours, the...

Embodiment 3

[0040] 1) Weigh 6.04875g of Na 2 MoO 4 The solid was dissolved in 100 mL of distilled water to prepare 0.25M Na 2 MoO 4 solution;

[0041] 2) Pipette 200 μl o-chlorophenol with a pipette gun, and dilute it in a 250mL volumetric flask to prepare a 1g / L o-chlorophenol stock solution;

[0042] 3) Take Na 2 MoO 4 The stock solution was added to distilled water (a solution) with a final molybdate concentration of 1 mM, and the pH was adjusted to 12; the o-chlorophenol stock solution was added to distilled water (b solution), and the pH was adjusted to 12, and the two solutions were mixed;

[0043] 4) Mix a and b solutions in step 2) and wrap the reaction bottle with a black bag to make the reaction under dark reaction conditions, add hydrogen peroxide to the system at a concentration of 1000 mg / L, and place the reaction system on a constant temperature shaker;

[0044] When the concentration of hydrogen peroxide is 1000mg / L at pH 12, the degradation of o-chlorophenol is as fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com