Polymer film and preparation method and application thereof

A technology of polymer film and conjugated polymer, which is applied in the field of polymer solar cells, can solve the problems of easy residue of additives, lower battery performance, unfavorable flexible plastic solar cells, etc., and achieve good stability, efficient transmission and collection, and low cost cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

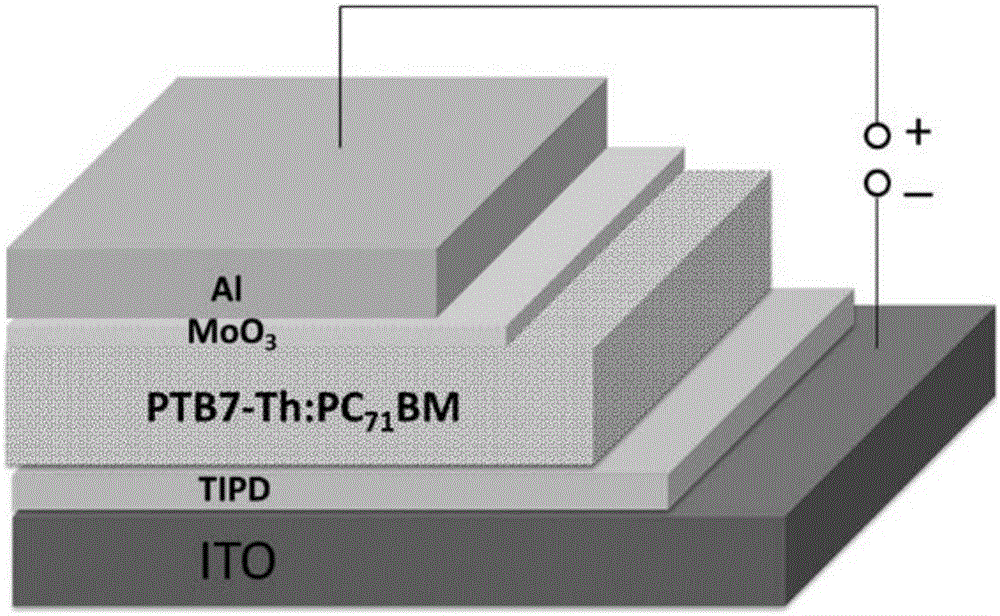

[0030] Embodiment 1 (as comparative example)

[0031] 1) Sputtered with doped indium SnO 2 (ITO) transparent conductive glass was ultrasonically cleaned twice with detergent, tap water, deionized water, acetone, and isopropanol in sequence, dried with nitrogen gas, and moved into a glove box for later use. Titanium acetylacetonate (TIPD) was diluted 20 times with isopropanol, spin-coated on ITO at 4000 rpm, and annealed on a hot stage at 150°C for 10 minutes;

[0032] 2) Dissolved active layer solution PTB7-Th:PC 71 BM (1:1.5w / w, polymer concentration 10mg / mL, chlorobenzene) was spin-coated on the ITO / TIPD substrate at 1700rpm to obtain a film of 80-120nm;

[0033] 3) Isopropanol is post-treated on the active layer by spin coating at 4000rpm;

[0034] 4) Move the substrate into the vacuum coating machine, at 5×10 -4 Molybdenum trioxide with a thickness of 10 nanometers and aluminum electrodes with a thickness of 100 nanometers were sequentially evaporated under Pa.

[003...

Embodiment 2

[0037] 3) O-chlorophenol was dissolved in isopropanol at a volume ratio of 0.1%, and spin-coated on the active layer at 4000 rpm for post-treatment.

[0038] Steps 1), 2), and 4) are all the same as in Example 1.

[0039] Under the simulated sunlight irradiation of 100 milliwatts per square centimeter, the prepared device has an open-circuit voltage of 0.78 volts, a short-circuit current of 18.06 milliamperes per square centimeter, a fill factor of 66.27 percent, and a conversion efficiency of 9.34 percent. Figure 6 It is the current-voltage curve of the device without light irradiation and under the simulated sunlight irradiation of 100 mW / cm2.

Embodiment 3

[0041] 3) O-chlorophenol was dissolved in isopropanol at a volume ratio of 0.2%, and spin-coated on the active layer at 4000 rpm for post-treatment.

[0042] Steps 1), 2), and 4) are all the same as in Example 1.

[0043] Under 100 milliwatts per square centimeter of simulated sunlight, the prepared device has an open circuit voltage of 0.78 volts, a short circuit current of 18.67 milliamperes per square centimeter, a fill factor of 65.62%, and a conversion efficiency of 9.51%. Figure 7 It is the current-voltage curve of the device without light irradiation and under the simulated sunlight irradiation of 100 mW / cm2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com