Intelligent fully-enclosed wet-process coke quenching and integrated recycling equipment

A technology of wet coke quenching and recovery equipment, which is applied in coke ovens, energy input, coke cooling, etc., can solve the problems of high operation and maintenance costs, poor economic benefits, large investment in dry coke quenching, and achieve good prevention Corrosion ability, reduce heat loss, and create economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

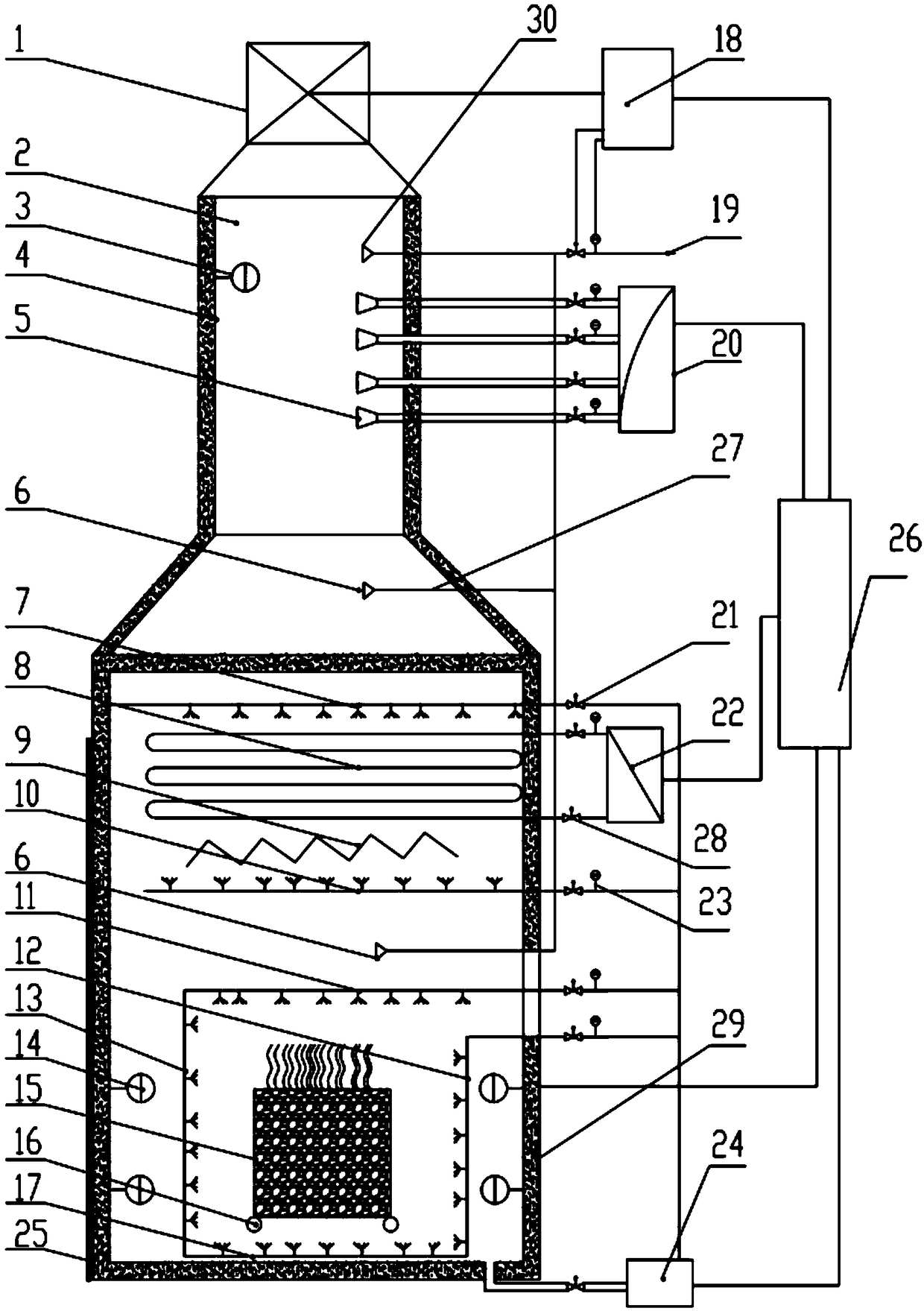

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0025] The present invention will be described in detail with reference to the accompanying drawings.

[0026] The present invention provides an intelligent fully enclosed wet coke quenching and comprehensive recycling equipment during specific implementation, including an explosion-proof valve 1, a closed coke quenching tower 2 and a waste gas recovery device 29. The explosion-proof valve 1 is arranged in the closed coke quenching tower. 2, a nitrogen pipeline 27 is arranged inside the closed coke quenching tower 2, the nitrogen pipeline 27 includes a first nitrogen pipeline 6 and a second nitrogen pipeline 19, and an upper flushing pipeline 7 is arranged below the nitrogen pipeline 27 and the lower flushing pipeline 10, the upper flushing pipeline 7 and the lower flushing pipeline 10 are provided with a flushing valve 21, one side of the lower flushing pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com